Shelf posture deviation detecting method and system based on characteristic information graph

A feature information and deviation detection technology, which is applied in the field of warehouse shelf detection, can solve the problems of shelf parking posture changes, handling failure, shelf deviation, etc., and achieve the effect of low price, low cost and good system versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

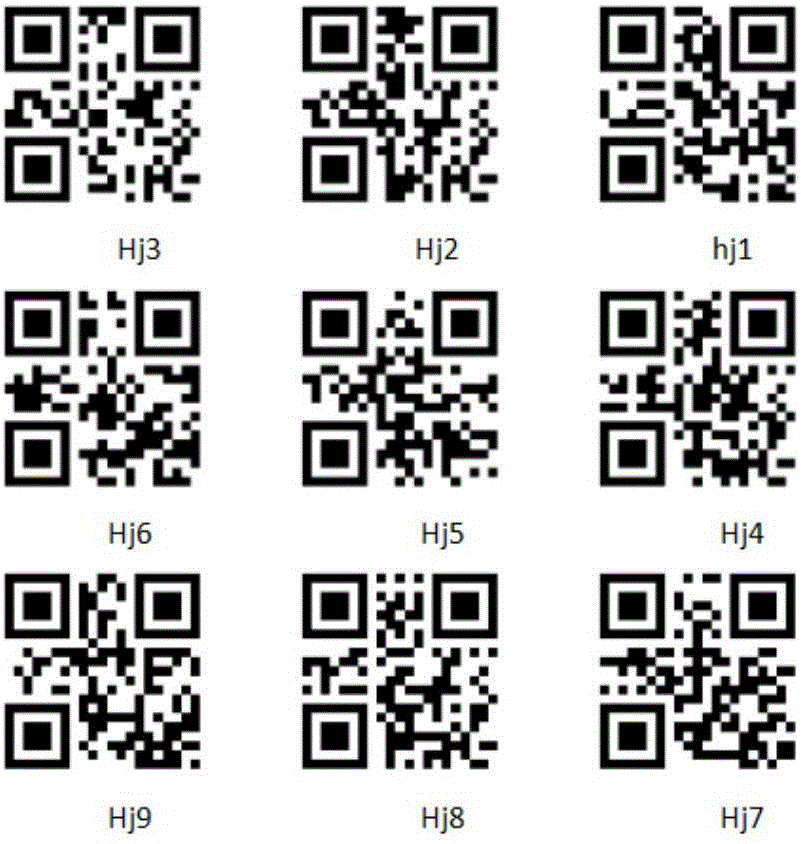

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The invention discloses a method for detecting shelf position deviation based on feature information graphics, which includes the following steps:

[0033] Step 1, install the upward-looking camera on the robot, so that the optical axis of the upward-looking camera faces upward, so that it is perpendicular to the bottom plane of the shelf;

[0034] Step 2, calibrate the mapping relationship between the camera pixel coordinate system and the robot coordinate system;

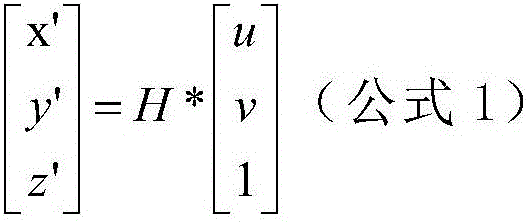

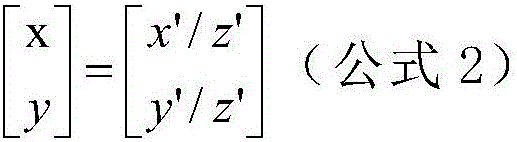

[0035] The mapping relationship refers to the homography matrix H of the camera, and its mathematical meaning is:

[0036]

[0037]

[0038] Among them, select the plane where the bottom of the shelf is located after the robot lifts the shelf as the reference plane, is the pixel coordinate of a point on the reference plane on the camera imaging plane, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com