Patents

Literature

107 results about "Bias detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detection bias [ditek′shən] a potential artifact in epidemiological data caused by the use of a particular diagnostic technique or type of equipment. As an example, cancer rates may vary in different regions or periods, not because of an actual difference in the incidence of the disease but because of different diagnostic technologies.

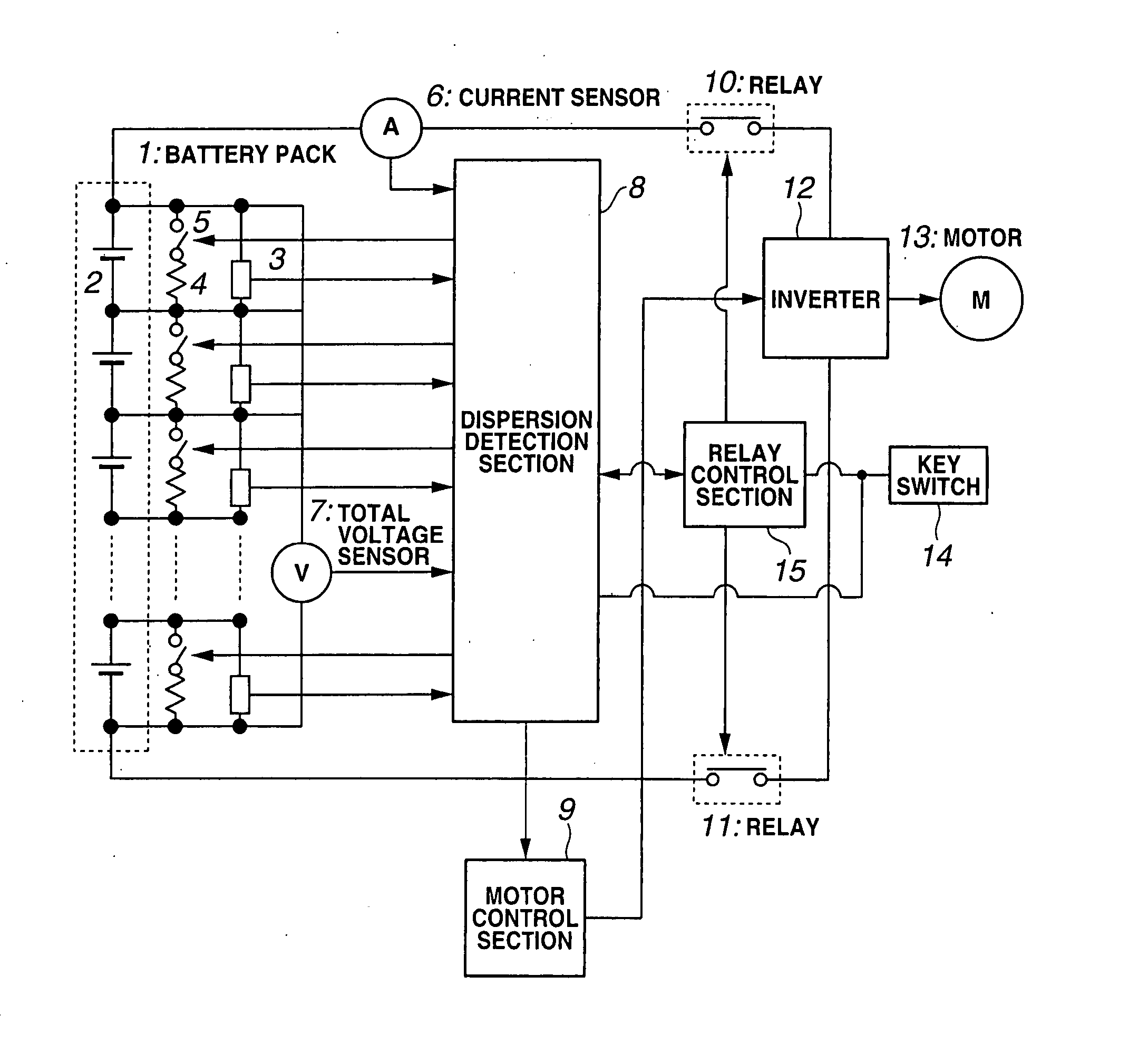

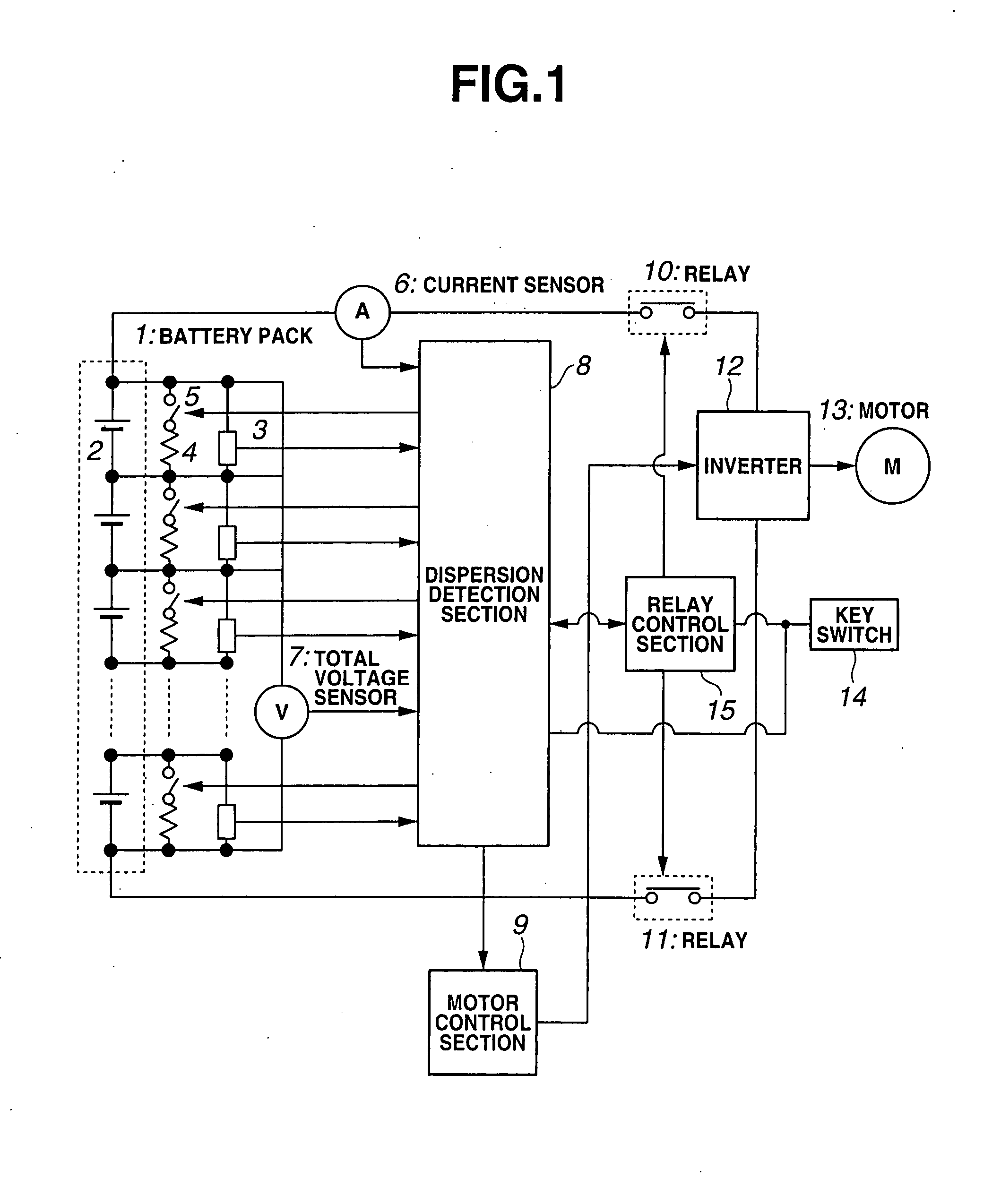

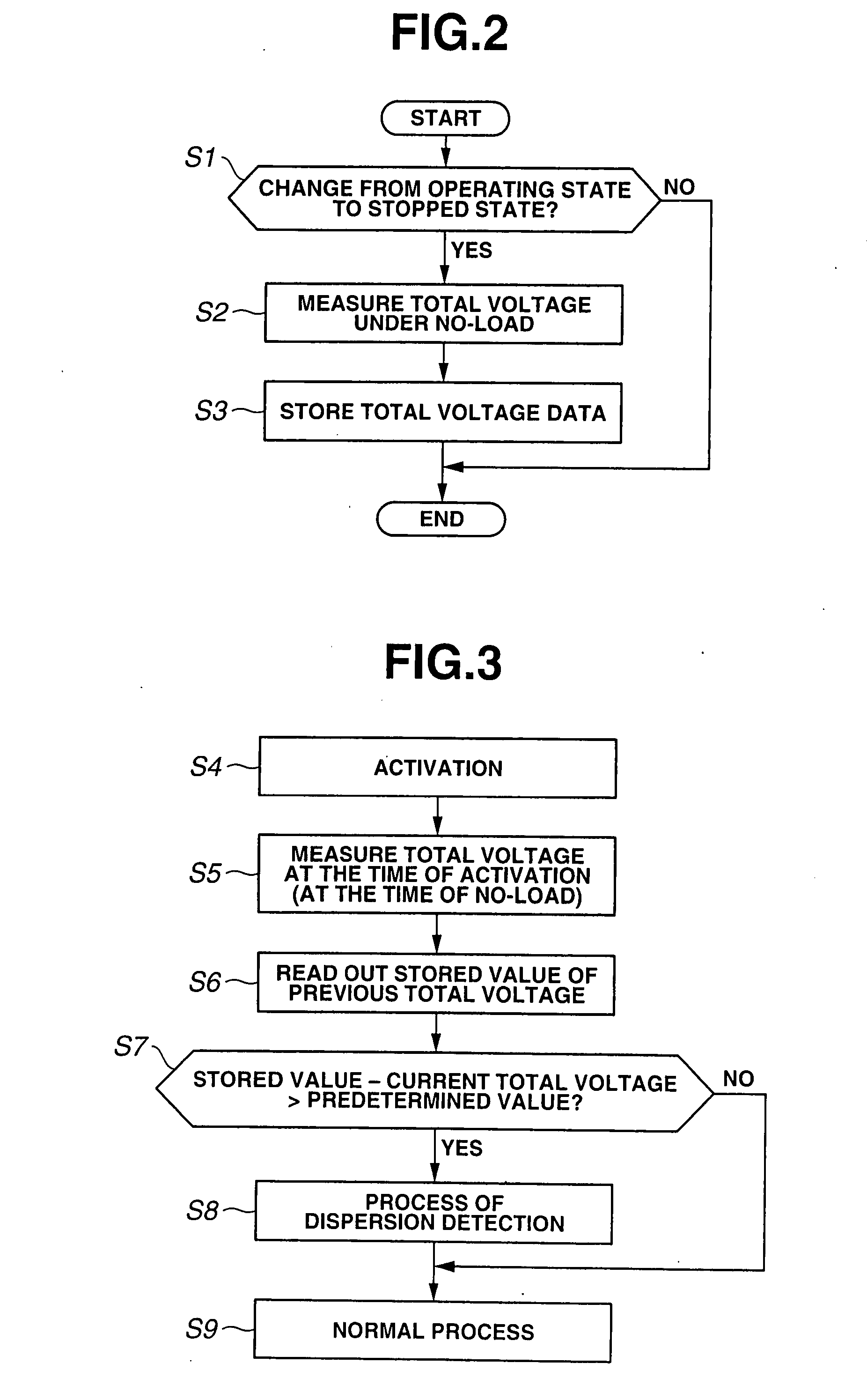

Remaining-capacity dispersion detecting apparatus and remaining-capacity control apparatus for battery pack

ActiveUS20080048617A1Batteries circuit arrangementsCurrent/voltage measurementTerminal voltageBias detection

A remaining-capacity dispersion detecting apparatus for a battery pack having a plurality of cells includes a total voltage sensing section adapted to sense a total voltage which is a terminal voltage of the whole of battery pack; a storing section adapted to store a value of the total voltage when the battery pack becomes under unloaded condition from loaded condition; and a dispersion detecting section. The dispersion detecting section is adapted to detect a value of the total voltage at a time of activation before the battery pack becomes under the loaded condition from the unloaded condition, to compare the currently-detected total voltage value with the total voltage value previously stored by the storing section, and to detect a dispersion in respective remaining capacities of the plurality of cells in the case where a difference between the currently-detected total voltage value and the previously-stored total voltage value is greater than or equal to a predetermined value.

Owner:NISSAN MOTOR CO LTD

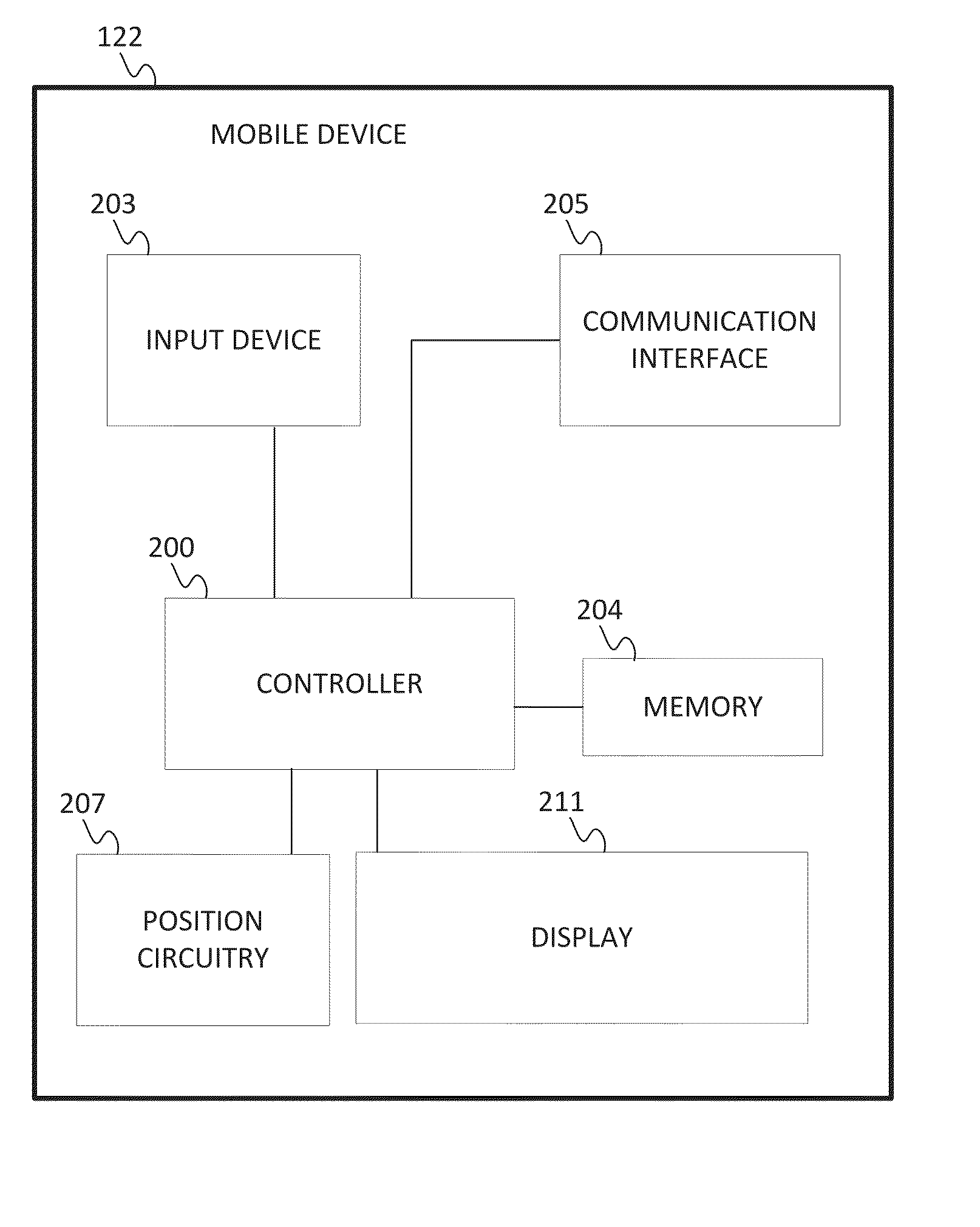

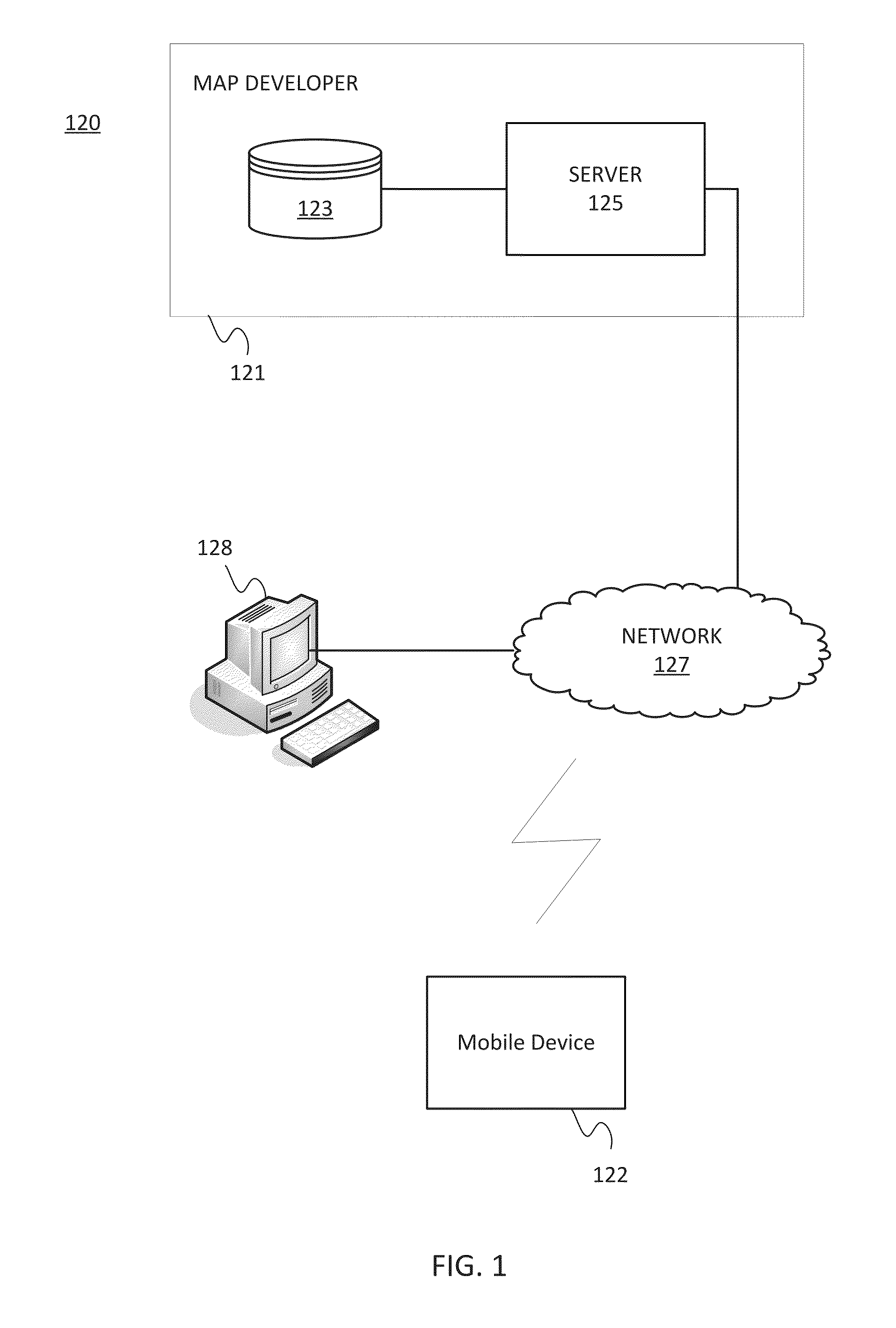

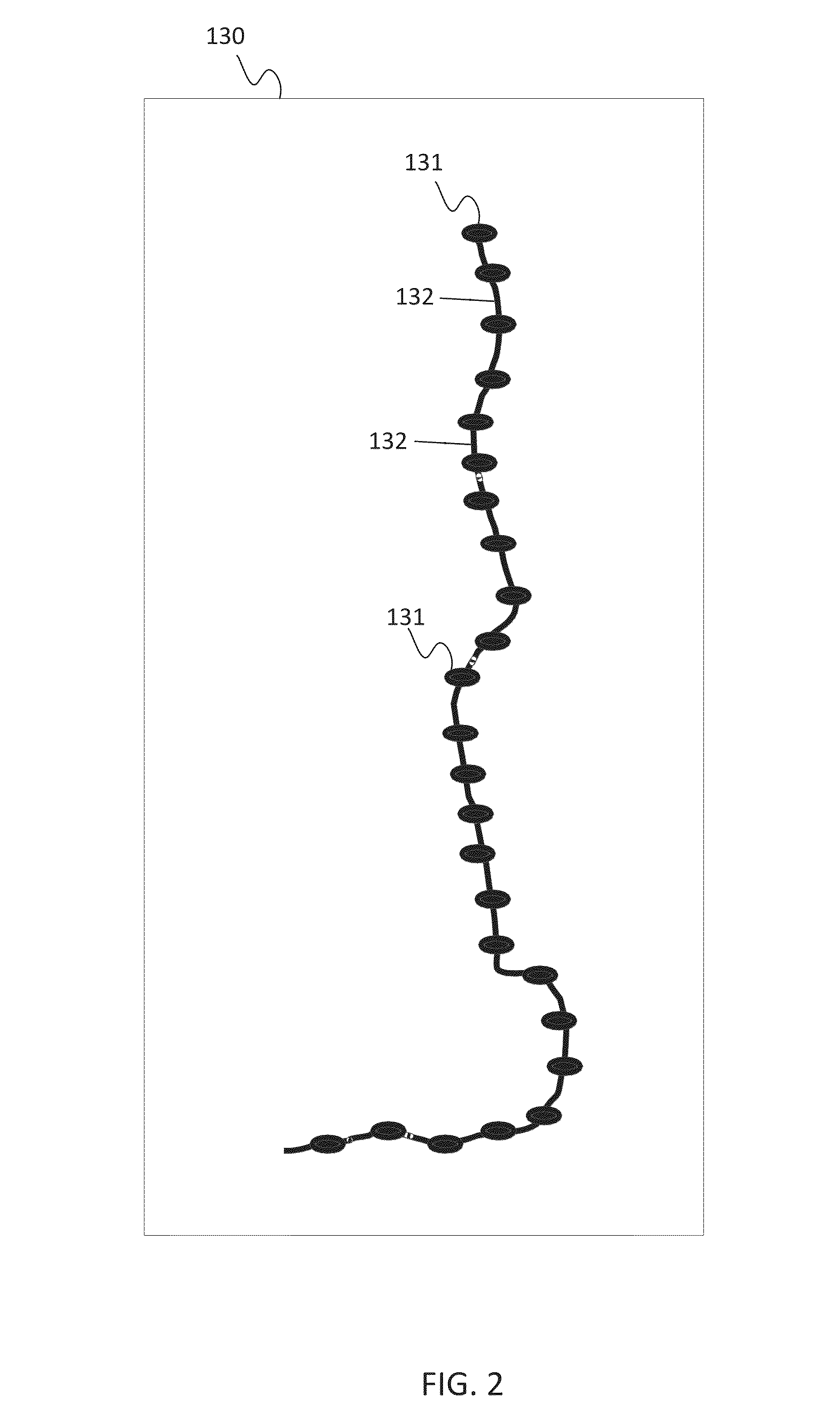

Deviation detection in mobile transit systems

ActiveUS20140200805A1Instruments for road network navigationNavigational calculation instrumentsTransit systemBias detection

In one embodiment, a mobile device or a network device is configured to identify when a transit vehicle deviates from a transit path. The mobile device is configured to perform a positioning technique to generate data indicative of the location of a mobile device. Based on the location of the mobile device, a path is identified. The path is associated with an estimated path width based on the classification of the path and / or the accuracy of the positioning technique. A target route is calculated using the estimated path width. As the transit vehicle travels, the target route is compared to the location of the mobile device. If the mobile device and or transit vehicle deviates from the target route, a message is generated. The message may indicate that the transit vehicle is being re-routed and / or recommends the computation of a new path.

Owner:HERE GLOBAL BV

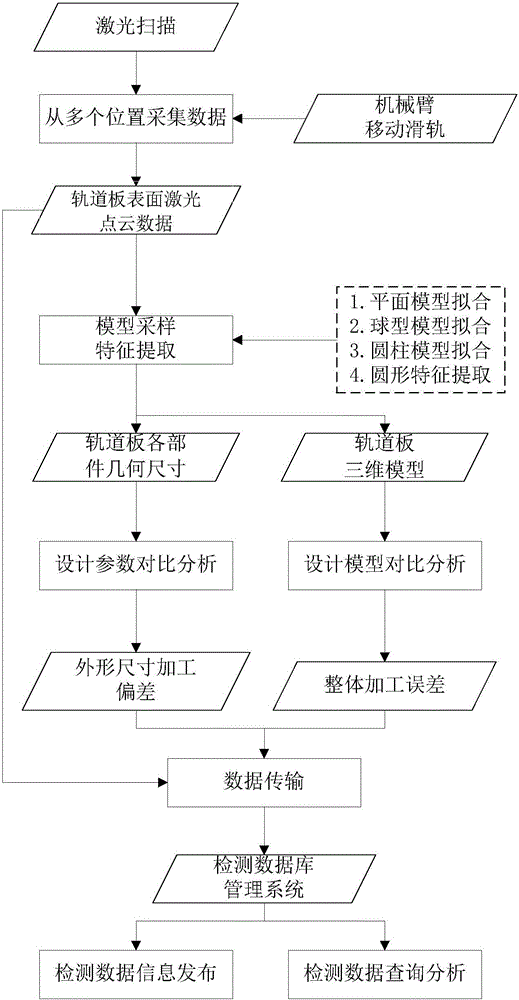

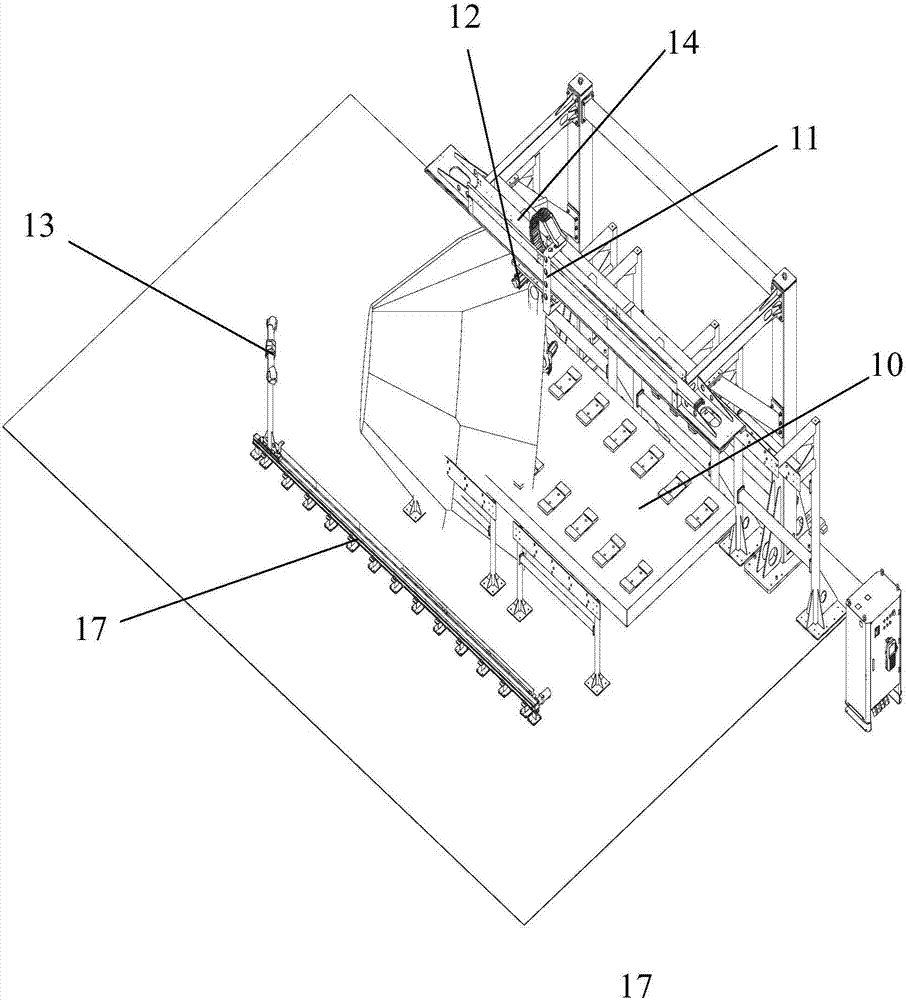

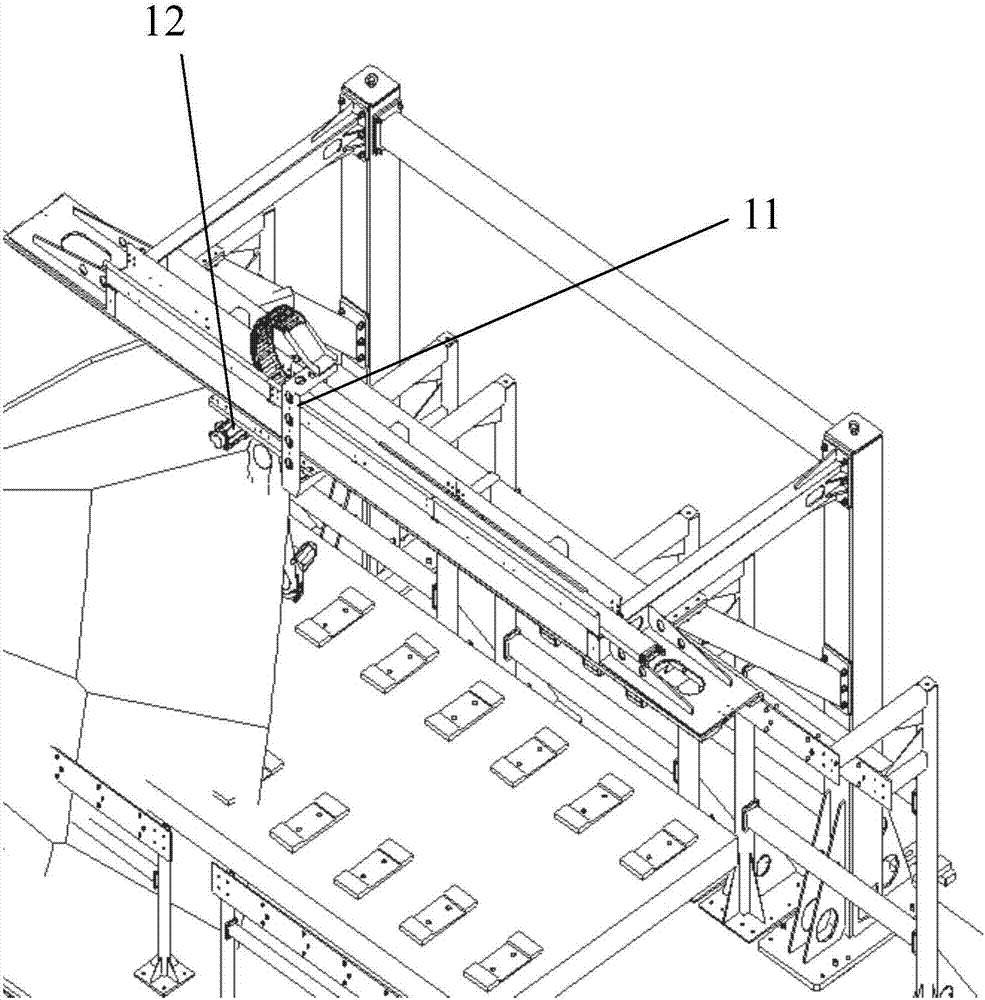

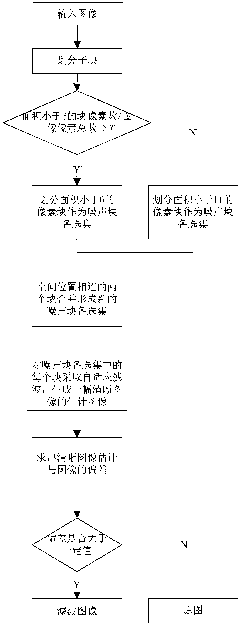

CRTS (Slab Ballastless Track) III type track slab machining deviation detection method and informatization method for detection results

