Patents

Literature

43results about How to "Improve winding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

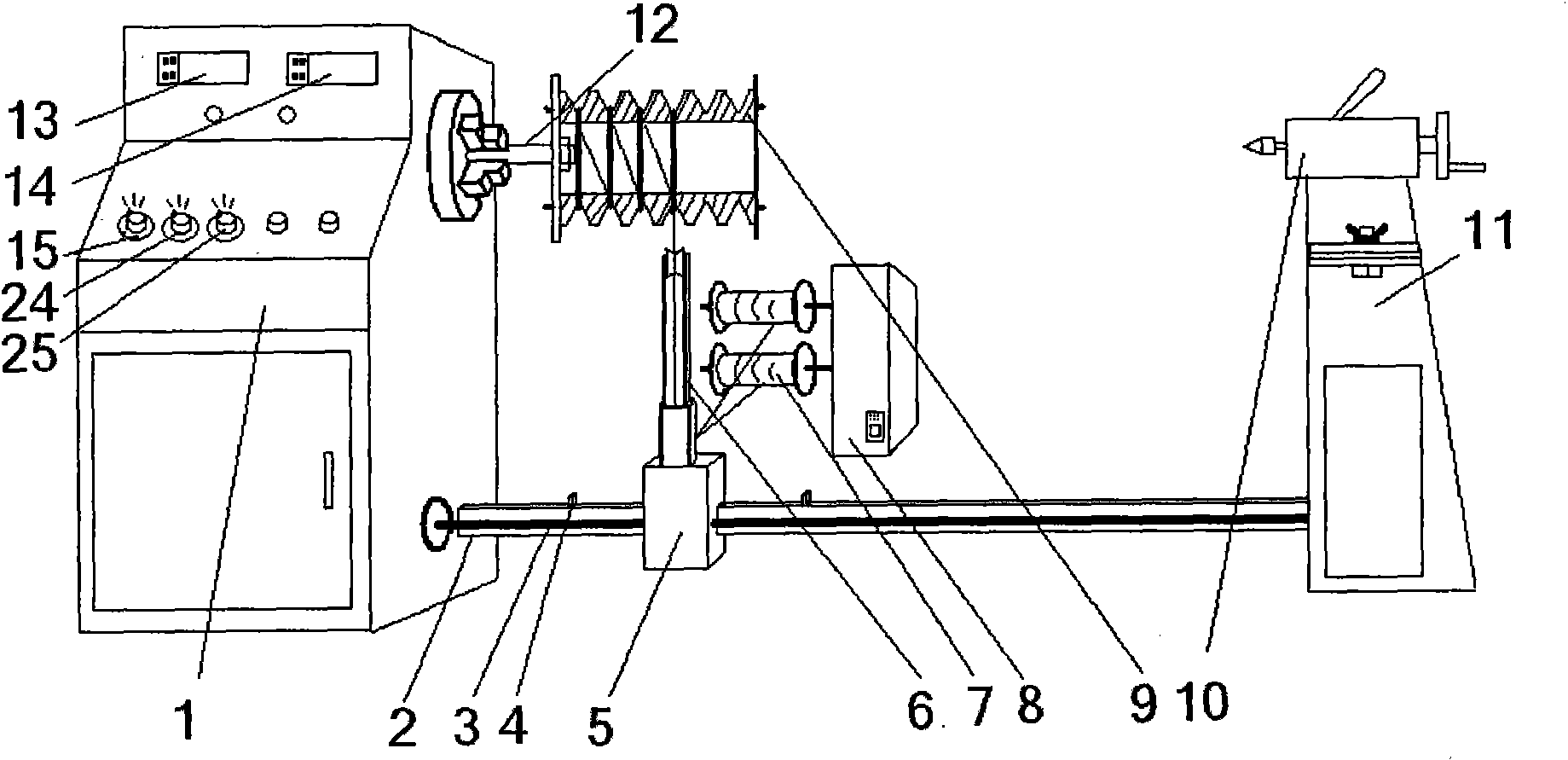

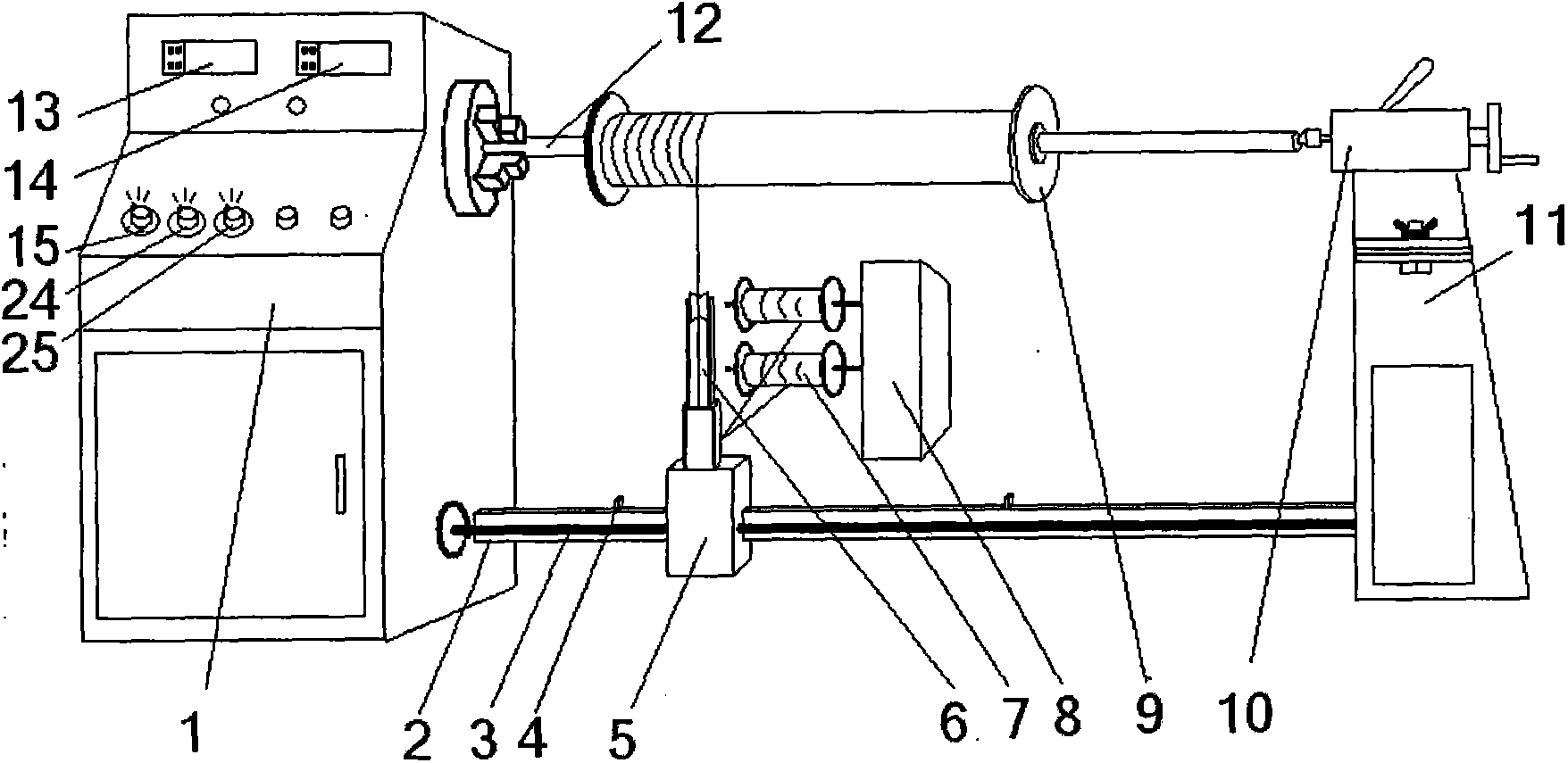

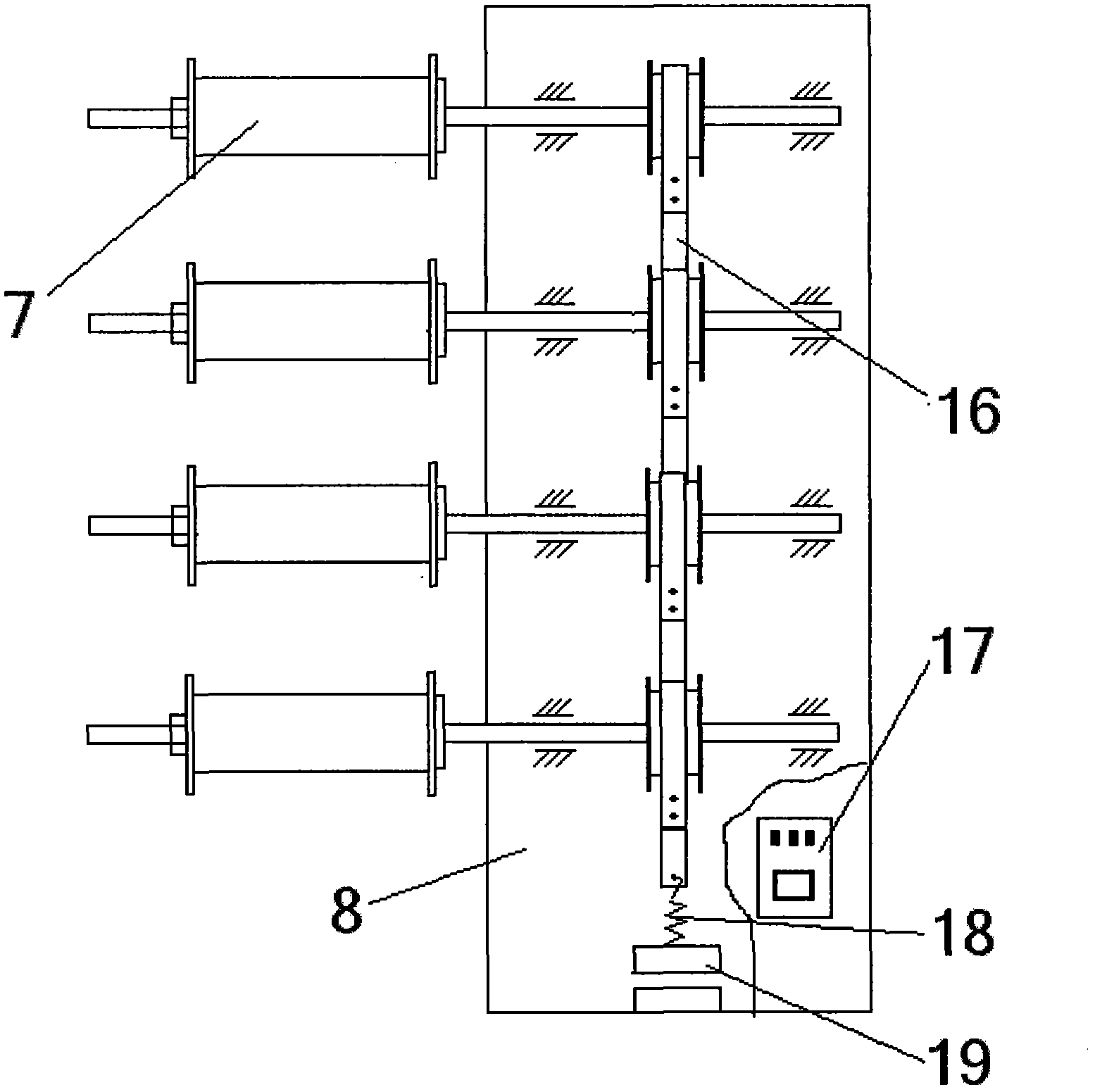

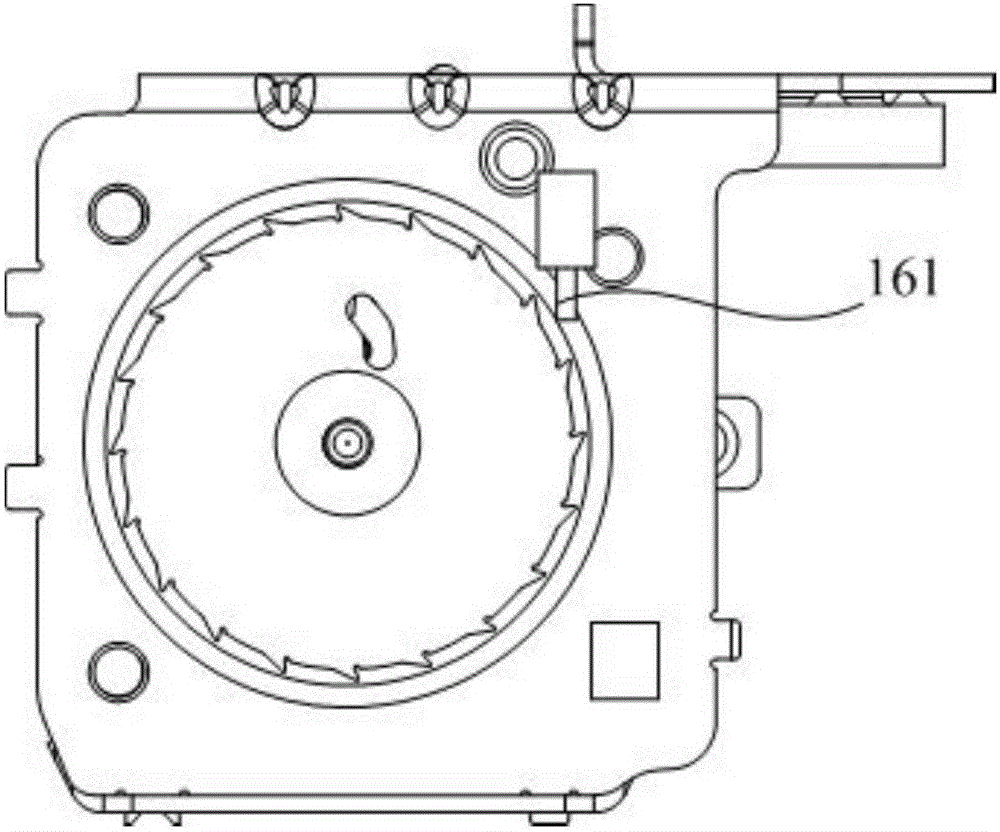

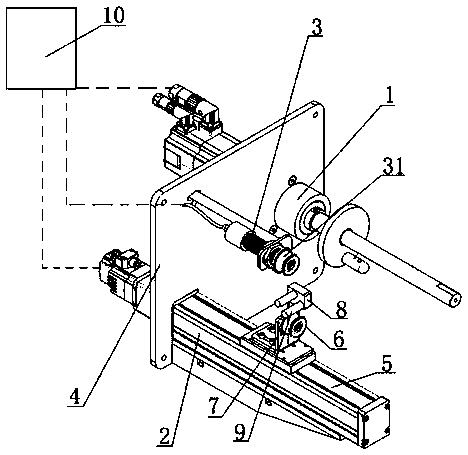

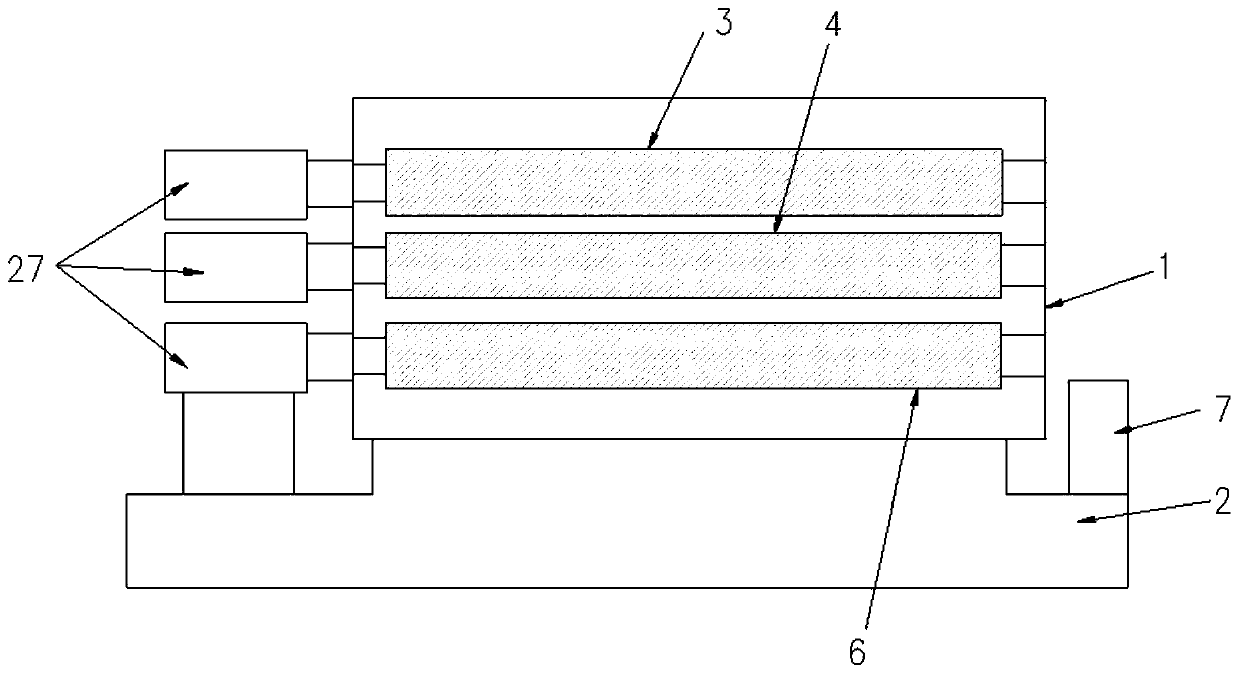

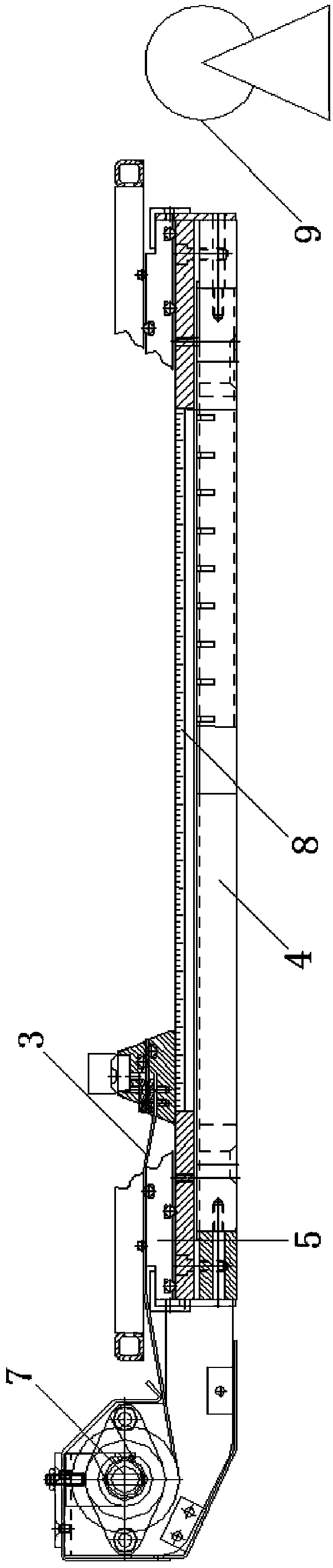

Multifunctional numerical control filament winder

InactiveCN103730252AHigh degree of automationStrong reliabilityFilament handlingCoils manufactureNumerical controlFilament winding

The invention discloses a multifunctional numerical control filament winder, and belongs to the field of electric machinery. The multifunctional numerical control filament winder comprises an electronic counting controller A and an electronic counting controller B, wherein the number of filament winding turns is counted and displayed, an instruction is sent out after filament winding is completed, and a series of motions including the parking motion of a filament winding rod, the parking motion of a pay-off device and the motion that a filament arraying frame moves to a next filament winding groove are completed through an electrical system. A filament winding die is fixed to the filament winding rod. The tail end of the filament winding rod can be positioned through the tip of a tip base. A limiting stroke switch is arranged on a horizontal walking rail of the filament arraying frame and below the filament winding die. The pay-off device with a filament roller is arranged opposite to the filament arraying frame. The multifunctional numerical control filament winder is high in automation degree, high in reliability, convenient to use, high in filament winding accuracy, and capable of saving labor, improving efficiency and conducting illumination and power supply through a 220V voltage.

