Unloading structure of belt conveyor

A belt conveyor and unloading belt technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of increased energy consumption, extra load on the belt, fast wear of coulters, etc., to ensure complete contact and avoid Effects of material leakage and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

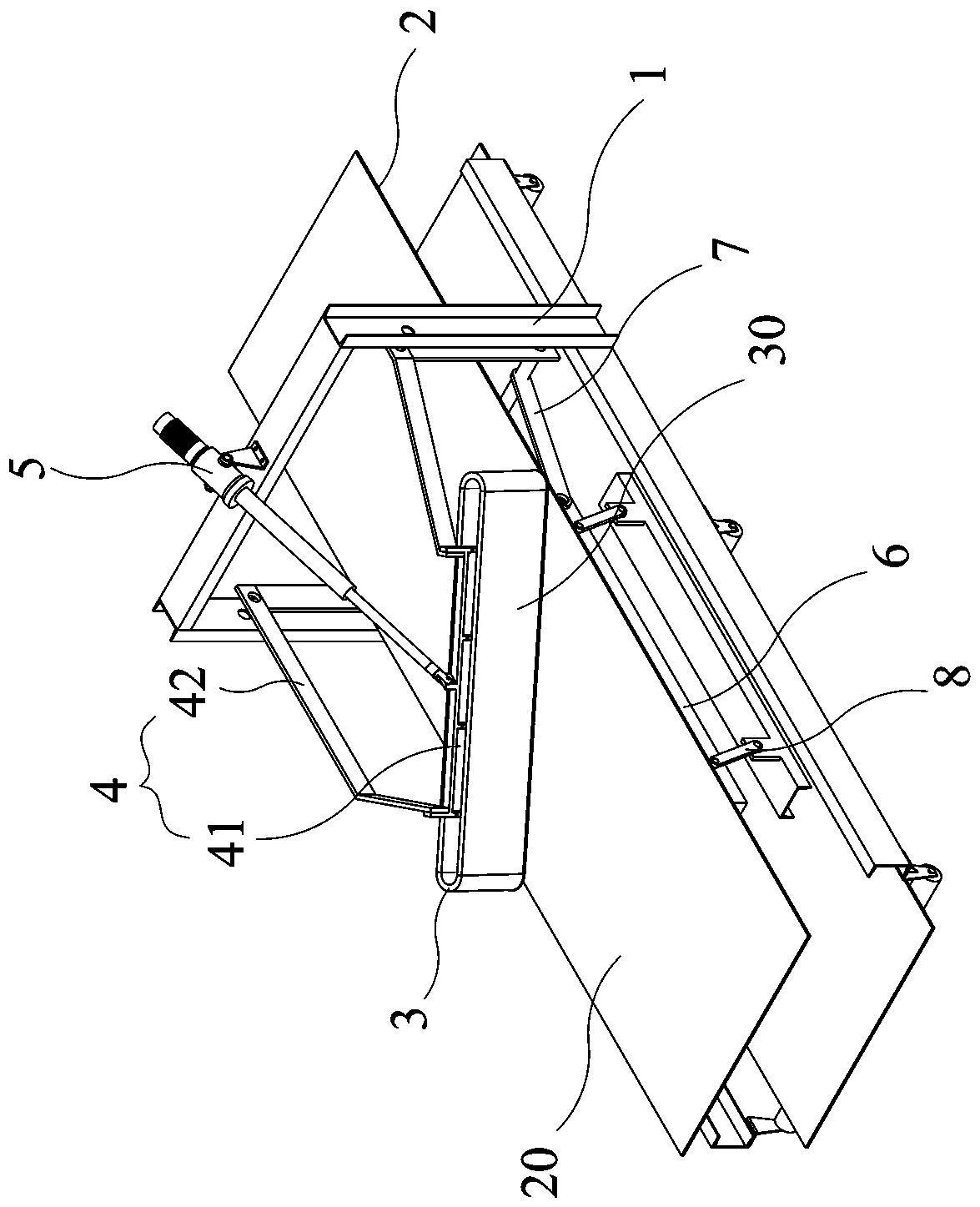

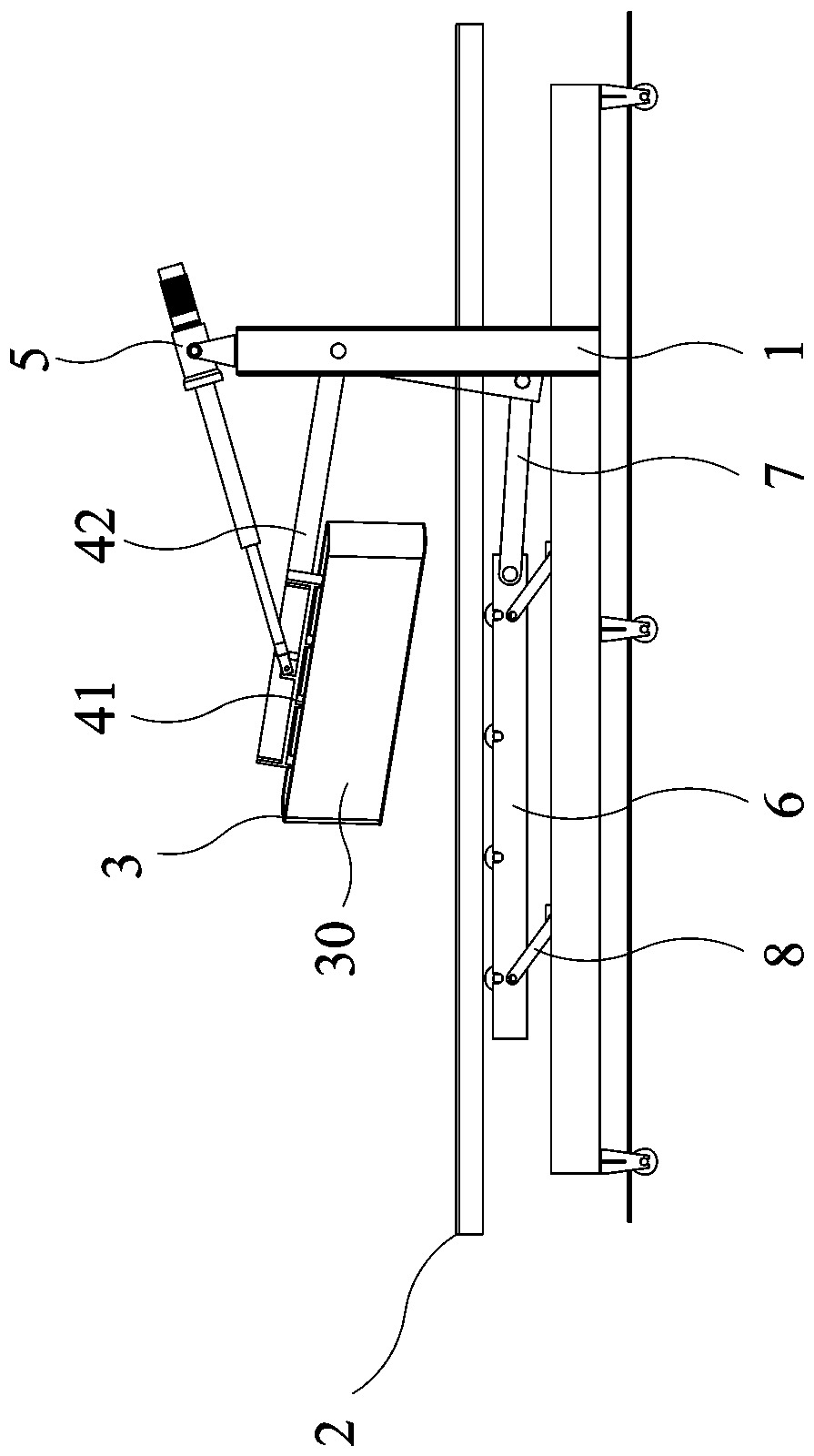

