Check method of photomask diagram position deviation

An inspection method and technology of photolithography plates, which are applied in microlithography exposure equipment, photolithography exposure devices, etc., can solve the problems of high cost, no effective way to check the pattern position deviation of photolithography plates, and no yield rate of products. , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The best mode for carrying out the present invention will be described below with reference to the drawings.

[0029] The invention uses a photolithography machine exposure test engraving method to monitor the pattern position deviation of the photolithography plate.

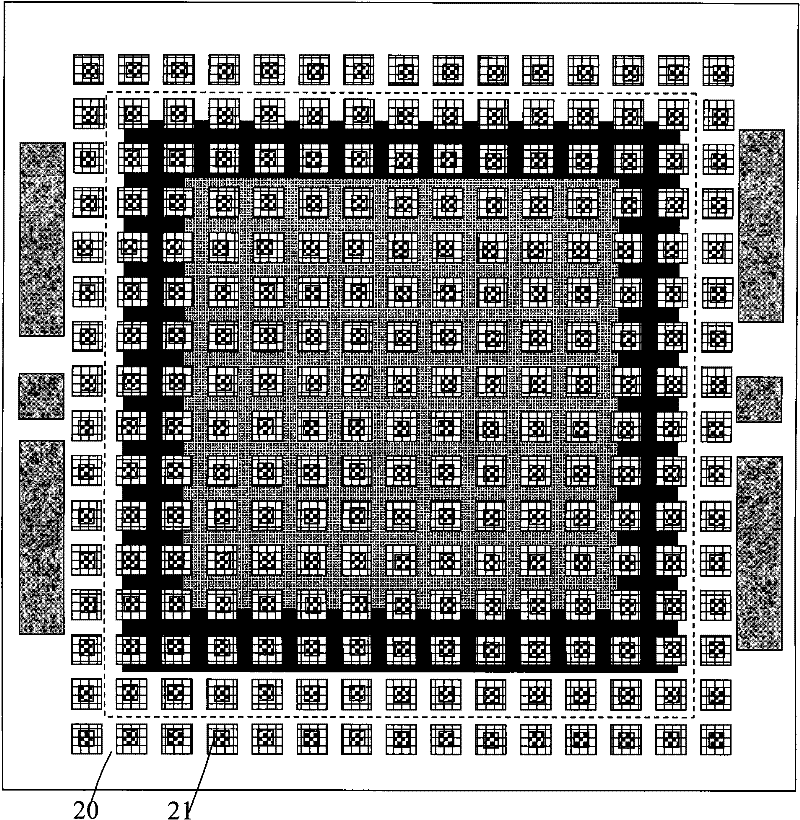

[0030] Photolithography overlay detection is a basic semiconductor photolithography process. The basic principle is to confirm the overlay value by comparing the difference in the center point distance of the left and right sides of the bar graph under the light of an optical microscope.

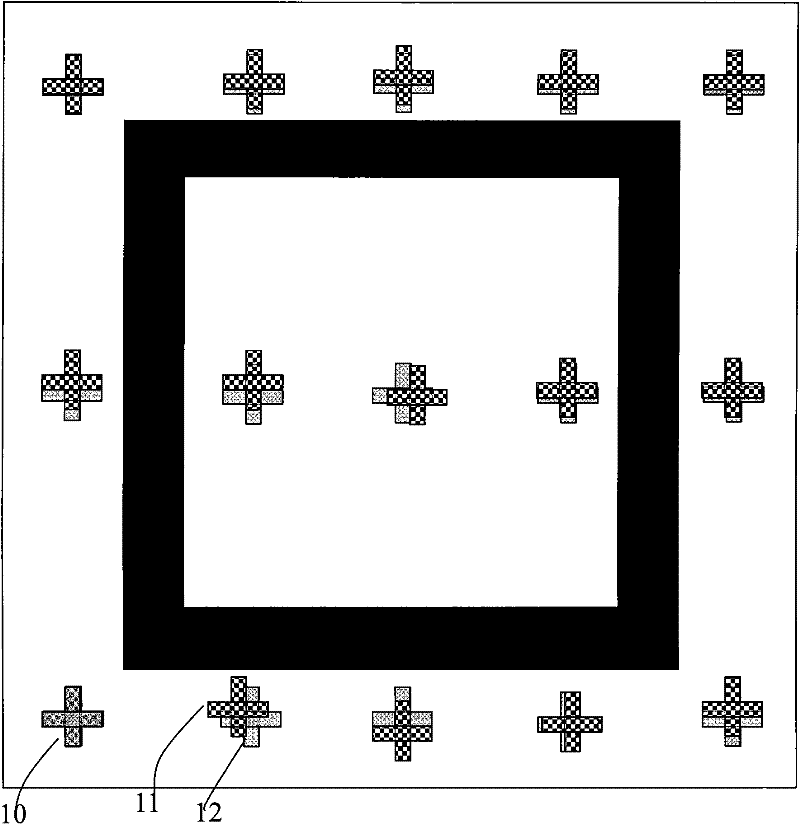

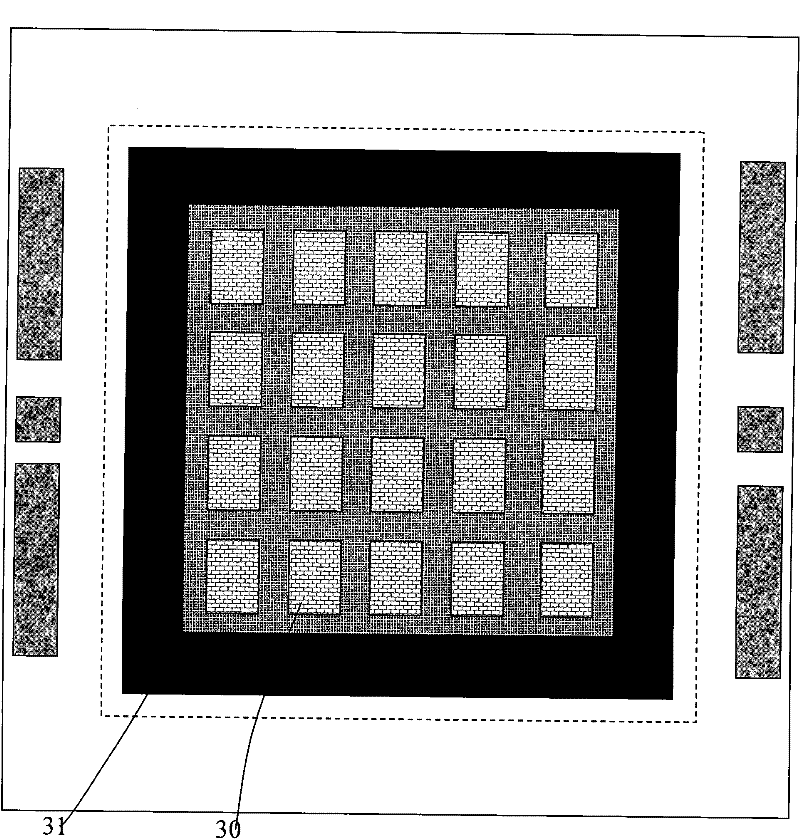

[0031] The invention is to place a lot of reference overlay outer frames on the wafer, place an inner frame on the photolithographic plate to be tested, and confirm the pattern position deviation of the photolithographic plate by measuring the overlay.

[0032] The present invention is to make a reference photolithographic plate first, and place the outer frame 20 of overlay mark on it, then test the graphic position de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com