Patents

Literature

485results about "Fixed angles setting out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

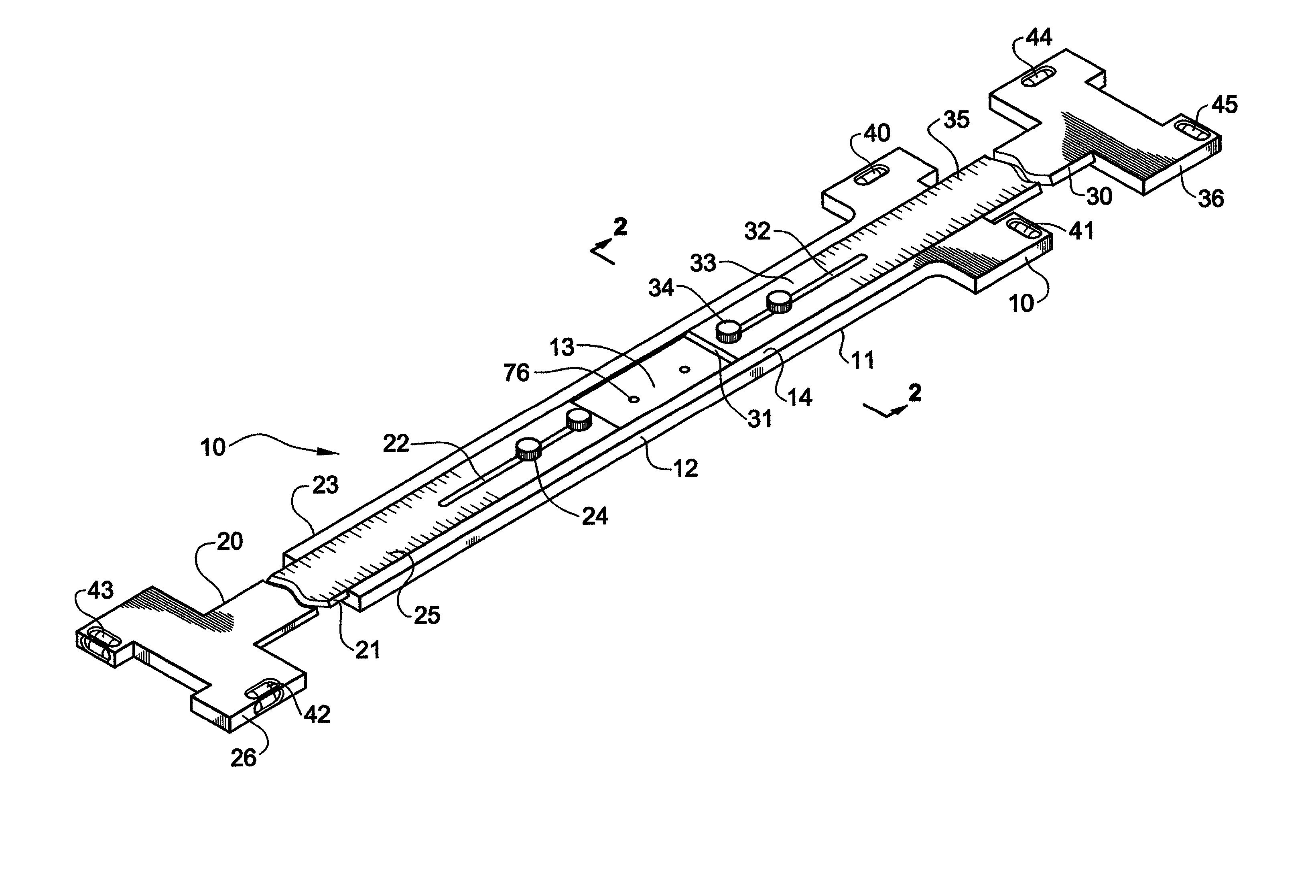

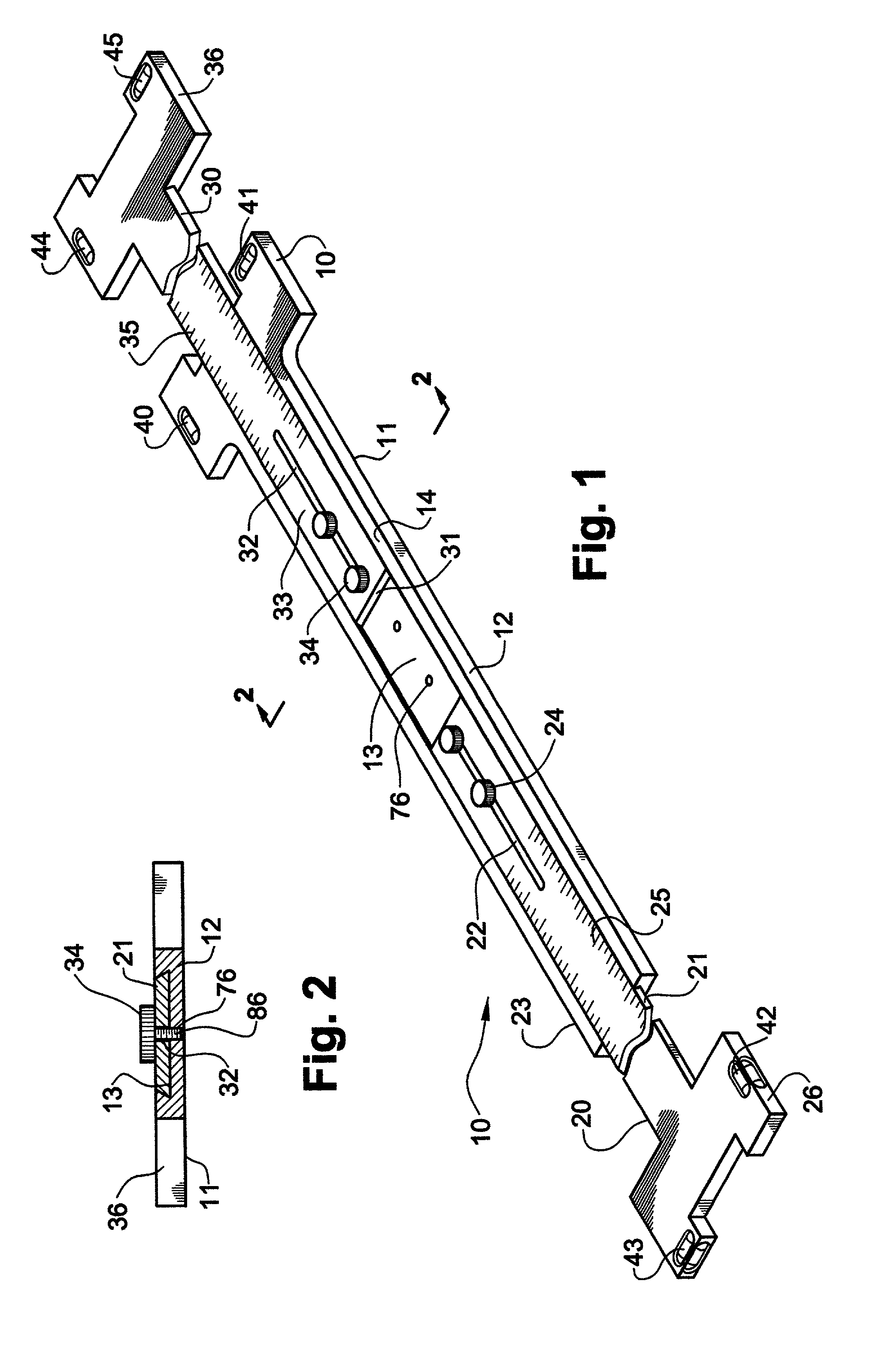

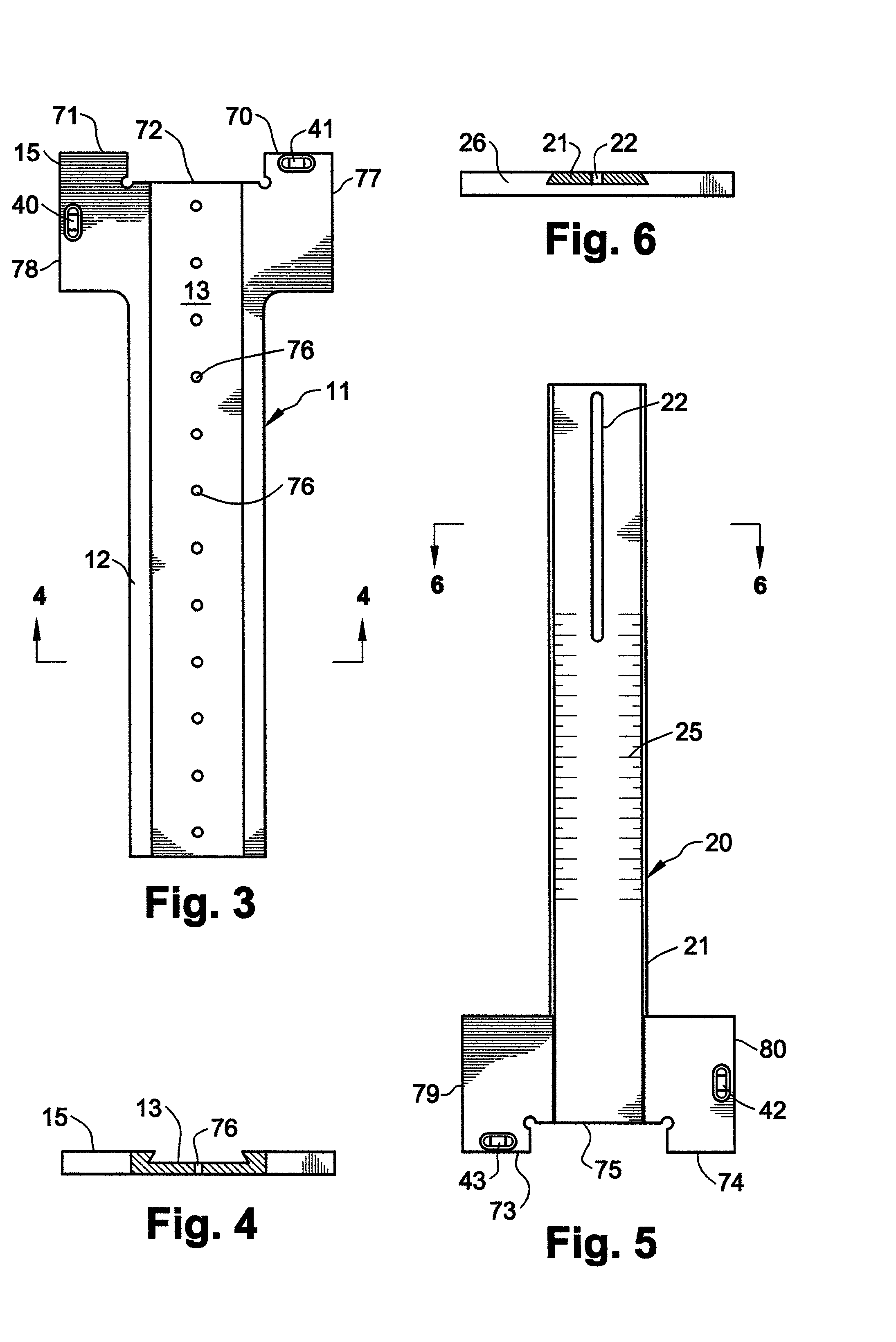

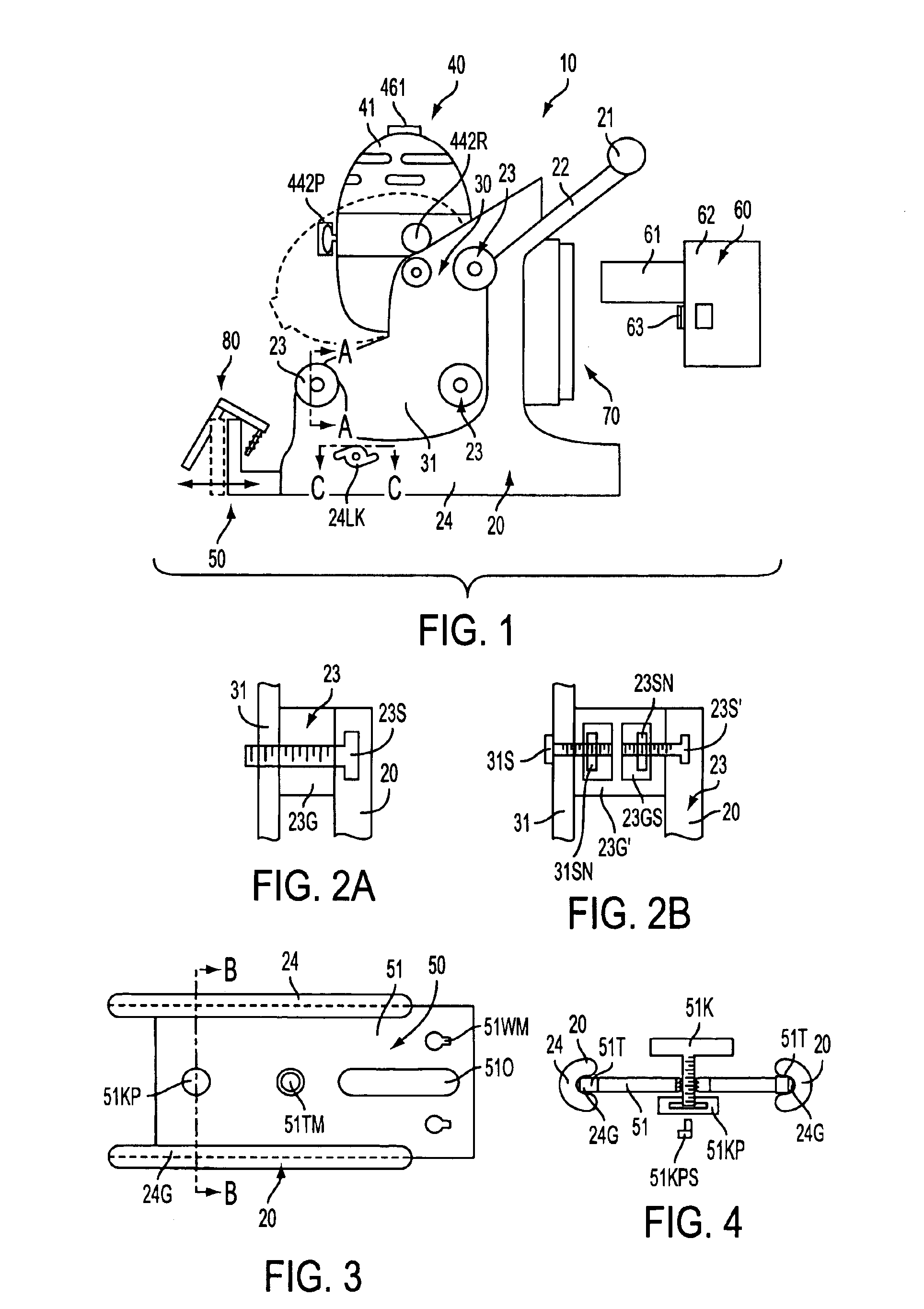

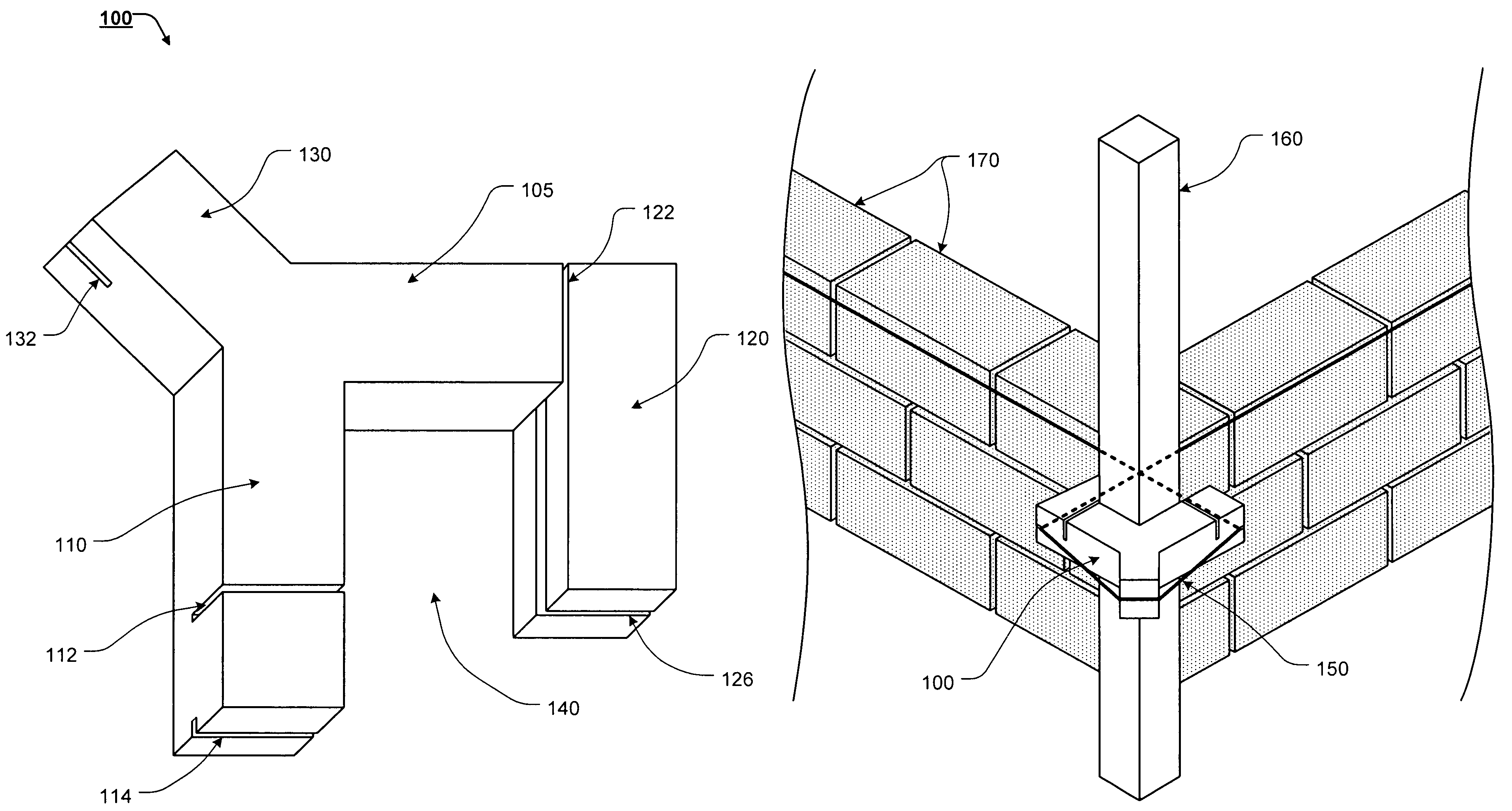

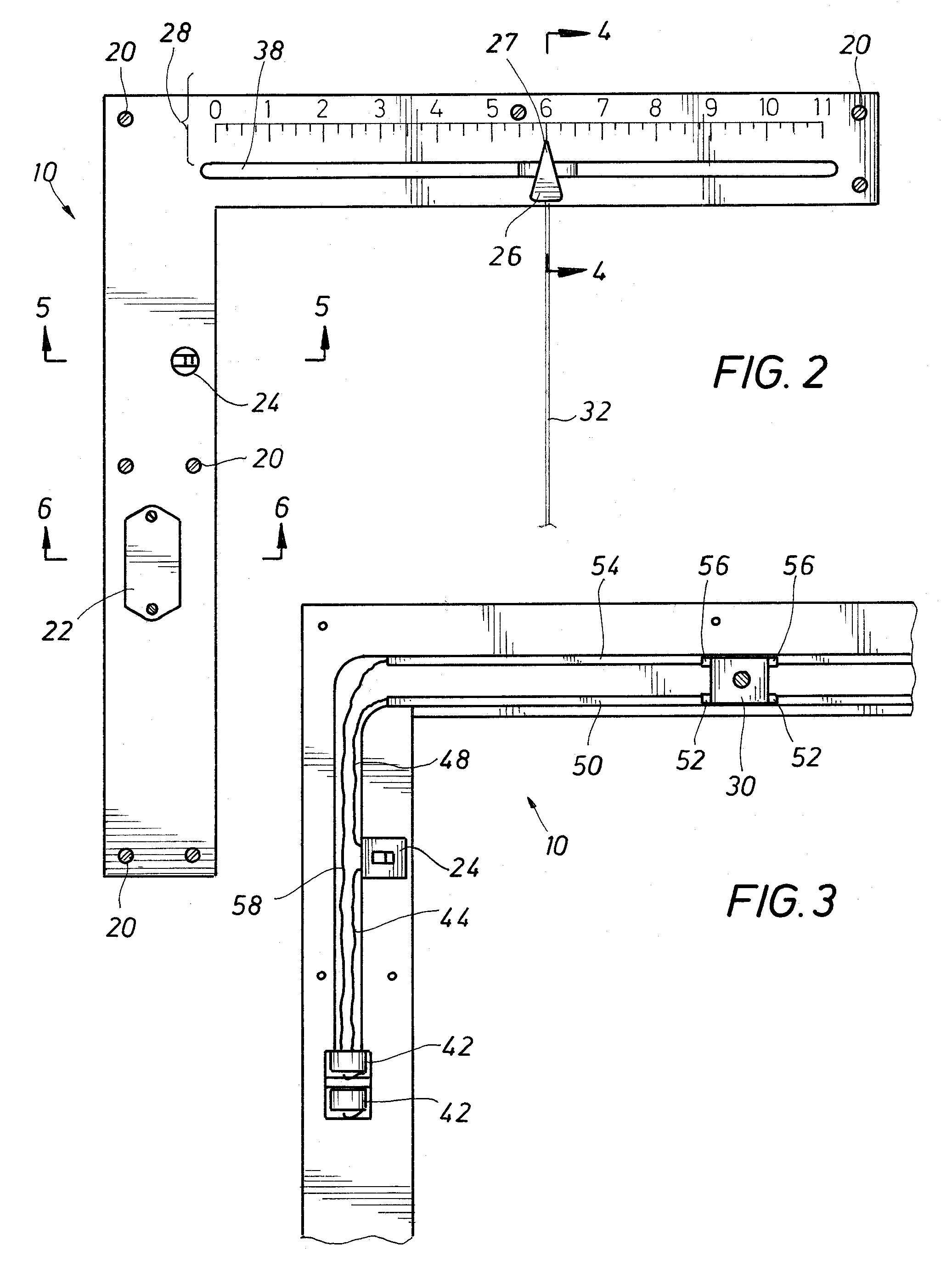

Door jamb alignment apparatus

InactiveUS20020170189A1Simple and inexpensive to fabricateDoors/windowsStraightedgesEngineeringMechanical engineering

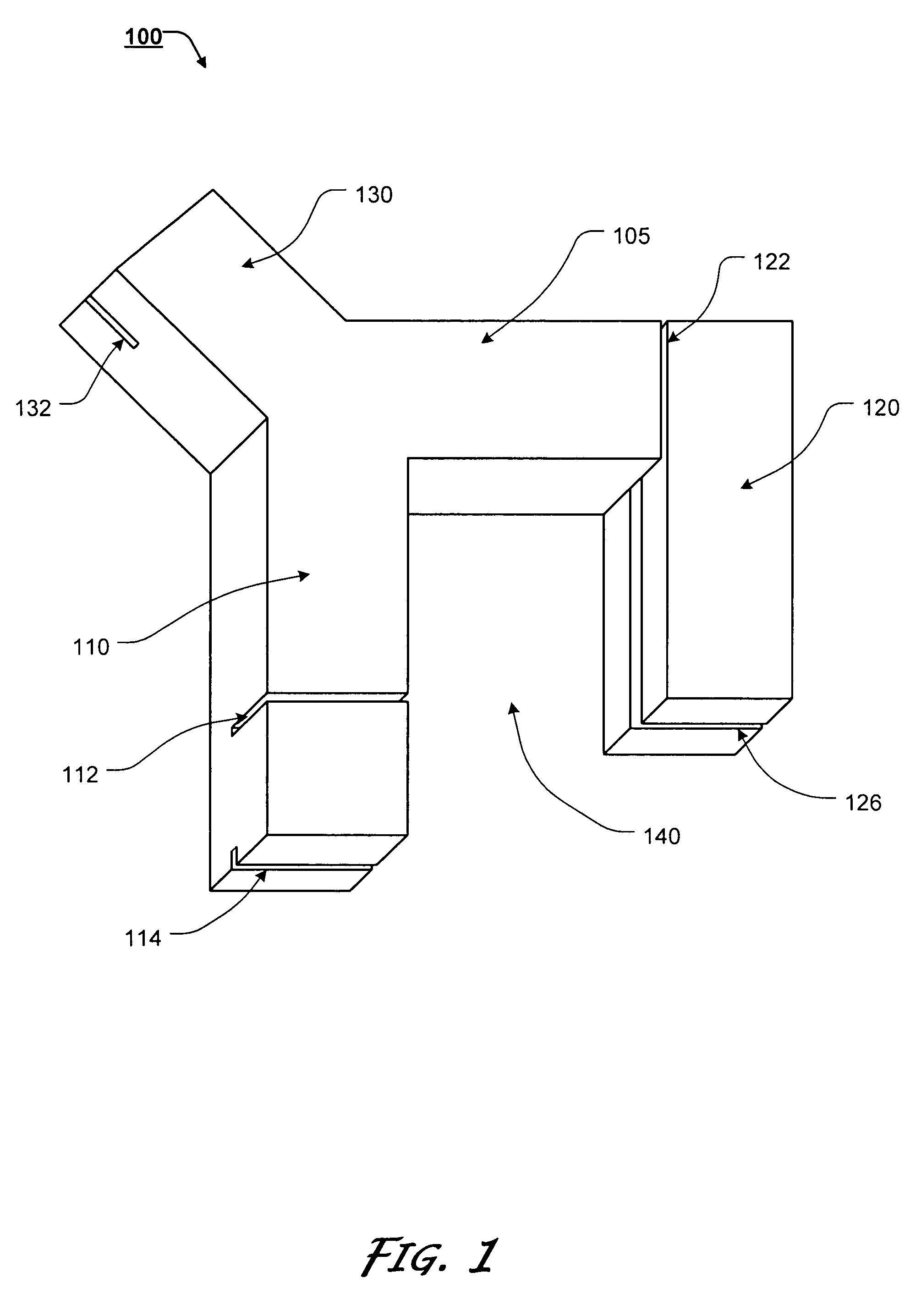

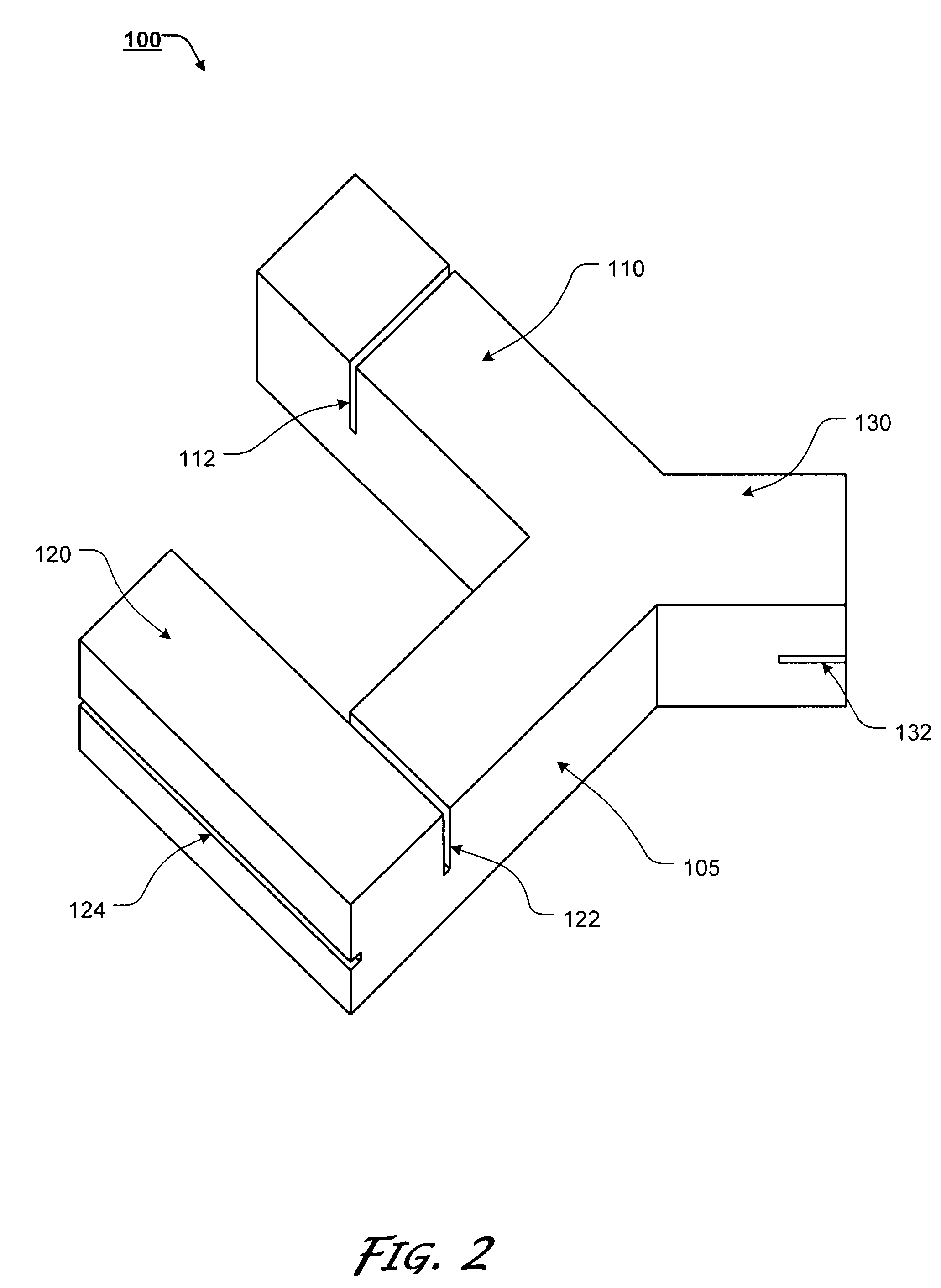

An apparatus used to align door jambs and like structures. A base member comprises a substantially longitudinal section through which a channel is formed in the top surface thereof, one end extending into a first jamb spreader. A first extension member is slidably coupled within the channel of the base member, the extended end of the extension member depending into a second jamb spreader. A second extension member is slidably coupled within the channel of the base member opposite the first extension member, the end opposing the second jamb spreader depending into a third jamb spreader. The jamb spreader of the first and second extension members include horizontal and vertical leveling members. By positioning the opposed jamb spreaders against the opposed door jambs or surfaces, the alignment of the door jambs and door frame may be determined to be in square and plumb alignment.

