Patents

Literature

33results about How to "Avoid rigid friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

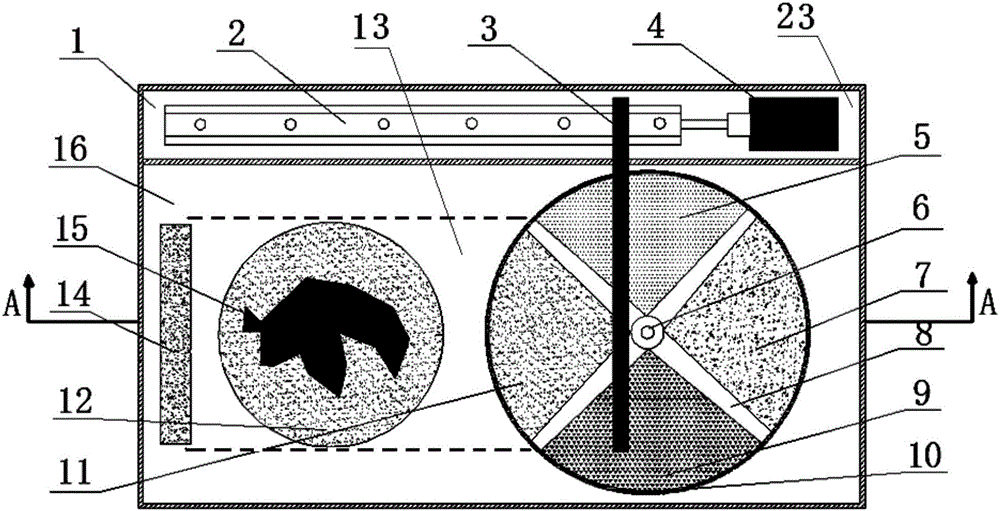

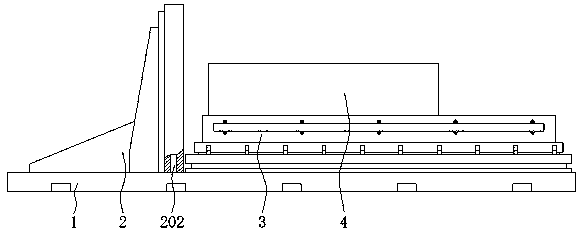

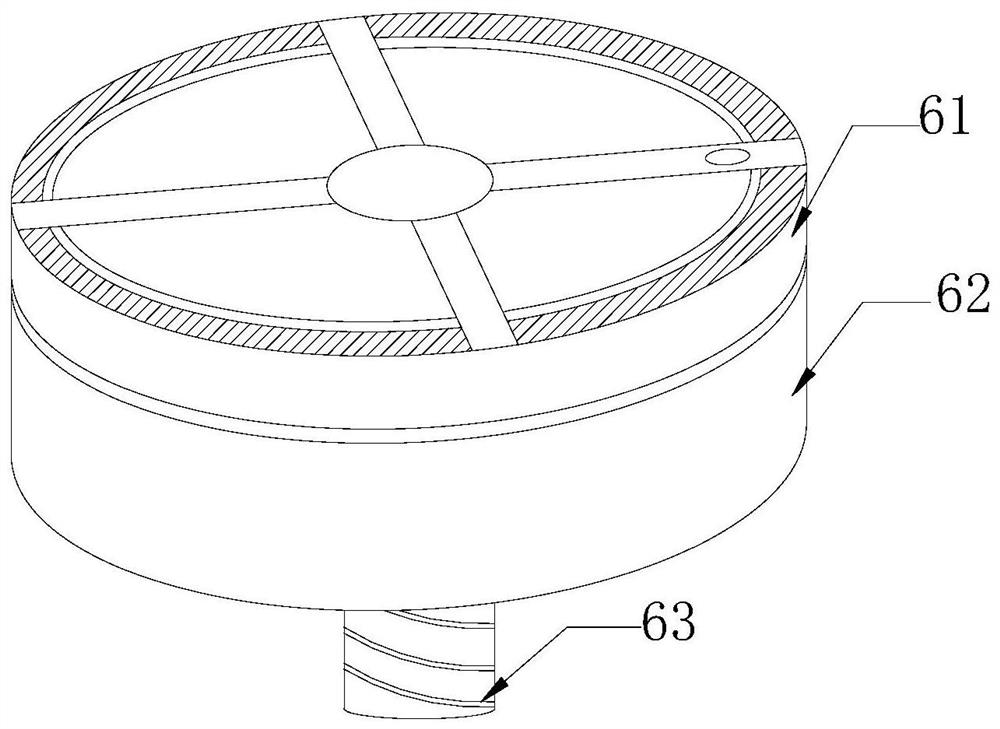

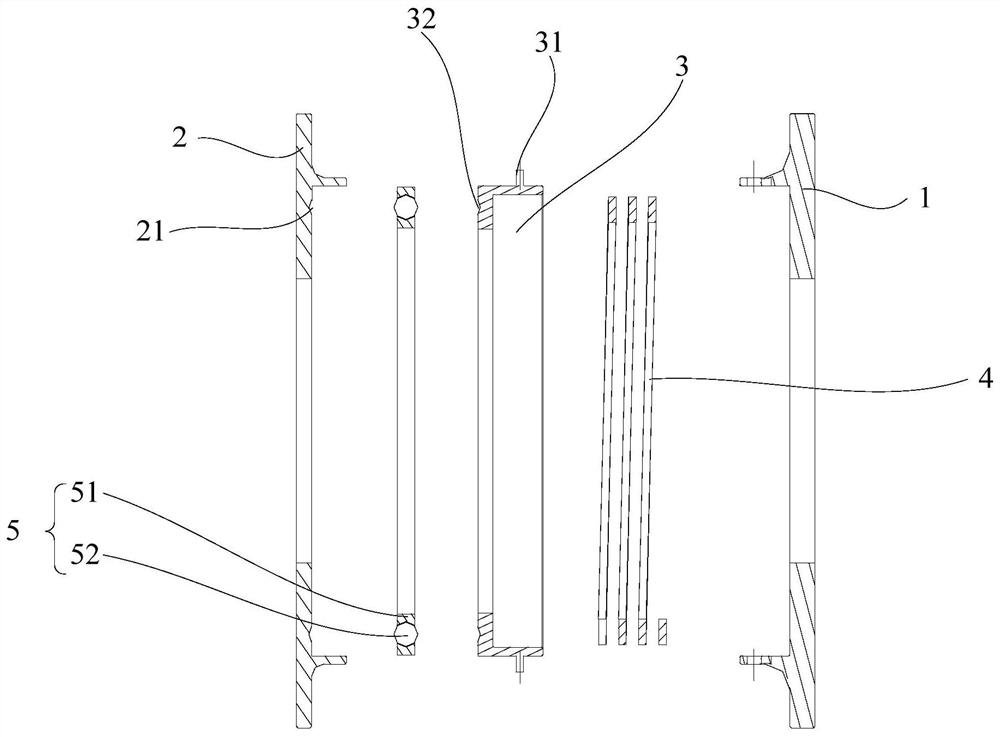

Wheel-disc-type multi-material selective laser melting molding device and method

InactiveCN106735219AAvoid rigid frictionGuaranteed barrier-free passageAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMulti material

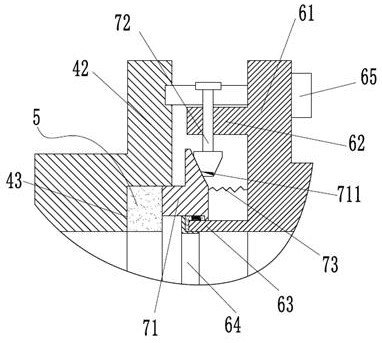

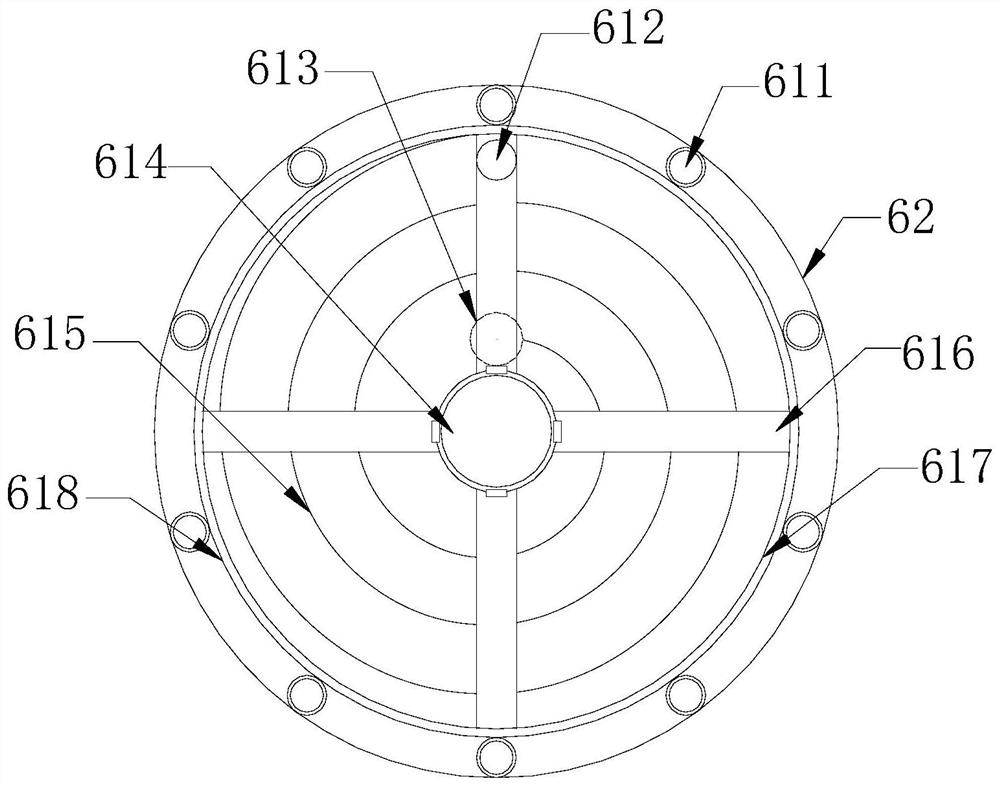

The invention discloses a wheel-disc-type multi-material selective laser melting molding device and a method. The wheel-disc-type multi-material selective laser melting molding device comprises a molding chamber, a powder supply device and the like, wherein the powder supply device is a rotatable wheel-disc-type powder cylinder and is of a cylindrical structure, partitions divide the interior of the wheel-disc-type powder cylinder into four equant powder cylinders, and the four powder cylinders can be used for holding powder of different materials; and when a rotating shaft of the wheel-disc-type powder cylinder rotates, the four powder cylinders are driven to alternate and to be aligned to a powder spreading station of the molding chamber, so that powder in the powder cylinder is spread onto the molding cylinder through the powder spreading mechanism. The four powder cylinders can hold powder of different materials, the flexibility is high, the structure is simple, the occupied space is small, the manufacturing cost is low, the molding requirement for processing various powder of a part is satisfied, and the molding efficiency and quality are greatly improved. As the molding chamber does not need to be opened for powder replacement during processing, the favorable metallurgical bonding performance of dissimilar materials of the part is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

