Method for detecting register deviation based on machine vision register control system

A technology of machine vision and registration deviation, which is applied to the general parts of printing machinery, printing machines, electrical testing/monitoring, etc., can solve the problems of unusable printing plates and increase the cost of plate replacement, achieve intuitive visual inspection, and promote industry Technological progress, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

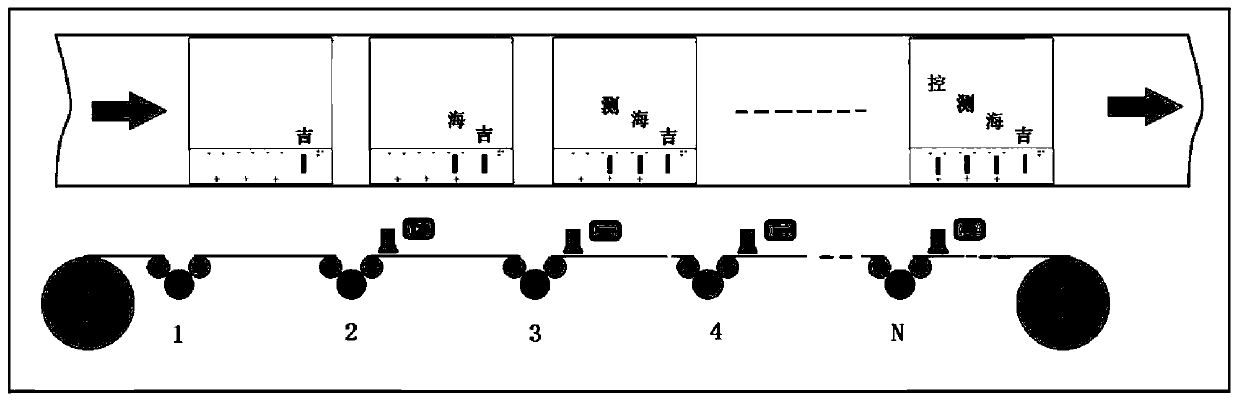

[0036] Embodiment 1 (rectangular photoelectric color scale)

[0037] 1) Set the camera of the machine vision registration control system so that the camera can obtain the image of the color mark area. For the rectangular photoelectric color mark, the image of the color mark area can contain two color marks before and after;

[0038] 2) The camera acquires the image of the color mark area, and recognizes the color mark of the previous color and the color mark of the current color according to the order of overprinting;

[0039] 3) According to the size parameters given by the color code, such as length l, height h, and the row pixel value n contained in the color code x and column pixel value n y , calculate the pixel equivalent k of the color scale area image x and k y ;

[0040]

[0041] 4) Identify the feature point coordinates (x 0 ,y 0 ), and at the same time identify the feature point coordinates (x', y') of the back-color color scale in the color scale area imag...