Owner:CHEATHAM THOMAS E

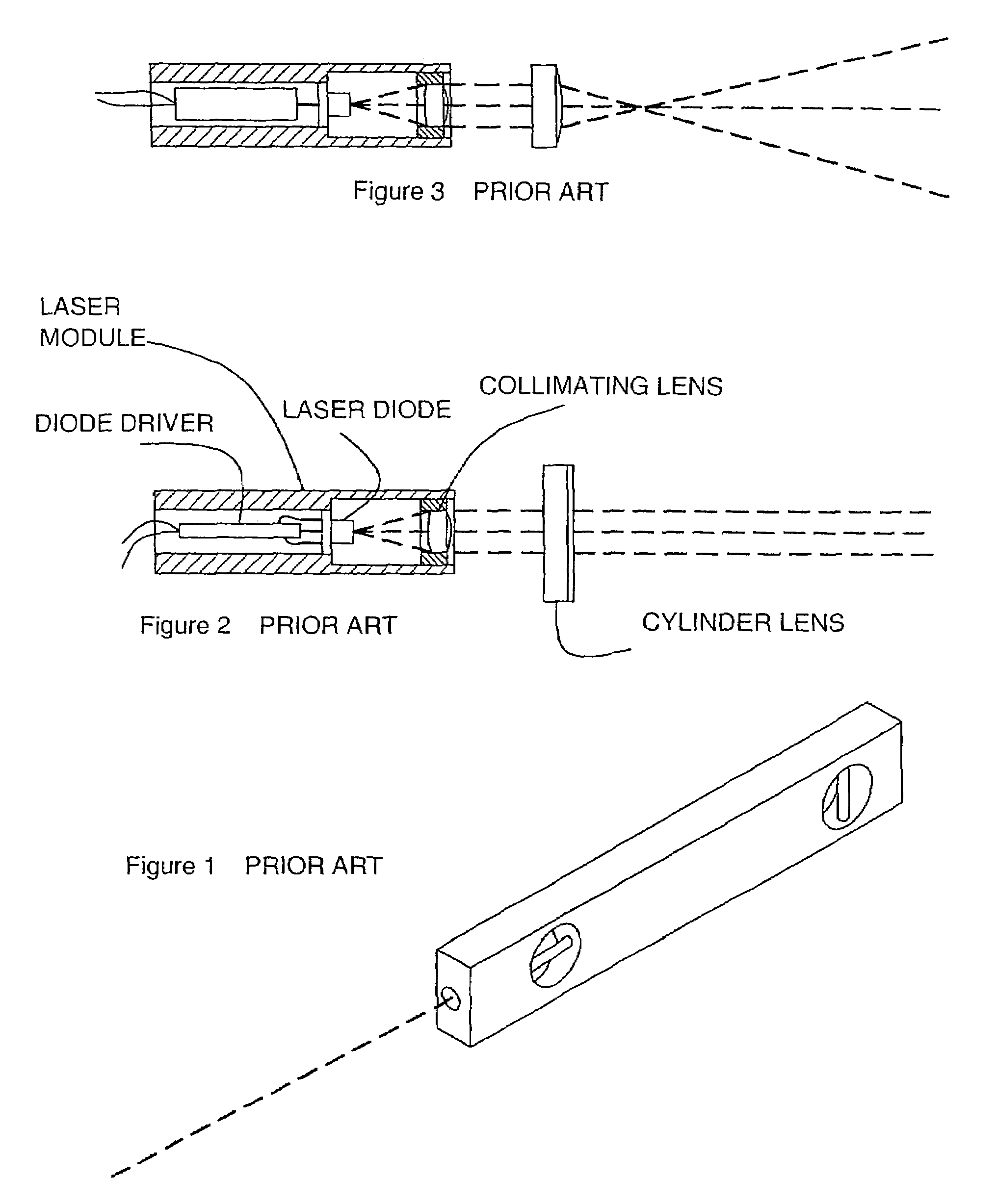

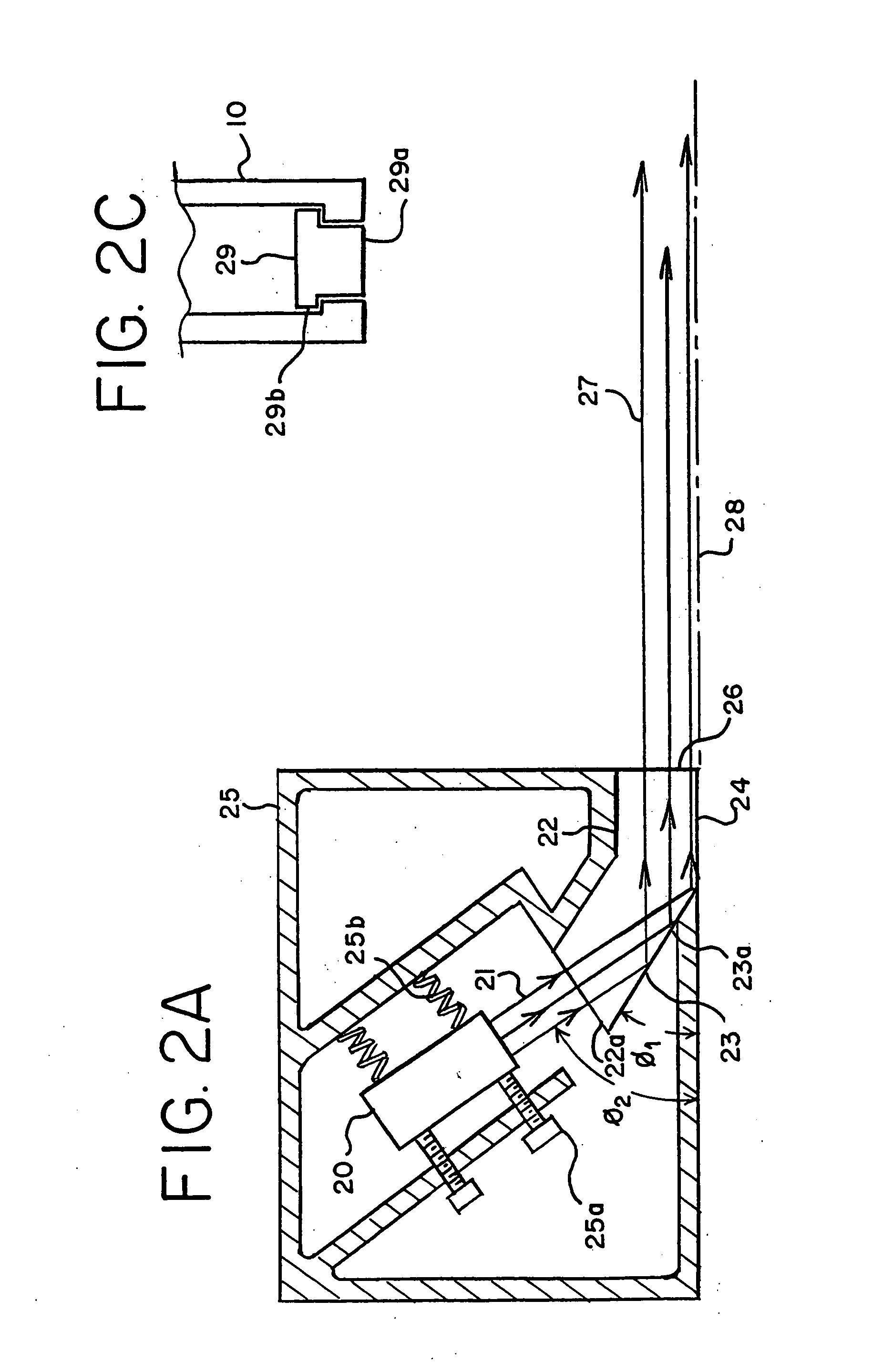

Laser level

A light detector which includes a housing having front and rear walls, a light receiving section disposed on the front wall, and displays disposed on the front and rear walls for showing the location of received light relative on the light receiving section. Also disclosed is a laser level including a motor, a shaft driven by the motor, a housing fixedly disposed on the shaft, the housing having a bore therein, a barrel pivotally connected to the housing, a laser diode module disposed within the barrel, and a screw disposed on the housing and contacting the barrel for adjusting the pivotal position of the barrel.

Owner:BLACK & DECKER INC

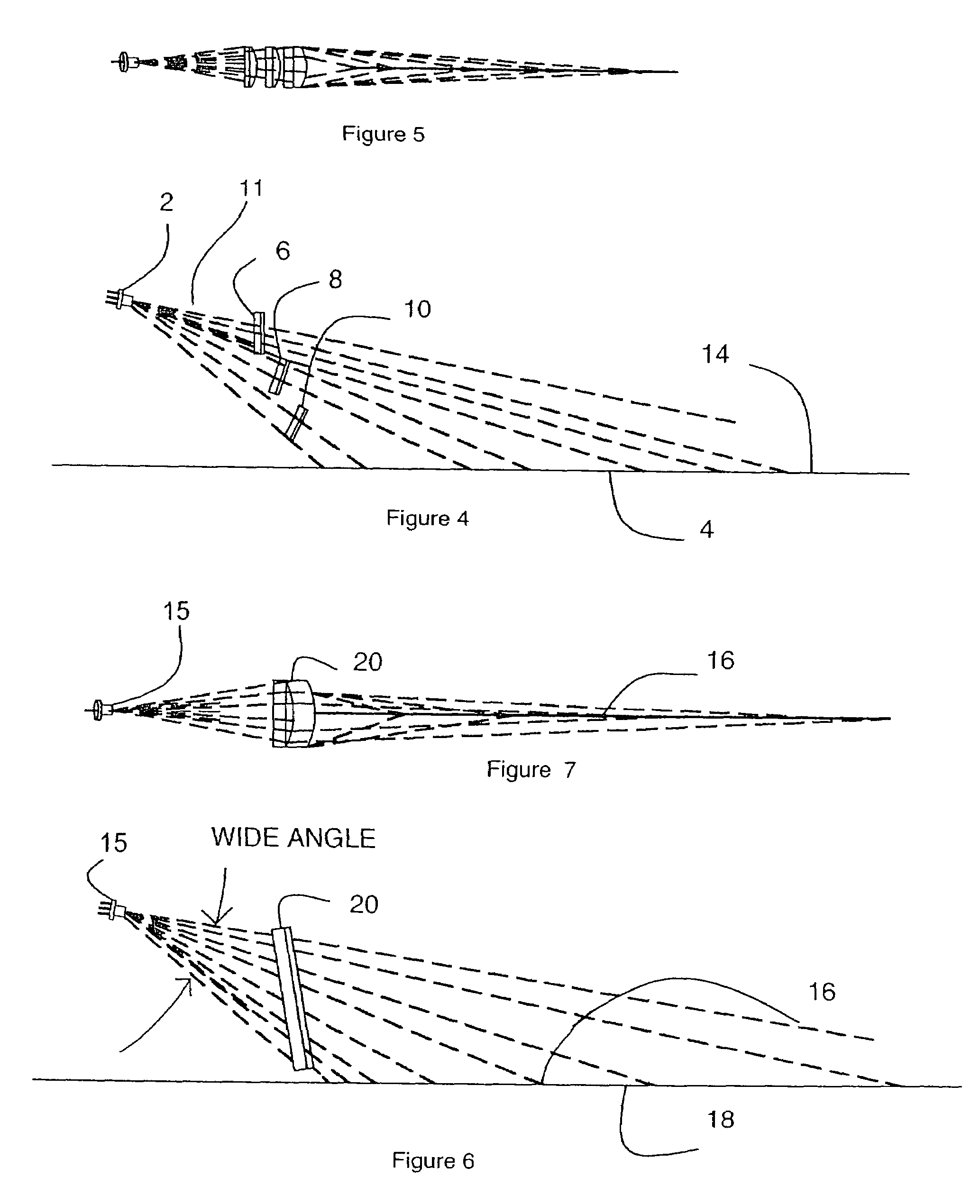

Apparatus for producing a visible line of light on a surface, particularly a wall

InactiveUS7287336B1Facilitates holdingHighly visibleMeasuring points markingWriting aidsCombined useLight beam

An apparatus and method for efficiently generating a visible line of light on a surface such as a wall or a floor for the purpose of facilitating the layout process used in construction. Reference marking elements on the instrument correspond to the light beam's position. One or more level vials may be included for indicating vertical and horizontal, as well as a magnet for mounting and a reference bracket for a stud-finder instrument. In one embodiment the instrument is self-leveling on one axis only and is useful for projecting one or more orthogonal lines on a wall surface. The instrument, self-leveling or not, can be combined with a stud finder.

Owner:TRIMBLE NAVIGATION LTD

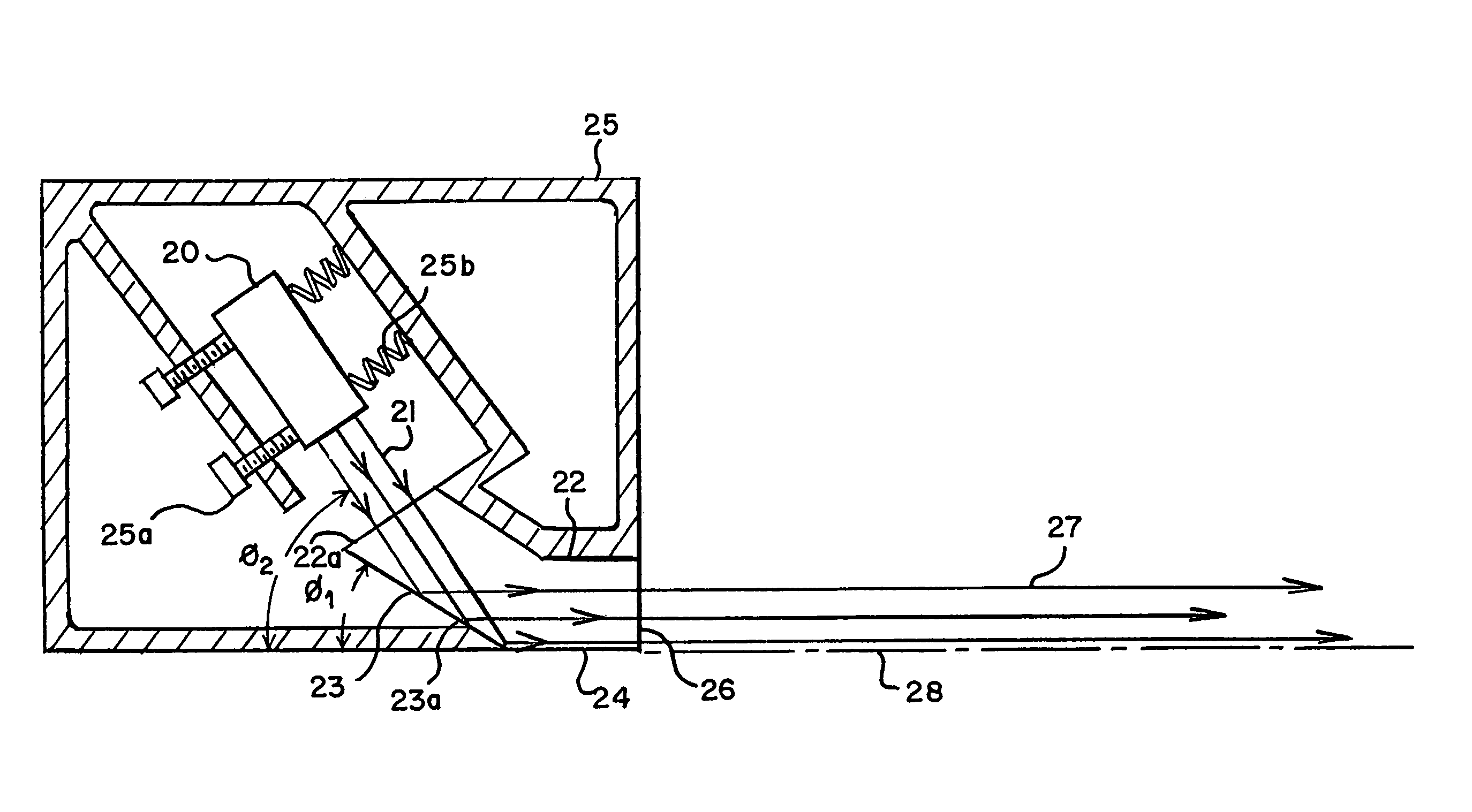

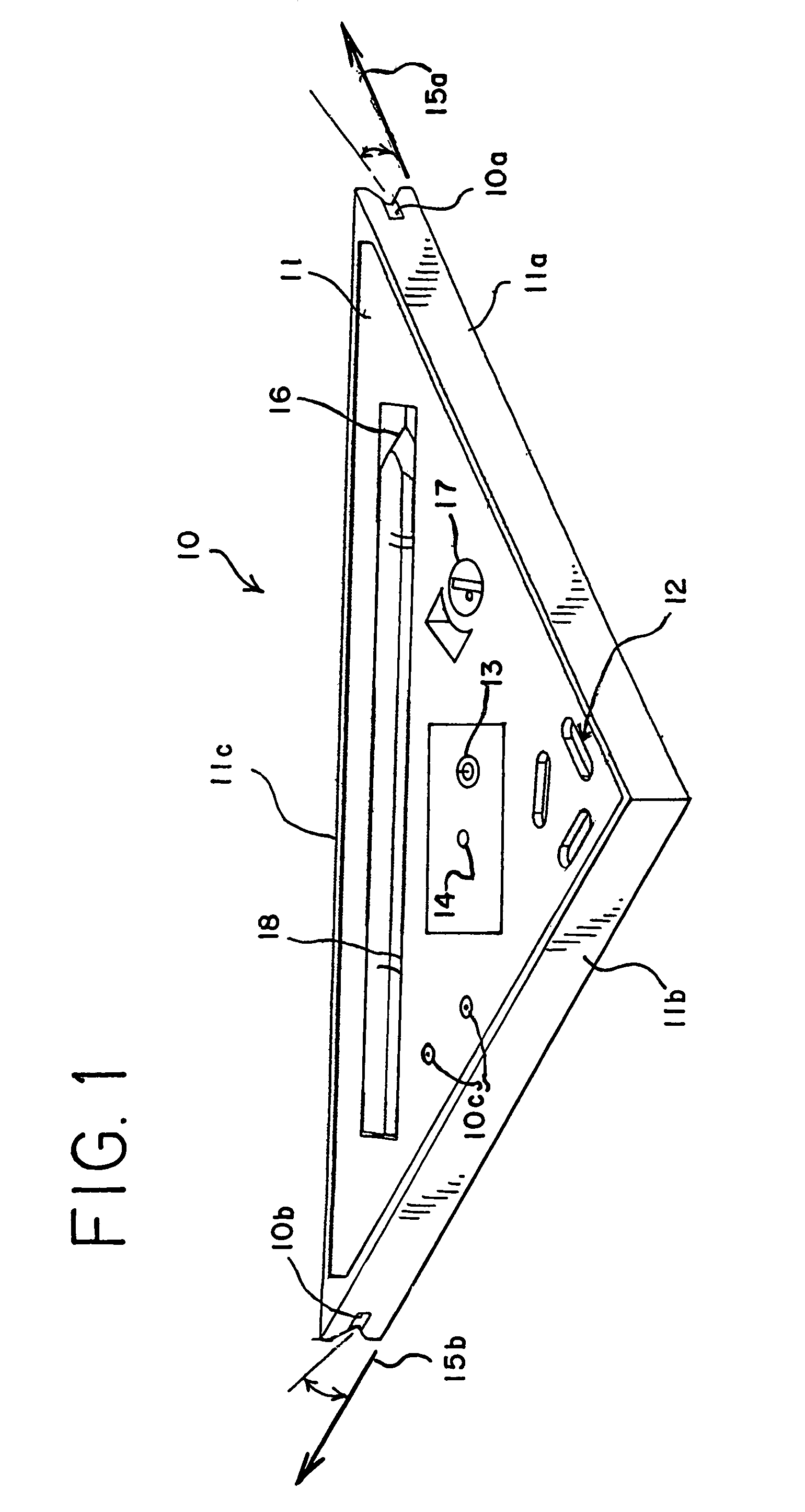

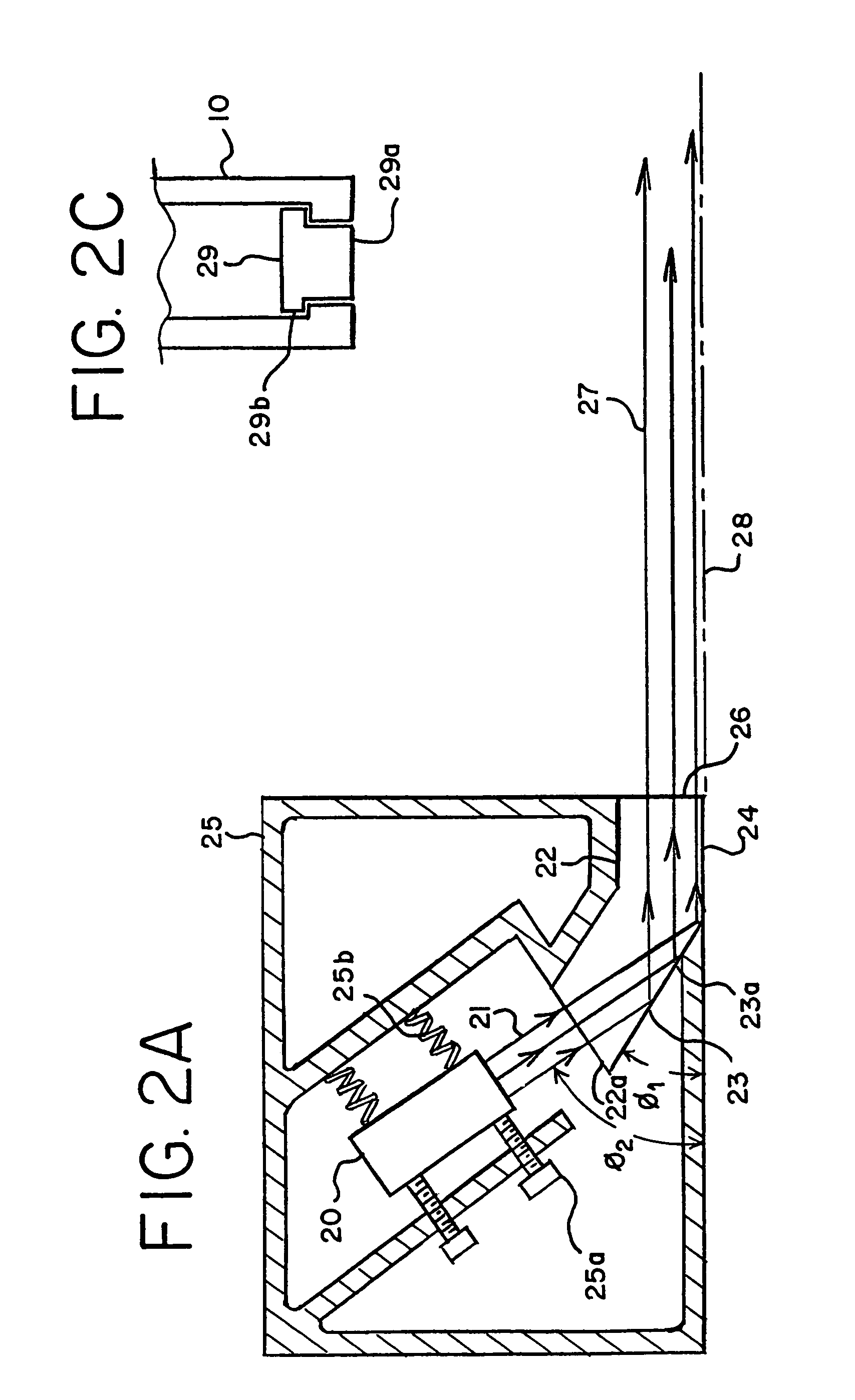

Laser line projected on an edge of a surface

A laser reference device includes at least one planar or flat surface and an internal laser light source for generating a laser light beam. A lens inside the device may convert the laser light into a fan-shaped beam, and project the beam adjacent the planar or flat surface of the housing. The fan-shaped beam thus projects along that surface of the housing. If the laser leveling device is placed with the flat surface on a table or floor, for example, the fan-shaped beam will be in a level plane. This allows a user to place the laser leveling device on a surface and generate a laser light to align surfaces or objects, such as objects on a wall.

Owner:BLACK & DECKER INC

Vertical detection device and method

The invention provides a device and a method for detecting cylinder verticality. The device for detecting cylinder verticality provided by the invention includes: a horizontal positioning ring, which is mounted on a guide rail and is parallel to the horizontal plane; at least three laser range finding sensors mounted on the horizontal positioning ring; a detection circuit and a host computer software system. The detection circuit detects output signals of the laser range finding sensors, and transmits the output signal to the host computer software system, and the host computer software system judges whether the cylinder is vertical according to the information output by the laser range finding sensors when the horizontal positioning ring is at different positions of the cylinder. Through the scheme provided by the invention, the cylinder verticality and deviation angle can be judged.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

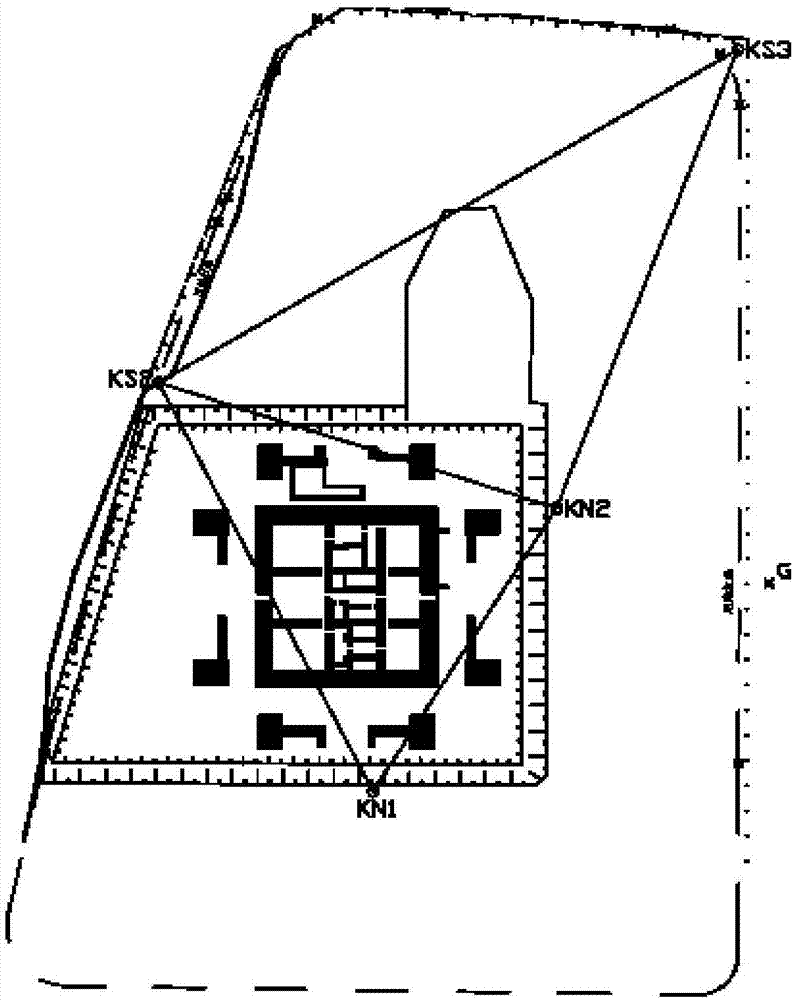

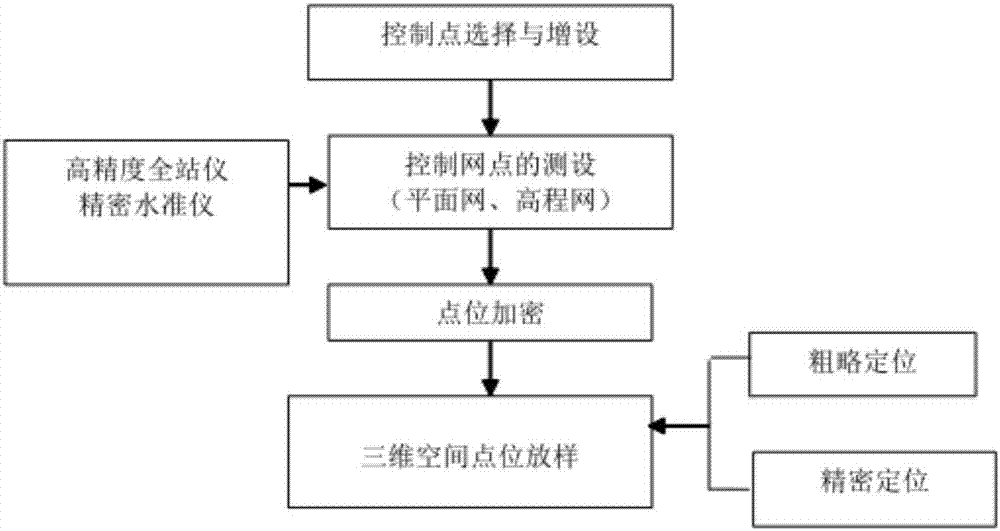

Supervision control method of super high-rise building engineering survey

The invention discloses a supervision control method of super high-rise building engineering survey. A survey supervision method is performed by adopting a method that a laser plummet apparatus is adopted to carry out vertical point location transfer, and a total station is utilized to perform mutual connection surveying and re-check on multiple sets ofsurvey and supervise a multi-set control network mutual connection surveyingre-check method. Through analyzing previous engineering, a supervision department adopts and usesthe method of using the laser plummet apparatus for carrying out verticalpoint location transfer, and utilizing the total station to perform mutual connection surveying and re-check on the multiple sets of control network to carry out survey supervisionis utilized to survey and supervise the multi-set control network mutual connection surveyingre-check method, and finally a super high-rise survey technology supervision method standard file is formed, so that the requirements on quality, safety and high efficiency are realized.

Owner:广州珠江监理咨询集团有限公司

Laser line projected on an edge of a surface

A laser reference device includes at least one planar or flat surface and an internal laser light source for generating a laser light beam. A lens inside the device may convert the laser light into a fan-shaped beam, and project the beam adjacent the planar or flat surface of the housing. The fan-shaped beam thus projects along that surface of the housing. If the laser leveling device is placed with the flat surface on a table or floor, for example, the fan-shaped beam will be in a level plane. This allows a user to place the laser leveling device on a surface and generate a laser light to align surfaces or objects, such as objects on a wall.