Owner:骆勇新

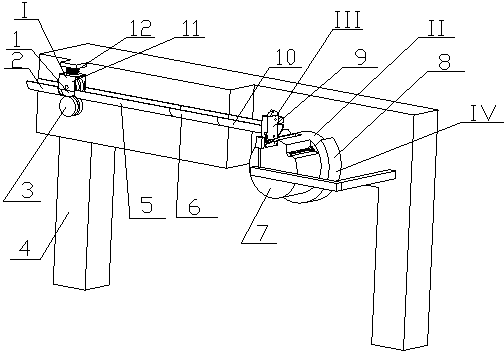

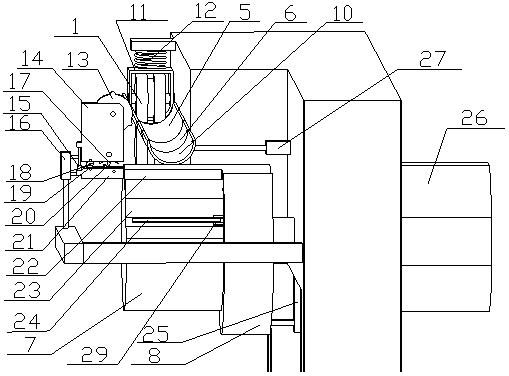

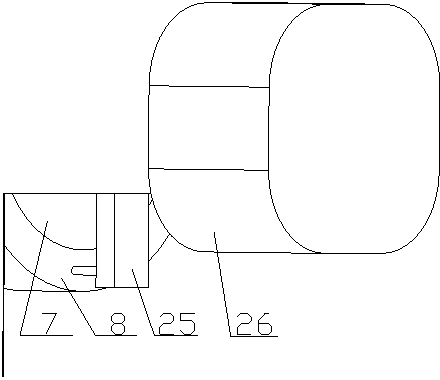

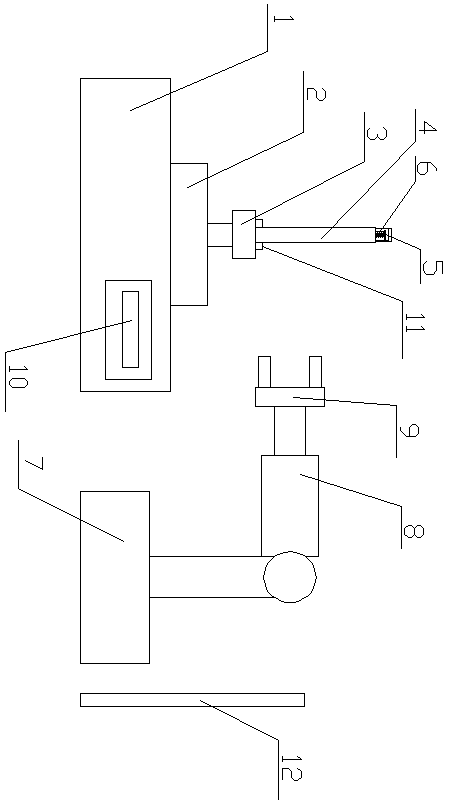

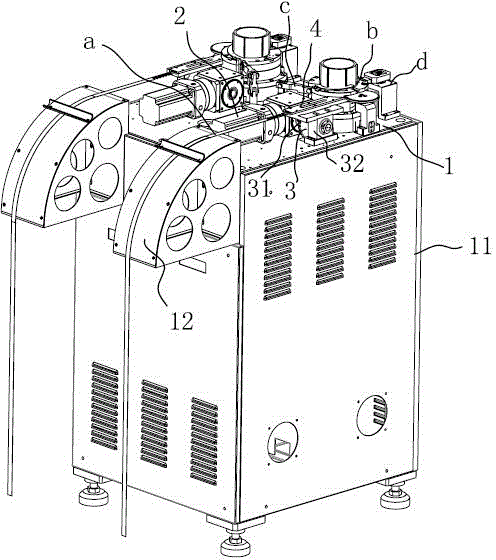

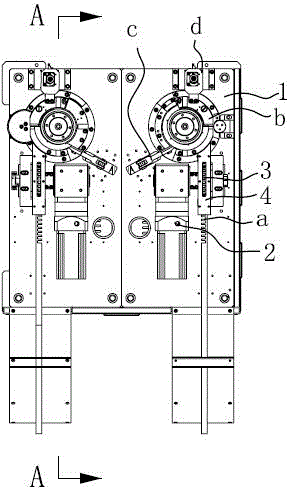

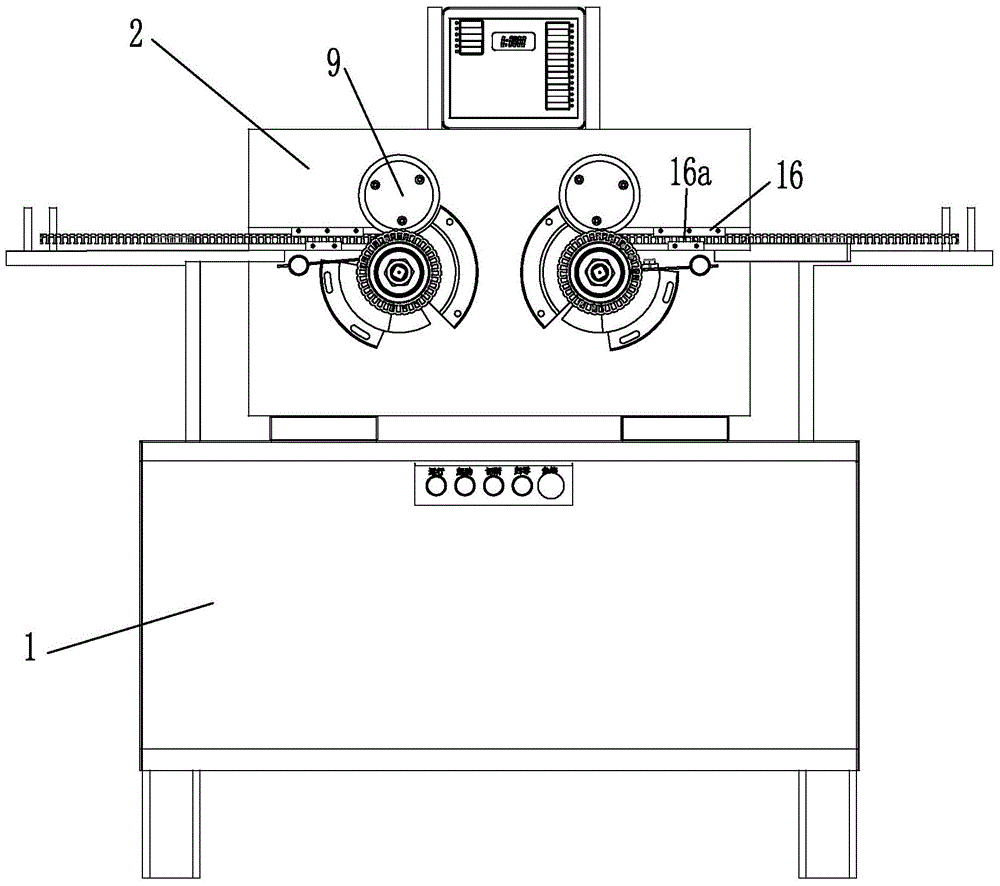

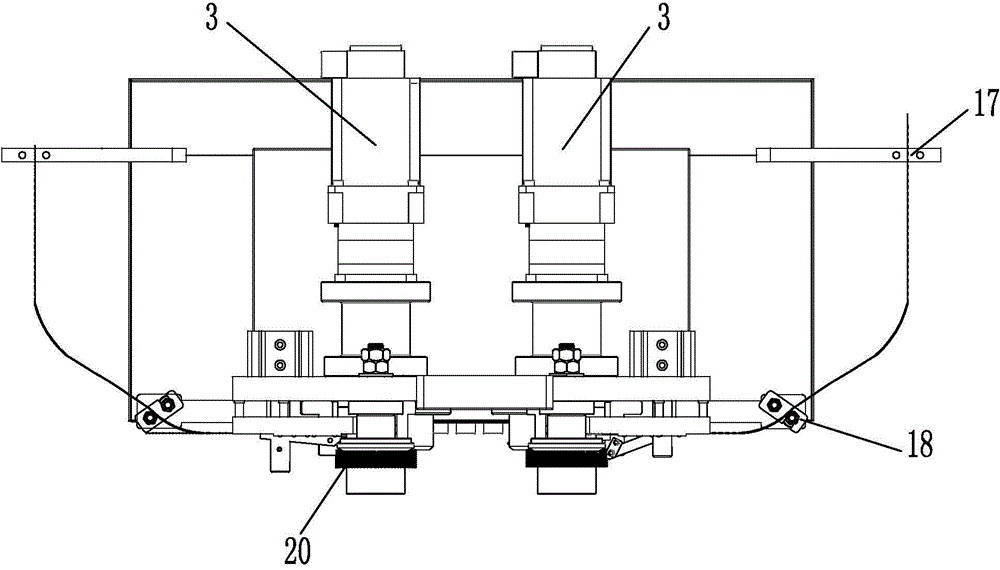

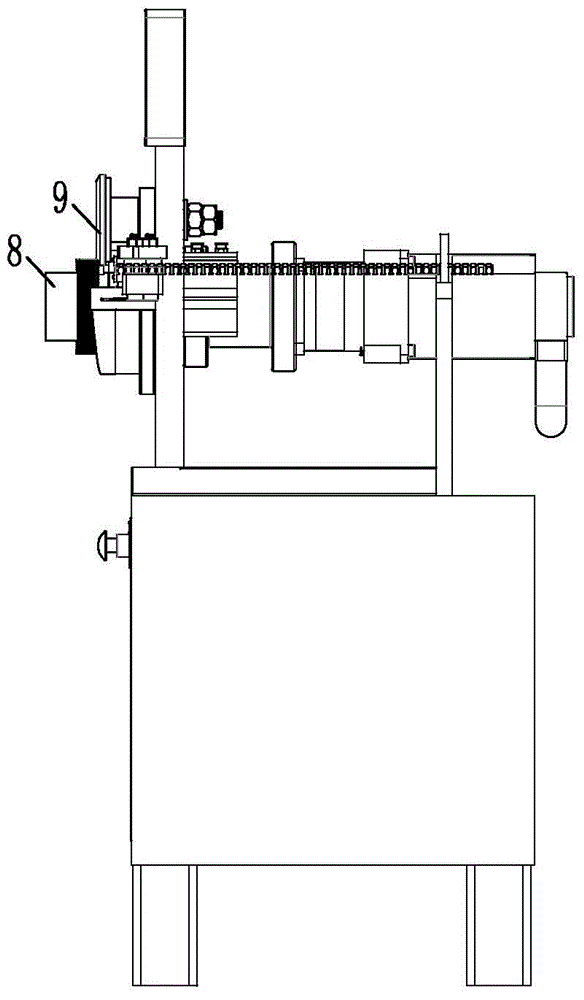

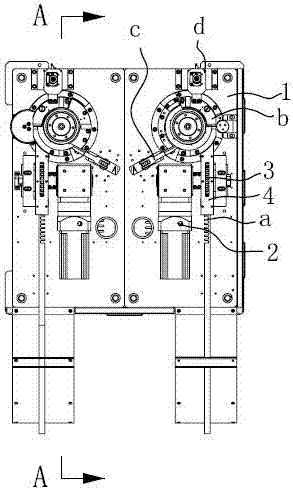

Lead wire looping machine

InactiveCN103738784AImprove winding accuracyHigh degree of automationFilament handlingAdhesive beltControl system

The invention discloses a lead wire looping machine. The lead wire looping machine comprises a machine rack, a wire feeding device, a wire winding device, an adhesive tape winding device and a wire pushing device. The wire feeding device consists of a fixed guide rail, a movable guide rail, a driving guide wheel and a driven guide wheel, wherein the movable guide rail is fixedly connected with an air cylinder, the driving guide wheel is connected with a motor in a machine rack case, and the driven guide wheel is connected with the machine rack through a spring. The wire winding device consists of a motor, a winding drum and a wire pressing rod external member, wherein the motor controls rotation of the winding drum, and a control system controls pressing of a wire pressing rod and release of the lead wire end. The adhesive tape winding device consists of an adhesive tape winding assembly and two air cylinders, wherein one air cylinder controls horizontal motion of the adhesive tape winding assembly and finishes adhesive tape winding, the other air cylinder control vertical separation of the adhesive tape winding assembly and achieves the purpose of passing in and out of a winding drum groove. The wire pushing device consists of a wire pushing ring and an air cylinder, wherein the air cylinder pushes the wire pushing ring to push a looped lead wire away from the winding drum. Lead wire looping can be effectively finished by adopting the reasonable structural design.