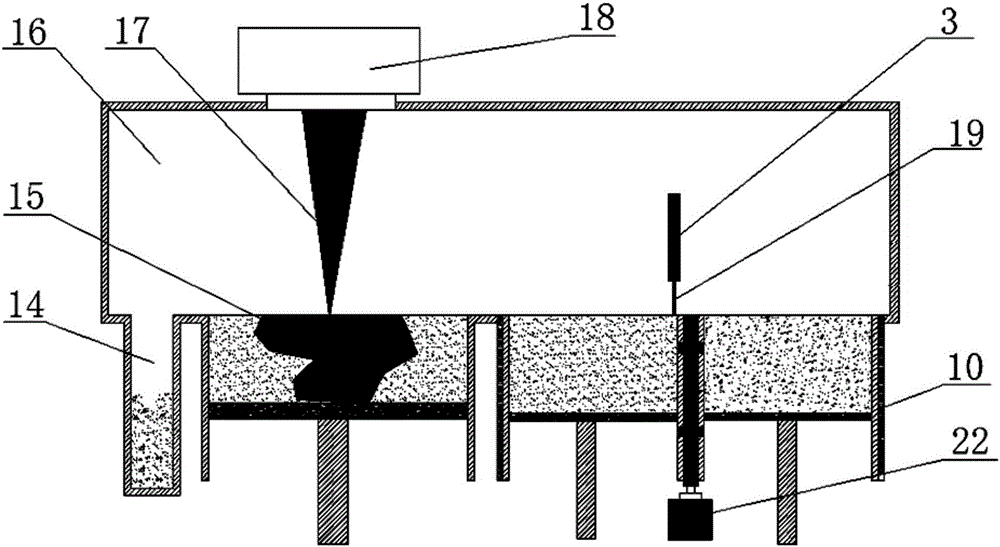

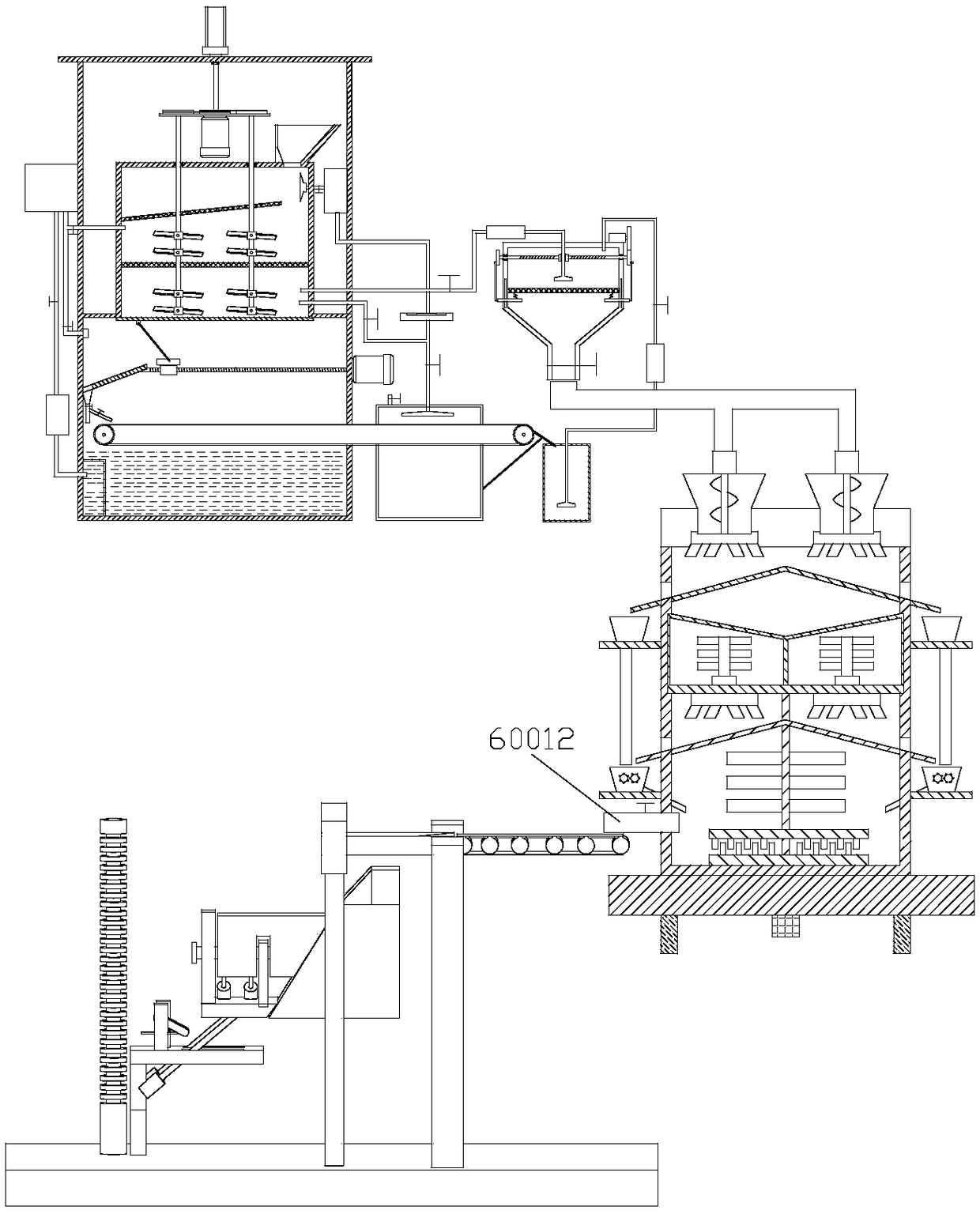

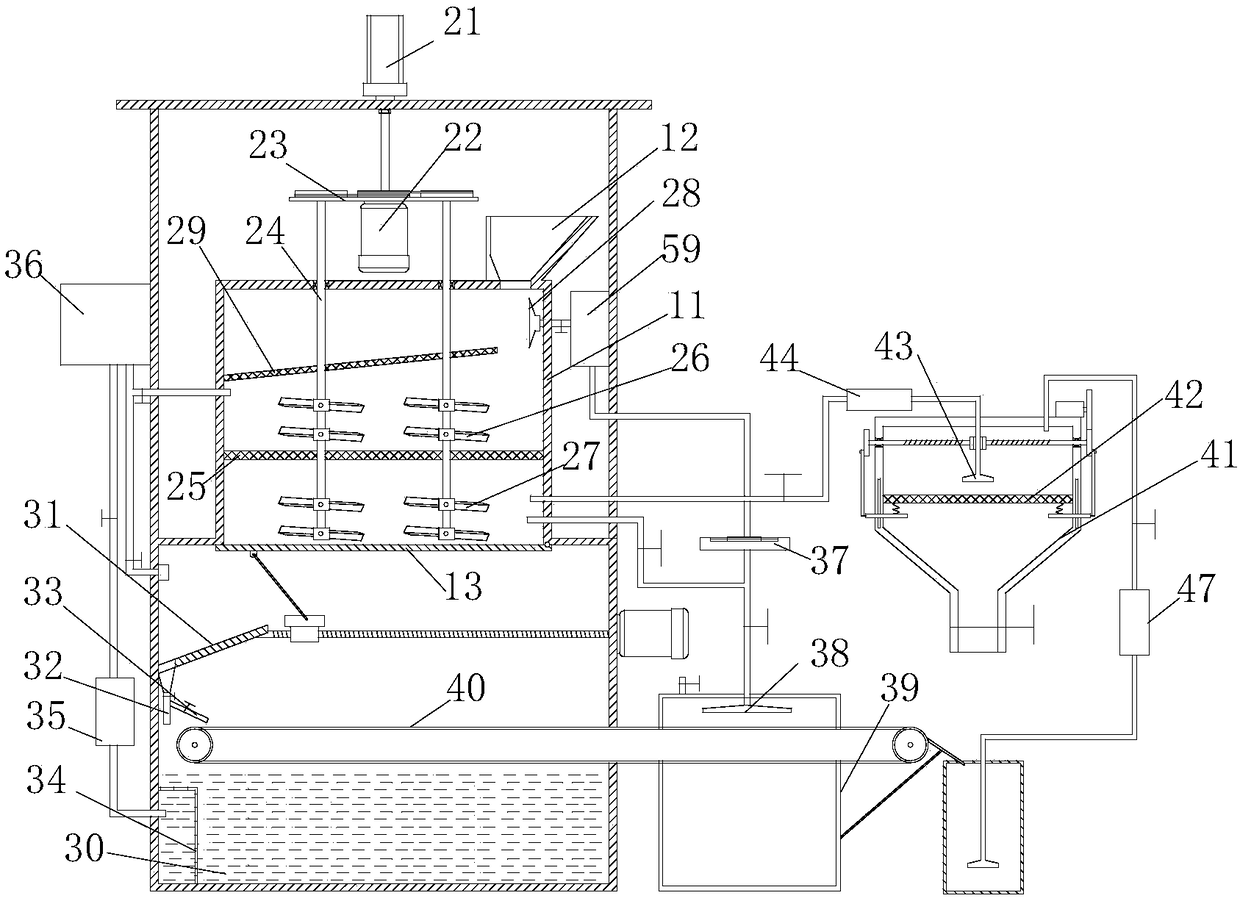

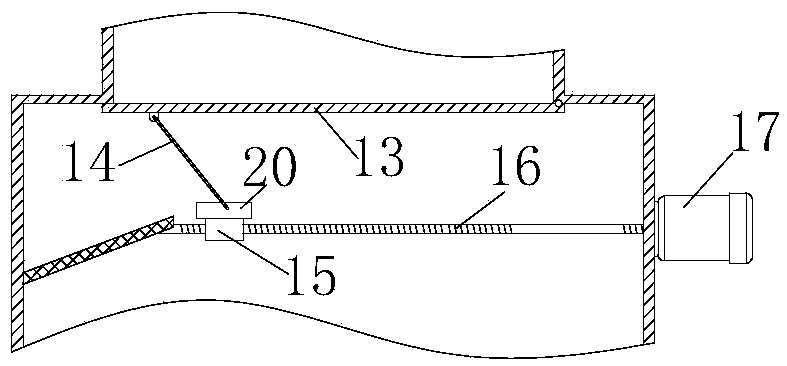

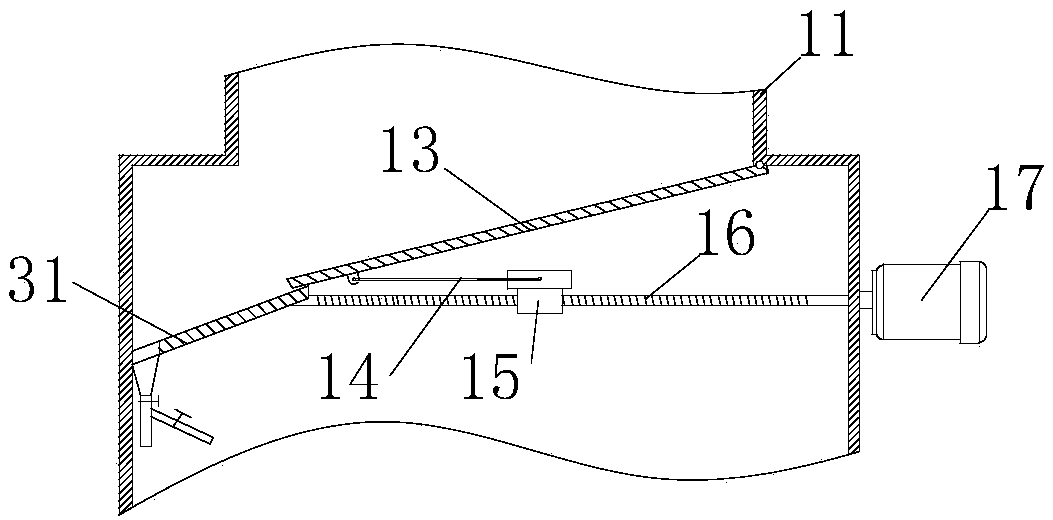

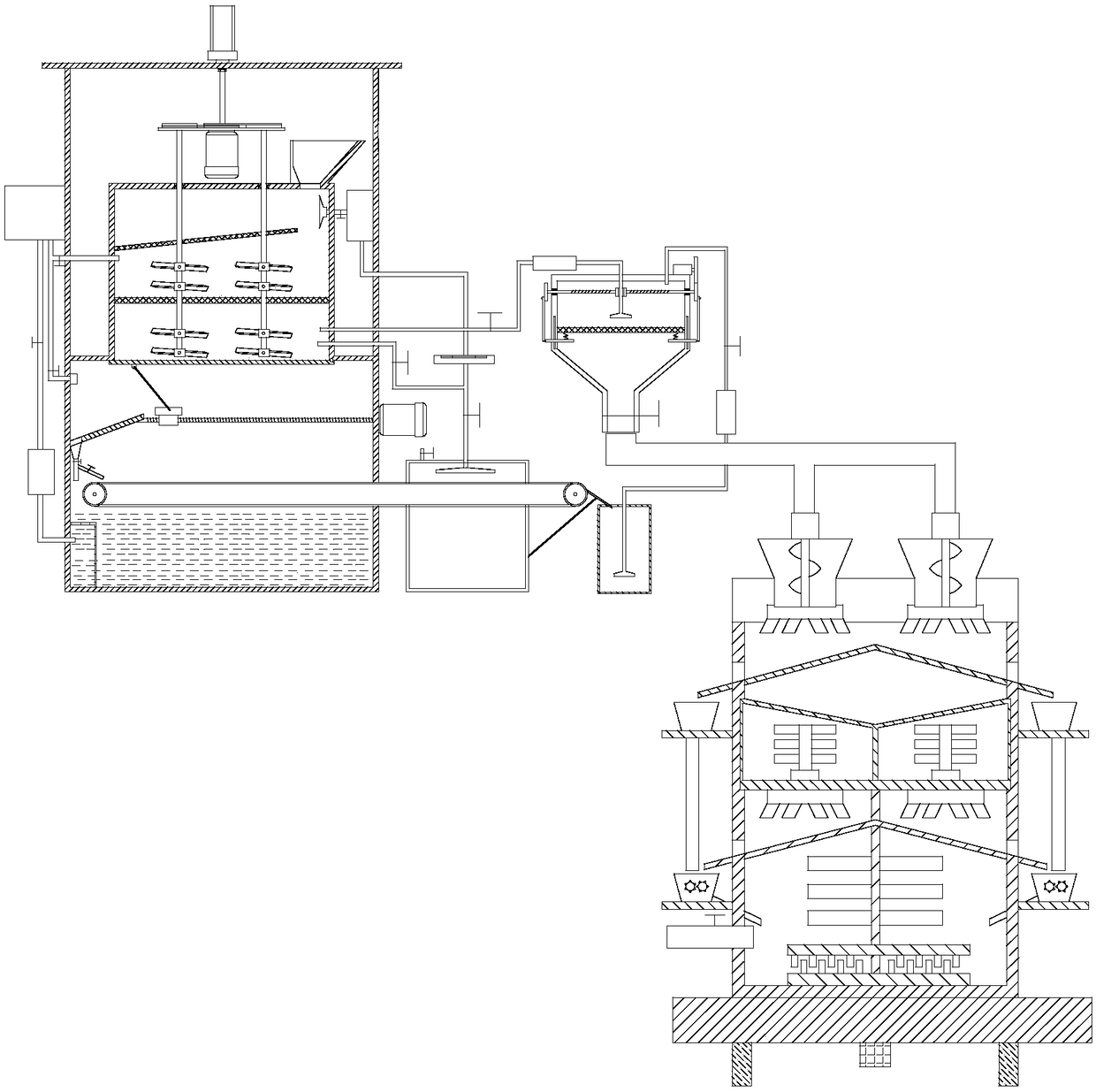

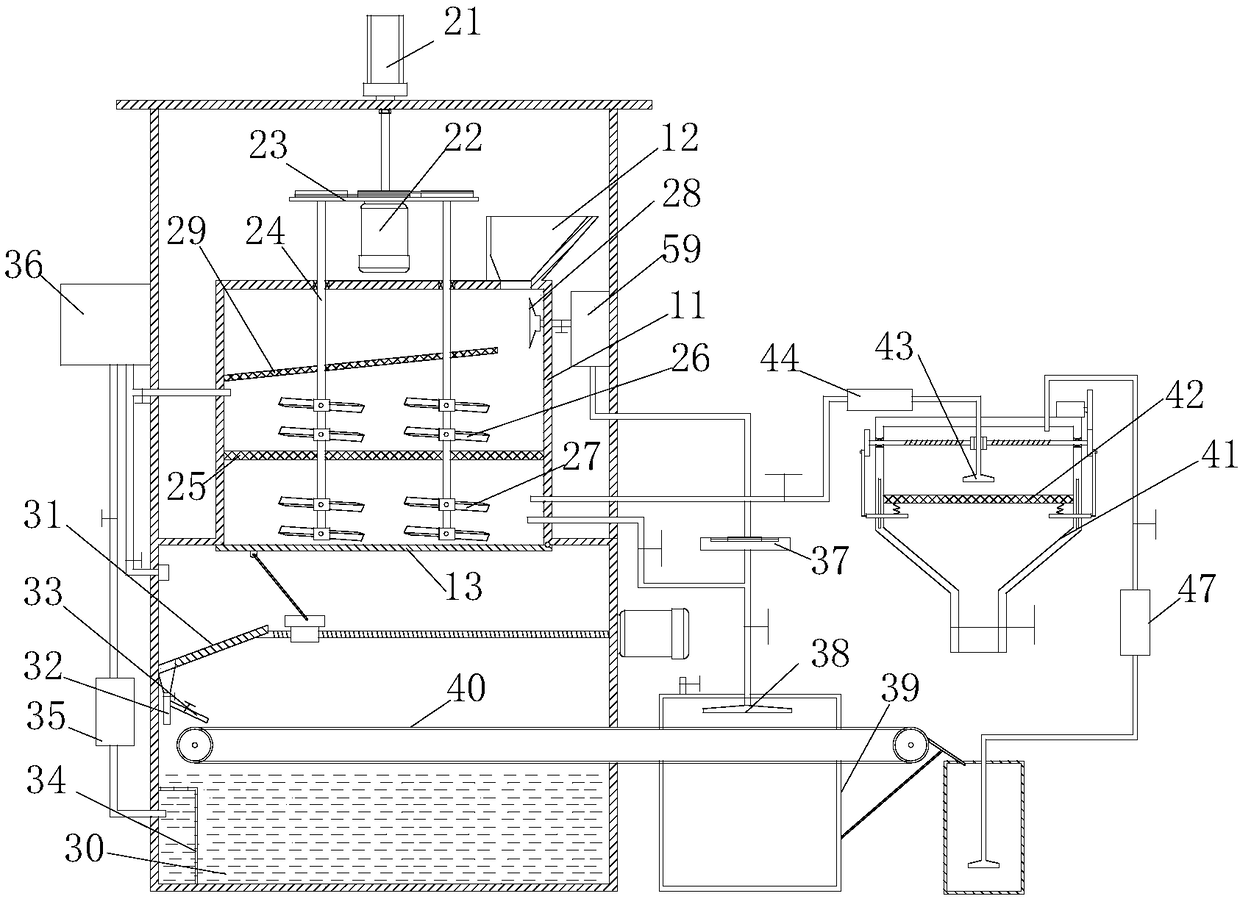

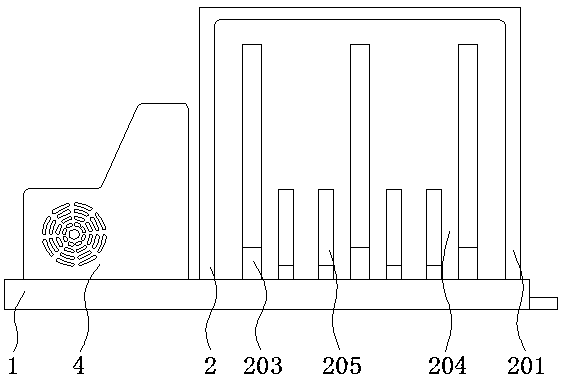

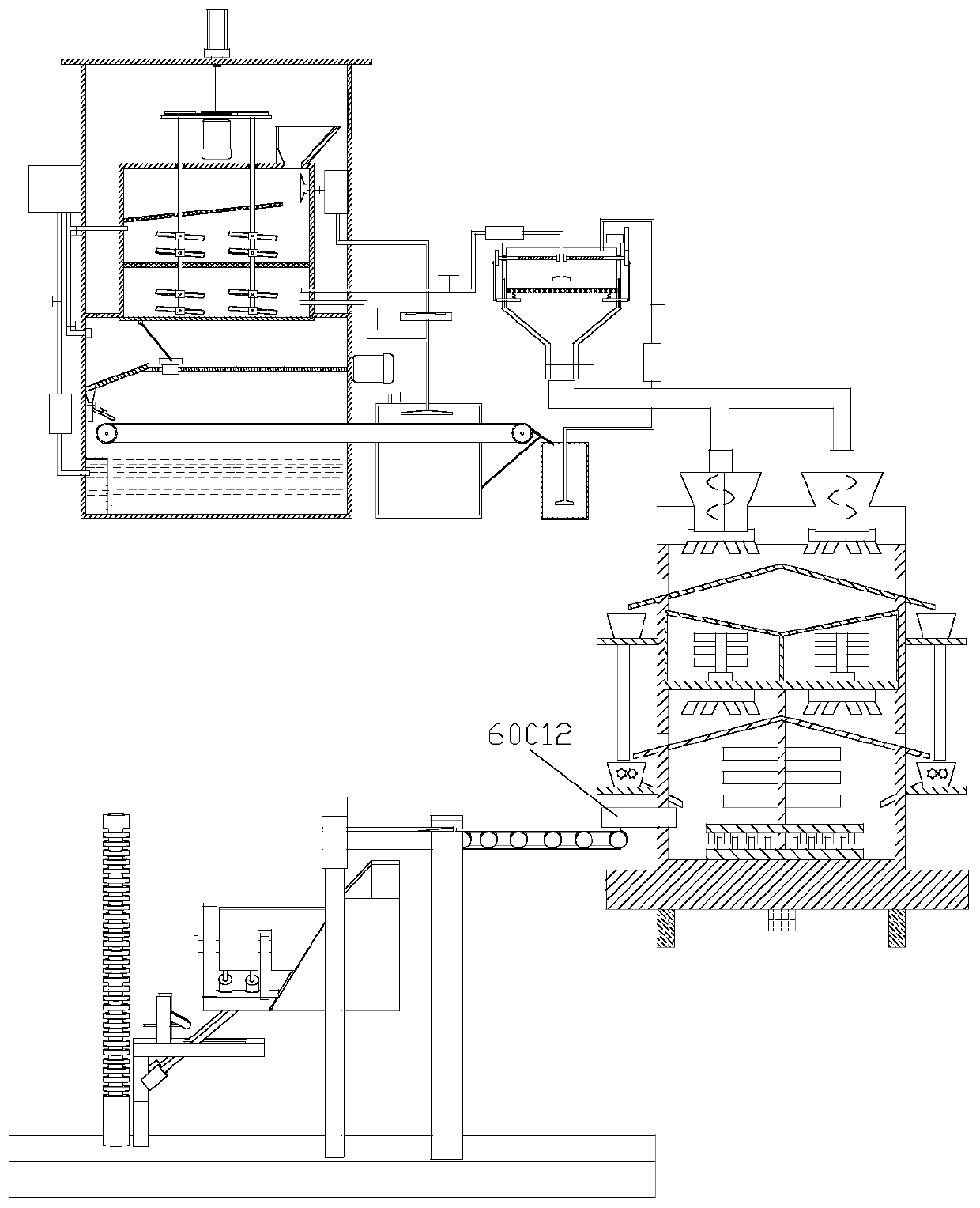

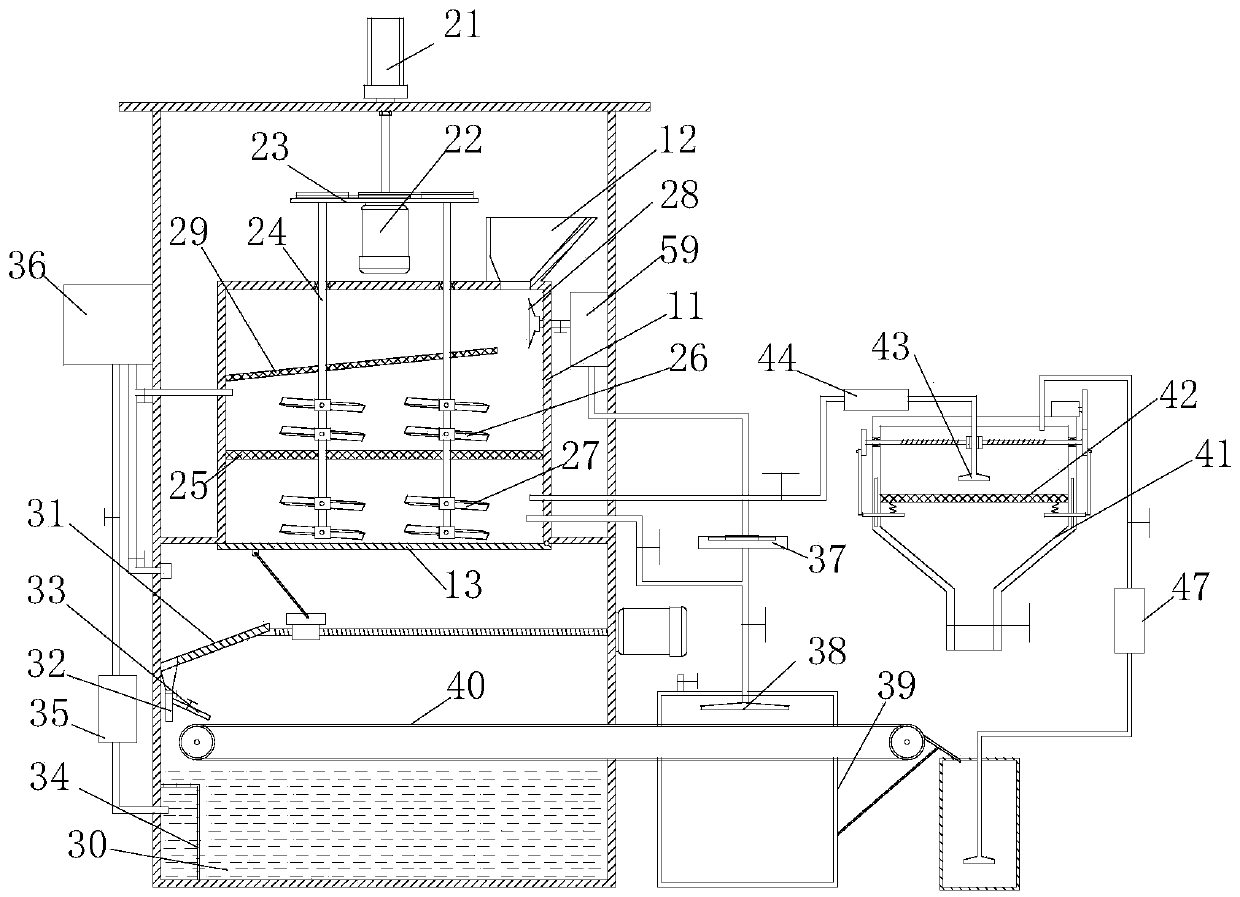

Corn flour production and processing mechanism based on multidirectional feeding

ActiveCN108654757AGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsCorn flourEngineering

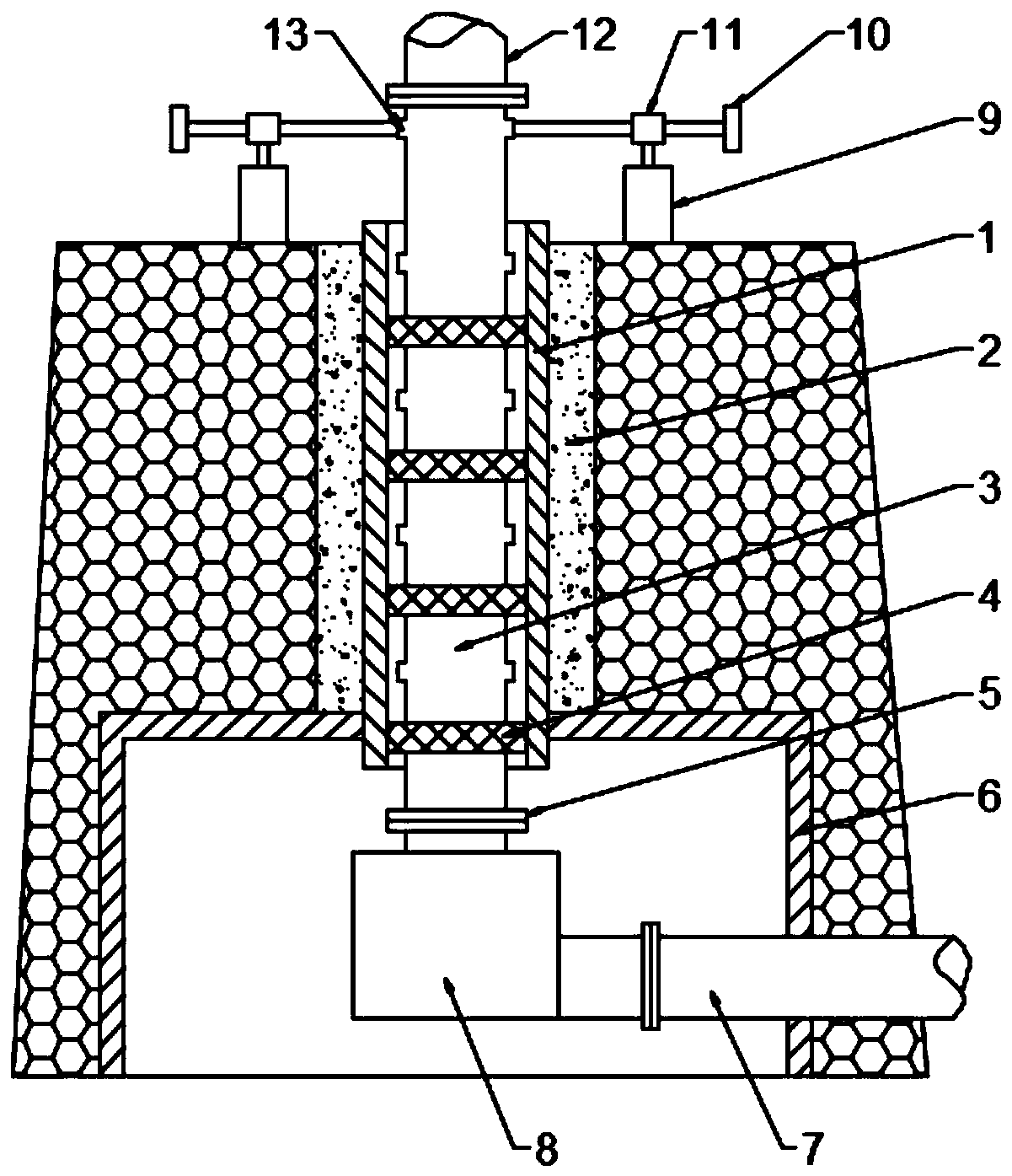

The invention discloses a corn flour production and processing mechanism based on multidirectional feeding. The corn flour production and processing mechanism comprises a corn grain crushing device, apowder mixing device and a powder transfer device according to the technological process from front to back. The corn grain crushing device comprises a crushing unit, a drying unit and a material return device according to the technological process in sequence. The powder mixing device comprises a material mixing tank and a material mixing upper cover covering the material mixing tank, and a cavity of the material mixing tank is internally provided with a first material mixing and screening plate, a first mixing chamber, a second material mixing and screening plate and a crushing / mixing integrated chamber from top to bottom in sequence. The powder transfer device comprises a transfer conveyor belt, a turnover discharging device, a transfer baffle, a conveyer bucket, a transfer elastic device and a transfer lifting base station from front to back in sequence. The corn flour production and processing mechanism has the advantages of quality guarantee of produced corn flour, good mixing effect of corn flour and flour, high continuity of operation, precise single feeding quantity and high working efficiency, and is not liable to caking or blockage.

Owner:安徽双全面粉有限公司

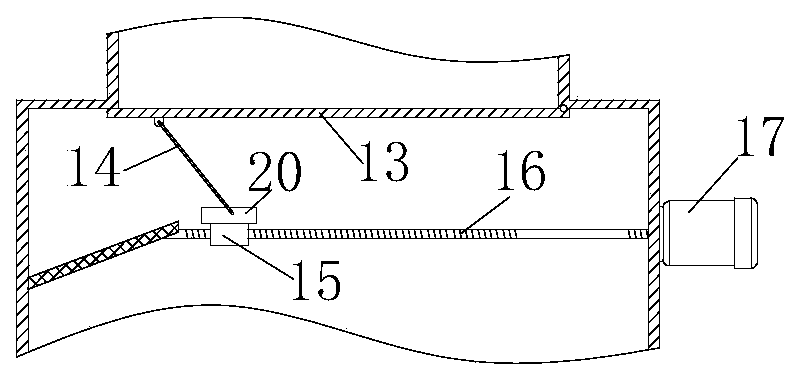

Corn flour dry-mixing mechanism

InactiveCN108435090AImprove product qualityReduce wearTransportation and packagingMixersEngineeringMixing chamber

The invention discloses a corn flour dry-mixing mechanism, which comprises a corn kernel grinding device and a powder mixing device sequentially from front to back according to a technical process. The corn kernel grinding device comprises a grinding unit, a drying unit and a return unit sequentially according to a technical process. The grinding unit comprises a grinding tank, a rotating shaft, adecontaminating mechanism, an upper grinding mechanism and a lower grinding mechanism, and the decontaminating mechanism, the upper grinding mechanism and the lower grinding mechanism are arranged inthe grinding tank. The top of the grinding tank is provided with a feeding port and an upper insertion port allowing vertical insertion of the rotating shaft, and the bottom of the grinding tank is provided with a discharging port. The powder mixing device comprises a mixing tank and an upper mixing cover which covers the mixing tank, and a cavity of the mixing tank is provided with a first mixing screen plate, a first mixing chamber, a second mixing screen plate and a grinding / mixing integrated chamber sequentially from top to bottom. The corn flour dry-mixing mechanism has advantages of guarantee of produced corn flour quality, effectiveness in mixing of corn flour and wheat flour and less proneness to caking and blockage.