Owner:BLACK & DECKER INC

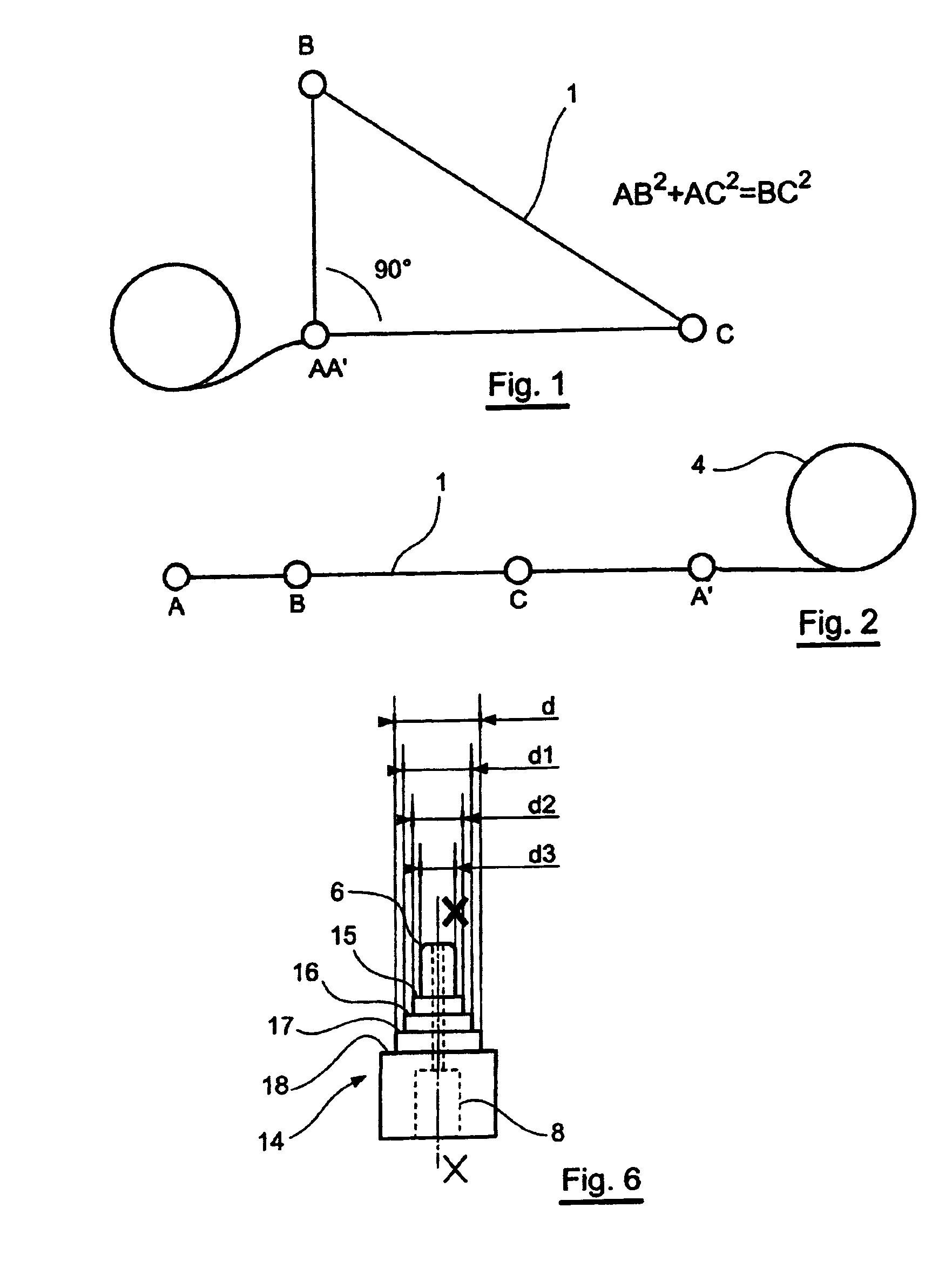

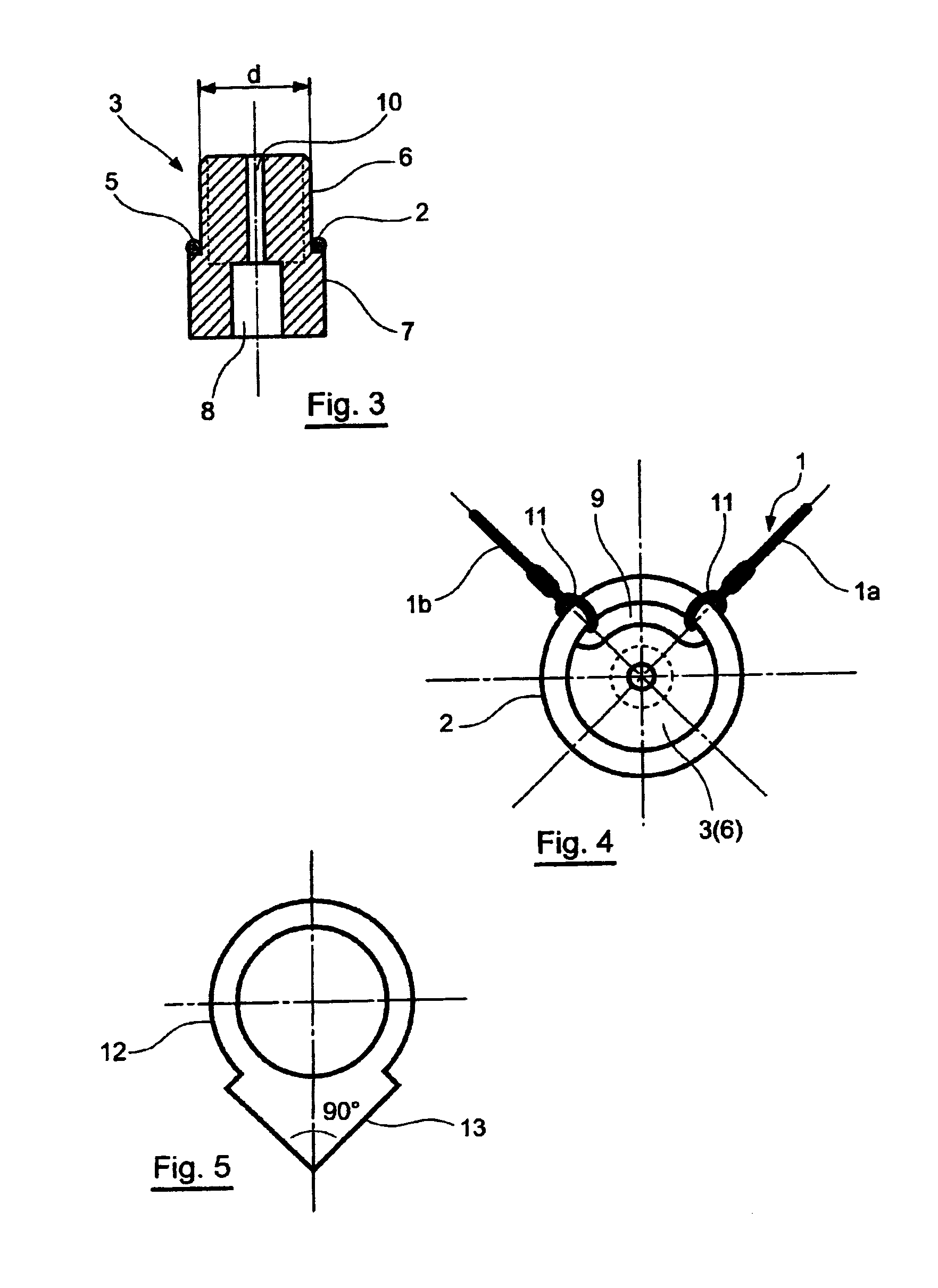

Right angle measuring device

The invention concerns a device comprising a flexible and non-elastic yarn divided by at least three retaining means fixed to predetermined locations and at least three fixing means adapted to support the retaining means and whereof the diameter of each fixing means is substantially equal to the internal diameter of the retaining means so as to position the yard along a direction perpendicular to that of the axis of the corresponding fixing means.

Owner:DOUBLET DANIEL P

Stand column perpendicularity measuring method

InactiveCN111174771AEasy to measureFast measurementFixed angles setting outSlant angleAzimuth direction

The invention discloses a stand column perpendicularity measuring method and adopts a prism-free distance measurement total station for measurement. The method comprises steps of preparing more than two control points with known three-dimensional coordinates and a centering rod in advance, erecting the total station at one control point, and leveling, centering and orientating the total station; determining an upper section and a lower section on a stand column, measuring azimuth angles on left and right sides of the upper section by using the total station, taking an average value of the twoazimuth angles as a central azimuth angle of the upper section, measuring a horizontal distance from the total station to a surface of the central azimuth angle of the upper section without a prism, and calculating central three-dimensional coordinates of the upper section according to the horizontal distance, a radius of the stand column and a vertical angle from the total station to the surfaceof the central azimuth angle of the upper section; measuring and calculating the lower section according to the same method to obtain the central three-dimensional coordinates of the lower section; and calculating an inclination angle and an inclination azimuth angle of the stand column by utilizing the central three-dimensional coordinates obtained by calculating the upper section and the lower section, and finally obtaining perpendicularity of the stand column.

Owner:CHINA MCC17 GRP

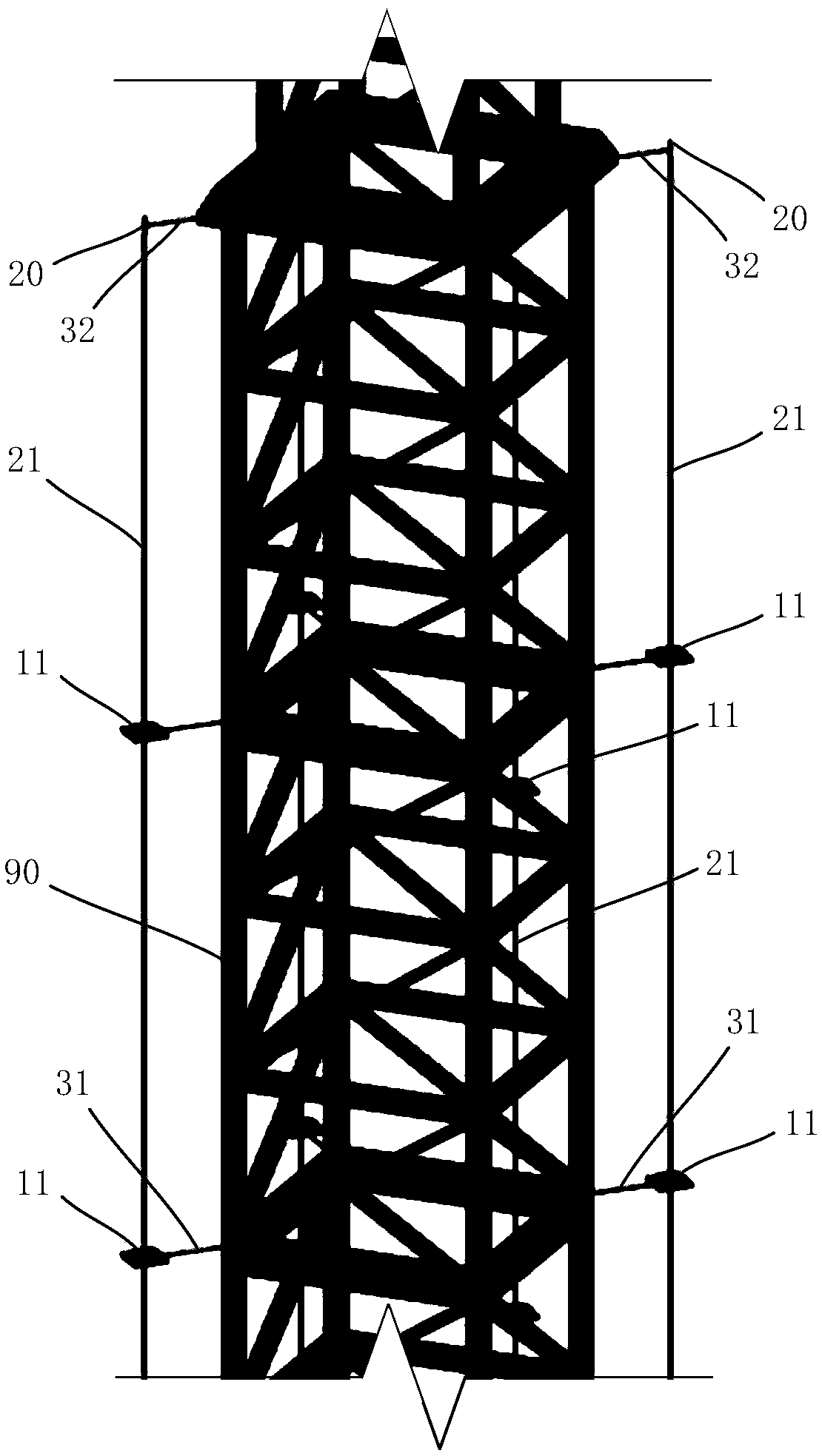

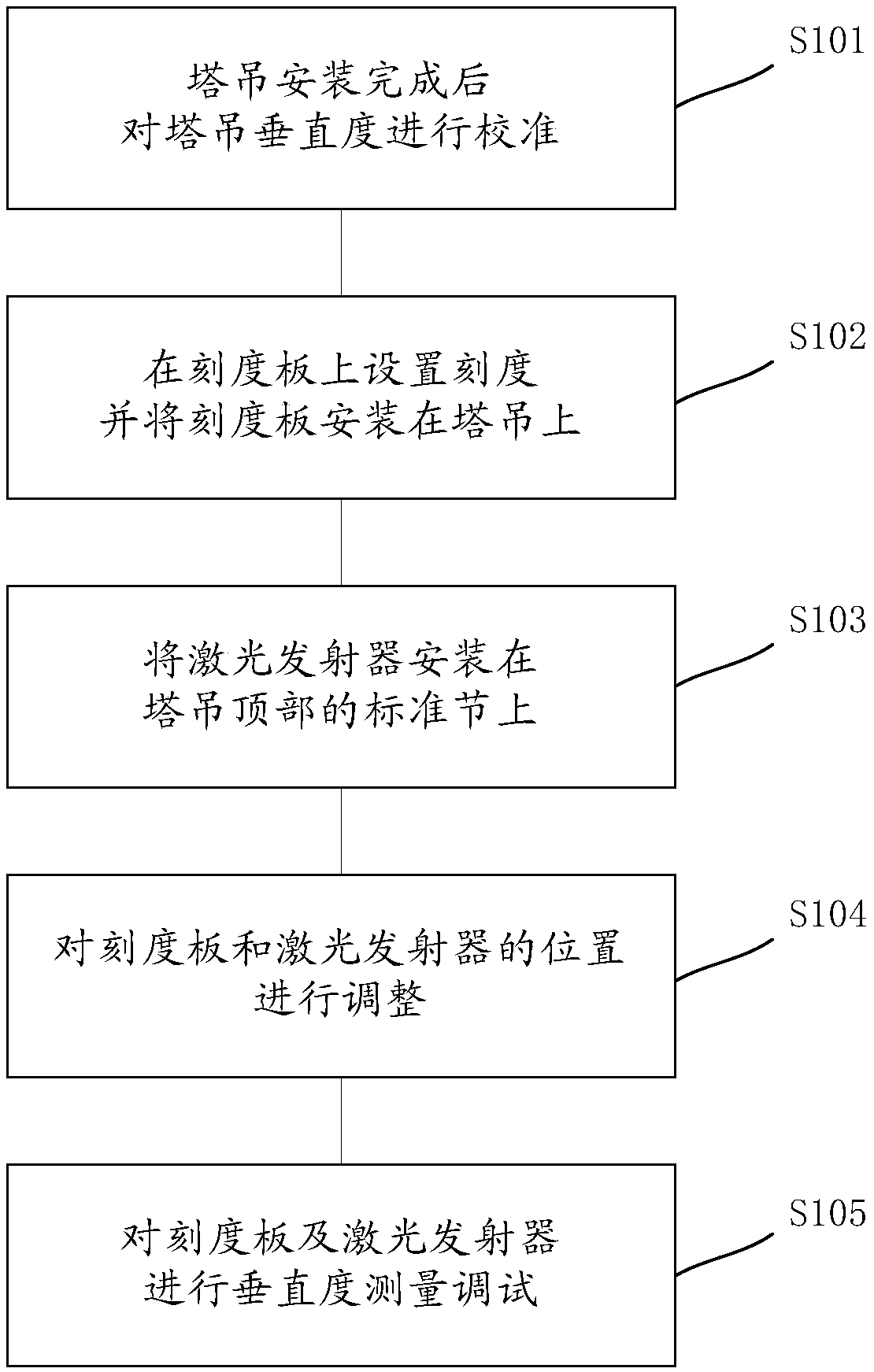

Monitoring device and monitoring method for verticality of tower crane

PendingCN108775896AVerticality MonitoringFixed angles setting outLaser transmitterClassical mechanics

The invention relates to a monitoring device and monitoring method for the verticality of a tower crane. The monitoring device comprises: scale plates, which are horizontally arranged on the tower crane, wherein each scale plate is provided with a scale; and laser emitters, which are arranged on the top parts of the scale plates and corresponding to the scale plates, wherein a laser beam emitted by one laser emitter vertically irradiates the center of a corresponding scale plate, and the verticality of the tower crane is determined by observing whether the laser beam deviates from the center of the scale plate or not. specifically, when the tower body of the tower crane is inclined and bends, inclination of the laser beam is generated with the inclination of the top part of the tower crane, and the laser beam deviates from the center of one scale plate and irradiates a scale, so the degree of inclination and bending and the direction of inclination of the tower crane are reflected in real time.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Angle measurement tool

Owner:AKIHARY TENNY M

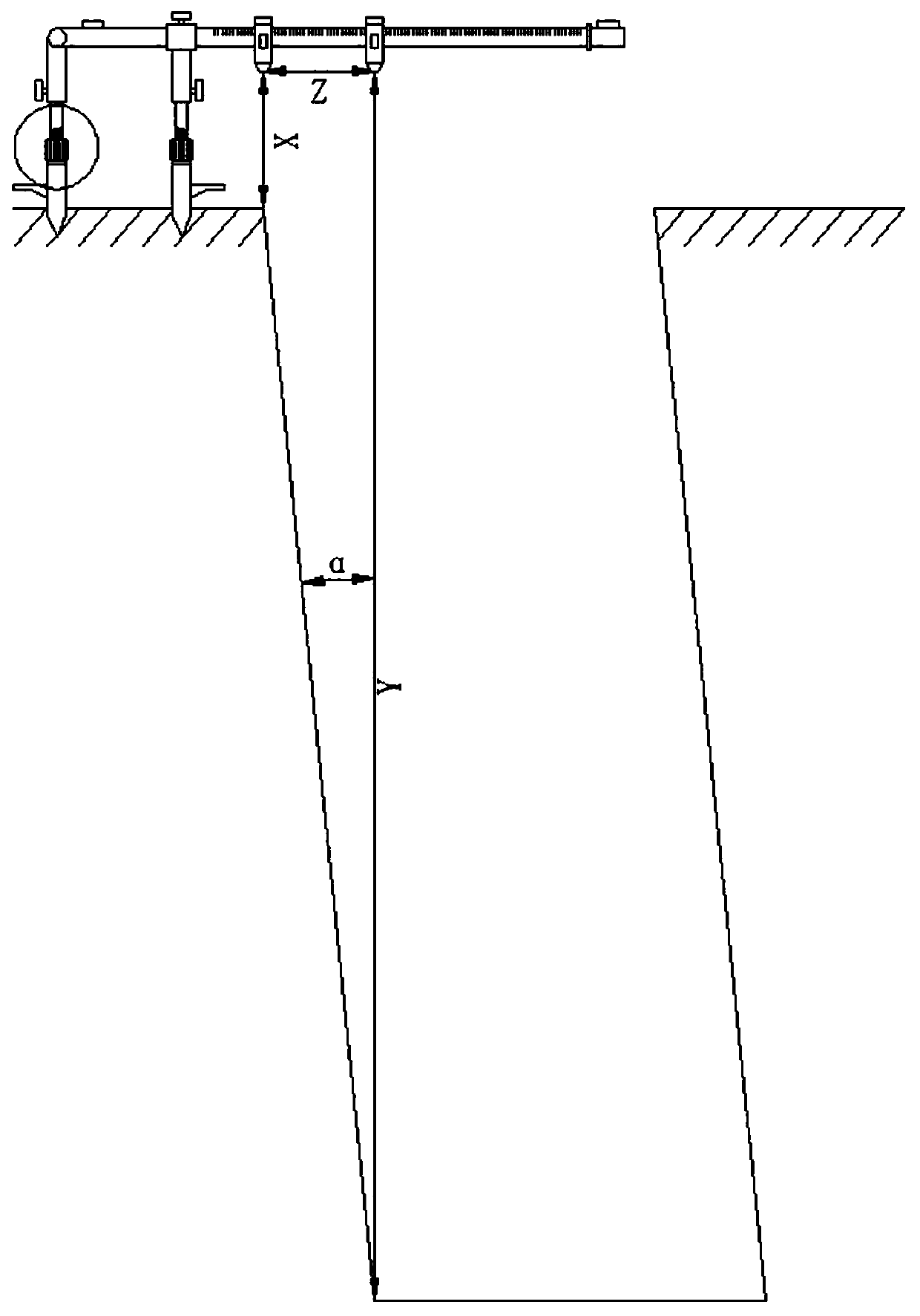

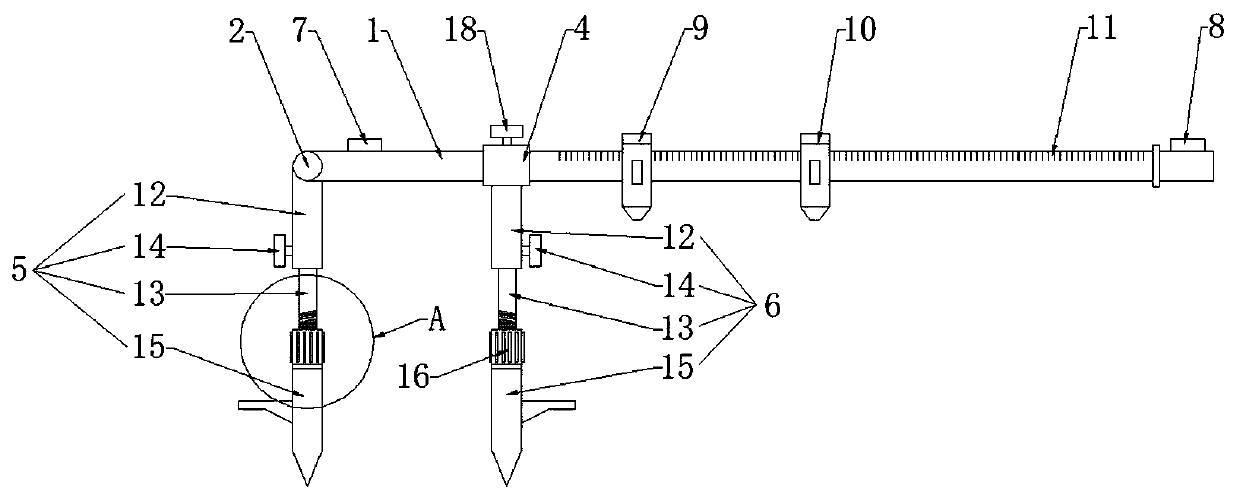

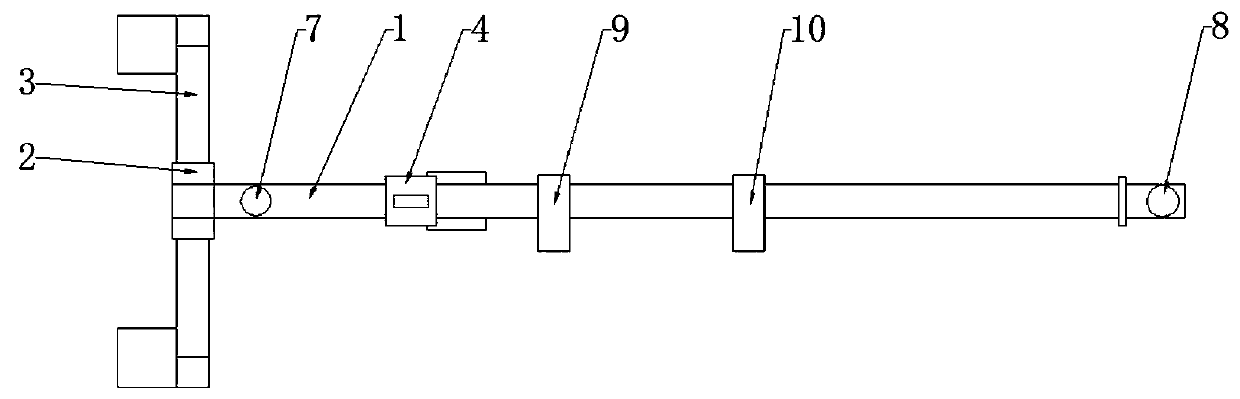

Measuring instrument and measuring method for verticality and azimuth of pile hole

InactiveCN109556583AQuick erectionQuick levelingAngle measurementSurveying with inclination sensorLaser rangingMeasuring instrument

The invention discloses a measuring instrument and a measuring method for the verticality and the azimuth of a pile hole. The measuring instrument comprises a measuring rod, a hinge, a support rod, asliding base, two first support parts, a second support part, a water level gauge, a compass, a first laser range finder, a second range finder, and a scale. Each support part comprises a support cylinder, a support telescopic rod, a first fixing knob, and a fixing rod. The middle part of the support rod is connected to the measuring rod through the hinge. The sliding base is slidably connected tothe second measuring rod. Two first support parts are arranged at the two ends of the support rod. The second support part is arranged at the bottom of the sliding base. And the water level gauge andthe compass are arranged at the measuring rod. According to the measuring instrument and the measuring method for the verticality and the azimuth of the pile hole, the measuring instrument realizes the fast and accurate measurement of the verticality and the azimuth of the pile hole, by arranging the measuring rod, the hinge, the support rod, the sliding base, the two first support parts, the second support part, the water level gauge, the compass, the first laser range finder, the second laser range finder, and the scale.

Owner:重庆南江建设工程有限公司

Line block

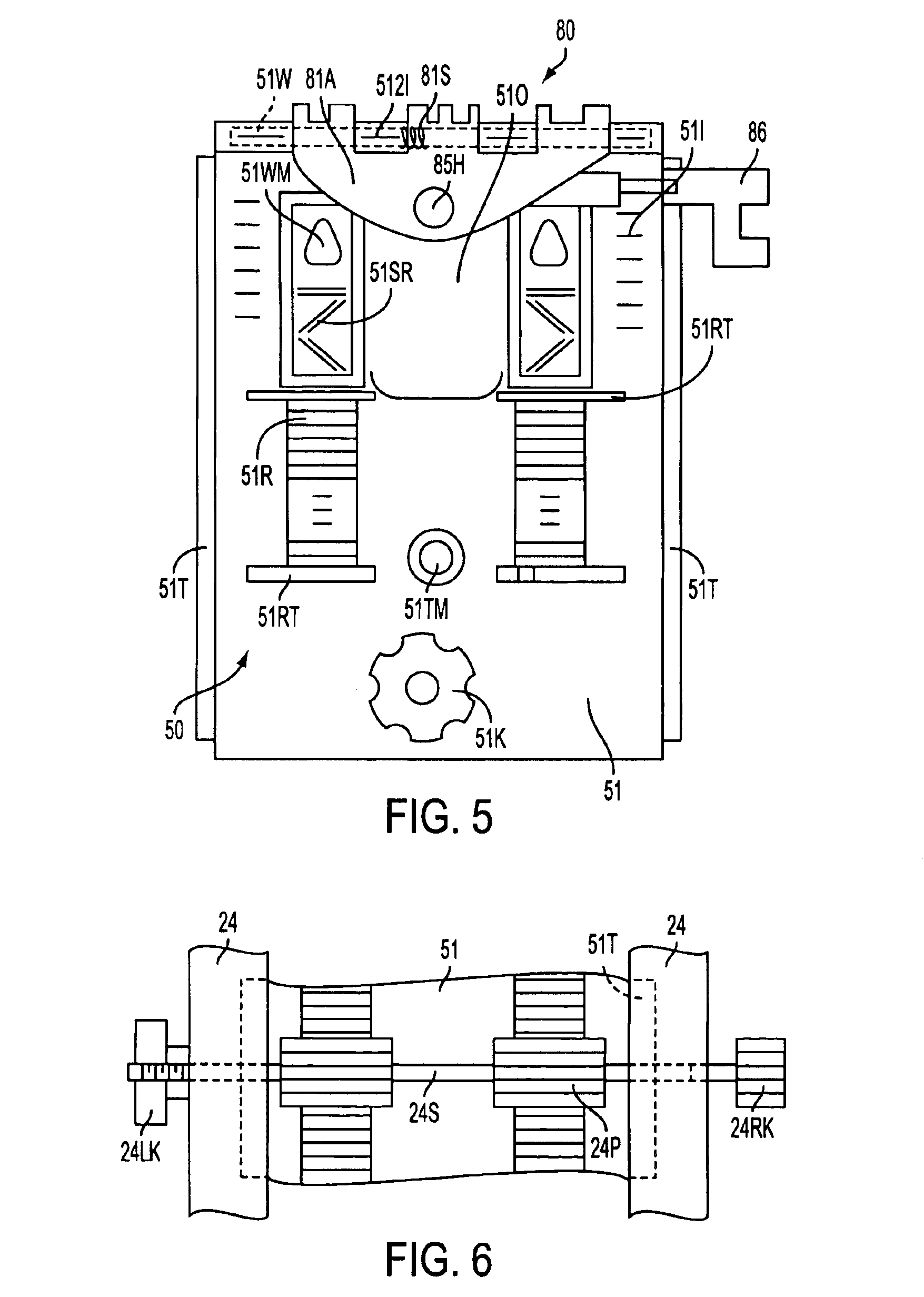

InactiveUS7673393B1Easy to moveEasy to operateWriting aidsBuilding material handlingMechanical engineeringQuoin

A line block having a body; a first leg extending substantially perpendicular to a longitudinal axis of the body; a first leg quoin line groove extending from a front surface of the first leg; a first leg wall line groove extending from a bottom surface of the first leg; a second leg spaced apart from the first leg, wherein the second leg extends substantially perpendicular to a longitudinal axis of the body, wherein a corner pole receiving groove is defined between at least a portion of the body, the first leg, and the second leg; a second leg quoin line groove extending from a front surface of the body and a front surface of the second leg, along a portion of an inner wall surface of the second leg; and a second leg wall line groove extending from a right side surface of the second leg.