Embodiment 2

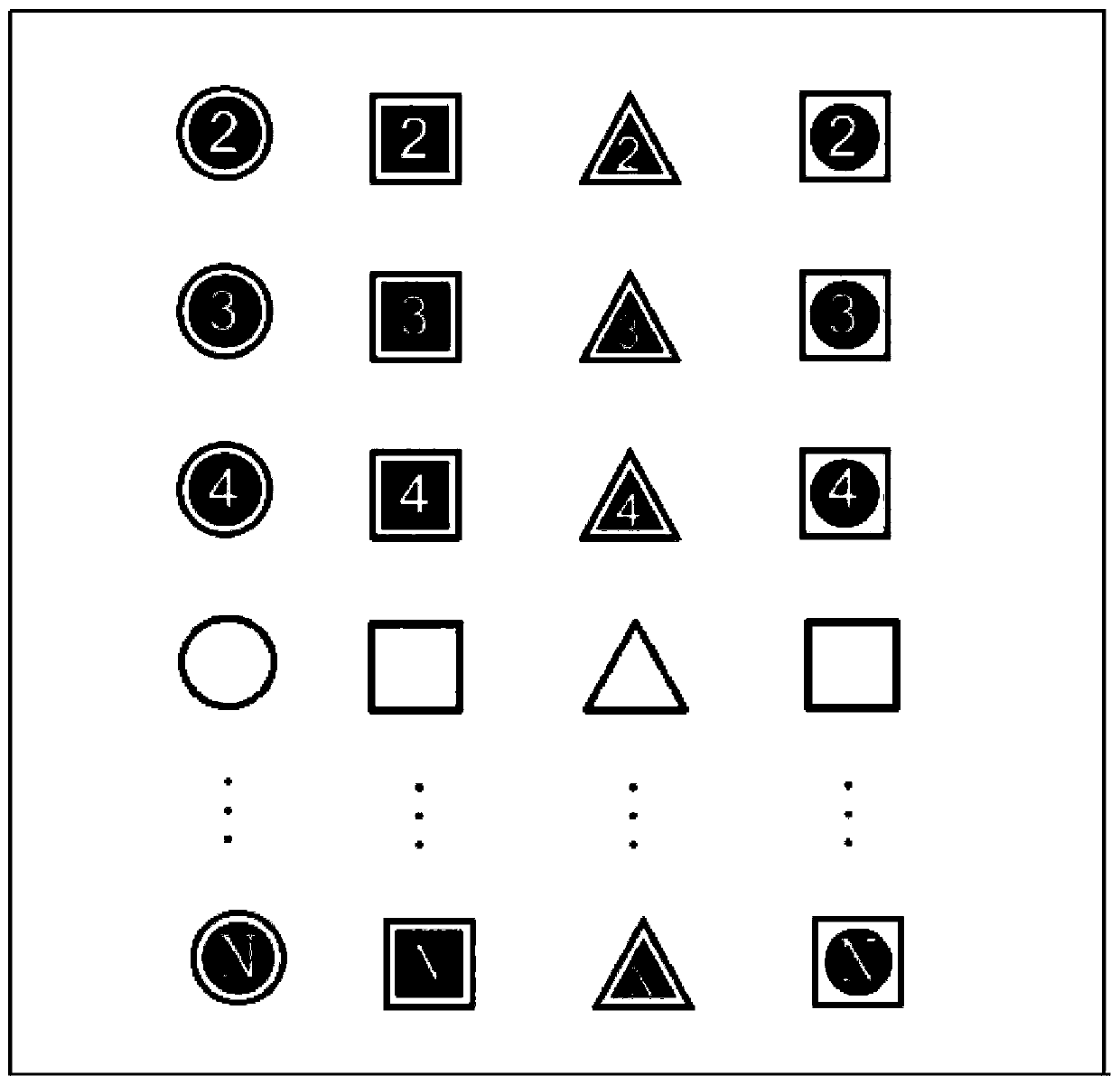

[0051] Embodiment 2 (circular image color scale)

[0052]1) Set the camera of the machine vision registration control system so that the camera can obtain the image of the color mark area. For the circular image color mark, the color mark area image can contain the color mark of the first color (equivalent to the color mark of the previous color) and the current color mark;

[0053] 2) The camera acquires the image of the color mark area, and recognizes the color mark of the previous color and the color mark of the current color according to the order of overprinting;

[0054] 3) According to the size value of each part of the color mark given during printing and plate making, such as the diameter of the circle 2r, according to the size parameter of the color mark and the row pixel value n contained in the color mark in the image x and column pixel value n y , calculate the pixel equivalent k of the color scale area image x and k y ;

[0055]

[0056] 4) Identify the f...