Owner:SHANGHAI UNIV

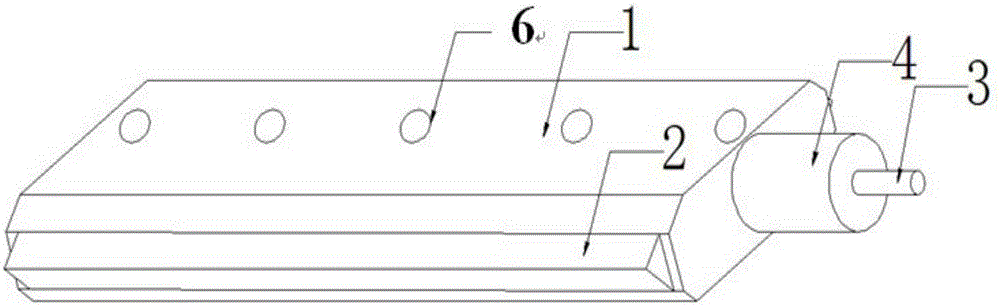

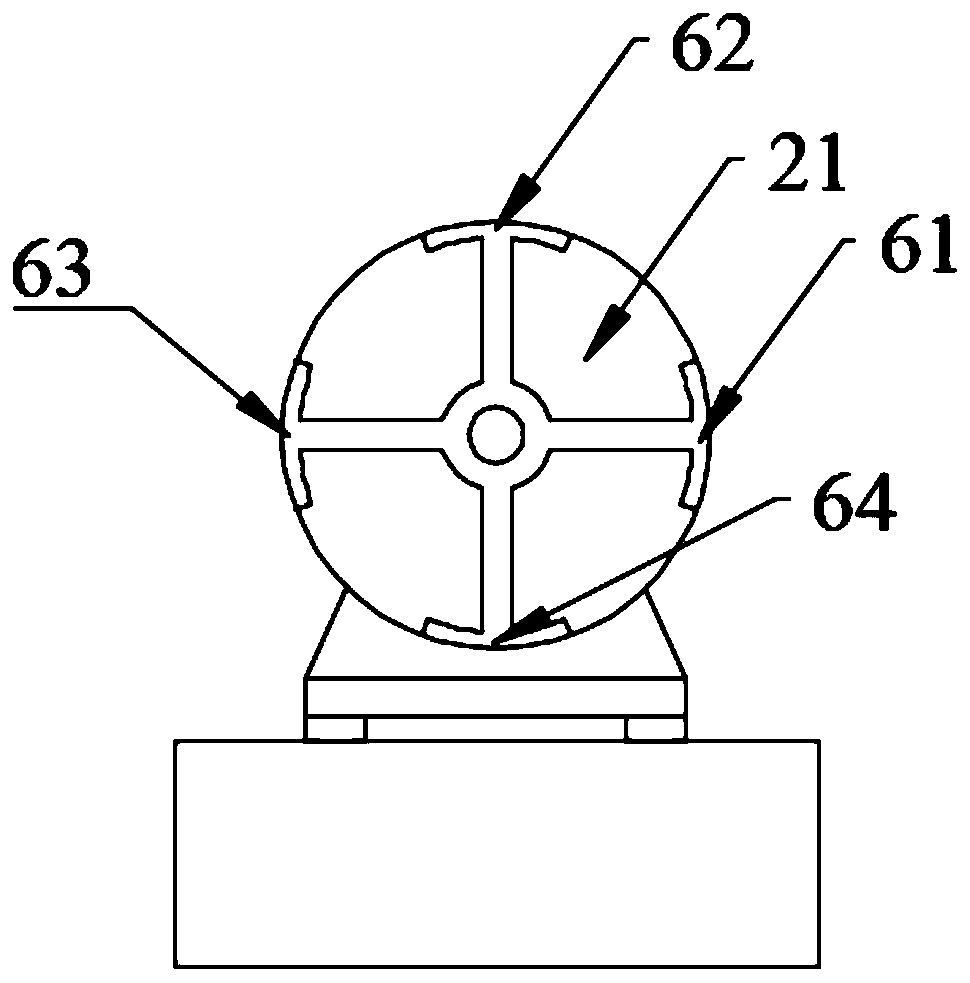

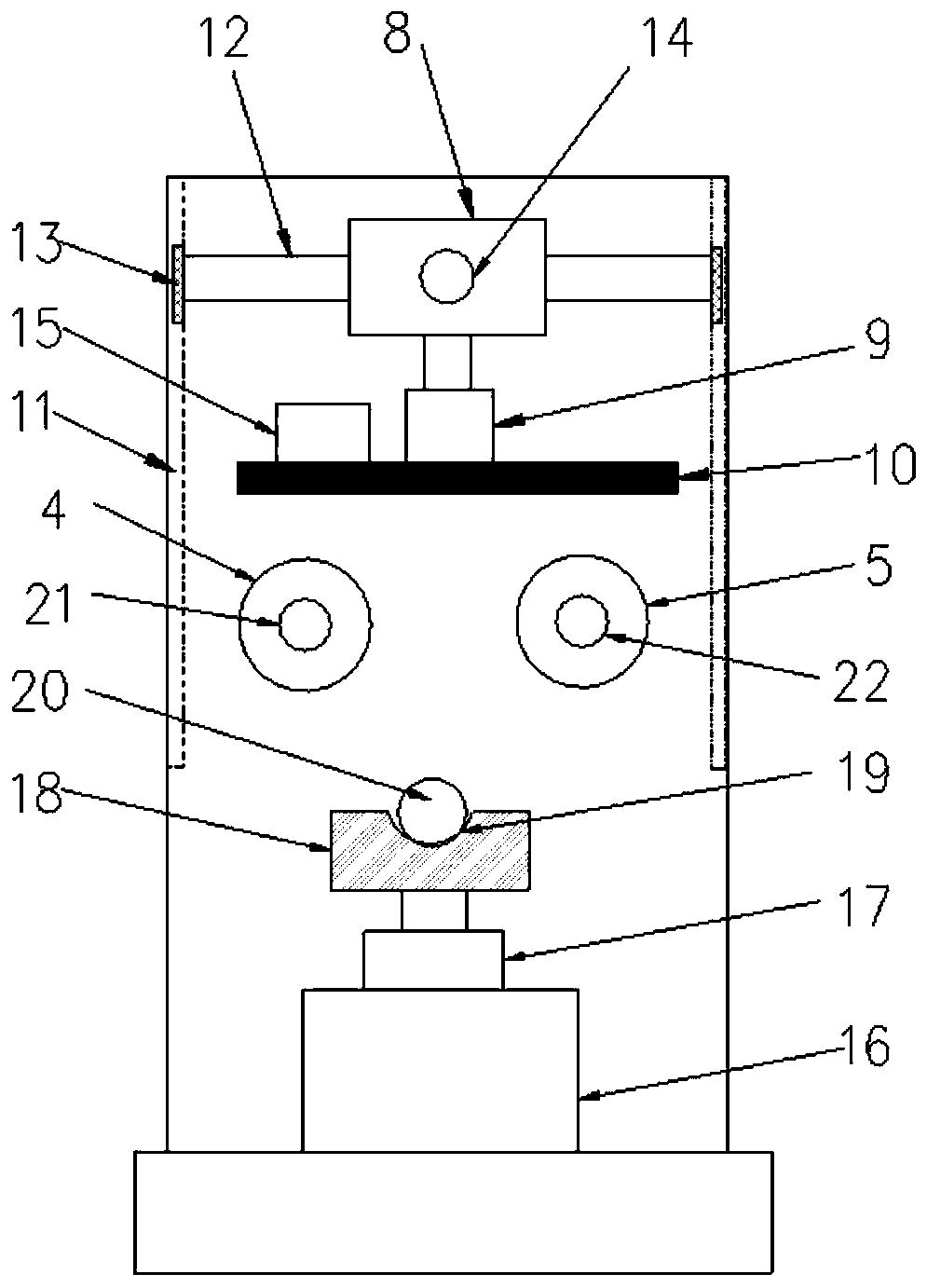

Lithium ion battery winding needle

ActiveCN105226327ASmooth outReduce frictionFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The invention discloses a lithium ion battery winding needle which comprises a winding needle shell, wherein a cylinder is arranged in the winding needle shell, two elongate holes are oppositely formed at the two sides of the cylinder, a pull rod is arranged in the cylinder, at least one connection support is arranged on the pull rod, connection rods are rotatably connected with the two sides of the connection support, pass through the elongate holes on the cylinder and are rotatably connected with a telescopicbody, the telescopicbody is arranged at the two sides of the winding needle shell and matched with a telescopicbody groove arranged on the winding needle shell, an air inlet is arranged at one end of the cylinder and used for introducing air, and an exhaust hole is arranged on the winding needle shell. The lithium ion battery winding needle disclosed by the invention is applied to a cell winding process, and when the needle is needed to be withdrawn after cell winding is completed, the problem that the winding needle is difficult to be taken out of a cell caused by large friction force between the cell and the winding needle can be effectively solved.