ActiveCN106055820AAvoid randomnessReduce omissionsGeometric CADUsing optical meansInformatizationPoint cloud

The invention discloses a CRTS (Slab Ballastless Track) III type track slab machining deviation detection method. The method comprises the following steps: scanning a track slab by a laser scanning system of a mechanical arm and / or a mechanical slide track, correcting acquired data into track slab surface laser point cloud data of a unified coordinate system; automatically extracting component models of the track slab from the laser point cloud data, and acquiring geometrical sizes of components of the track slab; comparing the acquired geometrical sizes of the components of the track slab with design parameters of the track slab, and calculating an overall dimension machining deviation of the track slab; and comparing the track slab surface laser point cloud data with a three-dimensional design model of the track slab to obtain an overall machining deviation of the track slab, managing track slab detection data in a database way, and uploading original detection data and result data to a remote server in real time to realize informatization management of track slab detection results through a network release system. The method has the advantages of high detection efficiency, low personnel investment and no need of detection tools.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

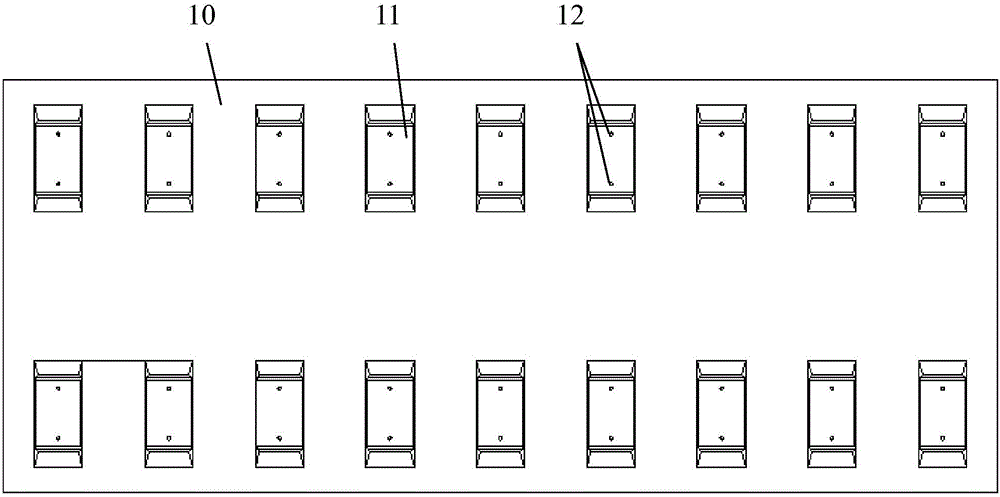

Quick and intelligent detection system and method for dimensions of rail transit infrastructure

The invention discloses a quick and intelligent acquisition system for dimensions of rail transit infrastructures. The system is composed of a laser range finder, an infrastructure type identification device and a laser point cloud collection system. The laser range finder tracks and measures distance information of infrastructures in real time. The infrastructure type identification device is used for obtaining design parameter information of the infrastructures. And the laser point cloud collection system consists of an industrial robot, a laser scanner and an optical tracker; the industrial robot drives the laser scanner to dynamically obtain laser point cloud data of the surfaces of the infrastructures; and the optical tracker tracks the laser scanner and provides real-time spatial position and attitude information for the laser scanner. In addition, the invention also discloses a dimension offset detection system and detection method of rail transit infrastructures. According to the detection method, no detecting person intervention is needed; and automatic, intelligent and informationized detection of large infrastructures like a ballastless track slab can be realized. Compared with the prior art, the provided detection method enables the efficiency to be improved by over five times and the detection precision to be improved by one magnitude order.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

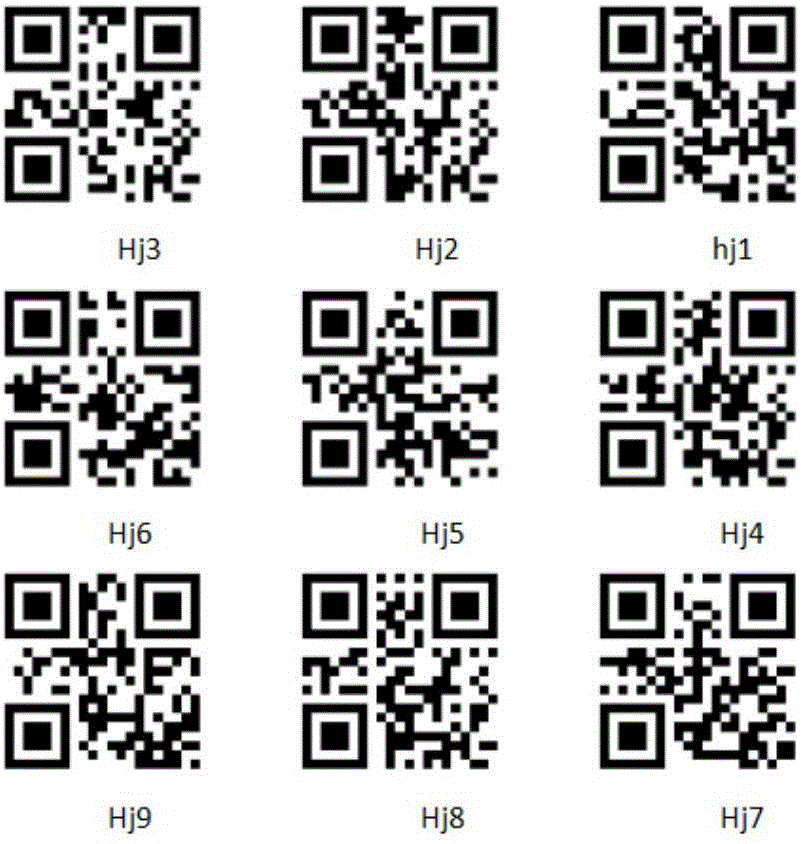

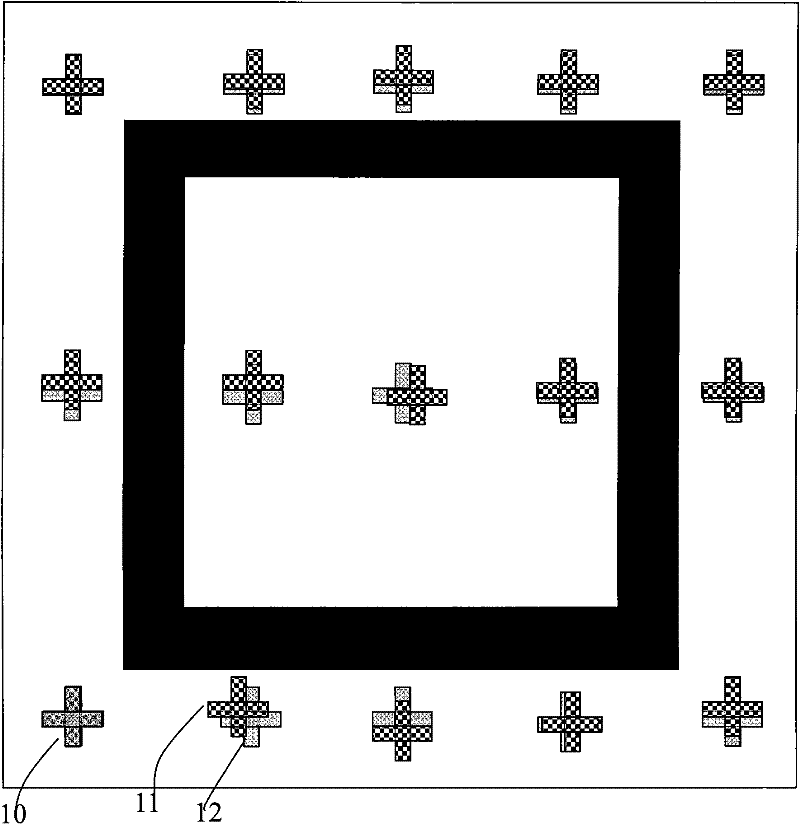

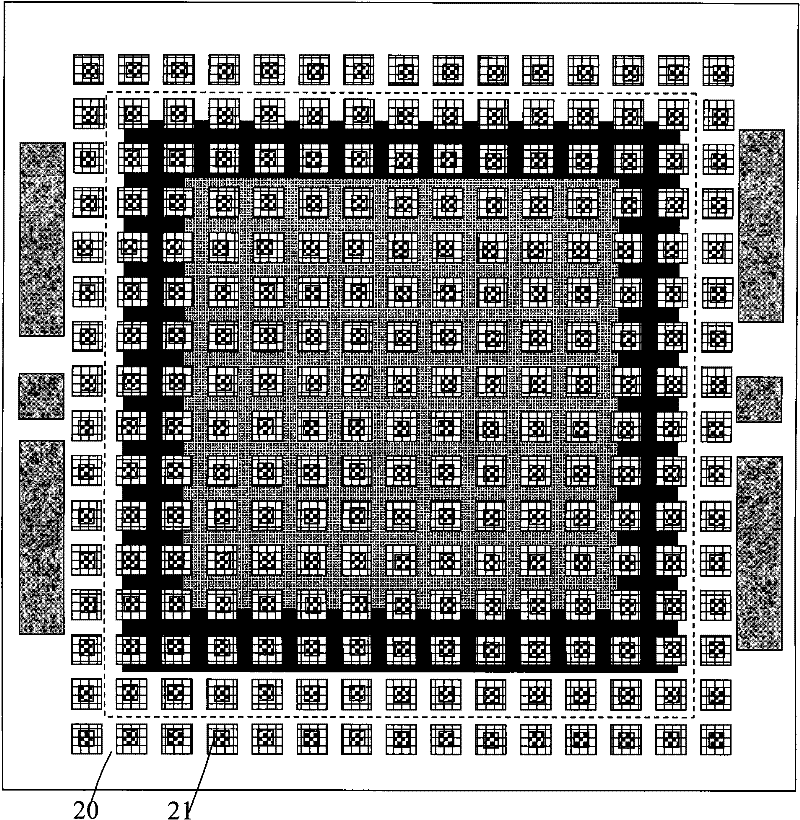

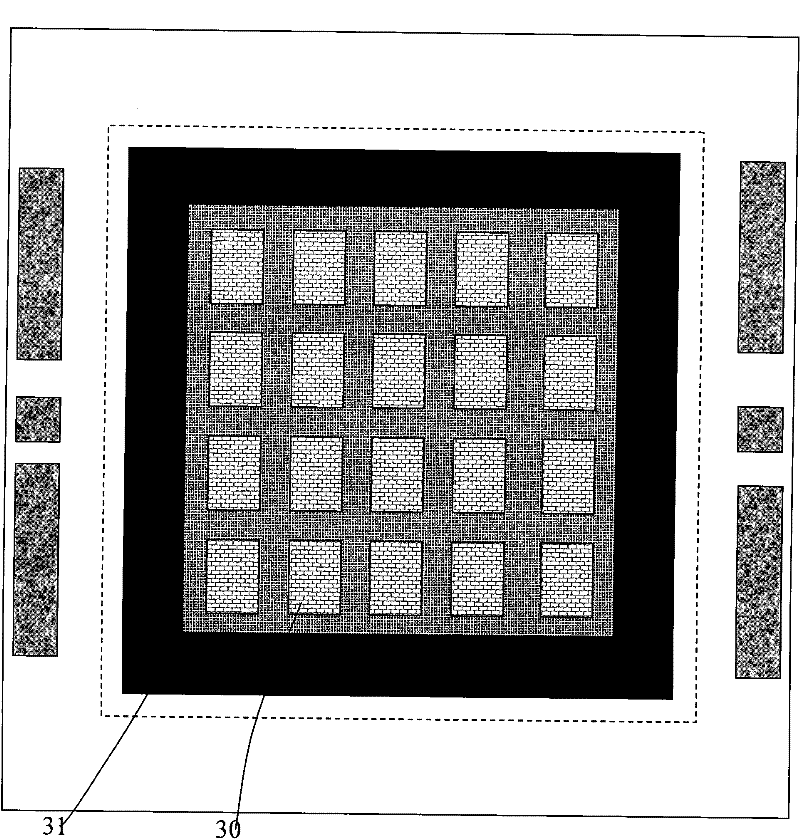

Shelf posture deviation detecting method and system based on characteristic information graph

The invention provides a shelf posture deviation detecting method and system based on characteristic information graph. The method comprises the following steps: 1) installing an upward viewing camera on a robot; 2) marking the mapping relationship between the camera pixel coordinate system and the robot coordinate system; 3) configuring a graph with characteristic information at the bottom of the shelf; measuring the coordinates of the graph characteristic points in the shelf coordinate system; 4) when the shelf is lifted by the robot, scanning the graph by the upward viewing camera to obtain the pixel coordinates of the graph characteristic points; 5) through the mapping relationship in step two, calculating and obtaining the coordinates of the pixel coordinates of the graph characteristic points mapped in the robot coordinate system; and 6) calculating the posture deviation of the shelf relative to the robot. The invention detects the posture deviation of a shelf through a camera. The entire implementation process of the invention is convenient and rapid. As the price of the camera is low and it is not necessary to make modifications to a large number of shelves, the cost is therefore reduced.

Owner:ZHEJIANG GUOZI ROBOT TECH

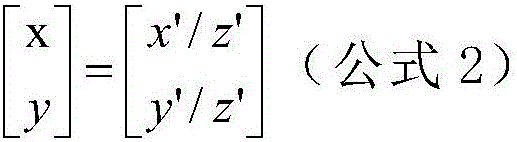

Detection of interferers using divergence of signal quality estimates

InactiveUS20090180521A1Polarisation/directional diversityTransmission path divisionCommunications systemSignal quality

A method, system, and computer-readable medium for detecting an interferer in a wireless communication system are provided. The method includes receiving a signal having P tones, each of the P tones being associated with a frequency, determining a first signal quality of each of the P tones, determining a second signal quality of each of the P tones, and detecting the interferer that occupies the same frequency as one of the P tones based on the respective first signal quality and the respective second signal quality. The first signal quality and second signal quality behave differently when the interferer is present. The detecting the interferer includes determining a discrepancy in the behavior of the first signal quality and the second signal quality.

Owner:QUALCOMM INC +1

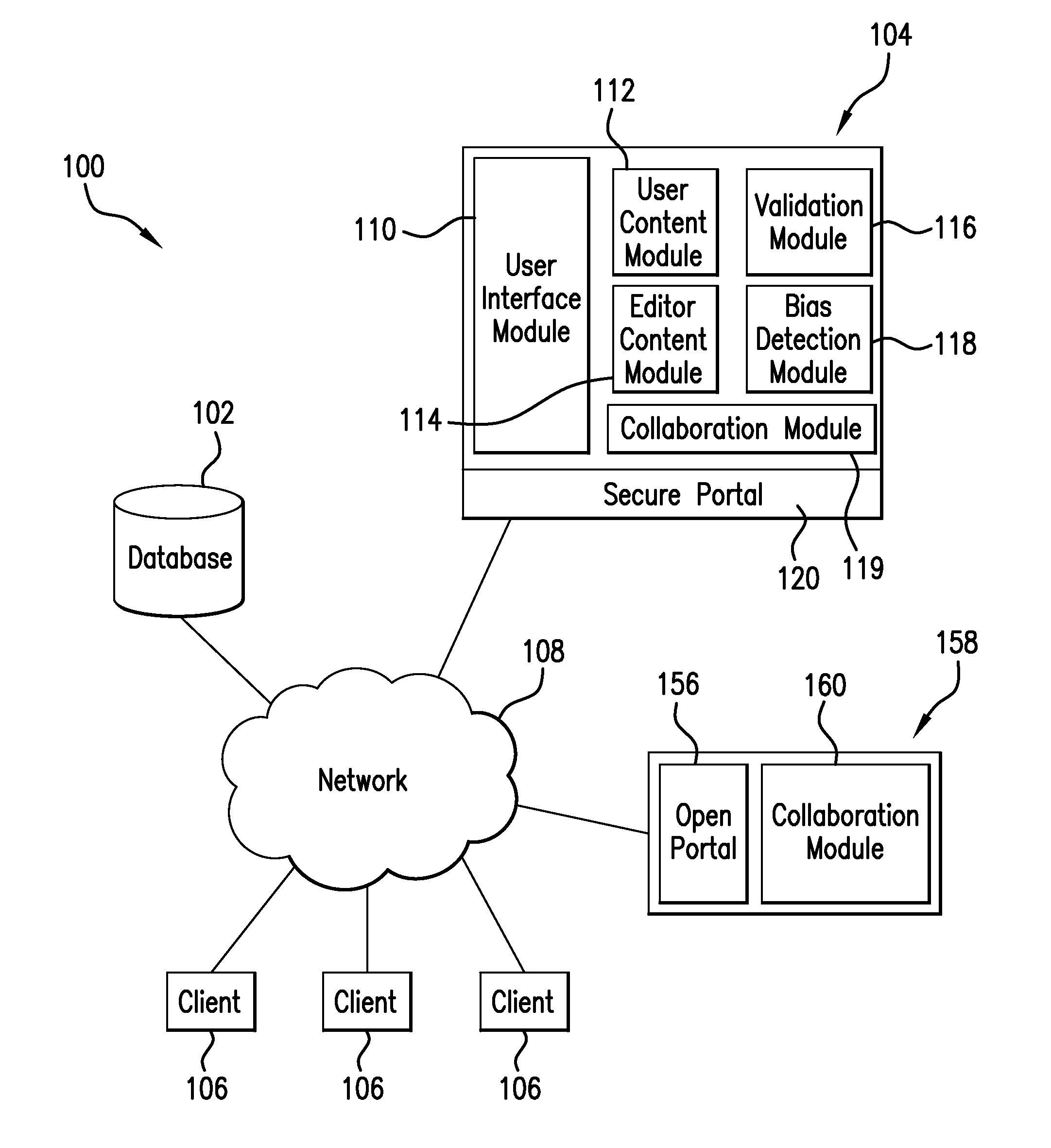

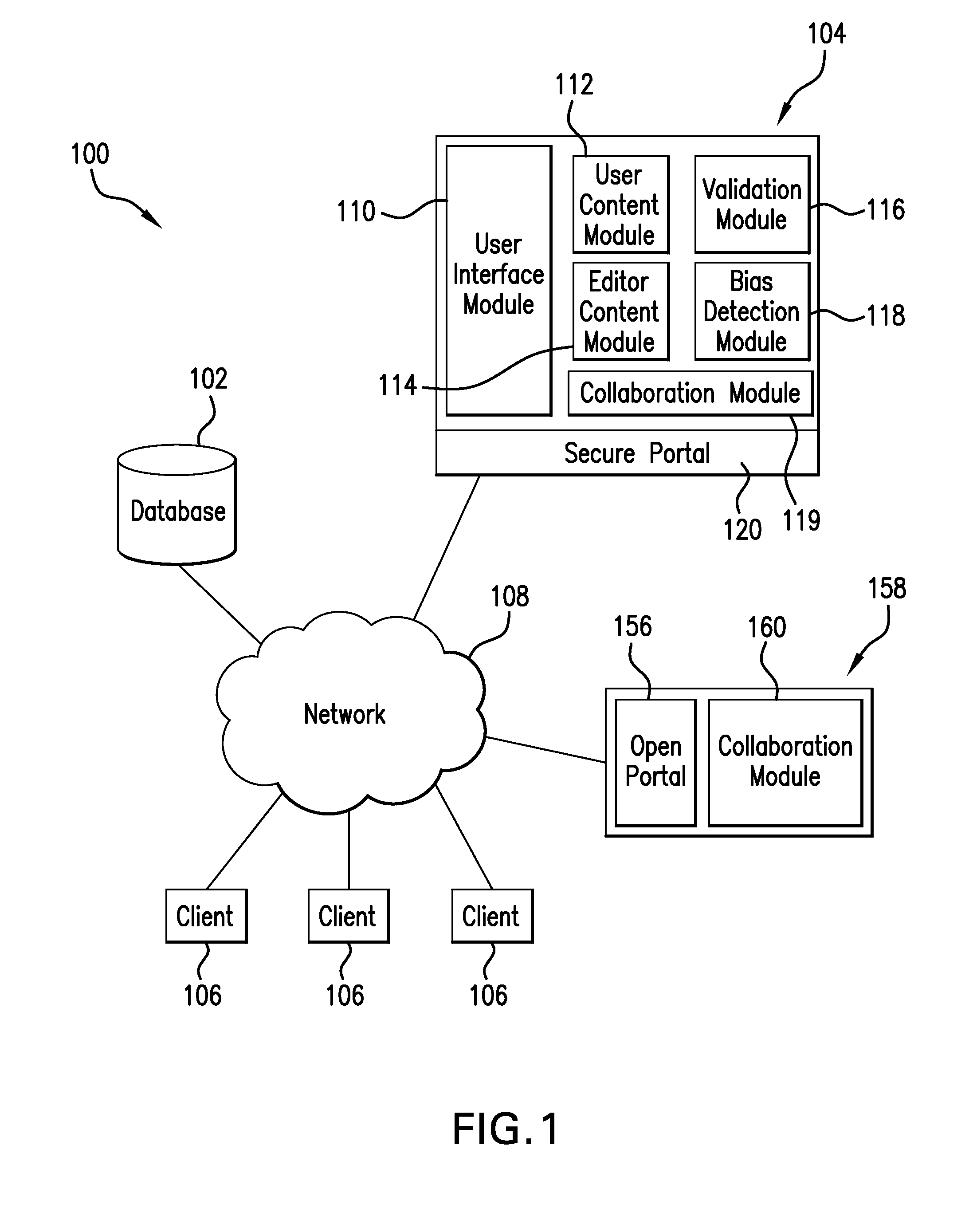

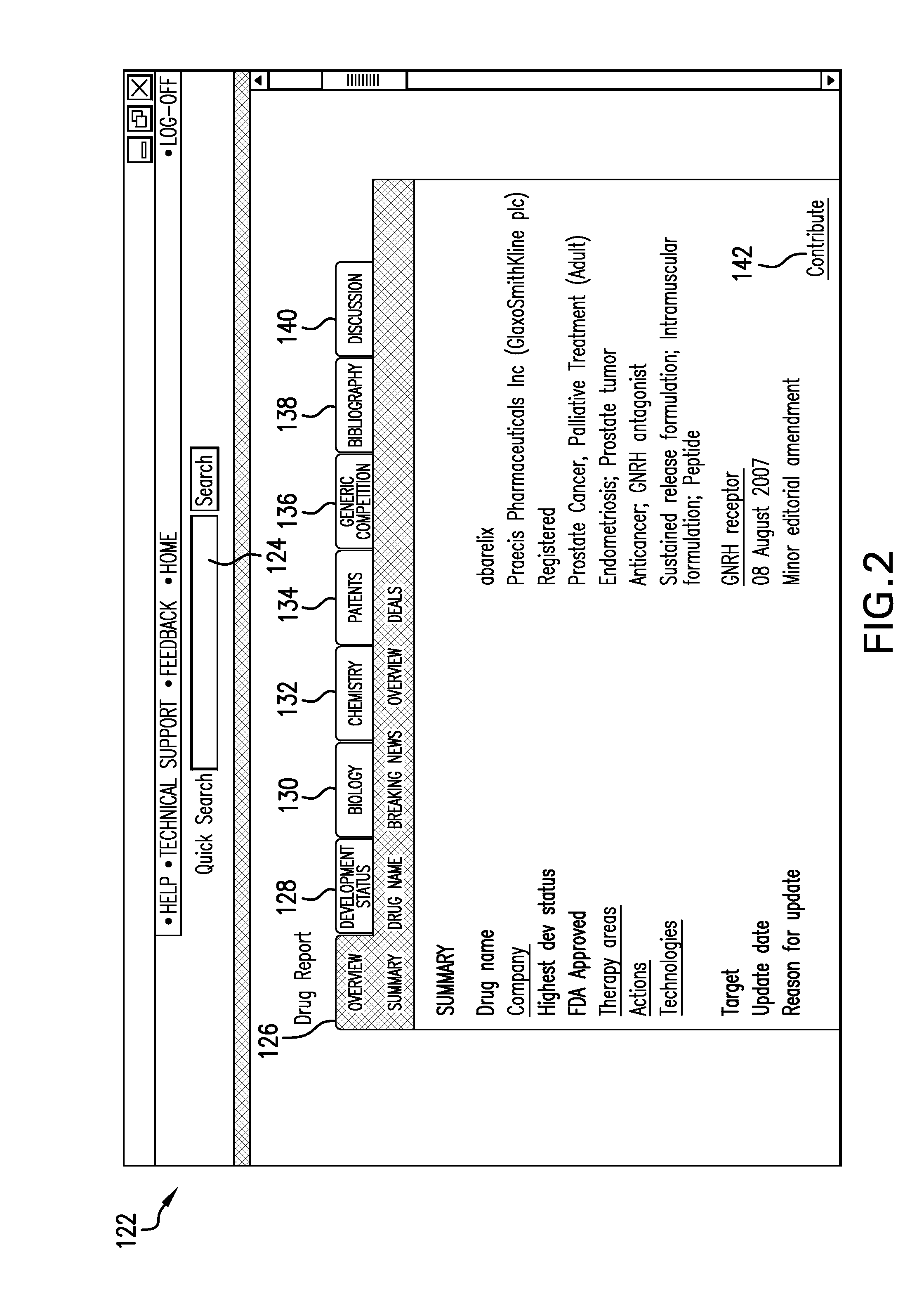

Systems and methods for integrating user-generated content with proprietary content in a database

InactiveUS20090281978A1Verify accuracyOffice automationFuzzy logic based systemsUser inputUser-generated content

A system for managing and displaying collaborative content in a database. The database is configured to store both editor-generated content and user-generated content. The system also includes a server interfacing with the database, a display device connected to the server, a editor content module interfacing with the database and configured to display the editor-generated content on the display device, a user interface module running on the sever, a user content module configured to receive the user input from the user interface module and display the user input as user-generated content on the display device, a validation module interfacing with the user content module, wherein the validation module is configured to verify the accuracy of the user-generated content, and a bias detection module interfacing with the user content module, wherein the bias detection module is configured to detect bias in the user-generated content.

Owner:CAMELOT UK BIDCO LTD

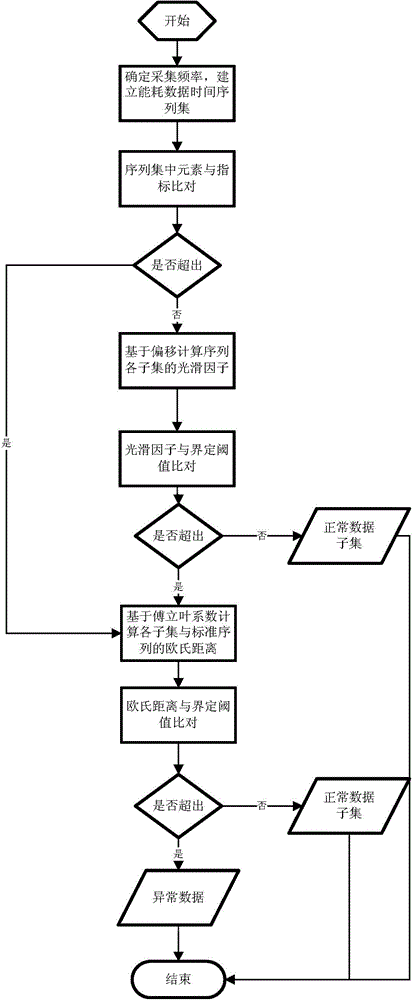

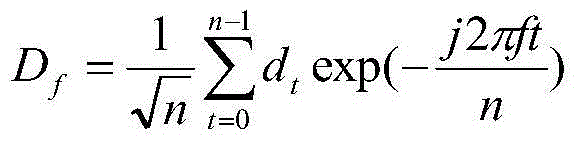

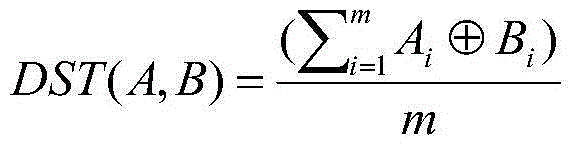

Detection method for building abnormal energy consumption data

ActiveCN104636999APrecise screeningEffective judgmentData processing applicationsEnergy efficient computingBuilding energyOriginal data

The invention discloses a detection method for building abnormal energy consumption data. The detection method comprises the following steps of firstly collating original data according to a time series; then, performing judgment by referring to industry indexes so as to find out abnormal data in a specific time slot; then, filtering out an abnormal value in the abnormal energy consumption data by adopting the deviation detection technology in data mining; finally, finding out an abnormal point in the data by adopting a discrete Fourier transform-based time series. The method for performing accurate positioning on the abnormal data in building energy consumption data, provided by the invention, is capable of replacing an empirical threshold judging method generally used in current energy industry; by means of an artificial intelligent analysis method in data mining and the application of the discrete Fourier transform principle, the abnormal energy consumption data is prevented from being misjudged, misreported and omitted, and effective abnormal energy consumption monitoring information is provided for energy consumption departments and personnel.

