Vibration pile driver for bridge construction

A technology for bridge construction and piling machine, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of low piling efficiency and limited length of pile hammer, and achieve the effect of improving winding accuracy and piling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

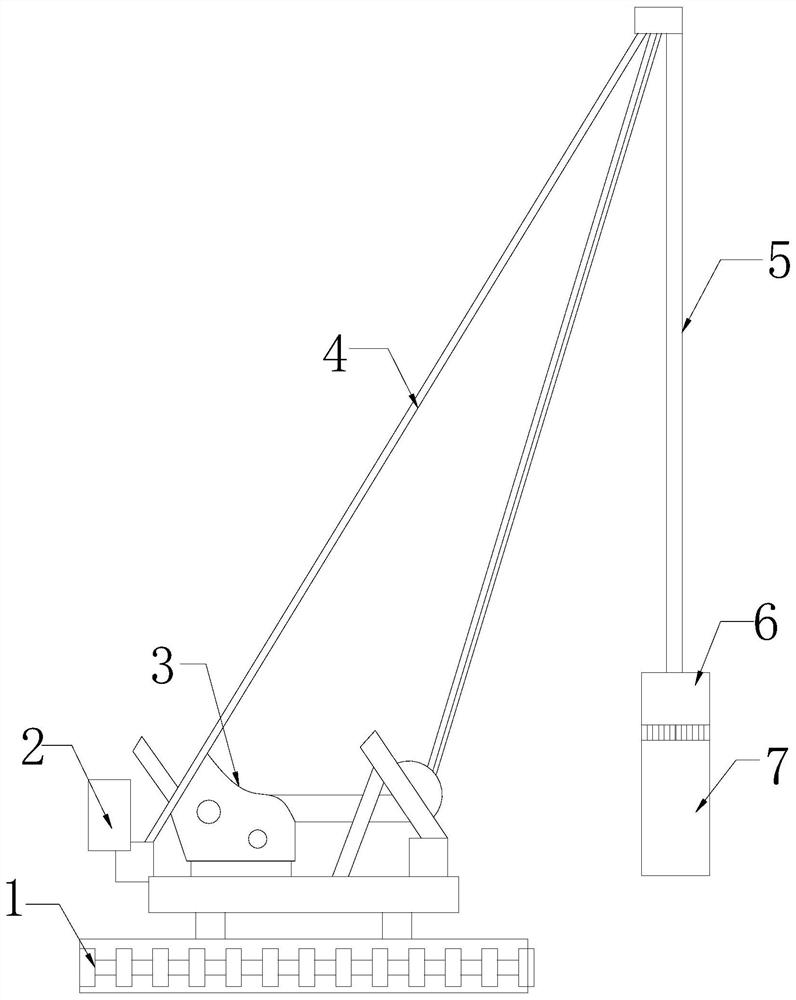

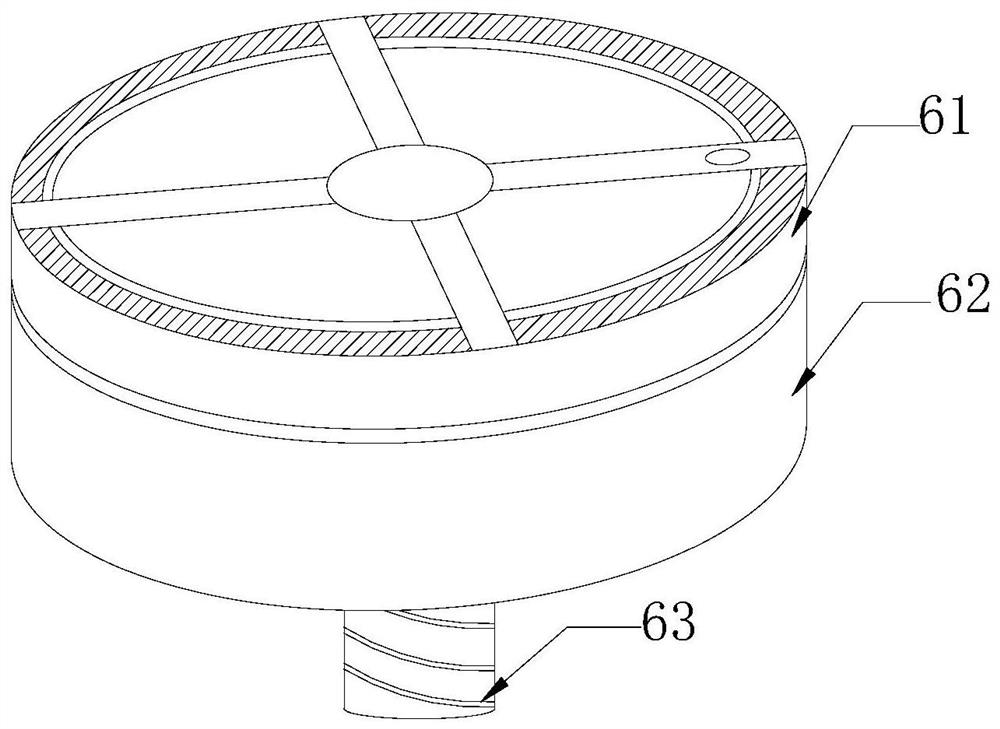

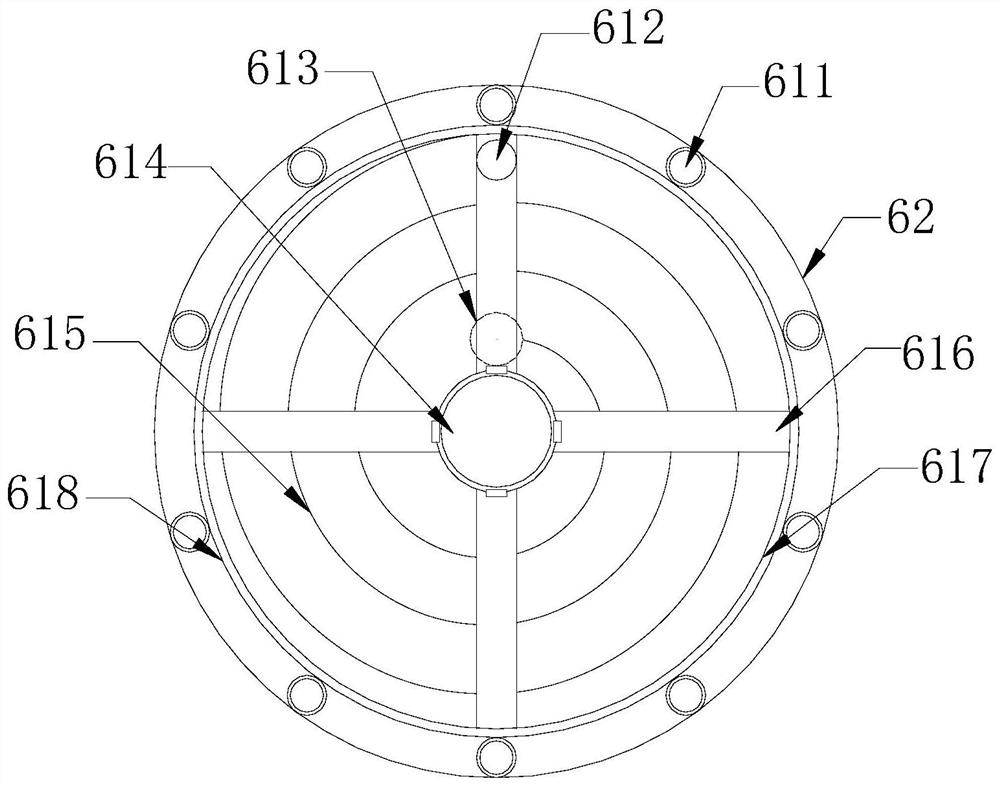

[0027] Such as Figure 1-Figure 6 As shown, the present invention provides a vibratory pile driver for bridge construction, its structure includes a walking base 1, an operating room 2, a driving platform 3, a traction cable 4, a lifting plate 5, a pile hammer 6, and a pile frame 7. The operation Room 1 controls the driving platform 3, the operating room 2 and the driving platform 3 are installed on the walking base 1, the driving platform 3 is connected to the lifting plate 5 through the traction cable 4, and the lifting plate 5 is movably connected with piles Hammer 6 and pile frame 7, described pile hammer 6 is mechanically connected with pile frame 7, and described pile hammer 6 comprises soil guide device 61, soil collection chamber 62, drill bit 63, and described soil guide device 61 is installed in soil collection chamber 62 Above, the bottom of the soil collection cavity 62 is provided with a drill bit 63, the drill bit 63 fits in the pile frame 7, and the soil guide d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com