Urea consumption deviation fault simulation device and method

A technology of deviation faults and simulation devices, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as urea waste, environmental pollution test costs, etc., to reduce the burden on enterprises, avoid waste and environmental pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

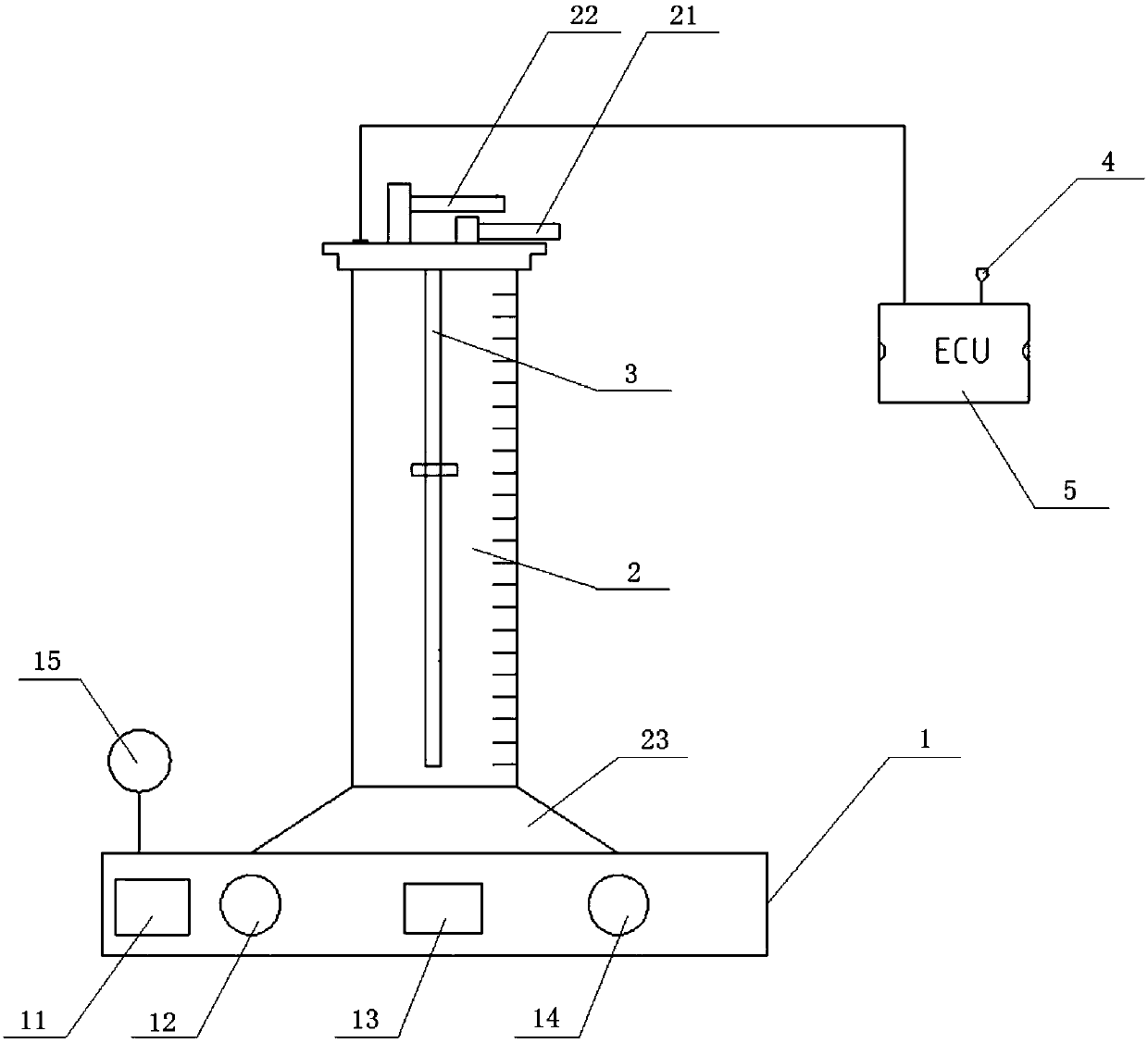

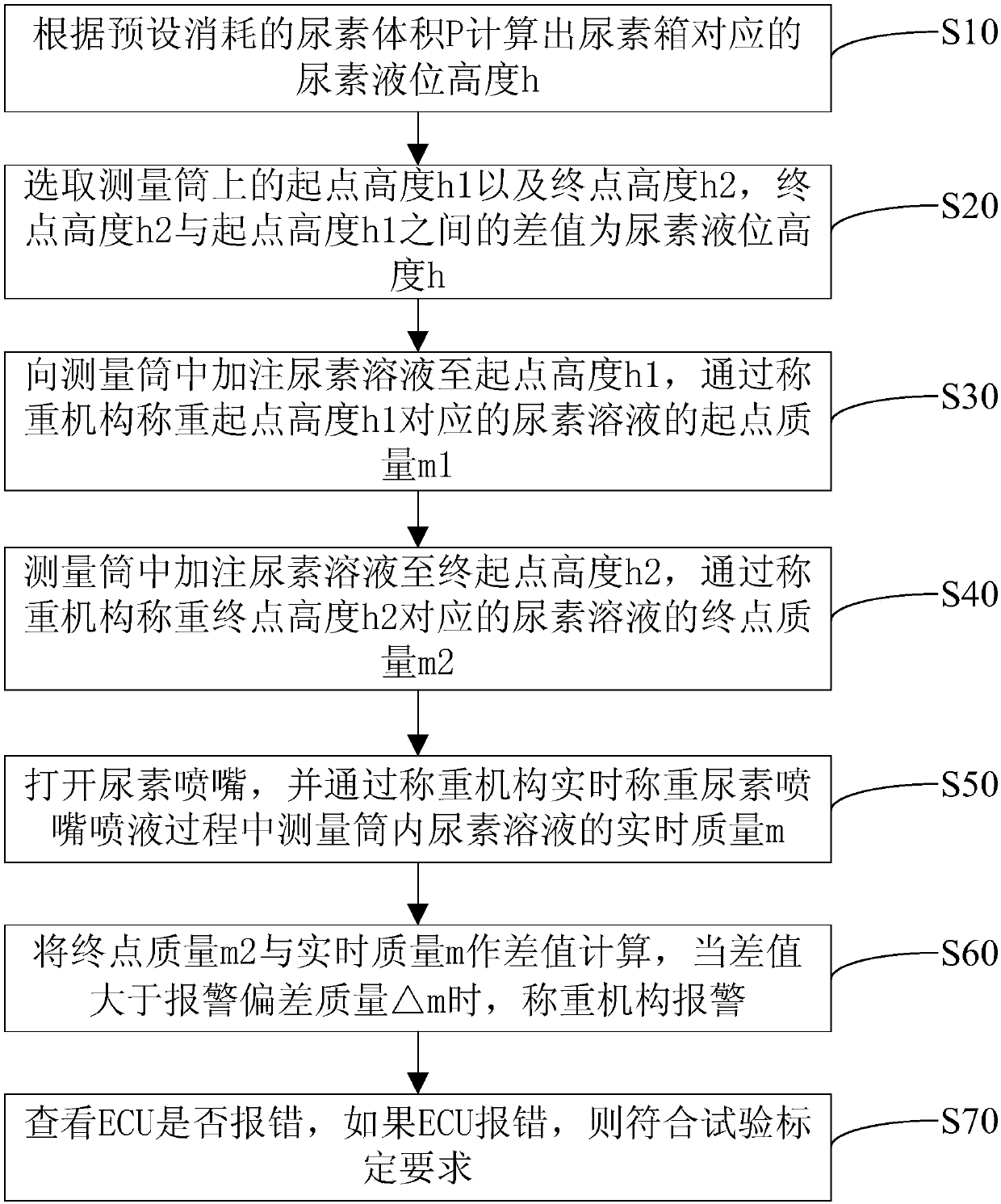

[0035] Such as figure 1 As shown, the present invention provides a urea consumption deviation fault simulation device, including a weighing mechanism 1, a measuring cylinder 2, a liquid level sensor 3, a urea nozzle 4, and an ECU 5, wherein:

[0036] The weighing mechanism 1 is used to weigh the measuring cylinder 2 and the urea solution in the measuring cylinder 2, and the weighing mechanism 1 is sequentially provided with a weight display 11, an initial value setting button 12, an alarm deviation value, etc. from left to right. Setting panel 13 and zero return button 14, wherein weight indicator 11 is used for displaying the weight of the urea solution in measuring cylinder 2 and measuring cylinder 2, initial value setting button 12 is used for setting reference quality, alarm deviation value sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com