Pressure container shape deviation detection method based on three-dimensional laser scanning

A three-dimensional laser and pressure vessel technology, which is applied in the direction of instruments, measuring devices, and optical devices, can solve the problems of difficult automatic measurement, high labor intensity, waste of resources, etc., and achieve easy automatic measurement, high measurement accuracy, and labor saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

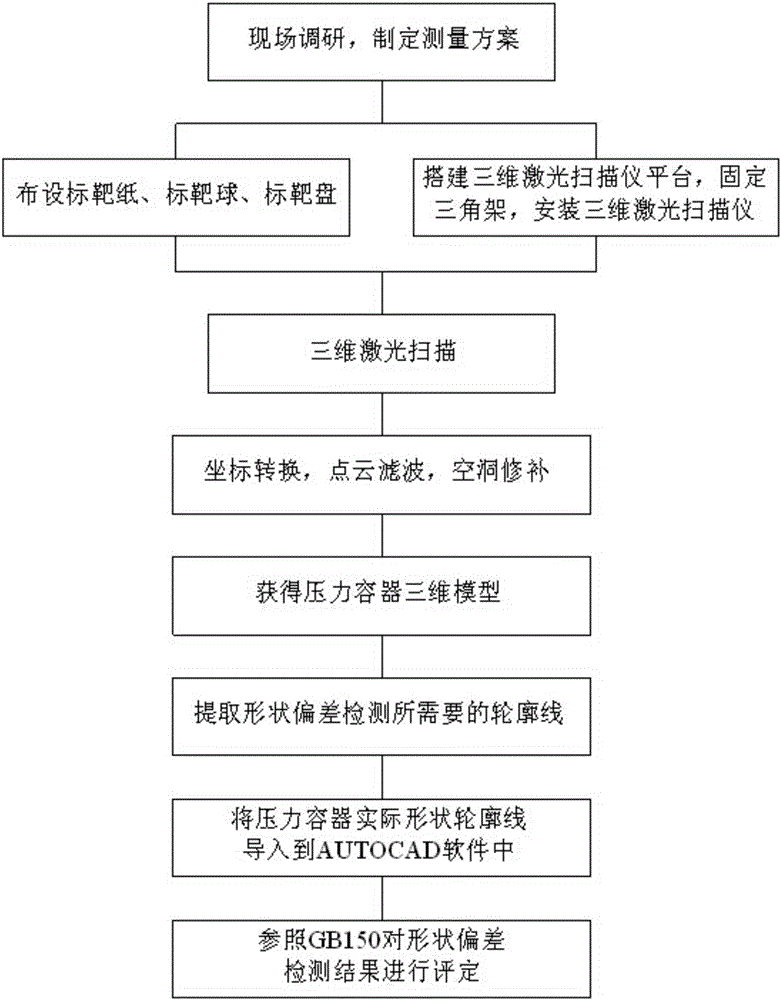

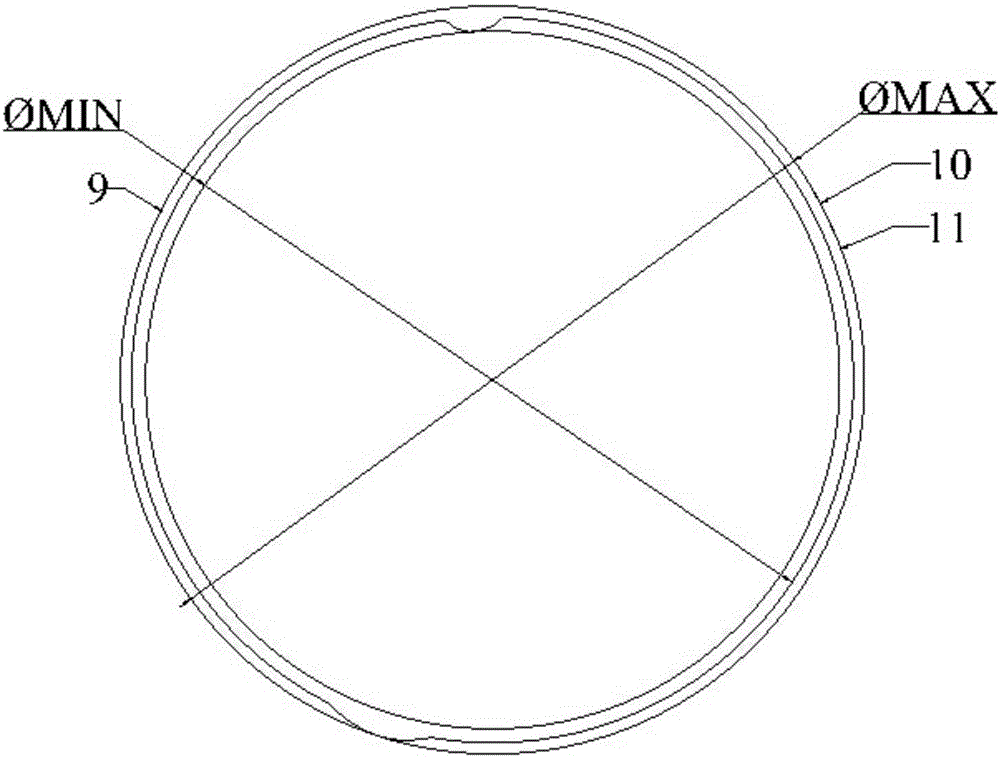

[0036] like figure 1 A method for detecting the shape deviation of a pressure vessel based on