Owner:国轩新能源(庐江)有限公司

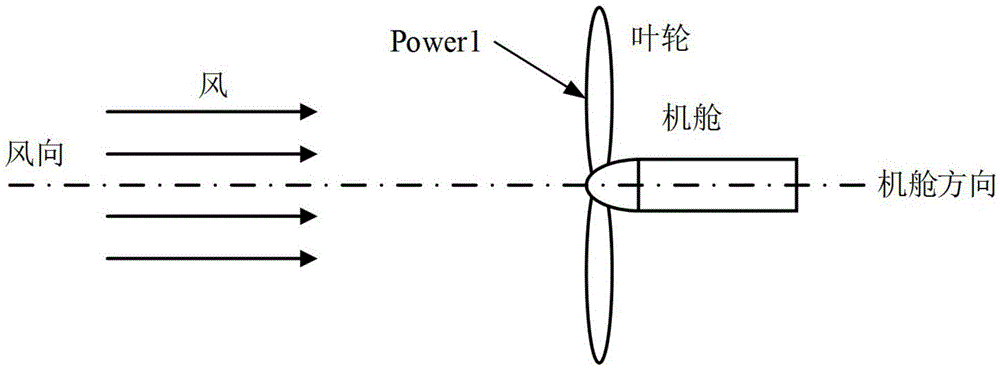

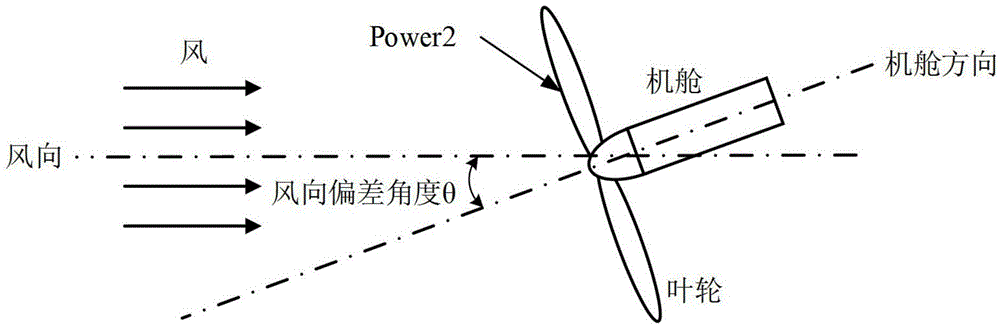

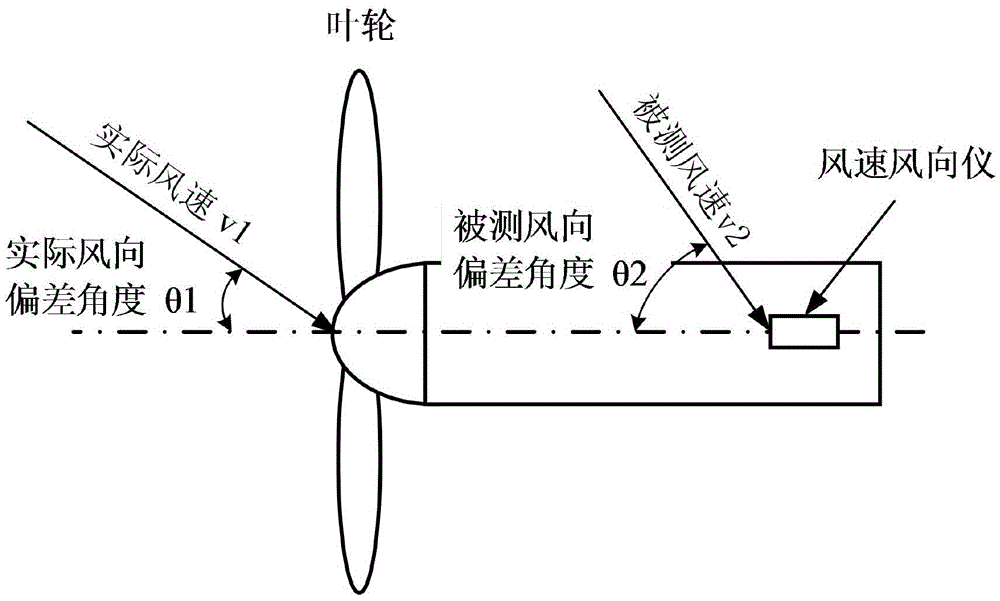

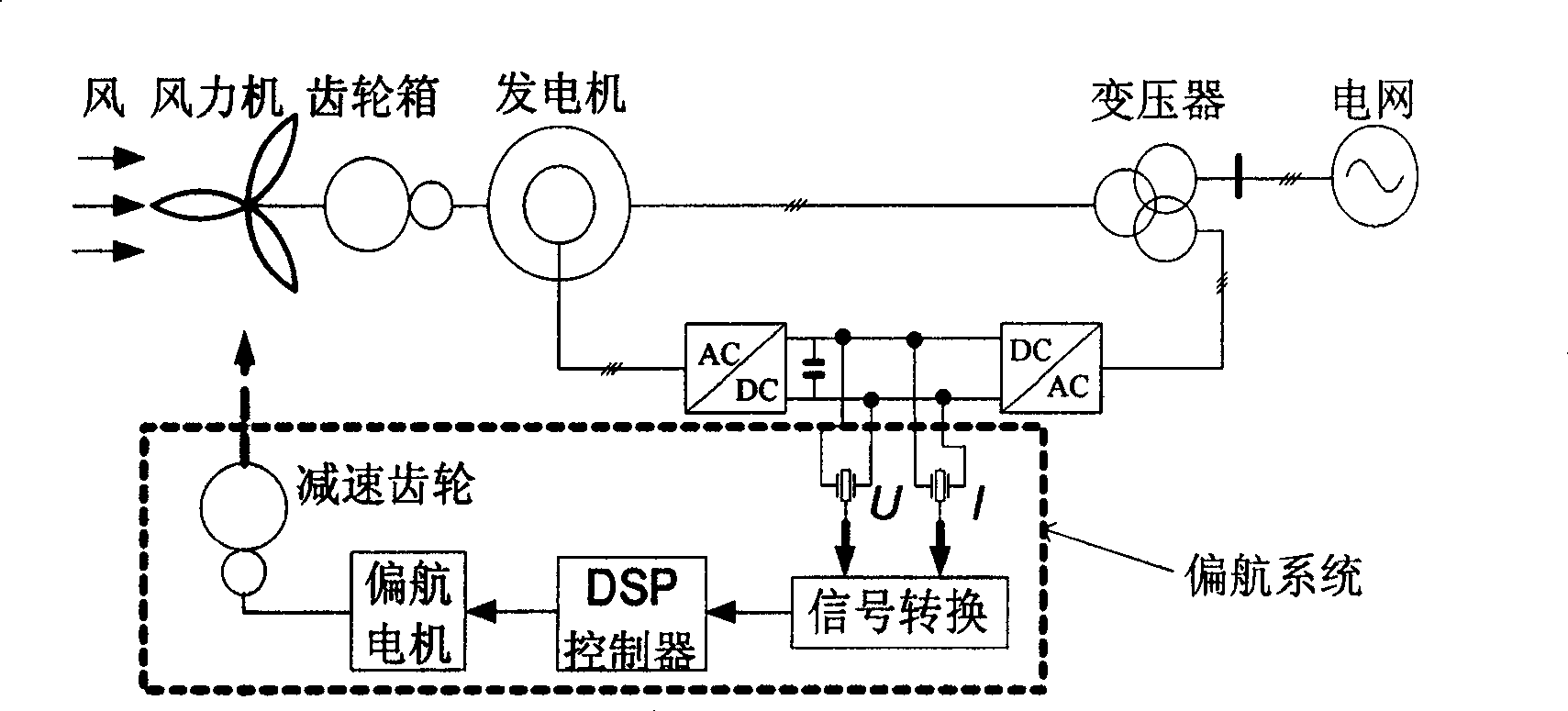

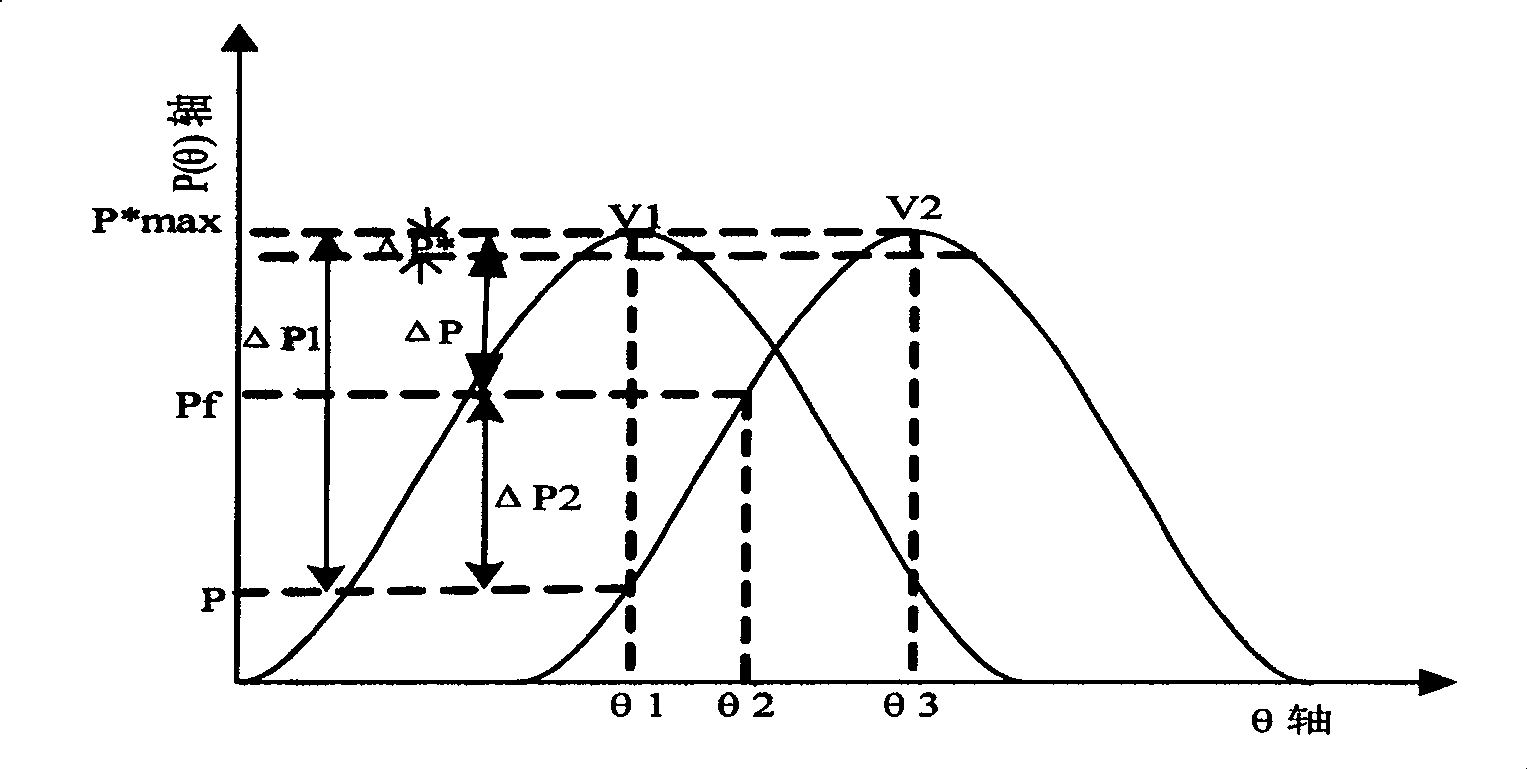

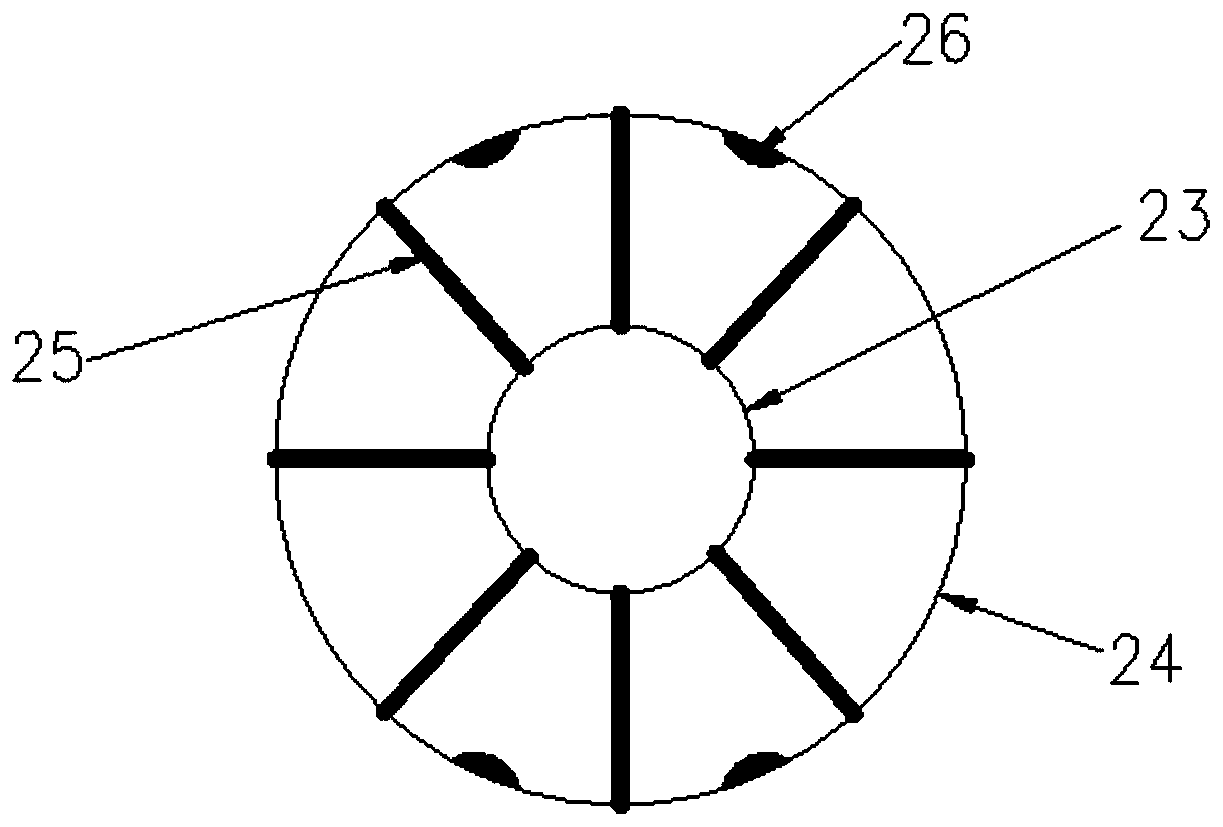

Angle measurement error compensation method based on wind speed and position influence

InactiveCN105545596AImprove wind accuracyImprove power generation efficiencyWind motor controlMachines/enginesImpellerError function

The invention discloses an angle measurement error compensation method based on wind speed and position influence. The method comprises the following steps: the orientation of the position of a target fan engine room is divided into eight areas; angle measurement error curves of the eight orientations of the position of the engine room are separately acquired by an anemorumbometer, and an actually-measured wind direction deviation angle theta2 is compensated by the anemorumbometer according to the angle measurement error delta of the selected orientation, and then is sent to a main control system. According to the method, the angle measurement error curves under different engine room position orientations are acquired through the classification of the fan engine room position orientations. On the basis of considering the influence of the wind speed on the angle measurement error, microcosmic site selection (the engine room position orientations) is considered at the same time. The defect that an angle measurement error function theta=f(v) only compensates the angle measurement error of the anemorumbometer according to the wind speed, while the angle measurement error of the anemorumbometer caused by the microcosmic site selection factor cannot be compensated is solved; and the yawing precision of the impeller of the fan is improved, and the power generation efficiency of the fan is accordingly improved.

Owner:DALIAN SHINERGY SCI & TECH DEV

Industrial cloth winding and placing device

InactiveCN109353857AInhibit sheddingImprove work efficiencyWebs handlingManipulatorIndustrial engineering

Owner:WUHU SHZ IND FABRIC

Contact positioning device of broad biaxially oriented film winder

ActiveCN101798030AImprove winding accuracyWaste film reductionWebs handlingDrive motorRoller bearing

The invention provides a contact positioning device of a broad biaxially oriented film winder, comprising a left C-type engine base, a right C-type engine base, a drive part, a driven part, a tension roller and a contact roller, wherein two ends of a film shut-off mechanism, the tension roller and the contact roller are assembled on the left C-type engine base and the right C-type engine base respectively by the drive part and the driven part, the contact roller is arranged above the tension roller and the film shut-off mechanism is arranged above the contact roller. When in operation, a contact roller drive motor drives the contact roller to be contacted with a reeled film, and stretch and wind the reeled film; along with the increase of the diameter of the reeled film, a linear motor also drives a contact roller bearing seat to enable the contact roller to move backwards and continues winding; when winding is finished, the film shut-off mechanism rotates downwards under the action of a hydraulic system thereof, a blade thereon shuts off the film and then resets; and the reeled film after winding is taken down and a hollow reel is installed, a tension roller drive motor drives the tension testers at the two sides to measure the tension of the winding film, and winding is carried out on the reeled film repeatedly.