Owner:HUDSON ROBERT E

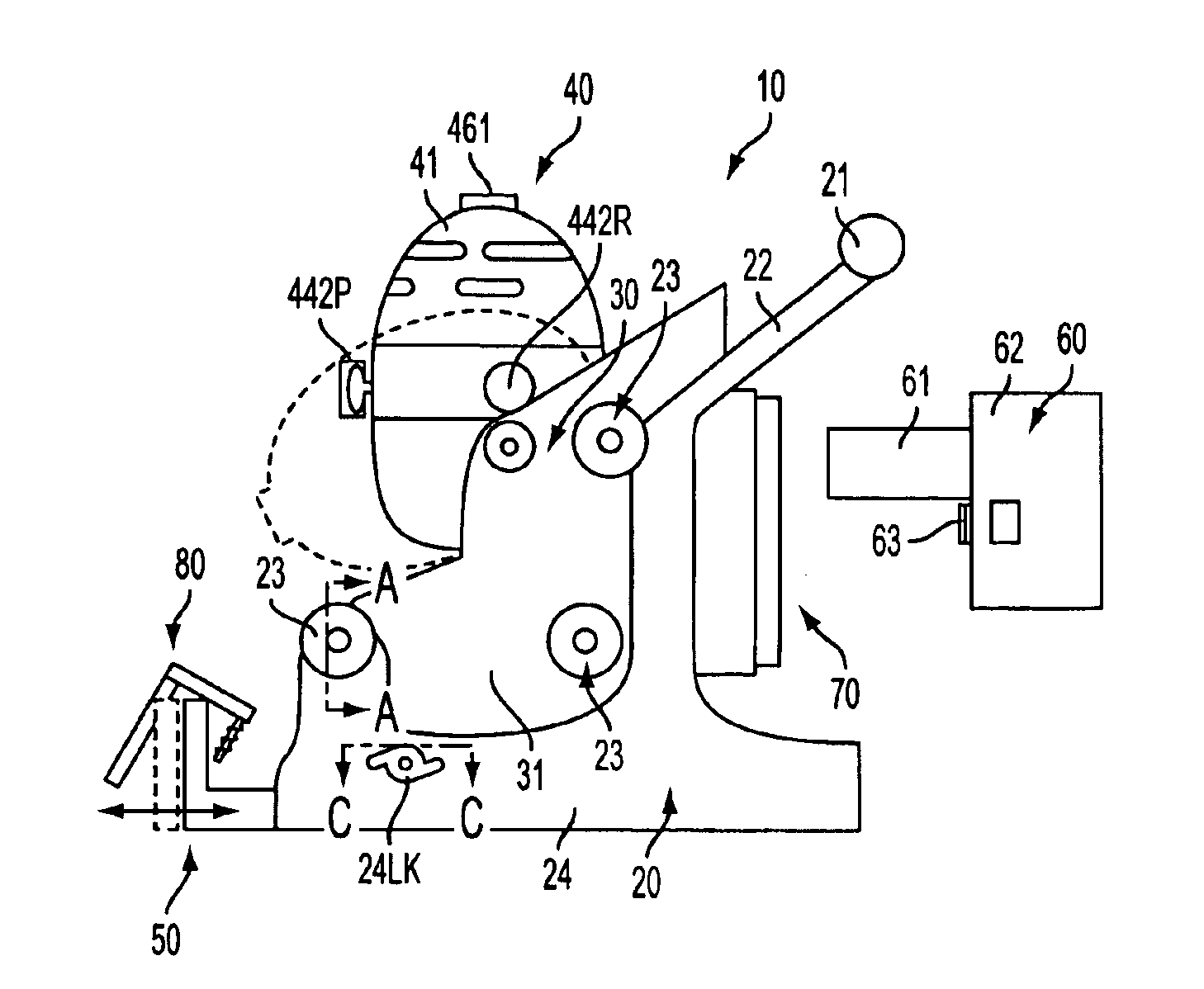

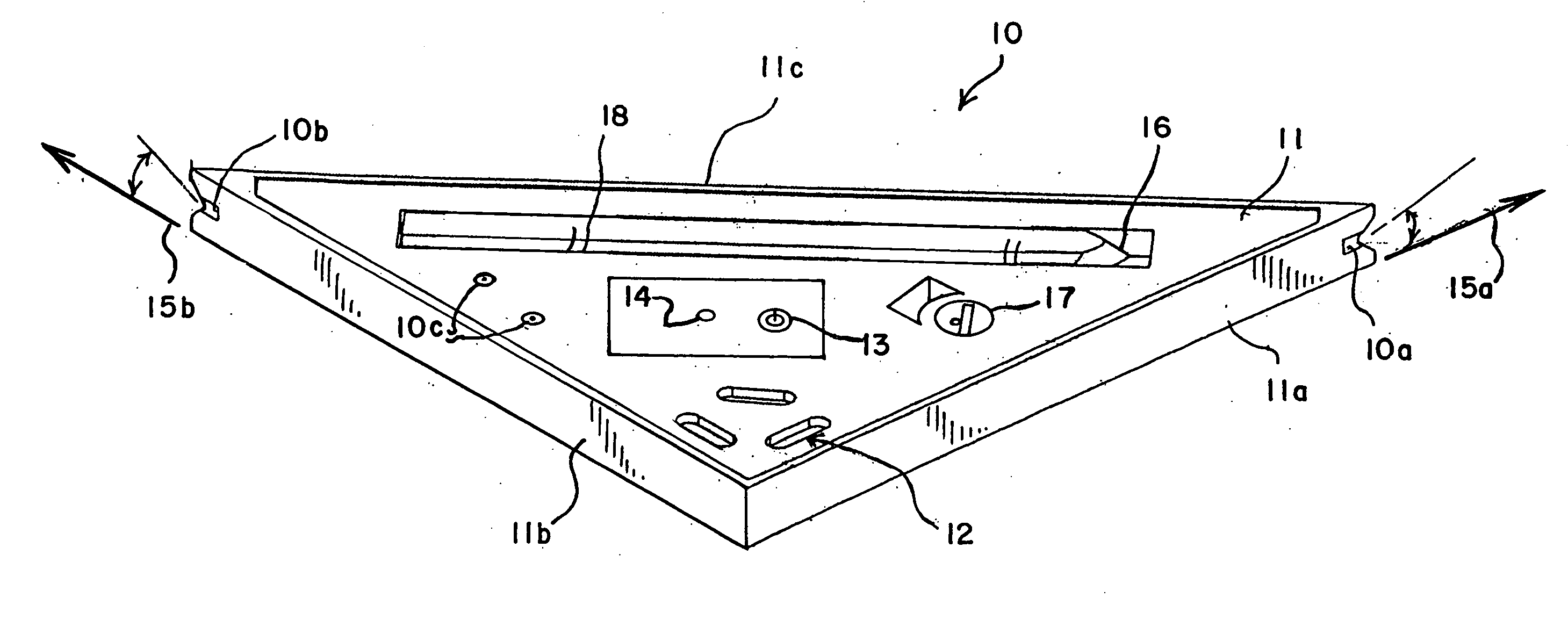

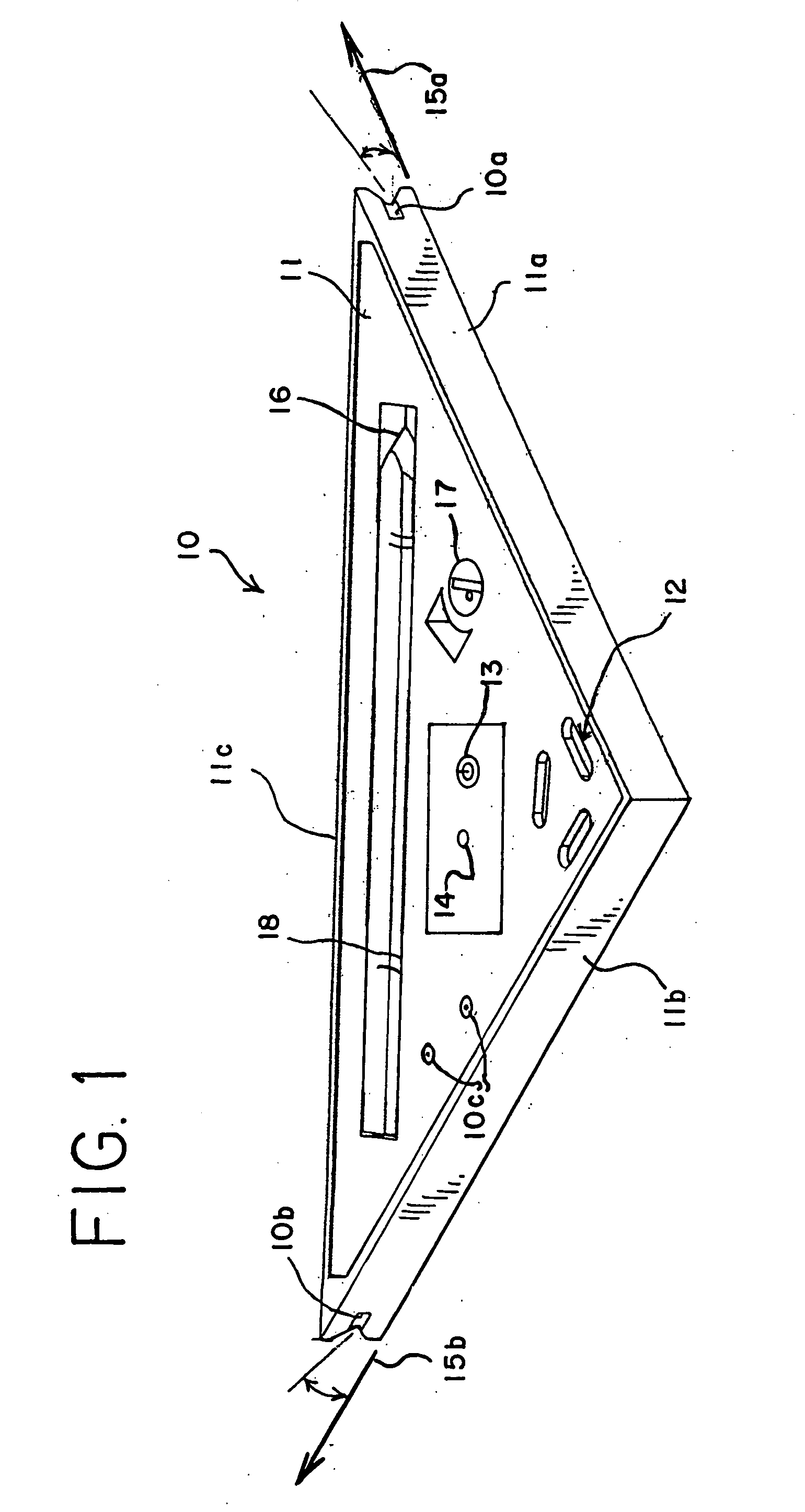

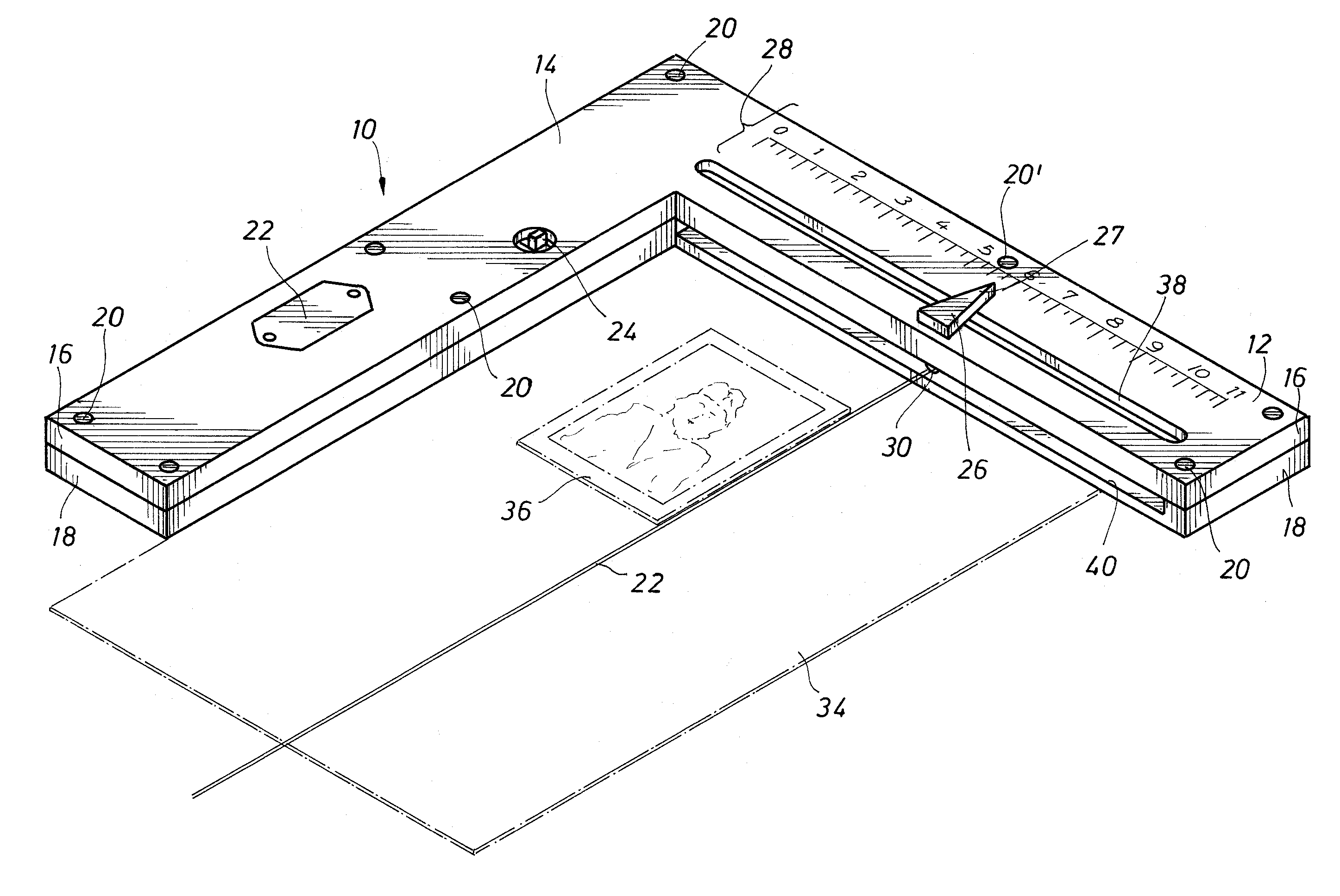

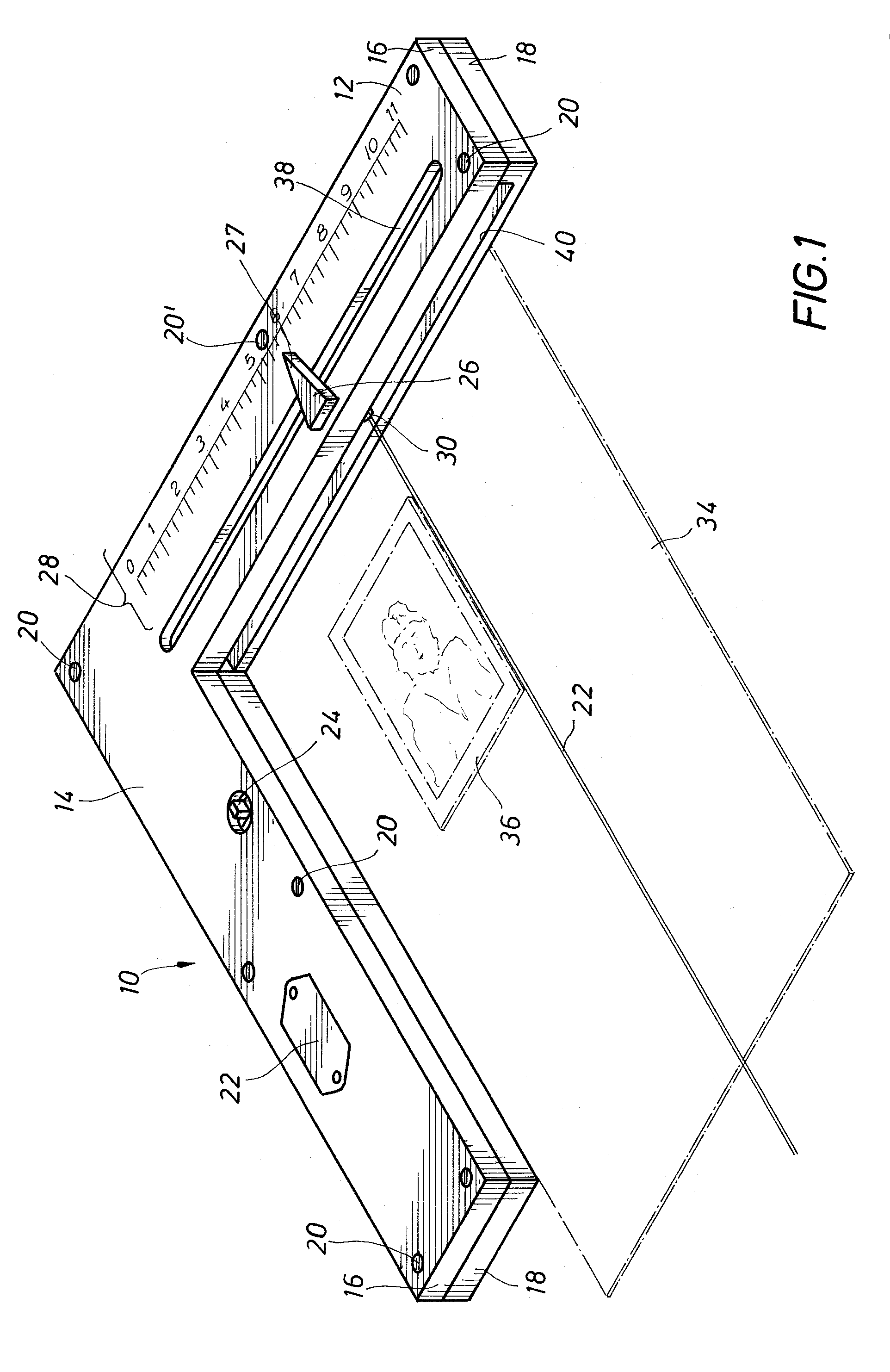

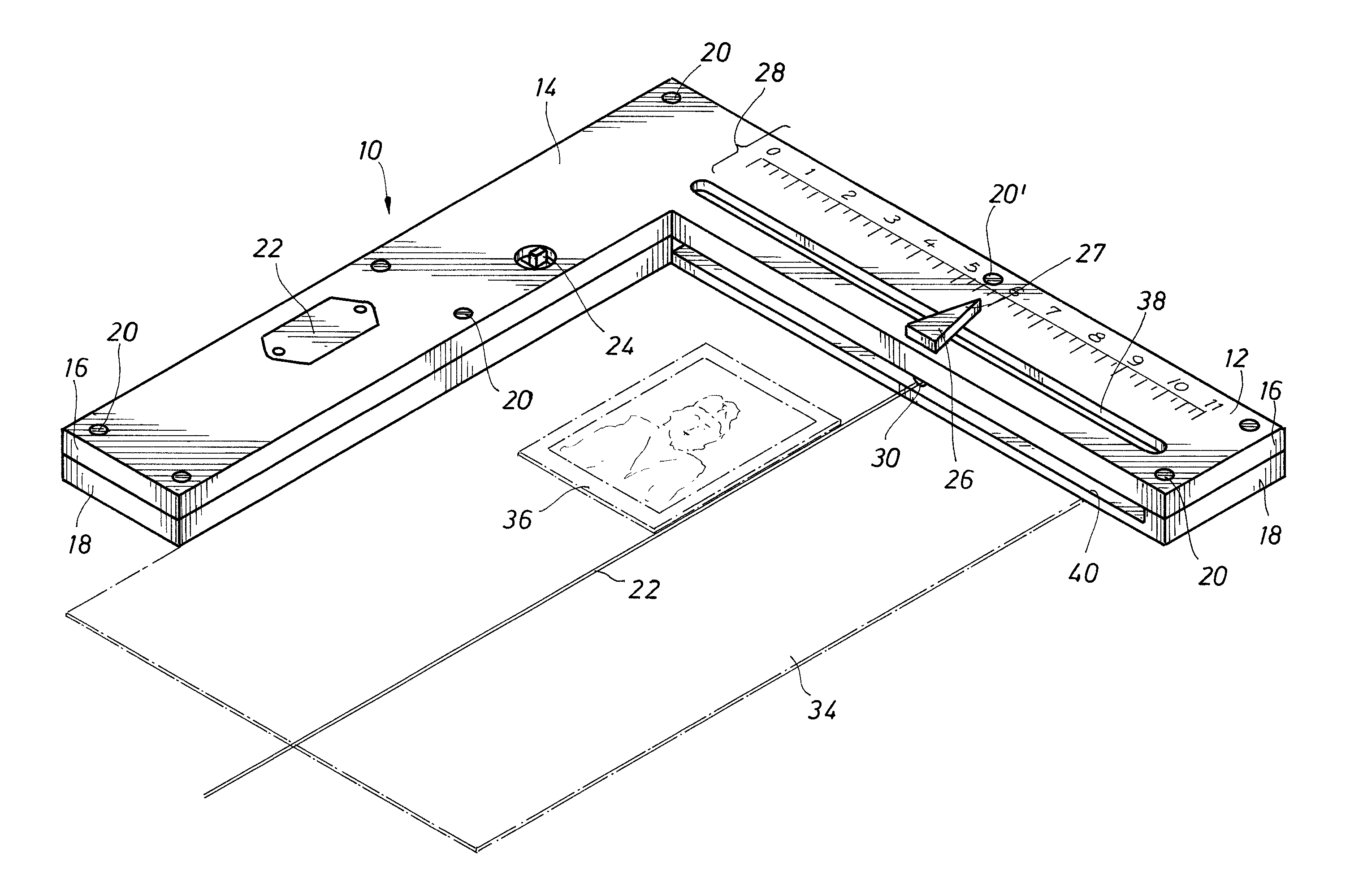

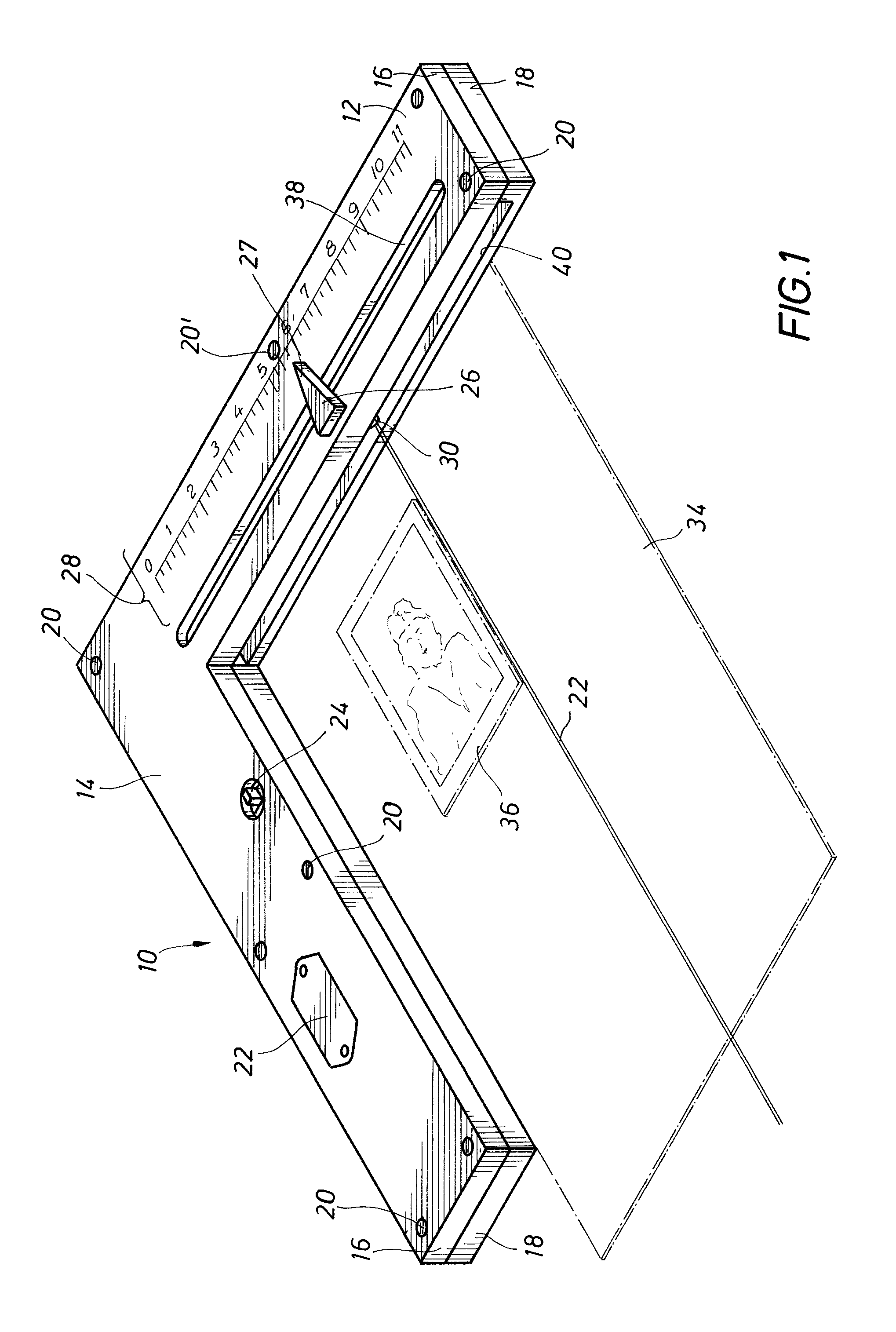

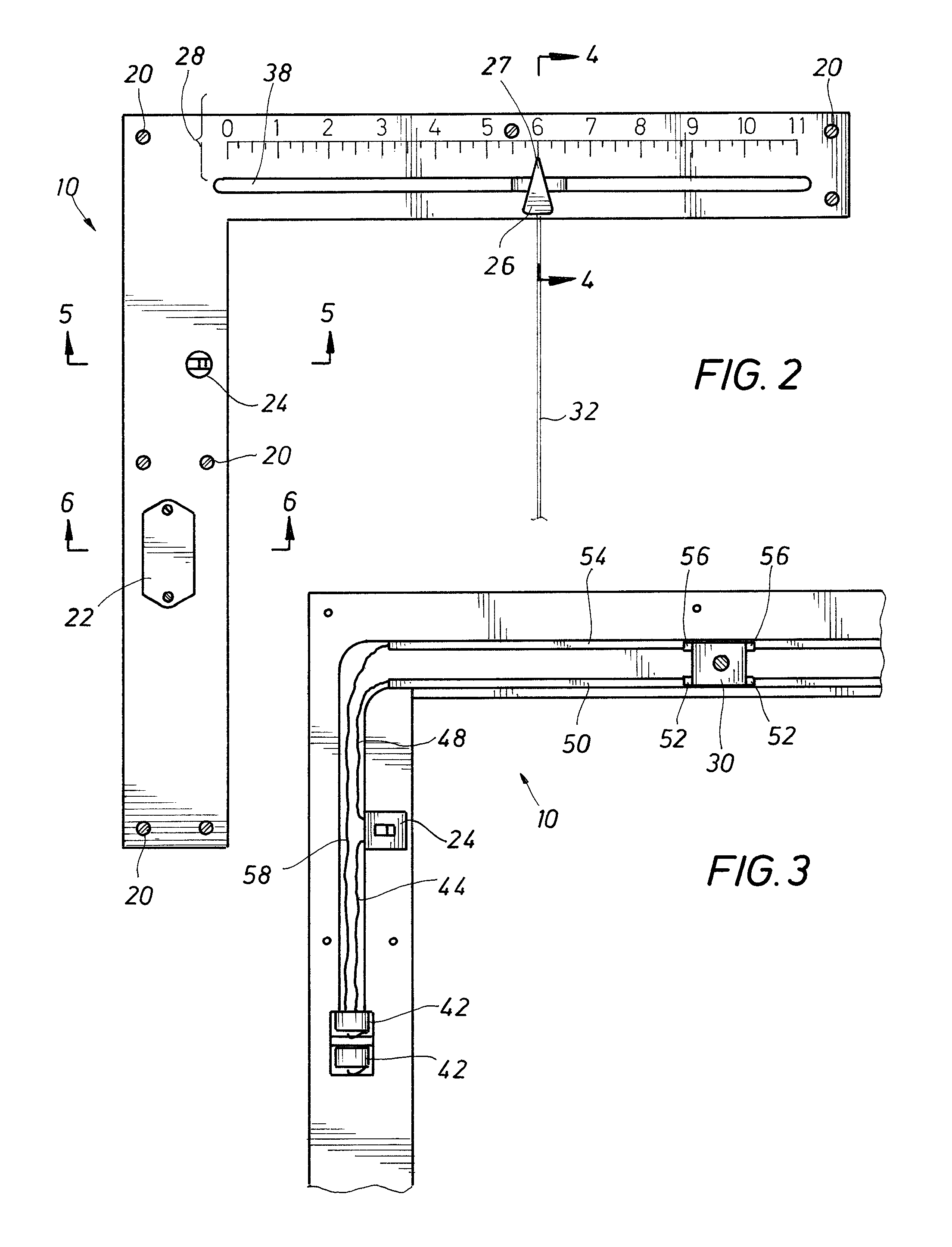

Laser Square

A square includes a laser indicator and comprises a two-part body with a channel running between them defining a pair of perpendicular arms. The channel holds a cavity for a battery or other portable power source as part of an electrical circuit. One or both arms may include a scale as well as an elongate opening on the top of the arm for a handle to move a laser / indicator back and forth along the opening. The arms preferably include a pair of bus bars to conduct electricity from the power source to the laser. The second arm may also include a laser light source that is capable of moving in a direction parallel to the arm, as well as rotating in place.