Owner:芜湖拓云农业技术有限公司

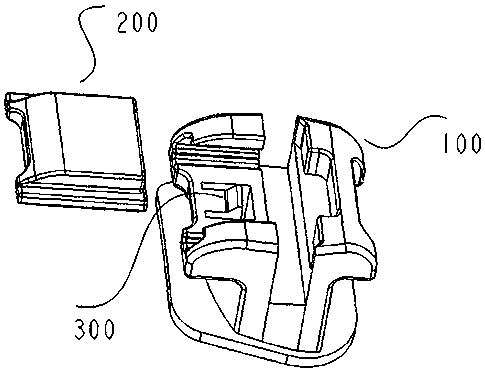

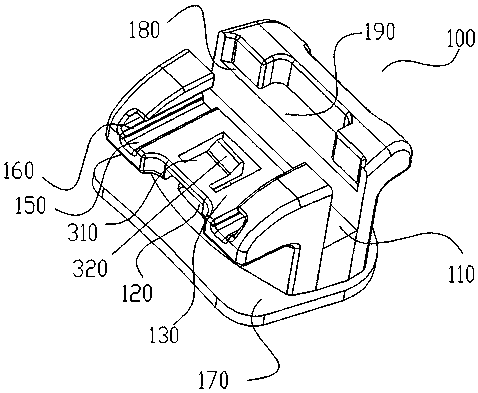

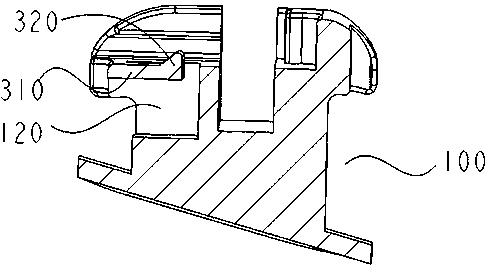

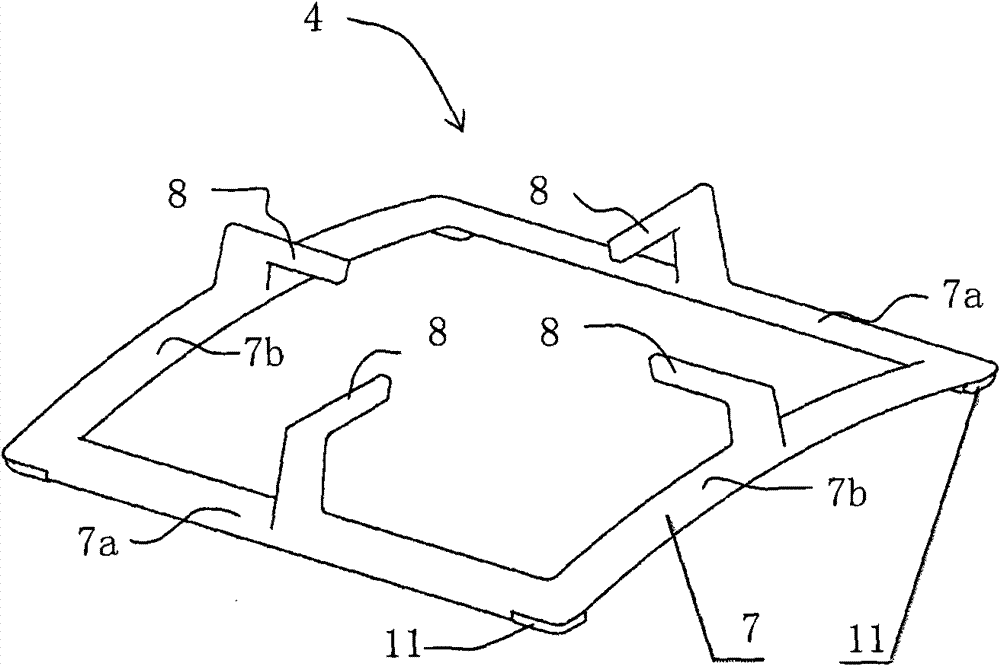

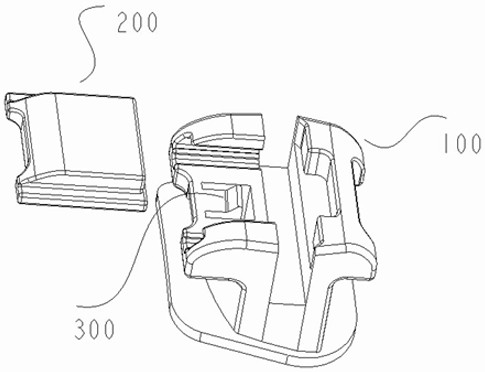

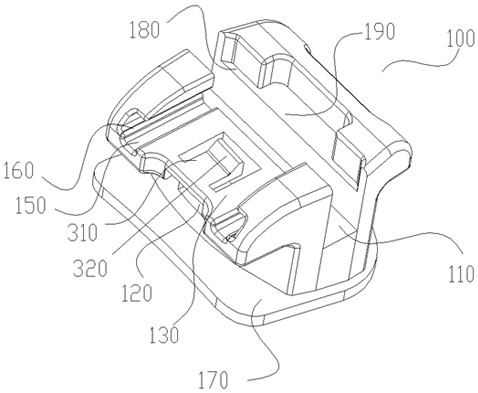

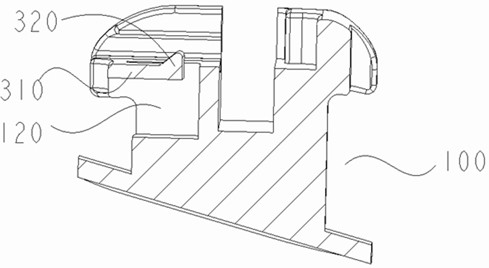

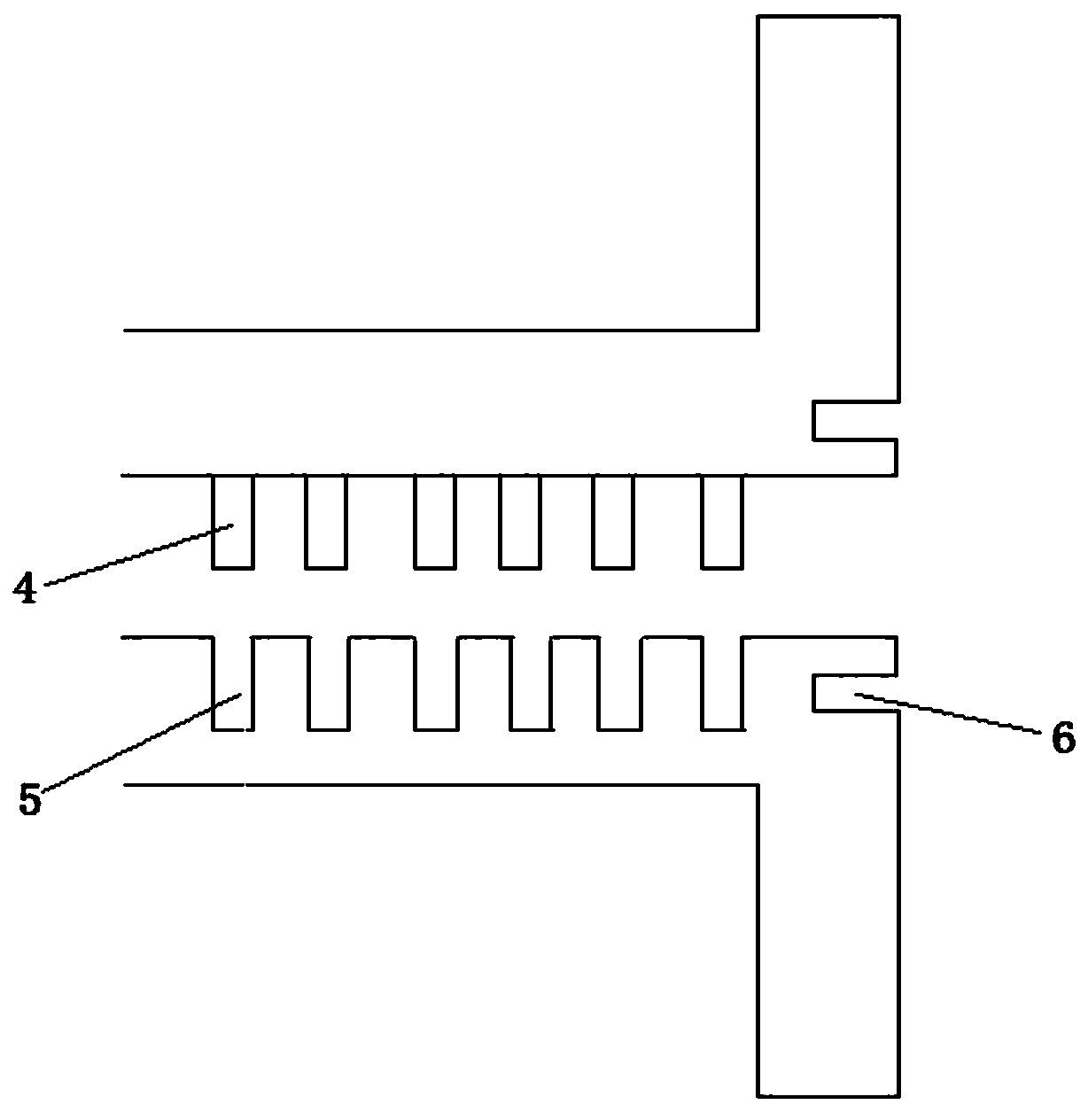

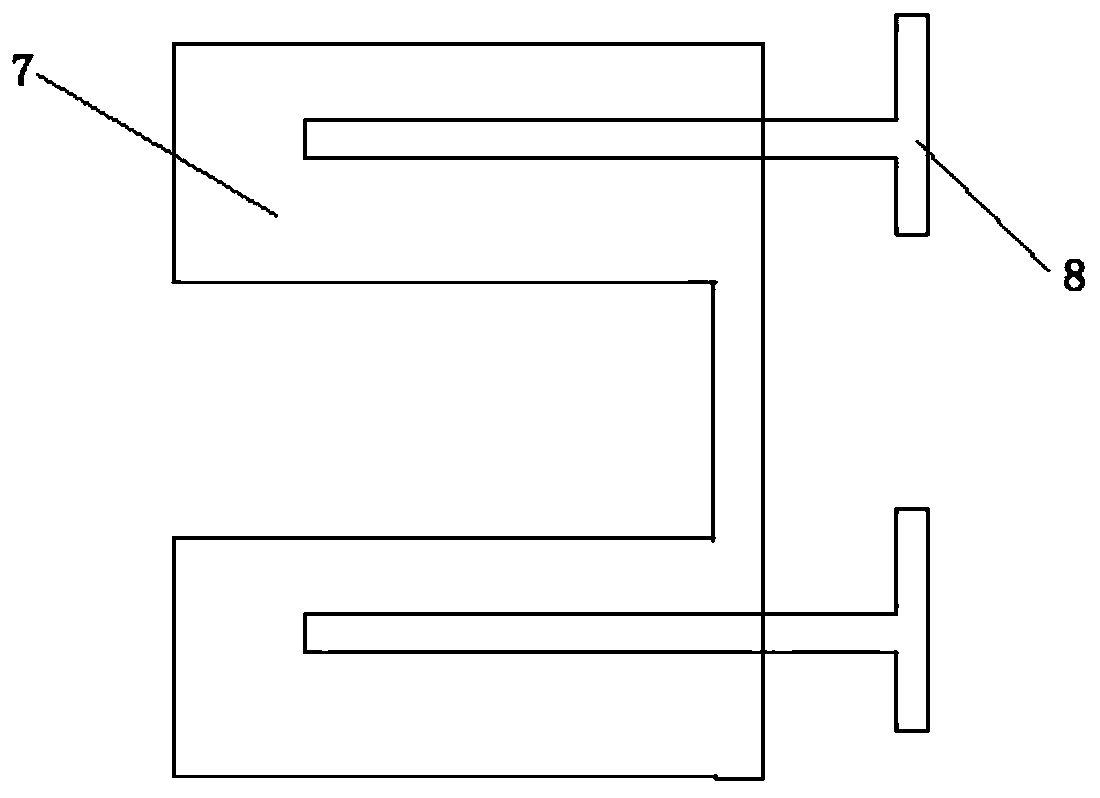

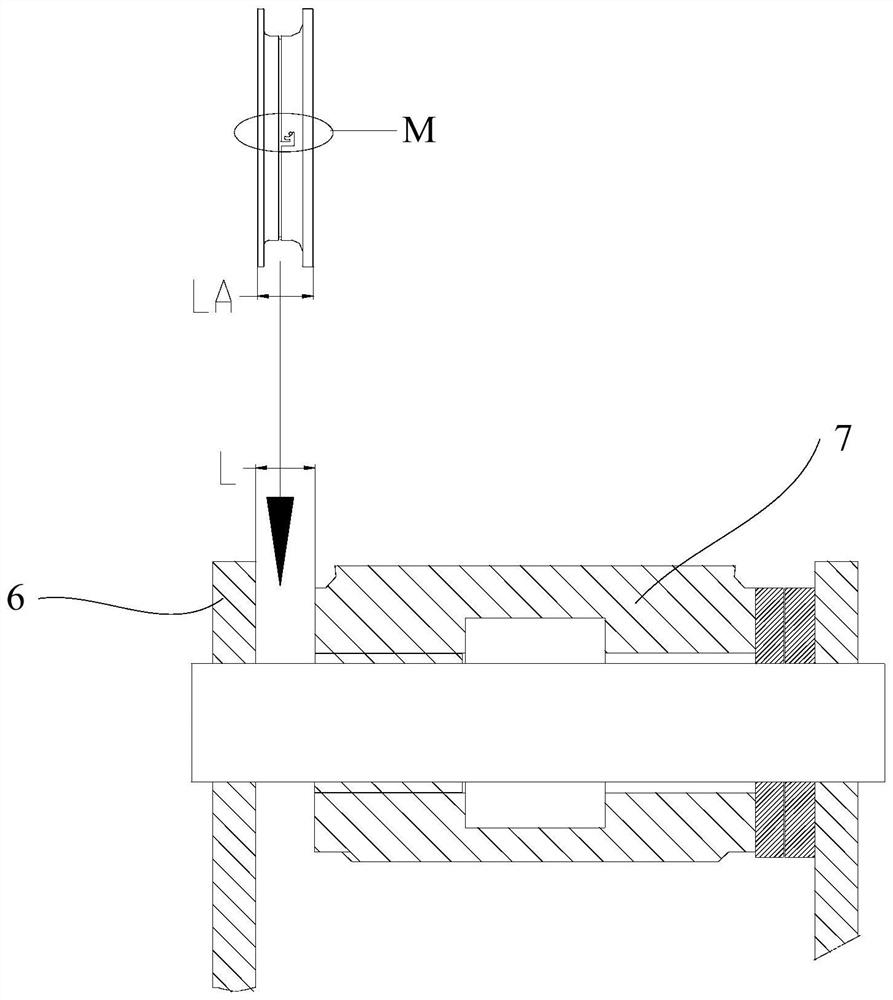

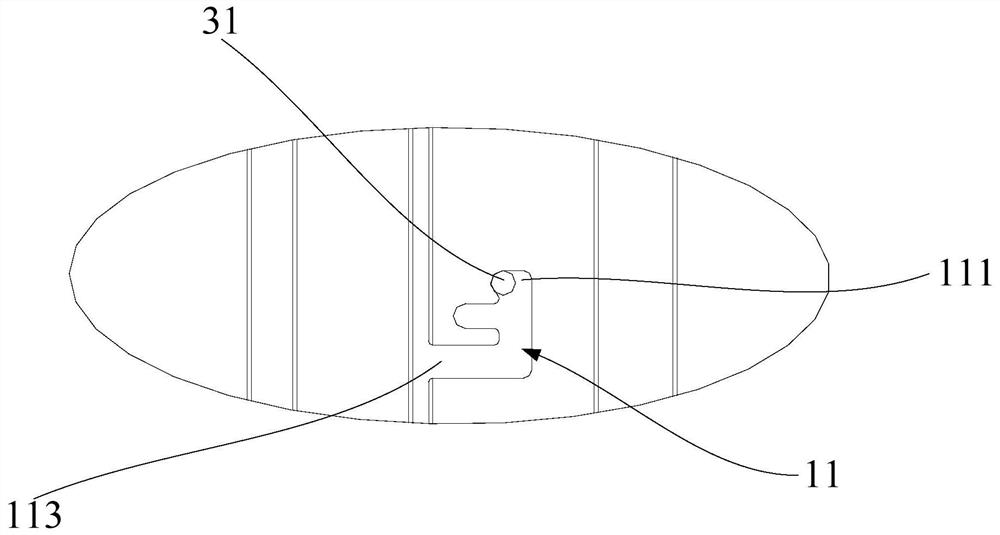

Self-ligating bracket

Owner:GUANGZHOU OO MEDICAL SCI LTD

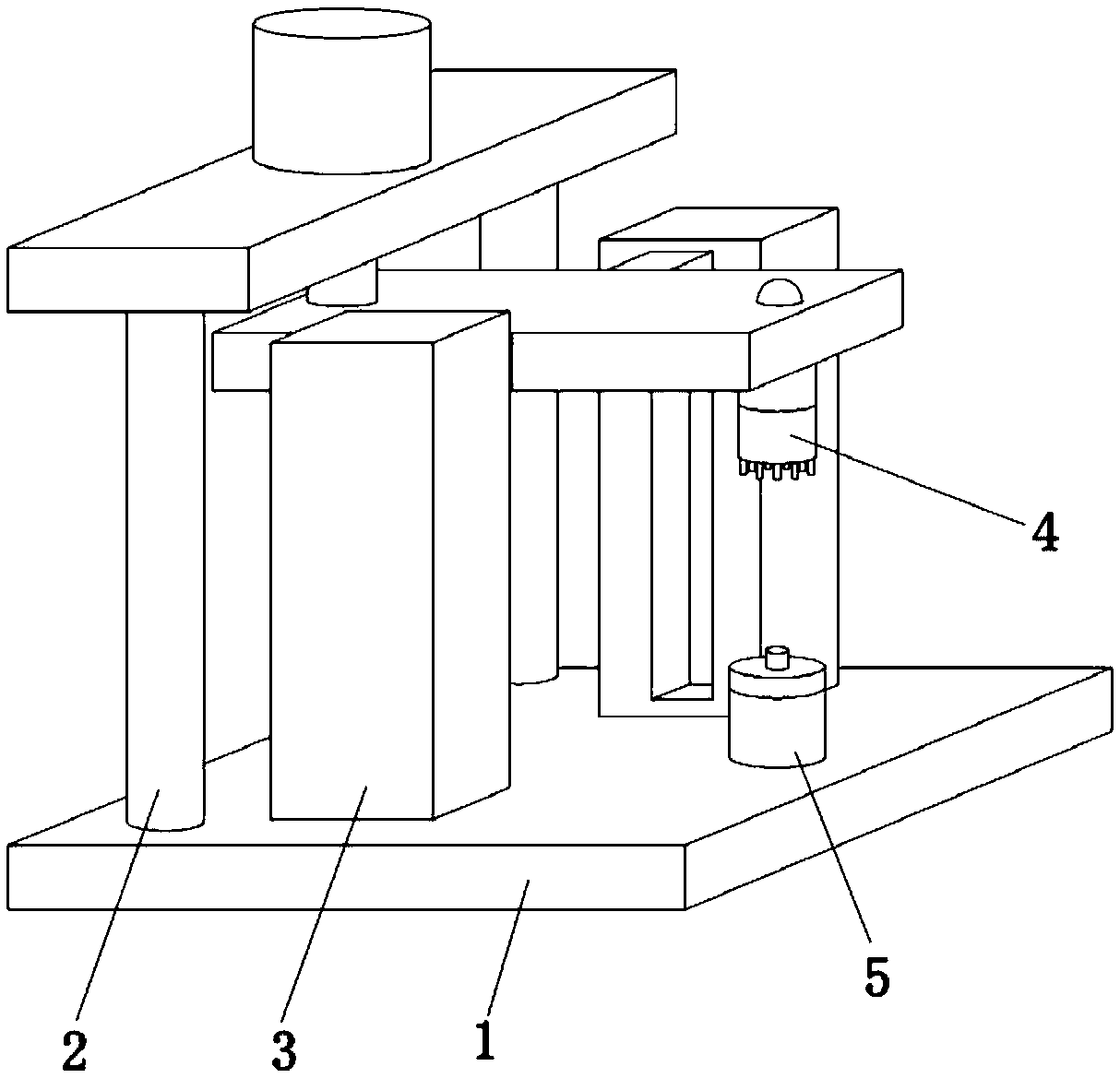

Bearing ball missing detecting device

InactiveCN109387367AAffect the appearanceMeet testing needsMachine bearings testingElectric/magnetic detectionMechanical engineeringEngineering

Owner:湖州华龙智能科技有限公司

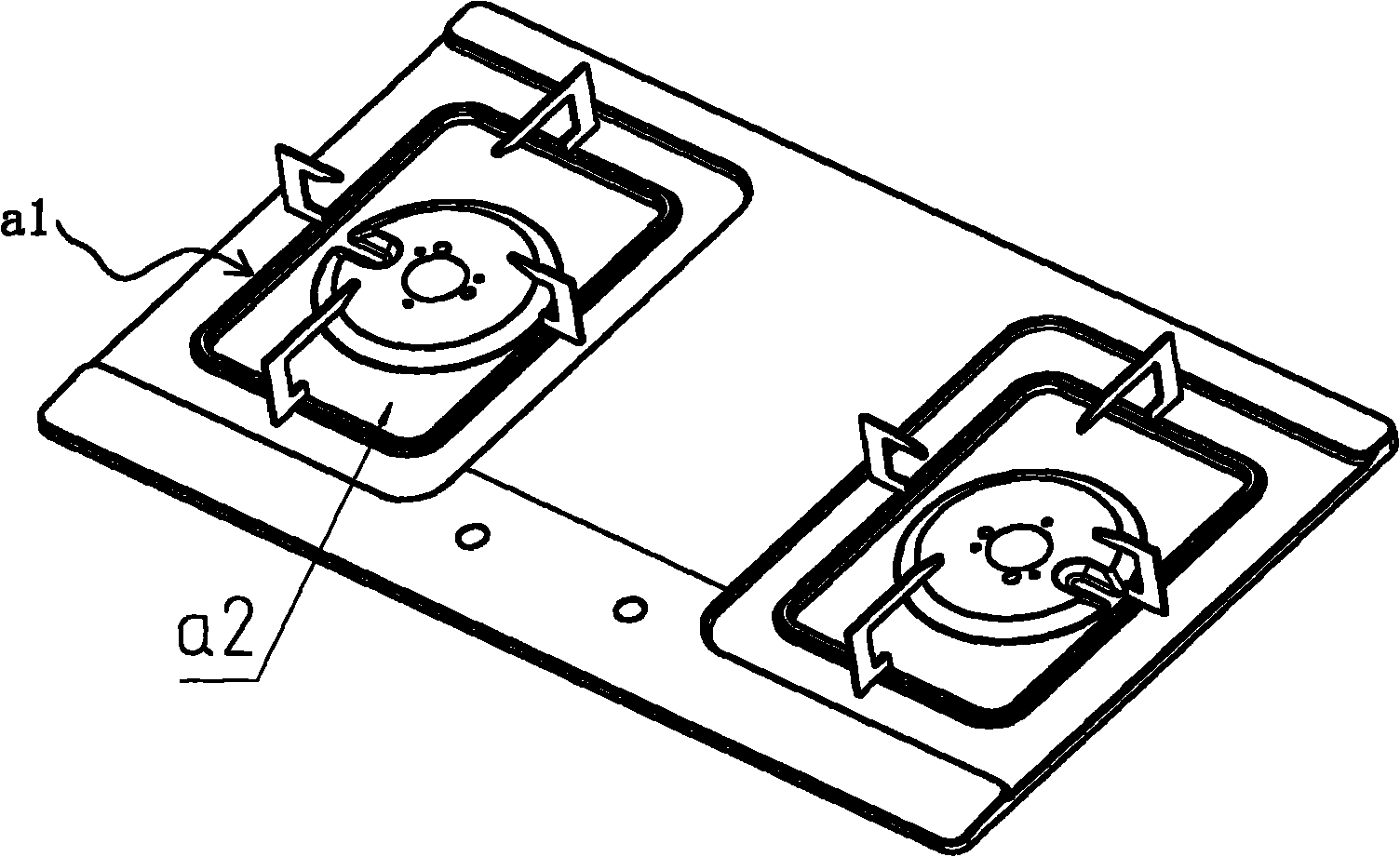

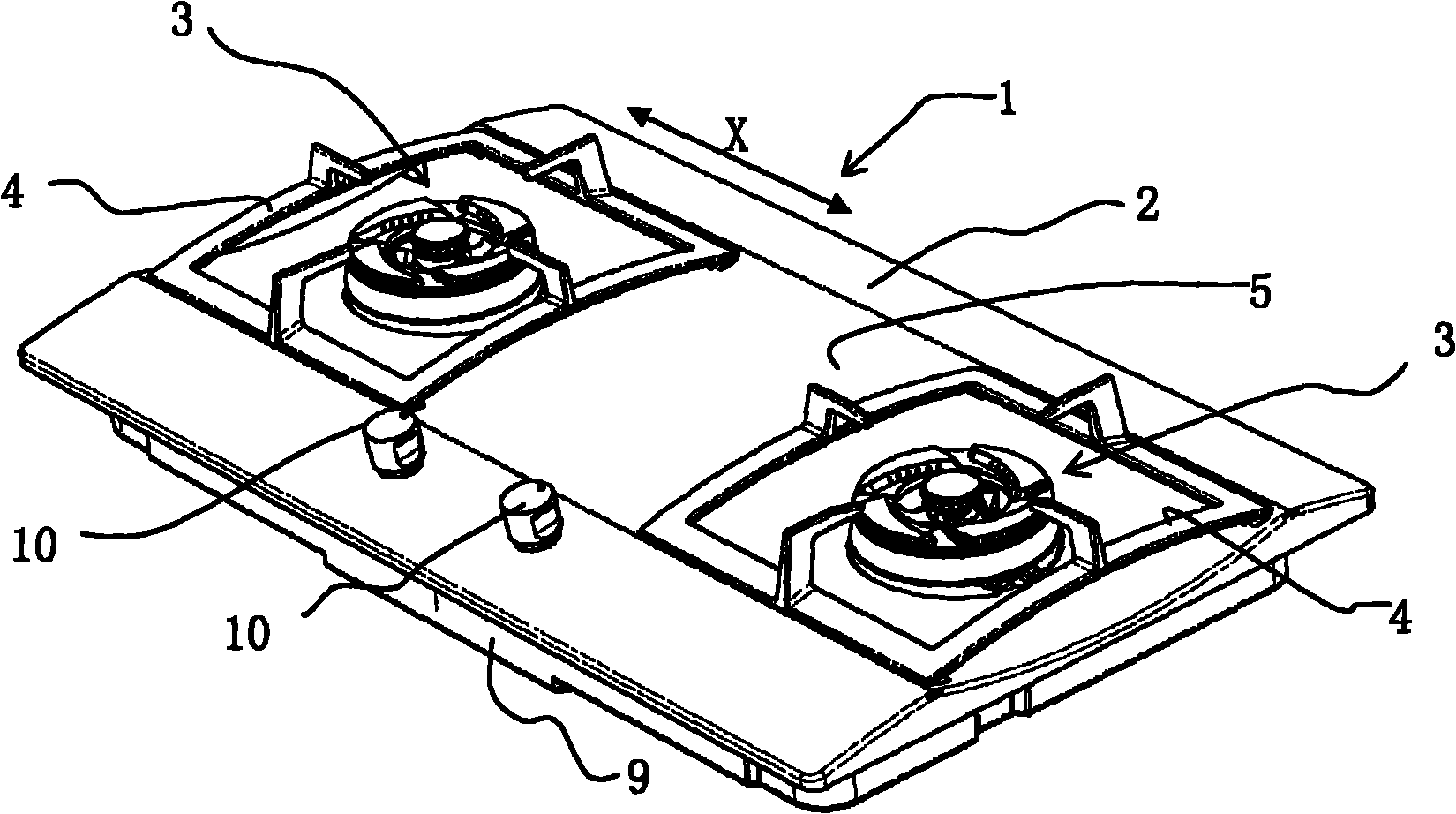

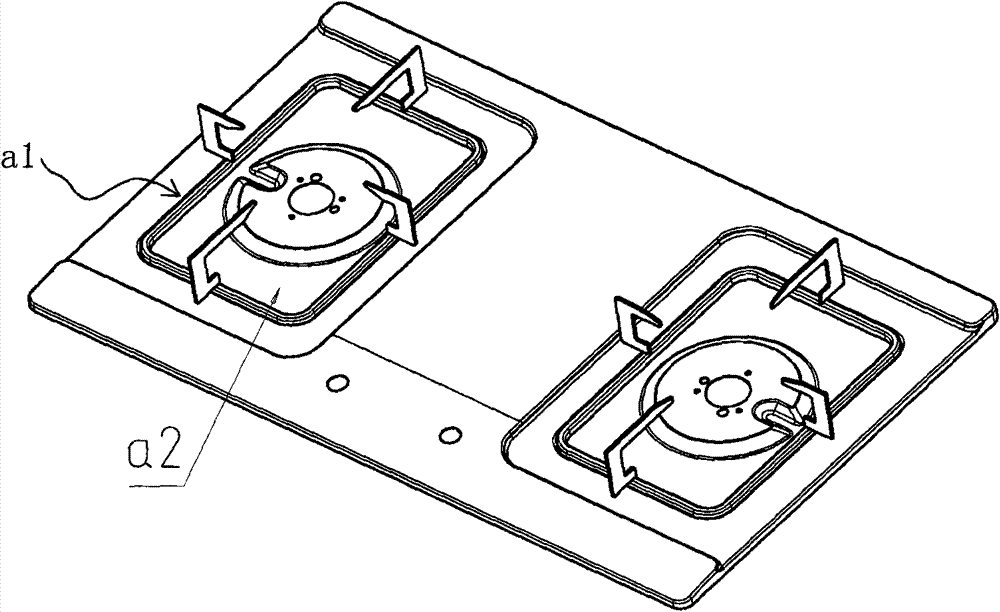

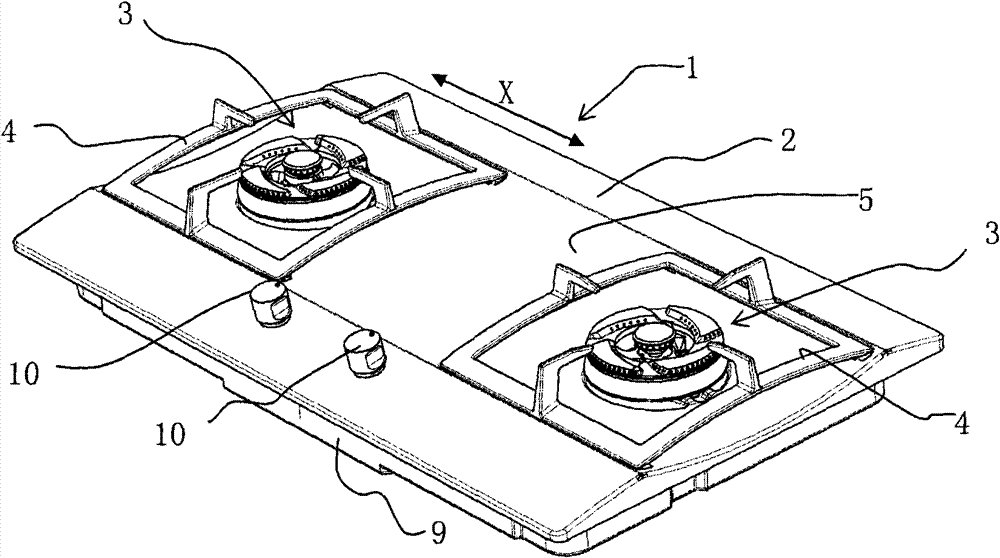

Gas stove

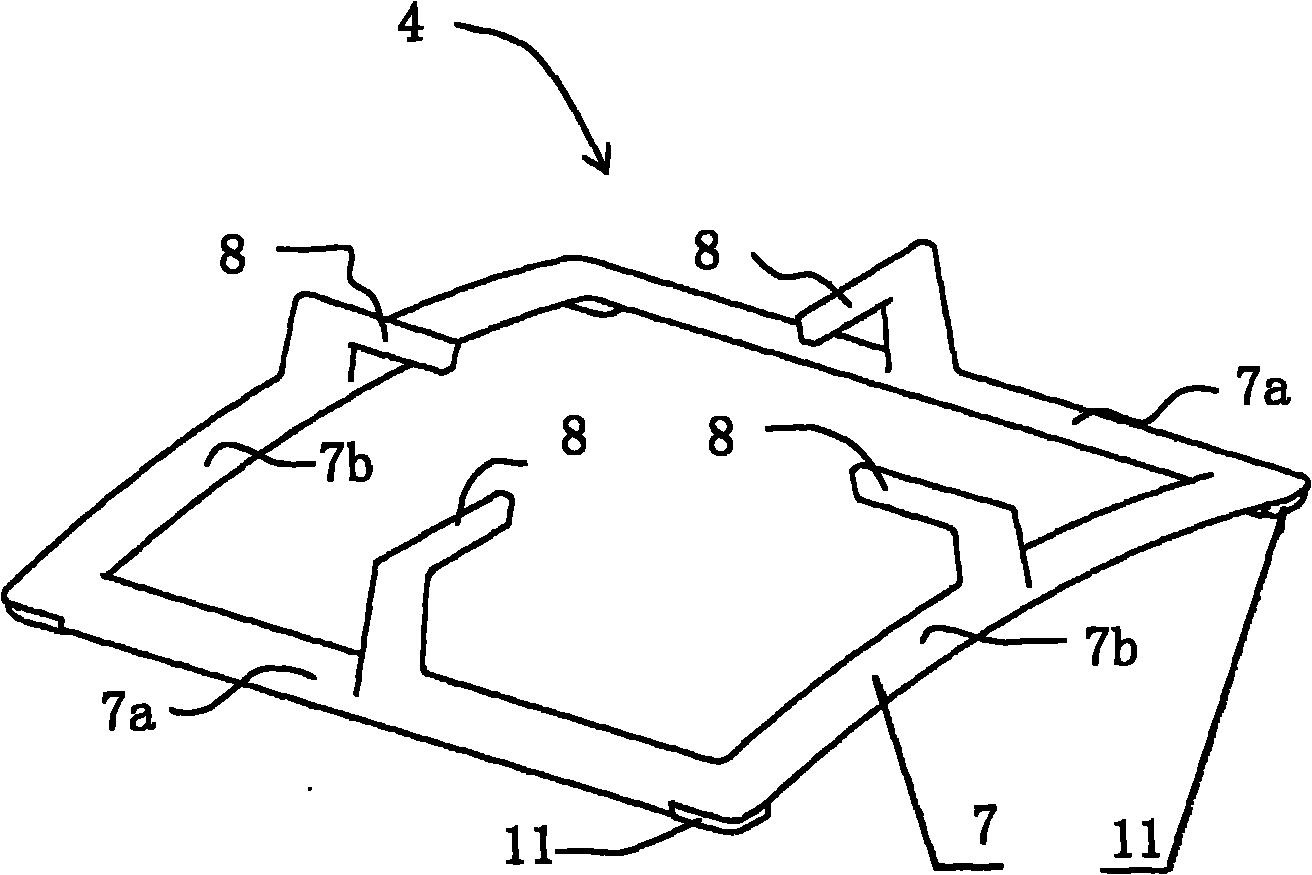

InactiveCN101995035AAvoid rigid frictionAvoid scratchesDomestic stoves or rangesLighting and heating apparatusEngineeringGas stoves