Owner:张春华

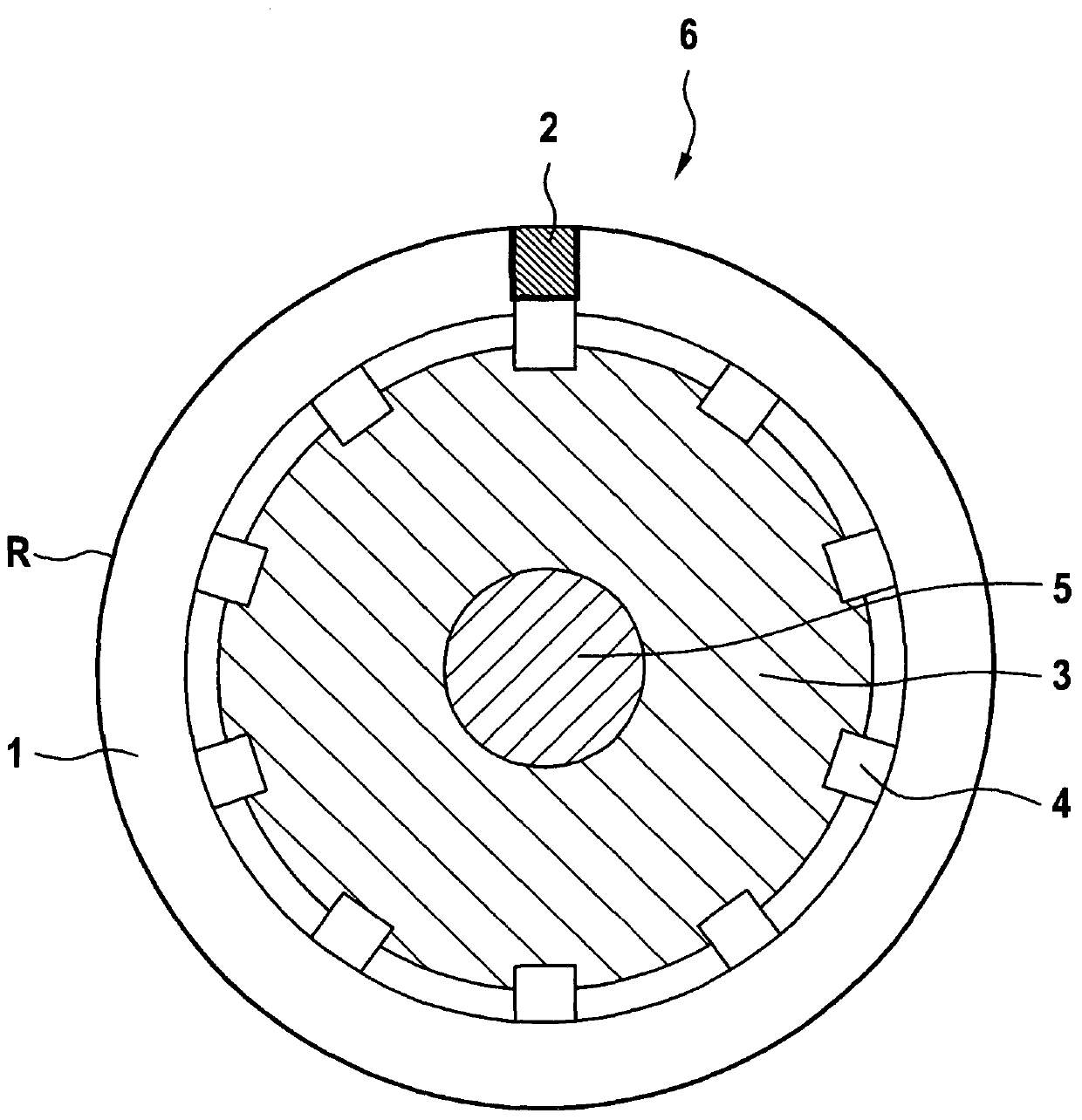

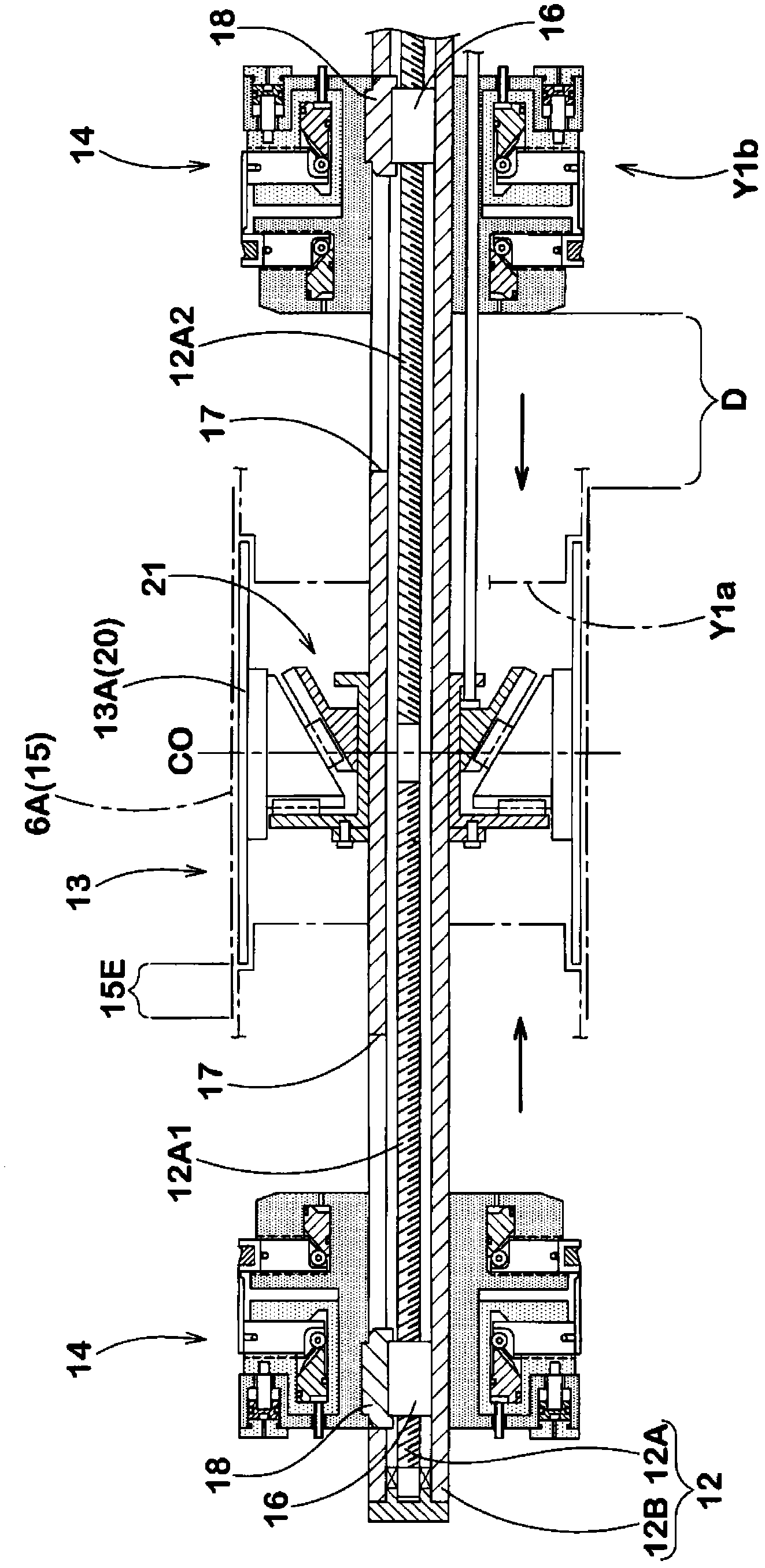

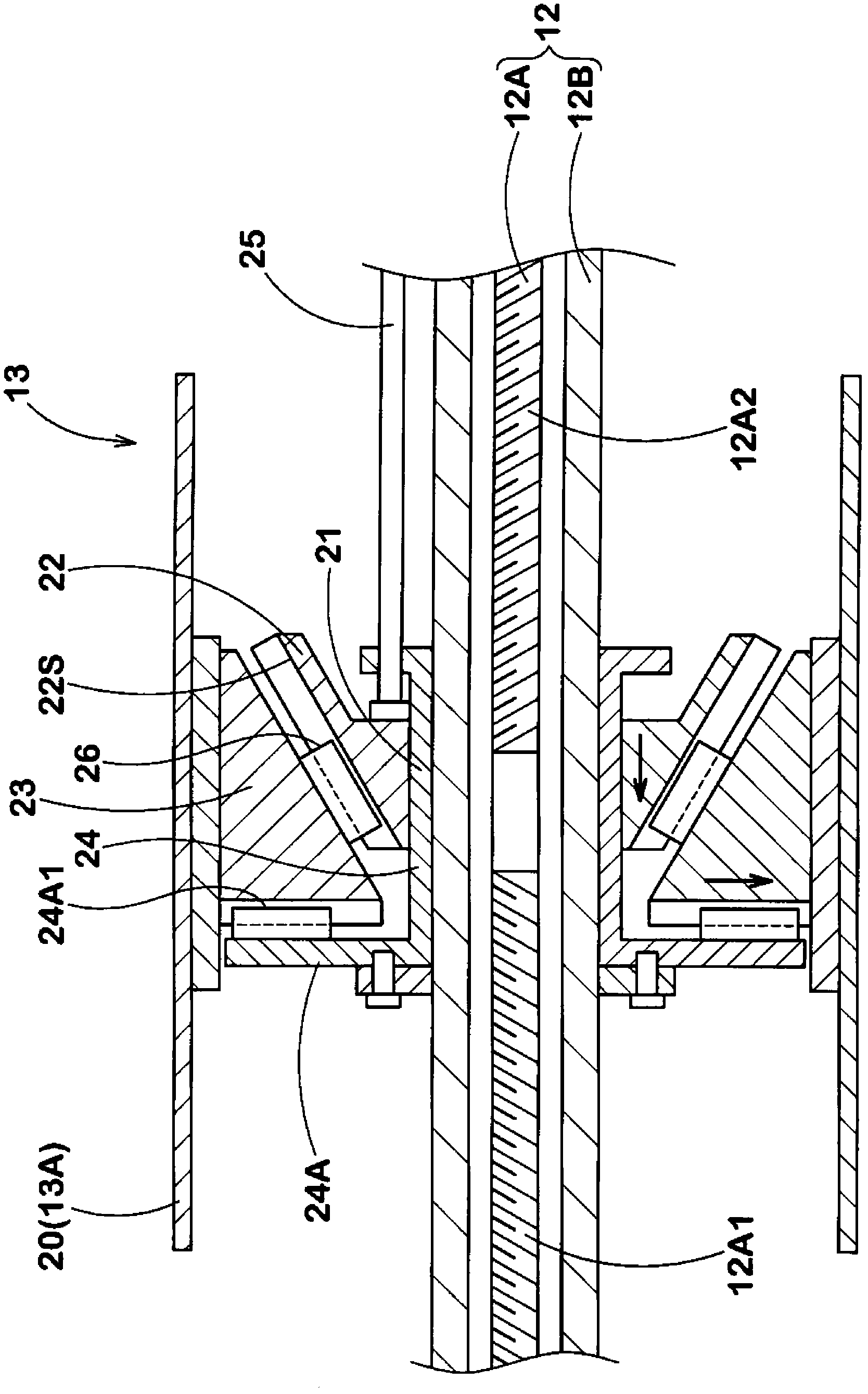

Arrangement for winding a web of material

The invention relates to an arrangement for winding a web of material, in particular a web of tire cord fabric, comprising a sleeve-like winding body (1), which can be set into rotation by a shaft coupled thereto, onto which the web of material is wound, and a holding mechanism that is based on a clamping force in order to hold an edge of the web of material to be wound to the winding body at thebeginning of the winding process. The winding body (1) is operable for the adjustment of the clamping force caused by means of the shaft coupling.