Owner:AMERICAN CRAFTS LC

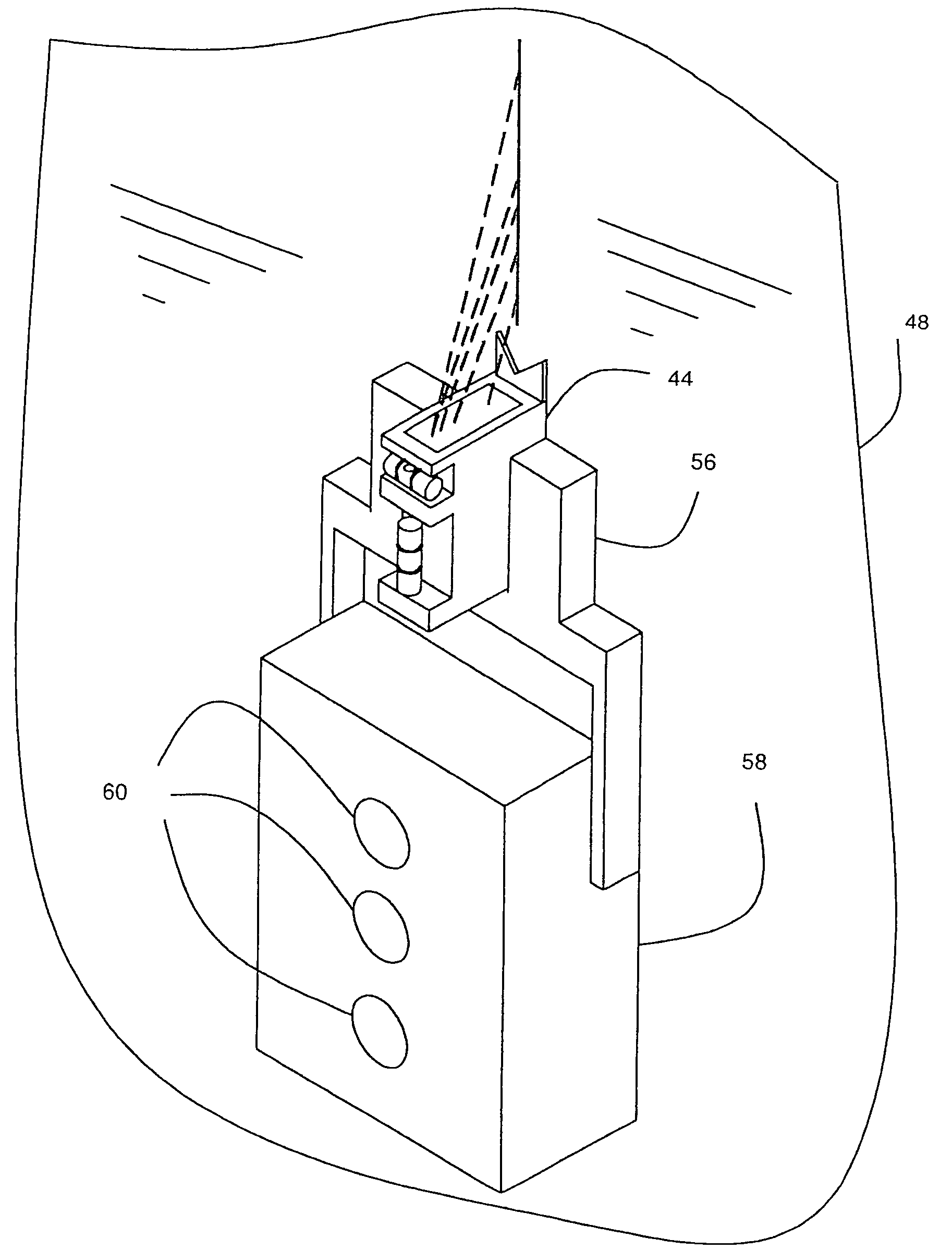

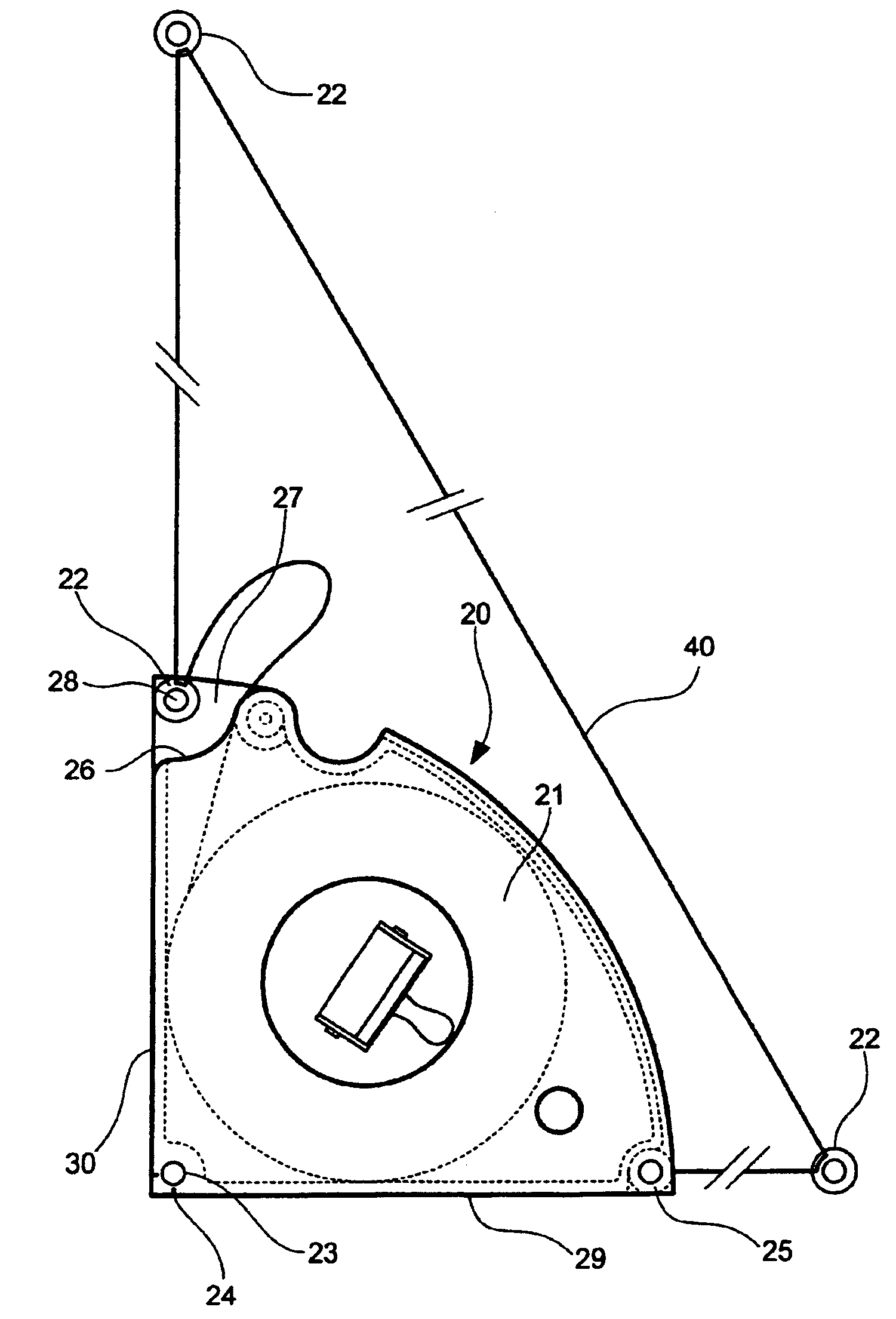

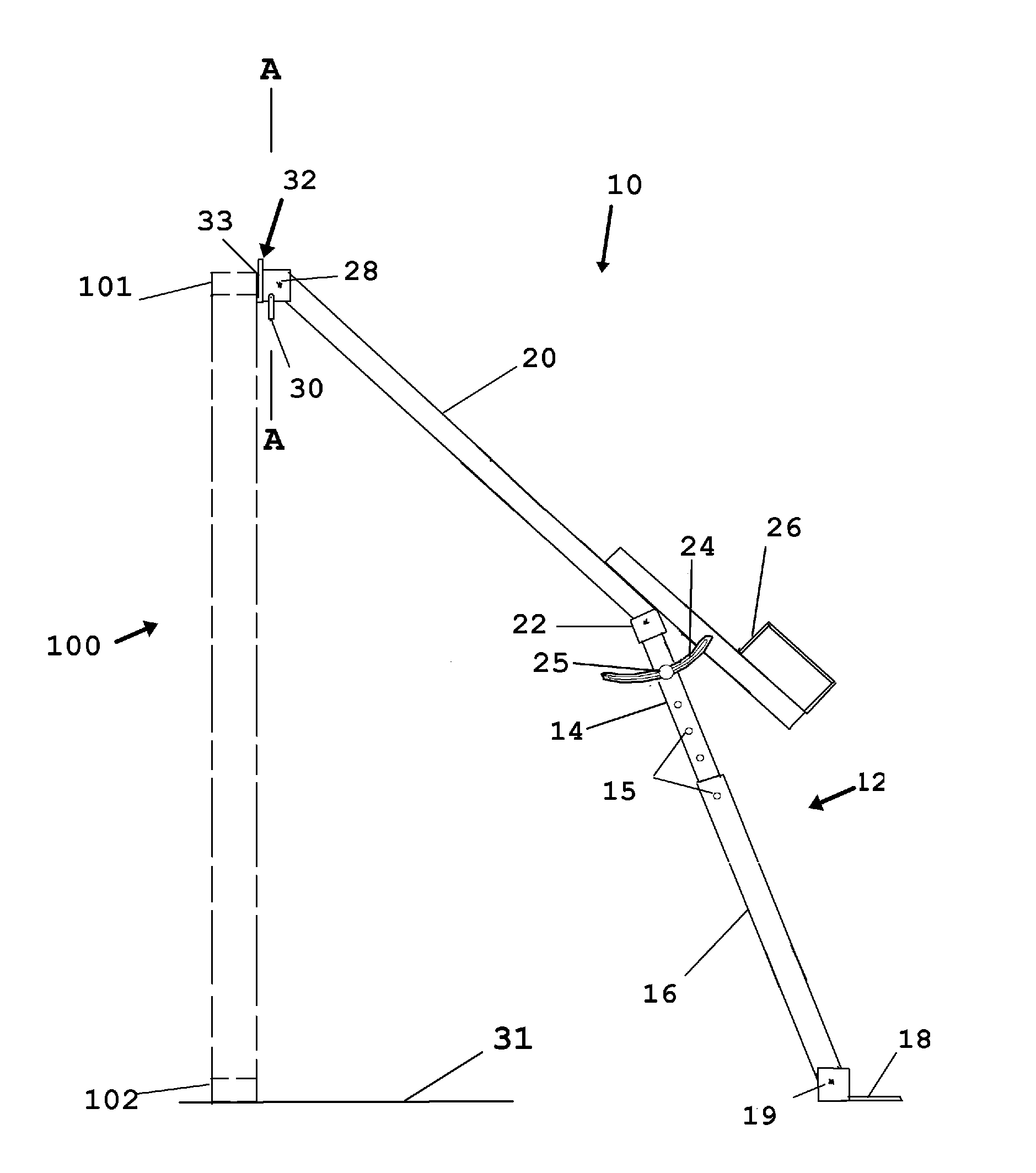

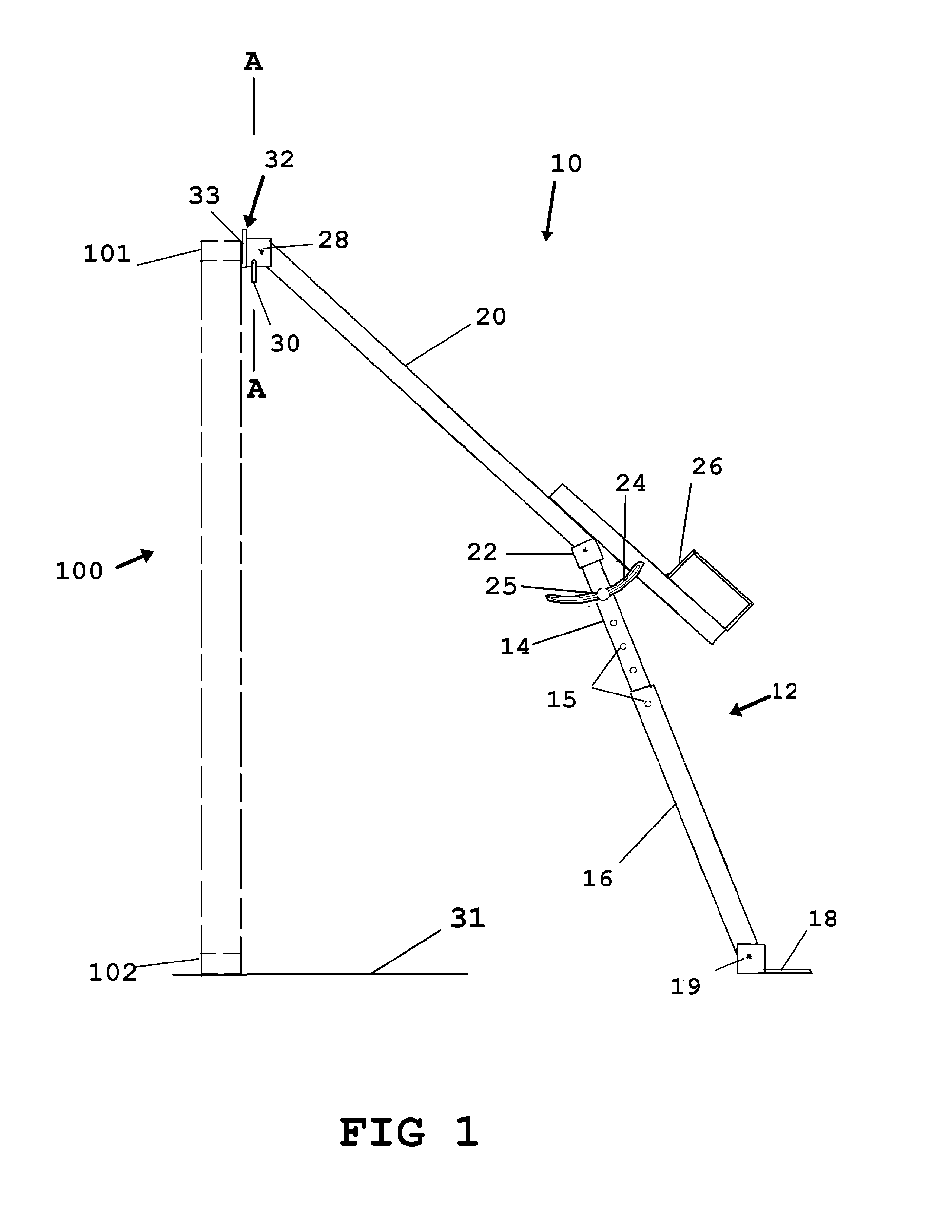

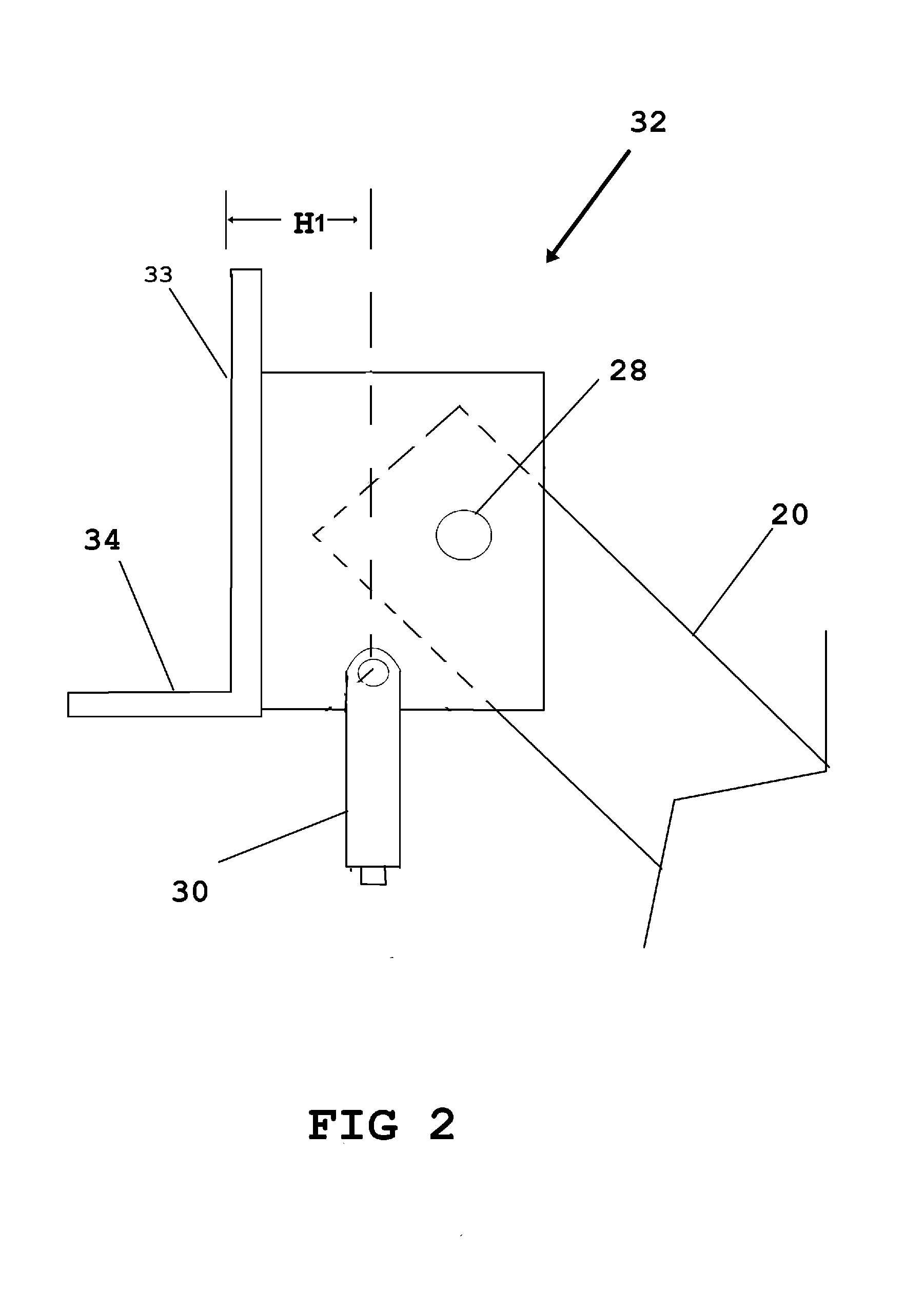

Light-Enabled Plumb Indicator and Wall Brace Device

InactiveUS20130340267A1Shorten the timeEasy to usePlumb lines for surveyingReference line/planes/sectorsLight beamEngineering

A device for positioning an object such as a framed wall plumb or perpendicular relative to a support surface therefor. The device features first and second elongated members which are rotationally engaged. With a first end of the second elongated member engaged to the vertically disposed object, and the distal end of the first elongated member positioned upon the support surface, a tilting of the wall is accomplished by pressure applied to a handle portion of the second elongated member. The tilting causes movement of a projected light beam from a position at the first end of the second elongated member. Continued tilting allows a user to align an illumination point of the light beam, with a mark on the support surface, and ascertain the object is plumb relative to the support surface.

Owner:CARBAJAL EDUARDO

Verticality detection device for constructional engineering

InactiveCN111536943AEasy to operateEasy to movePlumb lines for surveyingIncline measurementDrive wheelClassical mechanics

The invention discloses a verticality detection device for constructional engineering. The device comprises a base, moving wheels and a protection box; moving wheels are installed at the four cornersof the lower end of the base; a protection box is arranged at the upper end of the base; a plurality of heat dissipation holes are formed in one side of the protection box; push rods are arranged at the ends, close to the protection box, of the base; a storage battery is arranged on the left side in the protection box; a driving device is arranged on the right side in the protection box; an adjusting movable rod slides along an insertion hole, and the limiting plate is attached to the wall surface; a movable rod and a cross rod are fixed by a fixed bolt; a driving motor is started to drive a driving wheel to rotate; a belt wheel is used for driving a driven wheel to rotate, and a winding roller rotates; at the moment, the vertical line extends; a metal wire cone moves downwards under the action of gravity; the limiting sleeve limits the vertical line to reduce shaking of the vertical line; the vertical line can be kept in a vertical state quickly, and the detection efficiency is improved.

Owner:潍坊市兴源防水材料股份有限公司

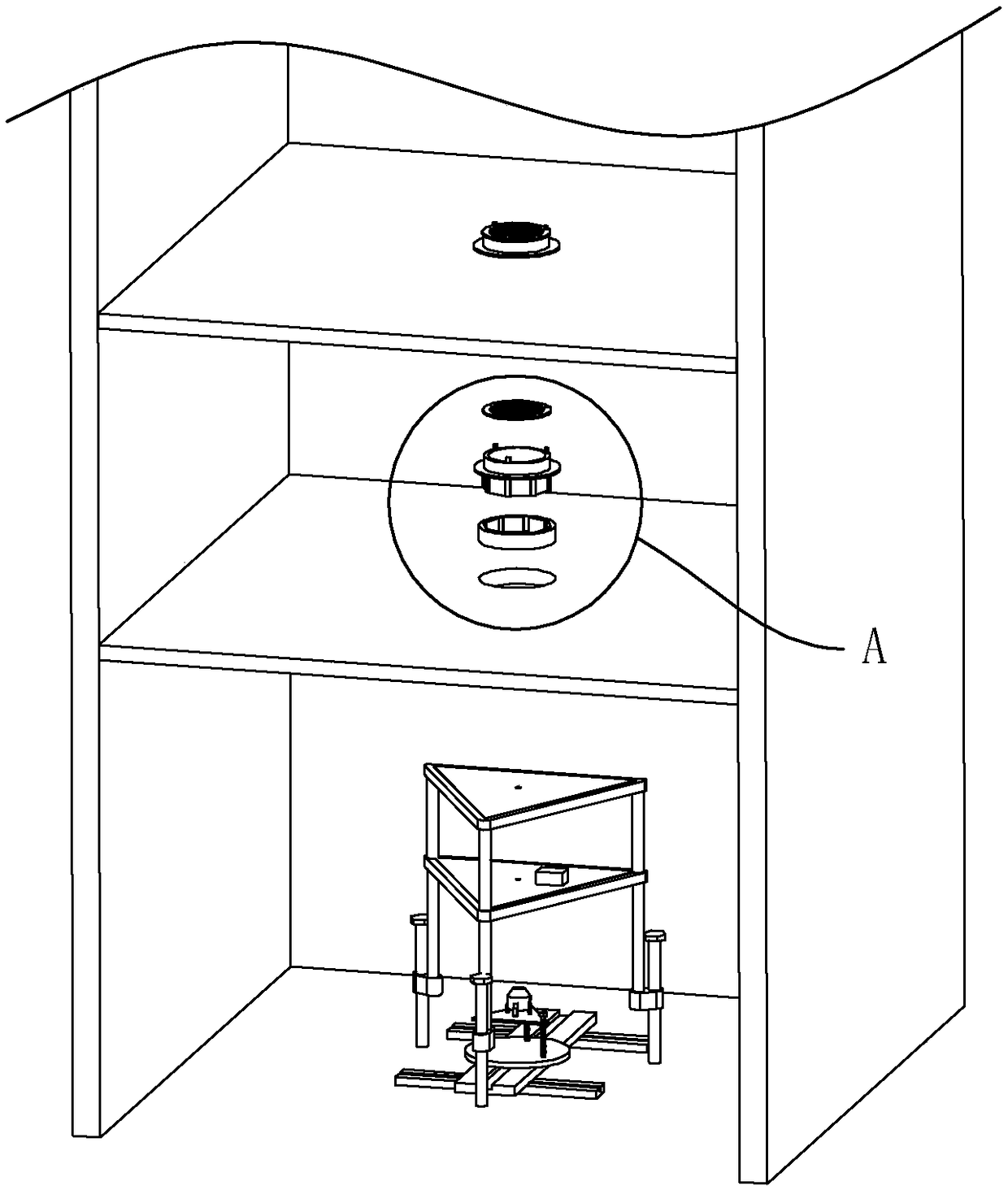

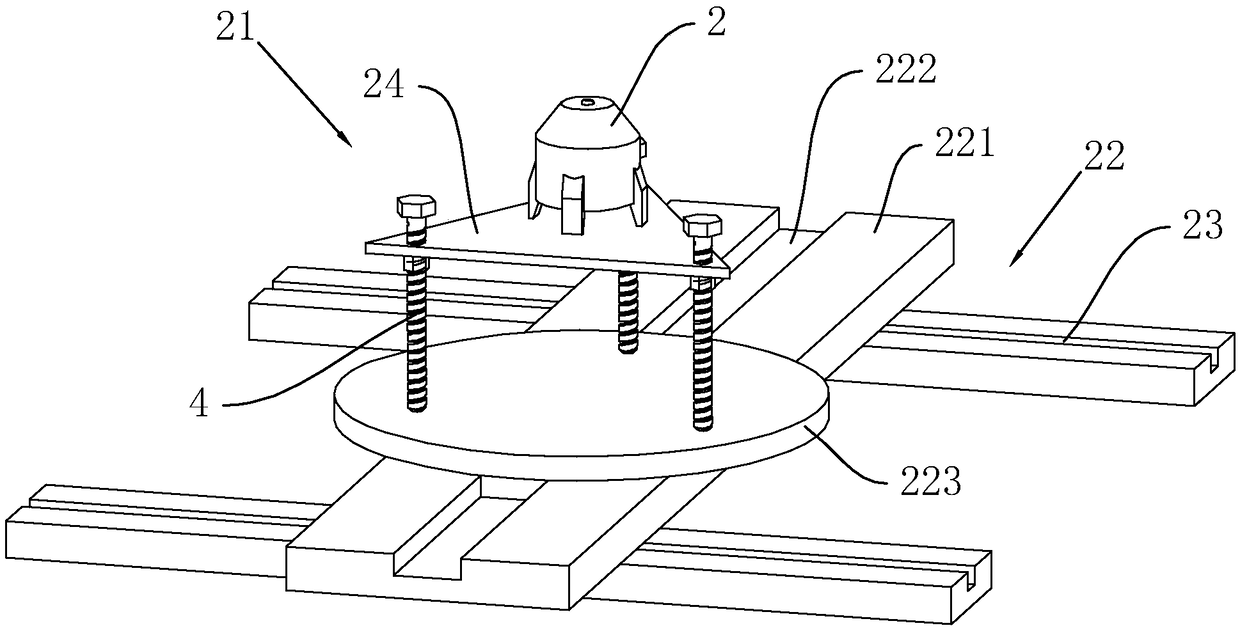

Supervision control method of super high-rise building project measuring

InactiveCN108253950AReal-time monitoring of weather conditionsEasy to measureSatellite radio beaconingPlumb lines for surveyingTotal stationEngineering

The invention relates to the technique of building measuring, in particular to a supervision control method of super high-rise building project measuring. The problem that a laser plummet apparatus ishard to maintain to be vertical with a floor, meanwhile, a receiving target is hard to maintain to be perpendicular to the corresponding floor, and accordingly the error of practical measuring is large is solved. The supervision control method is characterized in that division of measuring units are conducted, the error of the laser plummet apparatus is reduced by utilizing a standard support, avertical adjusting mechanism and a horizontal adjusting mechanism, the laser plummet apparatus is used for measuring, a total station apparatus is used for conducting recheck, then the RTK (real timekinematic) technique is utilized to recheck again, and the obtained measuring result is small in error and high in accuracy through comparative analysis of data.

Owner:YUEQING CONSTR SUPERVISION CO LTD

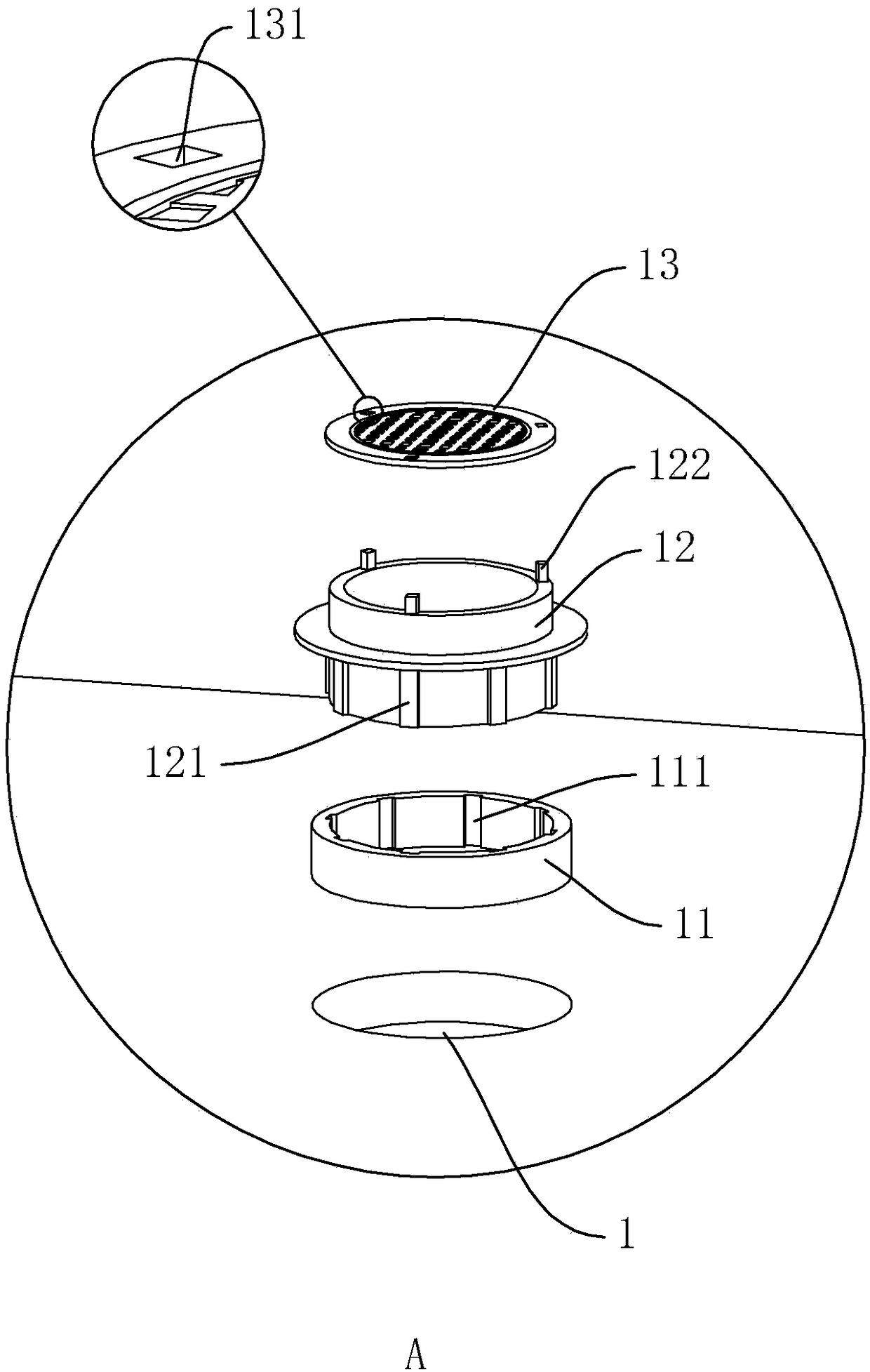

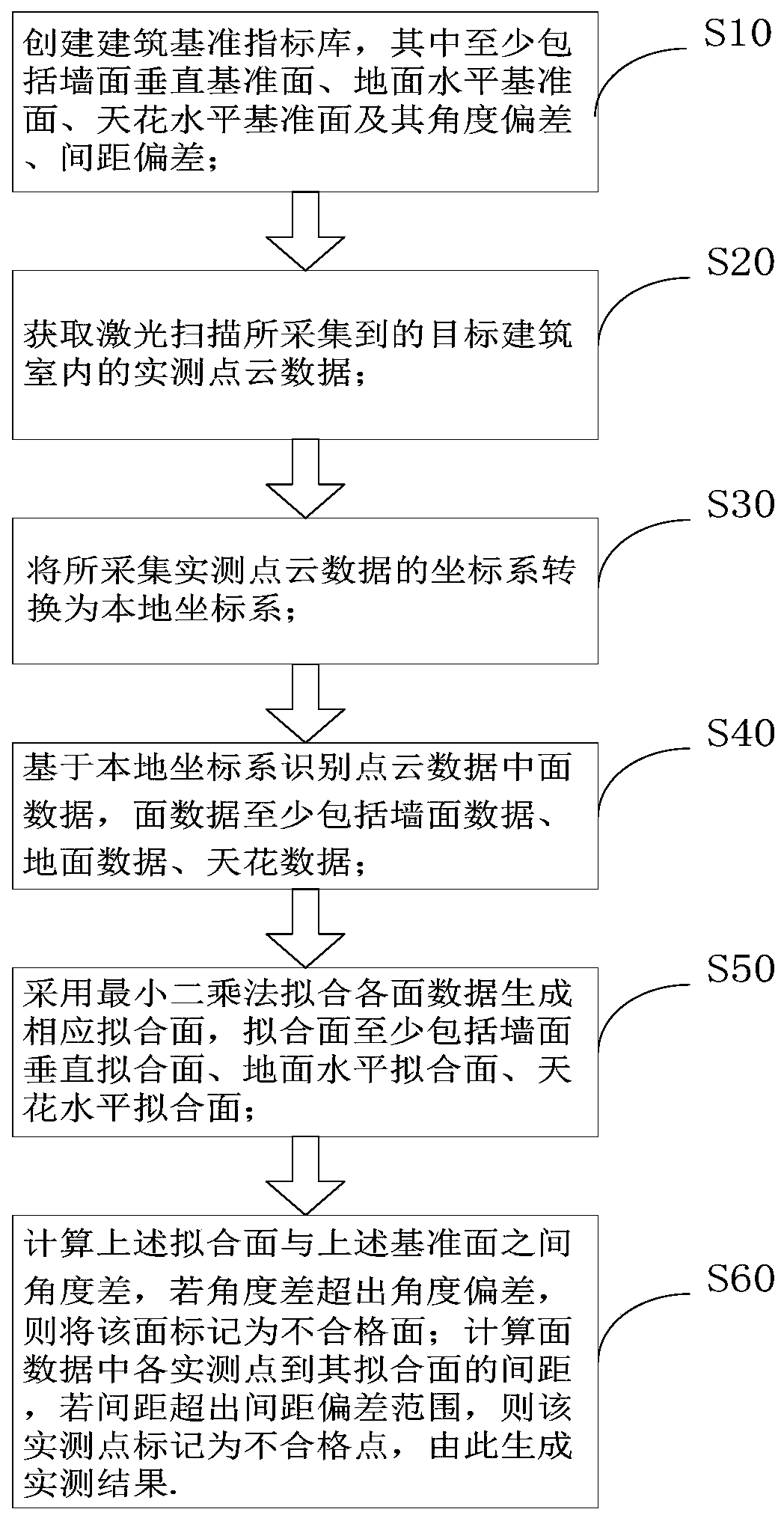

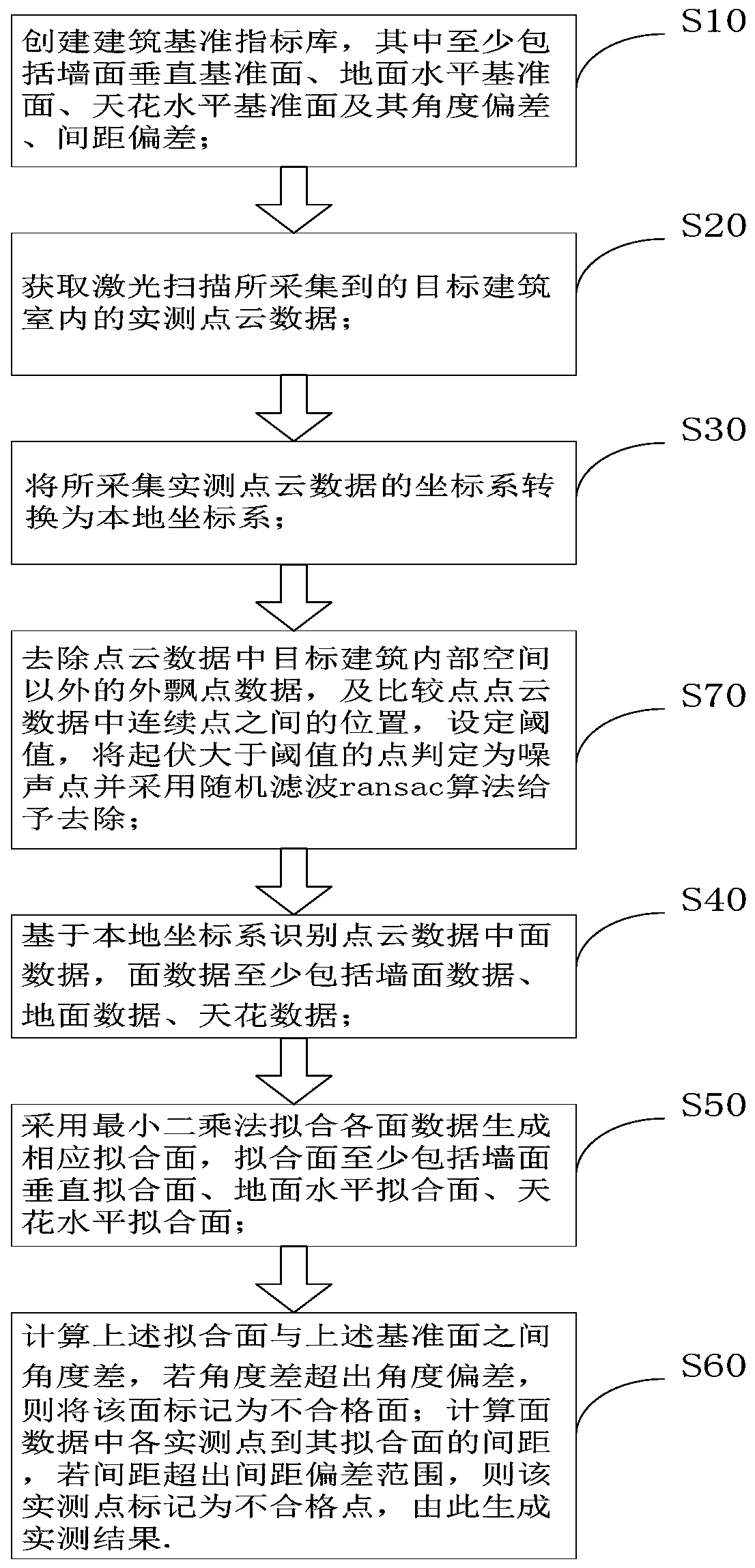

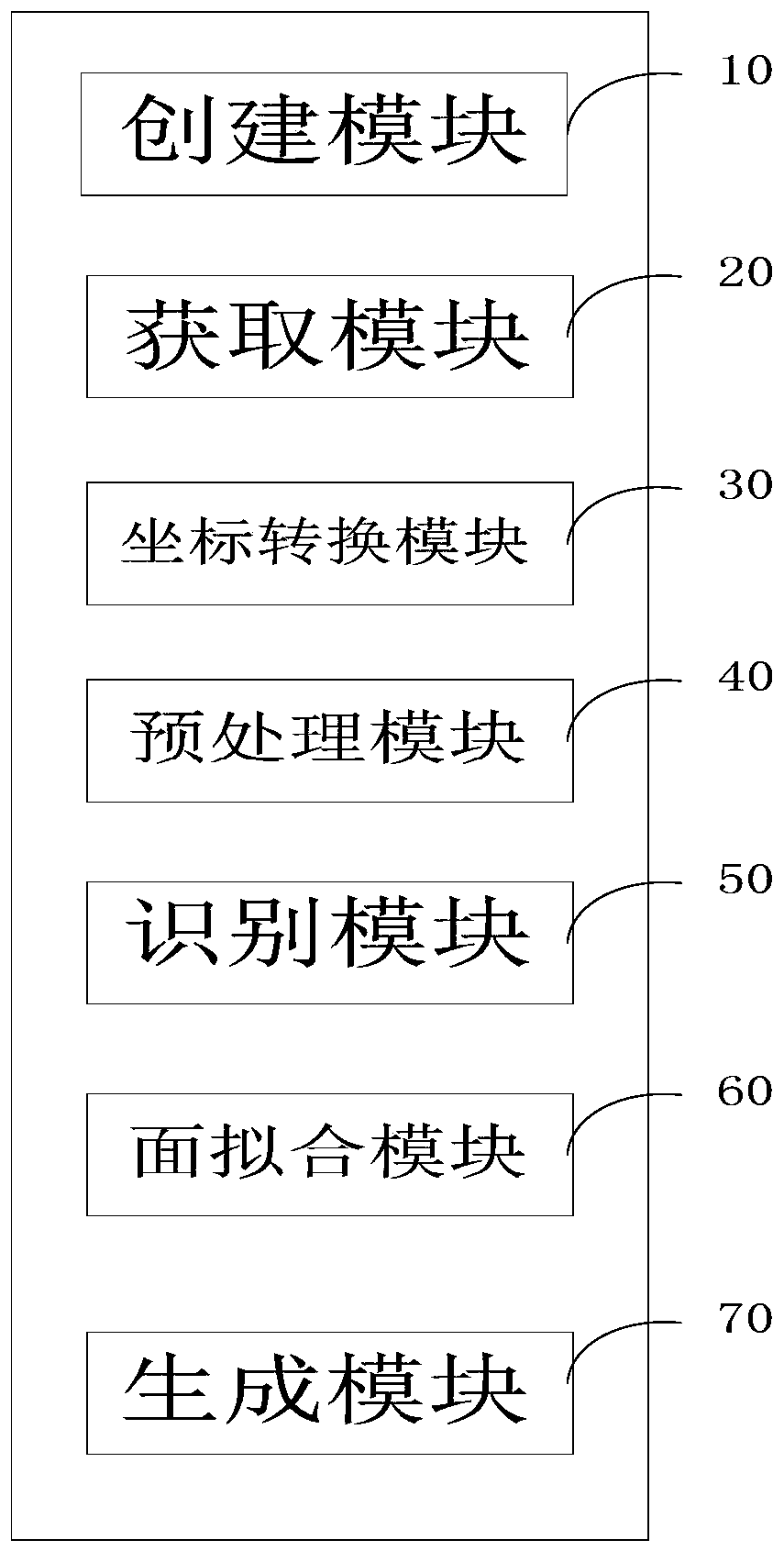

Building detection method and device based on point cloud data analysis

ActiveCN111197979AGuaranteed accuracyImprove quality levelAngle measurementData processing applicationsPoint cloudLaser scanning

The invention discloses a building detection method and device based on point cloud data analysis, and the device is used for achieving the method, and the method comprises the steps: building a building reference index library which at least comprises a wall surface, a ground, a ceiling horizontal reference surface and the angular deviation and spacing deviation of the wall surface, the ground and the ceiling horizontal reference surface; acquiring indoor actual measurement point cloud data of the target building acquired by laser scanning; converting a coordinate system of the actual measurement point cloud data into a local coordinate system; identifying surface data in the point cloud data, wherein the surface data at least comprises wall surface data, ground data and ceiling data; fitting the data of each surface by adopting a least square method to generate a corresponding fitting surface; calculating the angle difference between the fitting surface and the reference surface, andif the angle difference exceeds the angle deviation, marking the surface as an unqualified surface; and calculating the distance between each actual measurement point in the surface data and the fitting surface of the actual measurement point, and if the distance exceeds the distance deviation range, marking the actual measurement point as an unqualified point, thereby generating an actual measurement result. The detection method does not need manual intervention, and is efficient, rapid and accurate in data.