Owner:江苏联宏智慧能源股份有限公司

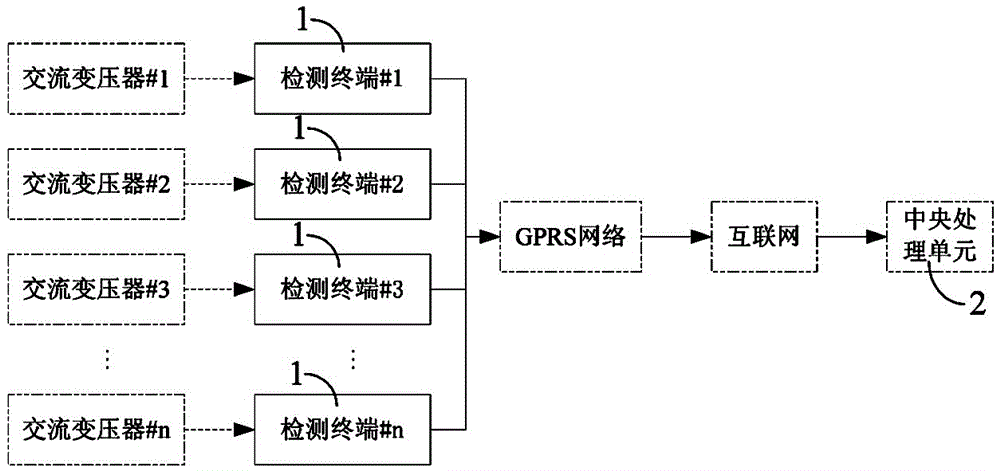

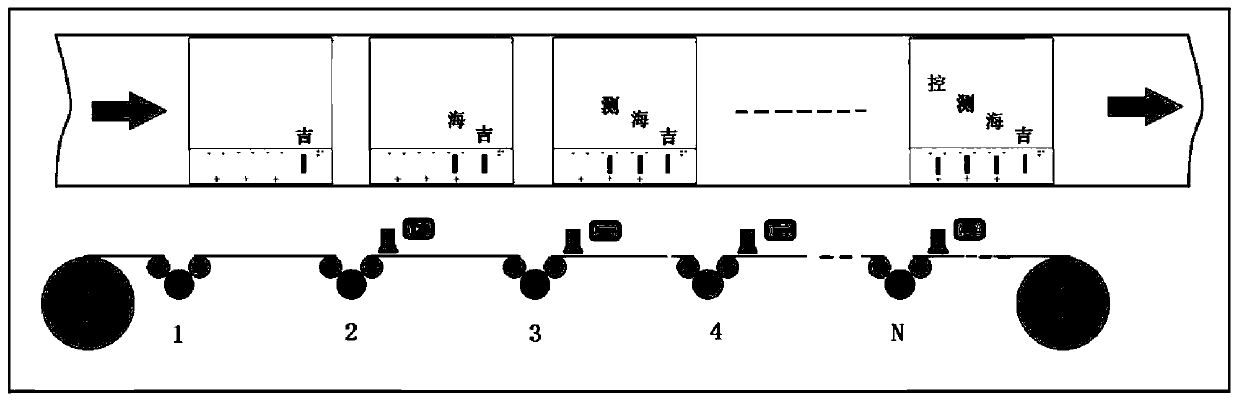

A distributed converter transformer direct current bias detection system and a detection method thereof

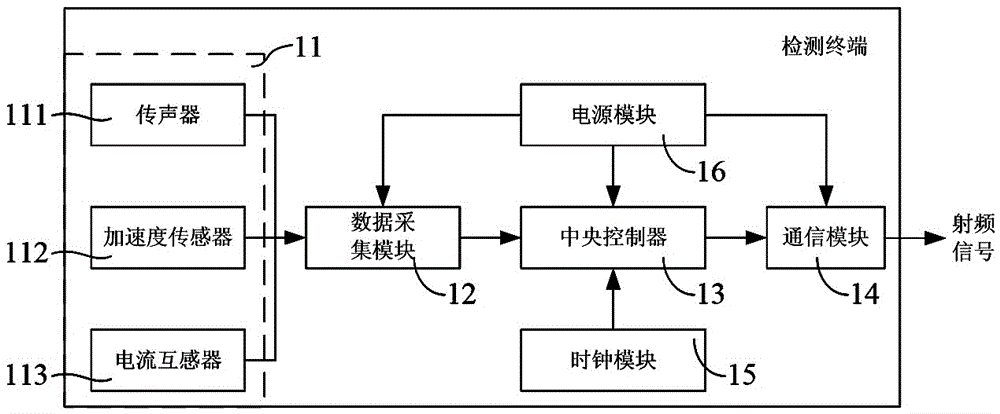

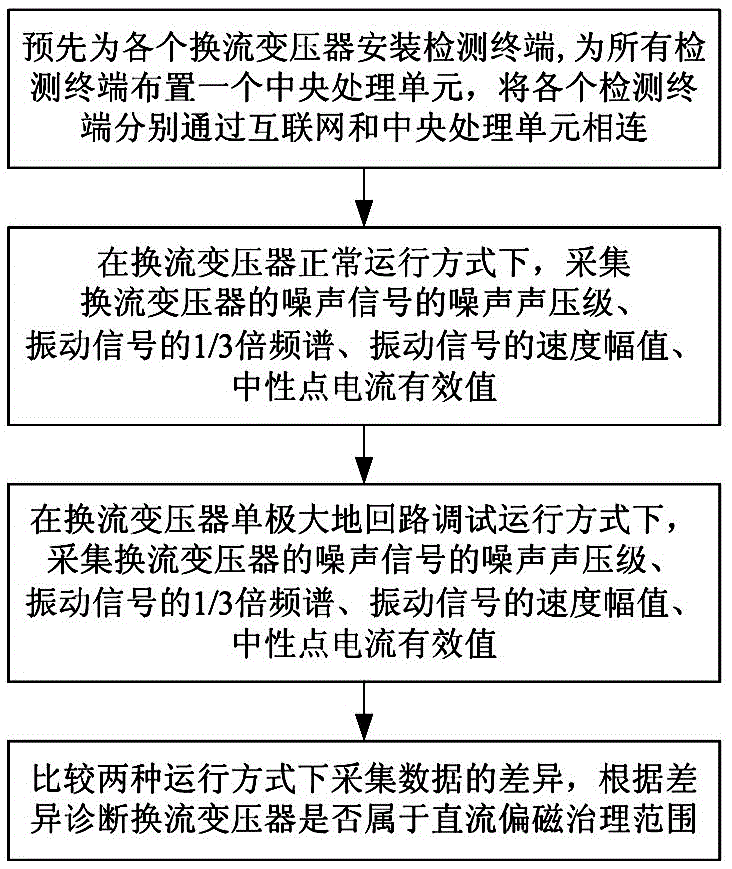

ActiveCN105467241AOvercome a wide range of distributionFlexible detection methodElectrical testingFrequency spectrumData acquisition

The invention discloses a distributed converter transformer direct current bias detection system and a detection method thereof. The detection system comprises a plurality of detection terminals. Each detection terminal comprises a sensor module, a data acquisition module, a central controller, a communication module, a clock module and a power supply module; the sensor module comprises a microphone, an acceleration sensor and a current transformer. The method comprises the steps of installing a detection terminal in advance, separately acquiring a noise sound pressure level of noise signals, a 1 / 3 times frequency spectrum, a speed amplitude of vibration signals and a neutral point current effective value in two operation modes which are a normal operation mode of a converter transformer and a single-pole ground-loop debugging operation mode, comparing differences between acquired data in the two operation modes and diagnosing whether the converter transformer belongs to a direct current bias treatment scope according to the difference. The distributed converter transformer direct current bias detection system and the detection method thereof of the invention can overcome problems of a broad distribution scope and a large quantity of transformer stations, do not need excessive manpower and equipment resources, and have advantages of a flexible mode and relatively low cost.

Owner:STATE GRID CORP OF CHINA +2

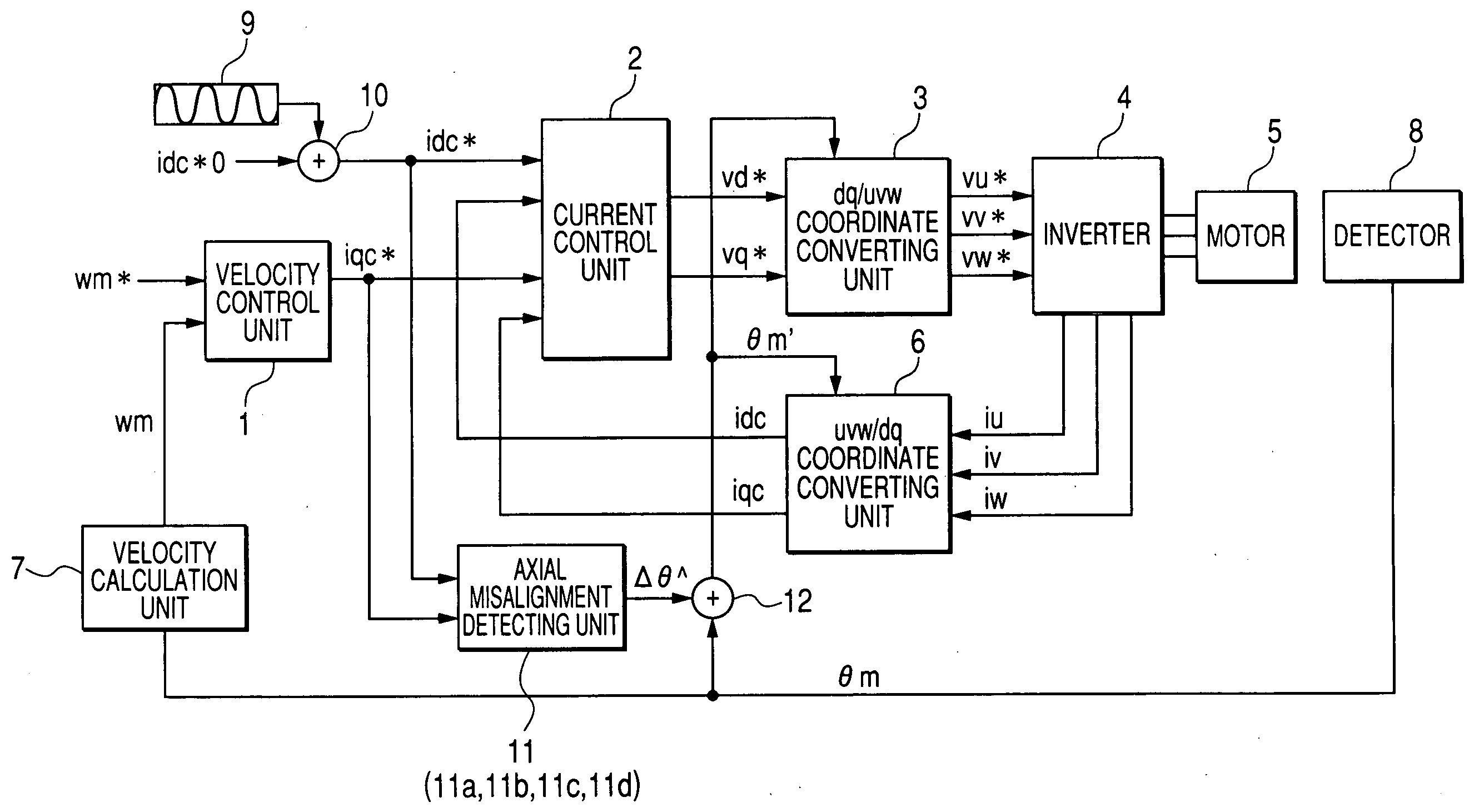

Motor control device

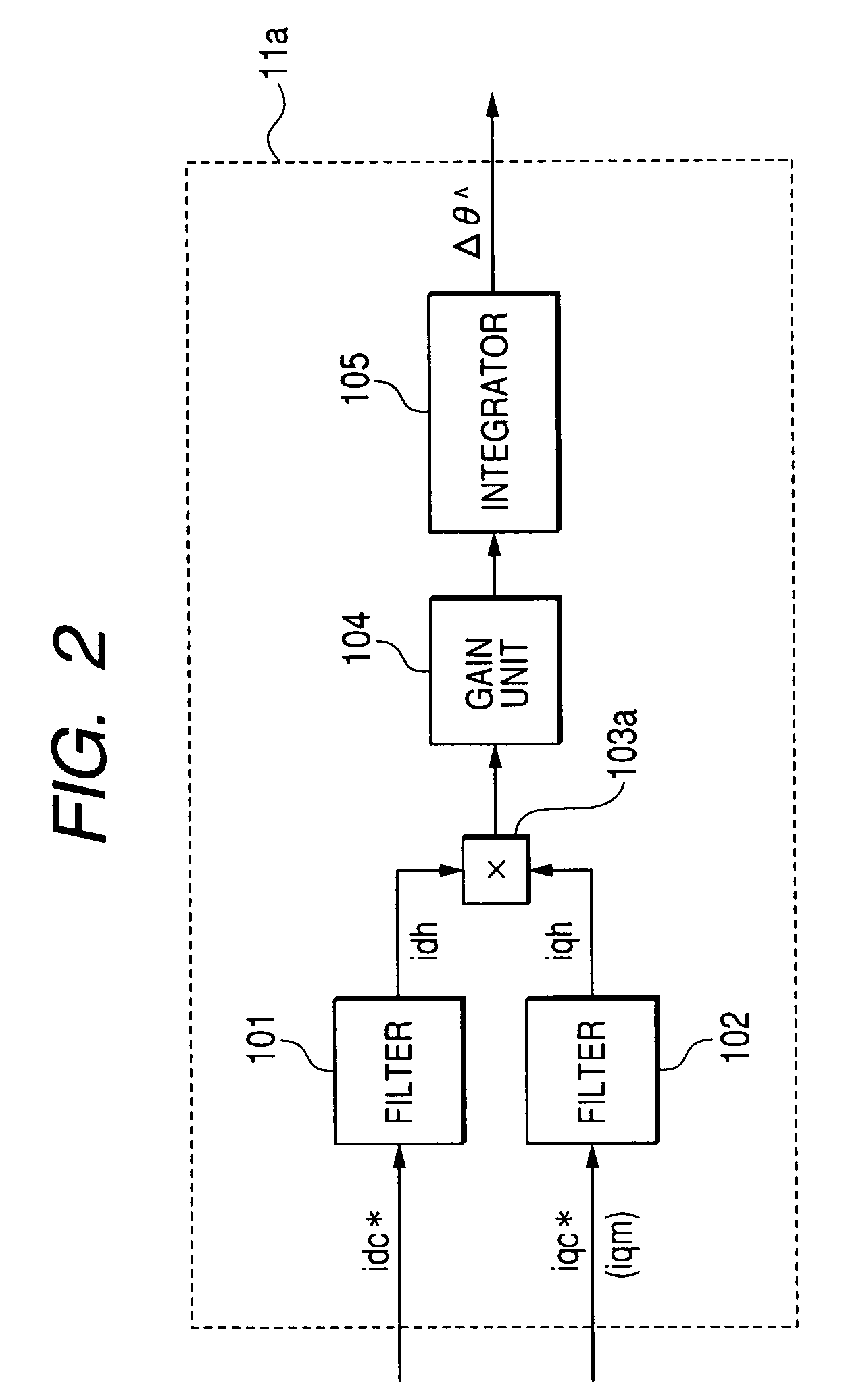

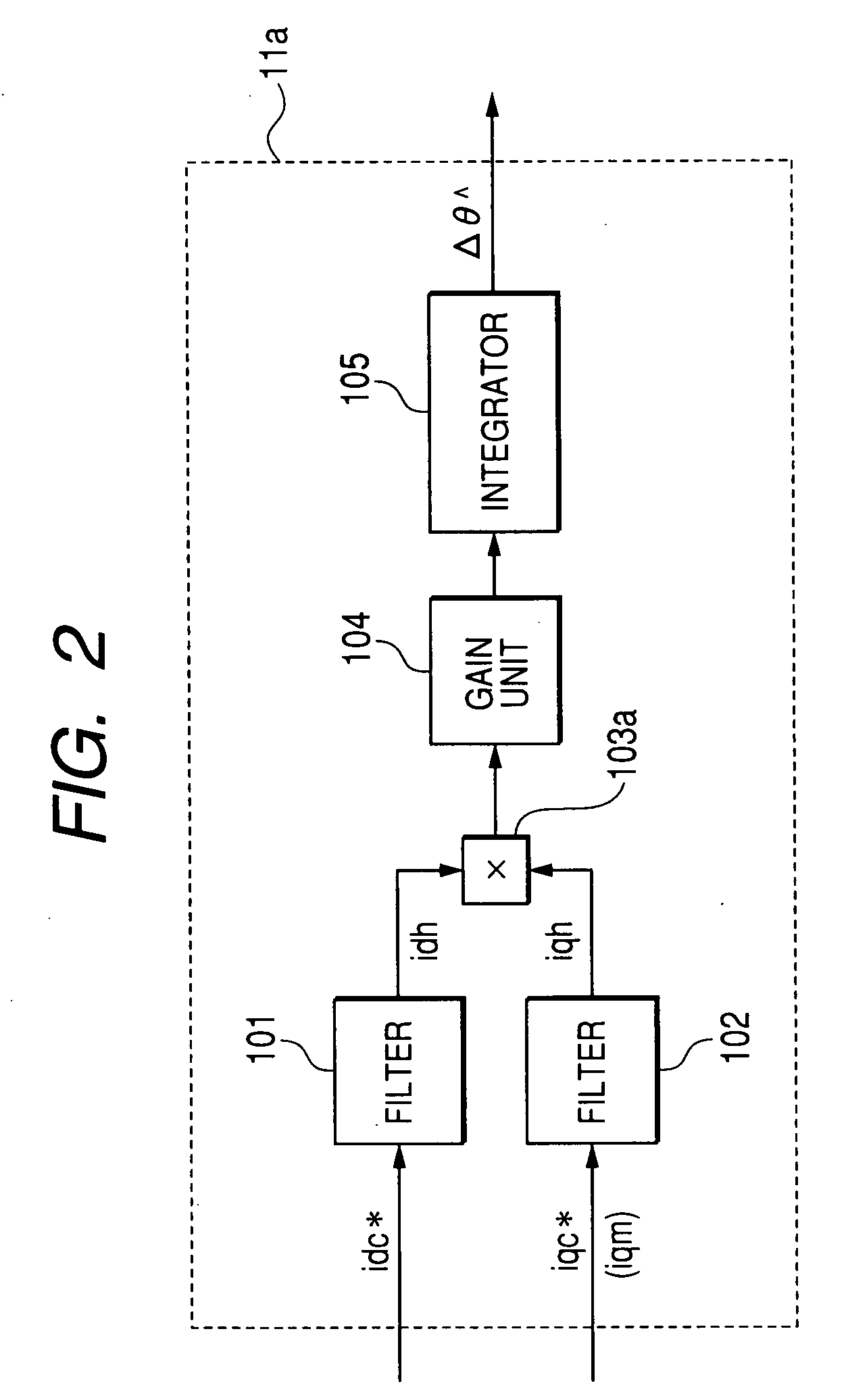

InactiveUS7511448B2Improve workabilitySynchronous motors startersVector control systemsElectric machineWave shape

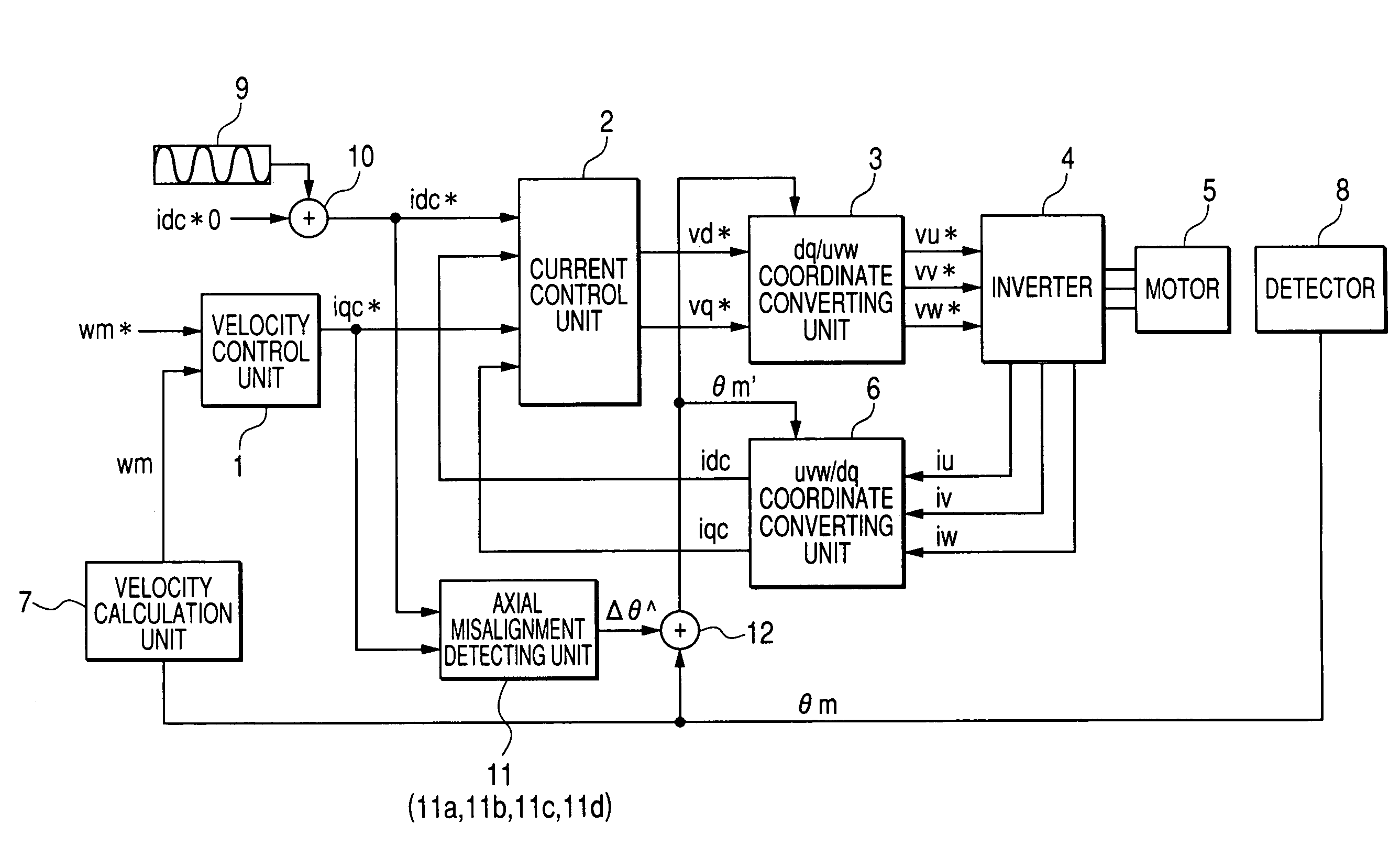

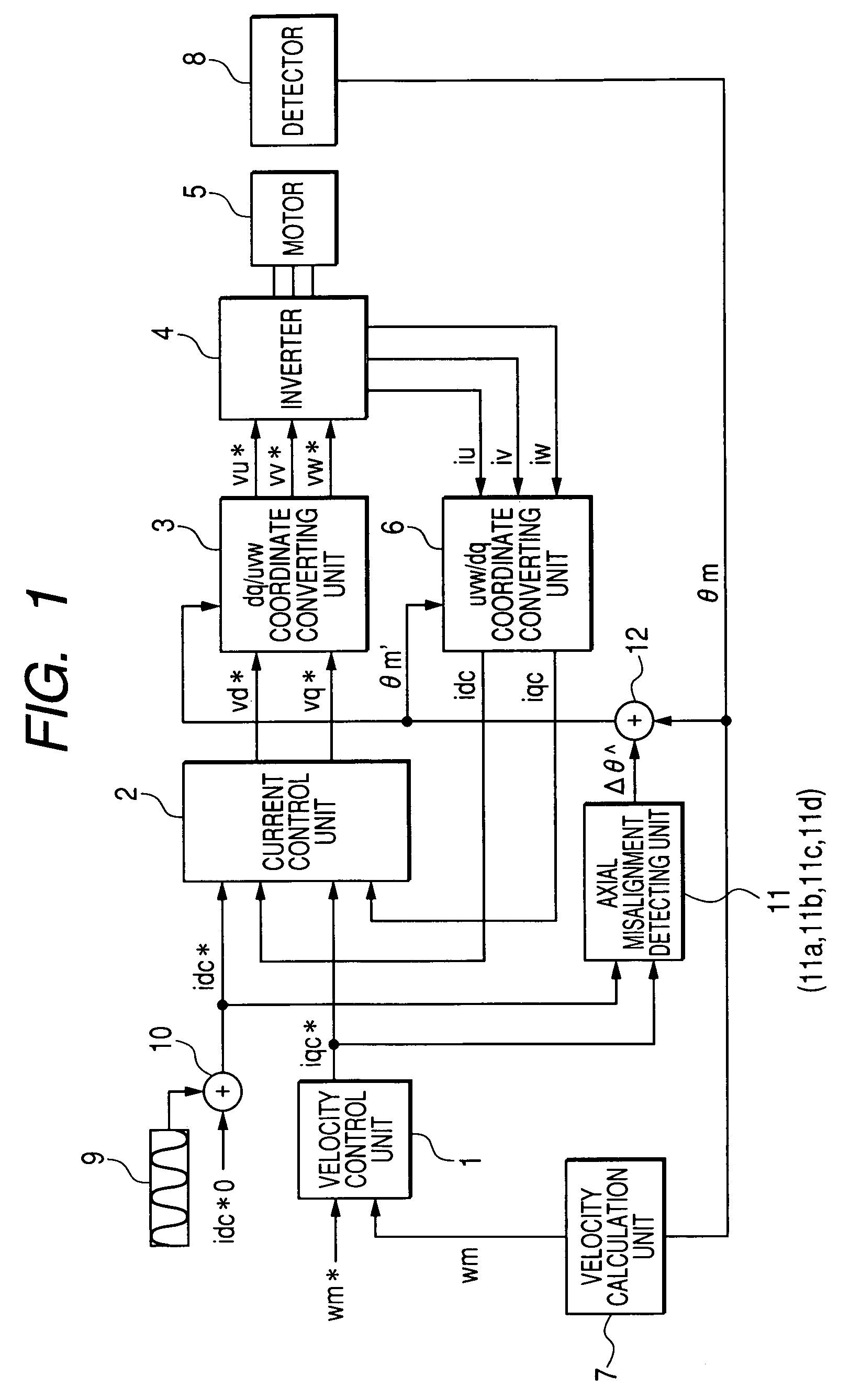

In a motor control device according to the invention, upon velocity control of a motor, a superimposed signal generating unit 9 outputs a superimposed signal idh of a repetitive waveform, such as a triangular wave or a sine wave. A d-axis current command generating unit 10 adds the superimposed signal idh generated by the superimposed signal generating unit 9d to a d-axis current command idc*0 and outputs a d-axis current command idc*. An axial misalignment detecting unit 11 (11a, 11b, 11c, and 11d) receives the d-axis current command idc* and a q-axis current command iqc* and outputs an axial misalignment angle estimation value Δθ^. An axial misalignment correction unit 12 receives the axial misalignment angle estimation value Δθ^ and an actual detected position θm and outputs a position after correction θm′. Therefore, detection and correction can be performed in real time through calculation at a given timing during a normal operation.

Owner:MITSUBISHI ELECTRIC CORP

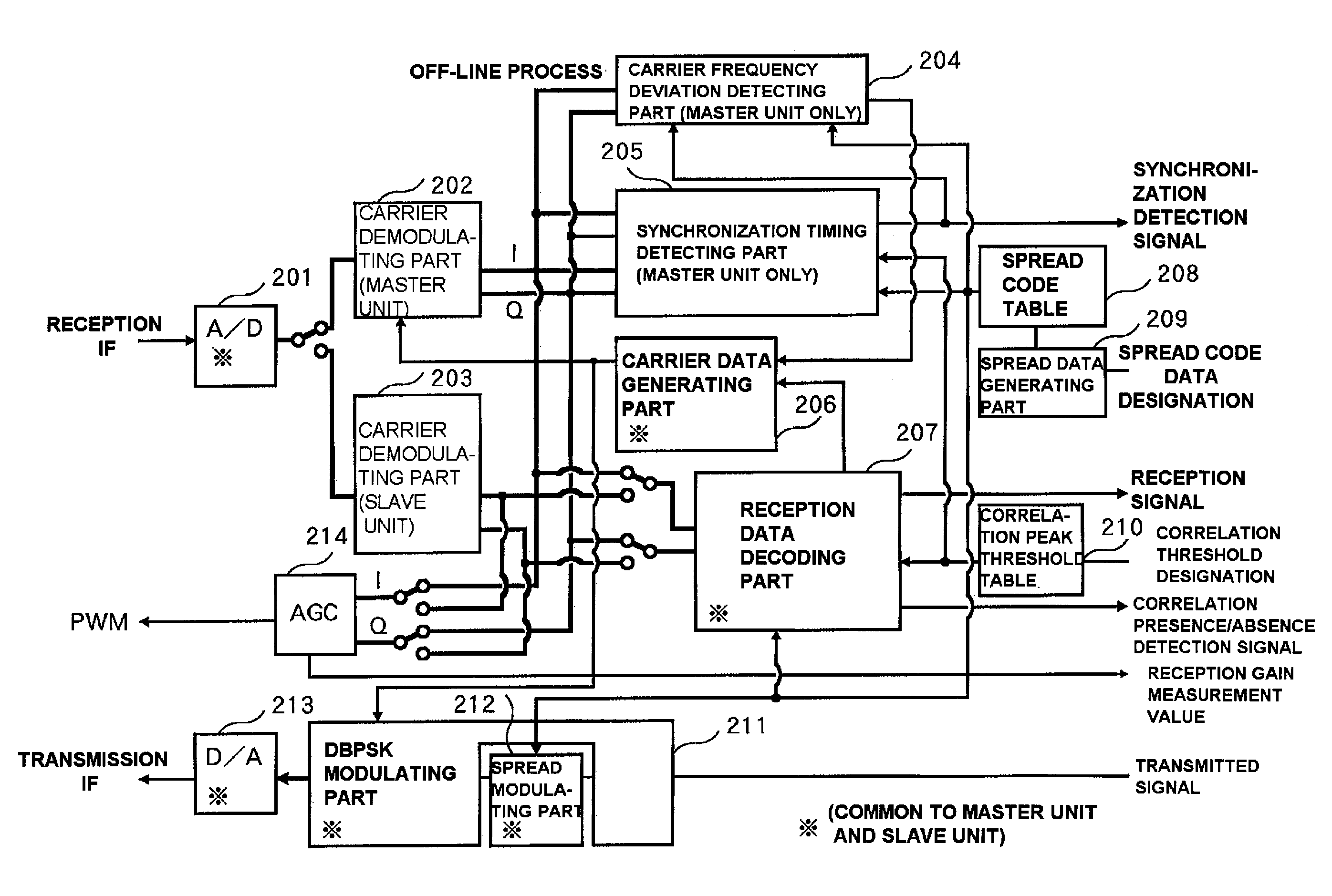

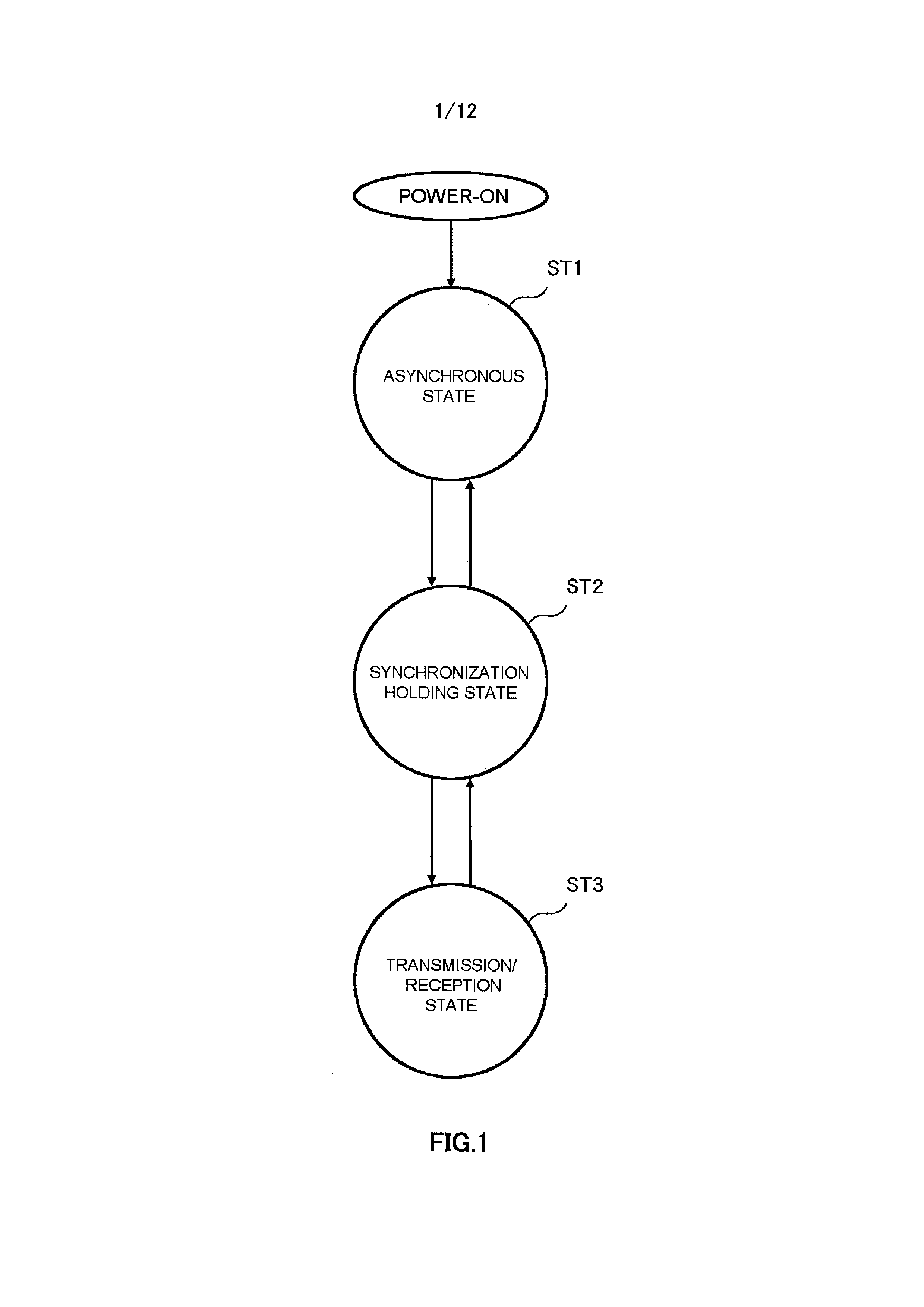

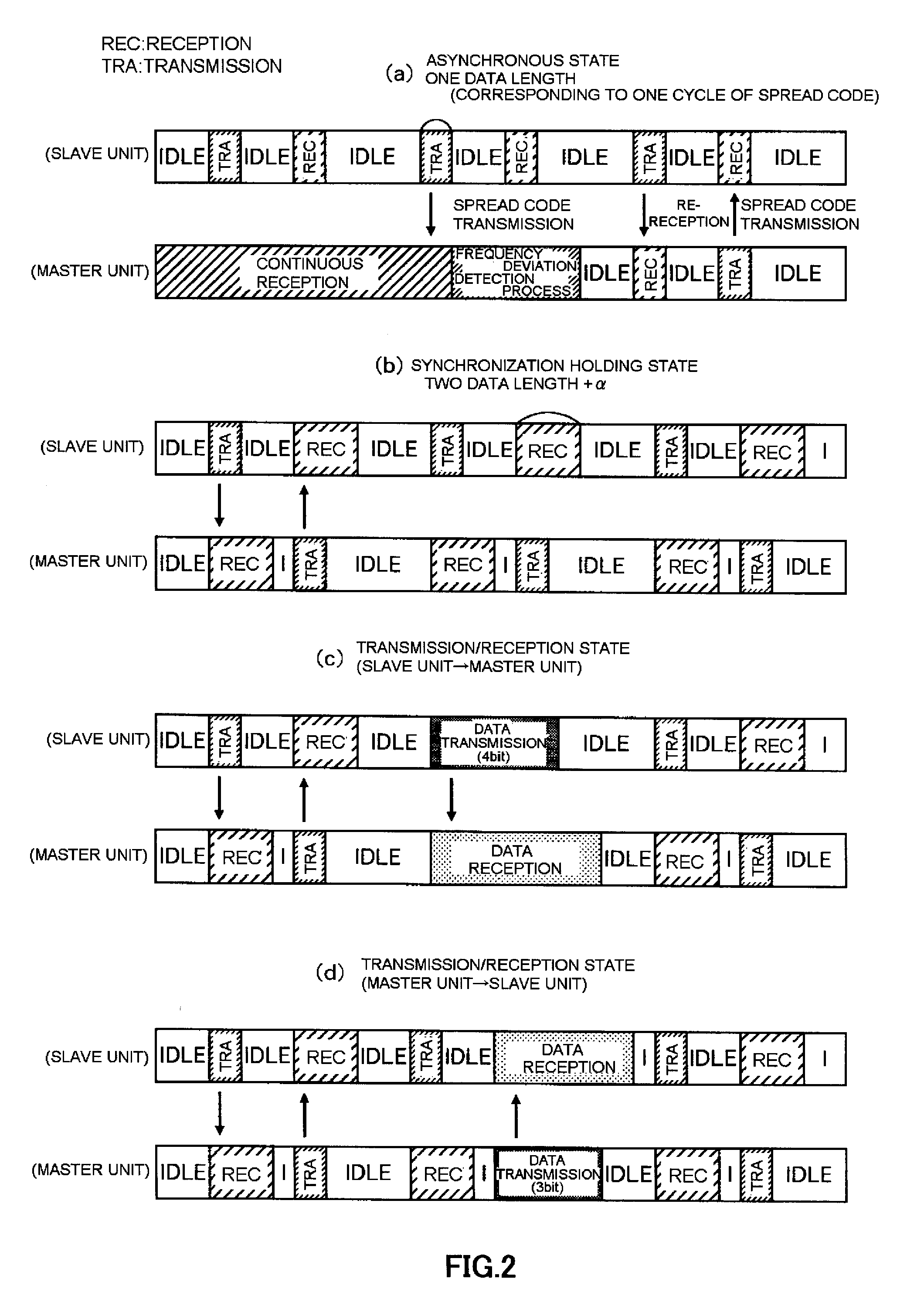

Spread spectrum communication method adn system using very weak power, and high frequency radio apparatus

InactiveUS20090207889A1Slow spreadSlow performanceAmplitude-modulated carrier systemsDiversity/multi-antenna systemsRadio equipmentCarrier signal

Provided is a high frequency radio apparatus capable of correcting a frequency of a carrier of the own apparatus in accordance with a frequency of a reception carrier when performing spread spectrum communication using very weak power. A carrier demodulating part demodulates a spread code received from a communication counterpart radio apparatus by using default carrier data, and sends the demodulated spread code to a synchronization timing detecting part. When the synchronization timing detecting part detects the spread code from the carrier demodulated data, a carrier frequency deviation detecting part performs a frequency analysis of the spread code to detect a deviation amount of the carrier frequency. A carrier data generating part generates corrected carrier data based on the detected deviation amount. A DBPSK modulating part uses the corrected carrier data to perform data transmission to the communication counterpart radio apparatus.

