Fully-mechanized coal mining face measuring robot device and automatic measuring system

A technology for measuring robots and fully mechanized mining faces, which is applied to measuring devices, radio wave measuring systems, active optical measuring devices, etc., can solve the problems of long time for north-seeking, weak adaptability, and high price of gyro total stations, and achieve Solve the effect of long north-seeking time, save cost, and save measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

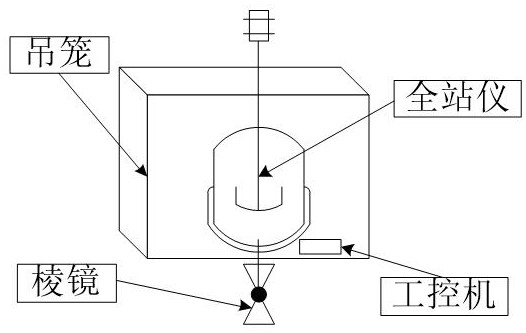

[0045] refer to figure 2 , shows a schematic structural diagram of a fully mechanized mining face measuring robot of the present application, as figure 2 As shown, a measuring robot device for a fully mechanized mining face, the measuring robot components include a cage, a total station, a prism, and an industrial computer, wherein:

[0046] The cage is installed on the top beam of the hydraulic support in the fully mechanized mining face of the mine, and is used to load the total station, industrial computer and prism; the cage has an automatic leveling function to ensure that the total station in the cavity of the cage remains horizontal; The cage is a waterproof, dustproof and shockproof closed space, and according to the measurement of the working surface, the front and rear viewing directions are approximately linear characteristics, and transparent windows are set at the front and rear of the cage for observation by the total station;

[0047] The total station is a m...

Embodiment 2

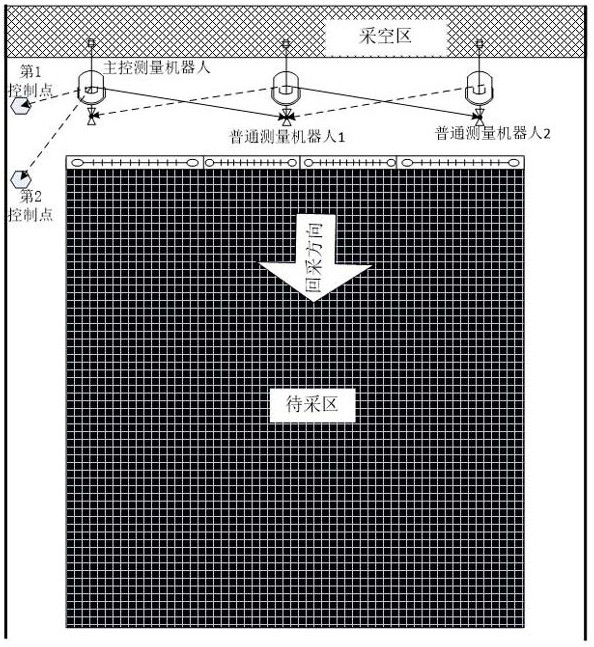

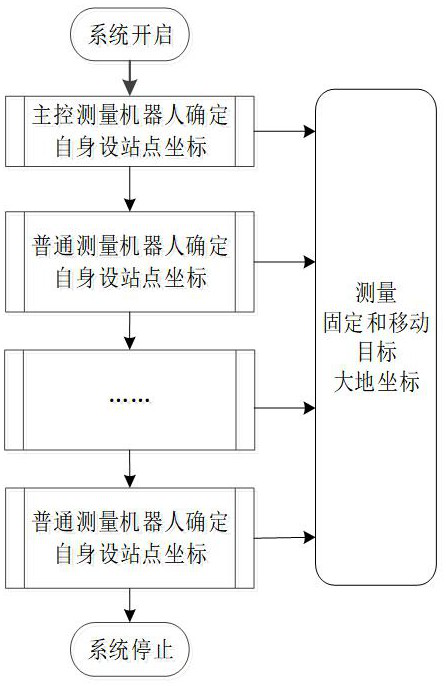

[0062] refer to figure 1 , which shows a schematic diagram of equipment layout of an automatic measurement system for a fully mechanized mining face in the present application, as figure 1 As shown, an automatic measurement system includes a measurement robot device as provided in Embodiment 1 of the present application, wherein:

[0063] The control point prism is arranged on the coal wall of the machine head or the same side of the machine tail in the fully mechanized mining face, such as figure 1 As shown, the black boxes on both sides of the figure represent the coal wall, and the geodetic coordinates of the control point where the control point prism is located are measured in advance, and the control point is used as the backsight control point of the main control measuring robot;

[0064] The main control measuring robot is fixedly installed on the head beam of the fully mechanized mining face or on the hydraulic support top beam of the tail;

[0065] According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com