Owner:广东领慧数字空间科技有限公司

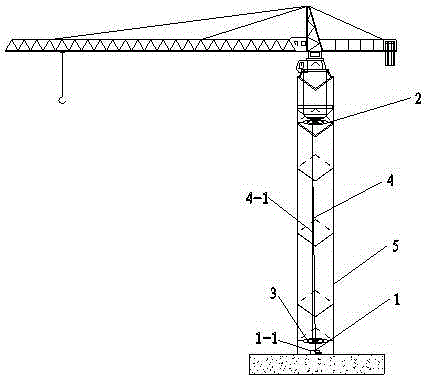

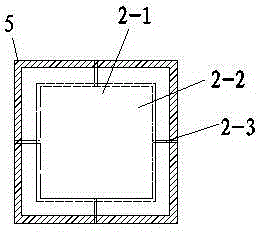

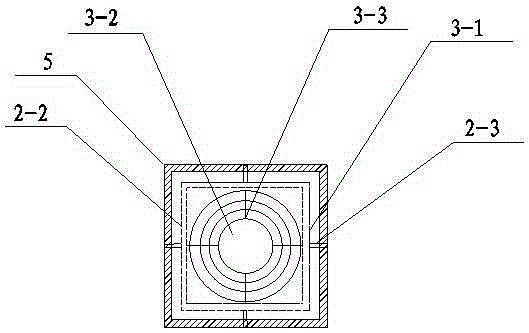

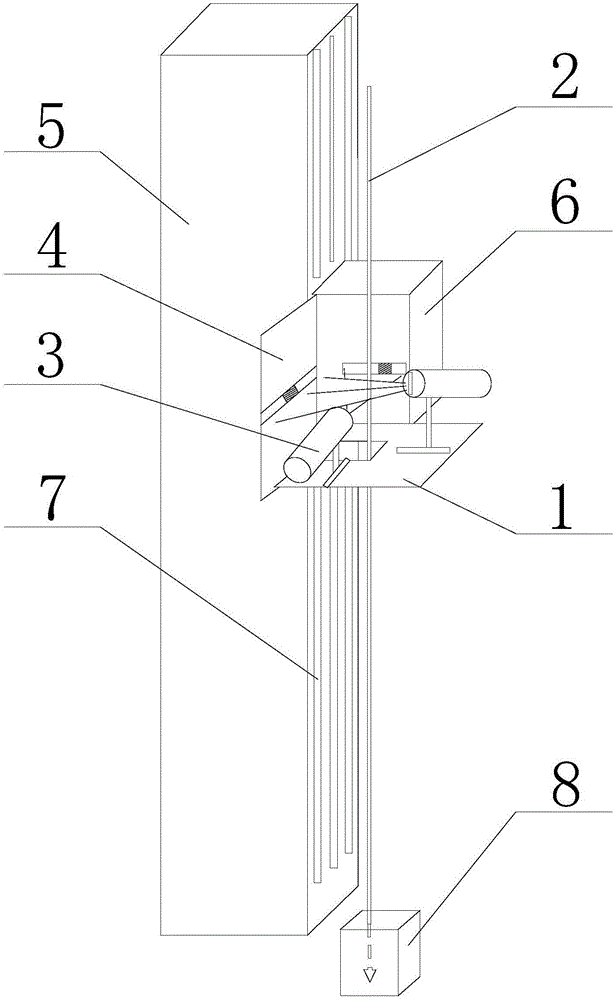

Device for calibrating perpendicularity and rectifying deviation of tower crane and construction method thereof

ActiveCN105174085AReasonable structureEasy to manufactureCranesFixed angles setting outLaser transmitterOptoelectronics

The invention discloses a device for calibrating perpendicularity and rectifying deviation of a tower crane and a construction method thereof. The device comprises a laser calibration device and a hydraulic deviation rectifying device, wherein the laser calibration device comprises a laser emitter, a laser reflector and a laser receiver; the laser emitter is mounted in a center hole in the upper surface of a base bracket; a power supply adapter is mounted in the base bracket; the laser reflector comprises a reflection lens, a lens framework and a framework transverse frame. The device has the advantages that the device is high in practicability and is safe and reliable, the problem of deviation of a standard section of the tower crane is solved by a deviation rectifier, the problem of calibration of the perpendicularity of the tower crane is solved by the laser calibrator, the working efficiency is improved, and the potential safety hazard is eliminated.

Owner:CHINA MCC17 GRP

Laser square

A square includes a laser indicator and comprises a two-part body with a channel running between them defining a pair of perpendicular arms. The channel holds a cavity for a battery or other portable power source as part of an electrical circuit. One or both arms may include a scale as well as an elongate opening on the top of the arm for a handle to move a laser / indicator back and forth along the opening. The arms preferably include a pair of bus bars to conduct electricity from the power source to the laser. The second arm may also include a laser light source that is capable of moving in a direction parallel to the arm, as well as rotating in place.

Owner:AMERICAN CRAFTS LC

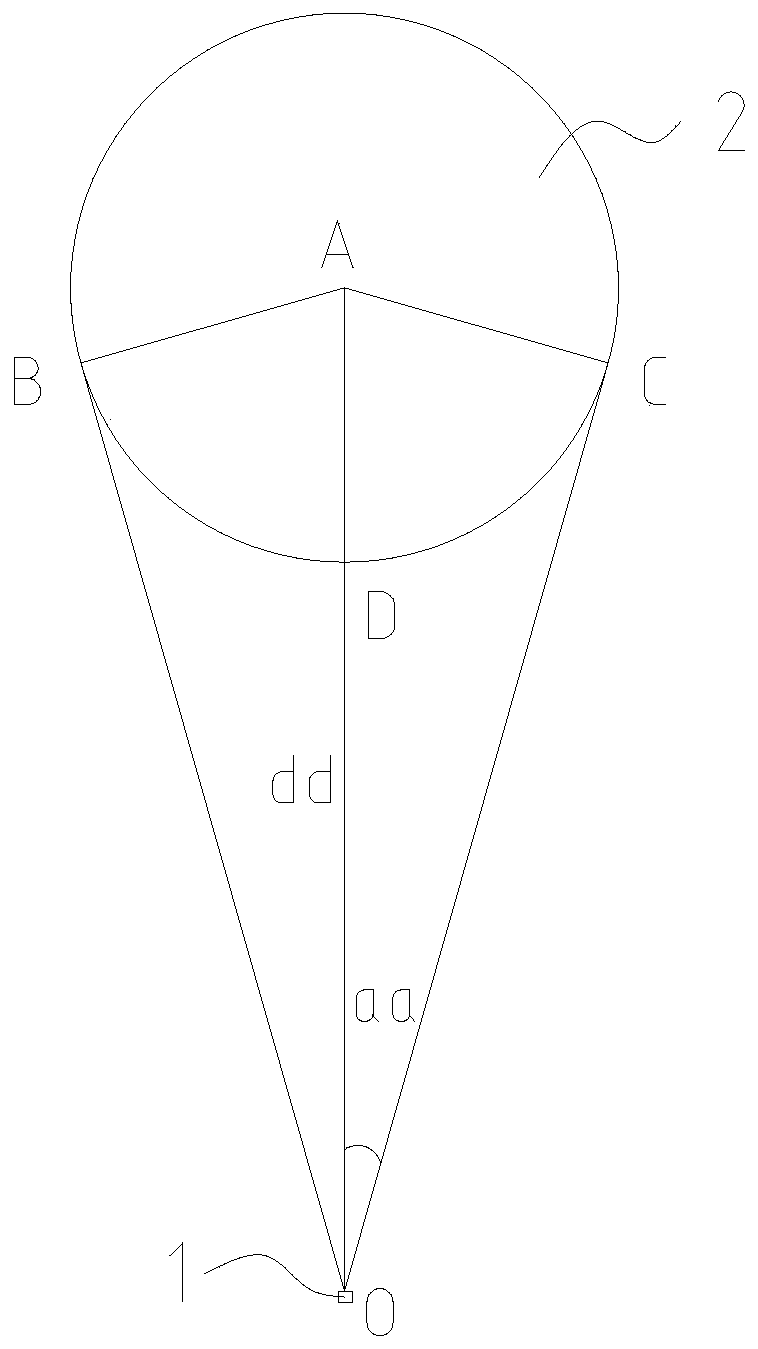

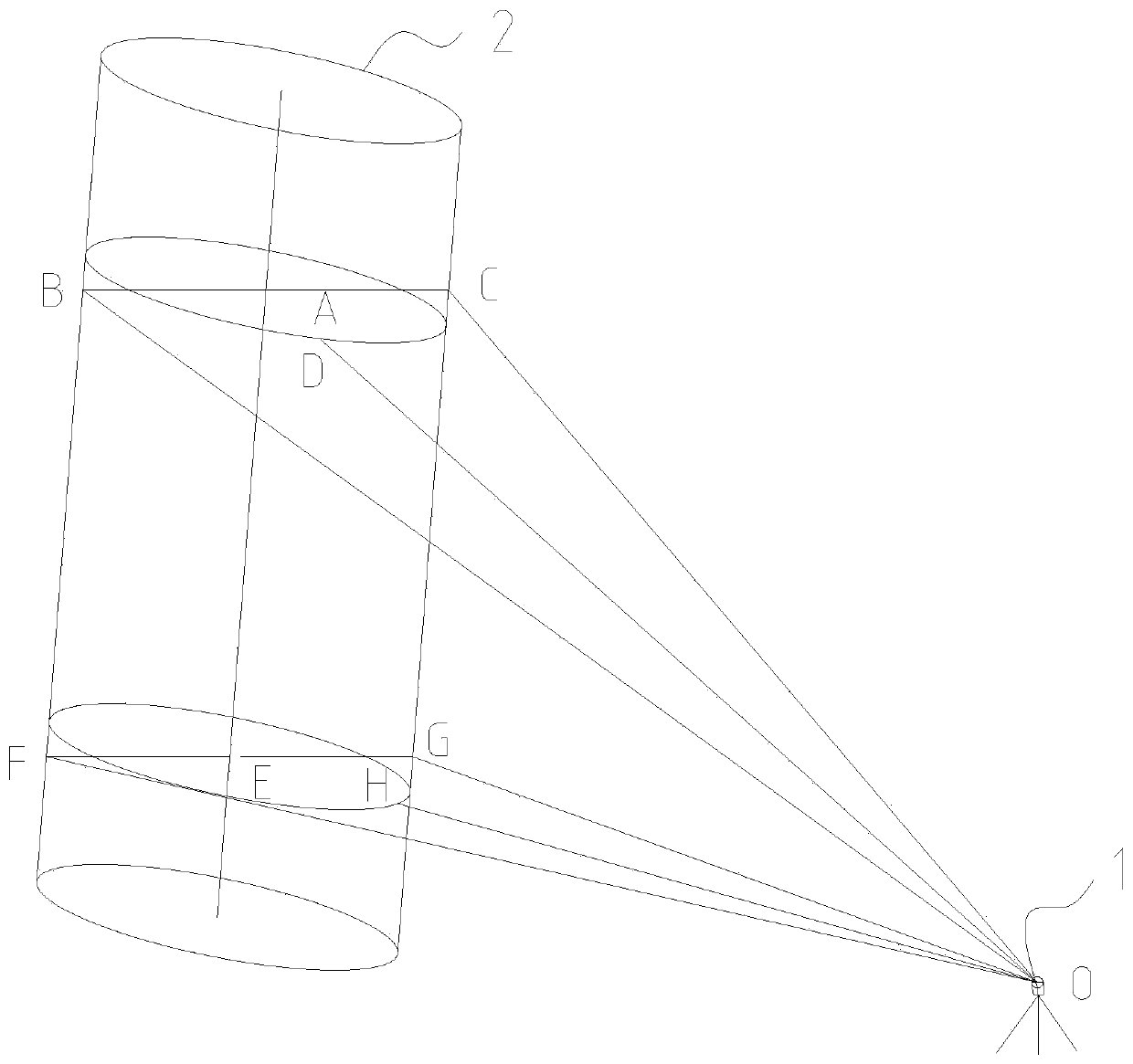

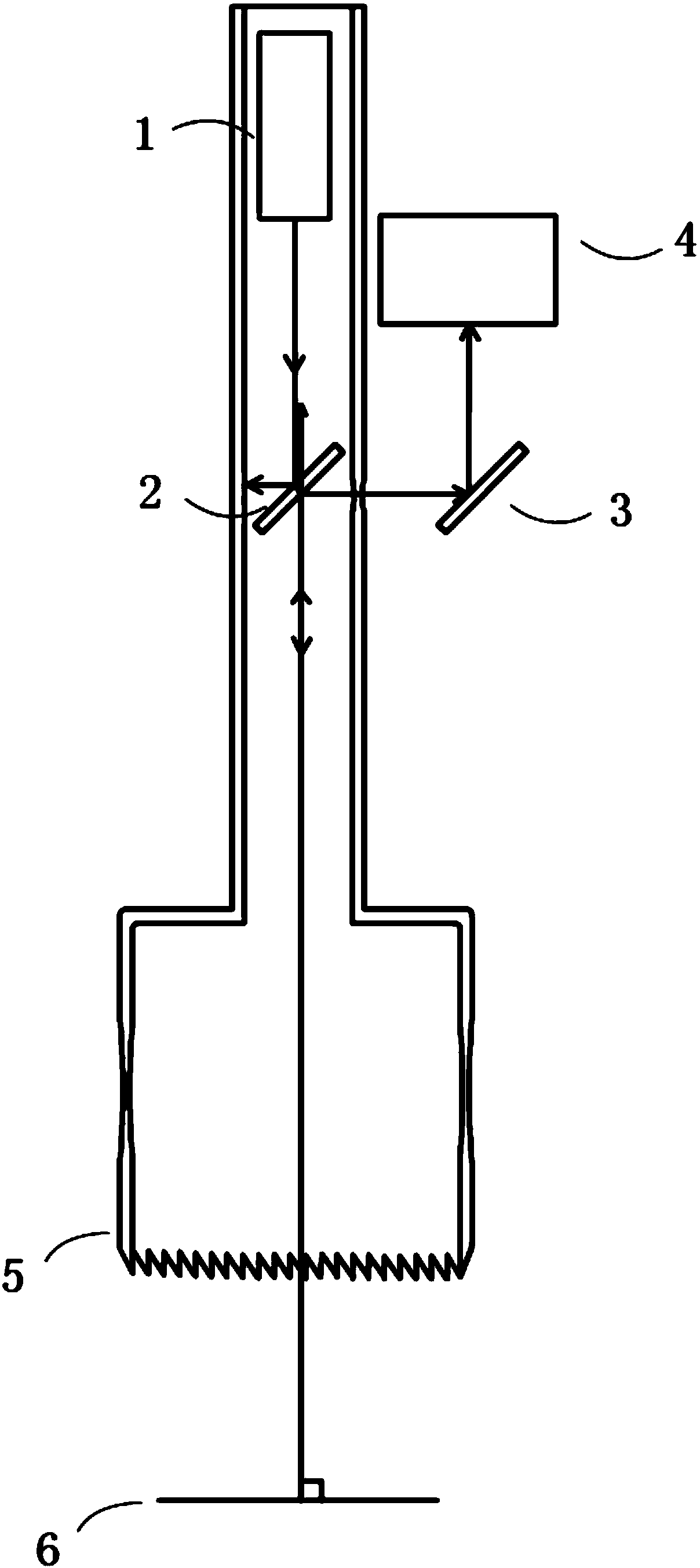

Semiconductor laser alignment-based reflection type verticality detection system and method

PendingCN107702664AReduce manufacturing costReduce the difficulty of productionUsing optical meansFixed angles setting outLight beamErbium lasers

The invention relates to a semiconductor laser alignment-based reflection type verticality detection system and method. The system comprises a perforator which has an axially hollow structure shaped like an inverted T, an end part of the perforator corresponds to a surface of an arc object, a semiconductor laser device and a semitransparent mirror are arranged in an extension part perpendicular tothe end part, a side wall of the extension part is provided with a via hole, a circle center of the via hole and a center of the semitransparent mirror are positioned on the same horizontal line, a laser beam emitted via the semiconductor laser is split into first transmitted light and first reflected light after being transmitted to the semitransparent mirror, the first transmitted light is reflected to the semitransparent mirror after vertically irradiating onto the surface of the arc object after going through a transparent medium, the first transmitted light is again split into second transmitted light and second reflected light via the semitransparent mirror, the second reflected light irradiates on a mirror surface holophote positioned outside the perforator after running through avia hole, the mirror surface holophote corresponds to the via hole in terms of position, and the second reflected light is reflected to a CCD via the mirror surface holophote. The detection system andmethod disclosed in the invention can be used for verticality detection and positioning of the arc object.

Owner:BEIJING INFORMATION SCI & TECH UNIV

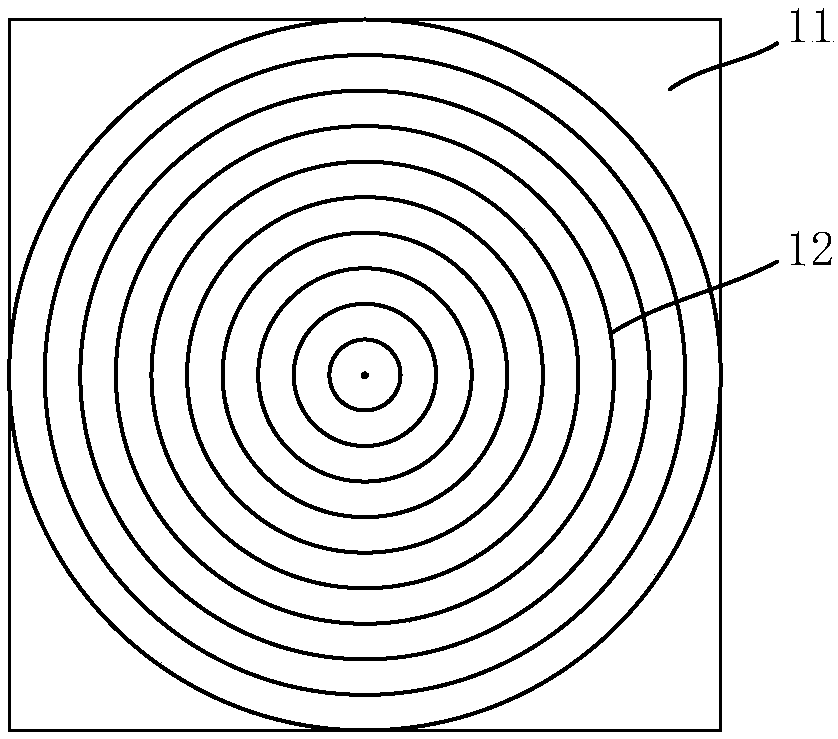

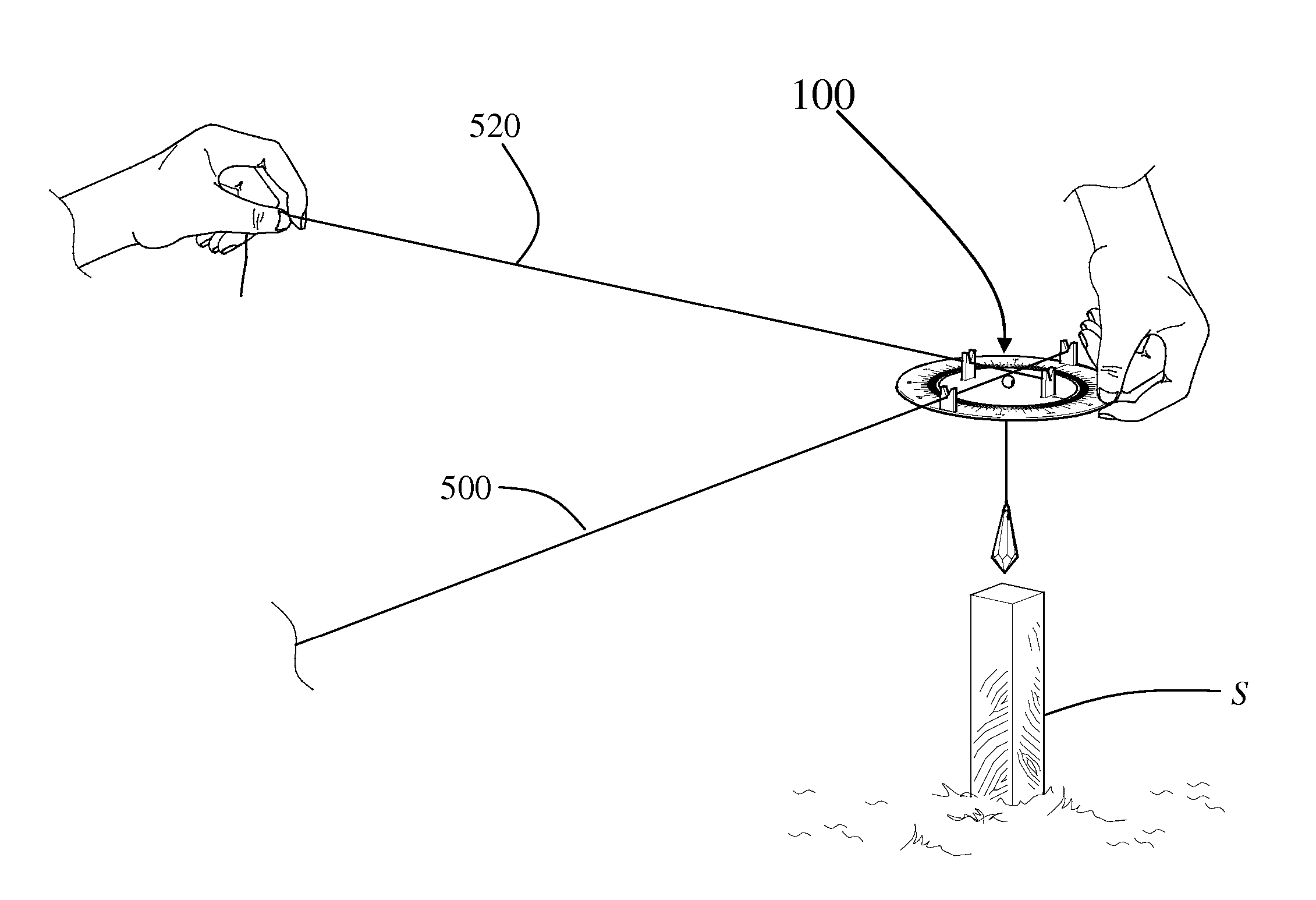

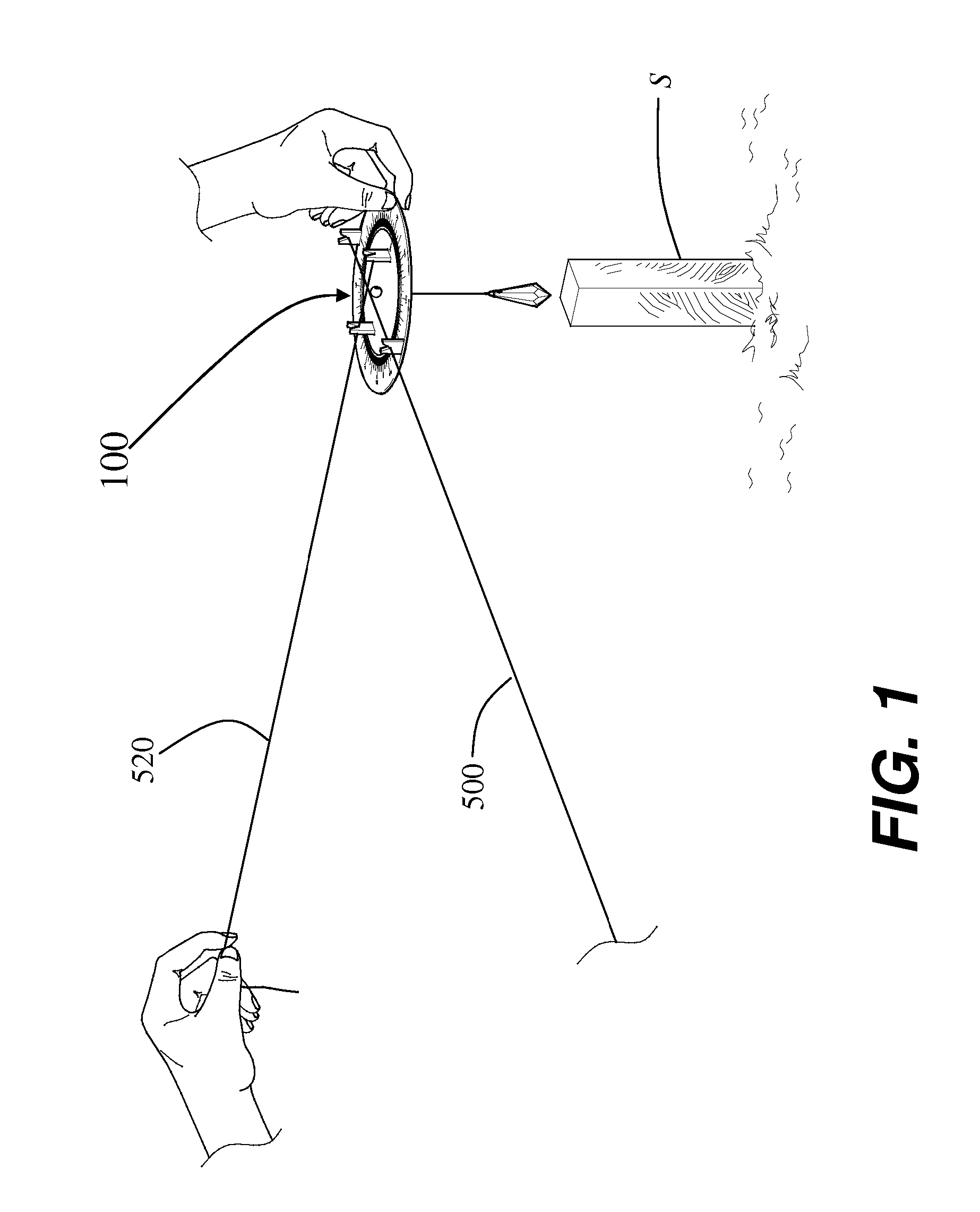

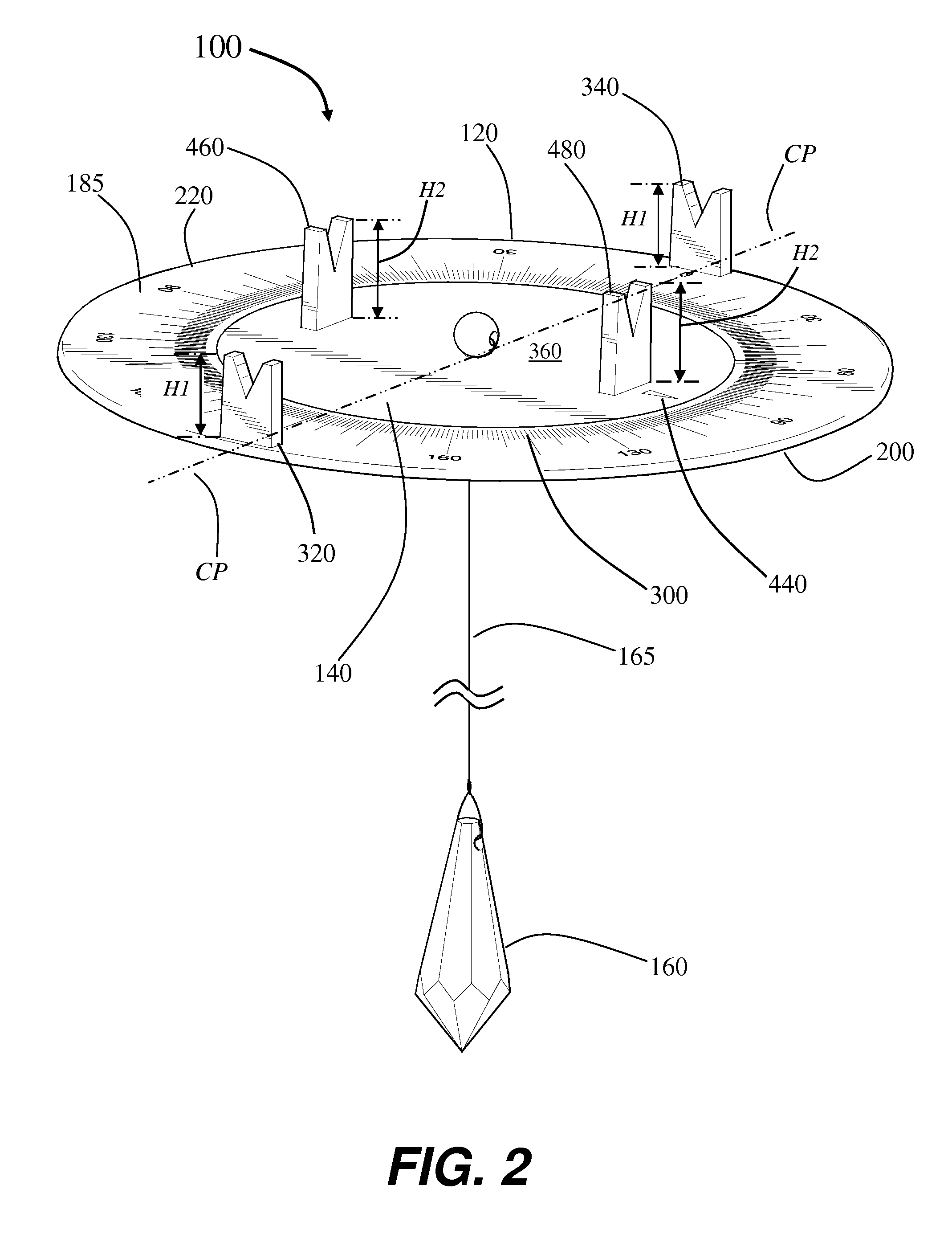

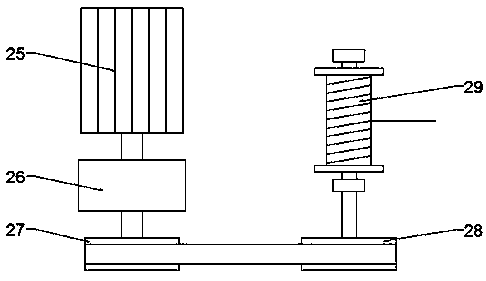

Perpendicularity measuring device

ActiveCN105910592AAvoid shakingHigh measurement accuracyFixed angles setting outMeasurement deviceEngineering

The invention discloses a perpendicularity measuring device which comprises a holding platform and a plumb bob. The perpendicularity measuring device is characterized in that a plumb bob preformed opening is formed in the holding platform; the top of the plumb bob is fixed and vertically penetrates through the plumb bob preformed opening; two light sources are arranged on the holding platform; the light emitting directions of the light sources face to the plumb bob preformed opening and are perpendicular to each other; scale plates are arranged on opposite sides of the light emitting directions of the light sources; the plumb bob is positioned between the light sources and the scale plates; horizontal scales are arranged on the scale plates; scales on the two scale plates are positioned on a same horizontal plane; the holding plate is connected on the machine head of a tower body and moves up and down along with the machine head along a guide track; the projection scale values of the plumb bob on the scale plates are measured so as to test the perpendicularity of the tower body. By adopting the perpendicularity measuring device disclosed by the invention, the problem that relatively large read errors can be caused as the plumb bob is shaken when a conventional method is adopted to measure is solved, the measurement result precision is effectively improved, and the quality of deposit products is improved.