Owner:NIHON DEMPA KOGYO CO LTD

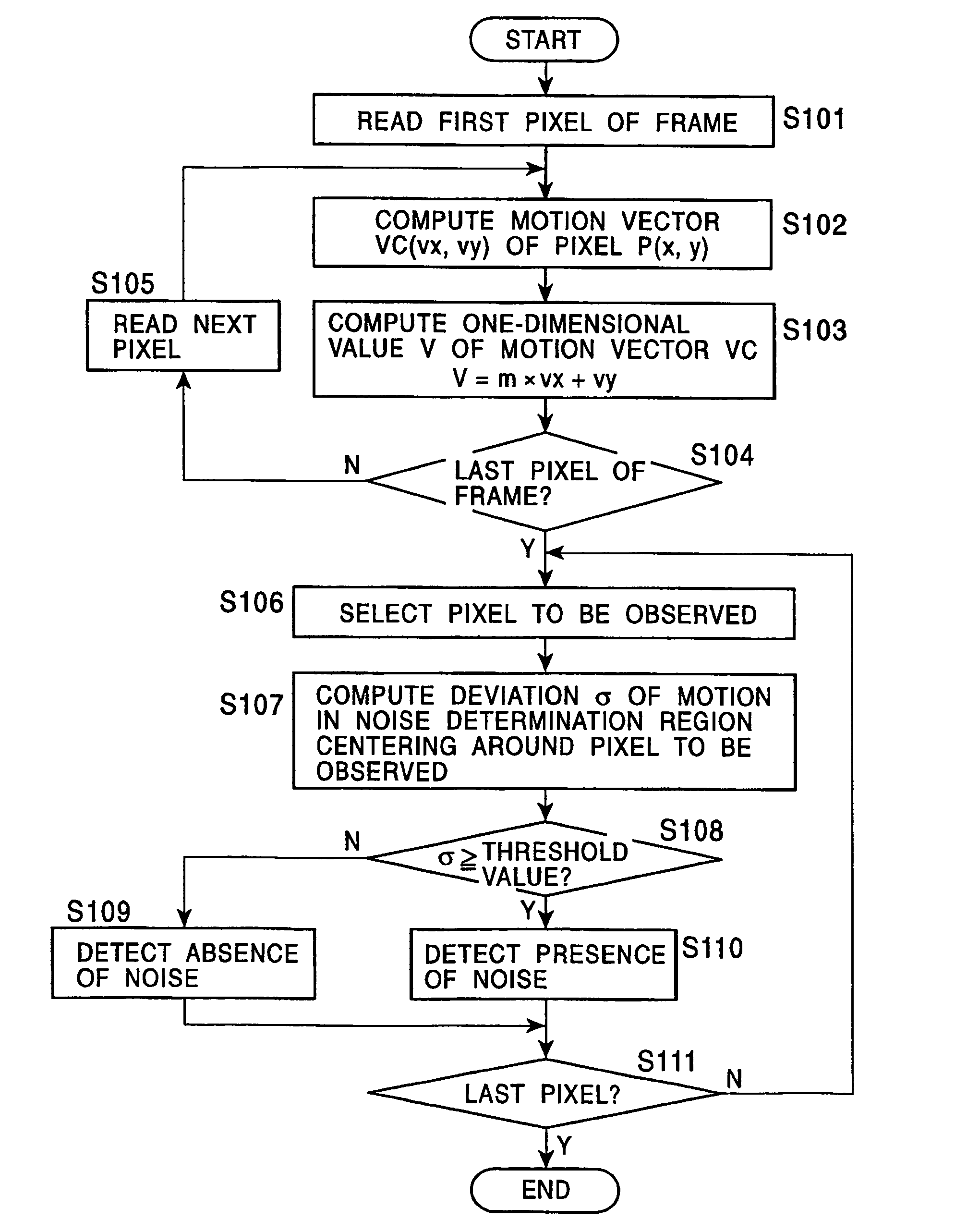

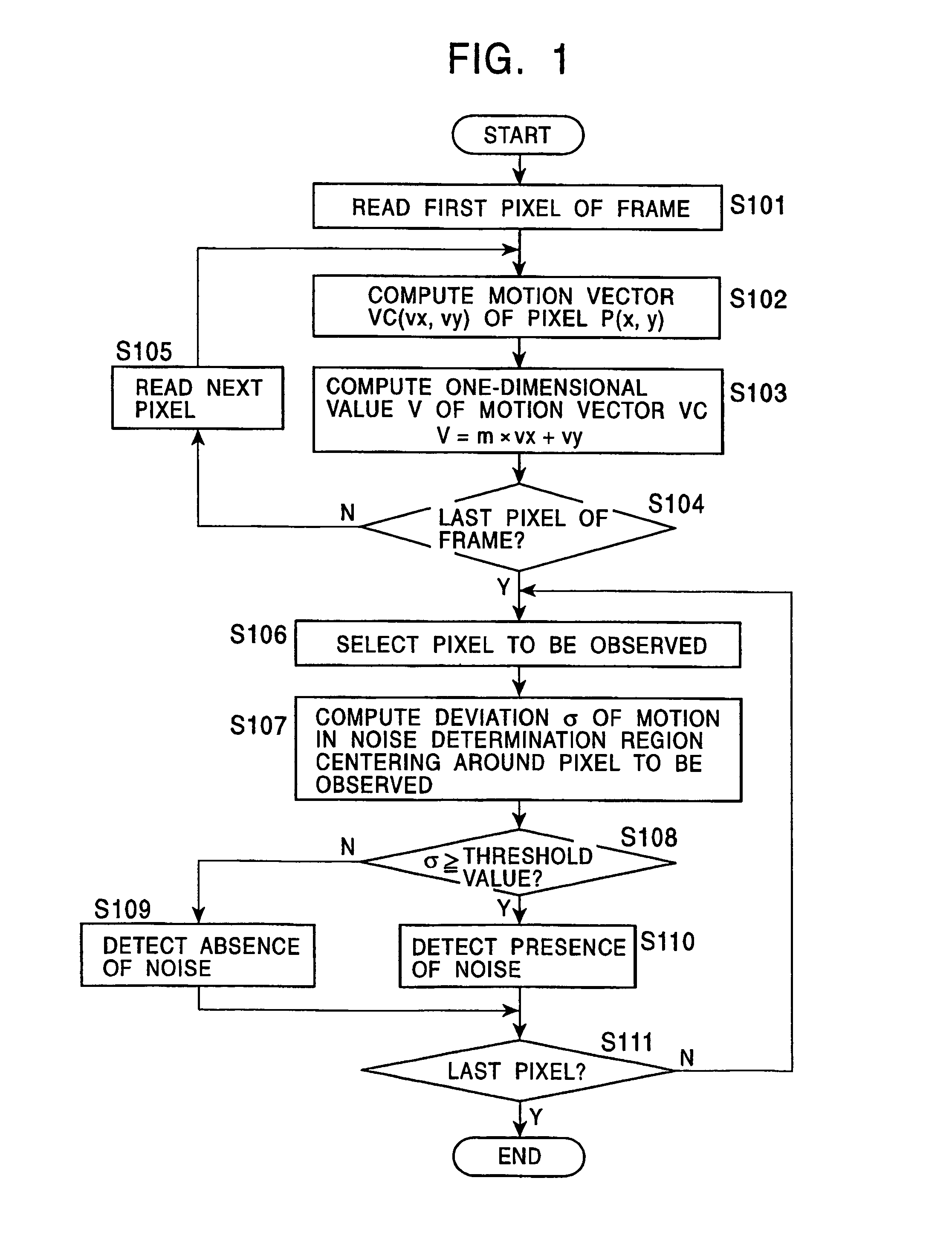

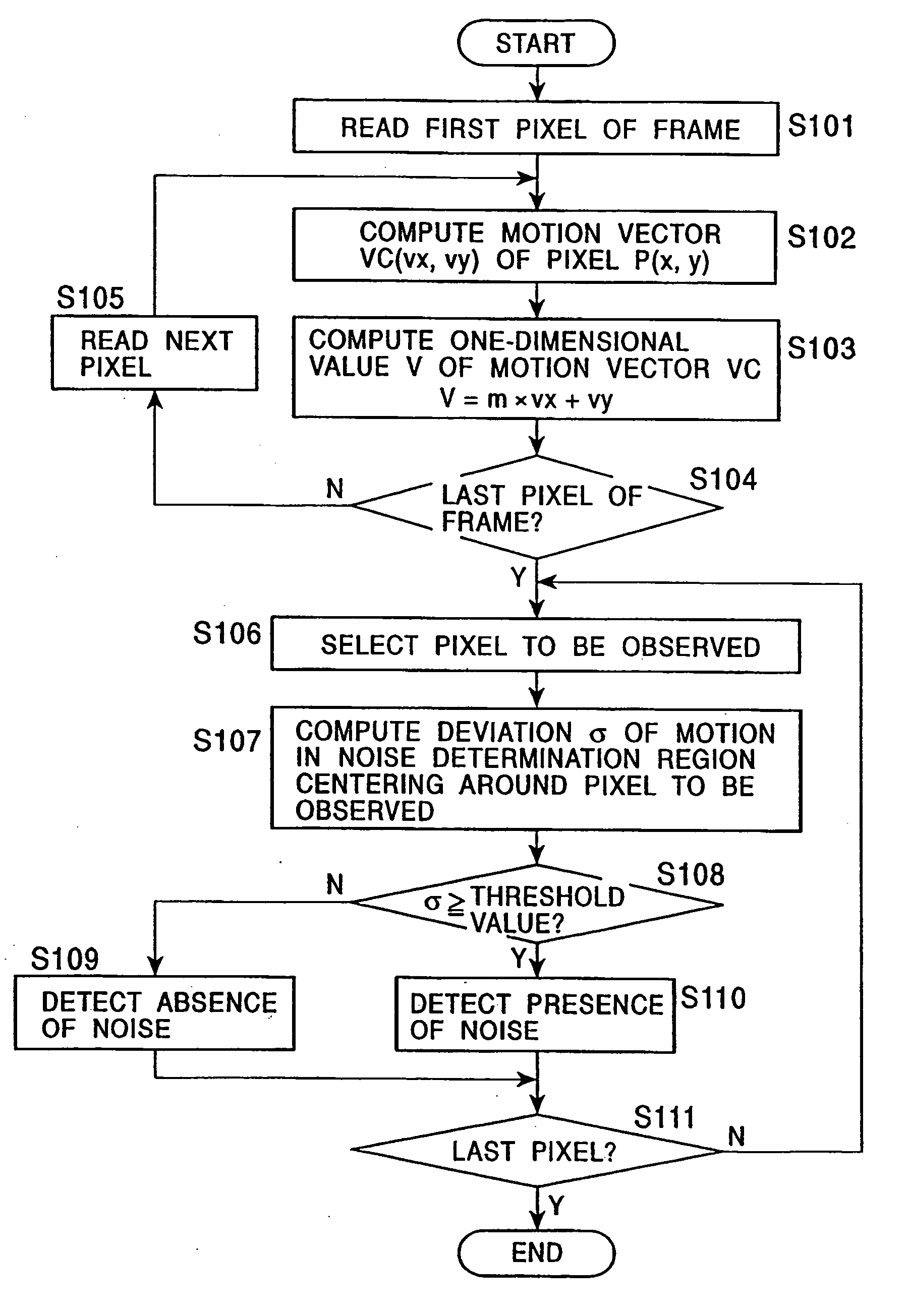

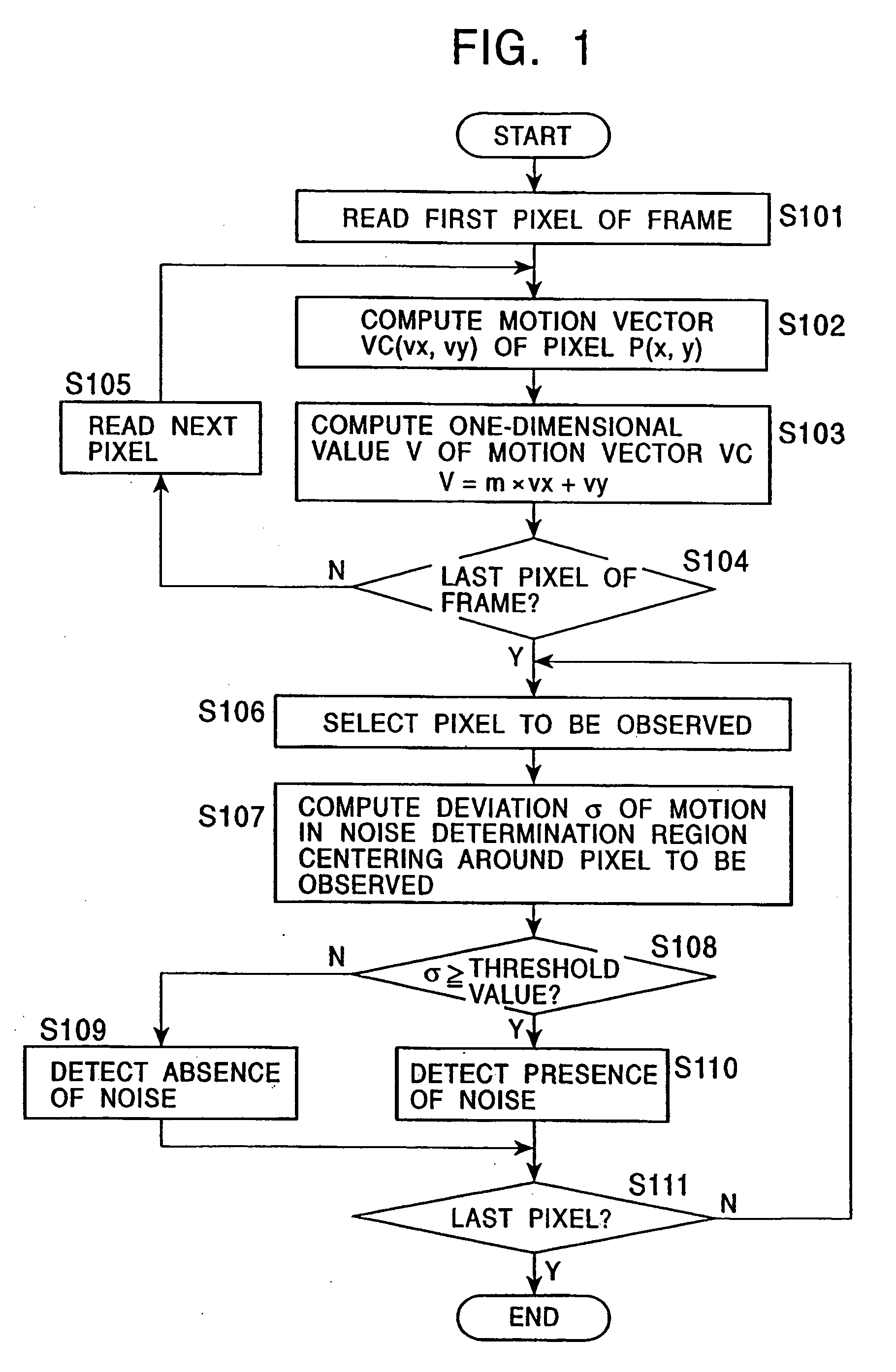

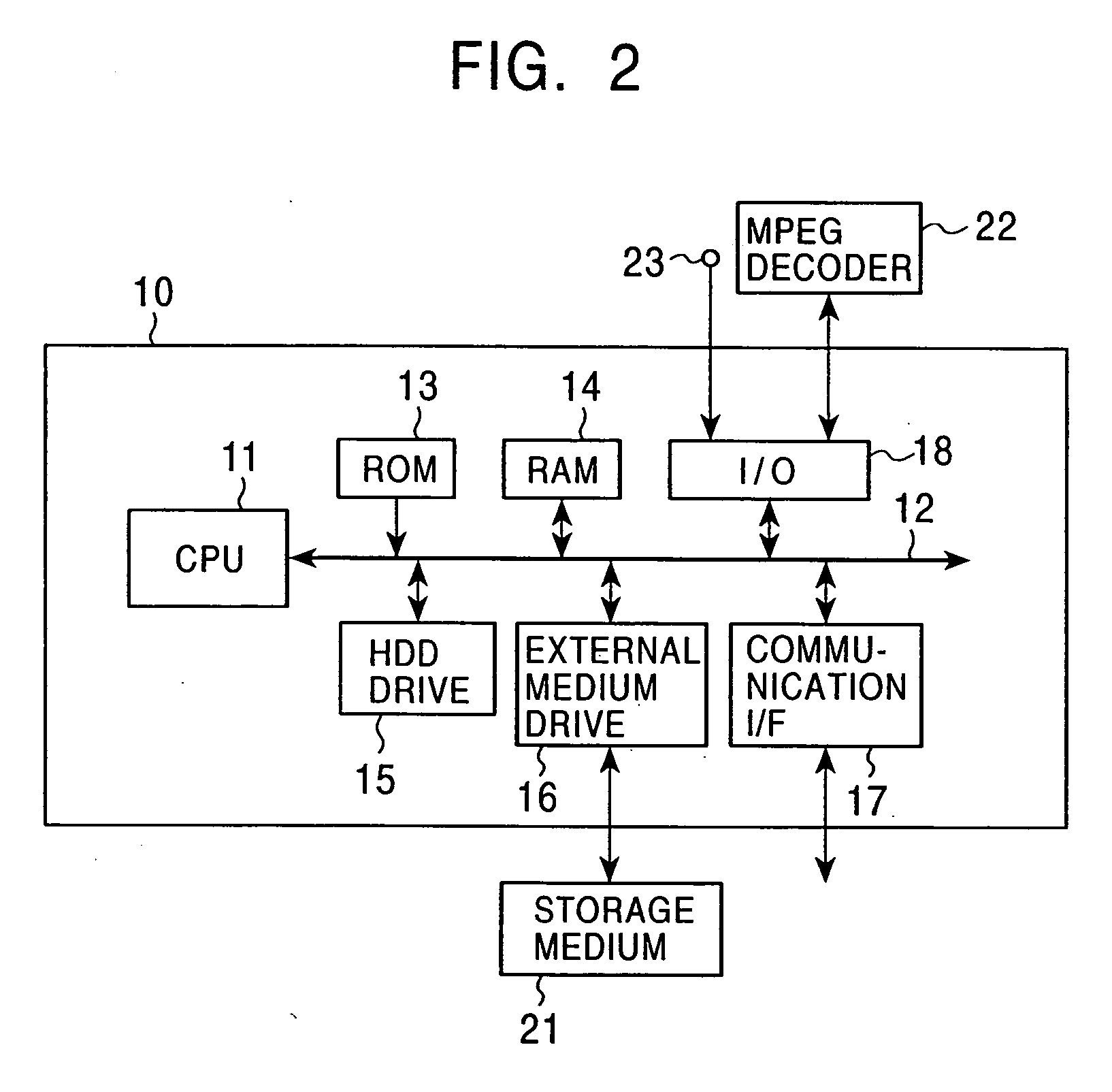

Image-data processing apparatus

An image processing apparatus detects a noise area in image data generated by decoding encoded data encoded by a frequency transform method and a lossy compression method. The image processing apparatus includes a motion detection unit for detecting motion in an area having at least one pixel in the image data, a deviation detection unit for detecting the deviation of the image motion in the area having at least one pixel, and a noise detection unit for detecting the noise area in accordance with the deviation of the image motion.

Owner:SONY CORP

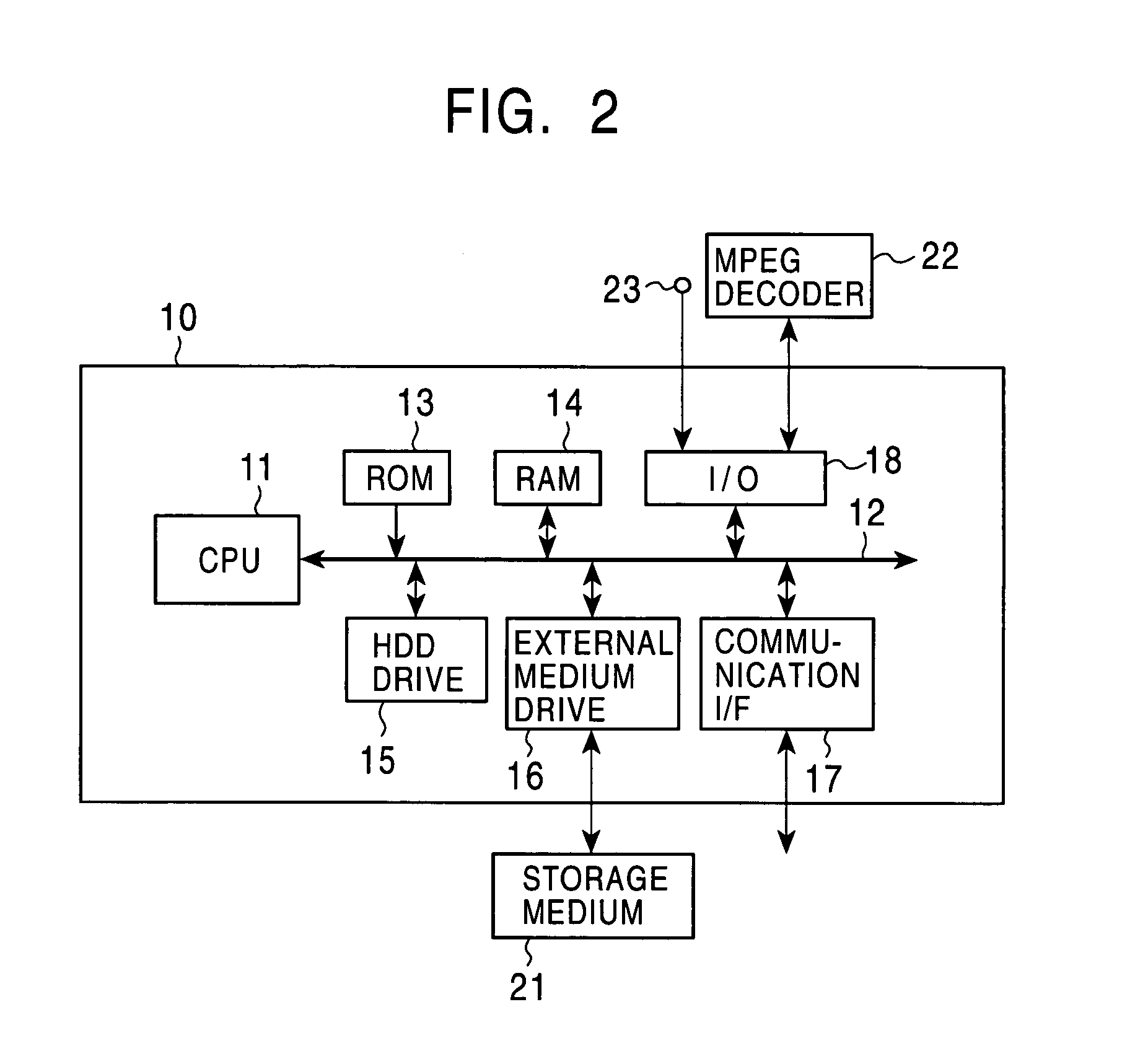

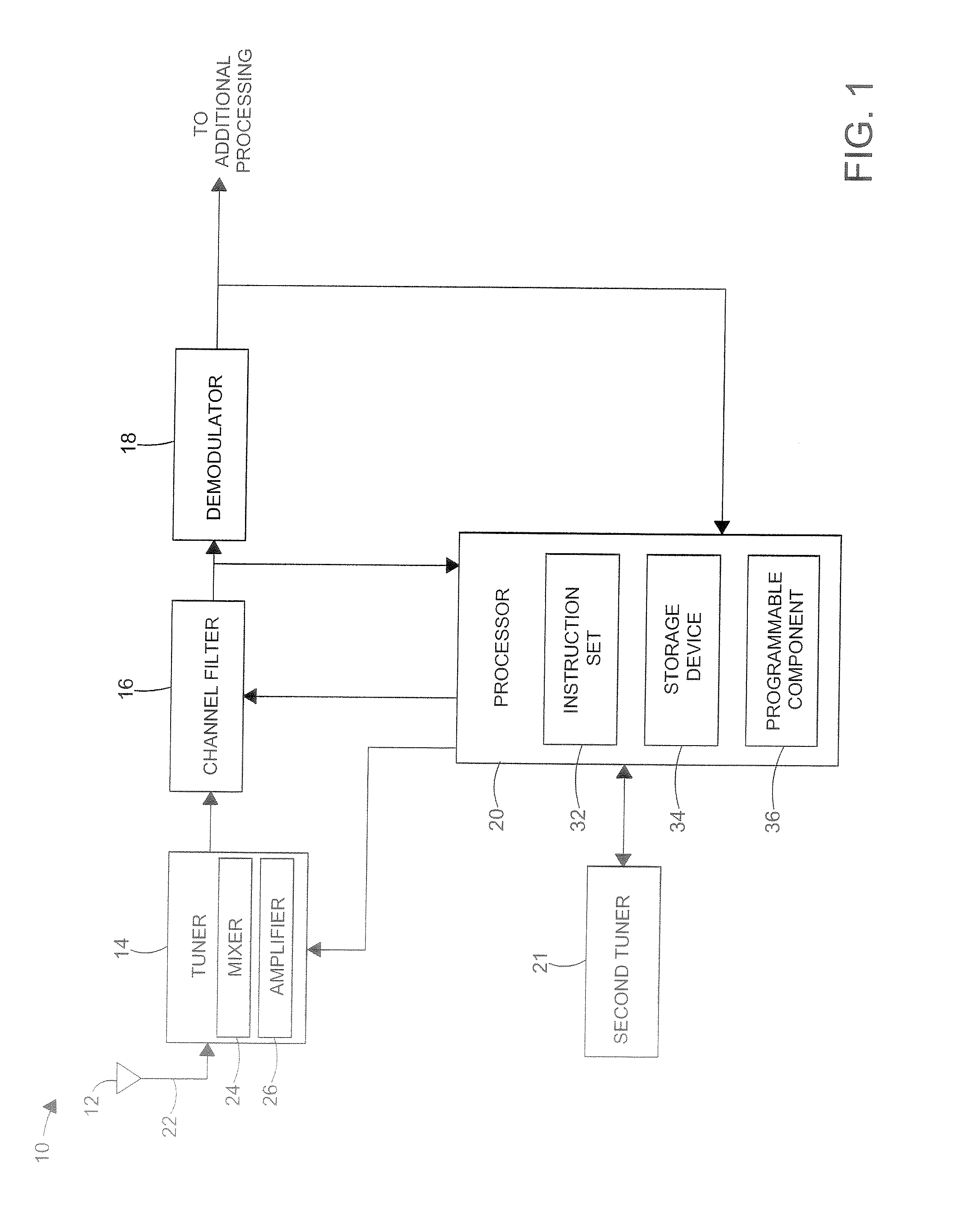

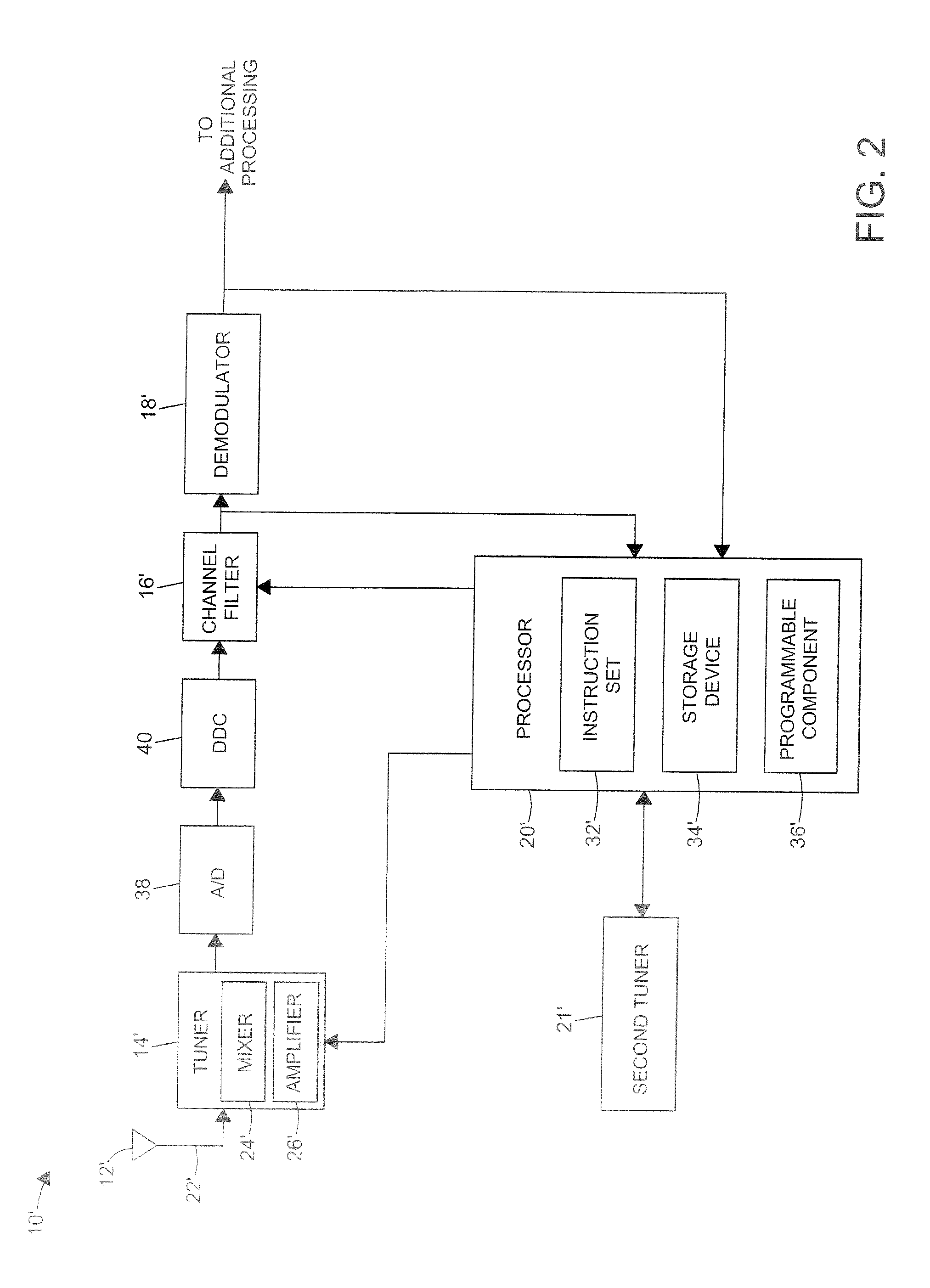

Automatic bandwidth control with high-deviation detection

ActiveUS20100130152A1Interference minimizationMaximize bandwidthError preventionLine-faulsts/interference reductionSignal onControl signal

A signal processing system and methods for controlling a bandwidth of the signal processing system are disclosed. One method includes the steps of detecting a presence of an adjacent signal on at one adjacent channel relative to a desired channel, detecting a modulation characteristic of the desired channel, measuring a signal strength on the at least one adjacent channel, measuring a signal strength on the desired channel, and adjusting a bandwidth filter applied to the desired channel in response to the measurements and detection steps.

