Elevator guide rail comprehensive parameter detection and evaluation method and detection system

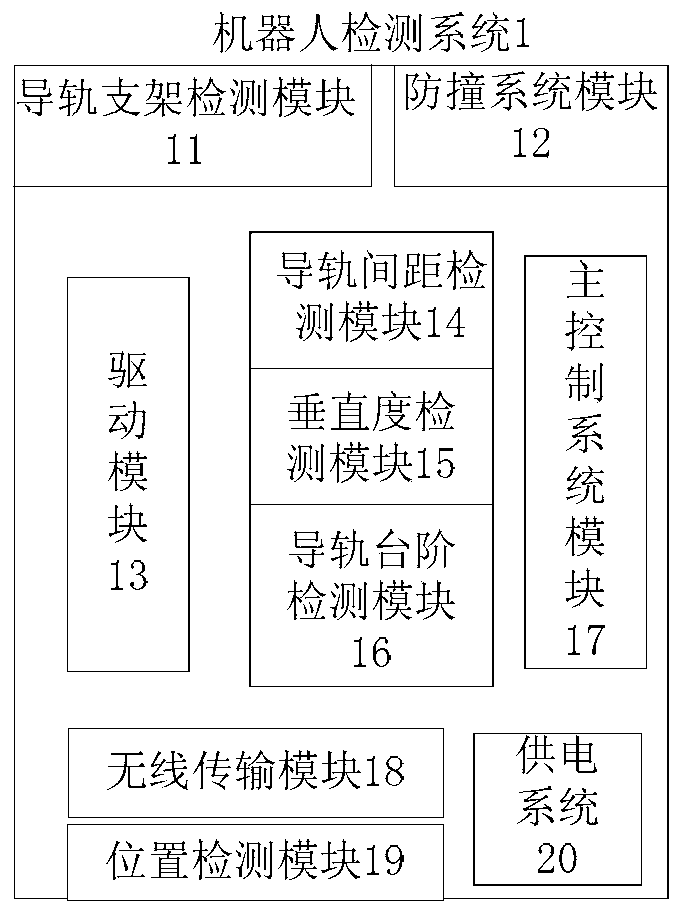

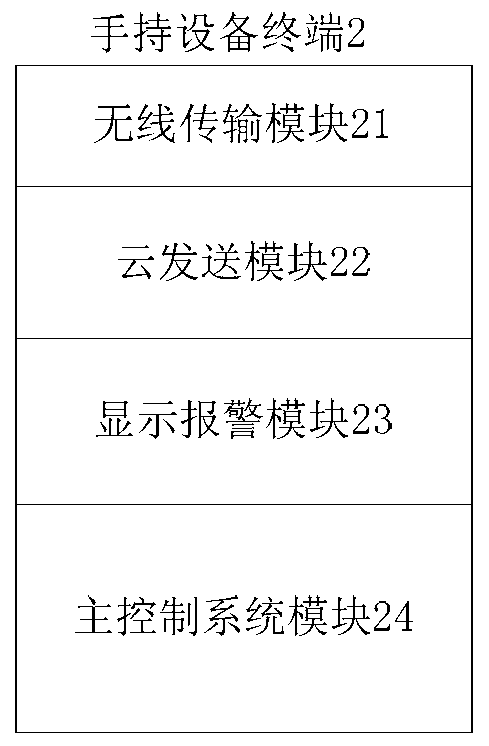

A technology of comprehensive parameters and elevator guide rails, applied in general control systems, control/adjustment systems, measuring devices, etc., can solve the problems of robot assembly error, no detection items, and inaccurate detection results, etc., and achieve compact structure, Ease of on-site operation and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

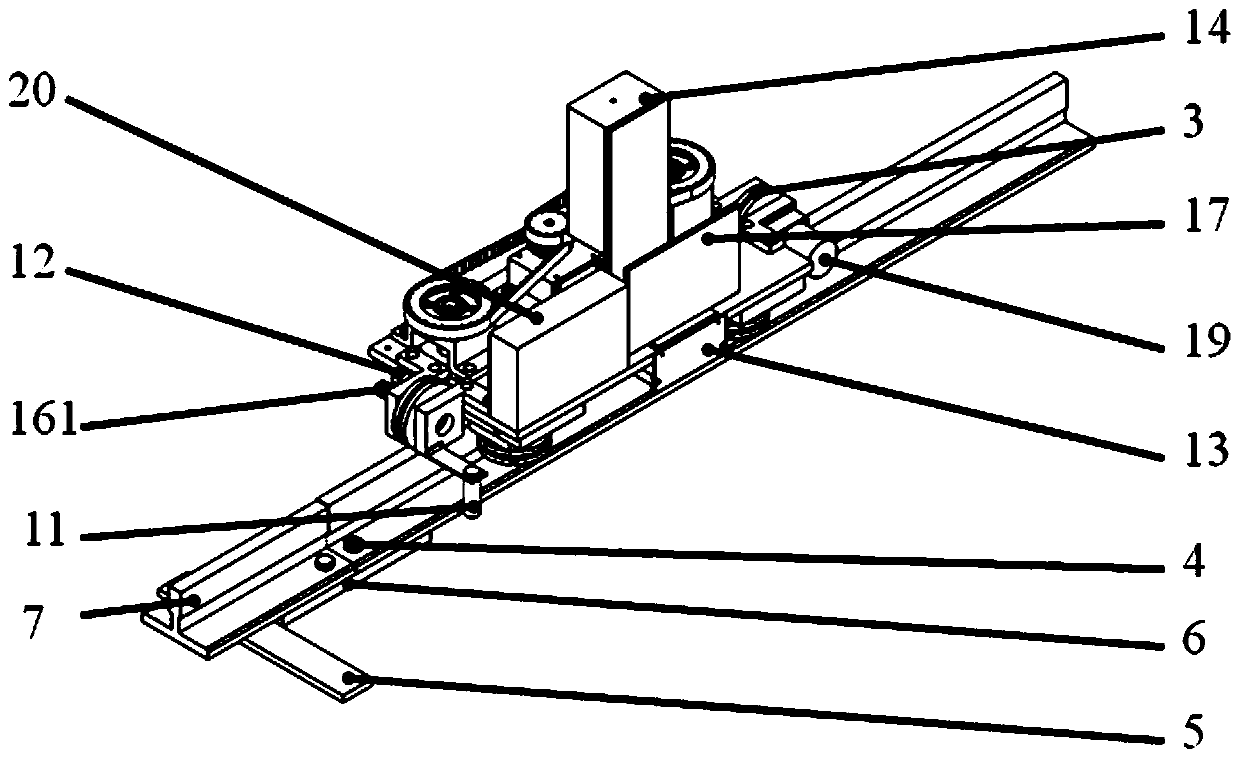

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0045] Such as Figure 4 Shown, the present invention a kind of evaluation method of comprehensive parameter detection of elevator guide rail, comprises

[0046] (1) Rail bracket detection: When the rail bracket approaches the sensor and detects that the rail bracket is directly below the sensor, the main control system of the robot is triggered to check the current position height S of the robot. i Save; when the guide rail bracket proximity sensor detects the position of the next guide rail bracket, the main control system of the robot is triggered to check the current position height S of the robot. i+1 to save. According to two adjacent height values, calculate the height difference △S=S i+1 -S i , determine the distance △S between the guide rail brackets, and judge whether it is greater than 2.5m.

[0047] According to the requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com