Owner:CHENGDU FUTONG OPTICAL COMM TECH +1

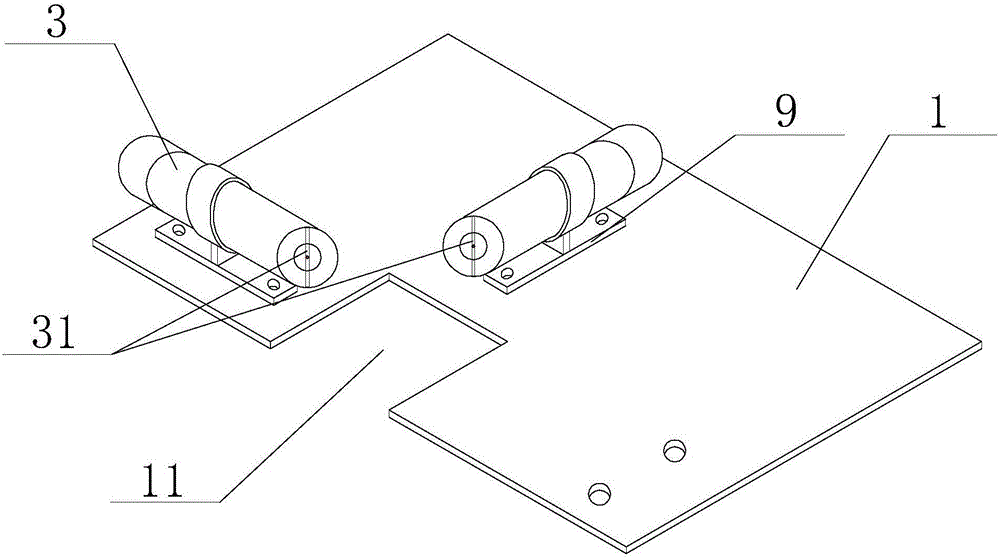

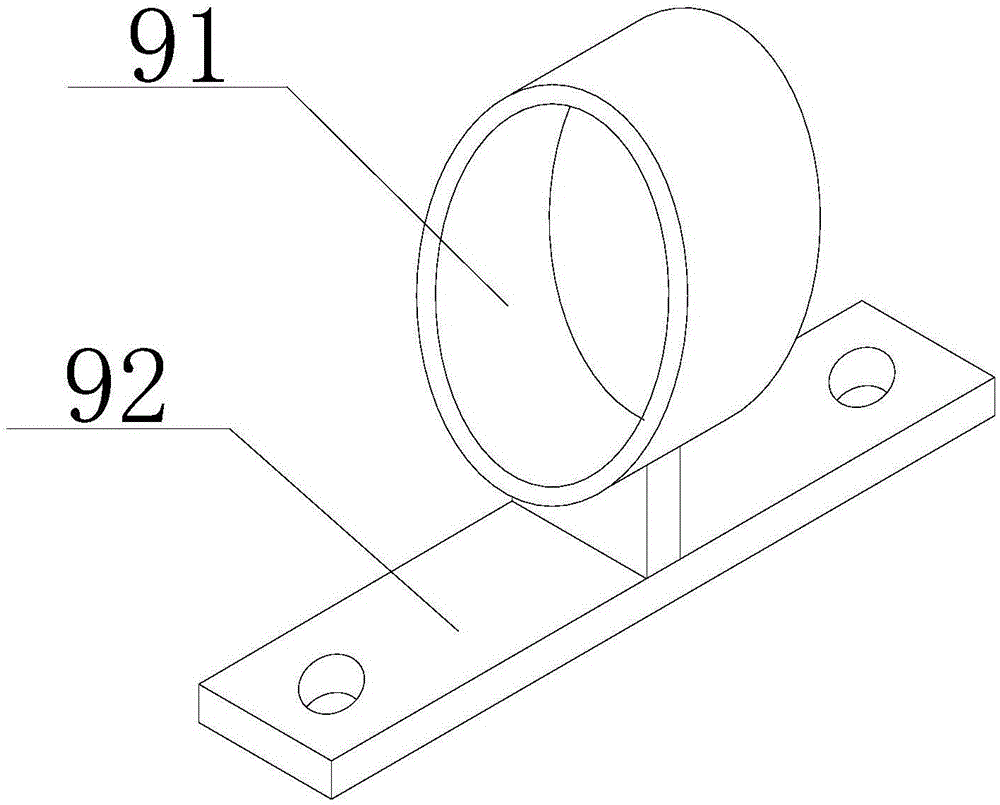

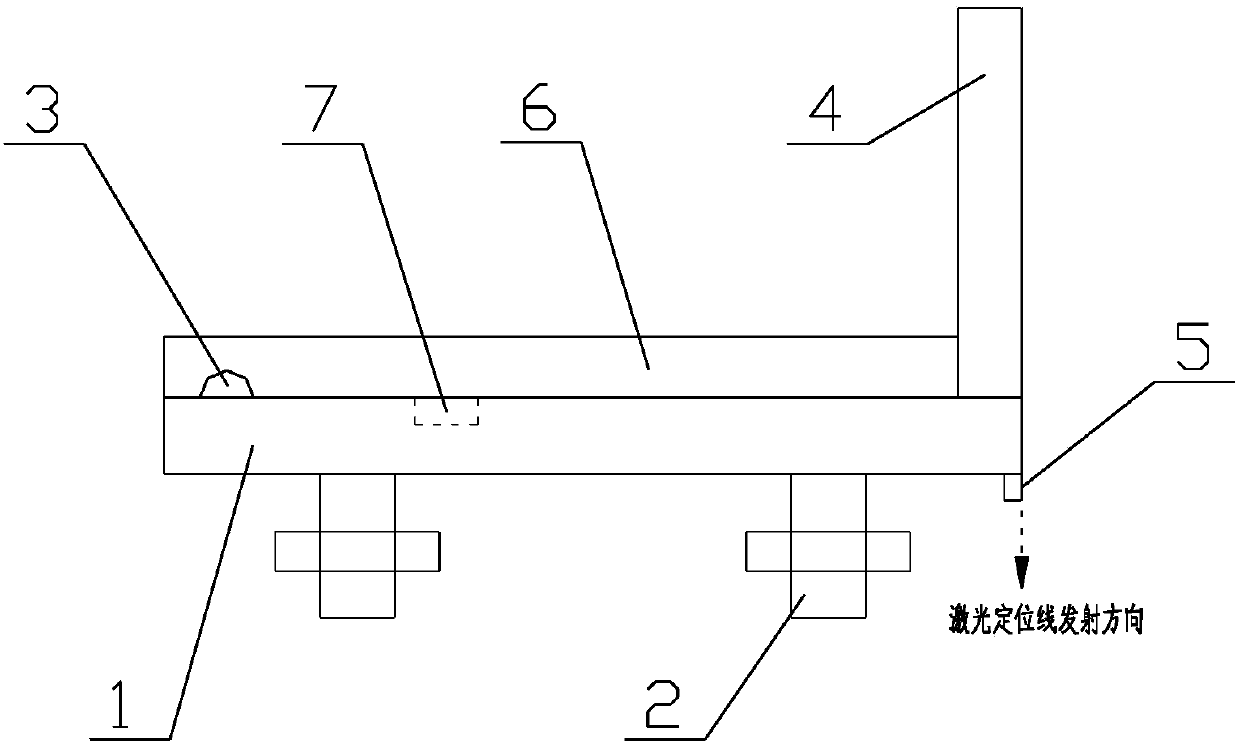

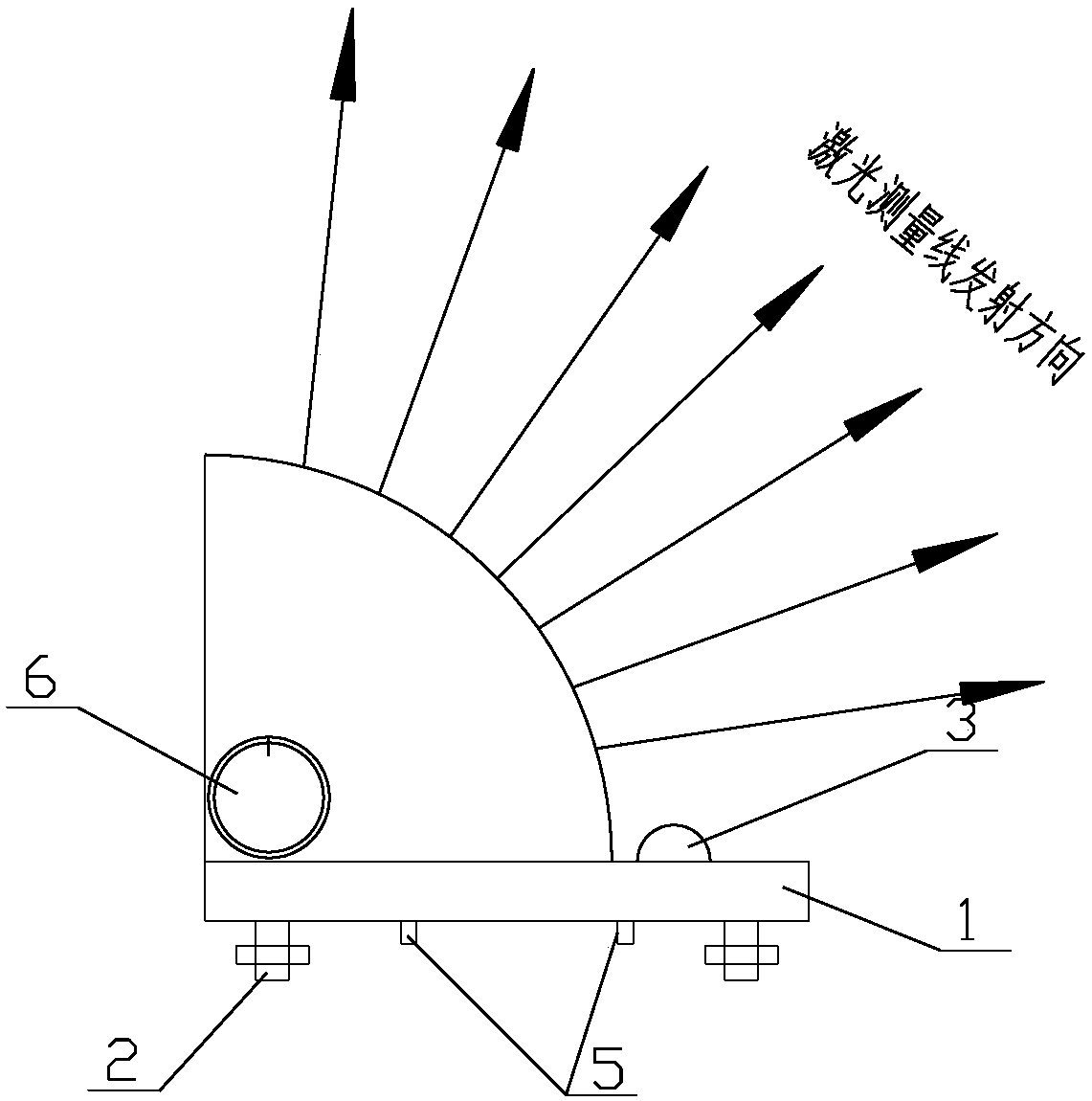

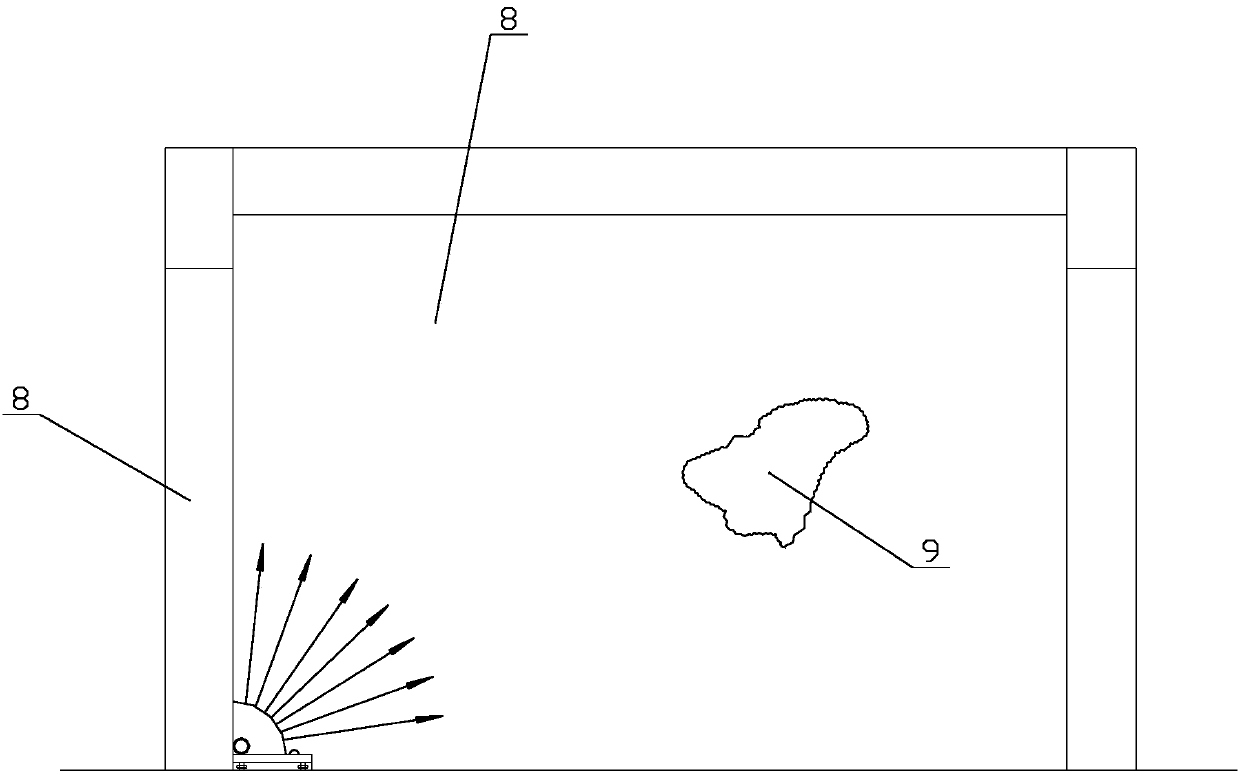

Device and method for detecting deviation of flatness and verticality of wall surface

ActiveCN107727014AImprove applicabilityEasy to measureUsing optical meansFixed angles setting outLaser transmitterBias detection

The invention relates to a device and method for detecting deviation of flatness and verticality of a wall surface. The device comprises a horizontal plate, leveling knobs, a leveling bubble, a sector-shaped laser emitter, a one word line laser, and a scale, wherein several leveling knobs are arranged at the bottom of the horizontal plate, the leveling bubble and the scale are arranged on the topof the horizontal plate, the sector-shaped laser emitter is arranged above the horizontal plate and can slide along the scale, the laser emission direction of the sector-shaped laser emitter is perpendicular to the scale direction of the scale, the one word line laser is arranged at the bottom of the horizontal plate, below the starting position of the scale, and the laser positioning line of theone word line laser is vertically downward and is in the same elevation plane as the zero scale point of the scale. The device and method can conveniently and quickly measure the absolute deviation ofthe flatness and verticality of various parts of the entire wall surface and have high measurement accuracy.

Owner:CHINA THIRD METALLURGICAL GRP

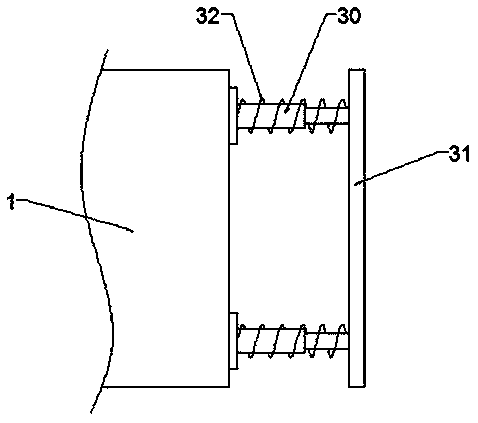

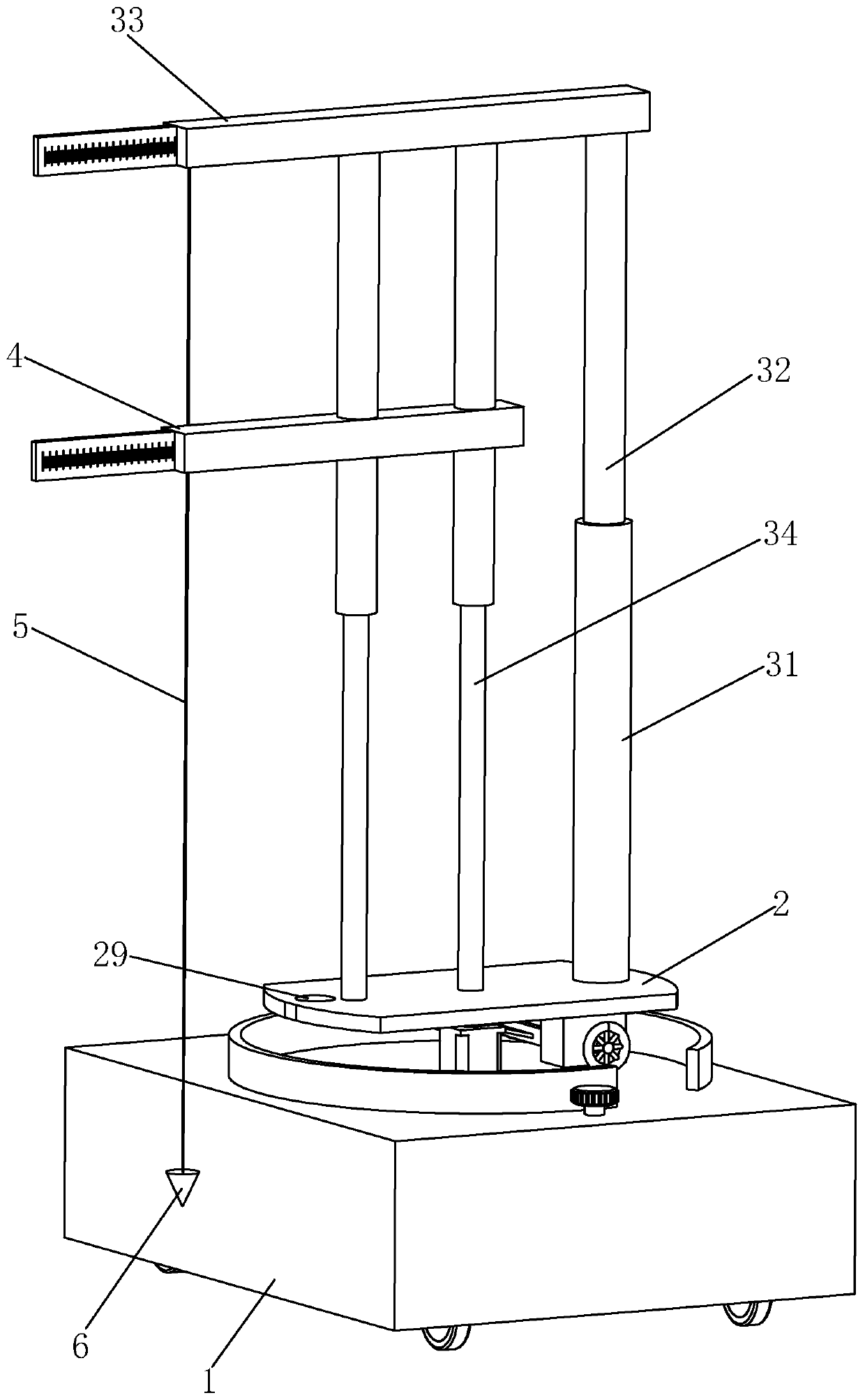

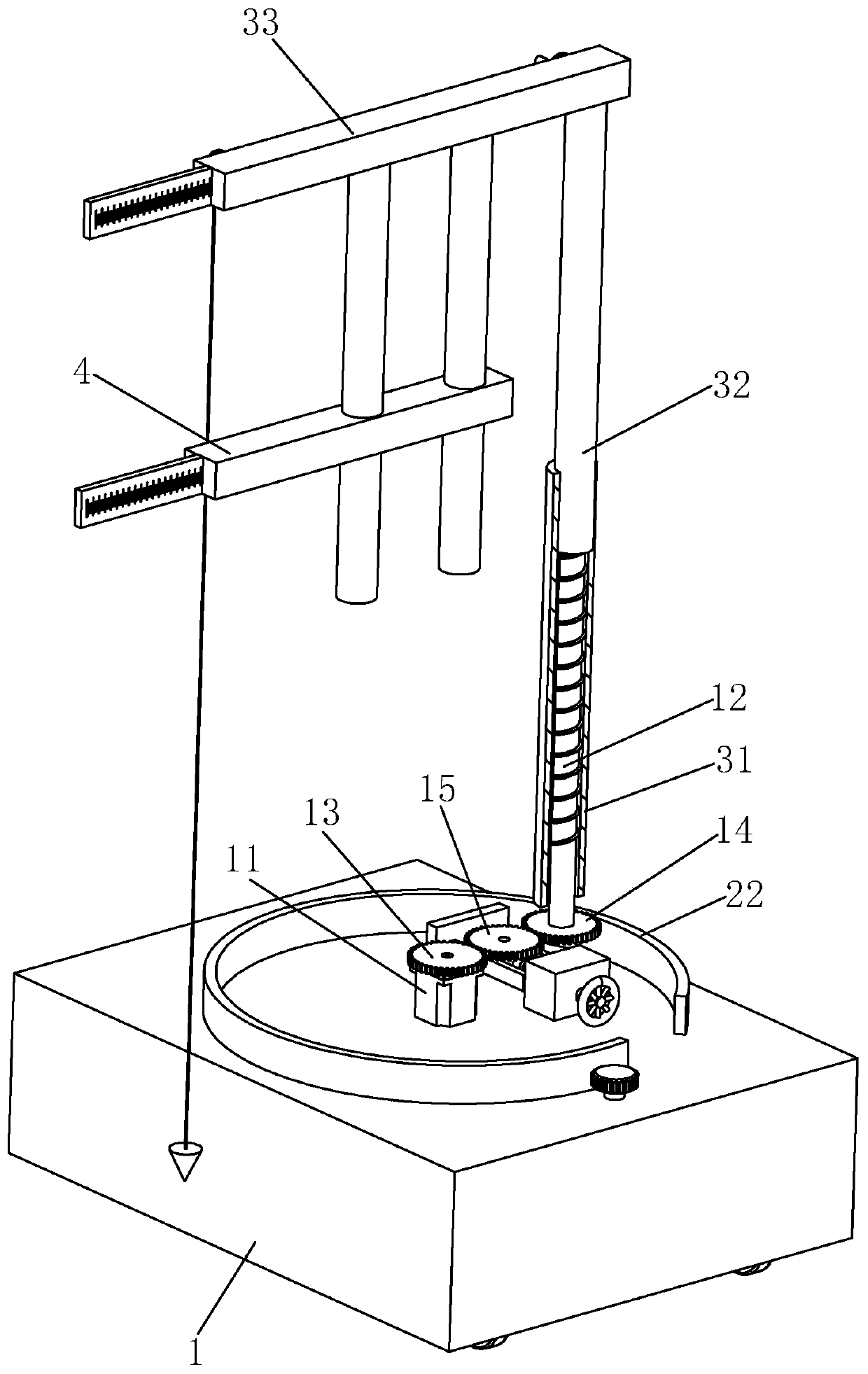

Constructional engineering verticality detection device

ActiveCN111174770AImprove uniformityAchieve rotationFixed angles setting outWire wheelClassical mechanics

The invention relates to the technical field of constructional engineering detection equipment, in particular to a constructional engineering perpendicularity detection device which is characterized in that a base is provided with a cavity, and inner walls of two opposite sides of the cavity are movably connected with a roller assembly and a control assembly; a turntable is rotationally borne on an upper surface of the base; a level bubble and a telescopic frame are respectively arranged on an upper surface of the turntable; a cross beam and a measuring mechanism are respectively arranged on the telescopic frame; the measuring mechanism is located under the cross beam, one side of the cross beam rotatably bears a wire wheel, a steel wire rope is wound around the wire wheel, a free end of the steel wire rope is connected with a plumb bob, a driving piece and a power assembly are arranged on the base, and an adjusting assembly used for winding the steel wire rope to stay at different positions to adjust the height position of the plumb bob is arranged on the wire wheel. According to the invention, the problems in the prior art that although the movement is convenient, the stability is poor in the detection process, the rotation and height position adjustment of the measuring mechanism cannot be realized can be solved.

Owner:惠州亿安建筑工程有限公司

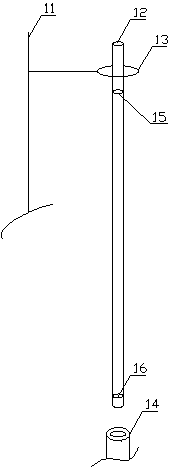

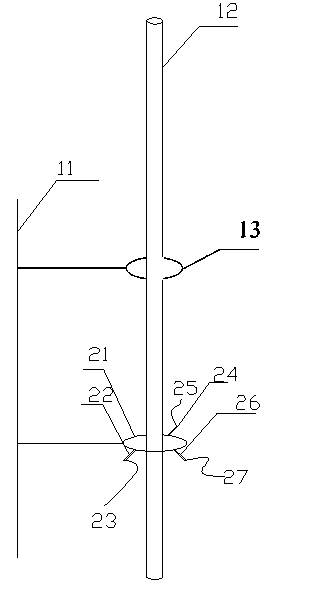

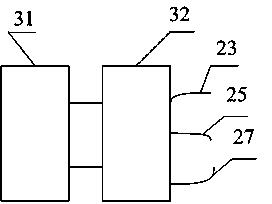

Concrete template verticality detector

InactiveCN105180912AOvercome efficiencyOvercoming dangerSurveying with inclination sensorFixed angles setting outLaser transmitterEngineering

The invention relates to a concrete template verticality detector, which comprises a vertical rod, wherein the middle portion position of the vertical rod is provided with a circular level for detecting the precision of the concrete template verticality detector, both ends of the vertical rod are respectively and fixedly connected to an upper portion leaning point and a lower portion leaning point, the upper portion leaning point and the lower portion leaning point are parallel to each other, a laser transmitter is suspended below the upper portion leaning point through a rope, and the lower portion leaning point is provided with scales for matching with the laser transmitter so as to read the template verticality. According to the present invention, the concrete template verticality detector collects the verticality of the vertical rod through the circular level and the lower portion leaning point having the scales reads the verticality of the template, such that the disadvantages of low efficiency and risk of the traditional detection method are overcome, the work efficiency can be significantly improved, the precision is provided, the construction speed can be accelerated, the construction time limit can be saved, the labor can be saved, and the construction cost can be reduced.