three-dimensional laser scanning is shown, which is used to detect the roundness of the cylinder and the shape deviation of the elliptical head, which specifically includes the following steps:

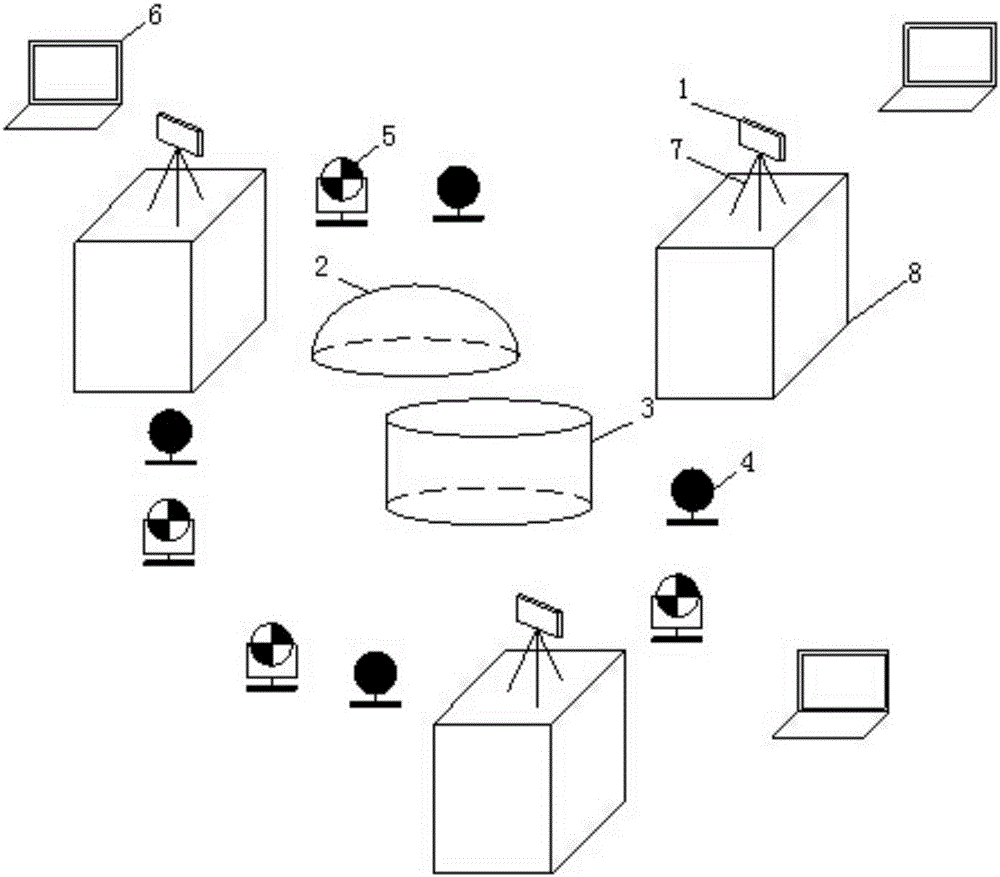

[0037] (1) Arrange a three-dimensional laser scanning device around the cylinder body 3 and the head 2 . The three-dimensional laser scanning device comprises a three-dimensional laser scanner 1, a tripod 7, a three-dimensional laser scanner installation platform 8, a target paper, a target ball 4, a target disc 5 and a computer 6 capable of receiving wireless signals; wherein, the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com