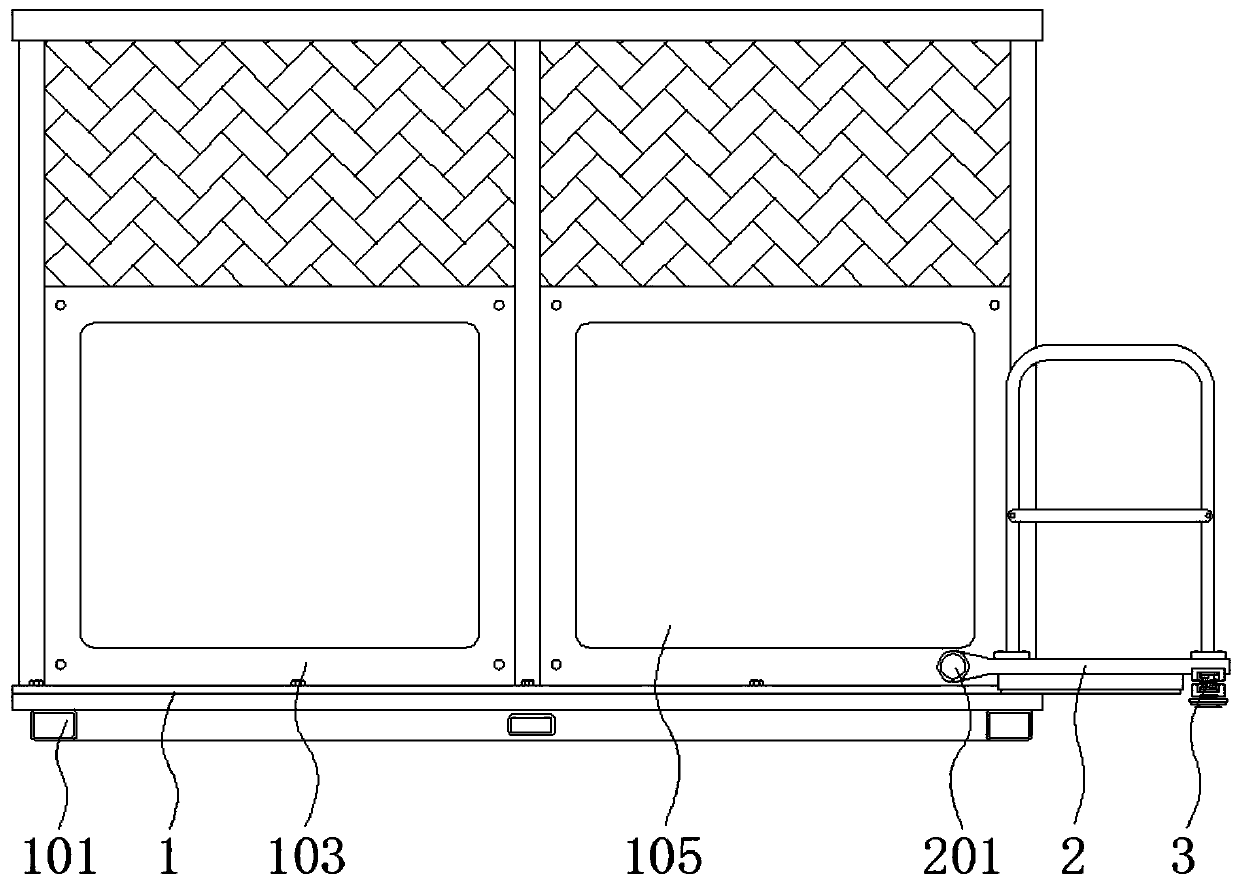

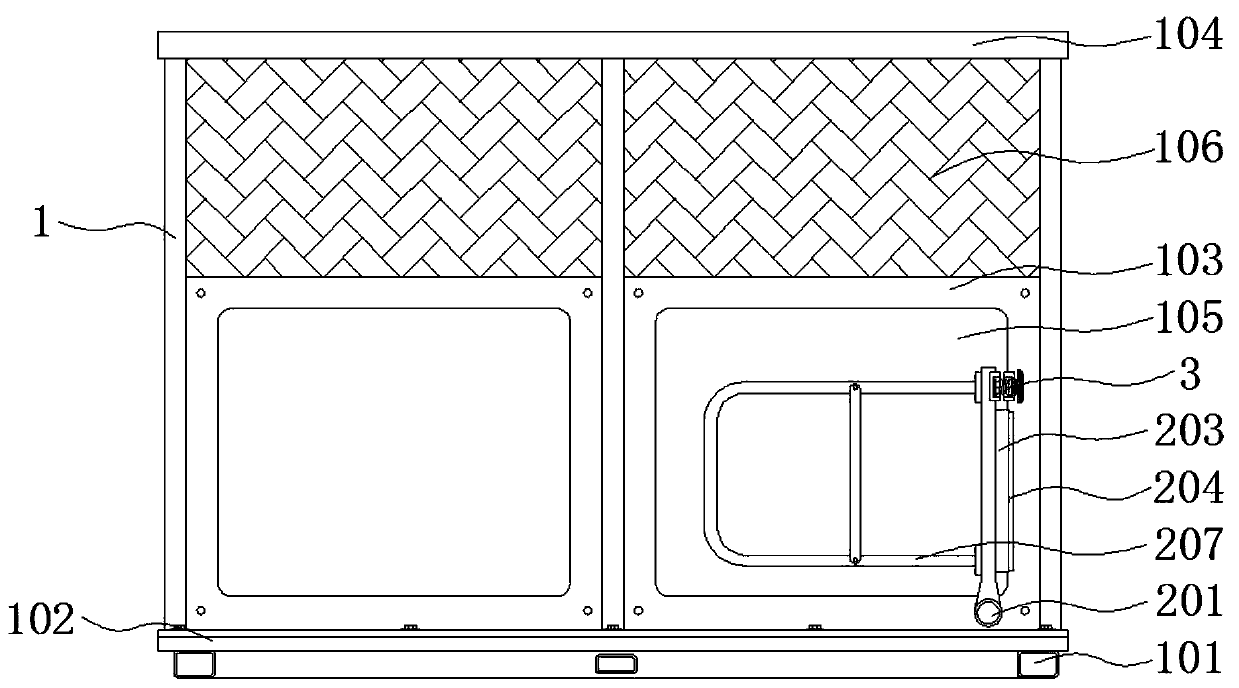

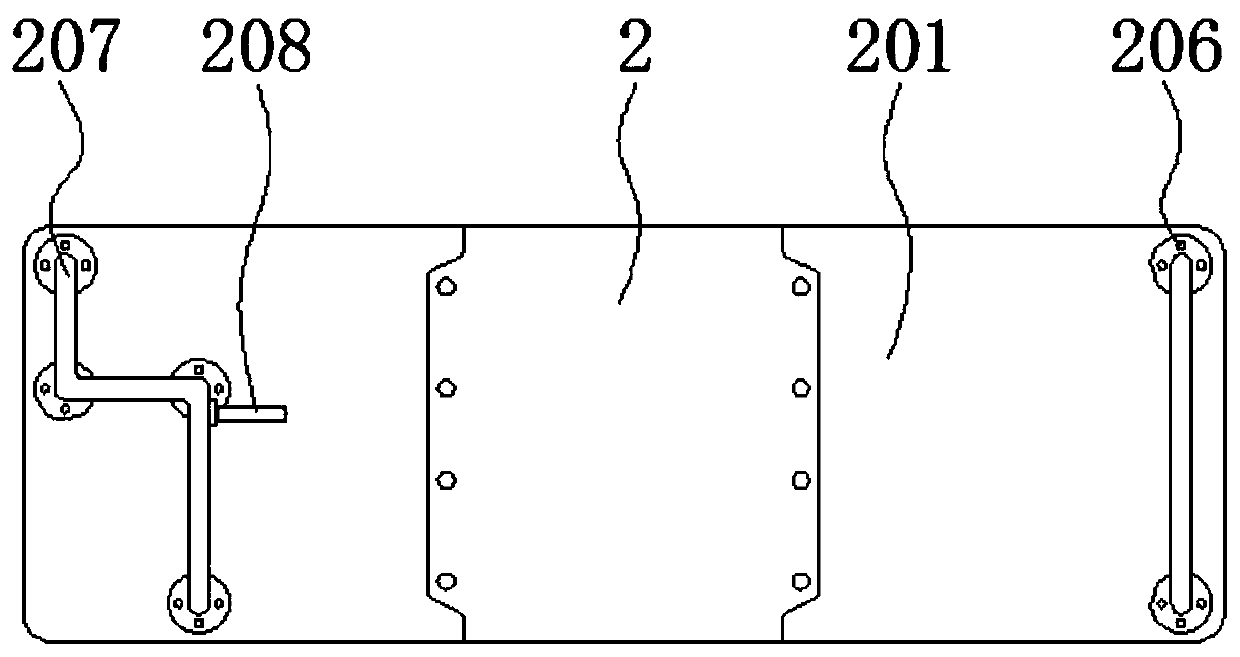

The invention relates to a gas stove (1), which comprises a panel (2) and a burner (3) and a pot support (4) which are arranged on the panel, and is characterized in that a groove (5) which extends parallel to the traverse direction of the panel is arranged on the panel, the cross section of the groove is of a circular arc shape, a structure for holding the burner is arranged at the bottom of the groove, and the pot support strides over the edges of the groove. In the gas stove in the technical scheme, the area needing contact for a long term between the pot support and the gas stove panel is reduced so as to avoid forming obstinate stains generated due to long-term hiding as much as possible. Meanwhile, because the pot support is erected over the groove, the outer flame can be effectively utilized when the gas stove is used, thereby improving the combustion efficiency of the whole gas stove.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

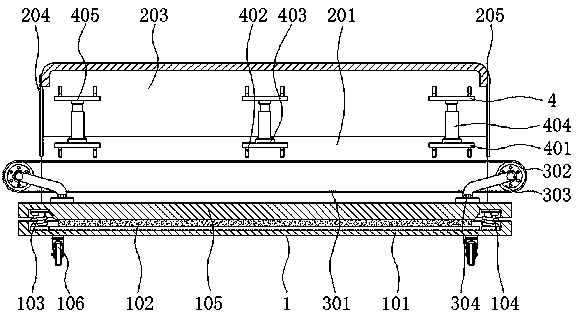

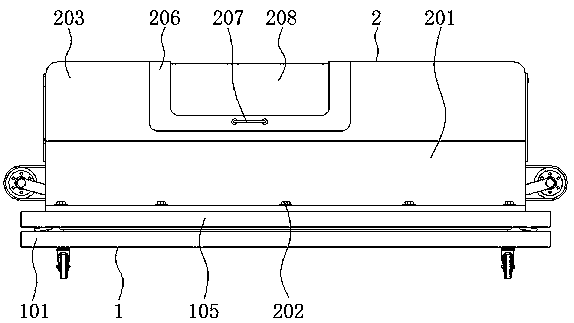

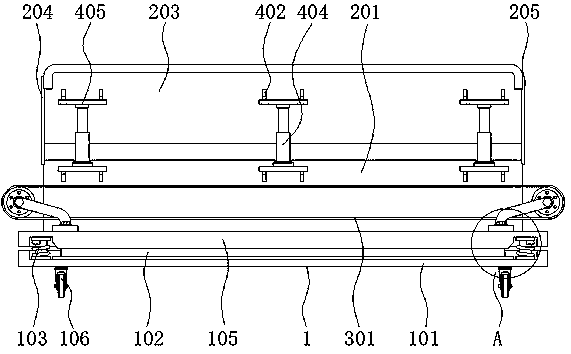

Transmission device with dust-proof structure for flexible pasting film production

InactiveCN111168986AAvoid rigid frictionAchieving Elastic Cushioning CapabilityFouling preventionEngineeringMaterials science

Owner:GUANGDONG HUST IND TECH RES INST

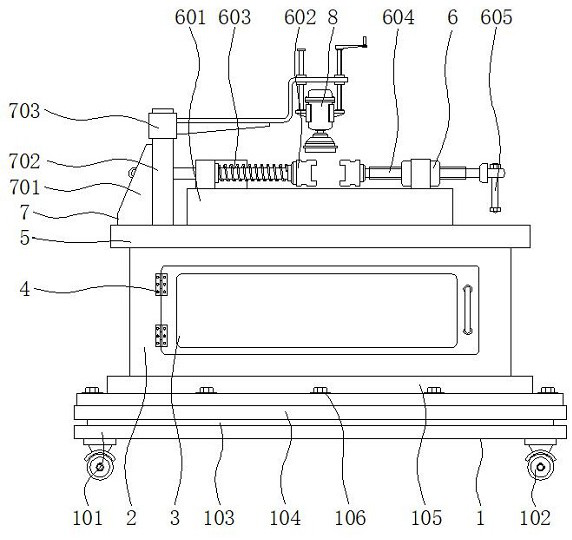

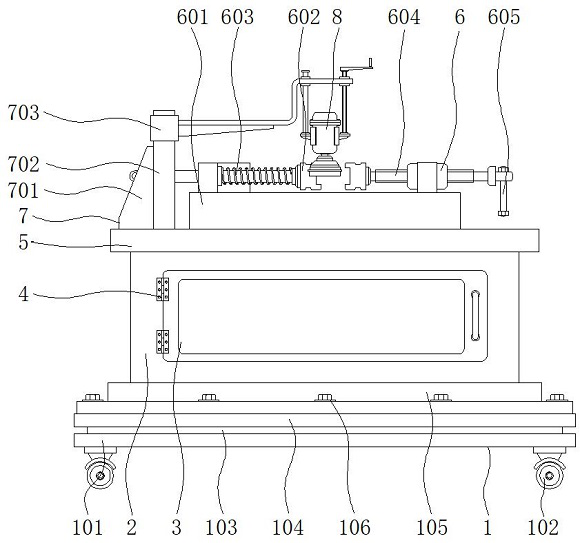

Air tightness test equipment facilitating internal part cleaning for railway track health maintenance

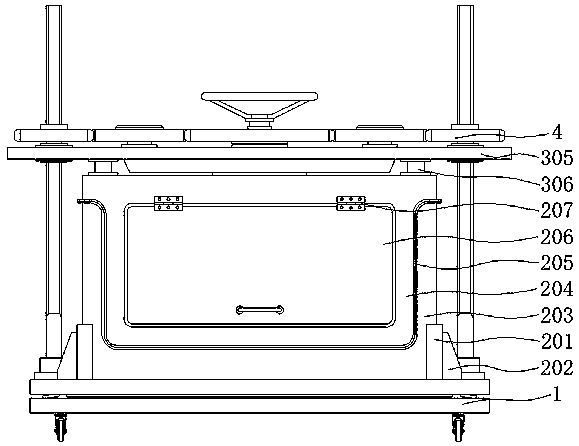

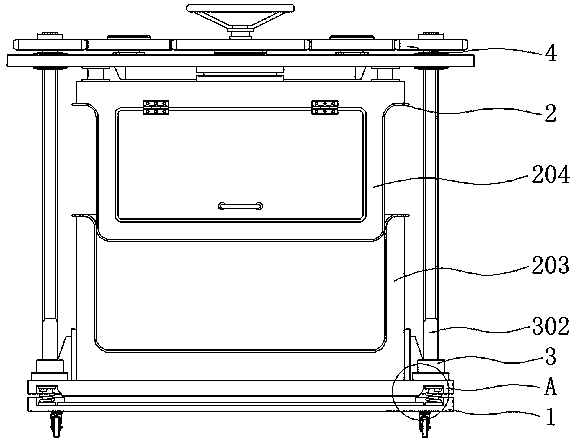

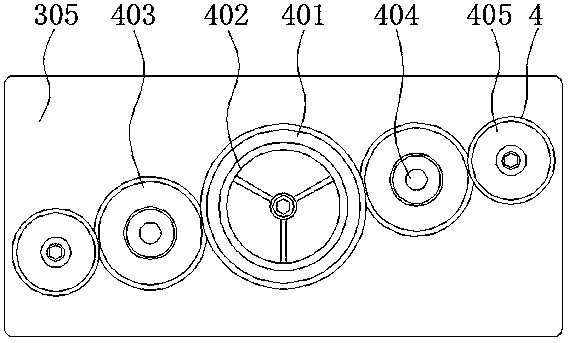

InactiveCN110763401AAvoid rigid frictionGuaranteed stabilityFluid-tightness measurement using fluid/vacuumGear wheelAir tightness

The invention discloses air tightness test equipment facilitating internal part cleaning for railway track health maintenance, relates to the technical field of railway track test equipment, and in particular relates to the air tightness test equipment facilitating internal part cleaning for railway track health maintenance. The air tightness test equipment facilitating internal part cleaning forrailway track health maintenance comprises a support base and a power control mechanism; a main body shell is arranged over the support base; the power control mechanism is arranged over the main bodyshell; the power control mechanism comprises a power gear, a rotating wheel, transmission gears, rotating shafts, control gears and threaded sleeves; both the left and right sides of the power gear are each provided with the transmission gear; and the control gears are arranged at one sides, away from the power gear, of the transmission gears. According to the air tightness test equipment facilitating internal part cleaning for railway track health maintenance in the invention, the use performance of the whole device is greatly improved while the structure is increased; the improved equipmentis relatively simple and convenient when in use; with the help of gear meshing transmission, opening and closing of the device are realized; and use requirements of people are effectively satisfied.

Owner:DONGGUAN UNIV OF TECH

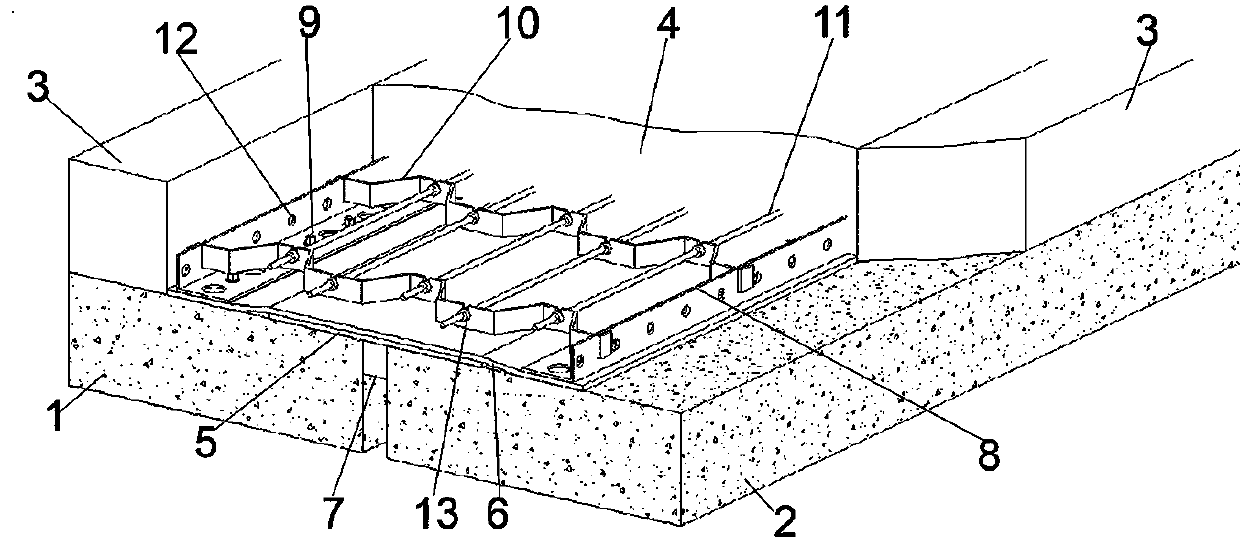

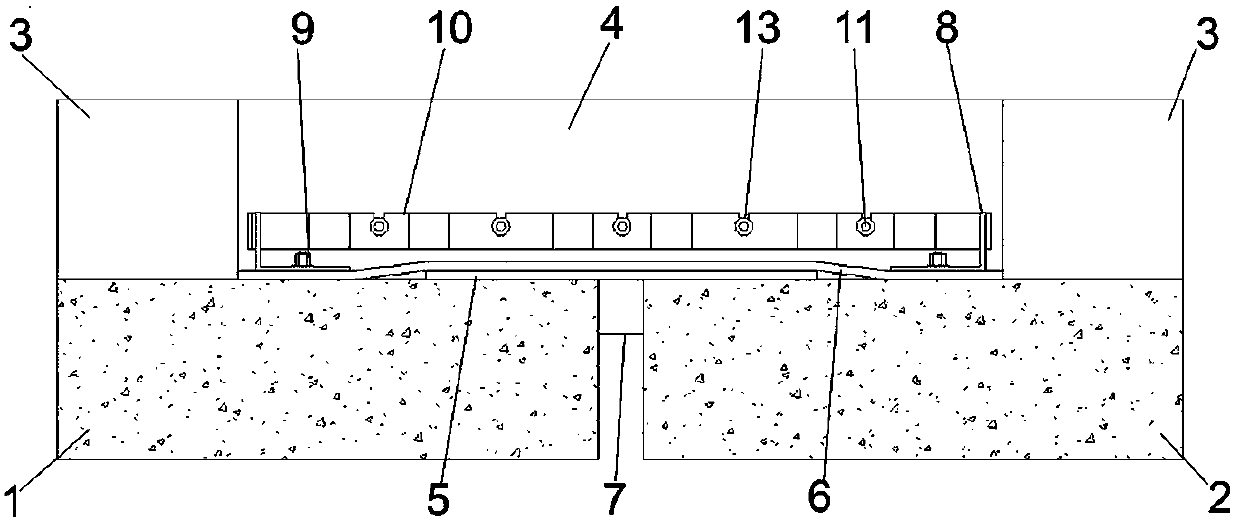

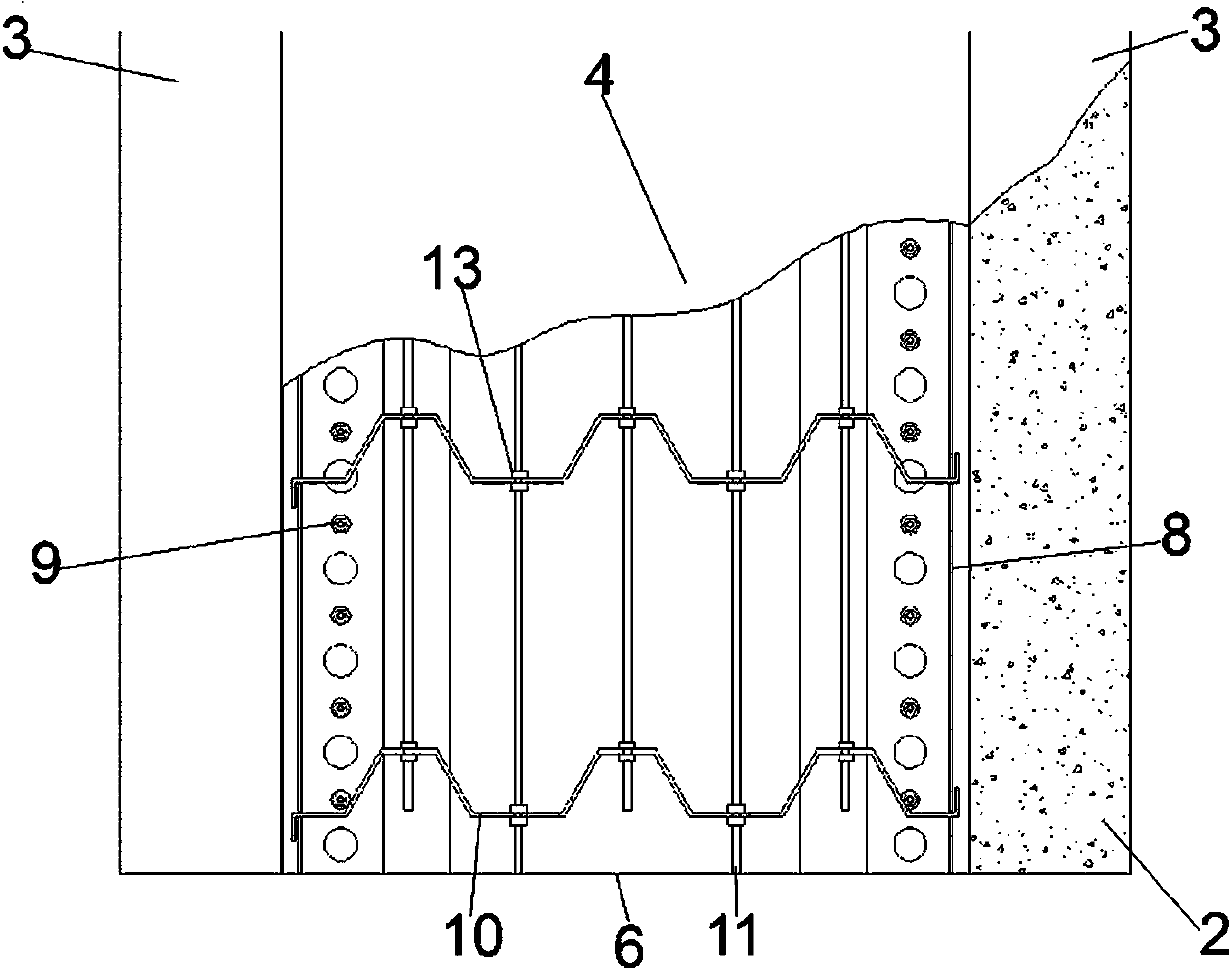

Landfill type bridge expansion device and construction method

PendingCN110485288AAvoid direct contactPrevent osmotic blockageBridge structural detailsPolymer concreteEngineering

The invention belongs to the technical field of construction engineering, and particularly discloses a landfill type bridge expansion device and a construction method, the landfill type bridge expansion device comprises a stress framework, the stress framework comprises a tension and compression resistant steel plate group matched with an expansion joint, and further comprises a transverse steel bar group matched with the tension and compression resistant steel plate group; one end of the tensile and compression steel plate group is connected with the bridge, and the other end is connected with the back wall; the stress framework is filled with polymer concrete, and the polymer concrete is aligned with the pavement; the expansion joint is provided with a composite board set matched with the stress framework. Connection of the bridge expansion joint is achieved by arranging the stress framework, the device can be prevented from making direct contact with a vehicle through the landfill type design, the effect of driving comfort can be effectively achieved, the device can be prevented from making contact with external air, moisture and the like, and the service life of the device is prolonged.