Owner:VISTEON GLOBAL TECH INC

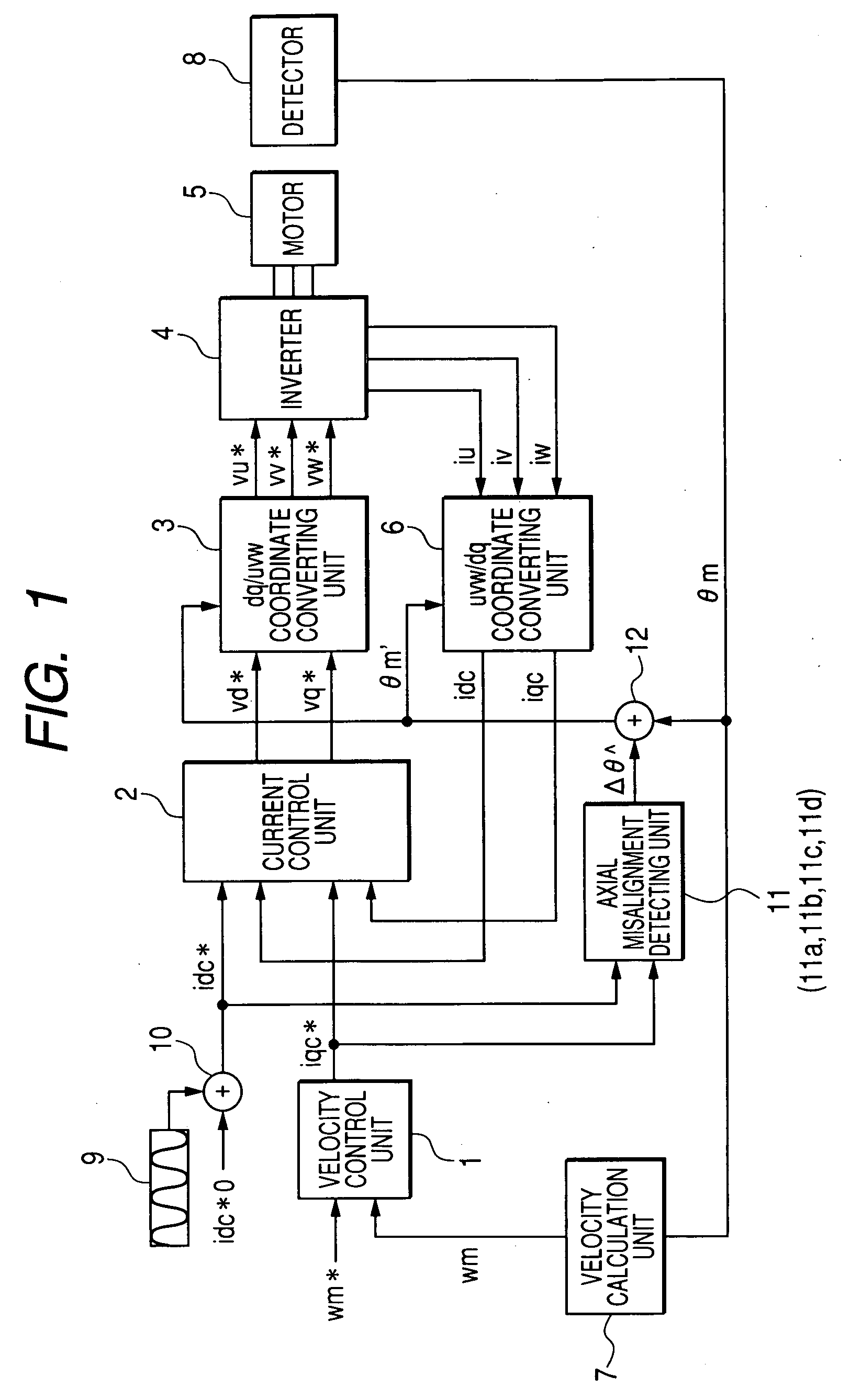

Motor Control Device

InactiveUS20080309265A1Misalignment detectionImprove workabilitySynchronous motors startersVector control systemsElectric machineWave shape

In a motor control device according to the invention, upon velocity control of a motor, a superimposed signal generating unit 9 outputs a superimposed signal idh of a repetitive waveform, such as a triangular wave or a sine wave. A d-axis current command generating unit 10 adds the superimposed signal idh generated by the superimposed signal generating unit 9d to a d-axis current command idc*0 and outputs a d-axis current command idc*. An axial misalignment detecting unit 11 (11a, 11b, 11c, and 11d) receives the d-axis current command idc* and a q-axis current command iqc* and outputs an axial misalignment angle estimation value Δθ̂. An axial misalignment correction unit 12 receives the axial misalignment angle estimation value Δθ̂ and an actual detected position θm and outputs a position after correction θm′. Therefore, detection and correction can be performed in real time through calculation at a given timing during a normal operation.

Owner:MITSUBISHI ELECTRIC CORP

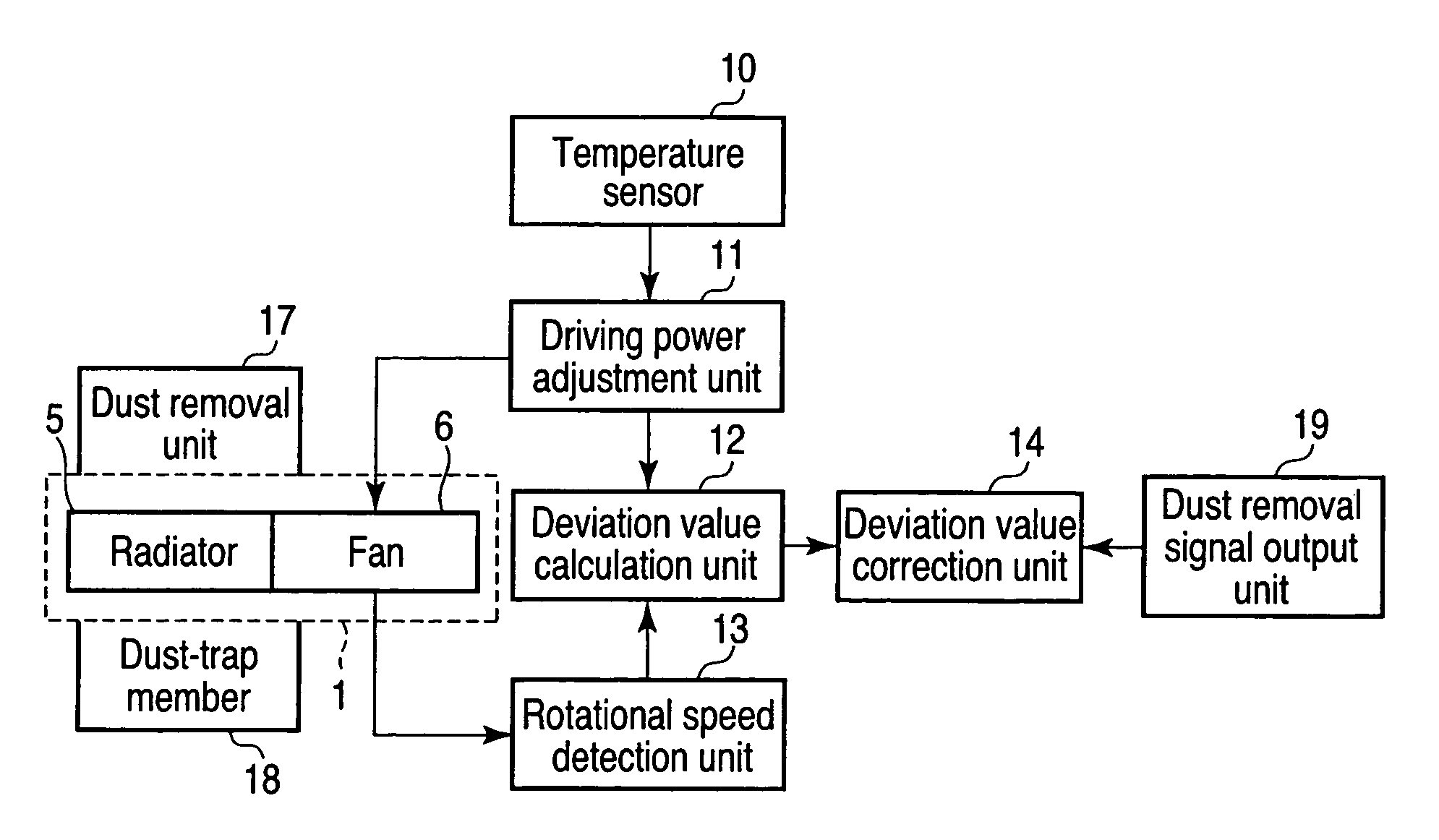

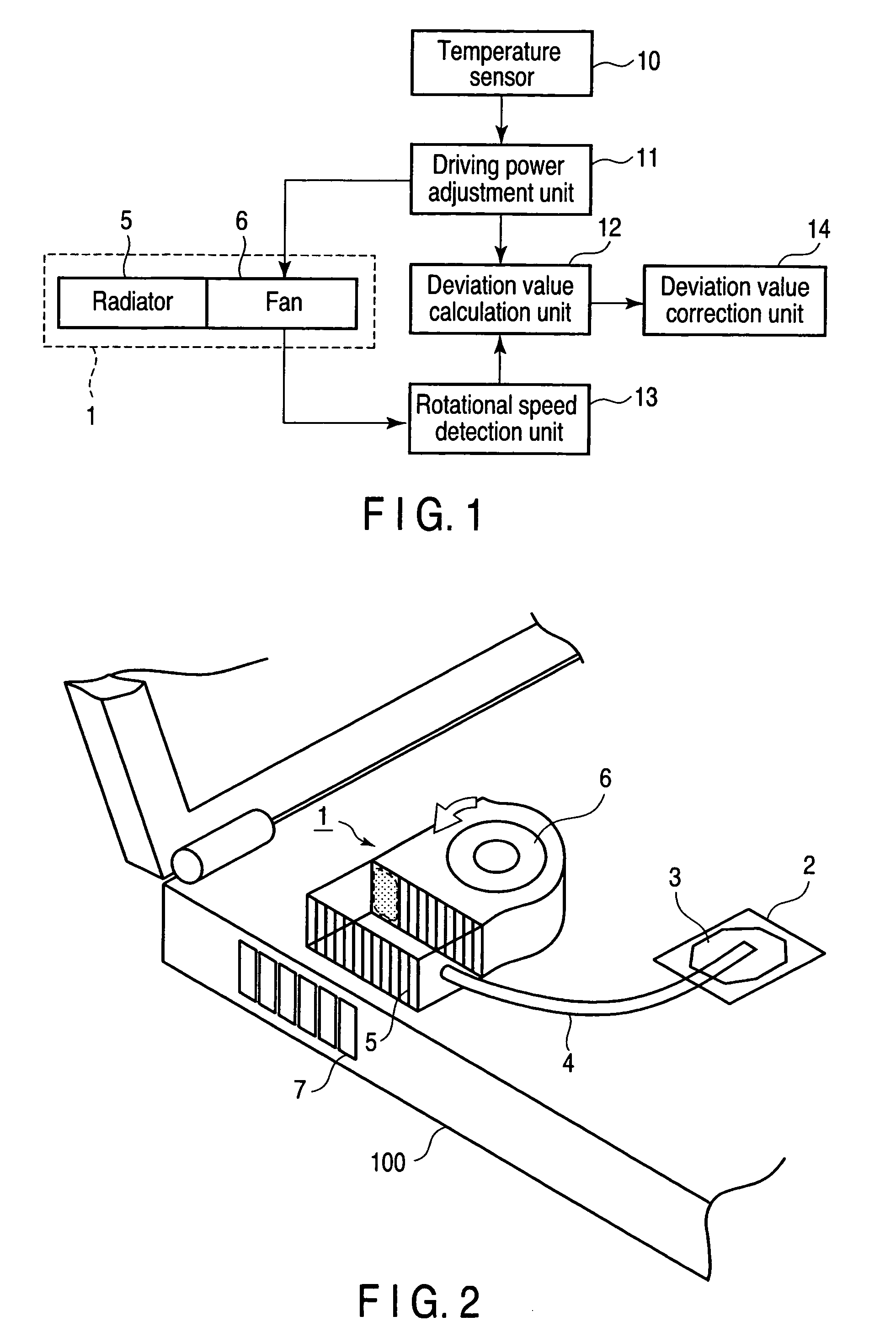

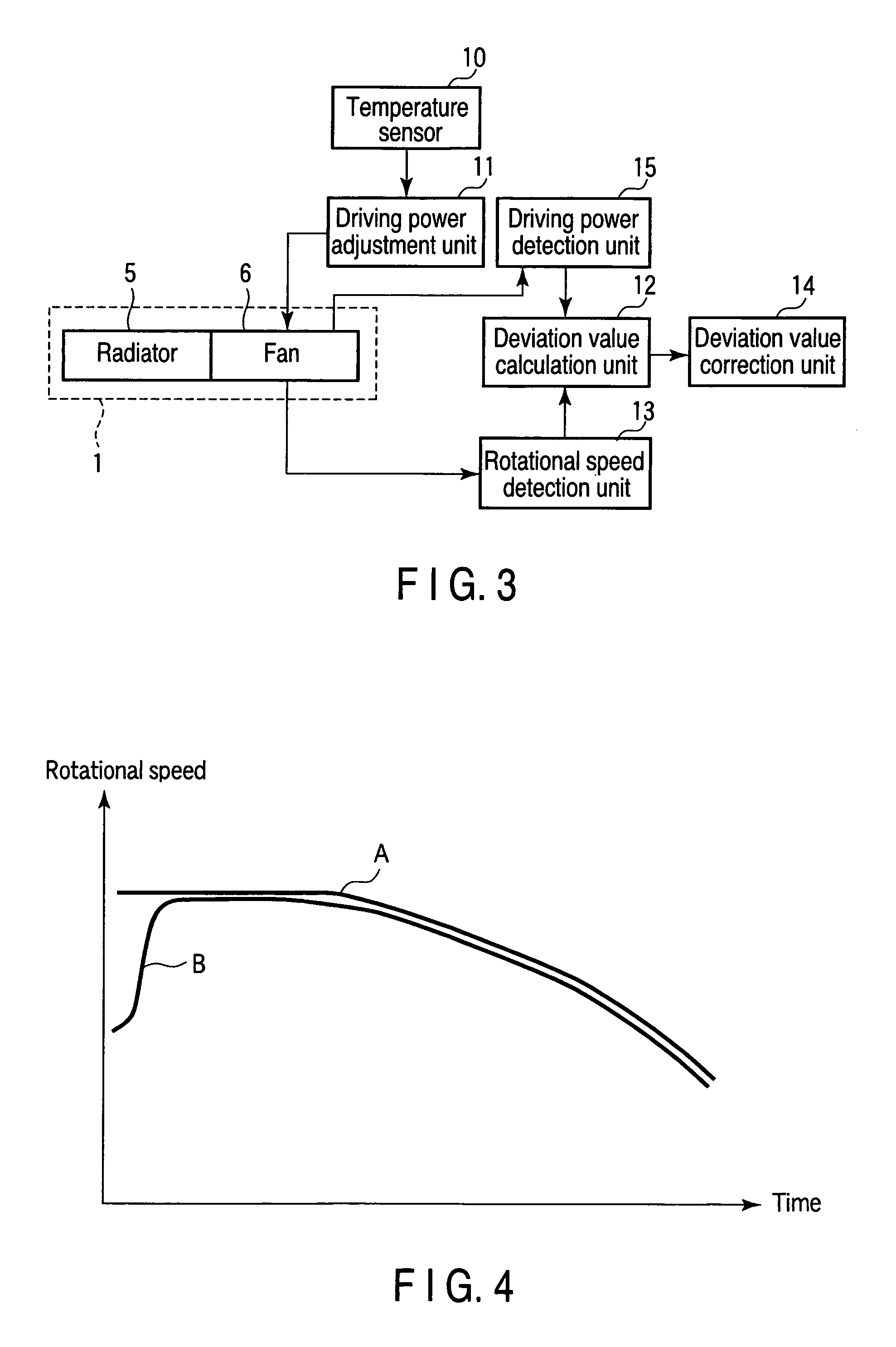

Electronic device

An electronic device includes a deviation value calculation unit which calculates a deviation value from the normal boundary of the relationship between a power index associated with the driving power and the measured rotational speed of the fan, a clogging detection unit which detects, based on the deviation value, clogging in an air duct through which the fan takes in air outside the case and sends it to the radiator, and a deviation value correction unit which corrects the deviation value in accordance with aging of performance of the fan to compensate for deterioration of the clogging detection capability of the clogging detection unit caused by the aging.

Owner:KK TOSHIBA

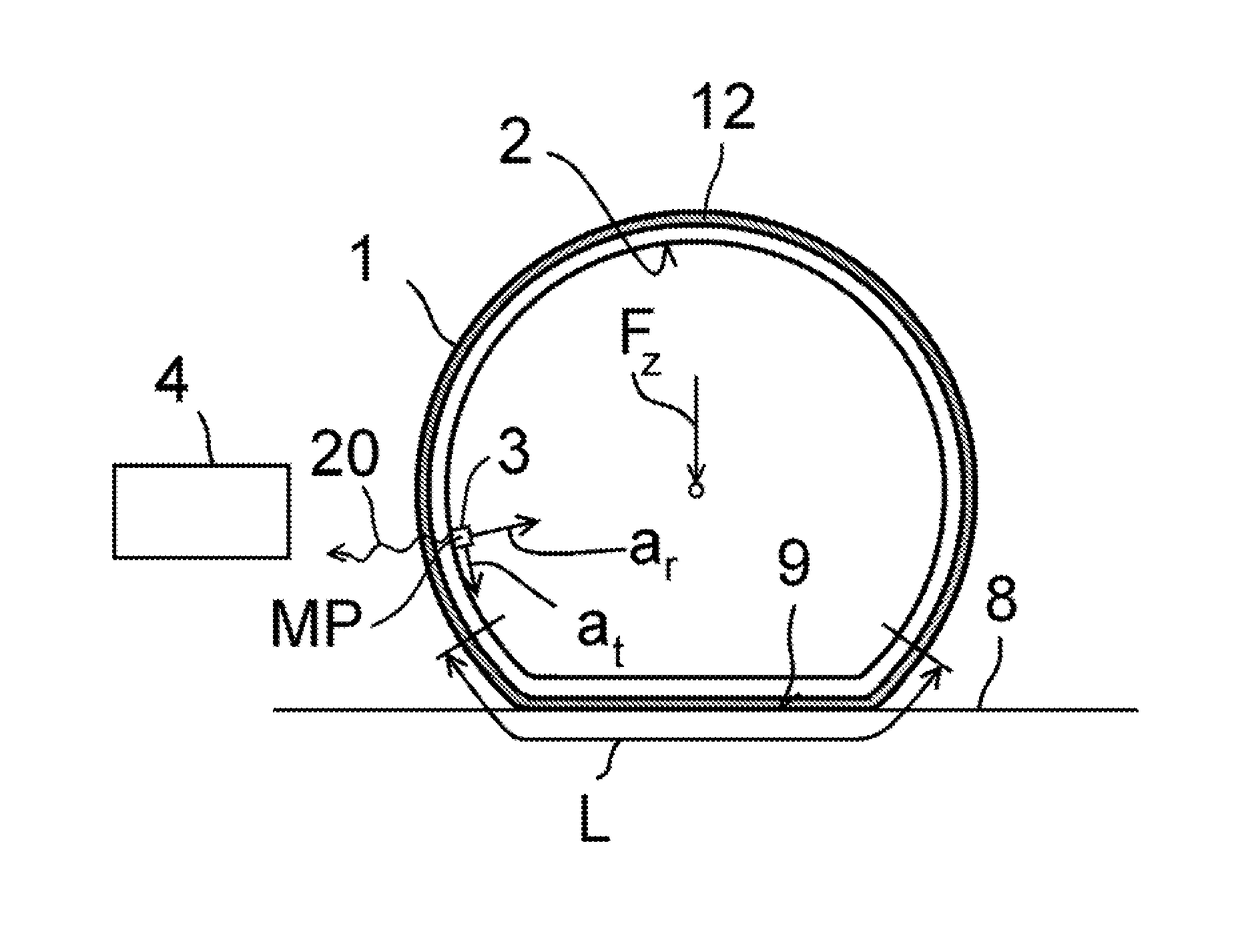

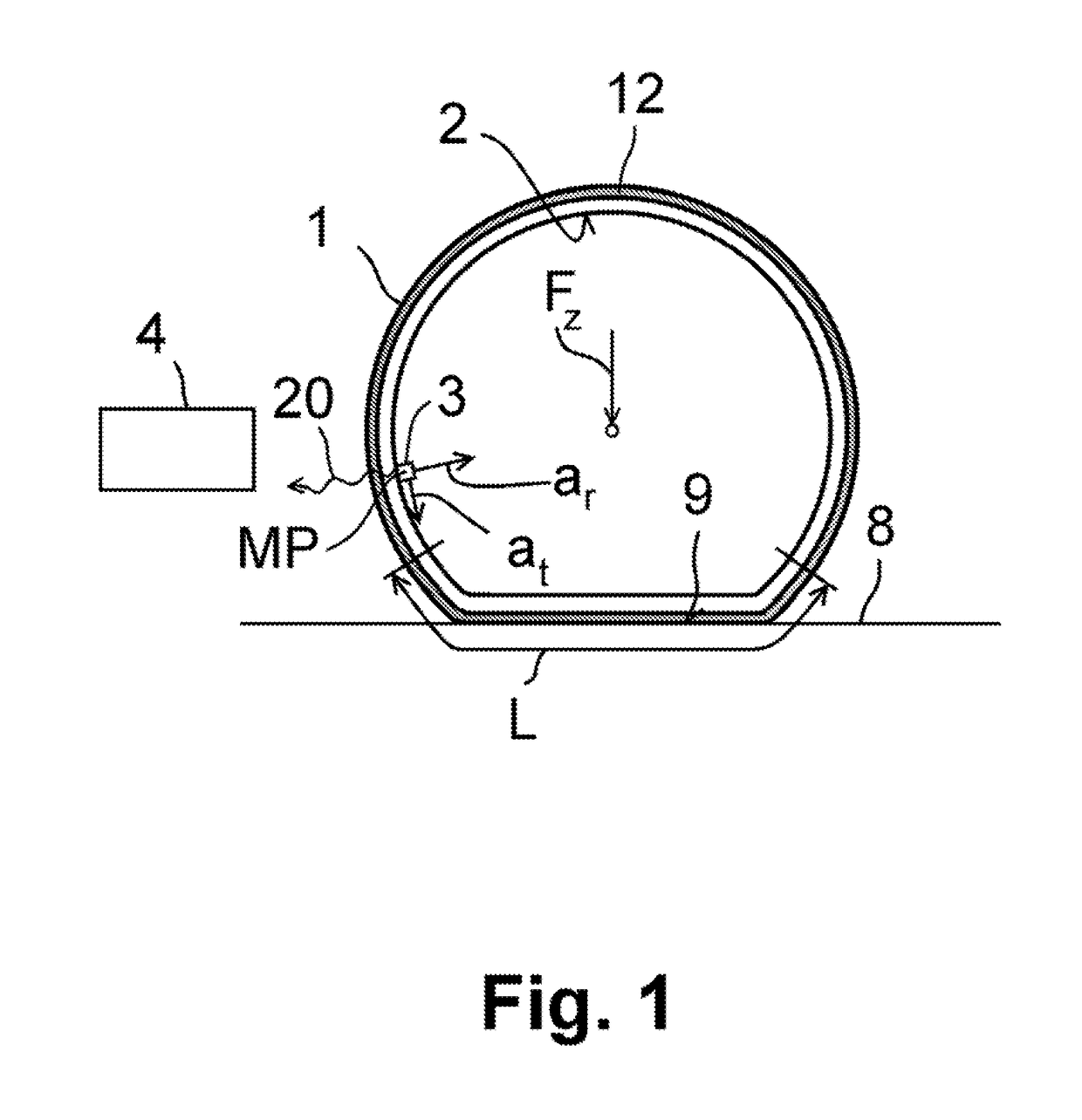

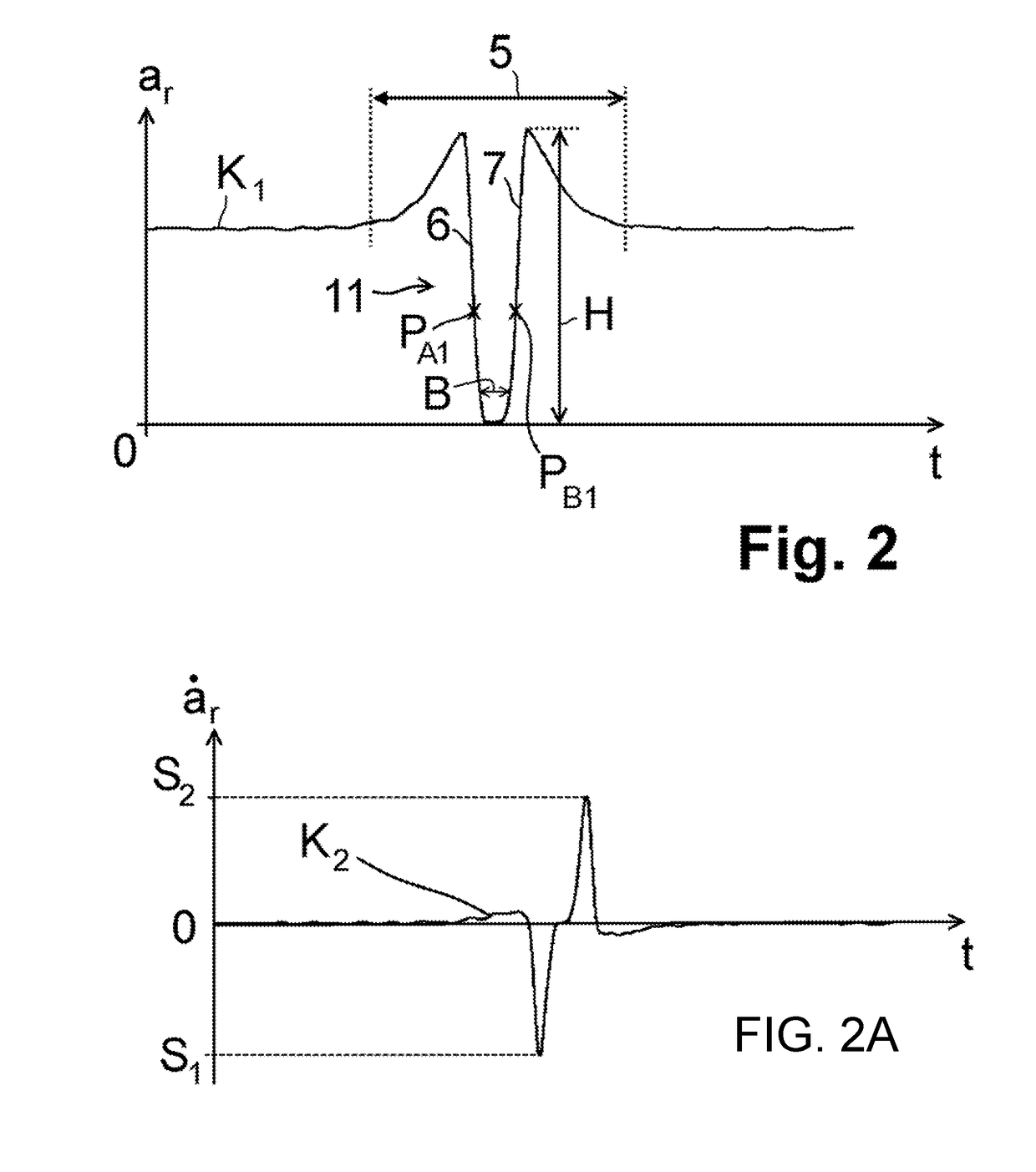

Method for determining a tread depth of a tire profile and control device therefor

ActiveUS20180188025A1Improve accuracyImprove reliabilityTyre tread bands/patternsVehicle tyre testingMeasurement pointBias detection

A method is for determining a profile depth of a tire profile. The method includes at least the following steps: a) detecting an acceleration of a measurement point on a tire inner side of a vehicle tire, wherein a deviation, caused by contact of the vehicle tire with a roadway, of the acceleration of the measurement point within an observation window is detected, b) deriving at least one analytical characteristic variable which is characteristic of the profile of the detected acceleration, wherein the at least one analytical characteristic variable characterizes the non-periodic profile of the detected acceleration within one tire rotation, c) determining the profile depth in a manner dependent on the at least one analytical characteristic variable, wherein a calibration curve yields the dependency between the analytical characteristic variable and the profile depth, and the calibration curve assigns a profile depth to the derived analytical characteristic variable.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Snow noise removing algorithm free of reference detection

Provided is a snow noise removing algorithm free of reference detection. First, pixel points adjacent in position and similar in gray scale (color) are classified into a block, and isolated blocks with the area smaller than a threshold value are judged to be noise points; the noise points are filtered, and non-noise points are directly output; when the number of signal points within a 7*7 neighborhood region around the noise points is zero, the noise points are not processed, and otherwise, a gray scale self-adaptation weighting average value of the signal points in the neighborhood region serves as a new gray scale value of the pixel points. The deviation between the filtering result and the original image pixel gray scale is subjected to statistics, snow noise is detected, when the deviation is larger than a certain value, it is thought that snow noise exists, the filtering result is output, otherwise, it is thought that no snow noise exists, and an original image is output.

Owner:WUHAN UNIV OF SCI & TECH

Image-data processing apparatus

An image processing apparatus detects a noise area in image data generated by decoding encoded data encoded by a frequency transform method and a lossy compression method. The image processing apparatus includes a motion detection unit for detecting motion in an area having at least one pixel in the image data, a deviation detection unit for detecting the deviation of the image motion in the area having at least one pixel, and a noise detection unit for detecting the noise area in accordance with the deviation of the image motion.

