Levelness calibrating device for metal doorframe horizontal frame

A technology of calibration device and levelness, which is applied to measurement devices, fluid devices, instruments, etc., can solve the problems of long idle time, low production efficiency, and more time consumption of equipment, so as to improve efficiency and reduce scrap rate. , the effect of reducing abnormal working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

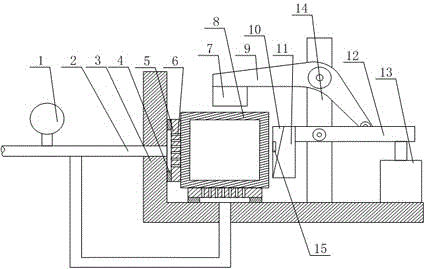

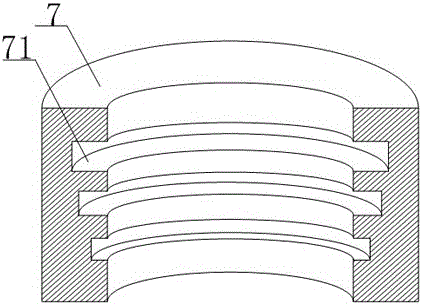

[0022] Such as figure 1 with figure 2 As shown, this embodiment includes an L-shaped bottom plate 3, a gas pipe 2 and a pressure gauge 1 mounted on the gas pipe 2. The vertical and horizontal sections of the bottom plate 3 are respectively provided with sealing rings 4, and the detection block 5 is fixed on On the sealing ring 4, a plurality of air holes 6 are opened on the detection block 5. The air pipe 2 is divided into two paths which respectively penetrate the vertical section and the horizontal section of the bottom plate 3 and communicate with the air holes 6 on the horizontal section of the bottom plate. A column 14 and an air cylinder 13 are installed. The upper section of the column 14 is hingedly provided with a V-shaped adjusting rod 9, and the middle section of the column 14 is hingedly provided with a connecting rod 12, and at one end of the adjusting rod 9 is installed an elastic rubber material pressing block 7. The other end of the adjusting rod 9 is hinged wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com