Owner:TEXTILCORD STEINFORT

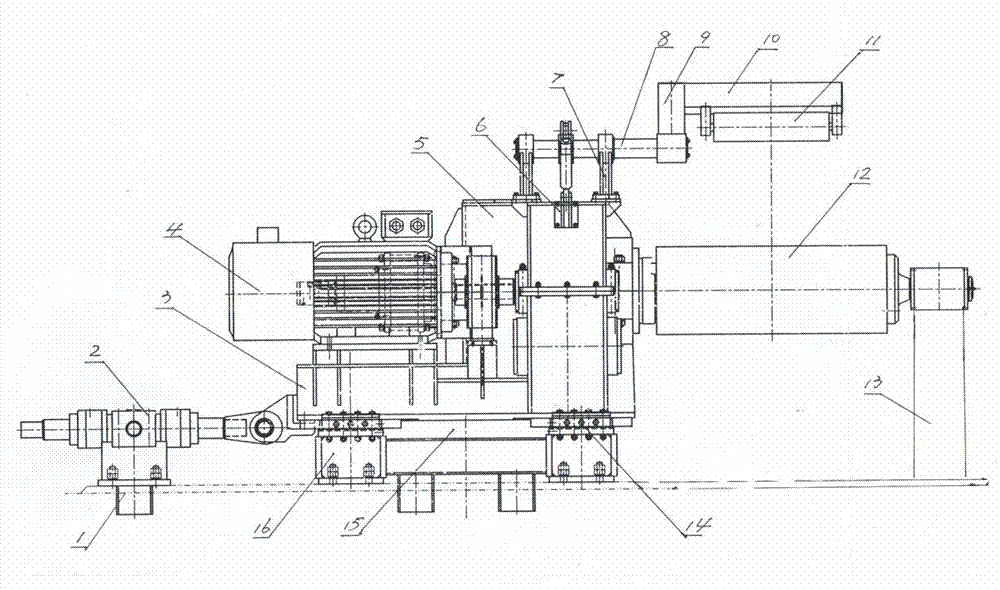

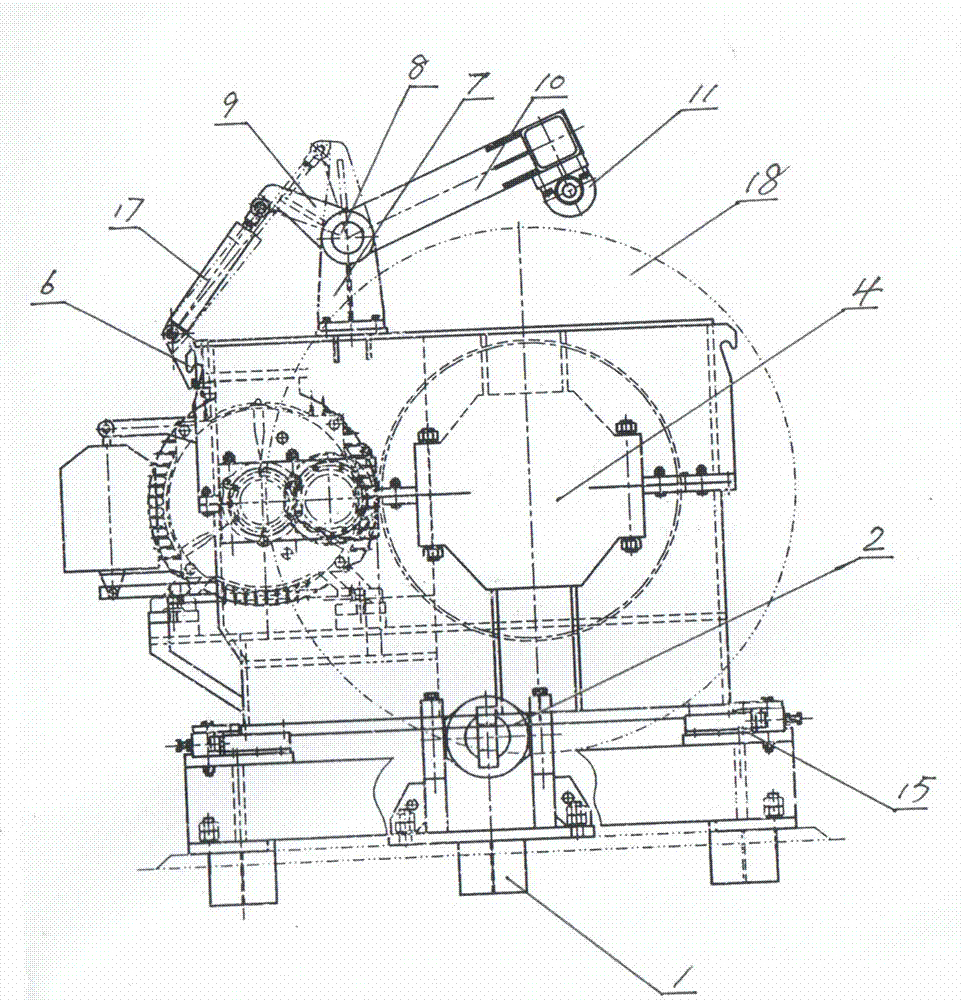

High-speed reeling machine

The invention relates to a high-speed reeling machine, and particularly relates to a high-speed reeling machine for reeling steel belts rolled by a rolling mill. The high-speed reeling machine comprises a base which is provided with a stander; the stander is provided with an electric motor, a speed reducer and a reel; an output shaft of the electric motor is fixedly connected with an input shaft of the speed reducer and an output shaft of the speed reducer is fixedly connected with the reel; the outer end of the reel is arranged on a first bracket by means of a shaft; and a winding drum is sleeved on the reel in a reeling state. The high-speed reeling machine is characterized in that the base is provided with two rails parallel to each other; and two columns of rollers are arranged at the bottom of the stander, are respectively arranged in the corresponding rails and can roll along the longitudinal direction of the rails. A second bracket is arranged on one side, far away from and opposite to the reel, of the base, a first hydraulic oil cylinder is fixed on the second bracket, and a piston rod of the first hydraulic oil cylinder is hinged with the stander together. The high-speed reeling machine is used for reeling steel belts, and is large in reeling diameter and high in reeling precision.

Owner:无锡亚新通用机械有限公司

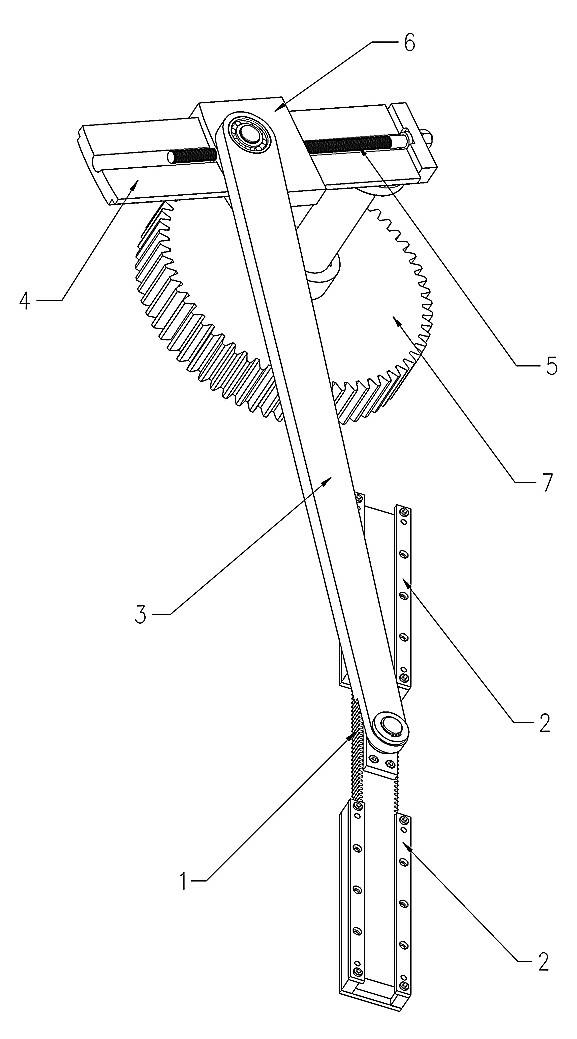

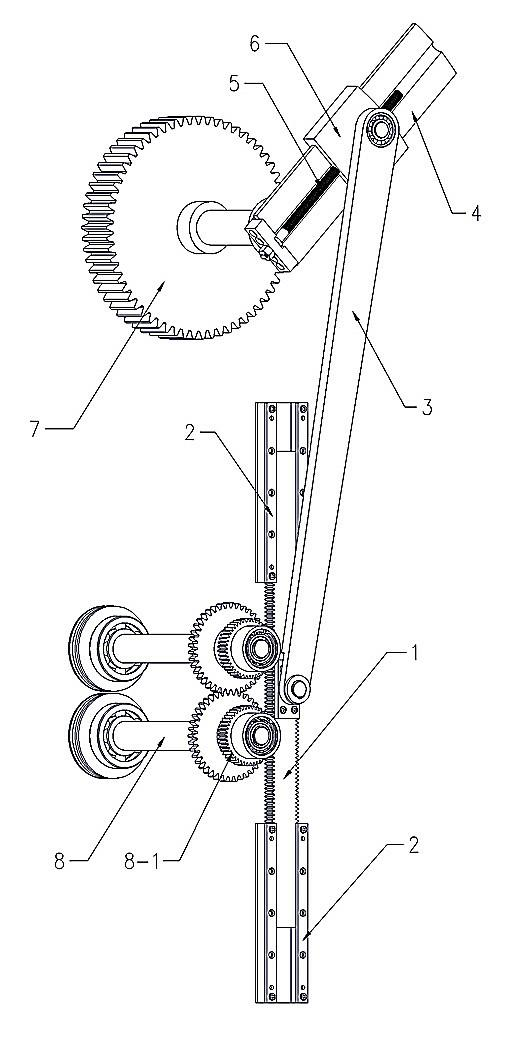

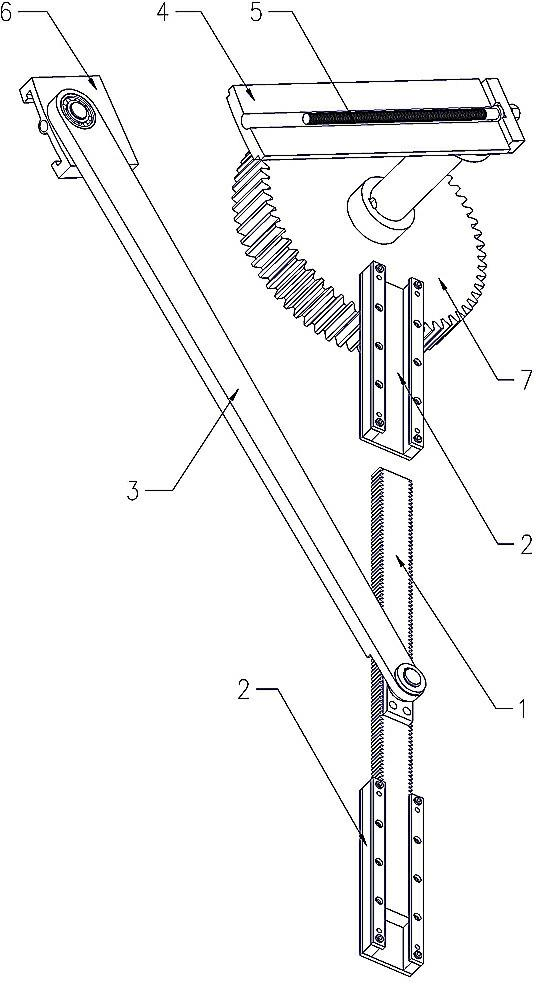

Variable-speed moving mechanism of rack of coiling machine

InactiveCN102527887AImprove winding accuracyExtended service lifeGearingWire springsGear wheelEngineering

A variable-speed moving mechanism of a rack of a coiling machine comprises a rack, slide seats, a connecting rod, a lead screw holder, a lead screw, a nut slider and a gear. The rack meshes with a clutch gear of a wire feeding wheel transmission device, the middle of the rack is connected with one end of the connecting rod through a pin, the rack is slidably connected between the two slide seats, and the slide seats are fixed on a framework. The other end of the connecting rod is connected to the nut slider through a pin. The gear is fixed on the framework through a bearing, and the gear and the lead screw holder are fixed on the same rotary shaft. The lead screw is connected to the lead screw holder through a bearing, the nut slider is connected to the lead screw holder through a slide tenon and is connected with the lead screw in a threaded manner, and the lead screw rotates to drive the nut slider to slide on the lead screw holder. The variable-speed moving mechanism has the advantages that a wire feeding wheel is driven to be subjected to variable-speed rotation by the rack, the acceleration and the speed of the wire feeding wheel are zero at the moment of starting and the moment of stopping, steel wires can be conveyed continuously without impaction, and accordingly the proportion of effective work time is high and production efficiency is high.