Owner:河南聚研材料科技有限公司

Gas stove

InactiveCN101995035BAvoid rigid frictionAvoid scratchesDomestic stoves or rangesLighting and heating apparatusEngineeringGas stoves

The invention relates to a gas stove (1), which comprises a panel (2) and a burner (3) and a pot support (4) which are arranged on the panel, and is characterized in that a groove (5) which extends parallel to the traverse direction of the panel is arranged on the panel, the cross section of the groove is of a circular arc shape, a structure for holding the burner is arranged at the bottom of the groove, and the pot support strides over the edges of the groove. In the gas stove in the technical scheme, the area needing contact for a long term between the pot support and the gas stove panel is reduced so as to avoid forming obstinate stains generated due to long-term hiding as much as possible. Meanwhile, because the pot support is erected over the groove, the outer flame can be effectively utilized when the gas stove is used, thereby improving the combustion efficiency of the whole gas stove.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

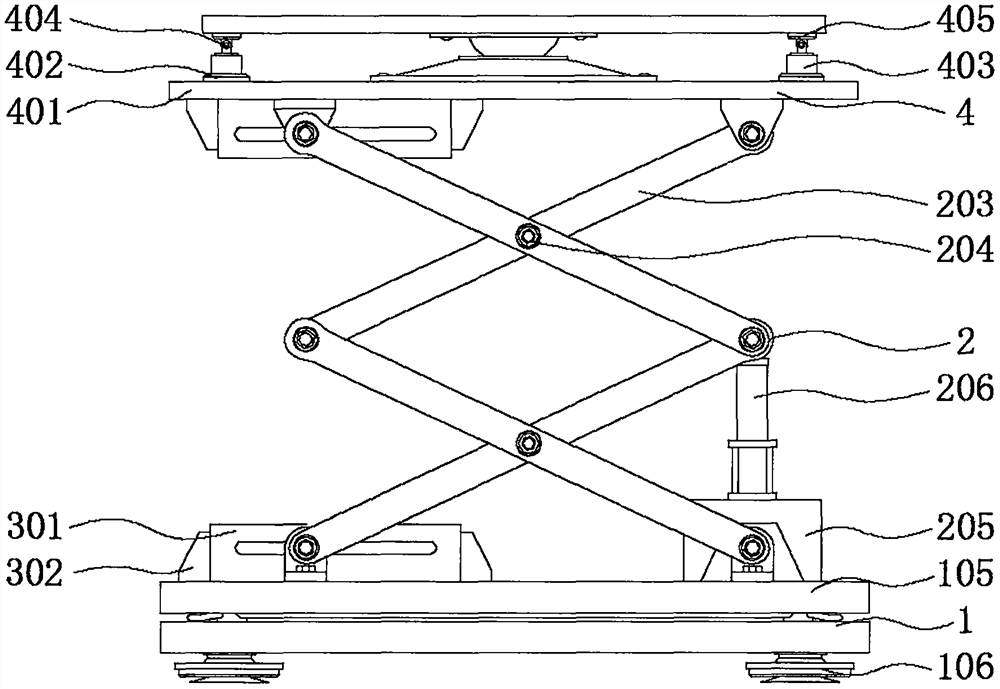

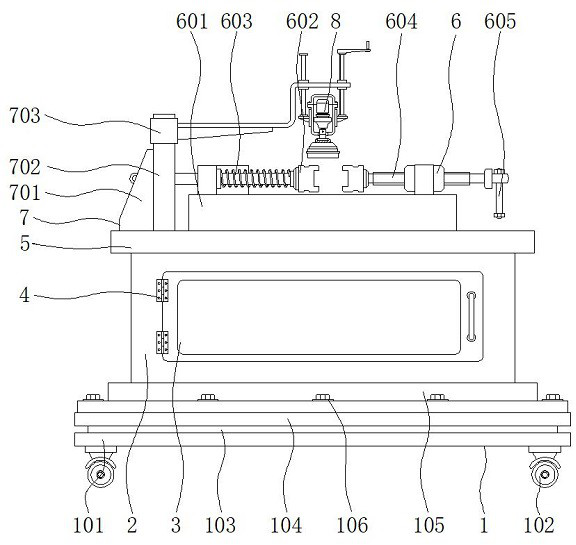

Convenient combined mounting equipment for jack

InactiveCN114654209AQuality improvementReduce clamping forceLifting devicesMetal working apparatusJackscrewCylinder block

The invention relates to the technical field of jacks, and discloses jack convenient combination and installation equipment which comprises a base, a fixing table and two supporting rods are welded to the top of the base, a fixing plate is slidably connected between the two supporting rods, a clamping plate is welded to the tops of the two fixing plates, and an air cylinder is always arranged above the clamping plate; a lubricating mechanism is welded to the bottoms of the two fixing plates, and an accurate shaft mechanism is arranged in the fixing table. The piston rod penetrates through the center of the movable disc, makes contact with the lubricating ball plug and extrudes the lubricating ball plug in the opposite direction to open the oil outlet pipe, and at the moment, the extruded lubricating oil in the feeding cavity is sprayed to the piston rod from the oil outlet pipe, so that the friction force on the side face of the piston rod is reduced; therefore, the effect of preventing rigid friction between the piston rod and the cylinder body when the piston rod is guided into the cylinder body is achieved, the piston rod is prevented from being scratched, and the quality of the assembled jack is improved.

Owner:郑奎春

Rail transit fault diagnosis simulation experiment rail device

InactiveCN110767013AAvoid rigid frictionRealize the collision test operationCosmonautic condition simulationsSimulatorsTrackwaySteel frame

The invention discloses a rail transit fault diagnosis simulation experiment rail device, and relates to the technical field of rail transit, in particular to a rail transit fault diagnosis simulationexperiment rail device. The rail transit fault diagnosis simulation experiment rail device comprises a pressure-bearing base and an experiment rail, wherein an anti-impact plate surface is arranged above the left end of the pressure-bearing base; the experiment rail is arranged on the right side of the anti-impact plate surface; the experiment rail comprises a composite layer, a mounting base, anembedded steel frame, a track main body, guide rail frames and connecting screws; the embedded steel frame is arranged in the upper end of the mounting base; the guide rail frames are arranged at thefront end and the rear end of the rail main body respectively; and a control console is arranged at the back of the experiment rail. According to the rail transit fault diagnosis simulation experiment rail device, the use requirement of the whole device is greatly improved while the structure is increased, the operability of the improved experiment rail device is more comprehensive, various performance tests can be carried out on the rail transit, and the use requirement of people is effectively met.

Owner:DONGGUAN UNIV OF TECH

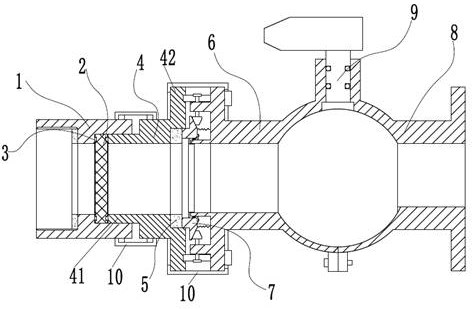

Detachable combined type valve structure

InactiveCN112747158AStable distanceStable sealingFlanged jointsFiltration separationPhysicsVALVE PORT

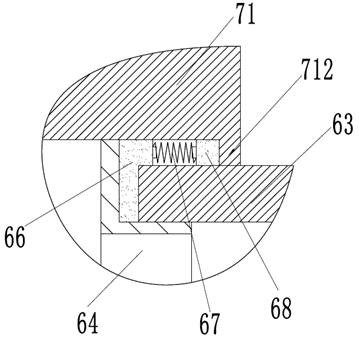

The invention discloses a detachable combined type valve structure. The detachable combined type valve structure comprises a connecting cylinder, a filter screen placed in the connecting cylinder, a pressing sleeve which is inserted into the connecting cylinder and abuts against the filter screen, a first valve body half shell and a second valve body half shell which are combined together, a valve element body limited between the first valve body half shell and the second valve body half shell, and an adjusting locking mechanism, wherein a valve body flange plate of the first valve body half shell is provided with a connecting pipeline communicating with the valve cavity, the adjusting and locking mechanism comprises a floating sliding sleeve arranged on the connecting pipeline in a sleeving mode, and a plurality of elastic reset pieces are connected between the floating sliding sleeve and the valve body flange plate; a floating sliding sleeve drive mechanism arranged on the valve body flange plate is used for driving the floating sliding sleeve to be away from the valve body flange plate so that the end part of the floating sliding sleeve can be inserted into a counter bore of the pressing sleeve, a sealing gasket is arranged between the pressing sleeve and the floating sliding sleeve, and a sealing piece is arranged between the floating sliding sleeve and the connecting pipeline. In a using process, parts are convenient to disassemble and replace, and the valve body and the sealing performance cannot be damaged.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Sleeving type underground conveying device for tailing paste filling

The invention discloses a sleeving type underground conveying device for tailing paste filling. The sleeving type underground conveying device comprises a drilling sleeve fixedly sleeved with a drilled hole and a slurry filling pipe sleeved with the drilling sleeve. The top of the slurry filling pipe is lifted by a lifting mechanism. An underground chamber is constructed at the lower portion of the drilled hole and internally provided with a slurry buffering cavity. The slurry buffering cavity communicates with the bottom of the slurry filling pipe through a flange. One side of the slurry buffering cavity is connected with a downhole filling pipe through a flange. By means of the sleeving type underground conveying device for tailing paste filling, due to the sleeving structural form of the drilling sleeve and the slurry filling pipe, the slurry filling pipe does not make direct contact with the drilled hole, when the slurry filling pipe is abraded to leak, the slurry filling pipe canbe replaced without damaging the drilled hole, the permanent use of the drilled hole is ensured, and filling cost is effectively saved.

Owner:HUNAN CHENZHOU MINING CO LTD

Unloading structure of belt conveyor

PendingCN110203668ADoes not affect the delivery effectGuaranteed full contactRollersBelt conveyorLeather belt

The invention discloses an unloading structure of a belt conveyor. The unloading structure comprises a rack, a conveying belt, an unloading belt and a mounting bracket; the conveying belt is arrangedon the rack; the mounting bracket comprises a mounting part and a connecting rod group; the unloading belt is movably arranged on the periphery of the mounting part in a sleeving manner, the lower endof the unloading belt is matched with the upper surface of the conveying belt, the mounting part is connected with one end of the connecting rod group, and the other end of the connecting rod group is arranged on the rack; and the unloading plane of the unloading belt is inclined to the conveying plane of the conveying belt, and the unloading direction of the unloading belt is inclined to the conveying direction of the conveying belt. The unloading plane and the unloading direction of the unloading belt are respectively inclined to the conveying plane and the conveying direction of the conveying belt, so that stress decomposition of the unloading belt is achieved to generate the line speed, the impact force of materials is decomposed, so that flying dust and spillage are reduced, the rigid friction between the unloading belt and the conveying belt is avoided, the abrasion is reduced, and the service life is prolonged; and the moving speed of the materials in the unloading direction isensured, and the unloading efficiency is improved.

Owner:厦门三烨清洁科技股份有限公司

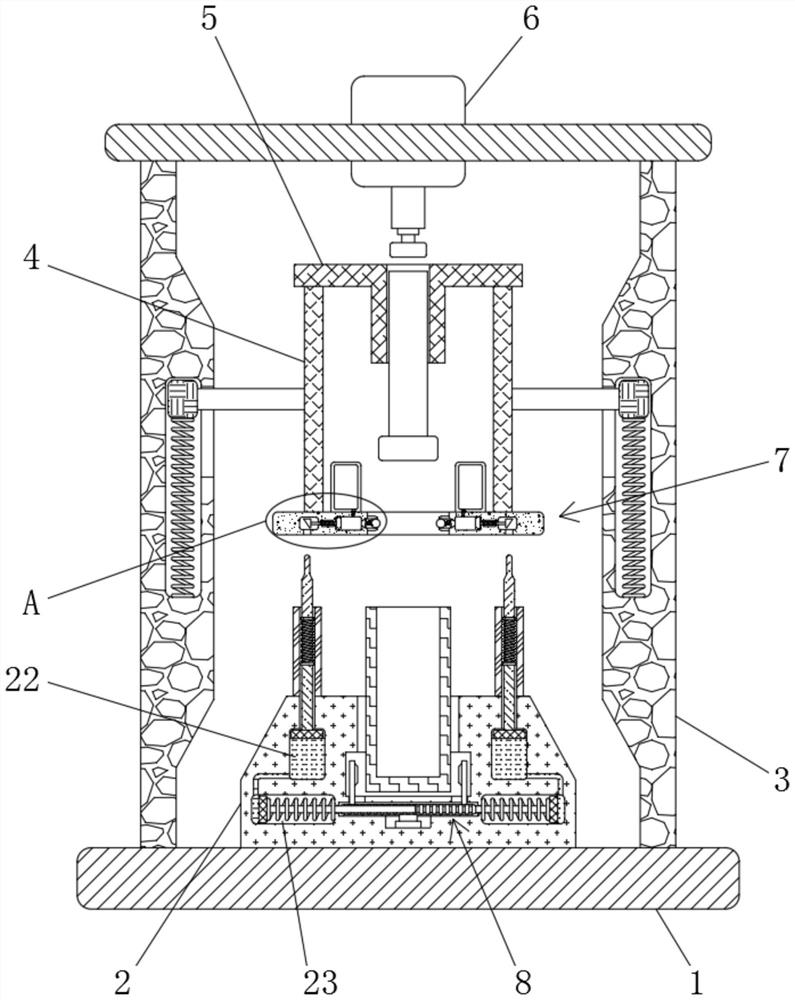

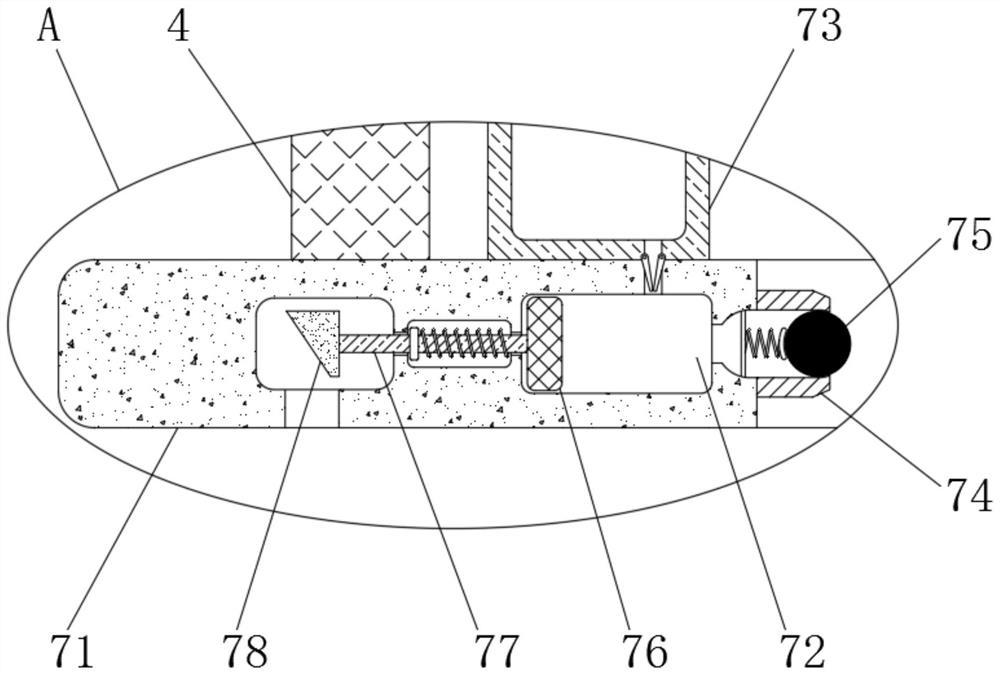

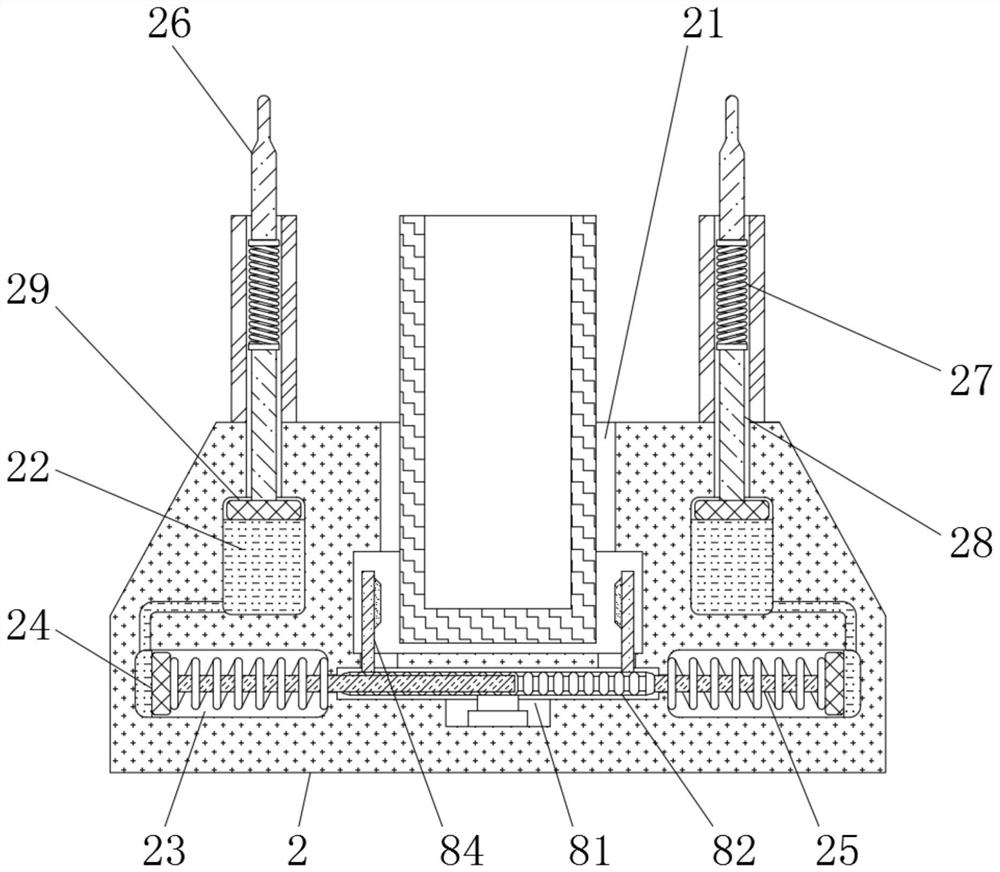

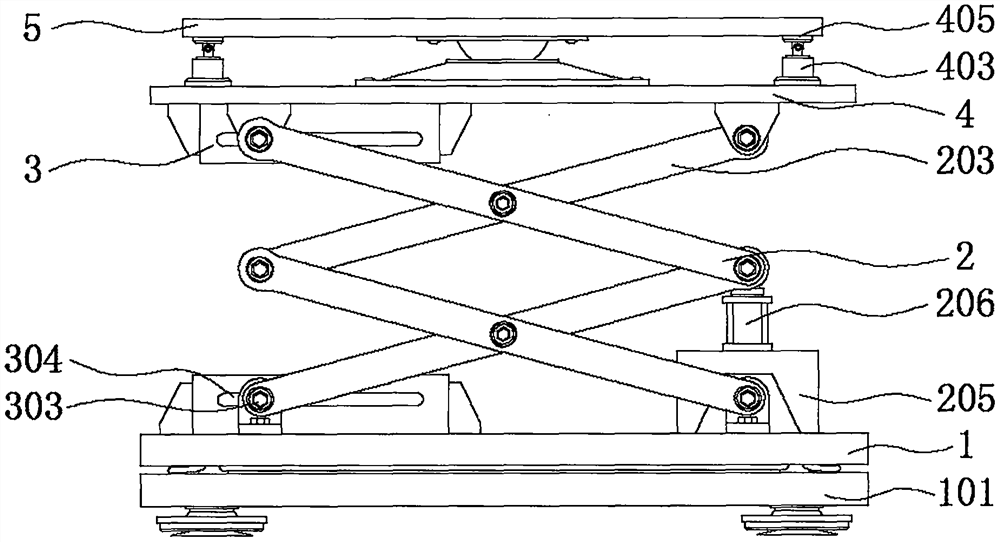

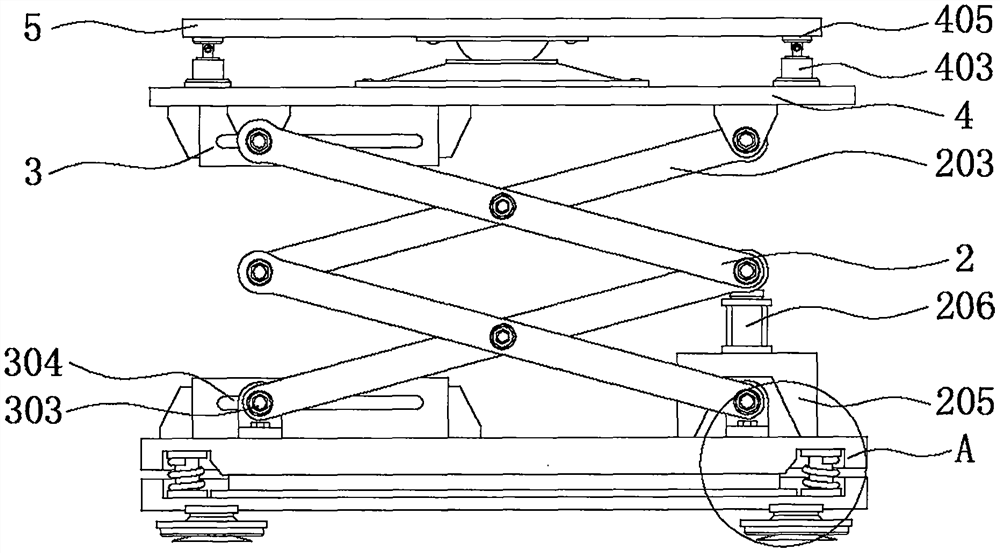

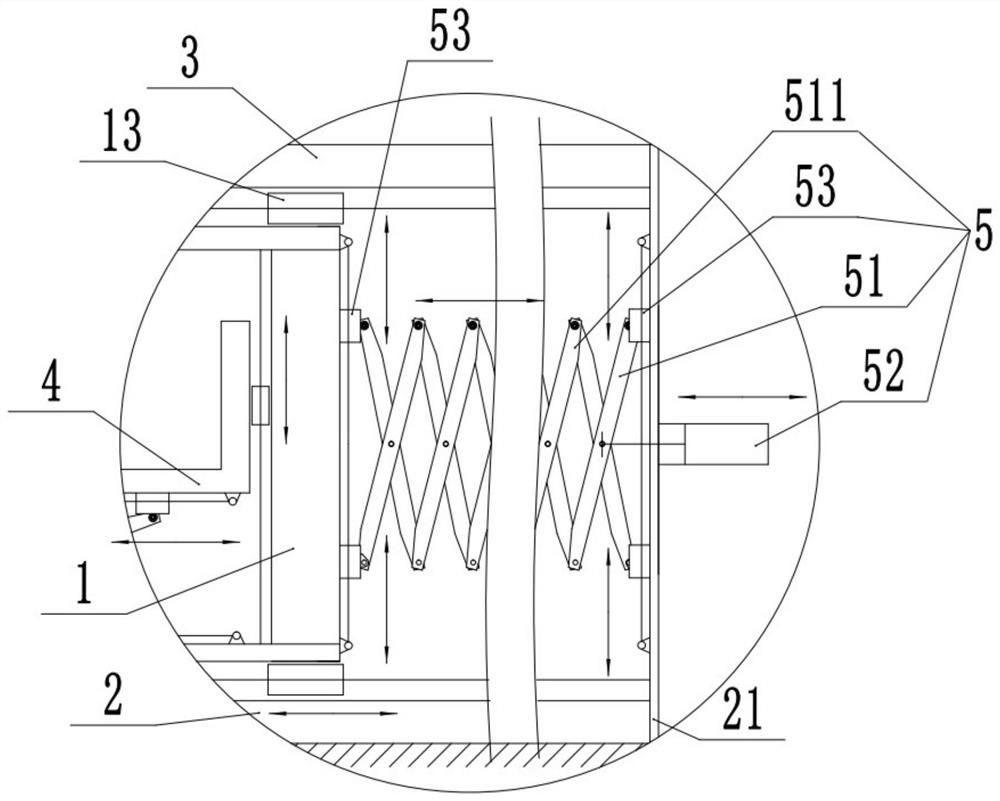

Research and development platform with lifting protection mechanism for electronic communication information technology

PendingCN112438492AAvoid rigid frictionRealize the buffering effectNon-rotating vibration suppressionVariable height tablesElectronic communicationProtection mechanism

The invention discloses a research and development platform with a lifting protection mechanism for an electronic communication information technology, and relates to the technical field of electroniccommunication information equipment, in particular to a research and development platform with a lifting protection mechanism for an electronic communication information technology. The research anddevelopment platform comprises a composite base and a supporting platform, a lifting frame is arranged above the composite base, an adjusting table board is arranged above the lifting frame, the supporting platform comprises a positioning supporting base, fixing rivets, balls, universal blocks and an operation base surface, and the fixing rivets are arranged at the left end and the right end of the positioning supporting base. According to the research and development platform with a lifting protection mechanism for the electronic communication information technology, the use performance of the whole device is greatly improved while the structure is increased, the improved equipment can ascend and descend, locking protection operation can be carried out after ascending or descending, sudden descending of the research and development platform is avoided, meanwhile, the levelness of the operation base surface can be adjusted, and the use requirements of people are effectively met.

Owner:西藏易华路信息技术服务有限公司

A self-locking bracket

ActiveCN108742896BMobile will notFixedArch wiresBracketsStructural engineeringMechanical engineering

Owner:GUANGZHOU OO MEDICAL SCI LTD

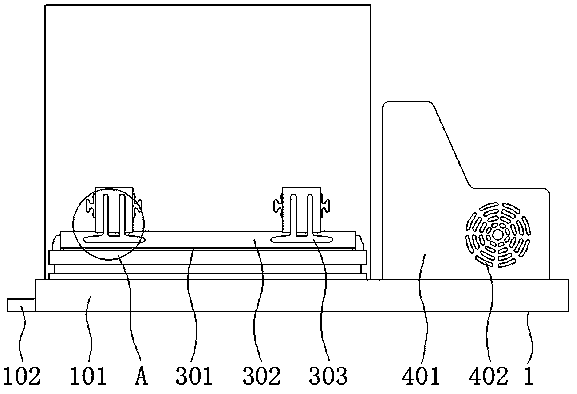

Laser cutting machine based on linear motor

InactiveCN110539086AAvoid rigid frictionGuaranteed verticalityLaser beam welding apparatusFixed bearingEngineering

The invention discloses a laser cutting machine based on a linear motor. The machine comprises a lower-layer base, a support base and a rolling guide rail; a composite rubber pad is arranged above thelower-layer base; the support base is arranged above the back end of the upper-layer base; a connecting base is arranged above the support base; a thread rod is arranged on the right side of a guidecolumn; a fixed ring is arranged at the front end of a limiting block; a dowel pin is arranged at the front end of the fixed ring; an ejector plate is arranged above a thread rod; a rocking handle isarranged above a fixed bearing; and a guide plate is arranged at the front end of the support base. Compared with a traditional general laser cutting machine, the laser cutting machine based on the linear motor greatly improves the use demands during adding of structures; and the improved equipment reasonably applies the horizontal moving capacity of the linear motor, and is simpler and more convenient for adjustment of laser equipment to effectively meet the people use demands.

Owner:永州市亿达自动化机械有限公司

Dust removal device with mobile phone part listening tube

PendingCN112770218AAvoid rigid frictionEasy to operateMouthpiece/earpiece sanitary/hygienic devicesCleaning using toolsEngineeringMechanical engineering

The invention discloses a dust removal device with a mobile phone part listening tube, and relates to the technical field of mobile phone maintenance equipment, in particular to a dust removal device with the mobile phone part listening tube, the device comprises a supporting mechanism and an operation platform, a supporting shell is fixedly connected above the supporting mechanism, and the front end of the supporting shell is movably connected with a movable door; a hinge is fixedly connected to the left end of the movable door, a clamping mechanism is fixedly connected to the upper portion of the operation platform, the operation platform is located above the supporting shell, a supporting adjusting mechanism is arranged on the left side of the clamping mechanism in parallel, and a dust removing mechanism is fixedly connected to the right end of the upper portion of the supporting adjusting mechanism; according to the dust removal device with mobile phone part listening tube, the number of the clamping blocks is two, one clamping block provides a spring damping rod to achieve the elastic clamping effect on a mobile phone, and the other clamping block exerts horizontal thrust on the mobile phone through cooperation between a threaded rod and a control handle and is matched with the spring damping rod to fix the mobile phone.