Owner:SONY CORP

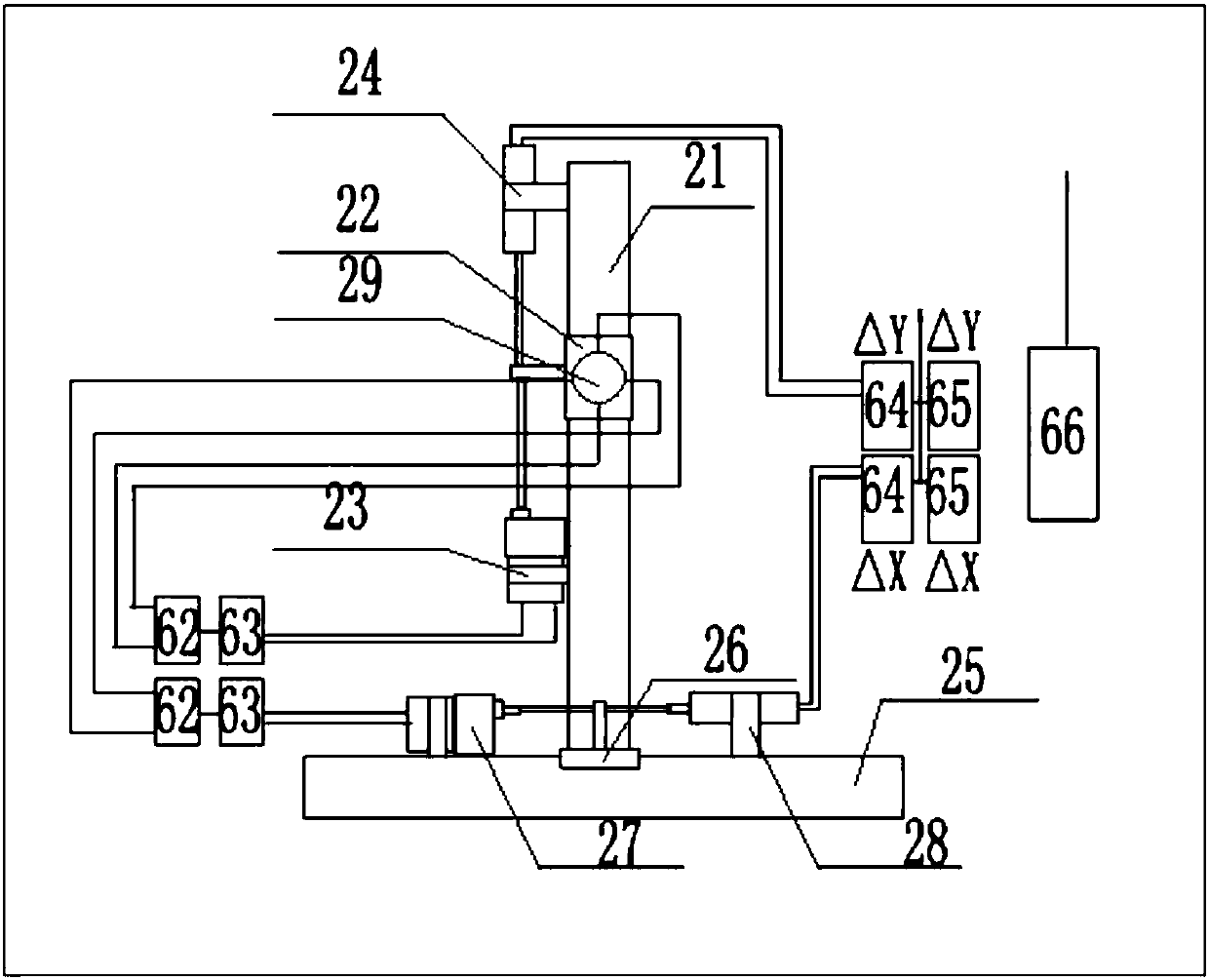

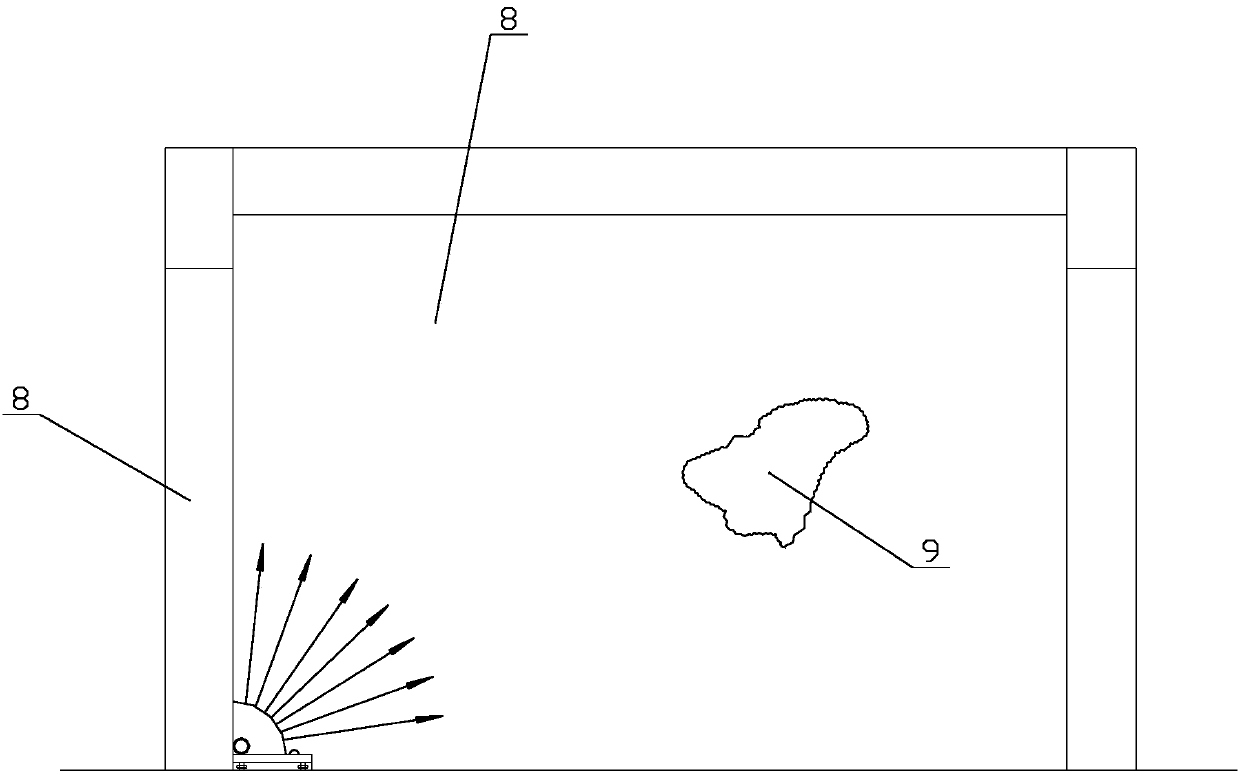

Device and method or detecting smoothness of laser track

PendingCN107764213AAccurate engineering detection valueReliable engineering detection valueUsing optical meansBias detectionStatistical physics

The invention provides a device and method for detecting the smoothness of a laser track, and the method comprises the steps: detecting and obtaining a horizontal base measurement value Xi and a vertical base measurement value Y1 of a to-be-measured position Pi through a photoelectric measurement target; detecting a horizontal random deviation value delta(Xi) and a vertical random deviation valuedelta(Yi) of a laser reference beam through a deviation detection unit on the photoelectric measurement target, and correcting the horizontal random deviation value delta(Xi) and the vertical random deviation value delta(Yi); superposing the horizontal base measurement value Xi and a horizontal random deviation correction value delta(Xi)*Ki, and obtaining an engineering detection value Xi' in a horizontal direction; superposing the vertical base measurement value Yi and a vertical random deviation correction value delta(Yi)*Ki, and obtaining an engineering detection value Yi' in a vertical direction. The method solves a problem that the engineering detection result of a conventional laser smoothness detection device is low in precision and poor in reliability. The method is suitable for other laser alignment engineering measurement in an outdoor environment under the long-distance condition.

Owner:王启华

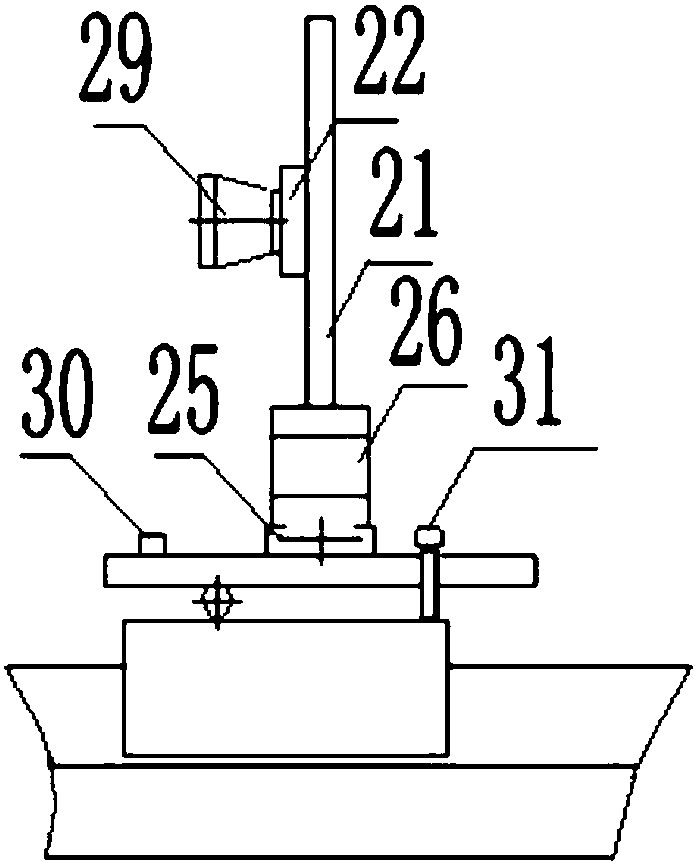

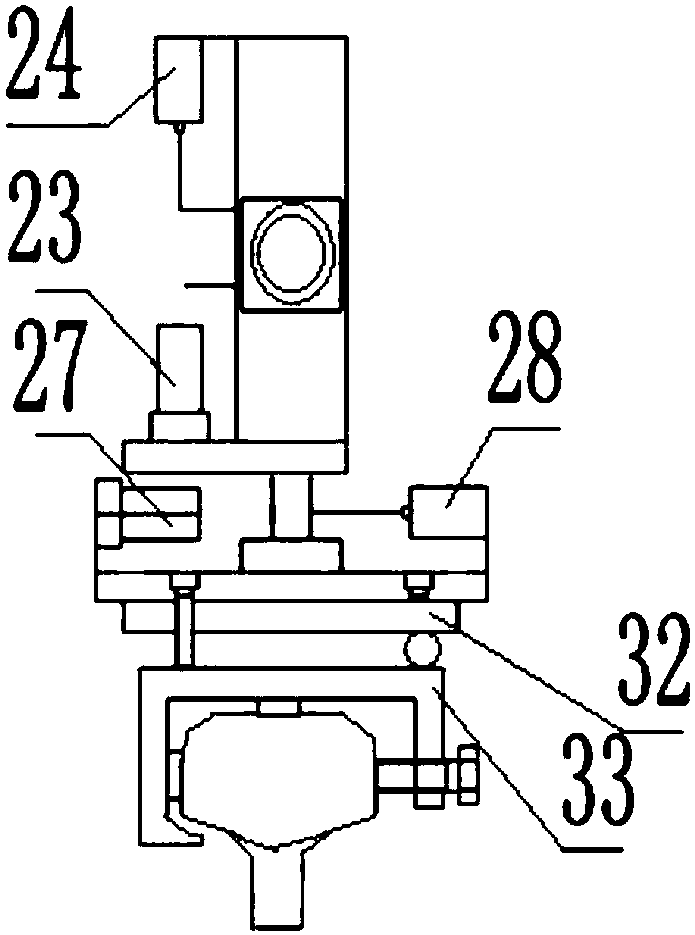

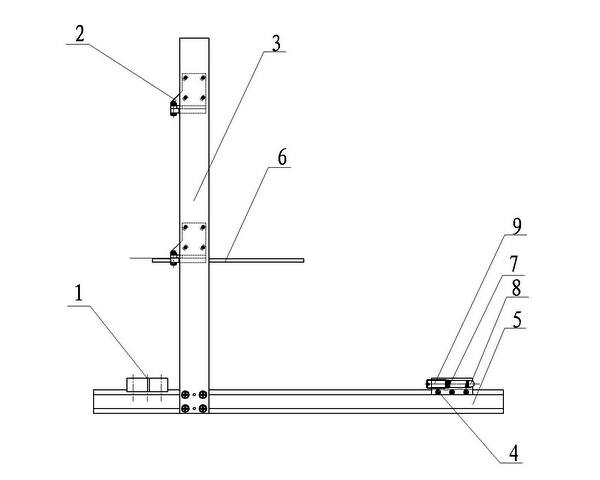

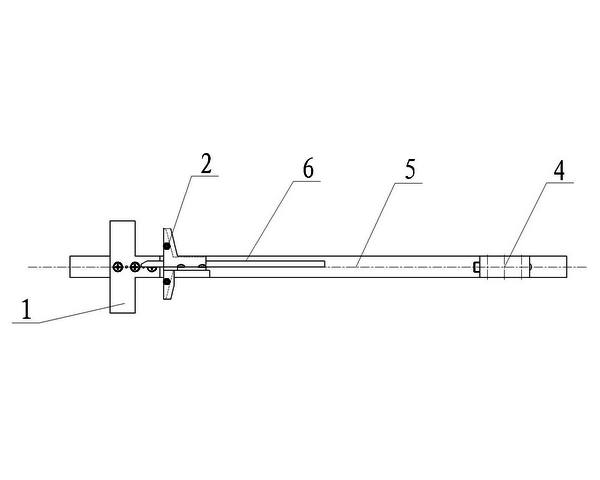

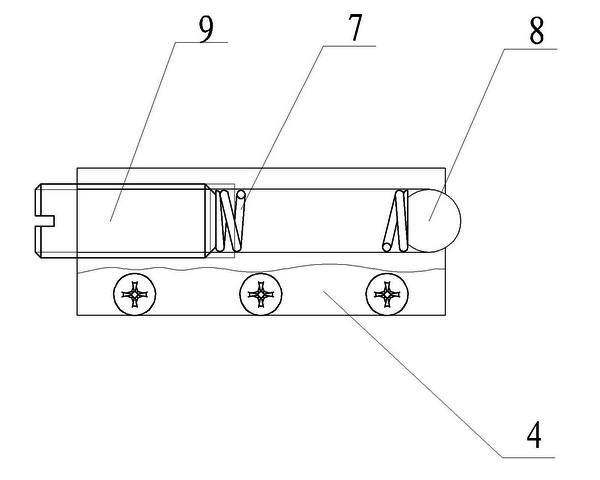

Coaxiality detection apparatus

InactiveCN102494595ASimple structureEasy to operateMechanical measuring arrangementsShortest distanceBias detection

The invention provides a coaxiality detection apparatus, relating to an apparatus which establishes a virtual axis to substitute a reference axis needing to be measured and employs a depth gauge to detect coaxiality deviations of various apertures and depths. A cross bar is provided with a vertical stick which is taken as a virtual reference axis for measurement. A locating piece and a jacking block are connected to the cross bar through taper pins. The cross bar is provided with connection holes used by the locating piece and the jacking block to move according to a measurement dimension. The jacking block is provided with a spring and a steel ball which are used by the jacking block to carry out short distance adjustment on the cross bar. The spring is positioned through a fastening screw. The depth gauge is installed on the vertical stick through a rule base which is fixed on the vertical stick through a taper pin. According to the invention, the vertical stick is used as the virtual reference axis, the virtual axis is established to substitute the reference axis needing to be measured, there is no need to find a relative position of the reference axis in a detection process, the coaxiality deviations of various apertures and depths are measured through the depth gauge, a structure is simple, operation is convenient, a measurement result is accurate, and the apparatus is especially suitable for a coaxiality deviation detection occasion.

Owner:CRRC LUOYANG CO LTD

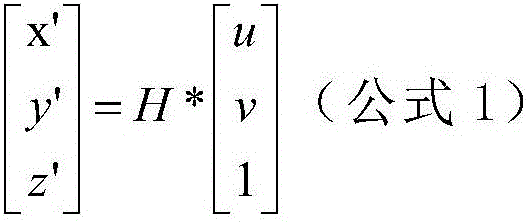

Method for detecting register deviation based on machine vision register control system

PendingCN109814536AAdd visual inspection line display functionIntuitive visual inspectionElectric testing/monitoringPrinting press partsAutomatic controlMachine vision

The invention discloses a method for detecting register deviation based on a machine vision register control system, and belongs to the technical fields of printing, packaging and other automatic control of mechanical register and positioning. In order to be able to avoid the increase of the plate-making cost caused by upgrading of the system by using the register control system based on machine vision by photoelectric color codes under the condition of not changing an existing printing plate, machine vision and image processing technologies are utilized, according to the property that the color codes have standard sizes, an image pixel is converted into a pixel equivalent, the influence caused by image distortion is also considered, the equivalent has two values of width and height, an image pixel coordinate is taken as a reference system, the center of the color code of the front color is calculated, a visual inspection line is generated, a center standard position of the color codeof the rear color is obtained according to the standard distance of the color code, the calibration work of register deviation can be carried out by comparing the center standard position and actual position of the color code of the rear color, and the visual inspection line is displayed on a display screen and can be used for manual calibration.

Owner:CHANGCHUN JIHAI OBSERVATION & CONTROL TECH

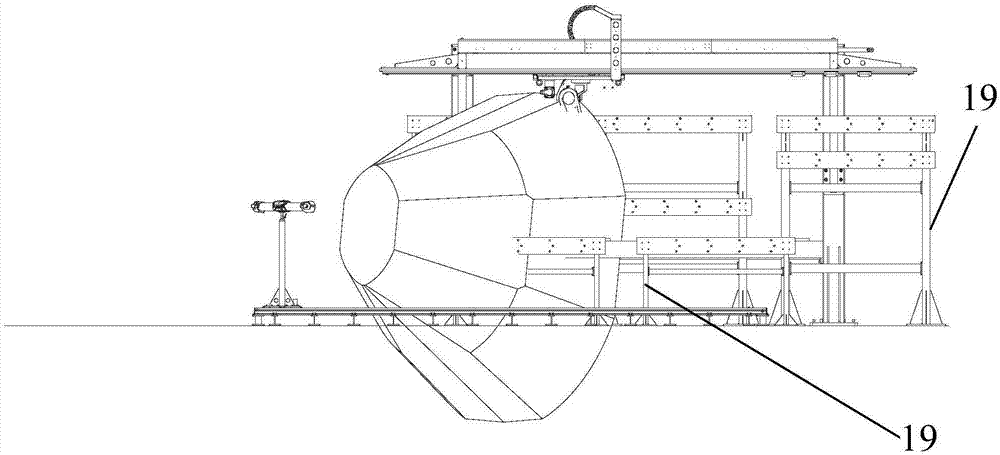

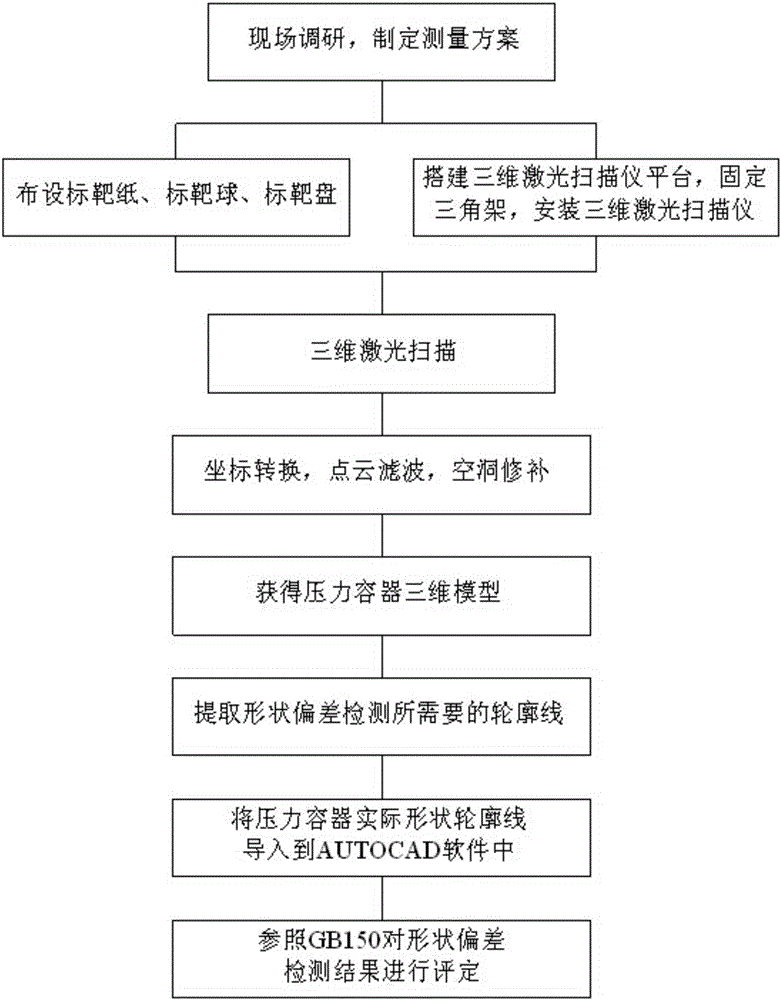

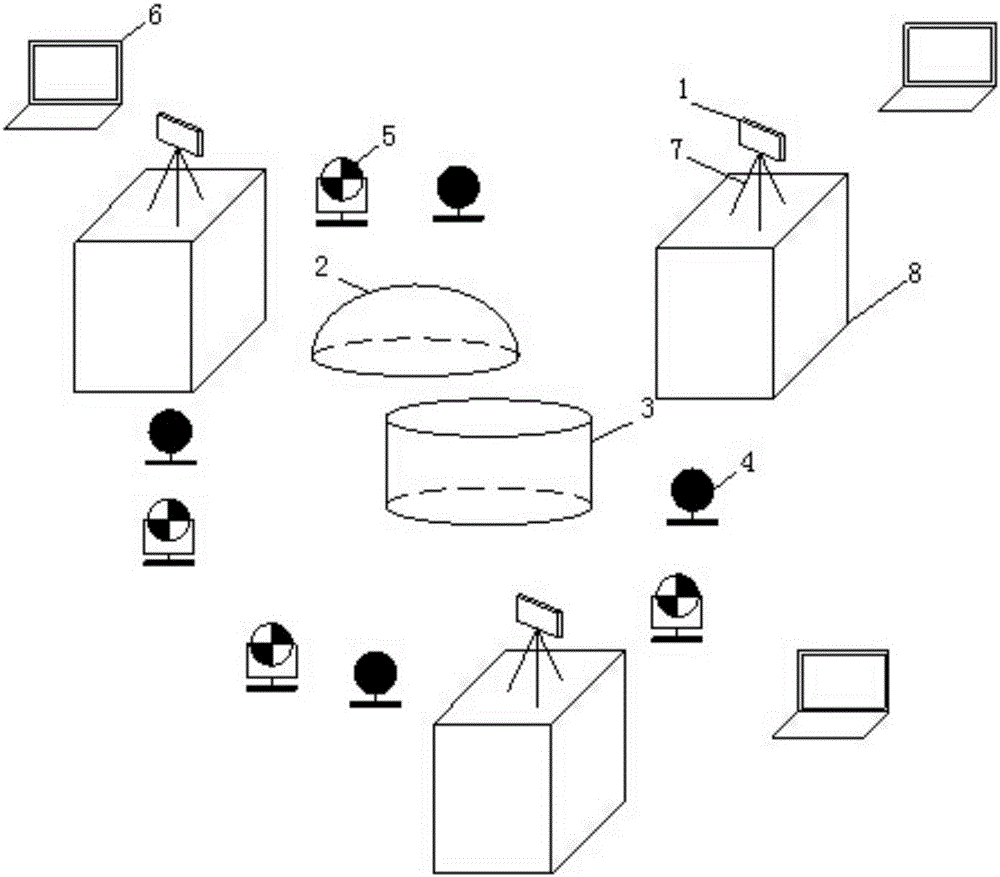

Pressure container shape deviation detection method based on three-dimensional laser scanning

ActiveCN105865368AAccurate measurementQuick measurementUsing optical meansPoint cloudShape deviation

The invention relates to shape deviation detection and provides a pressure container shape deviation detection method based on three-dimensional laser scanning. The pressure container shape deviation detection method based on three-dimensional laser scanning includes the steps that three-dimensional laser scanning devices are distributed around a pressure container; three-dimensional laser scanning is conducted on the pressure container to obtain the quantity of point cloud data; the point cloud data is processed to obtain a three-dimensional model composed of triangular patches; an outline required by shape deviation detection is extracted from the three-dimensional model; the extracted outline is compared with a designed shape outline to evaluate a shape deviation detection result. The method can be used for accurately, quickly and comprehensively measuring shape deviation of an oval end socket in a non-contact mode. The method is high in collection point location density, high in measurement accuracy, high in measurement speed, capable of saving labor time, low in labor intensity and capable of conveniently achieving automatic measurement, and accordingly the shape deviation of the pressure container can be accurately and quickly measured.

Owner:ZHEJIANG UNIV

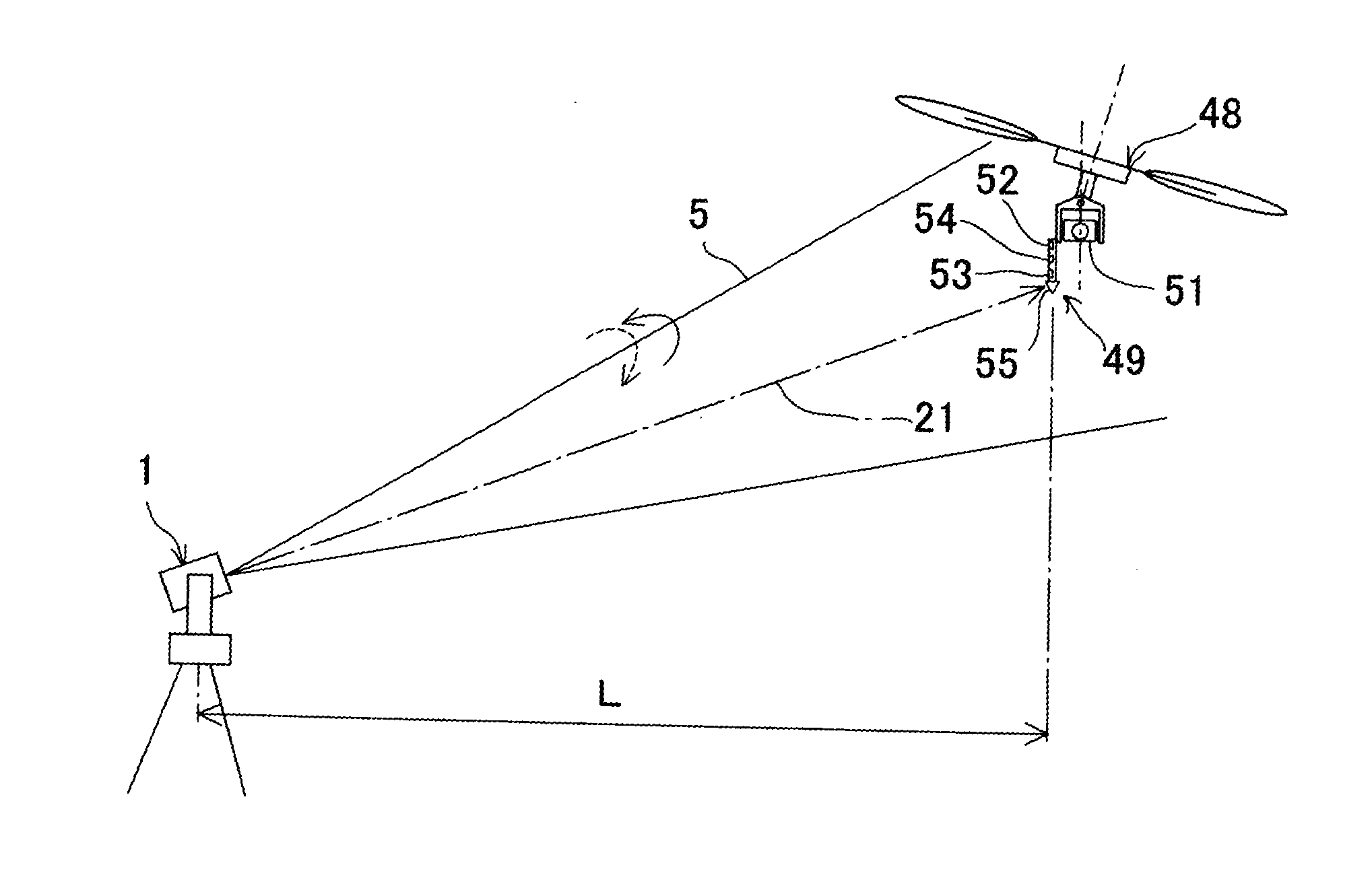

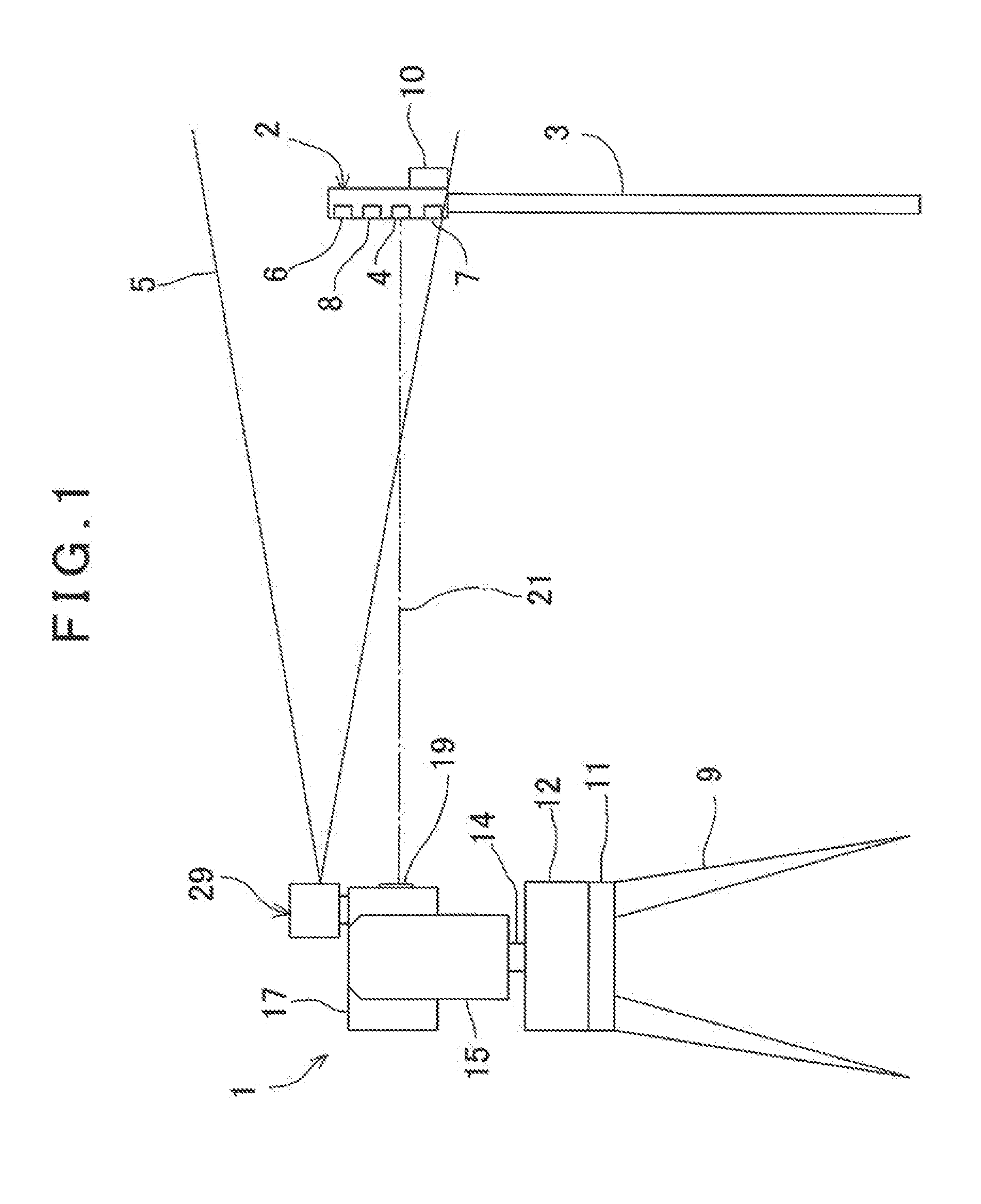

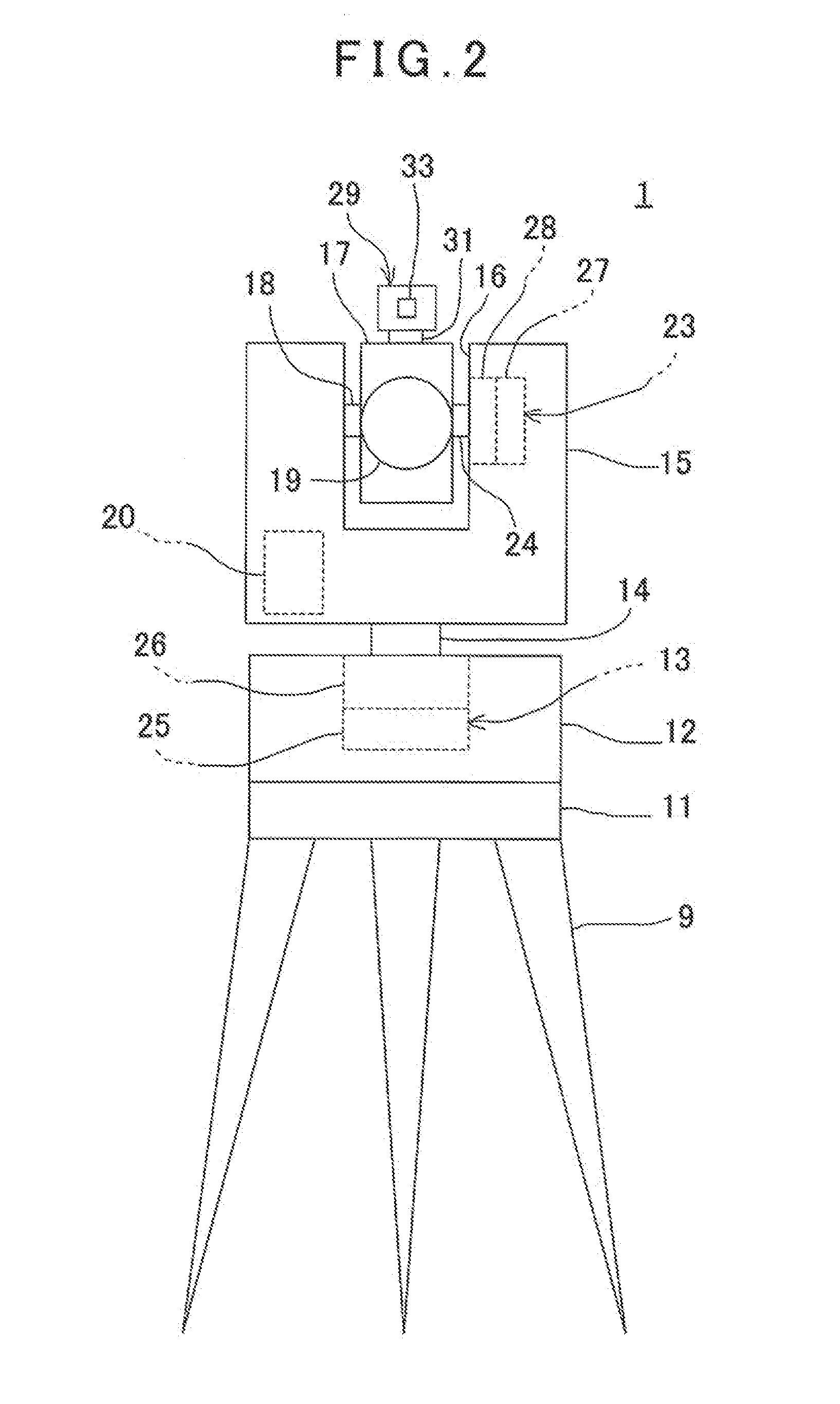

Tilt Detecting System And Tilt Detecting Method

ActiveUS20160131479A1Improve work efficiencyImprove accuracySurveyor's staffsMovable markersSurvey instrumentBias detection

The invention provides a tilt detecting system comprising, a surveying instrument having a distance measuring function and a line laser projecting unit installed as horizontally rotatable for projecting a vertical line laser, and a photodetection device having at least two photodetection units provided at a known interval, a target with a retro-reflectivity and an arithmetic unit, wherein the line laser projecting unit is rotated, each of the photodetection units are made to scan the line laser and the arithmetic unit detects a tilting angle of the photodetection device based on a deviation between a photodetection time moment of each photodetection unit and the distance measurement result of the target of the surveying instrument.