Owner:LUOYANG INST OF SCI & TECH

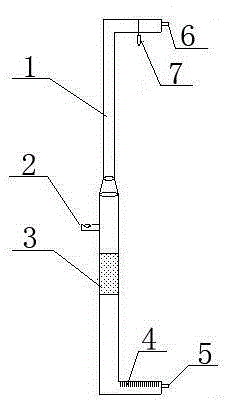

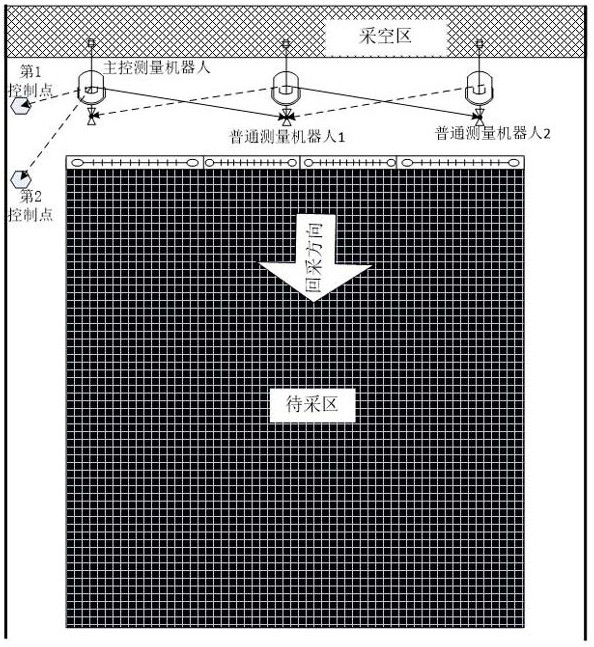

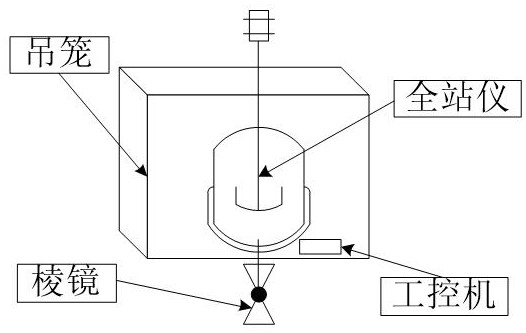

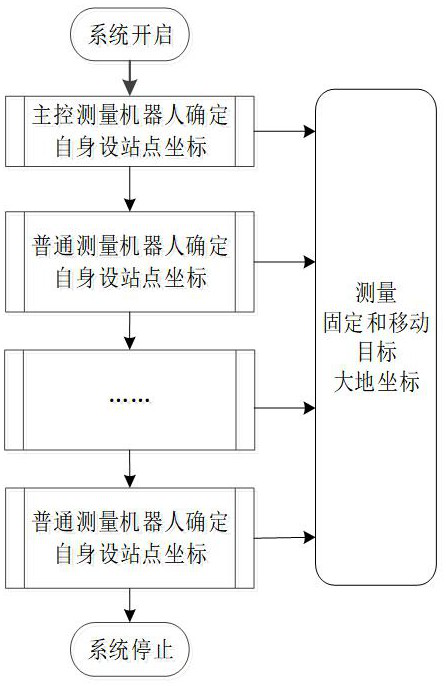

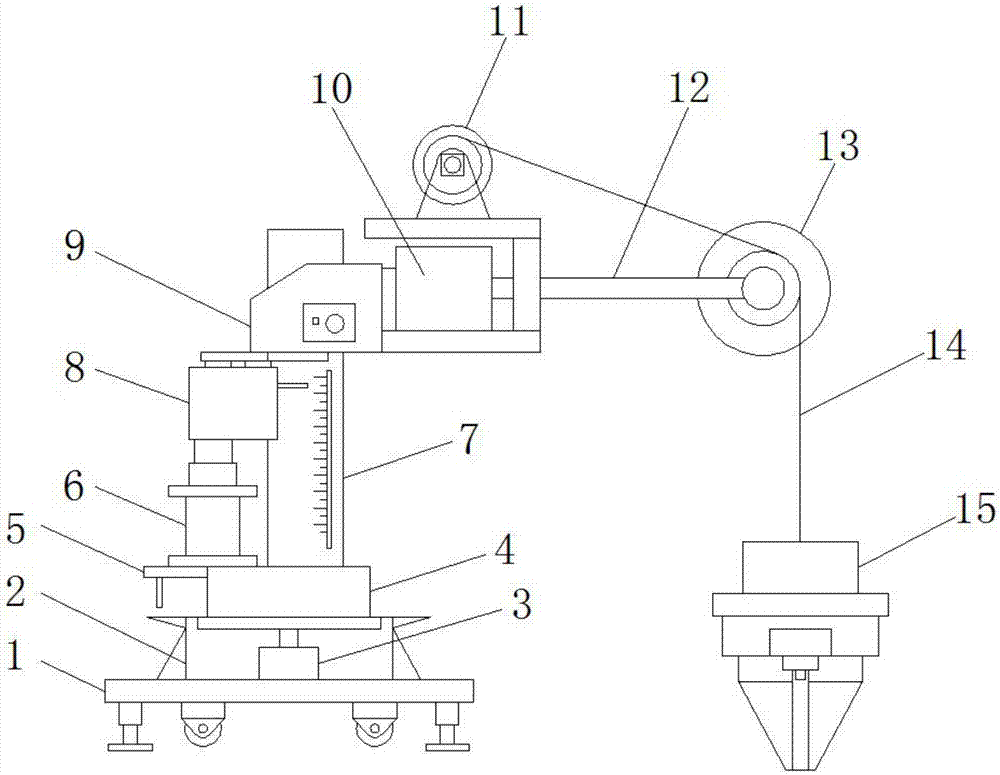

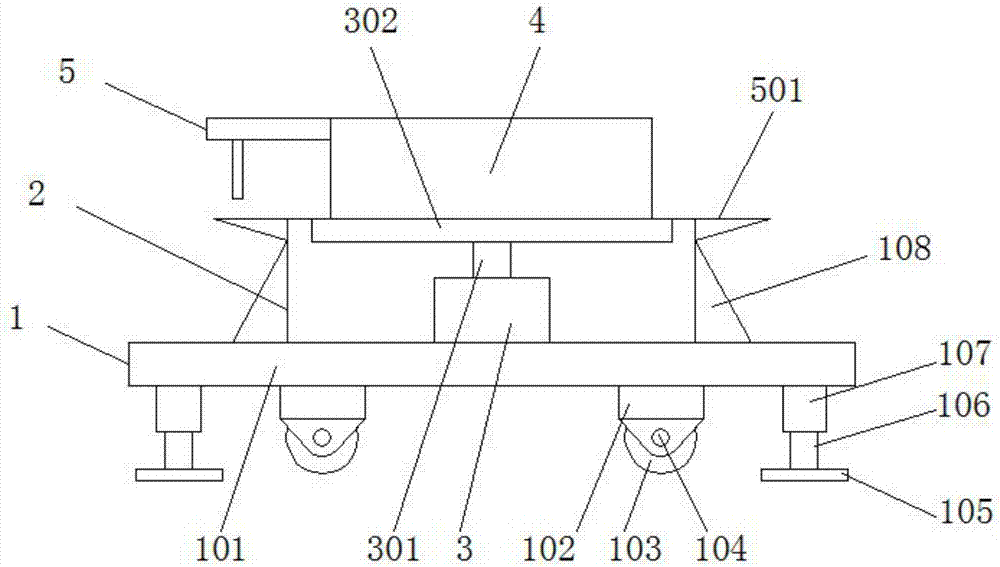

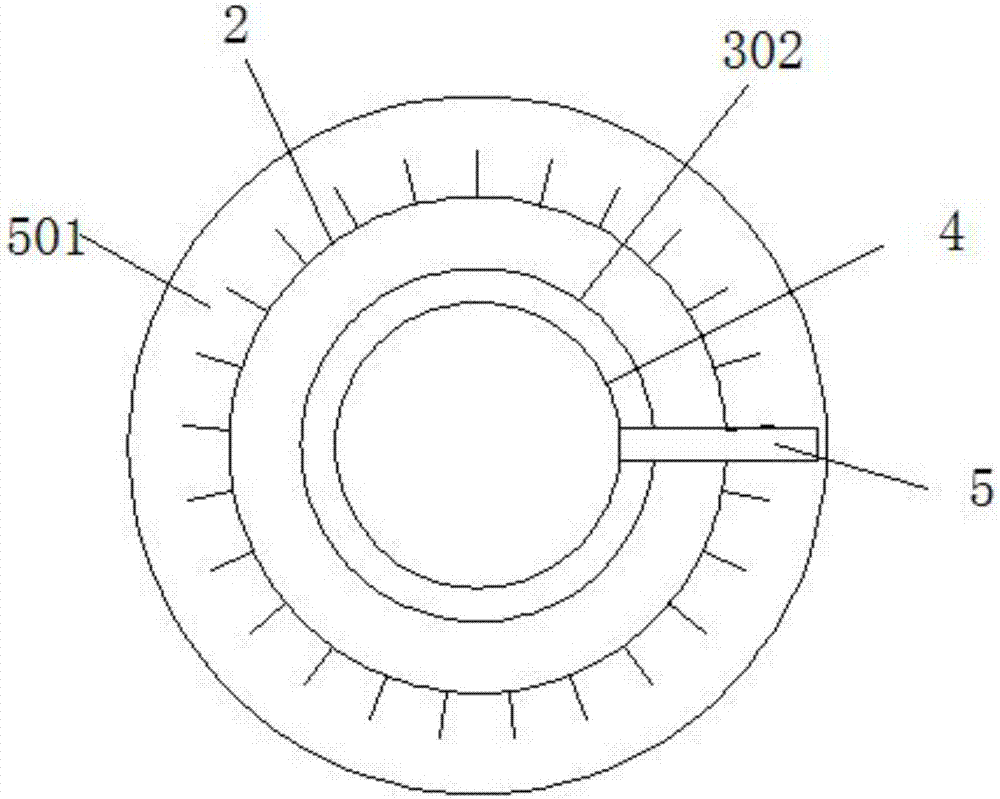

Fully-mechanized coal mining face measuring robot device and automatic measuring system

ActiveCN112378390ALow costReduced measurement timeVehicle position/course/altitude controlElectromagnetic wave reradiationMining engineeringPersonal computer

The invention discloses a fully-mechanized coal mining face measuring robot device and an automatic measuring system, belonging to the field of intelligent mining of coal mines. The measuring robot comprises a cage, a total station, a prism and an industrial personal computer. According to the invention, the suspension cage with an automatic leveling function is fixedly suspended on a top beam ofa hydraulic support, then the total station and the industrial personal computer are fixed in the suspension cage, and finally, the prism with a plug connector is in butt joint with a base of the total station to form the measuring robot device. According to the fluctuation of a fully-mechanized coal mining face of a mine, a plurality of measuring robots are sequentially arranged along the fully-mechanized coal mining face, and the adjacent measuring robots are intervisible to form the automatic measuring system for covering the fully-mechanized coal mining face of the mine. Accurate geodeticcoordinate measurement of fixed and moving targets of the fully-mechanized coal mining face is realized through the fully-mechanized coal mining face measuring robot device and the automatic measurement system.

Owner:BEIZHING LONGRUAN TEKNOLODZHIS INK +1

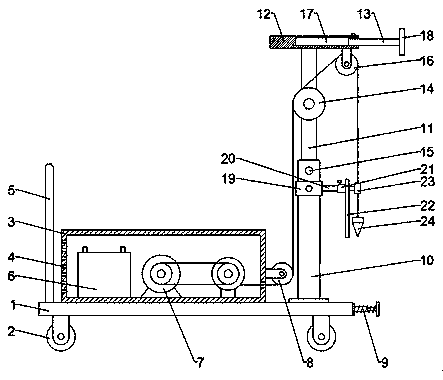

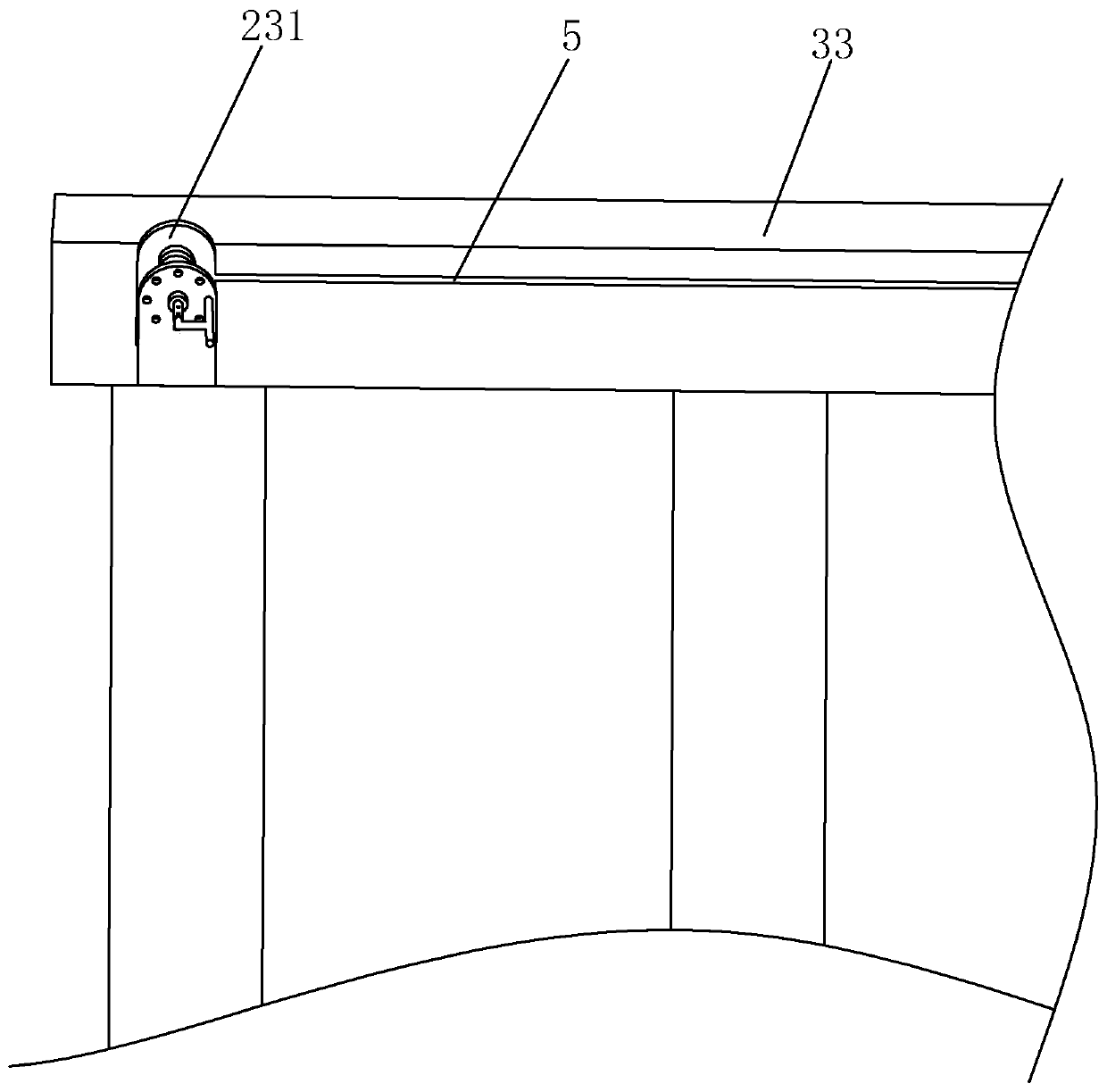

Elevator shaft perpendicularity detection device

InactiveCN107131873AStable structureEasy to operateActive open surveying meansFixed angles setting outEngineeringLaser beams

The invention discloses a verticality detection device for an elevator shaft, which comprises a load-bearing car body, a rotating pedestal, a guide column, a lifting slider, a horizontal support, a pay-off mechanism and a suspension measuring device. The middle part of the upper end of the load-bearing car body is welded with A motor is installed in the fixed base, the output end of the motor is connected to the rotating shaft, the upper end of the rotating shaft is welded with a limit turntable, and the upper part of the limit turntable is welded with a rotating pedestal; the upper end of the rotating pedestal is welded with a guide column, guiding The side of the column slides with a lifting slider, the bottom of the lifting slider is installed with a lifting cylinder, the lifting cylinder is fixed on the rotating pedestal, and the top of the vertical telescopic rod of the lifting cylinder is welded to the lifting slider; it is convenient to adjust the position of the suspension measuring device , which is convenient for laying out or winding the traction line. The laser emitting head emits a laser beam from the laser beam channel downward. The laser beam channel in the counterweight lead pendant is vertically downward, and the laser beam is irradiated vertically downward, which is convenient for elevator detection. verticality of the well.

Owner:宋衡星

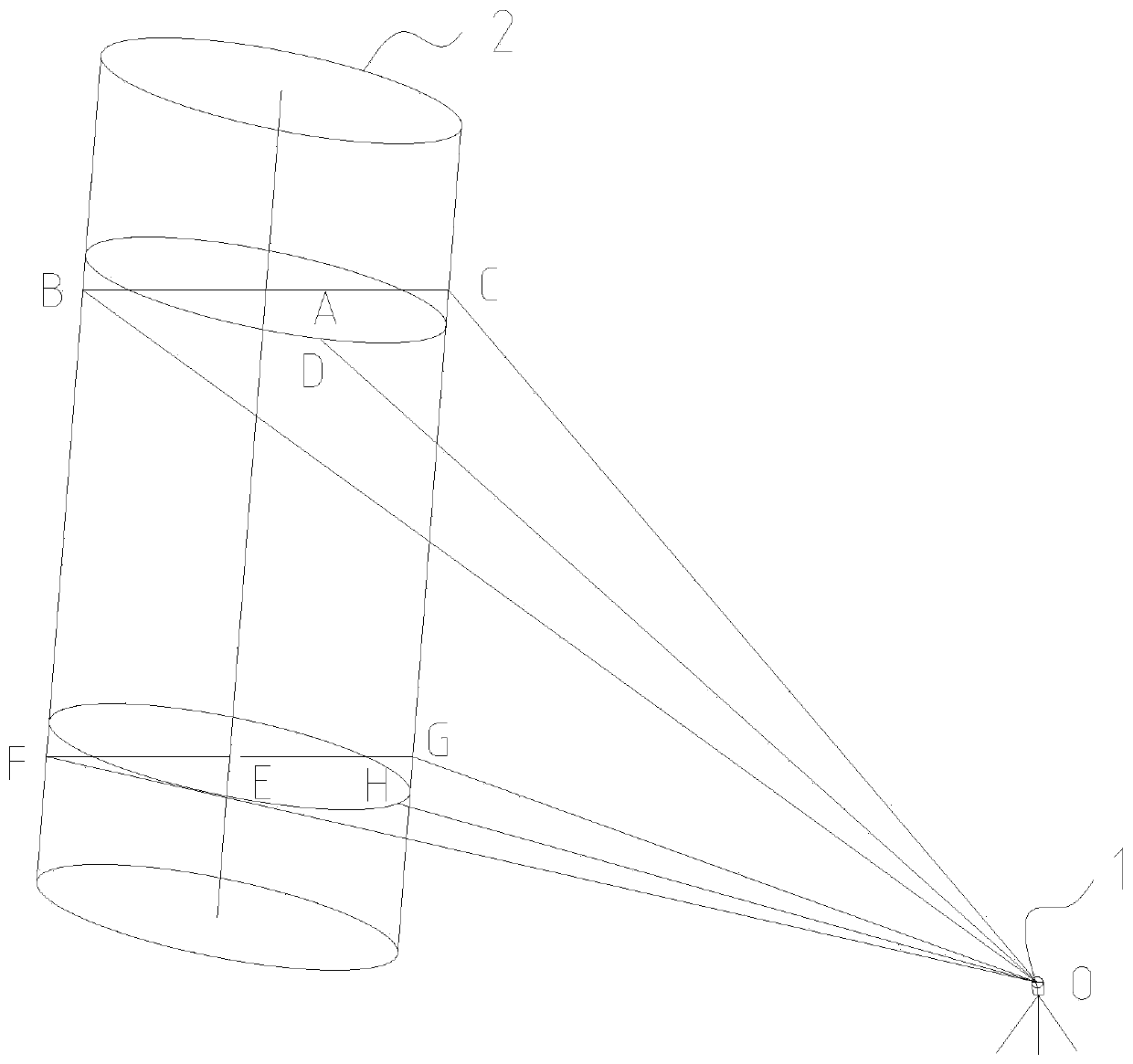

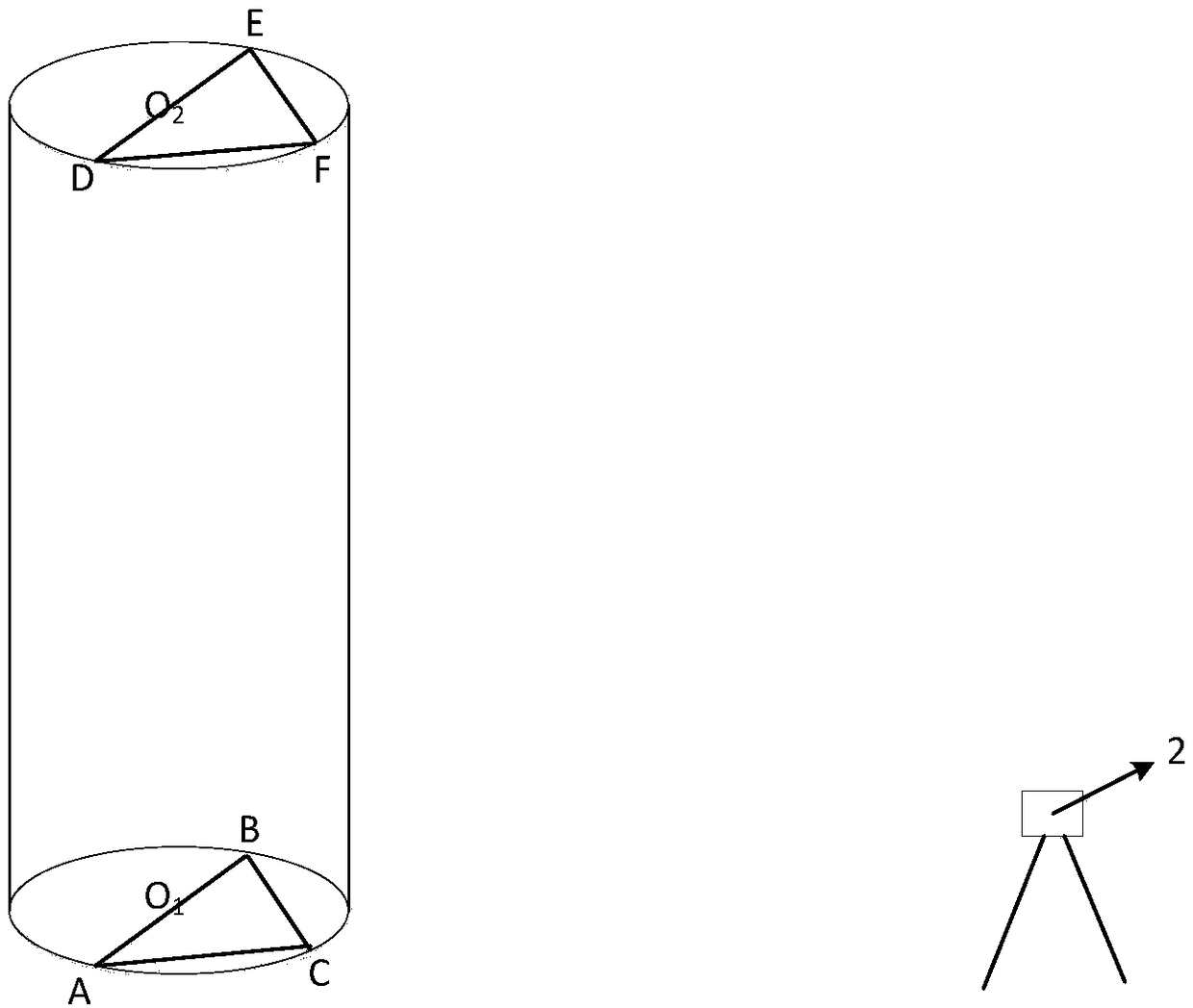

Circular column verticality detecting method

ActiveCN109405817AAvoid the dangers of working at heightsShorten the timeFixed angles setting outTotal stationComputer science

The invention relates to a circular column verticality detecting method. The method uses a total station to measure three points of two interfaces on a bridge column, calculates center coordinates ofthe interface from three points, and compares the left sides of centers of two sections to obtain the maximum offset and perpendicularity of the circular column; the method effectively solves the complicated operation in the process of detecting the verticality of the circular column and does not need to work at heights, can accurately measure the verticality and the deviation direction of the circular column, saves human resources, improves the accuracy of the date, and has the advantages of simple principle, convenient and fast operation, accurate and accurate data, strong practicality and wide applicability.

Owner:CHINA FIRST METALLURGICAL GROUP

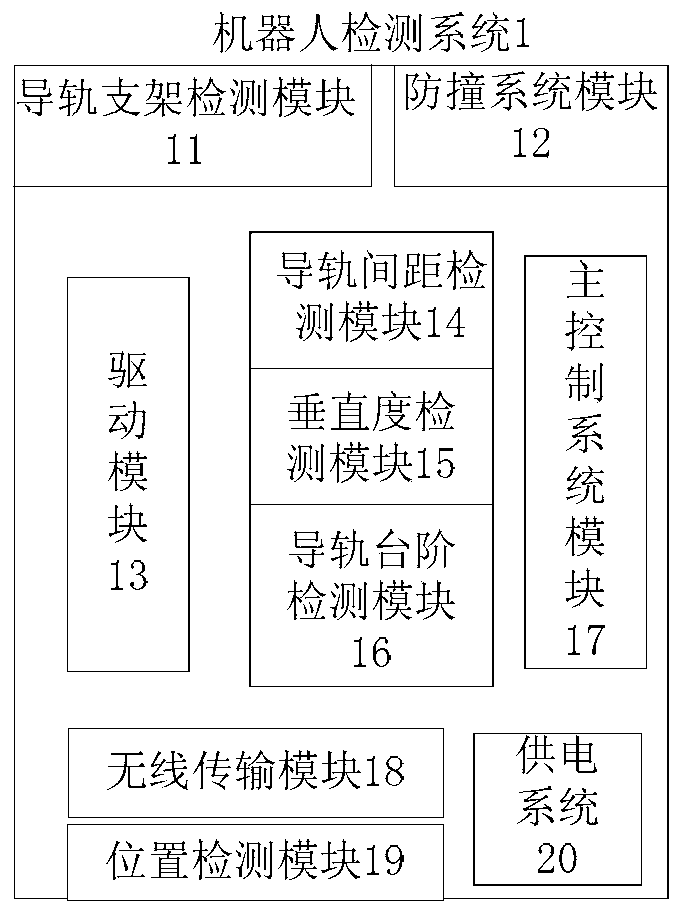

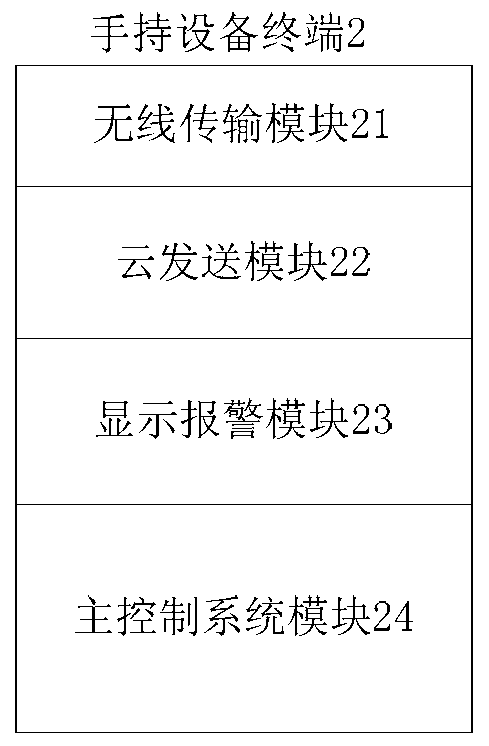

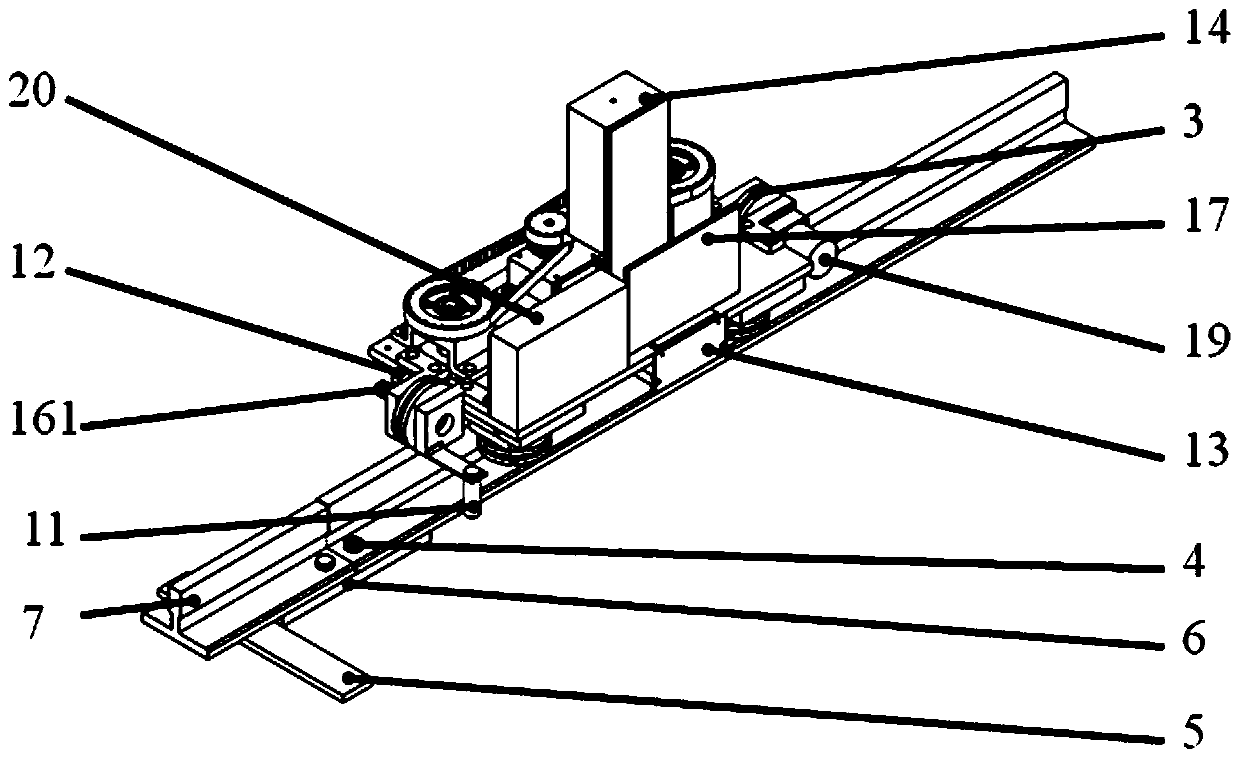

Elevator guide rail comprehensive parameter detection and evaluation method and detection system

PendingCN110500983AResolve detectionResolving conflicts between control tasksProgramme controlComputer controlSimulationDistance detection

The invention discloses an elevator guide rail comprehensive parameter detection and evaluation method and a detection system. A robot is installed on a detected guide rail, and the robot walk to a support detection position to detect guide rail steps, a guide rail distance and guide rail verticality. Detection data is wirelessly transmitted to a handheld equipment terminal. A detection robot anti-collision system detects a guide rail terminal, completes detection work and returns to an initial position. The method and the system have advantages that an independent control model can solve conflicts among multiple detections or control tasks, a guide rail climbing detection robot can detect a detection item specified by a standard only through one-time automatic operation, and detection efficiency is improved; the handheld equipment terminal is convenient to carry, and labor intensity is reduced; ' 'Internet +' ' and artificial intelligence technologies are adopted, potential safety hazards can be found in advance through data mining, and elevator safety is guaranteed; a guide rail distance detection module is in rigid connection with a step detection sensor, assembling errors caused by guide rail distance detection are avoided, and a detection result is accurate.

Owner:TIANJIN SPECIAL EQUIP INSPECTION INST +1

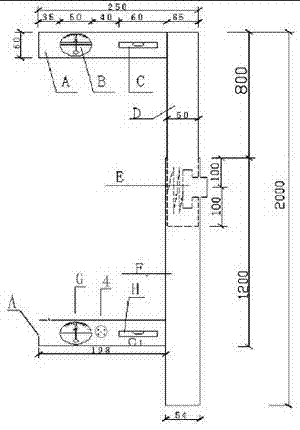

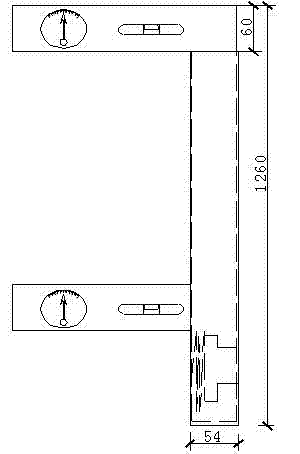

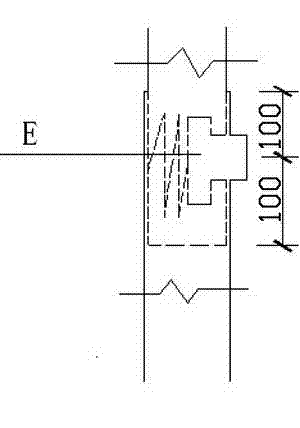

Verticality measuring instrument for formwork installation work

InactiveCN103047957ASolve the slow construction speedImprove construction qualityFixed angles setting outMeasuring instrumentWhole body

The invention relates to and discloses a verticality measuring instrument for building work formwork construction. The technical scheme is that the verticality measuring instrument for formwork installation work consists of aluminum alloy withdrawing framework rods, a verticality index dial, a leveling tube and a control circuit, wherein the aluminum alloy withdrawing framework rods are divided into an upper rod (D), a lower rod (F) and auxiliary rods (A); the upper rod (D) can be inserted into the lower rod (F); the upper auxiliary rod and the lower auxiliary rod are welded in a manner of being perpendicular to the upper rod and the lower rod respectively; the upper rod and the lower rod form a right angle relationship with the auxiliary rods; in such a way, after the formation of a whole body in a combining way, an F shape is formed; and the upper end of the lower rod (F) is provided with a spring press button (E) for control and fixation on / of the telescopic position of the upper rod (D). The verticality measuring instrument for the formwork installation work is simple to manufacture, convenient to operate, low in cost and practical in function, and can detect the verticality of installed various-height formworks in the daytime and at night; and therefore, the requirement on the construction work quality is met.

Owner:SHANGQIU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com