Owner:东莞市众创智能装备科技有限公司

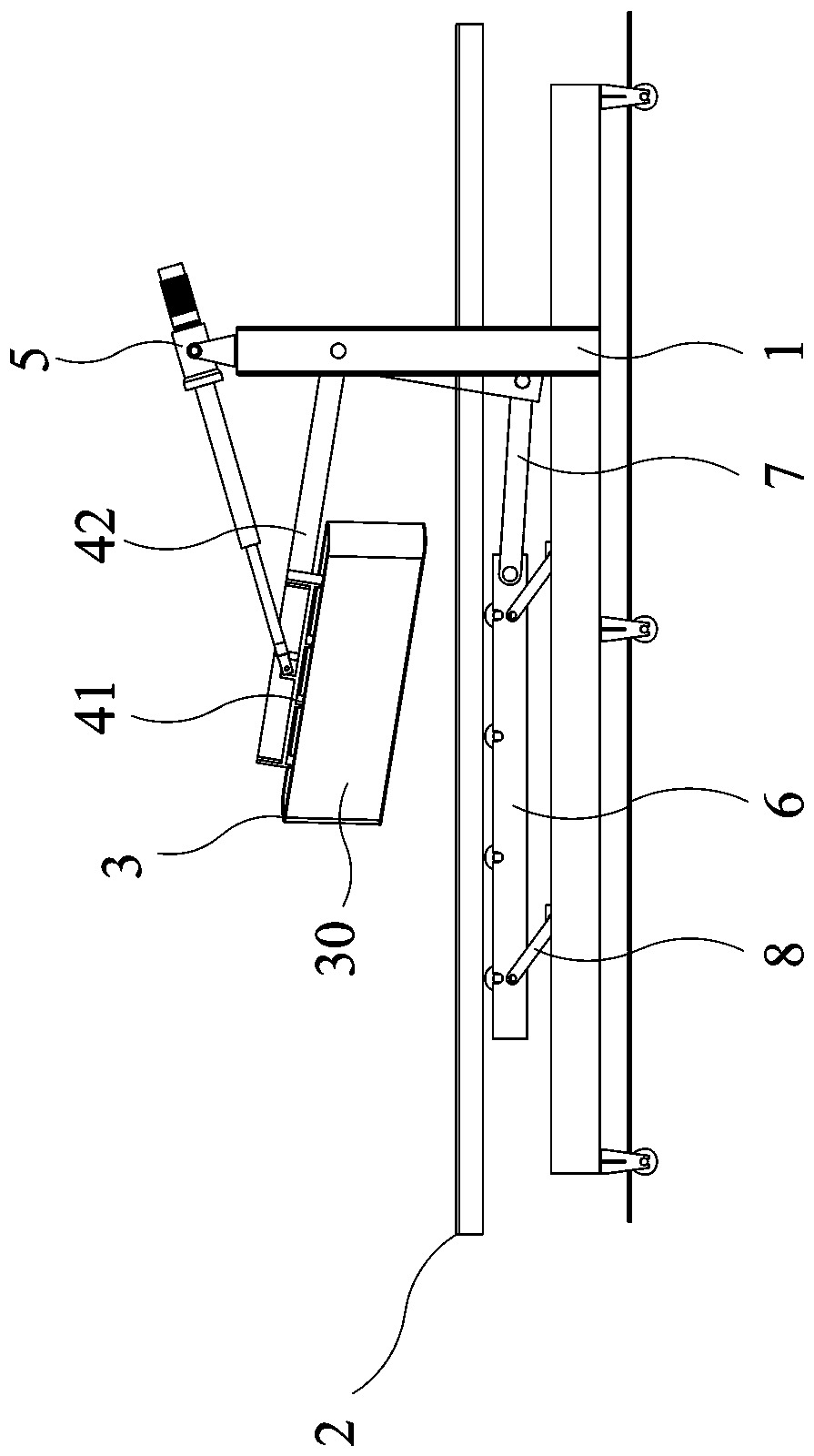

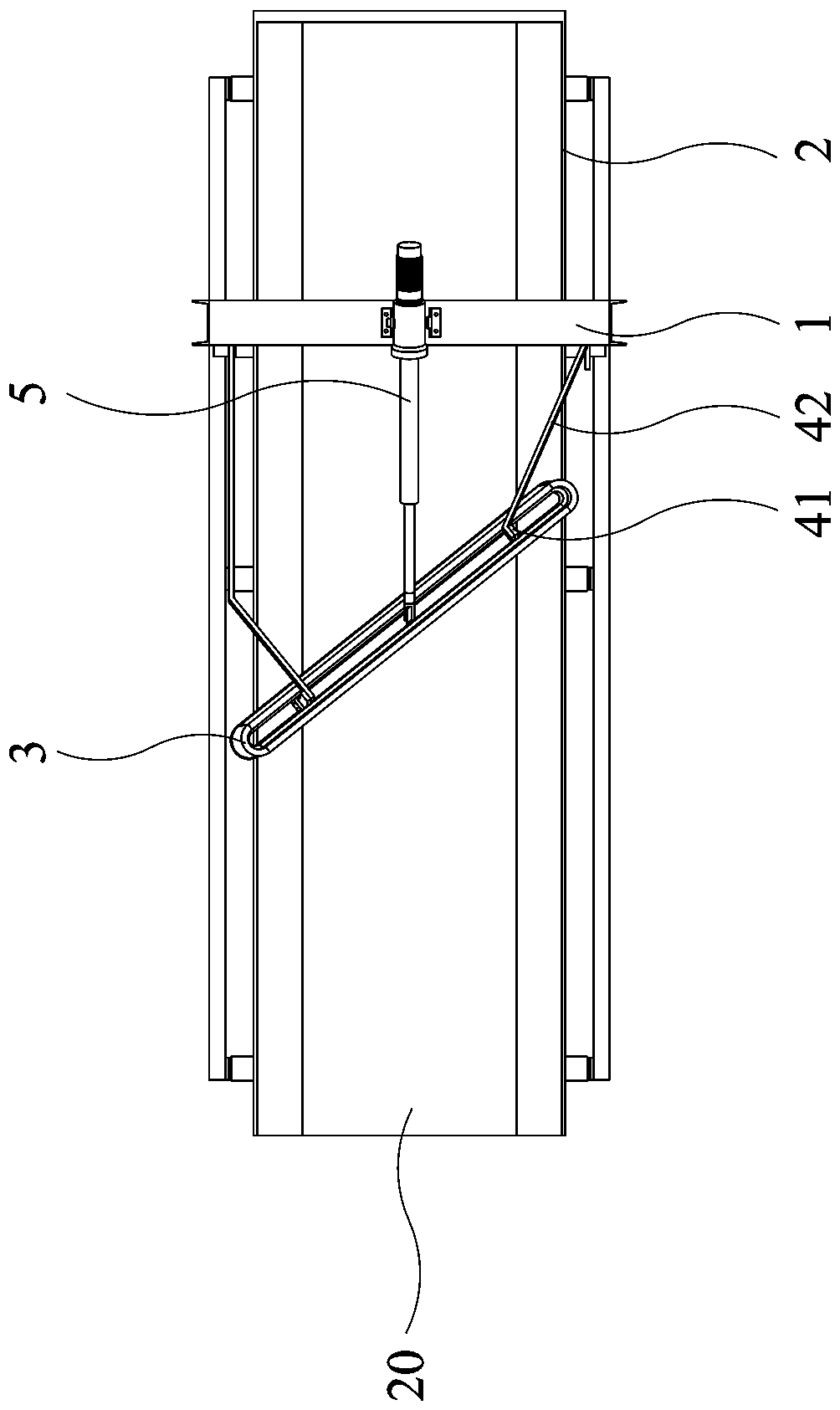

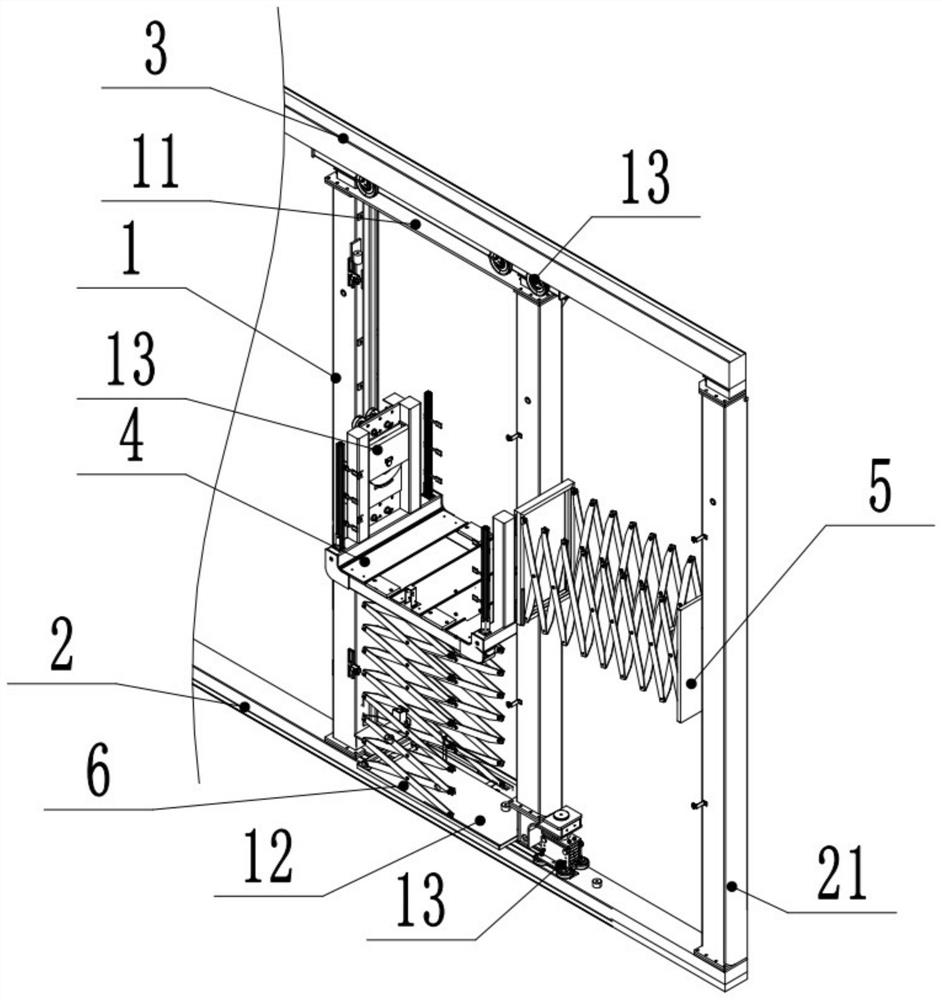

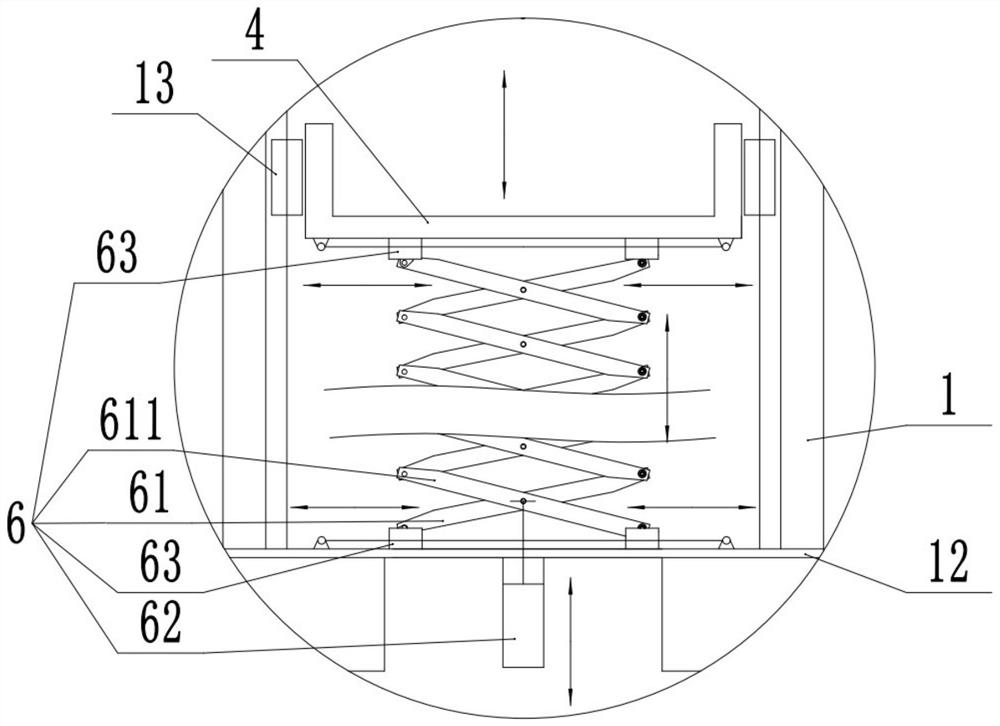

A stacker with high carrying capacity and its transportation method

InactiveCN110789894BAvoid rigid frictionImprove carrying capacityStorage devicesLinear motionStructural engineering

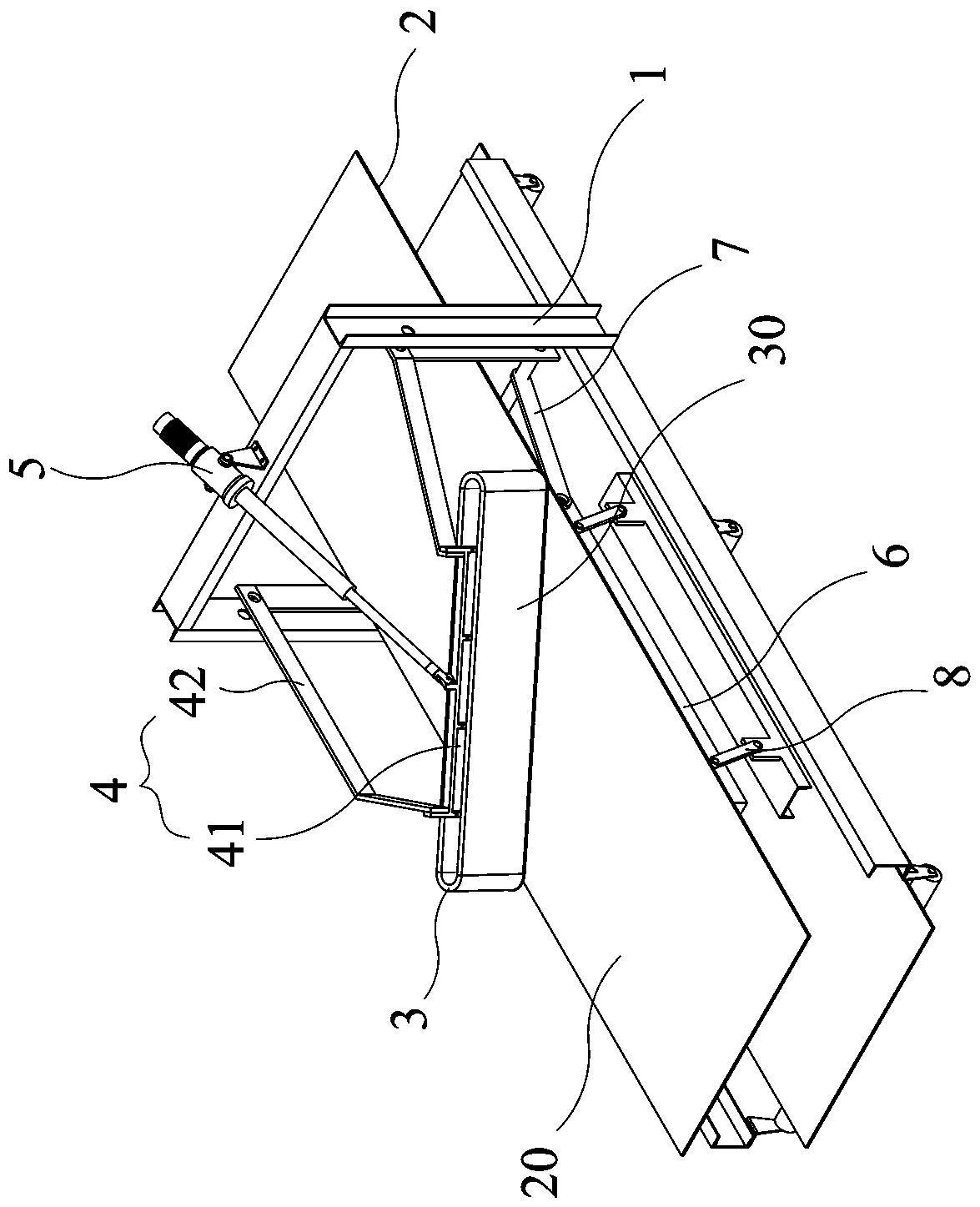

The invention discloses a stacker with high load-bearing capacity and a transportation method, belonging to the field of storage equipment. The stacker with high load-bearing capacity includes: a column, a lower rail, an upper rail, a telescopic fork, a transverse power assembly and a vertical Orientation power assembly, at least one column, the column moves horizontally in a straight line between the lower rail and the upper rail, the telescopic fork makes a vertical linear motion on one side of the column, and the middle position between one end of the horizontal power assembly and the other side of the column Fixed connection, the horizontal power assembly and the telescopic fork are respectively located on both sides of the column, one end of the horizontal power assembly is fixedly connected to the middle position of the bottom end of the telescopic fork, and both the horizontal power assembly and the vertical power assembly are rigidly driven; the present invention, through The horizontal power assembly and the vertical power assembly are rigidly driven in the middle of the column and the telescopic fork, so that the stacker can carry out high-load heavy load transportation, and reduces the probability of deviation during the work process, improving the use of life.

Owner:JINKEN COLLEGE OF TECH

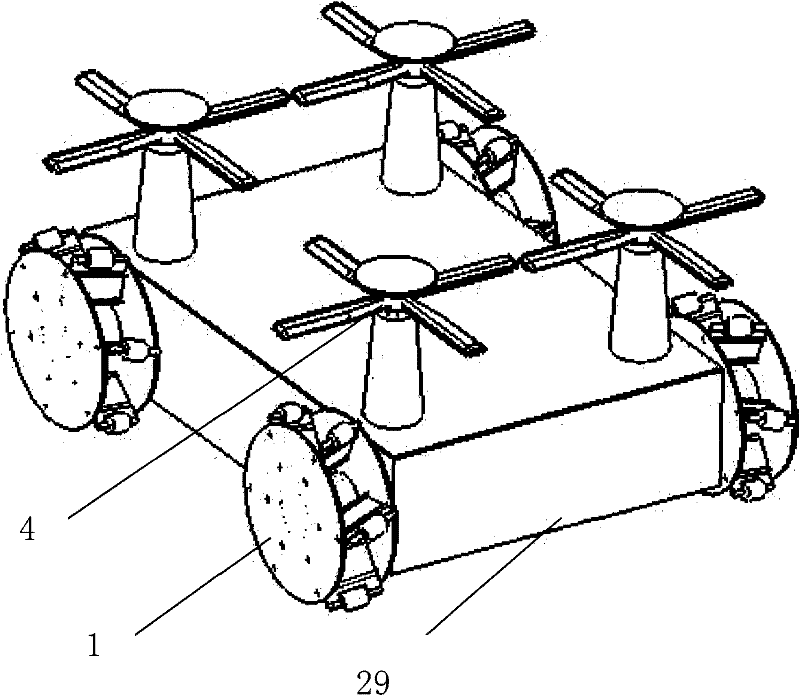

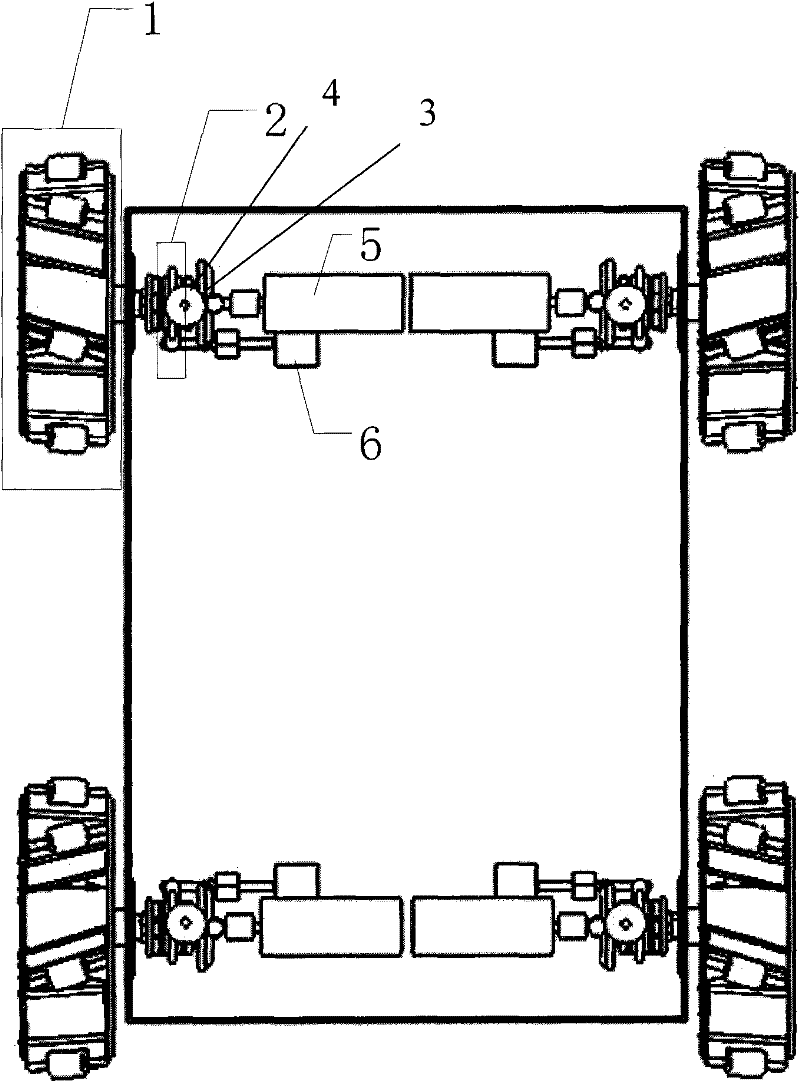

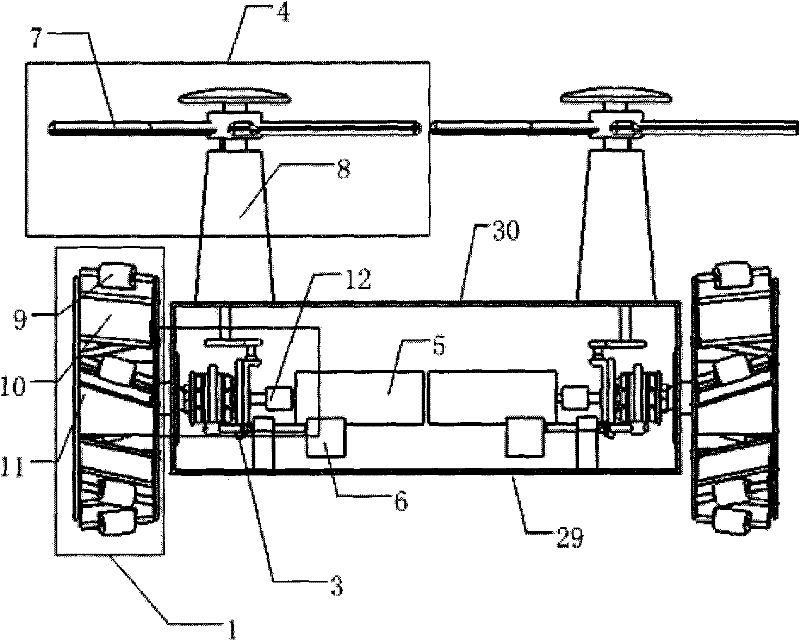

Triphibian omnibearing moving mechanism

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

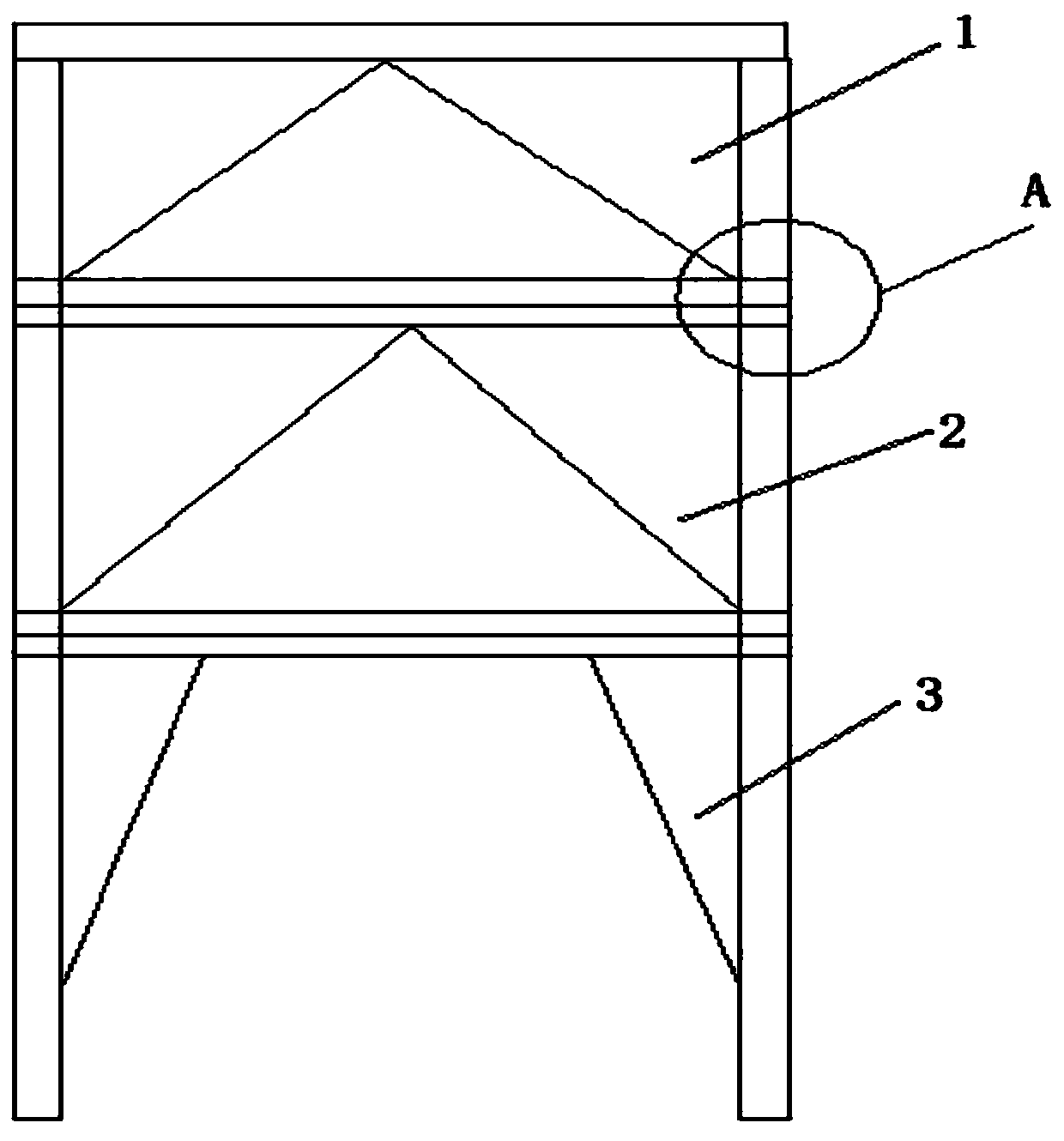

Stereo garage easy to assemble

InactiveCN110905252AReduce usageAvoid the problem of easy loosening and rustingParkingsStructural engineeringMechanical engineering