Owner:KK TOPCON

Check method of photomask diagram position deviation

InactiveCN102540735ALow costPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsBias detection

The invention provides a check method of photomask diagram position deviation, wherein the method comprises the following steps of: S100. preparing a test wafer; S101. preparing a standard photomask; S102. testing the diagram position deviation of all nested mark outer frames on the standard photomask; S103. placing tested mark inner frames on the product photomask, wherein the central position of each tested mark inner frame needs to be overlapped with the positions of the nested mark outer frames on the standard photomask, and the tested mark inner frames are only placed in a scribing groove or out of a prohibited area; S104. gluing the test wafer, carrying out para-position exposure by utilizing the standard photomask firstly, then carrying out para-position exposure by utilizing the product photomask, and developing after exposure twice and generating nested test diagrams; and S105, testing and nesting, and amending the nested data, thereby obtaining the diagram position deviation of the product photomask. According to the invention, the diagram position deviation of the photomask can be calculated without using a special diagram position deviation check device, and the cost is lower.

Owner:CSMC TECH FAB2 CO LTD

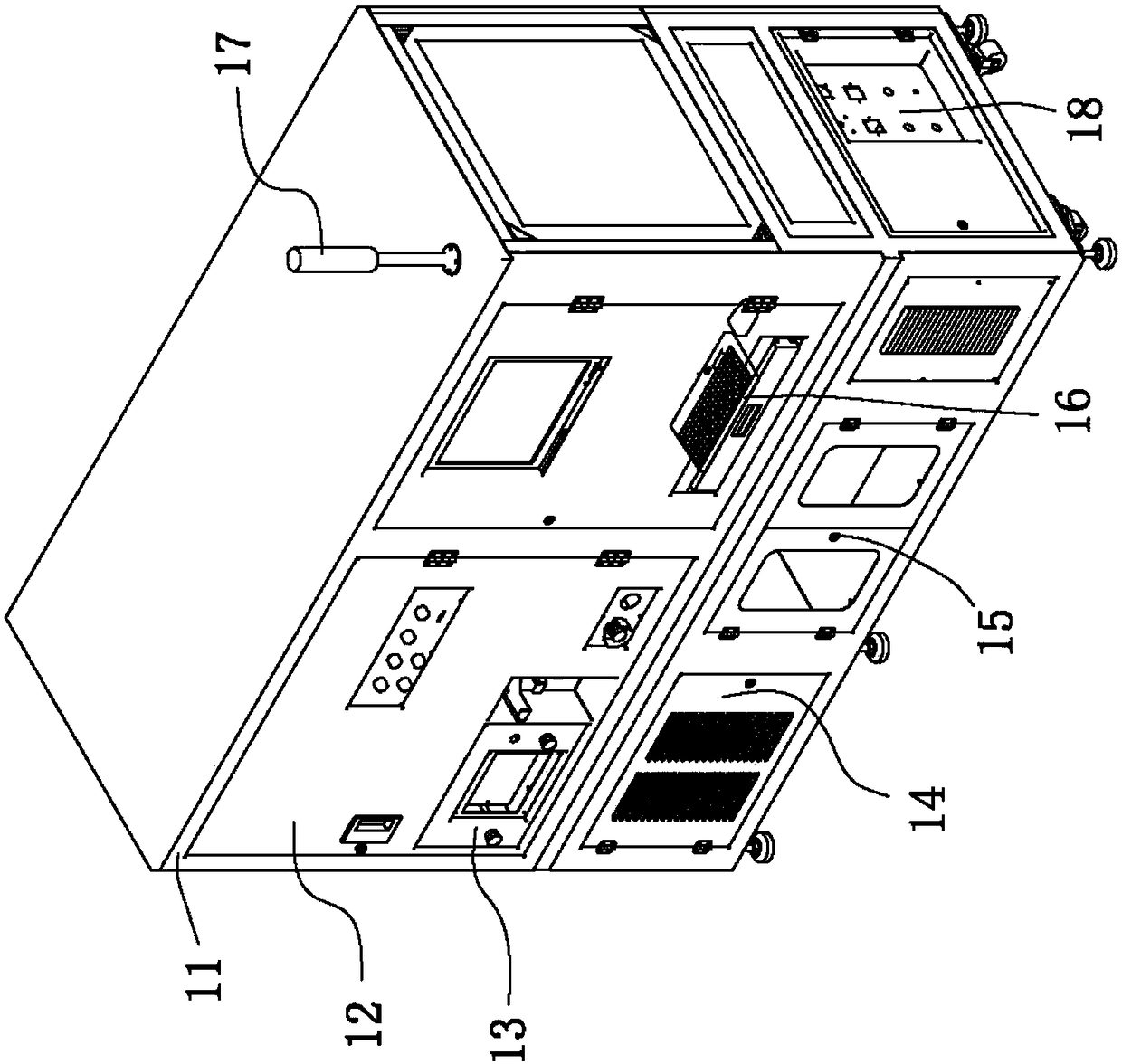

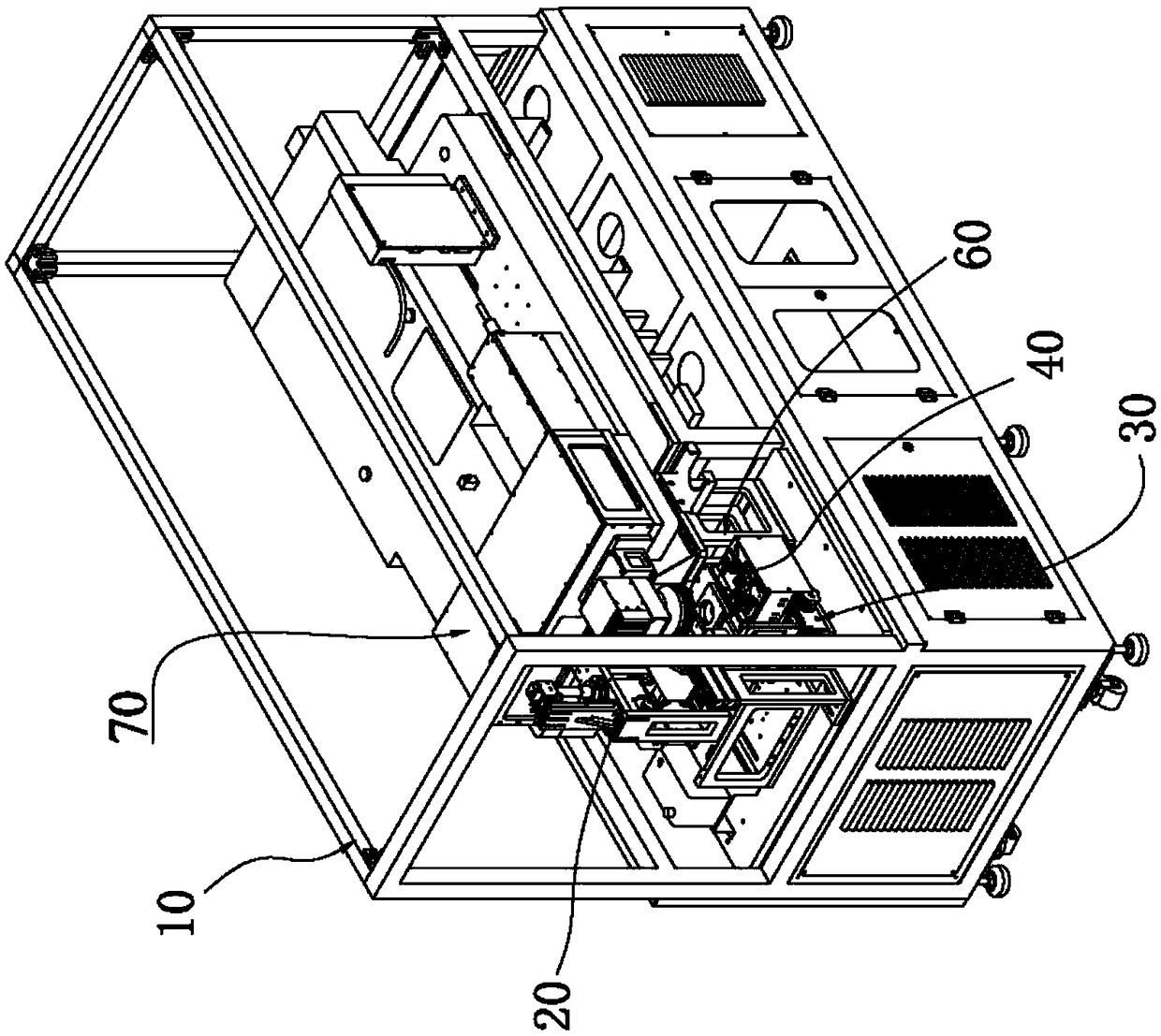

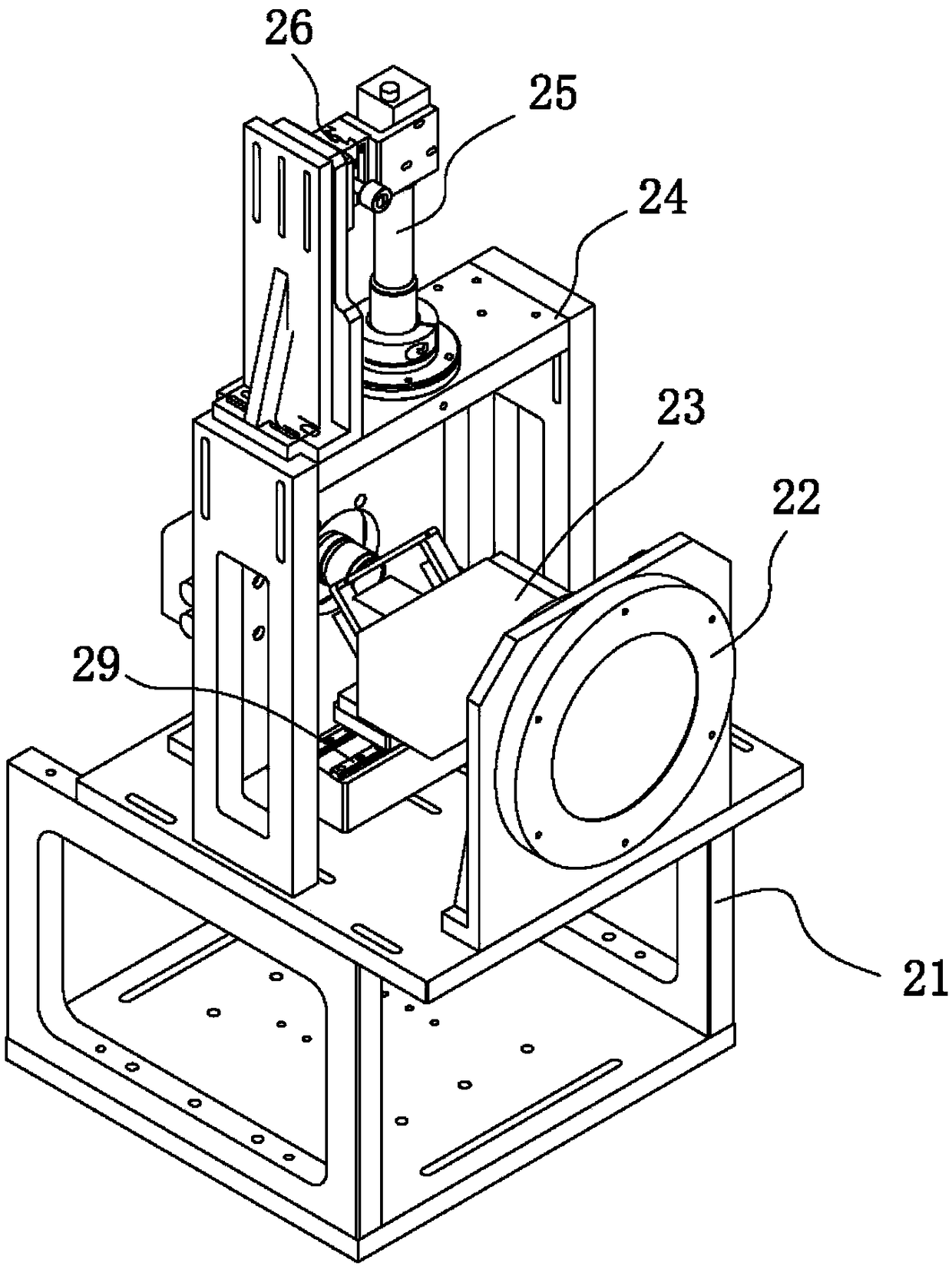

Dual-optical-path laser marking apparatus and making method thereof

ActiveCN108406089AWith automatic deviation detection functionGuarantee processing qualityLaser beam welding apparatusNanosecond laserPicosecond laser

The invention provides a dual-optical-path laser marking apparatus and a making method thereof. The dual-optical-path laser marking apparatus comprises a rack assembly, a camera assembly, a lifting platform mechanism, a jig assembly, a mirror assembly and an optics and galvanometer system. The camera assembly is used for carrying out bias detection on optical paths. The jig assembly is fixed to the lifting platform mechanism. The optics and galvanometer system comprises a platform, an optical fiber nanosecond laser device and a picosecond laser device, an optical path system, a galvanometer and a field lens, wherein the optical fiber nanosecond laser device and the picosecond laser device are fixed to the platform, the optical path system is arranged in front of the optical fiber nanosecond laser device and the picosecond laser device, the galvanometer is connected with the optical path system, and the field lens is located below the galvanometer. Lasers respectively emitted by the optical fiber nanosecond laser device and the picosecond laser device pass through the optical path system, then enter the galvanometer in an incidence manner, and carry out laser processing on productsthrough the field lens. According to the dual-optical-path laser marking apparatus, the picosecond laser device is used for carrying out high-speed outline scanning on products, the nanosecond laser device is used for outline filling, the processing quality is effectively guaranteed, and the production efficiency is improved at the same time.

Owner:深圳市大族半导体装备科技有限公司

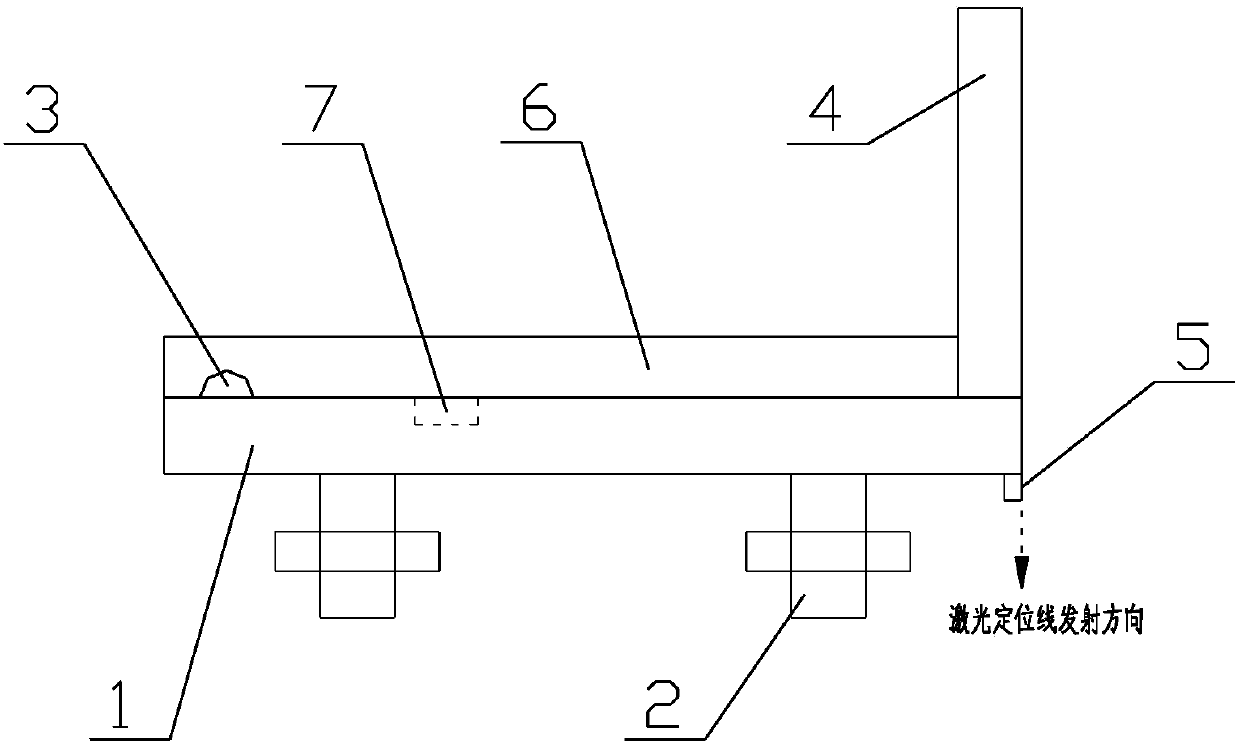

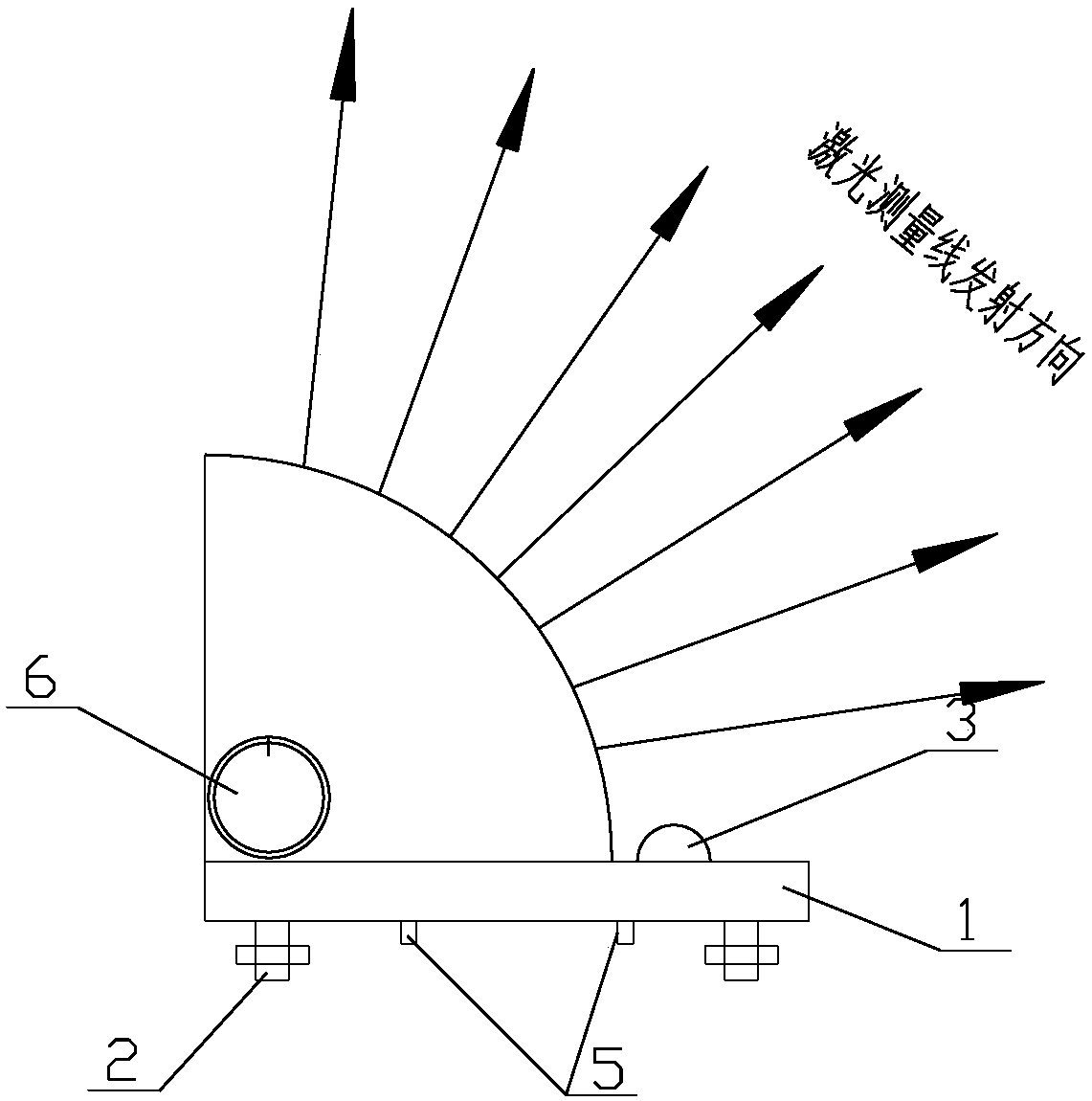

Device and method for detecting deviation of flatness and verticality of wall surface

ActiveCN107727014AImprove applicabilityEasy to measureUsing optical meansFixed angles setting outLaser transmitterBias detection

The invention relates to a device and method for detecting deviation of flatness and verticality of a wall surface. The device comprises a horizontal plate, leveling knobs, a leveling bubble, a sector-shaped laser emitter, a one word line laser, and a scale, wherein several leveling knobs are arranged at the bottom of the horizontal plate, the leveling bubble and the scale are arranged on the topof the horizontal plate, the sector-shaped laser emitter is arranged above the horizontal plate and can slide along the scale, the laser emission direction of the sector-shaped laser emitter is perpendicular to the scale direction of the scale, the one word line laser is arranged at the bottom of the horizontal plate, below the starting position of the scale, and the laser positioning line of theone word line laser is vertically downward and is in the same elevation plane as the zero scale point of the scale. The device and method can conveniently and quickly measure the absolute deviation ofthe flatness and verticality of various parts of the entire wall surface and have high measurement accuracy.

Owner:CHINA THIRD METALLURGICAL GRP

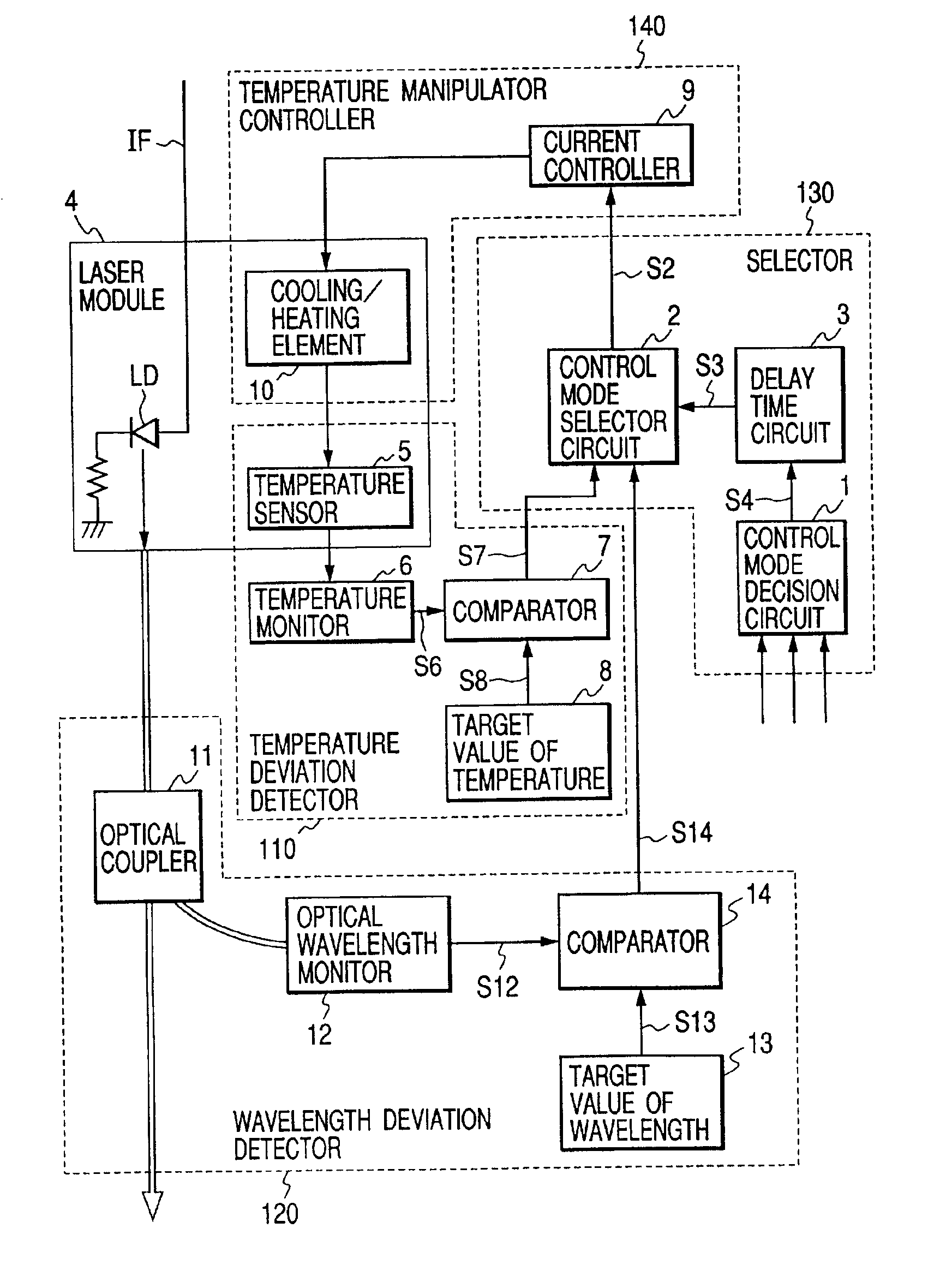

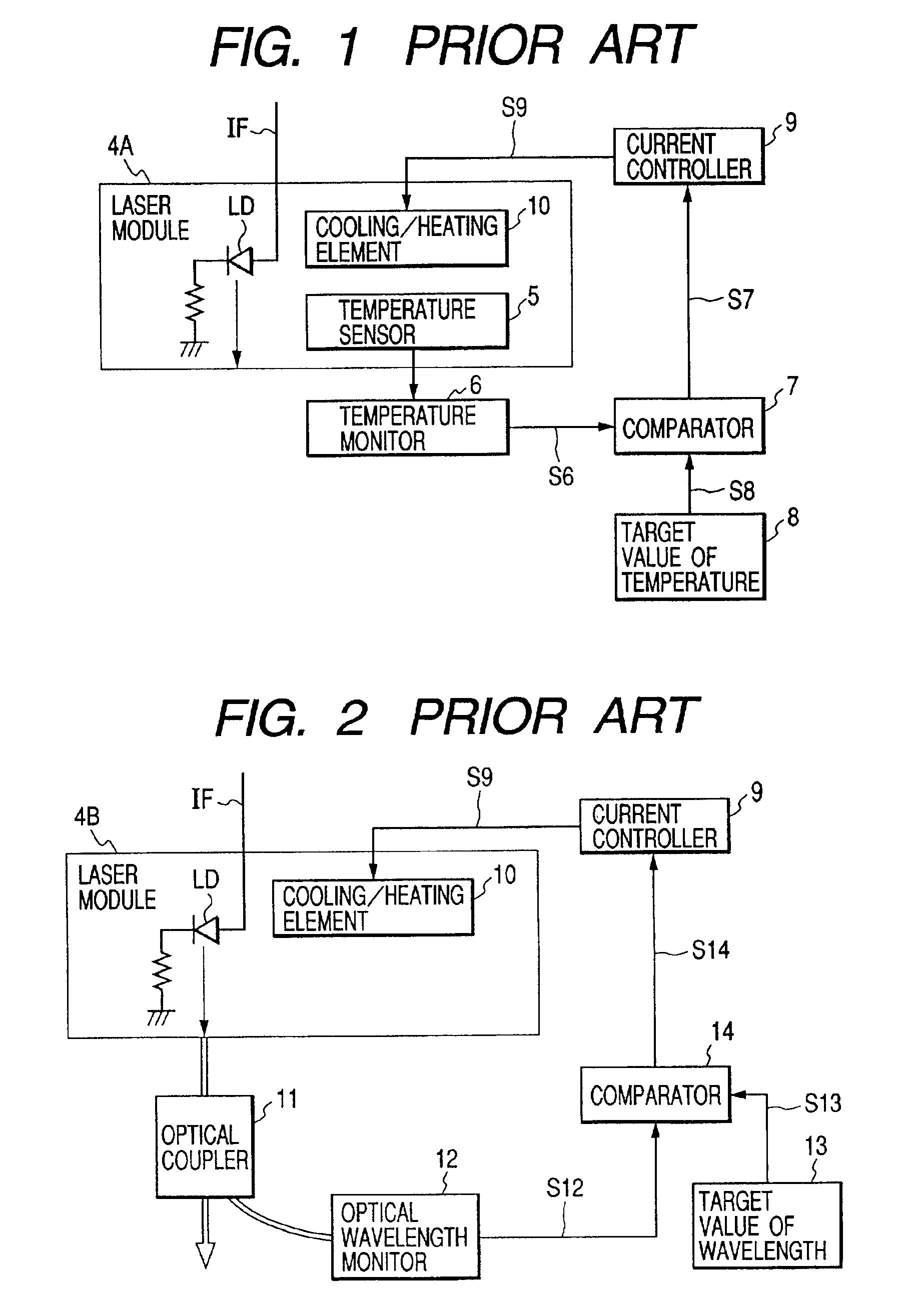

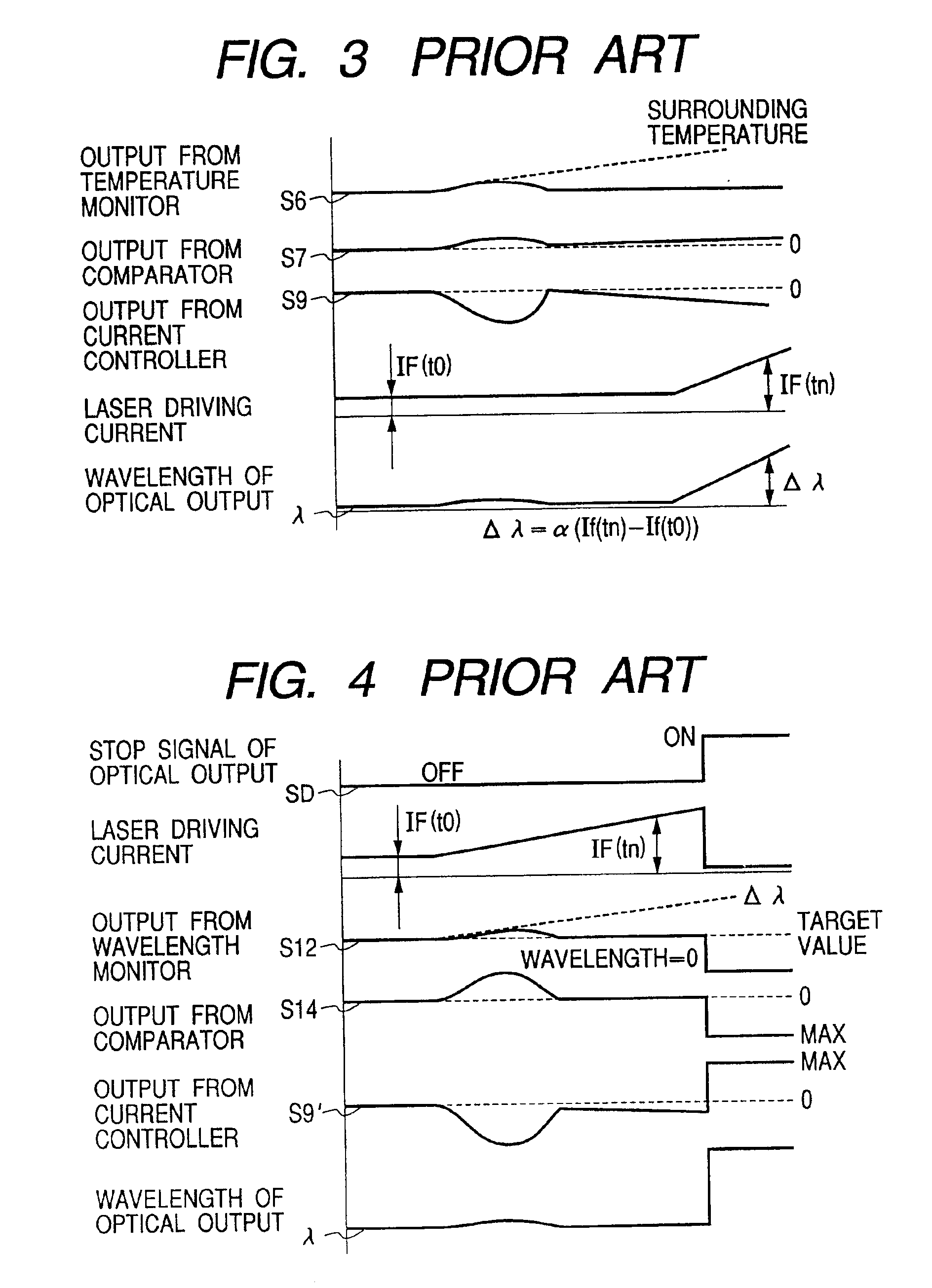

Control method and apparatus for stabilizing optical wavelength

InactiveUS6891867B2Improve accuracyImproved wavelength stabilityWavelength-division multiplex systemsDistortion/dispersion eliminationControl signalBias detection

A control apparatus for stabilizing optical wavelength output by a laser module in which a laser element, temperature sensor and cooling / heating element are installed, comprises a temperature deviation detecting circuit comprising a temperature monitor for detecting a laser temperature, and a first comparator for outputting a first control signal indicating a difference between the laser temperature and a control target value, a wavelength deviation detecting circuit comprising a wavelength monitor for detecting light output from the laser element, and a second comparator for outputting a second control signal indicating a difference between the wavelength of the detected output light and a control target value, a selector circuit for selecting either of the detecting circuits according to the external conditions of the laser element, and a current controller for controlling the current supplied to the cooling / heating element based on the output signal from the selected detecting circuit.