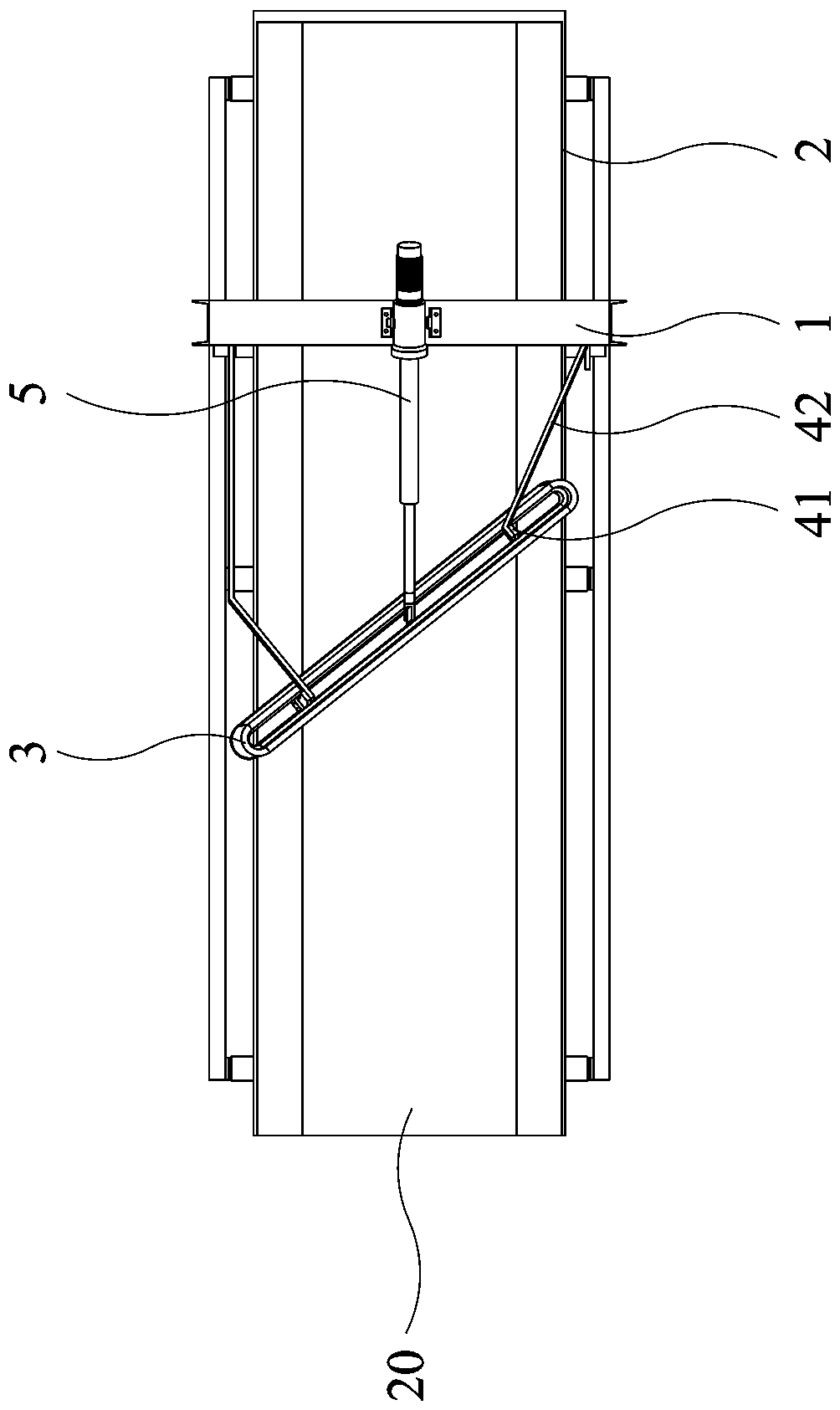

[0026] refer to Figure 1 to Figure 8 As shown, the present invention is a discharge structure of a belt conveyor, including a frame 1, a conveyor belt 2, a discharge belt 3 and a mounting bracket 4. Above-mentioned conveyor belt 2 is installed on the frame 1. The above-mentioned mounting bracket 4 includes a mounting part 41 and a connecting rod group 42. The discharge belt 3 is sleeved on the periphery of the mounting part 41, and the lower end of the discharge belt 3 is movably matched with the upper surface of the conveyor belt 2. The upper surface of the mounting part 41 is in contact with the One end of the connecting rod group 42 is connected, and the other end of the connecting rod group 42 is installed on the frame 1 . The inner ring of the above-mentioned unloading belt 3 is formed with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com