Embodiment 3

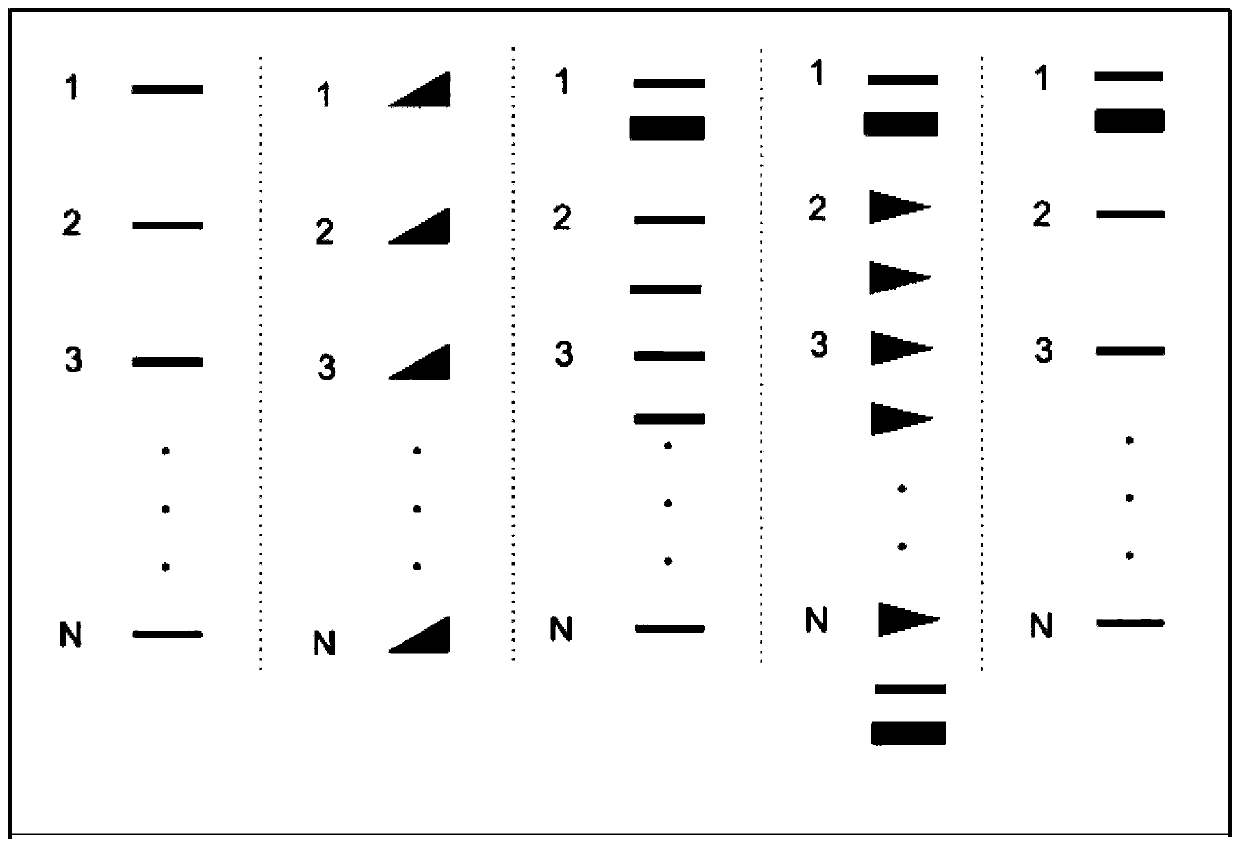

[0066] Embodiment 3 (dot matrix class image color scale)

[0067] 1) Set the camera of the machine vision registration control system so that the camera can acquire the image of the color mark area, and the color mark of the dot matrix image refers to the entire dot matrix area;

[0068] 2) The camera acquires the image of the color mark area, and recognizes the color mark of the previous color and the color mark of the current color according to the order of overprinting;

[0069] 3) According to the size values of each part of the color mark given during printing and plate making, such as length l, height h and diameter 2r, according to the given color mark parameters and the row pixel value n contained in the color mark in the image x and column pixel value n y , to calculate the pixel equivalent k of the color scale area image x , k y

[0070] or

[0071] 4) Identify the feature point coordinates (x 0 ,y 0 ), and at the same time identify the feature point coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com