Owner:西安优信机电工程有限公司

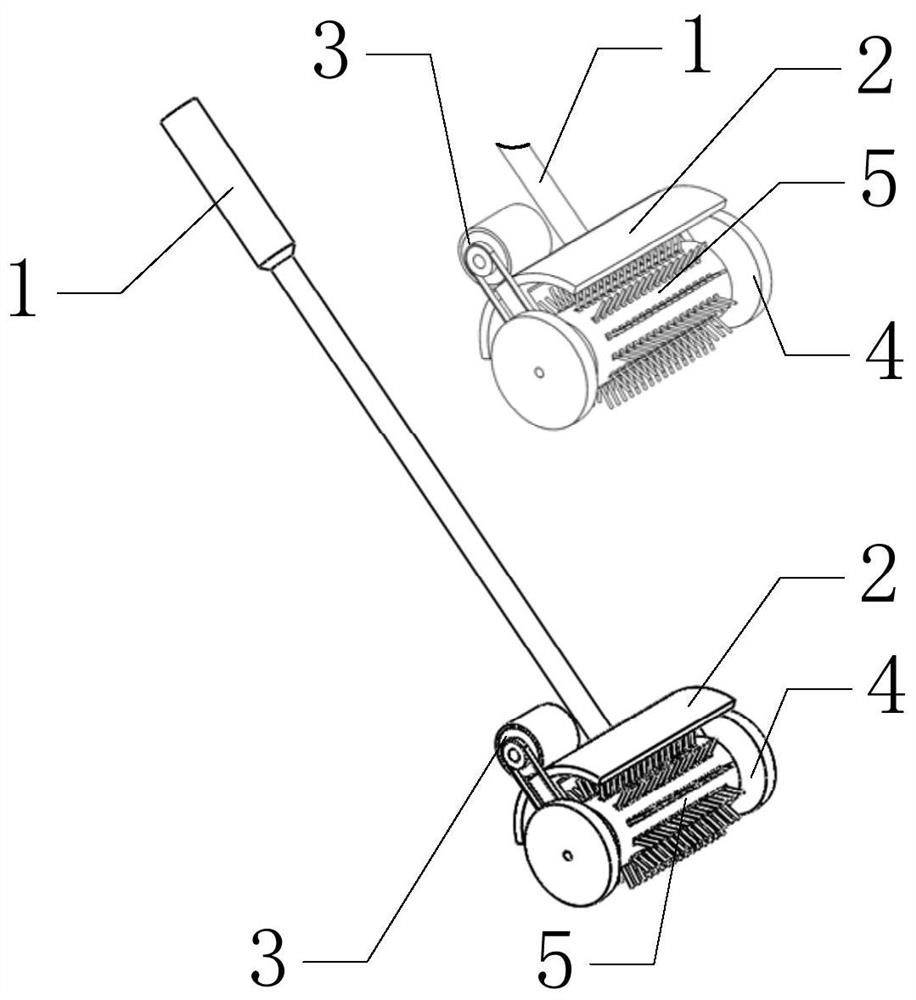

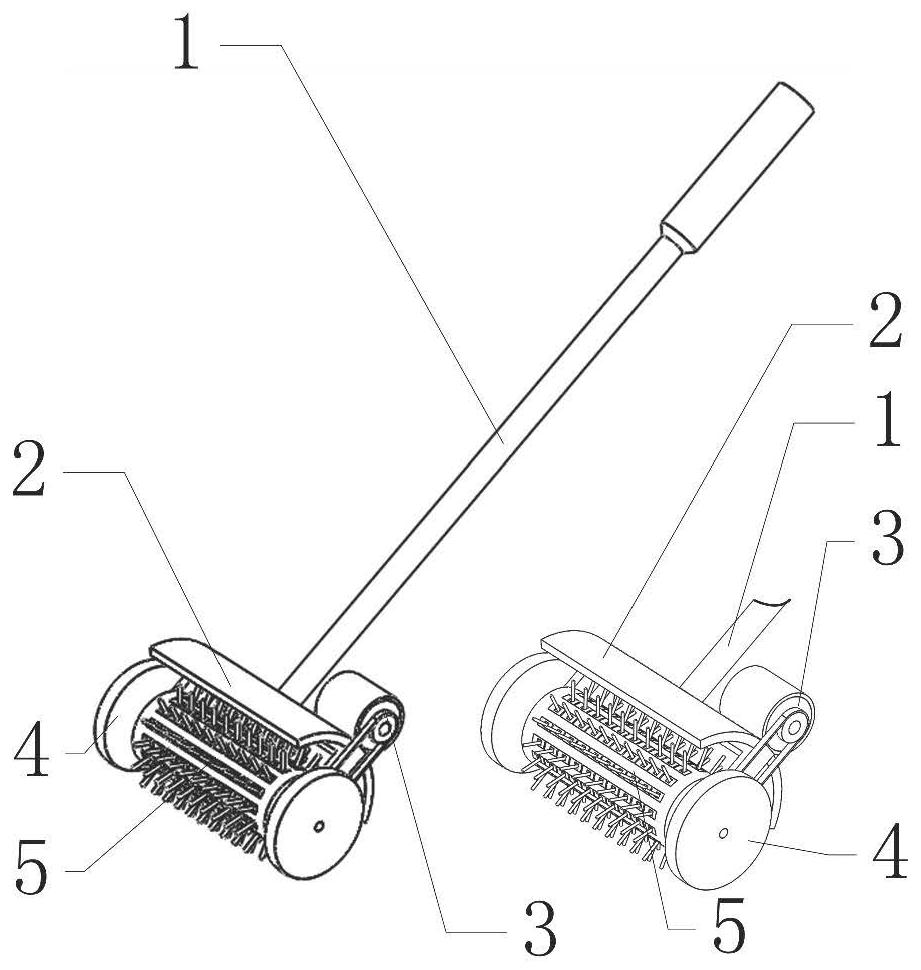

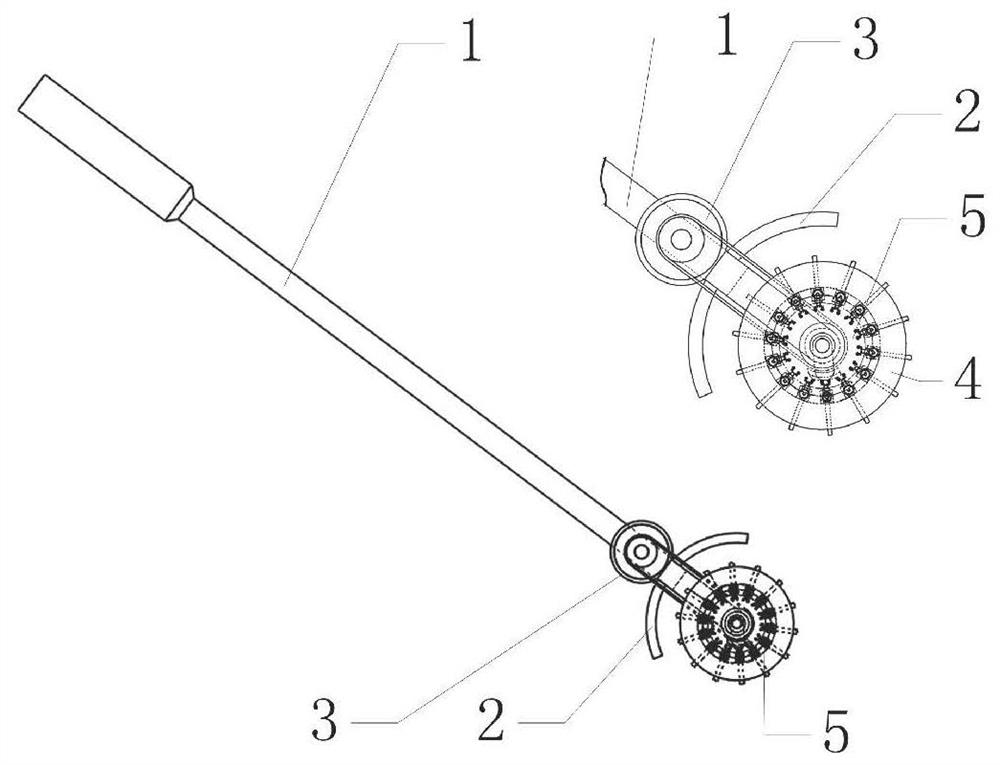

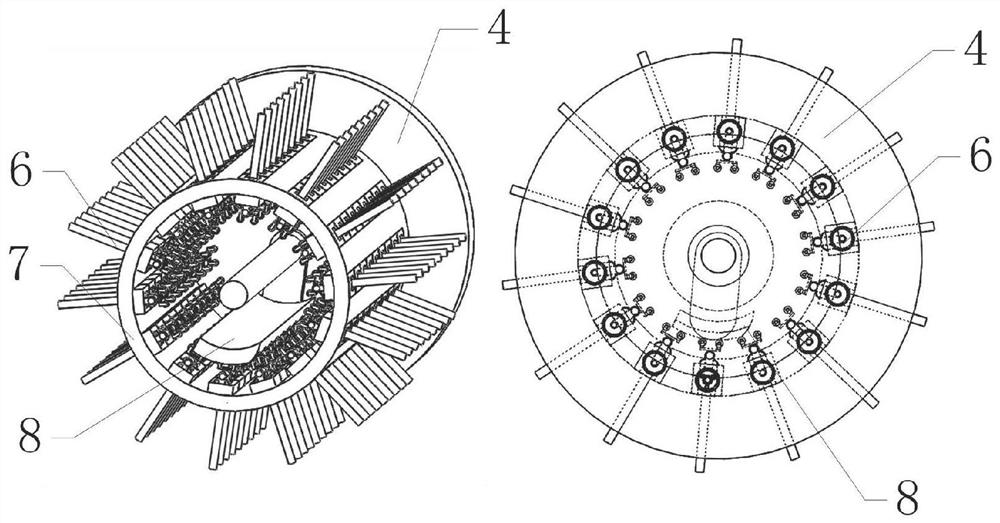

Cleaning equipment for construction site

ActiveCN111350149BImprove cleanlinessAvoid rigid frictionRoad cleaningBuilding material handlingGear wheelClassical mechanics

The invention belongs to the technical field of cleaning equipment, and in particular relates to a cleaning equipment used on a construction site. During the working process of the cleaning machine, if it encounters uneven ground, the rotation of the steel wire will be blocked and swing on the convex surface, and the impact of the convex surface on the steel wire will be prevented by swinging to prevent the steel wire from breaking or wearing. In the present invention, during the normal rotation of the steel wire, the arc-shaped tooth plate installed on the steel wire rotates until the brake gear contacts, that is, when the steel wire touches the ground particles, the swing of the steel wire is limited by the brake gear; Clean the ground particles on the ground to eliminate the impact of steel wire swing on cleaning. The two support wheels designed by the present invention can support the installation cylinder, so that the steel wire installed on the installation cylinder is supported by the two support wheels, which can prevent the steel wire from directly contacting the ground and increase the wear of the steel wire.

Owner:上安实业江苏有限公司

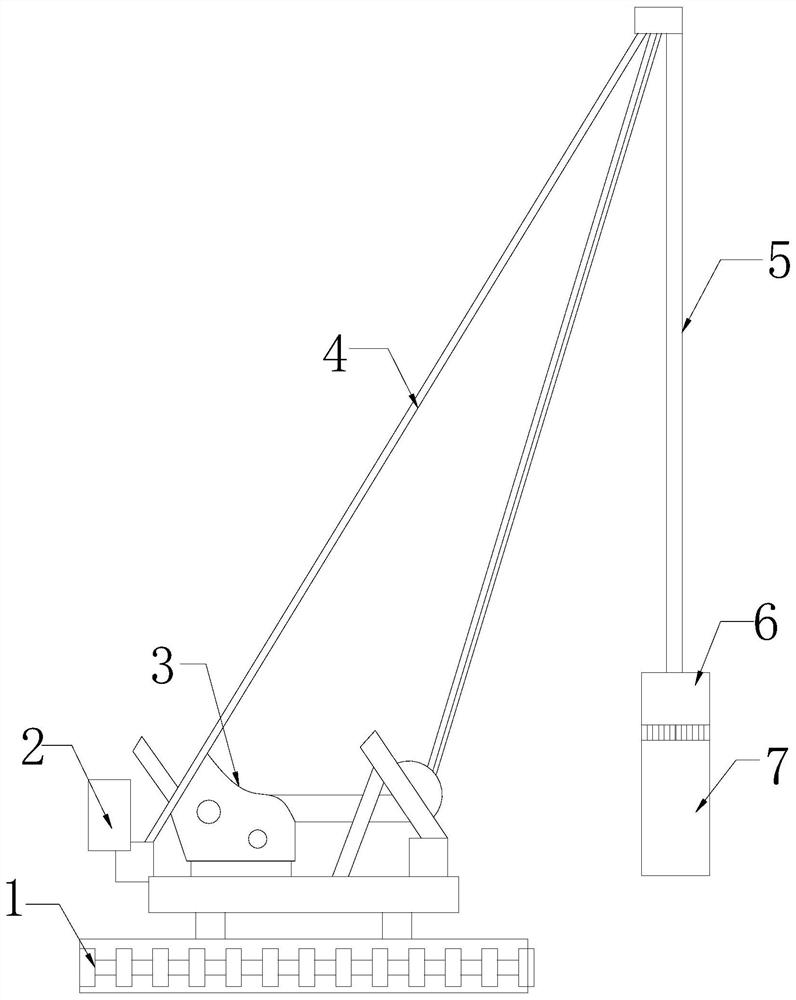

Vibration pile driver for bridge construction

InactiveCN112726609ARealize continuous operationRealize one-time soil guideBulkheads/pilesSoil scienceStructural engineering

The invention discloses a vibration pile driver for bridge construction. The vibration pile driver structurally comprises a walking base, an operation room, a driving table, a traction inhaul cable, a lifting plate, a pile hammer and a pile frame, wherein the operation room controls the driving table, the operation room and the driving table are installed on the walking base, the driving table is connected to the lifting plate through the traction inhaul cable, the pile hammer and the pile frame are movably connected to the lifting plate, and the pile hammer is mechanically connected with the pile frame; and the pile hammer comprises a soil guide device, a soil collecting cavity and a drill bit, the soil guide device is installed on the soil collecting cavity, the drill bit is arranged at the bottom of the soil collecting cavity, and the drill bit is arranged in the pile frame in a matched mode. The soil guide device is matched with the soil collecting cavity, a guide-out opening and a soil inlet formed in the soil guide device are connected with a soil guide pipe, the soil inlet is matched with the soil collecting cavity, soil in the soil collecting cavity is discharged out of the guide-out opening through the soil guide pipe via the soil inlet, the guide-out opening is connected to the exterior of the pile frame, continuous operation of soil guide of the pile hammer is achieved, one-time soil guide is achieved, and the pile driving efficiency is improved.

Owner:洪雯娜

Elevator and indoor gap bridge device

The invention discloses an elevator and indoor gap bridge device, and relates to the technical fields of gap bridge devices, in particular to an elevator and indoor gap bridge device. The gap bridge device comprises a support frame and a gap bridge mechanism; the gap bridge mechanism is arranged on the right side of the support frame; a damping base is arranged under the right end of the gap bridge mechanism; the gap bridge mechanism comprises a connecting shaft, a movable pedal, a support steel frame, a rubber pad, a connecting base, a fixing rivet, an operating side frame and a lifting handle; the support steel frame is arranged under the movable pedal; the connecting base is arranged on the upper portion of the movable pedal; and the operating side frame is arranged on the upper portionof the connecting base. According to the elevator and indoor gap bridge device, the application performance of the whole device is greatly improved while structures are added, the improved device ismore stable in use, safety hazards during use are reduced as much as possible, in addition, the device is provided with a local buffer structure during usage, the service life of the device is indirectly prolonged, and the application needs of people are effectively met.

Owner:杨小强

Clearance adjustment pad assembly and excavator

ActiveCN110984265BFill in the gapsAvoid rigid frictionMechanical machines/dredgersExcavatorIndustrial engineering

This application relates to the technical field of engineering vehicles, and in particular to a gap adjusting pad assembly and an excavator. The gap adjusting pad assembly includes: a first pad main body, a second pad main body and an elastic support member; a first pad The tray main body is arranged opposite to the second dolly main body, and the elastic supporting member is arranged between the first dolly main body and the second dolly main body. The gap adjustment pad assembly provided by this application can be easily and conveniently installed between the bucket and the arm, and can undertake the work of filling the gap for a long time, with a low probability of damage, avoiding the need to stop the excavator for maintenance, replace gaskets or wear-resistant plates , affecting the construction progress.

Owner:SANY HEAVY MACHINERY

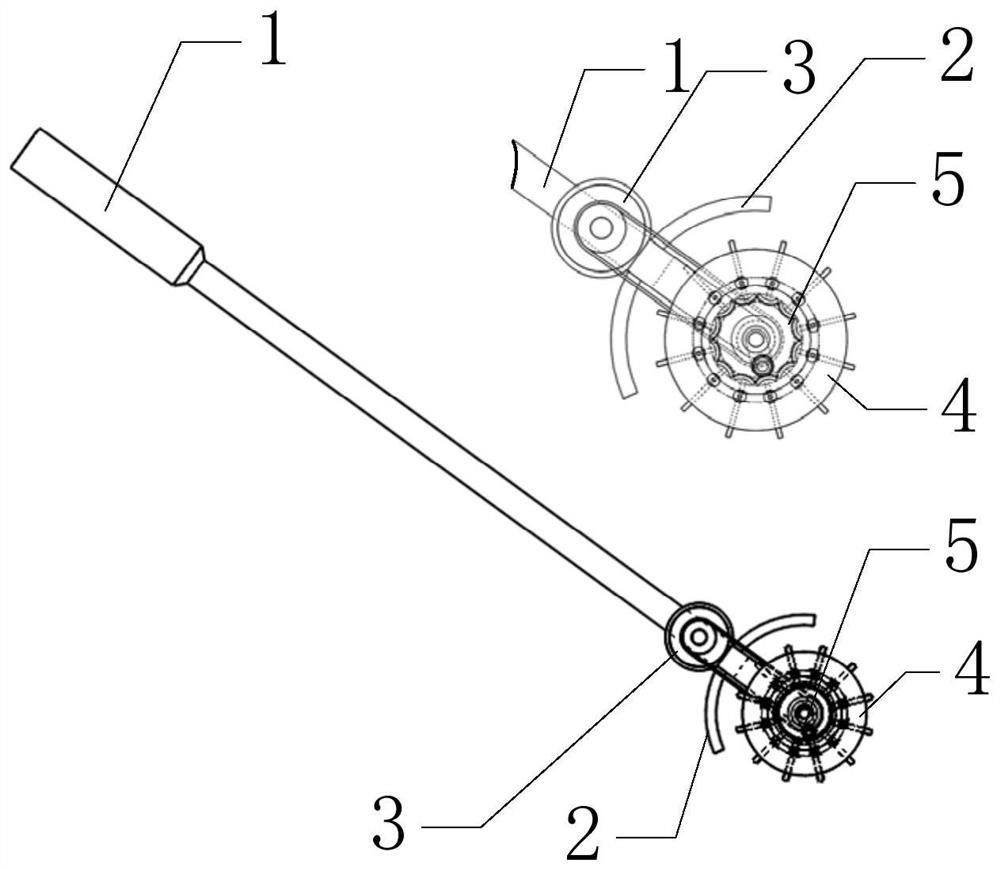

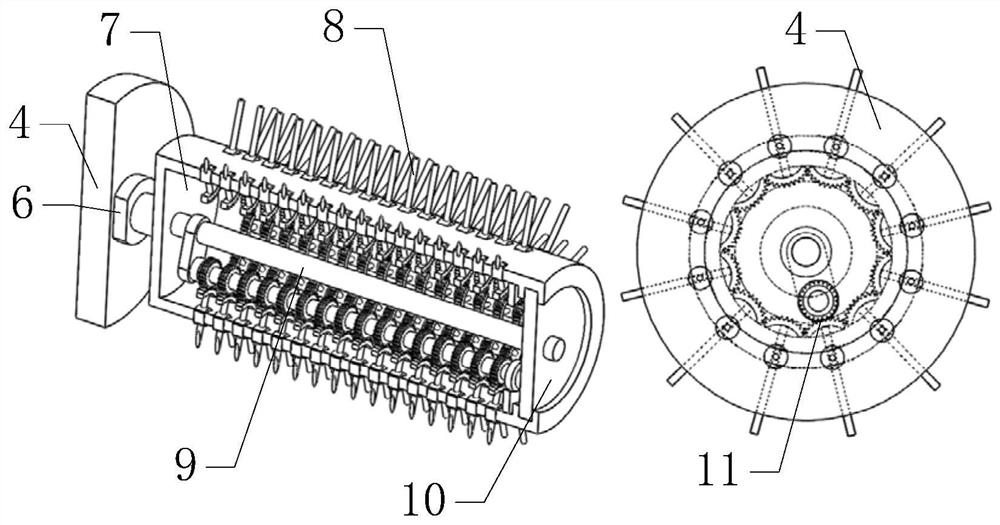

An automatic cleaning machine for construction sites

The invention belongs to the technical field of cleaning machines, and in particular relates to an automatic cleaning machine for a construction site, which includes a handle, a baffle, a motor, a cleaning wheel, and a bracket. In the cleaning equipment designed by the invention, the steel wire can swing relative to the installation cylinder. During the working process of the cleaning machine, if the ground is relatively flat, the steel wire will not rotate relative to the installation cylinder under the action of the leaf spring, and avoid rigid friction with the ground through its own elastic steel wire. The cleaning equipment designed by the present invention, in the working process of the cleaning machine, if it encounters a concave-convex ground, the rotation of the steel wire will be hindered and swing on the convex surface, and the influence of the convex surface on the steel wire will be prevented by the swing to prevent the steel wire from breaking or wearing. In the present invention, during the normal rotation of the steel wire, when the brake wheel on the cleaning unit rotates to contact with the arc-shaped brake plate, that is, when the steel wire hits the ground particles, the swing of the steel wire is limited by the arc-shaped brake plate; The oscillating steel wire cleans the ground particles on the ground, eliminating the influence of the steel wire oscillating on the cleaning.

