Coaxiality detection apparatus

A detection device and coaxiality technology, which is applied in the detection field, can solve problems such as measurement error and deviation value deviation, and achieve the effects of accurate measurement results, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

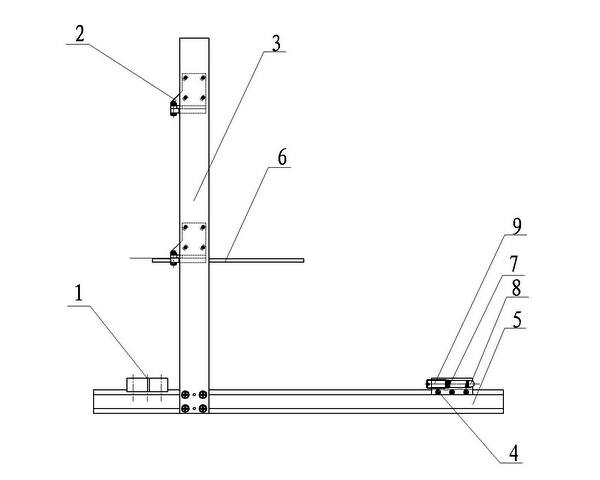

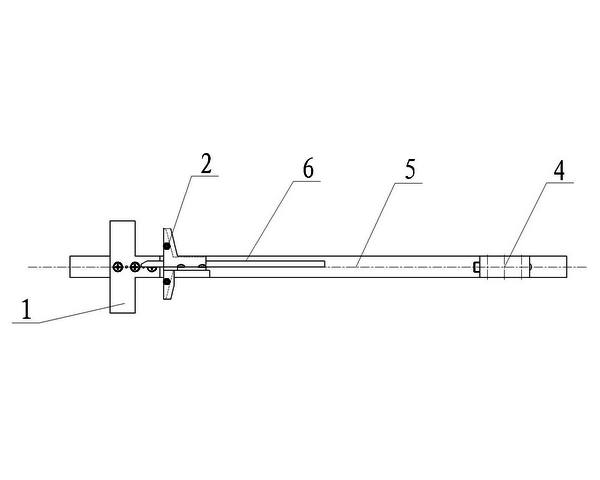

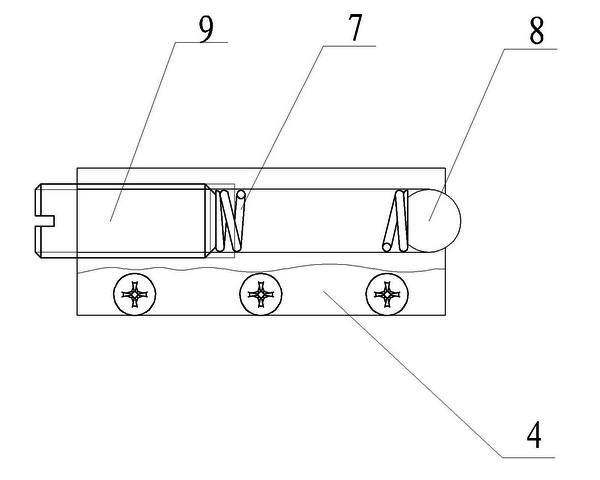

[0009] Such as figure 1 , figure 2 , image 3 As shown, the cross bar 5 is equipped with a vertical bar 3 as a virtual reference axis for measurement. The vertical bar 3 and the cross bar 5 can be replaced according to the depth and aperture of the measured product. On the bar 5, there are multiple connection holes on the cross bar 5, which are used for the positioning block 1 and the top block 4 to move according to the aperture of the measured product. The spring 7 and the steel ball 8, the spring 7 is positioned by the set screw 9, the depth gauge 6 is installed on the vertical rod 3 through the ruler base 2, and the ruler base 2 is fixed on the vertical rod 3 by the taper pin.

[0010] When measuring, the reference element (reference cylinder) is used as the basis for positioning, and the axis of the reference cylinder can be virtualized and replaced by a vertical rod 3 . When in use, first horizontally position the cross bar 5 on the end face of the reference cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com