Owner:LUMENTUM JAPAN INC

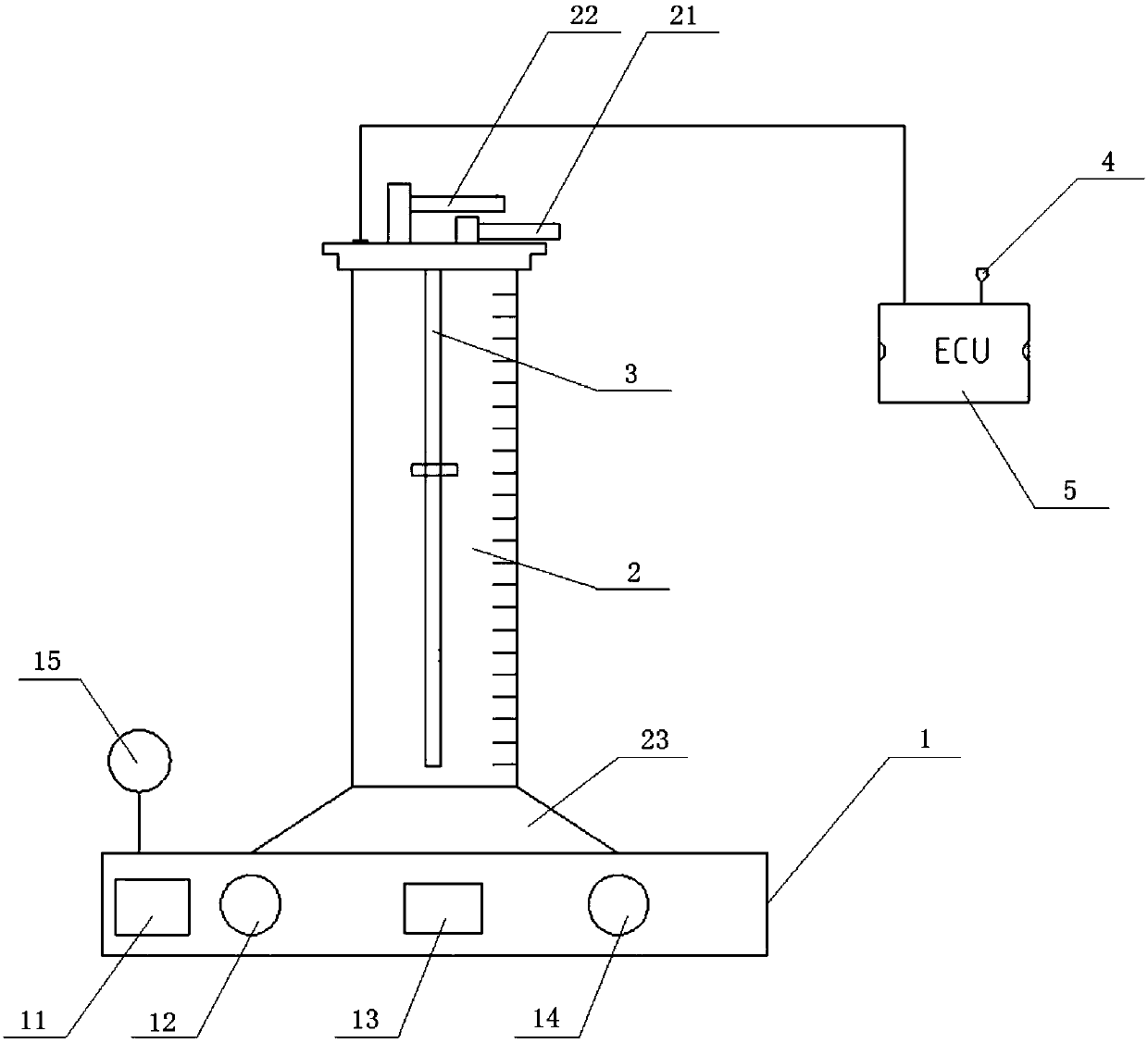

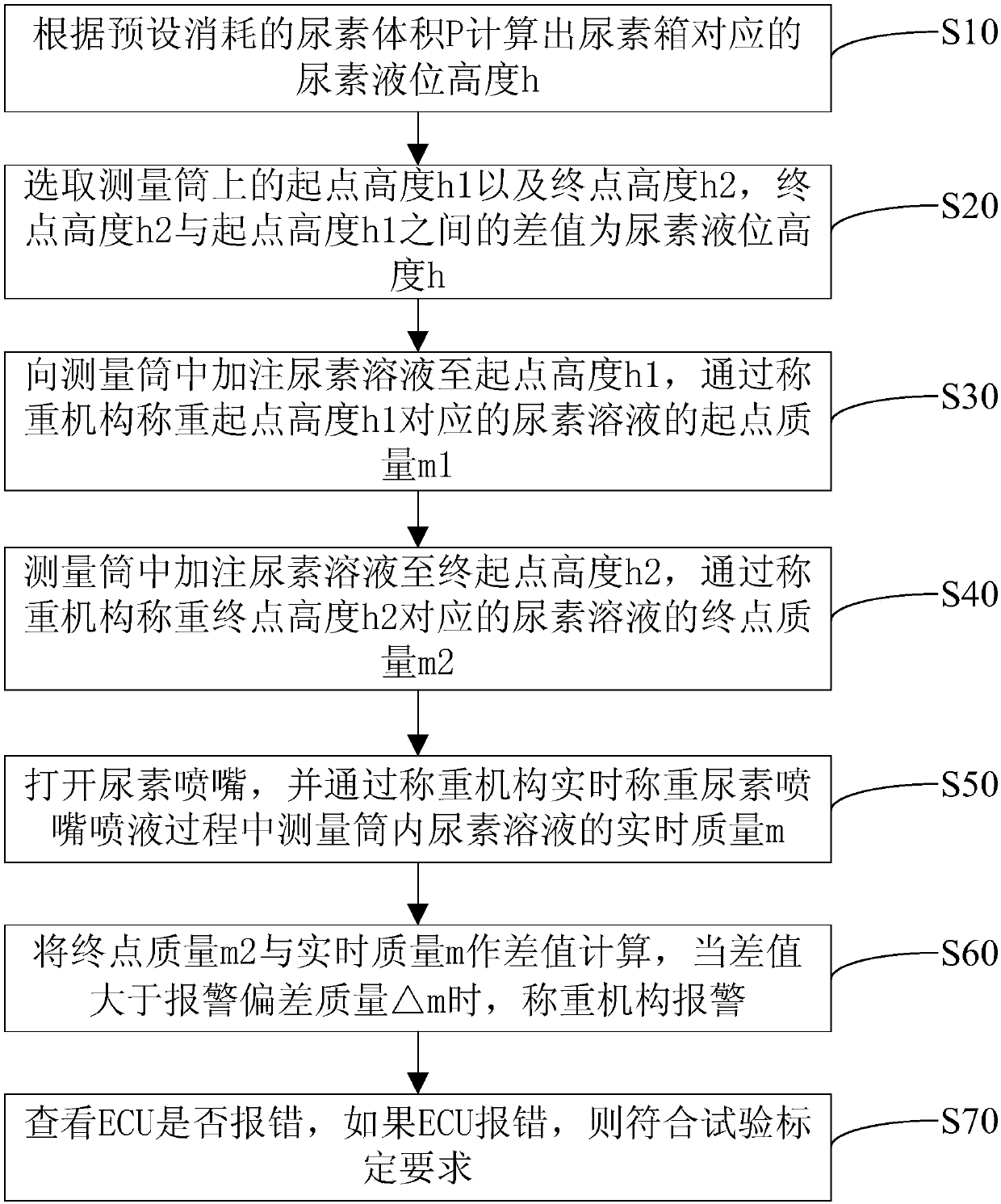

Urea consumption deviation fault simulation device and method

ActiveCN107942998ARealize simulationAvoid wastingProgramme controlElectric testing/monitoringBias detectionEngineering

The present invention belongs to the technical field of urea consumption deviation detection, and discloses a urea consumption deviation fault simulation device and method. The urea consumption deviation fault simulation device comprises a weighing mechanism, a measurement cylinder arranged on the weighing mechanism, a liquid level sensor arranged on the measurement cylinder and configured to detect a liquid level of urea solution in the measurement cylinder, a urea nozzle connected with the measurement cylinder, and an ECU connected with the liquid level sensor and the urea nozzle. The urea consumption deviation fault simulation device can achieve simulation of urea consumption deviation faults and replaces a mode of simulation through adoption of urea leakage in the prior art so as to avoid urea waste and environment pollution; and moreover, the urea consumption deviation fault simulation device is employed for simulation, is low in cost and can effectively reduce the burden of enterprises.

Owner:WEICHAI POWER CO LTD

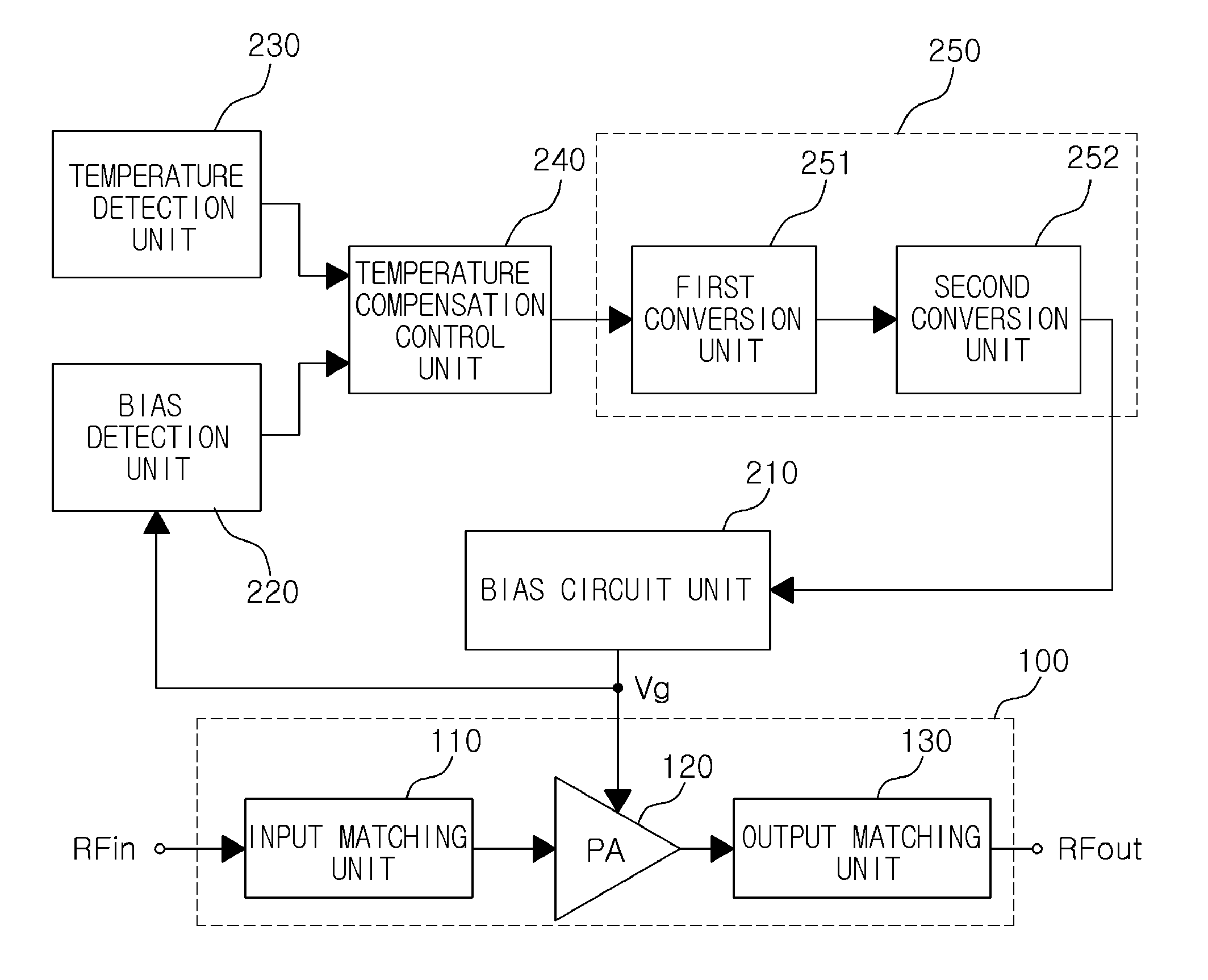

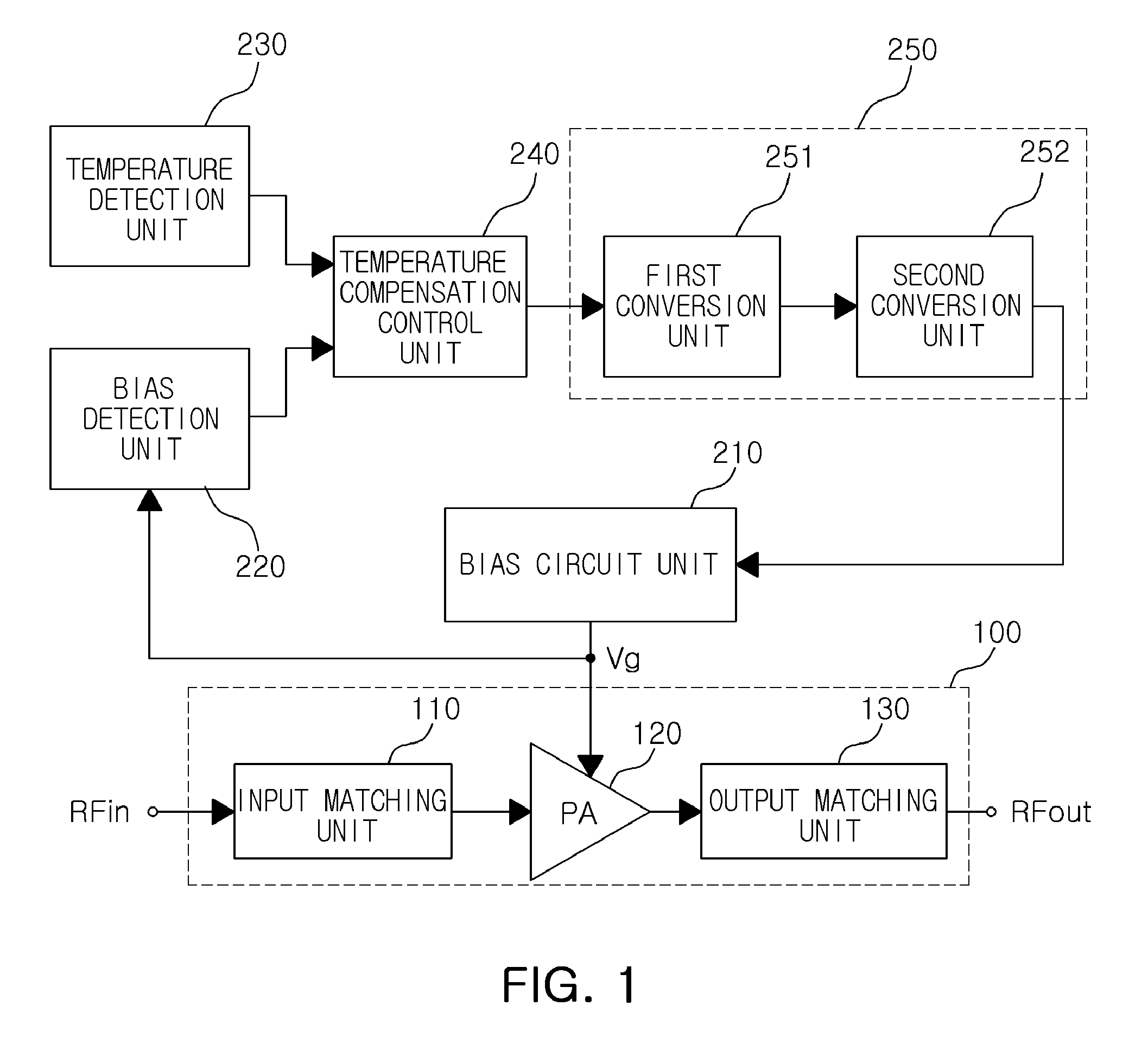

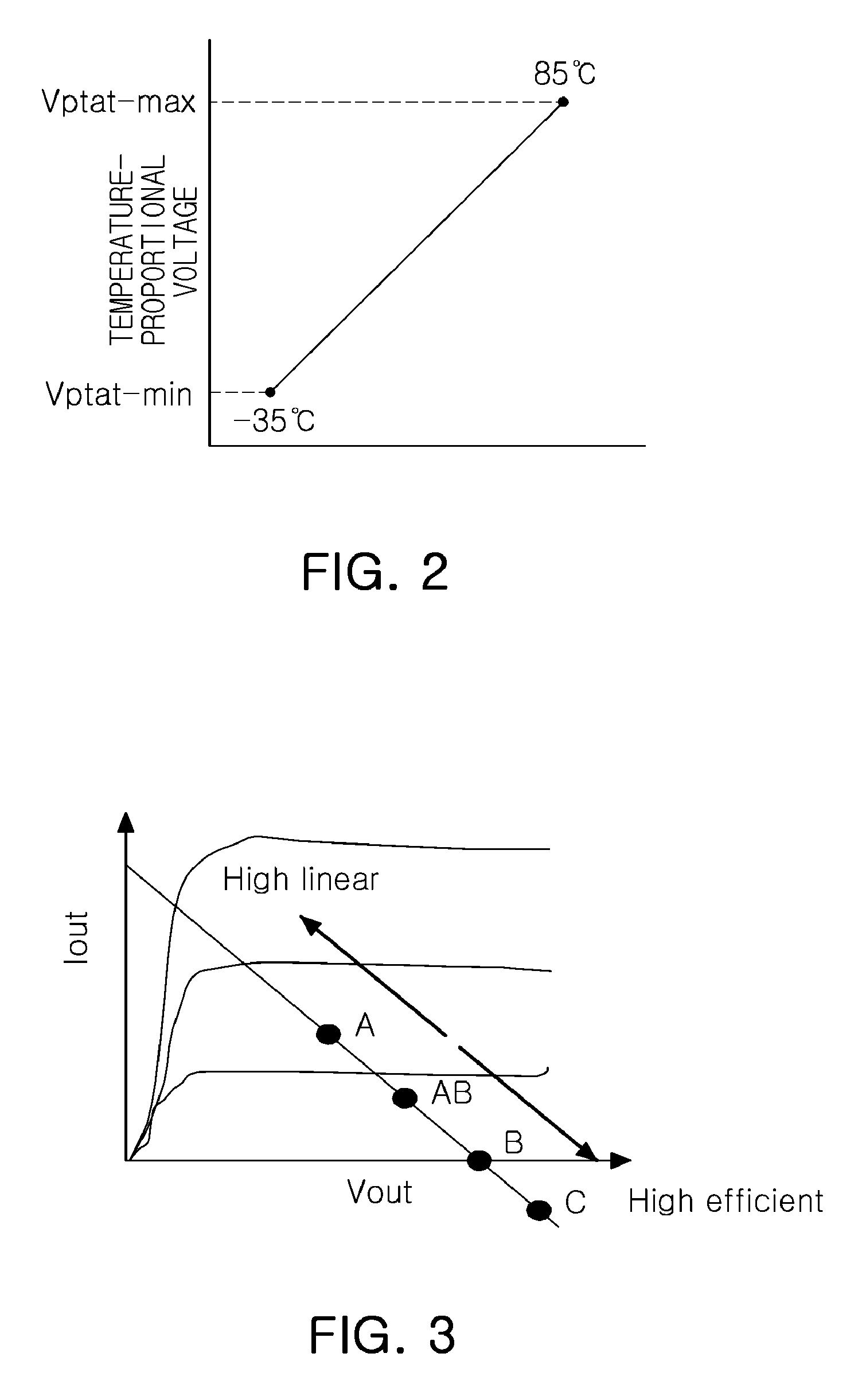

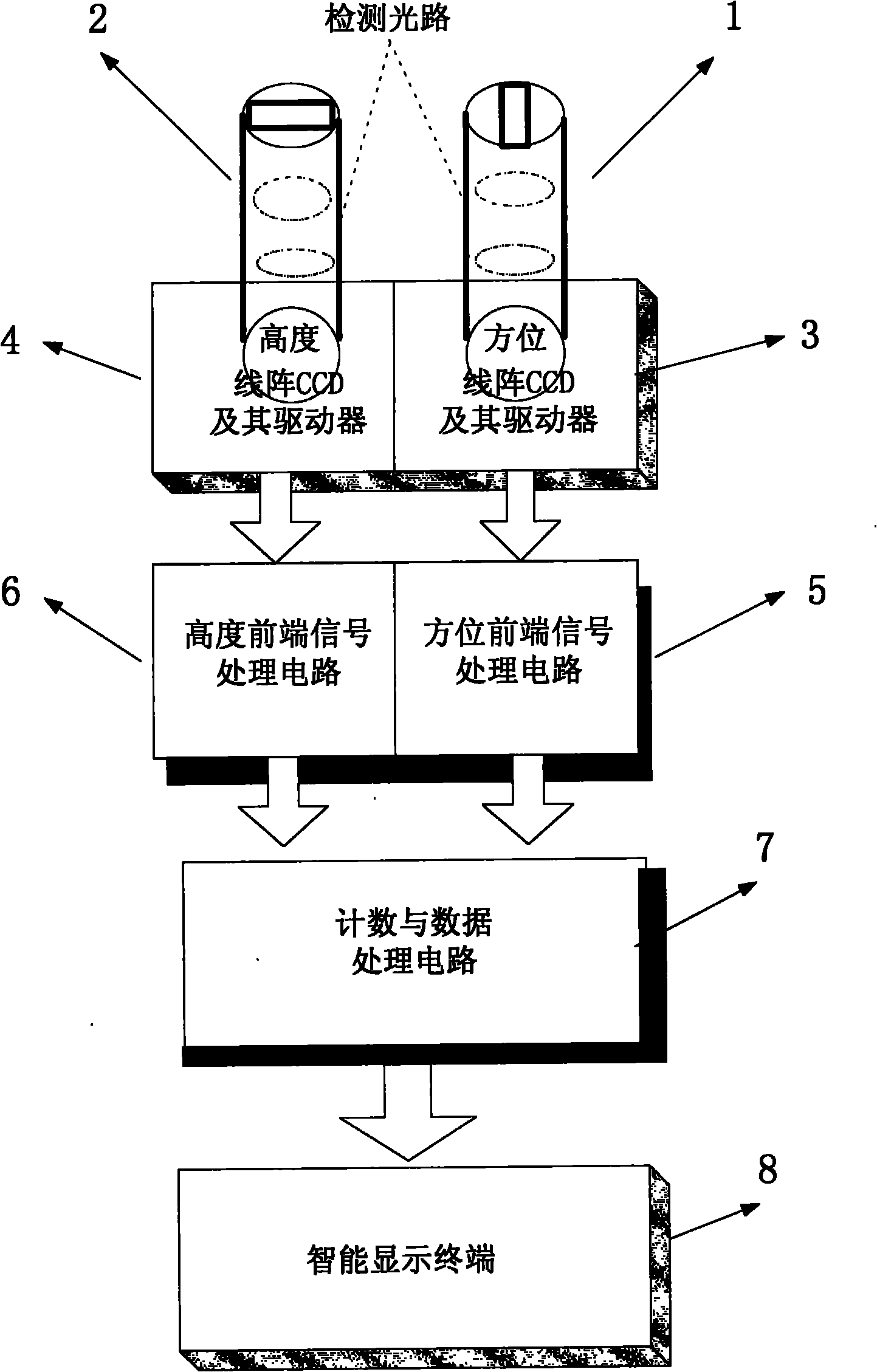

CMOS power amplifier and temperature compensation circuit thereof

ActiveUS8183928B2Amplifier modifications to reduce temperature/voltage variationGain controlBias detectionEngineering

Disclosed is a CMOS power amplifier. A temperature compensation circuit of a CMOS power amplifier may include: a bias circuit unit supplying a gate bias voltage to a power amplification circuit part; a bias detection unit determining a class type of the power amplification circuit part according to the gate bias voltage; a temperature detection unit detecting a temperature-proportional voltage in proportion to ambient temperature; a temperature compensation control unit generating a compensation control value according to the temperature-proportion voltage in the class type determined by the bias detection unit; and a conversion unit converting the compensation control value of the temperature compensation control unit into a linear bias control value and providing the linear bias control value to the bias circuit unit, wherein the bias circuit unit compensates the gate bias voltage according to the linear bias control value of the conversion unit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

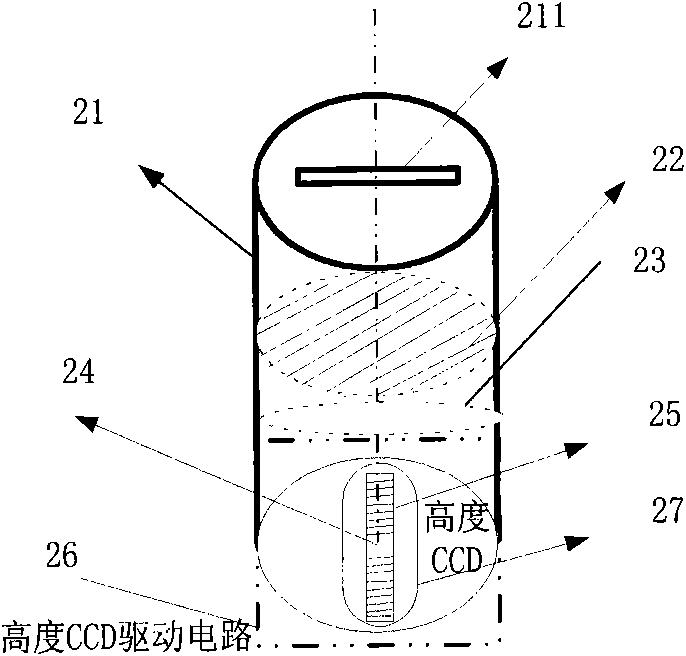

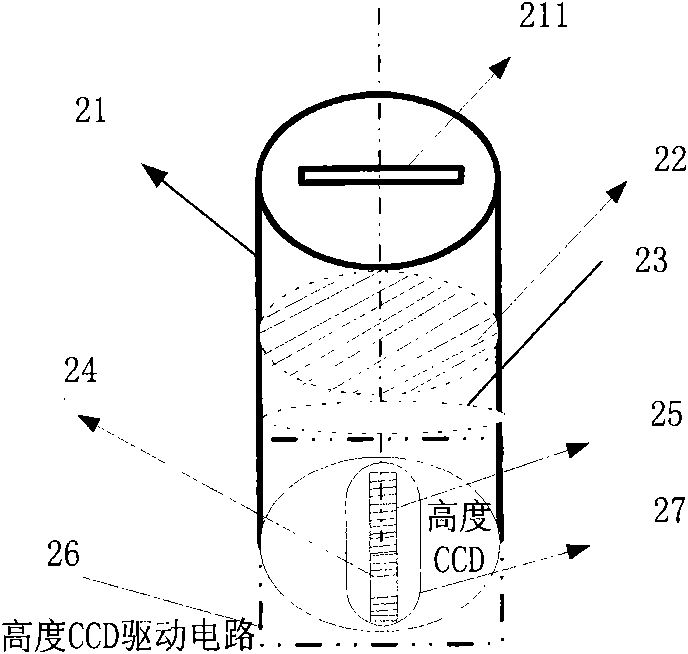

Solar tracking angular deviation detector for linear array CCD (Charge Coupled Device)

InactiveCN102062595AImprove developmentPromote perfectionAngle measurementSignal processing circuitsSolar tracking system

The invention discloses a solar tracking angular deviation detector for detecting errors of a tracking system in the photovoltaic power generation. By using the detector, the analytical value of the solar tracking angular deviation can be obtained, thereby reasonably and effectively evaluating the solar tracking precision of the traditional solar tracking angular deviation in the market in the photovoltaic power generation. The solar tracking precision is an important index of the solar tracking system and an important basis for measuring the quality of the solar tracking system. For achieving the aim, the solar tracking angular deviation can be measured by adopting the linear array CCD (Charge Coupled Device); an optical path and a signal processing circuit are designed; and the solar tracking angular deviation value can be determined according to the difference of sunlight incident angles and the change relationship of the imaging of the edge projection of a luminous seam on the CCD, mainly including the detection for the tracking angular deviation of an elevating angle and an azimuth angle; and finally, the detection result is subjected to the data processing and analyzing and is displayed by an intelligent display terminal, or can be transmitted to other processors through serial ports for further processing.

Owner:HEBEI INST OF METROLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com