Owner:南京六合高新建设发展有限公司

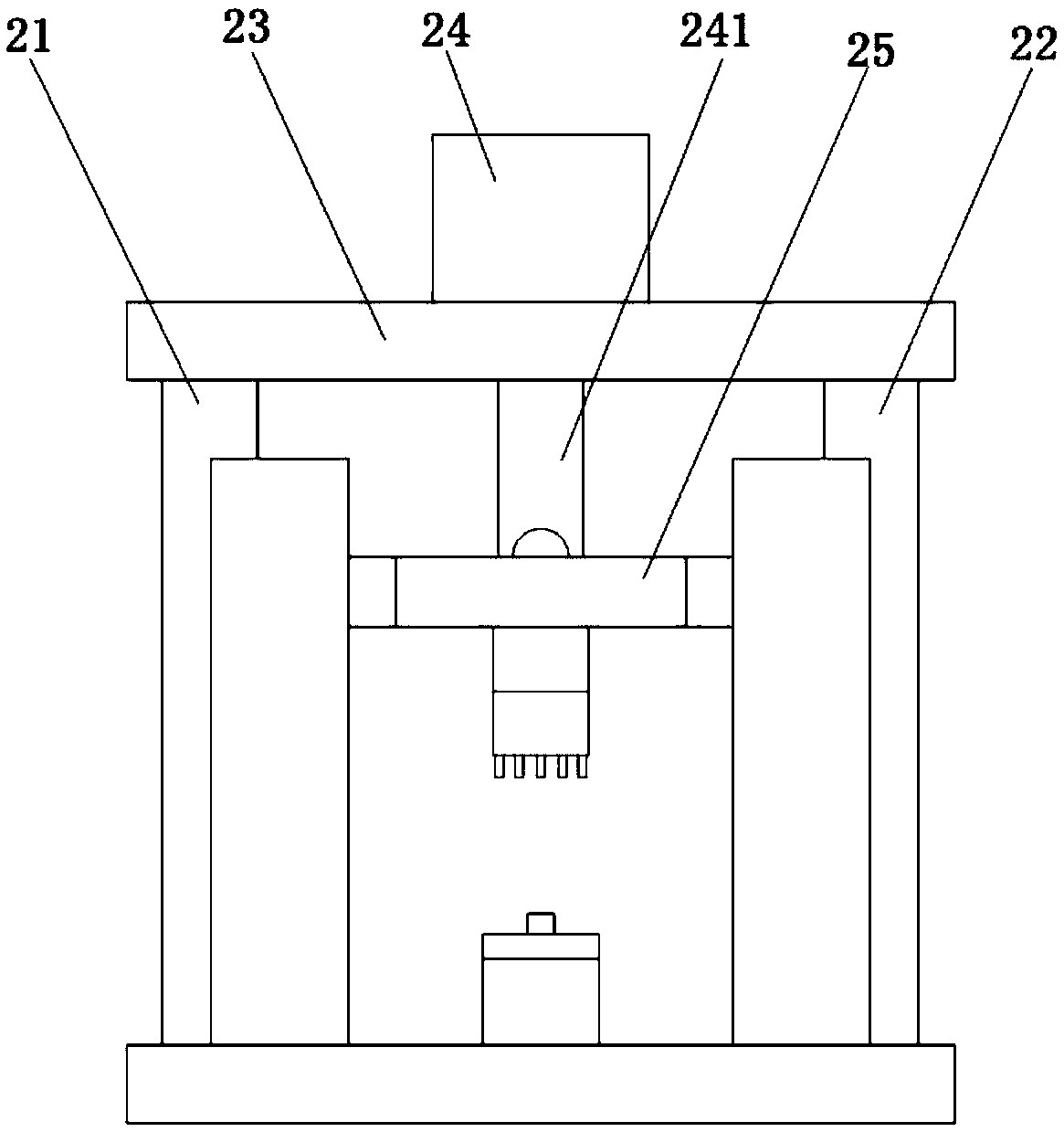

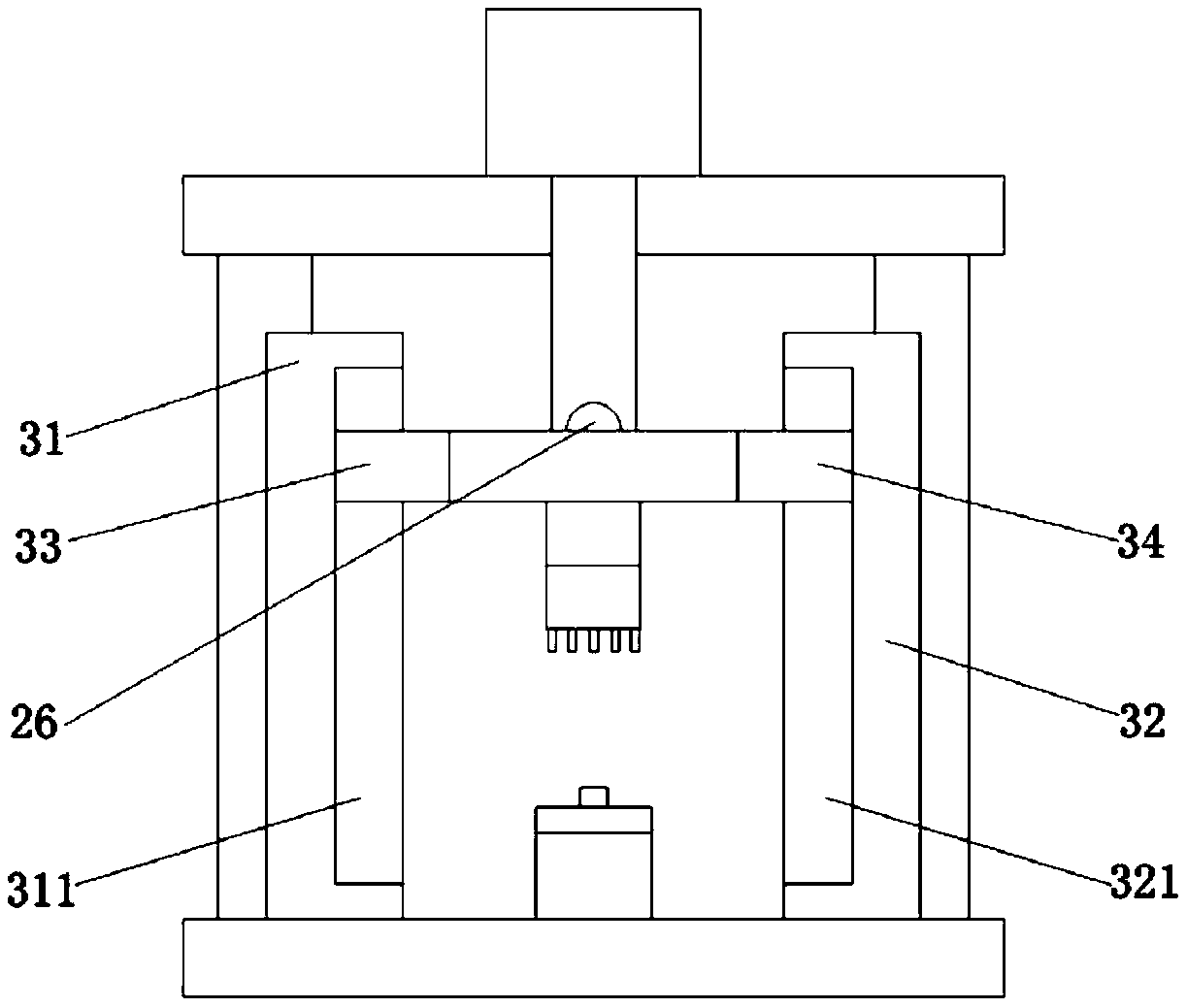

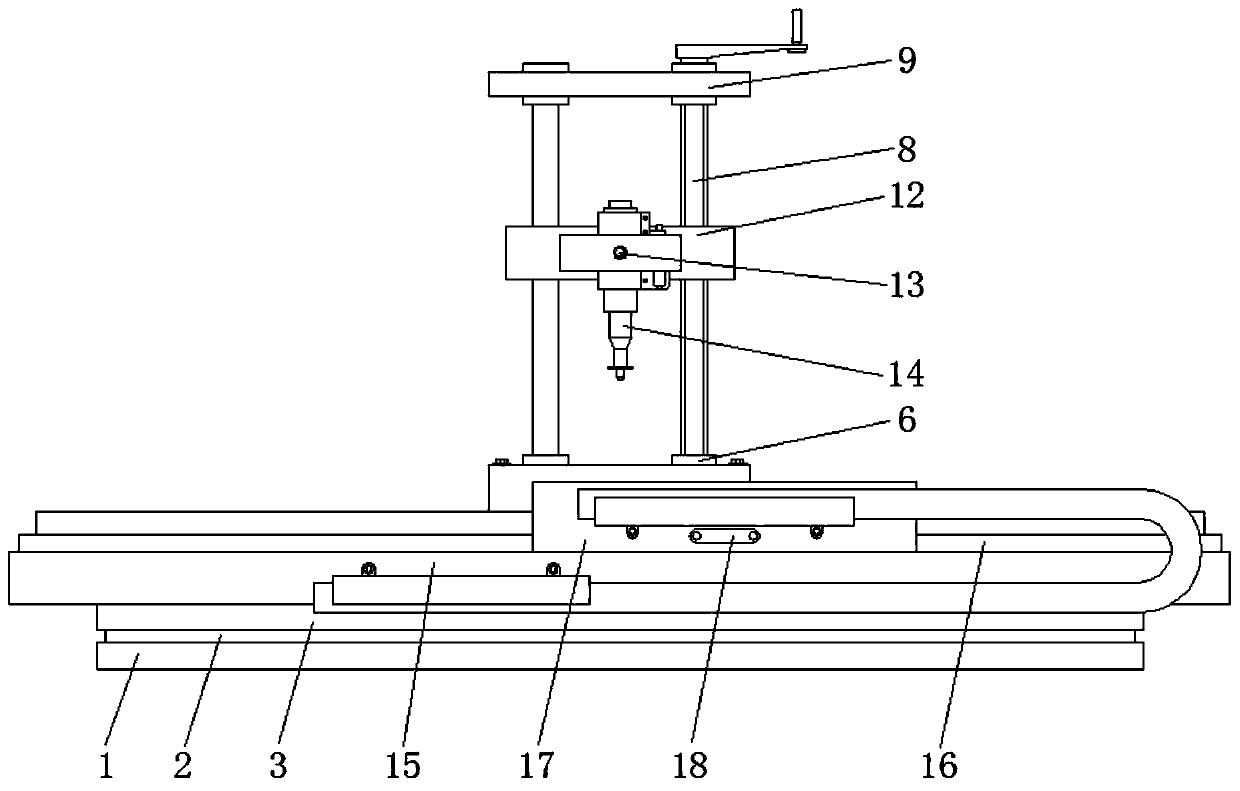

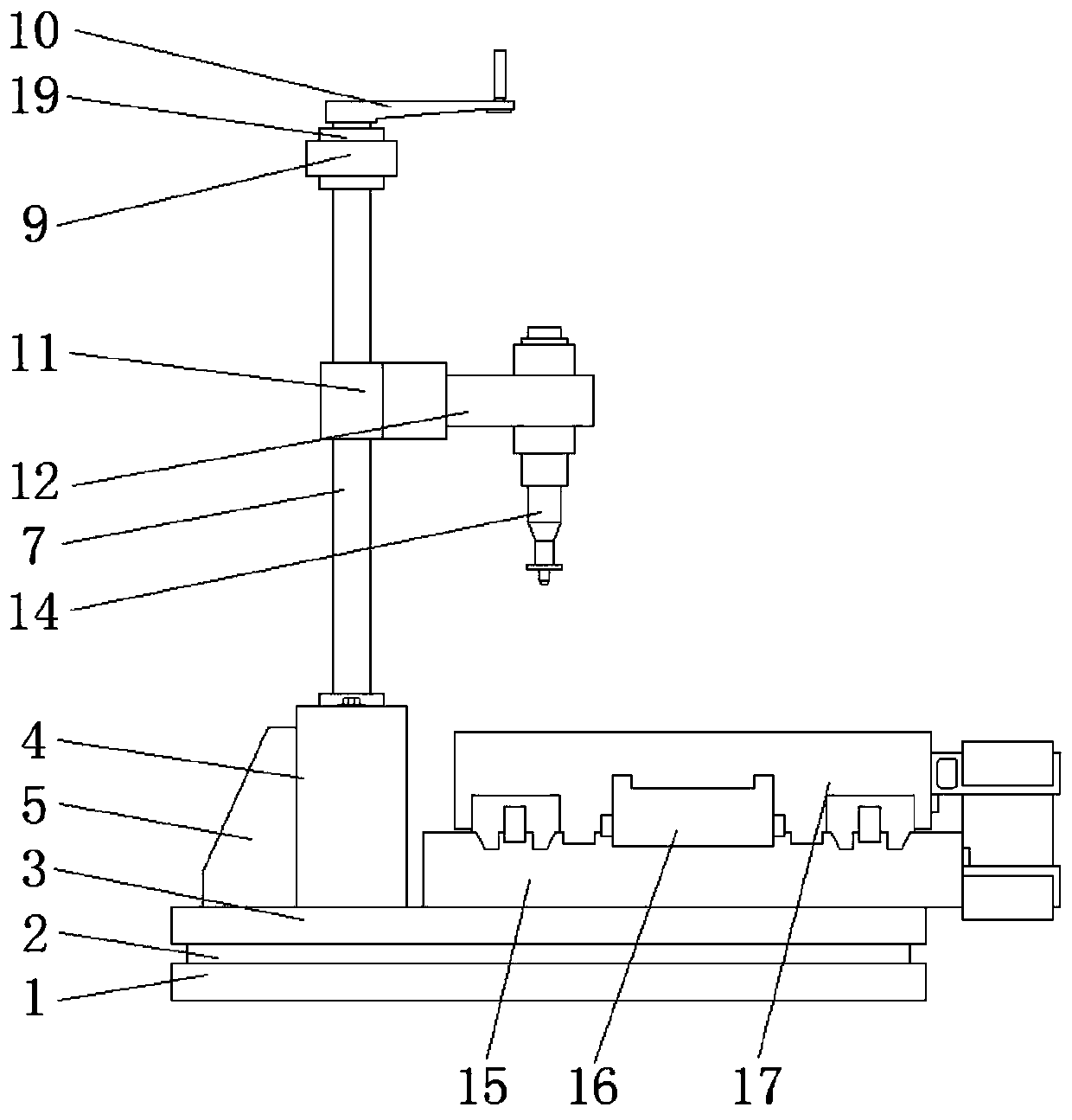

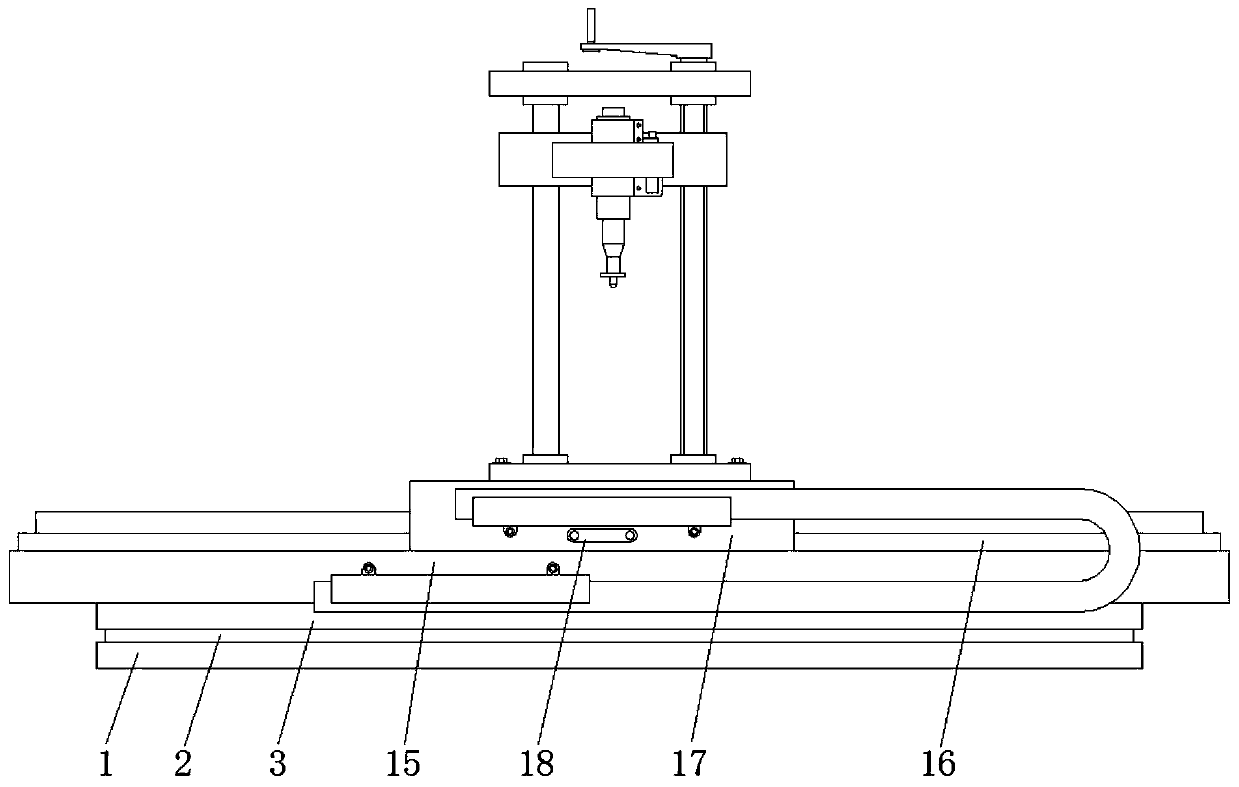

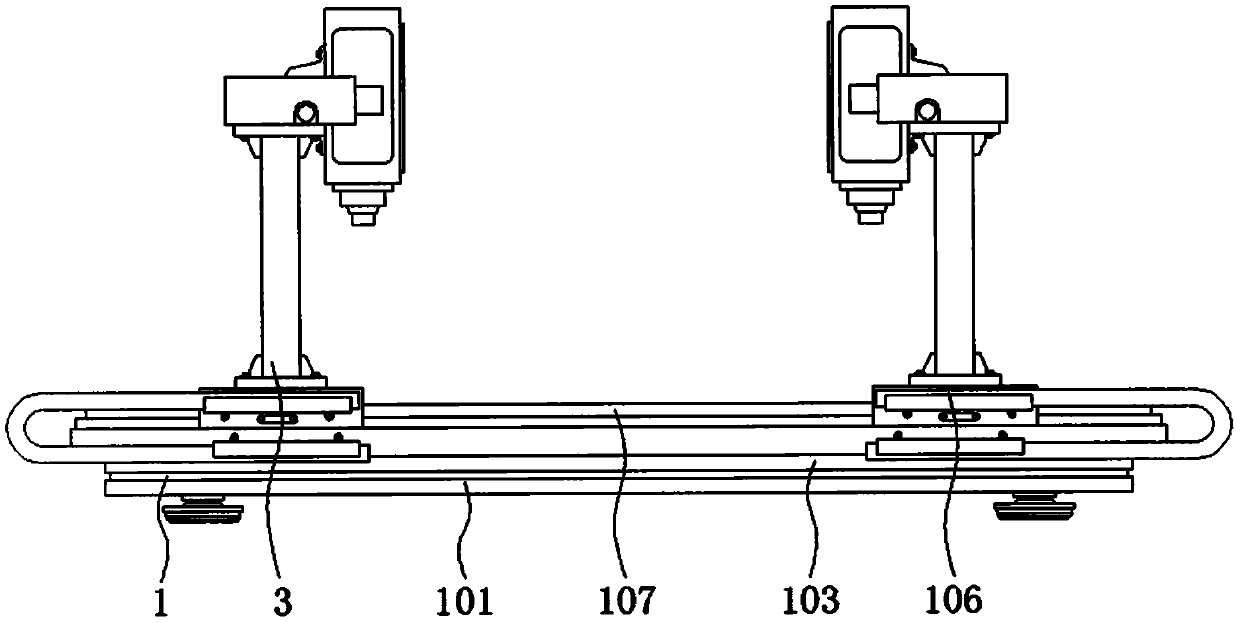

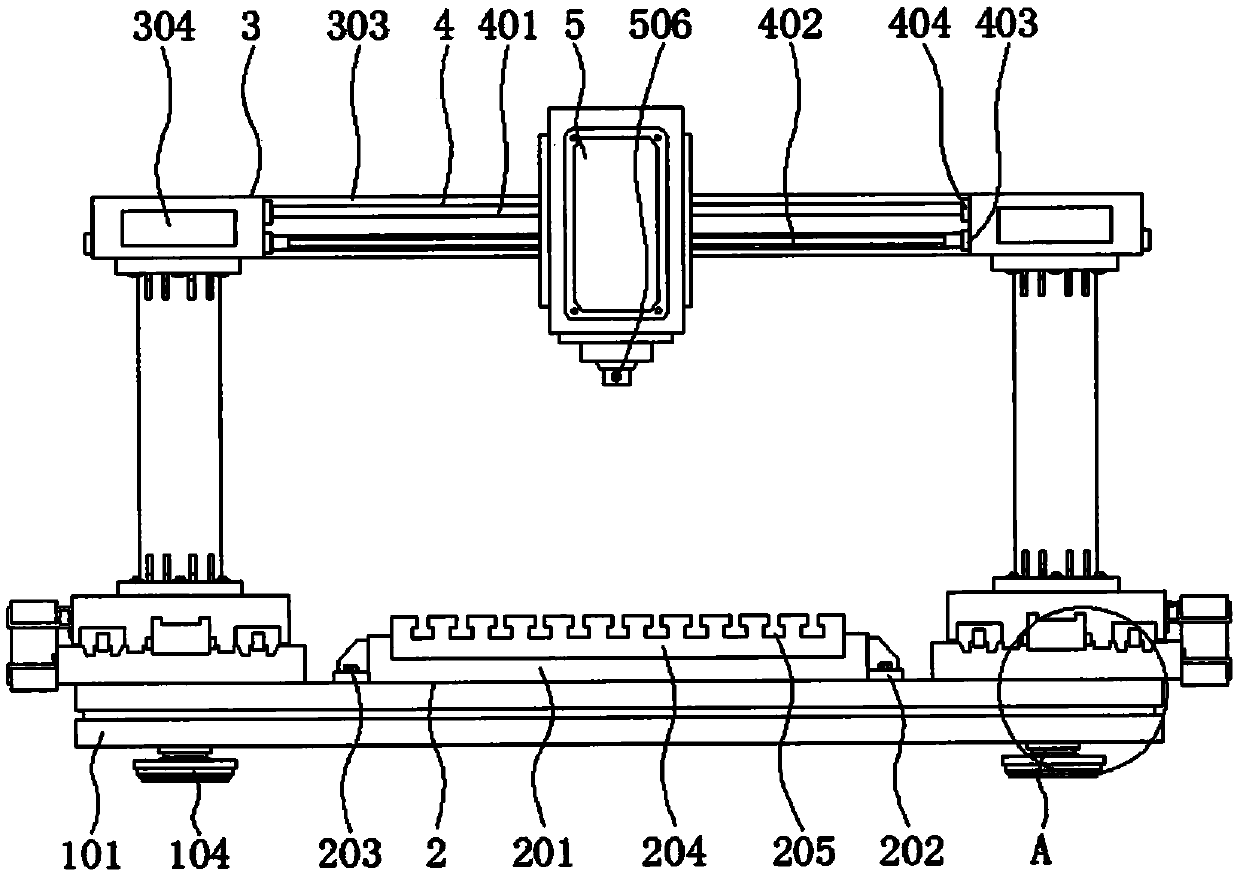

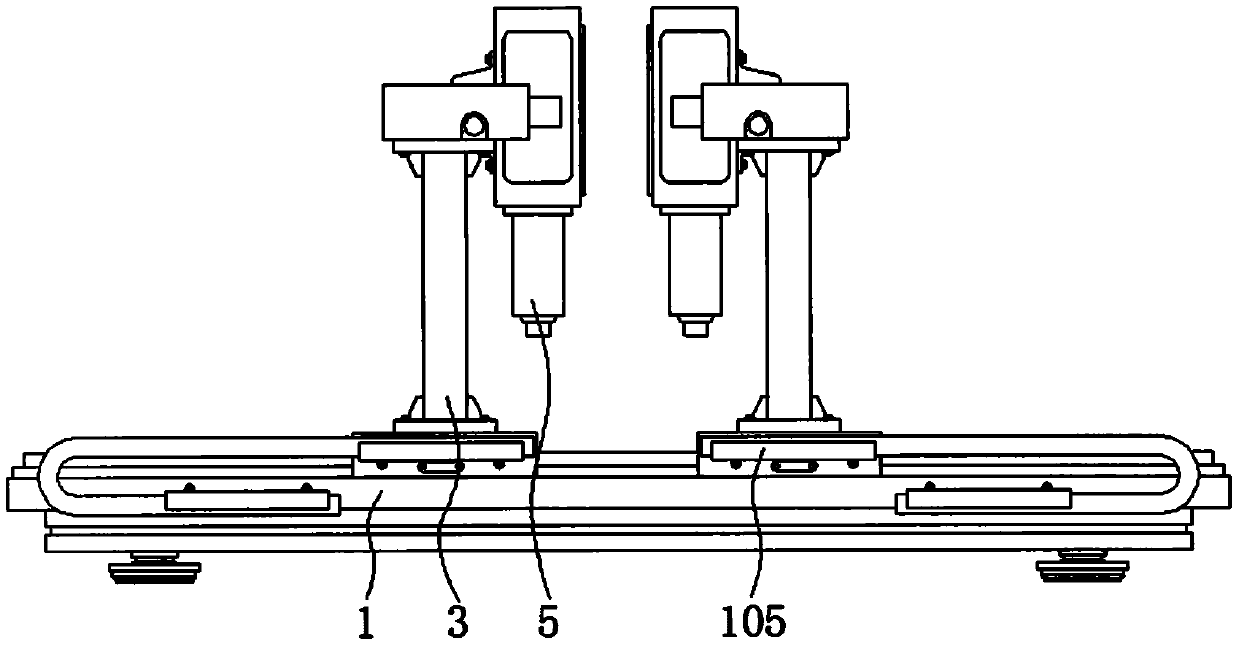

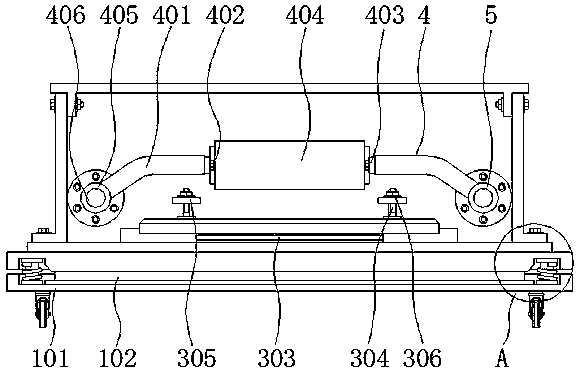

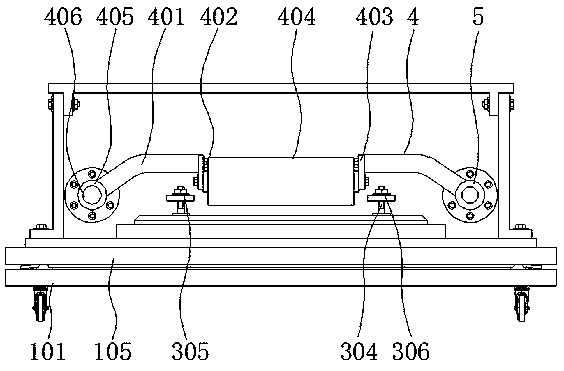

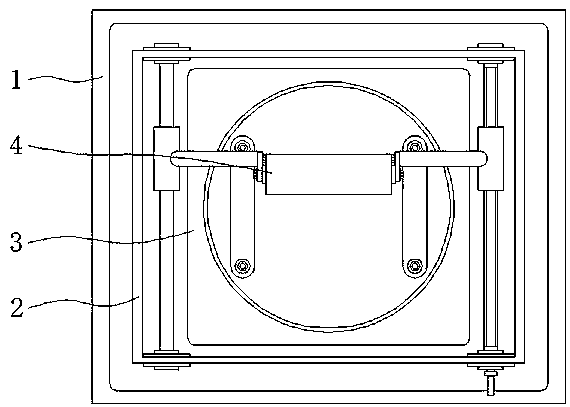

Dual-station drilling device for gantry machining

InactiveCN110653388AAvoid rigid frictionEasy to operateLarge fixed membersBoring/drilling machinesStructural engineeringMachining process

The invention relates to the technical field of drilling devices, in particular to a dual-station drilling device for gantry machining. The dual-station drilling device comprises a supporting mechanism and gantry frames. An installing base is arranged in the middle of the supporting mechanism. The gantry frames are arranged on the upper sides of the left end and the right end of the supporting mechanism correspondingly. Each gantry frame comprises a supporting column, a connecting screw, a horizontal beam and a distance sensor, wherein the connecting screw is arranged in the lower end of the supporting column, the horizontal beam is arranged on the upper side of the supporting column, and a horizontal guide mechanism is arranged in the upper end of the gantry frame. According to the dual-station drilling device for gantry machining, the use performance of the whole device is greatly improved when the structure is added; and the dual-gantry structure is adopted for the improved device,so the device is equipped with a plurality of machining platforms, the work efficiency of the device in the drilling machining process is indirectly improved, and use requirements of people are effectively met.

Owner:湖南九五精机有限责任公司

Polishing device provided with fixing structure and used for wrench machining

InactiveCN110860979AAvoid rigid frictionReduce rigid impactGrinding carriagesGrinding machinesPolishingControl arm

The invention discloses a polishing device provided with a fixing structure and used for wrench machining and relates to the technical field of wrench machining equipment, in particular to a polishingdevice provided with the fixing structure and used for wrench machining. The polishing device comprises a supporting mechanism and a polishing mechanism. An outer frame is arranged above the supporting mechanism. The polishing mechanism is arranged above a positioning installation mechanism. The polishing mechanism comprises supporting bending rods, positioning screws, control arms, a steel brushsleeve, positioning sleeves and guide pillars. The supporting bending rods are arranged on the right sides of the positioning sleeves. The control arms are arranged at the rear ends of the positioning screws. By means of the polishing device provided with the fixing structure and used for wrench machining, the structure is increased, meanwhile, the use performance of the whole device is greatly improved, when the improved equipment is used, a wrench clamping manner is simpler and more convenient, in addition, adjusting operation can be conducted on the polishing height through the device according to different specifications of wrenches, the equipment application face is indirectly enlarged, and the use requirements of people are effectively met.

Owner:东莞市史雷帝三维数控科技有限公司

A cornmeal production and processing mechanism based on multi-directional feeding

ActiveCN108654757BGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsAgricultural engineeringCorn flour

The invention discloses a cornmeal production and processing mechanism based on multi-directional feeding, which comprises a corn grain crushing device, a powder material mixing device and a powder material running device in sequence from front to back according to the technological process. The corn grain crushing device includes a crushing unit, a drying unit and a recycling unit in sequence according to the process flow. The powder mixing device includes a mixing tank body and a mixing upper cover covered on the mixing tank body. The cavity of the mixing tank body is sequentially provided with a first mixing sieve plate, a first mixing Chamber, second mixing sieve plate, crushing / mixing integrated chamber. The powder running device includes a running conveyor belt, a flip-type unloading device, a running baffle, a hopper, a running elastic device, and a running lifting base that are arranged in sequence from front to back. The invention has the advantages of ensuring the quality of the produced corn flour, good mixing effect of corn flour and flour, no agglomeration, no clogging, strong work continuity, accurate single feeding amount and high work efficiency.

Owner:安徽双全面粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com