Owner:SHAOXING JIADU SPRING MACHINE

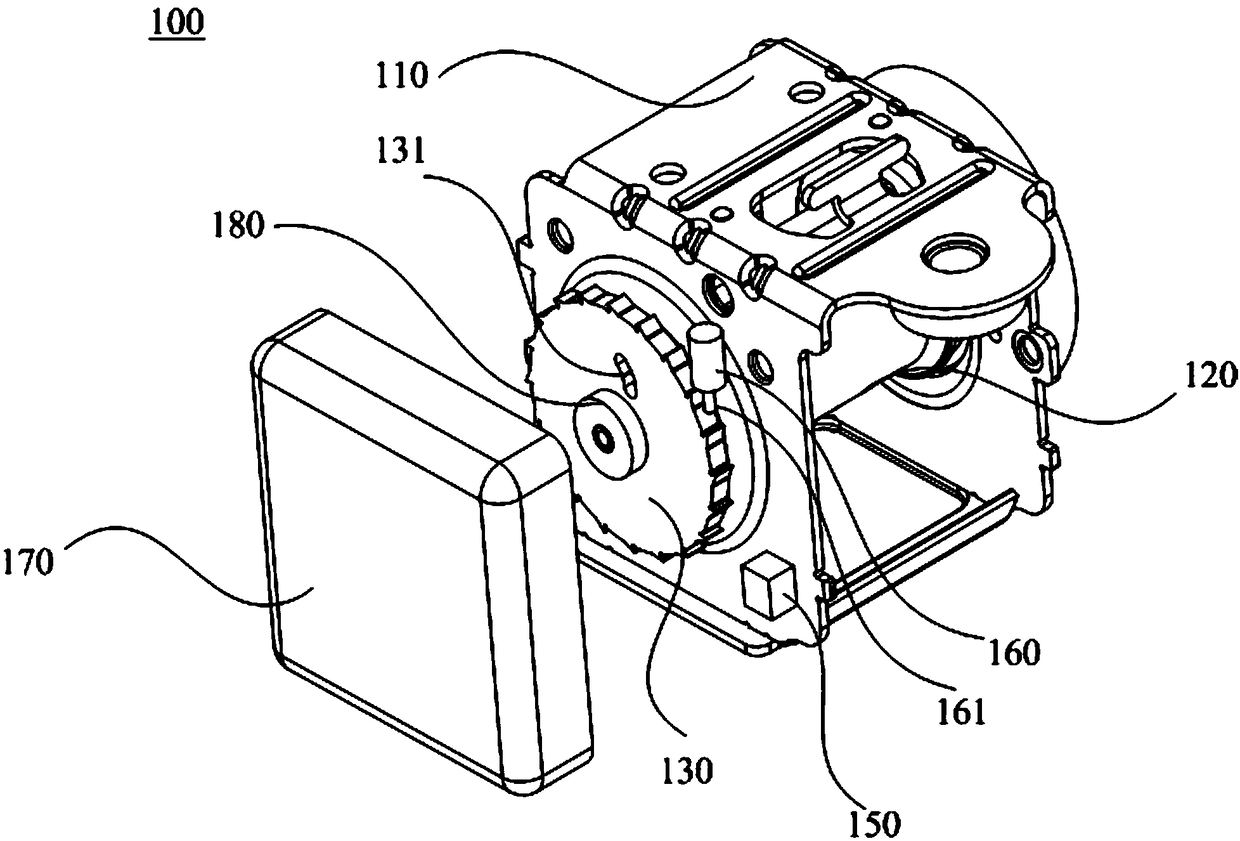

Electronic induction winding device

ActiveCN105946785AImprove winding accuracyHigh volume controllabilityBelt retractorsEngineeringConductor Coil

The invention relates to an electronic induction winding device used for winding a safety belt. The electronic induction winding device comprises a frame, a winding shaft, a first induction module, an electromagnetic switch and a control module, wherein the frame is used for containing the safety belt; the winding shaft is used for winding the safety belt and arranged in the frame, and one end of the winding shaft stretches out of the frame; the first induction module is used for inducing an angle signal and / or an acceleration signal of the frame; the electromagnetic switch is used for controlling the rotation and locking of the winding shaft; and the control module is in communication connection with the first induction module and the electromagnetic switch and is used for controlling the electromagnetic switch according to the angle signal or acceleration signal induced by the first induction module. The electronic induction winding device is low in noise, accurate in control and low in cost and can be locked in time.

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD +1

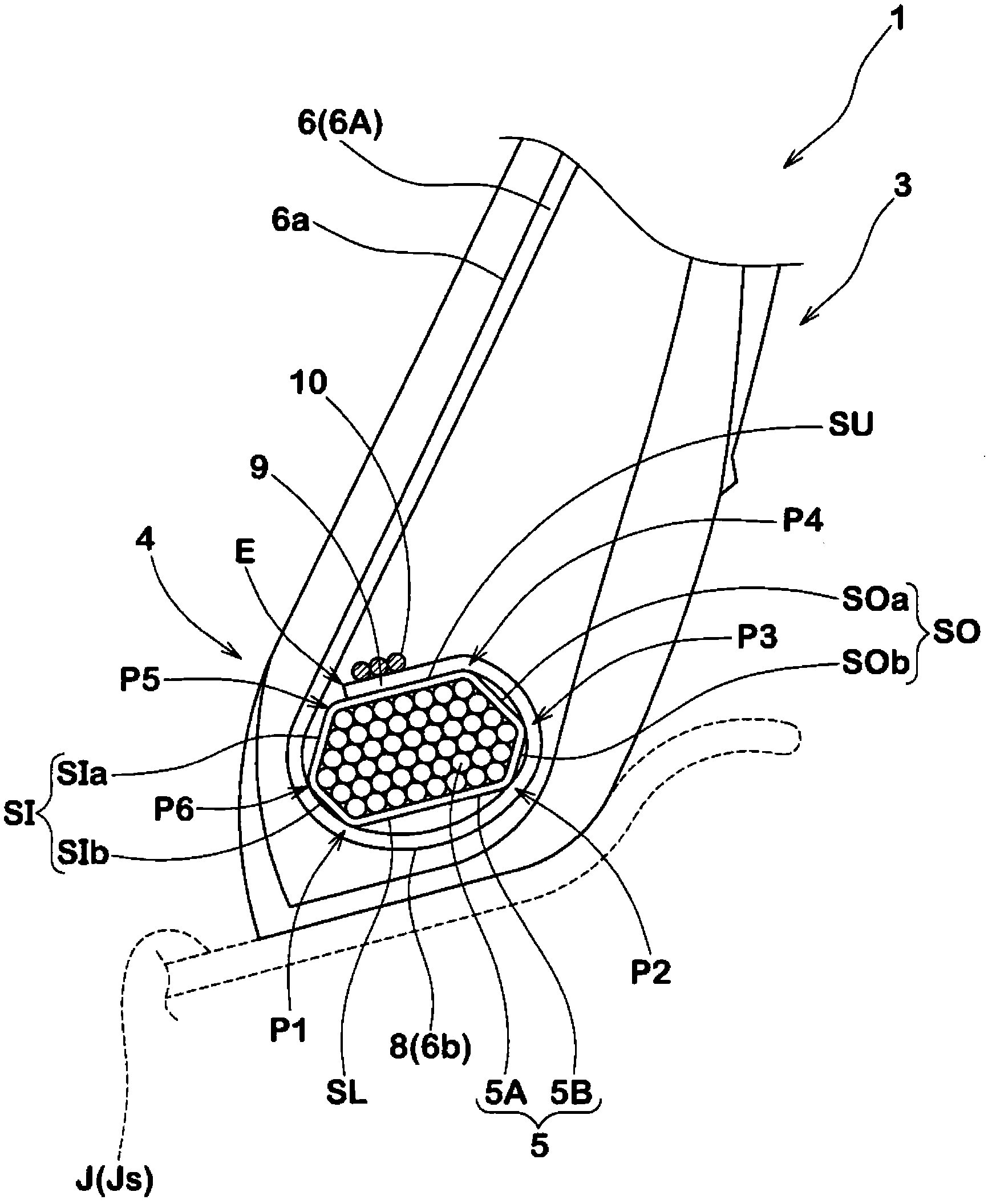

Raw tire forming method and raw tier forming apparatus

The invention provides a raw tire forming method and a raw tire forming apparatus enabling a tire body cord of a tire bead structure to reel a bead core with high accuracy and high efficiency. The raw tire forming method comprises a tire cylinder forming process which has a joint step of seaming the circumferential end edges of a tire body cord encircling a central drum for a round through a slide fastener, a side drum lateral shifting process, in which the side drum moves from a separating status to an approaching status of approaching the central drum and receiving the outer end part of the tire body cylinder, a tire bead locking process, in which the bead core externally inserted in an outer end part is maintained through the expanding of a locking ring disposed on the side drum, and a tire body reeling process, in which the protruding part of the tire body cylinder reels around the bead core. The tire body reeling process comprises a step of making the protruding part stand up through the cord disposed at a position that is more adjacent to the outer side of the axle center direction compared with a locking ring covering a ring expanding.

Owner:SUMITOMO RUBBER IND LTD

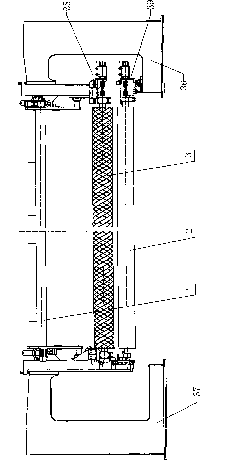

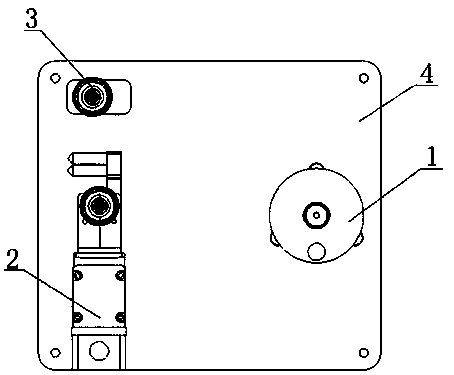

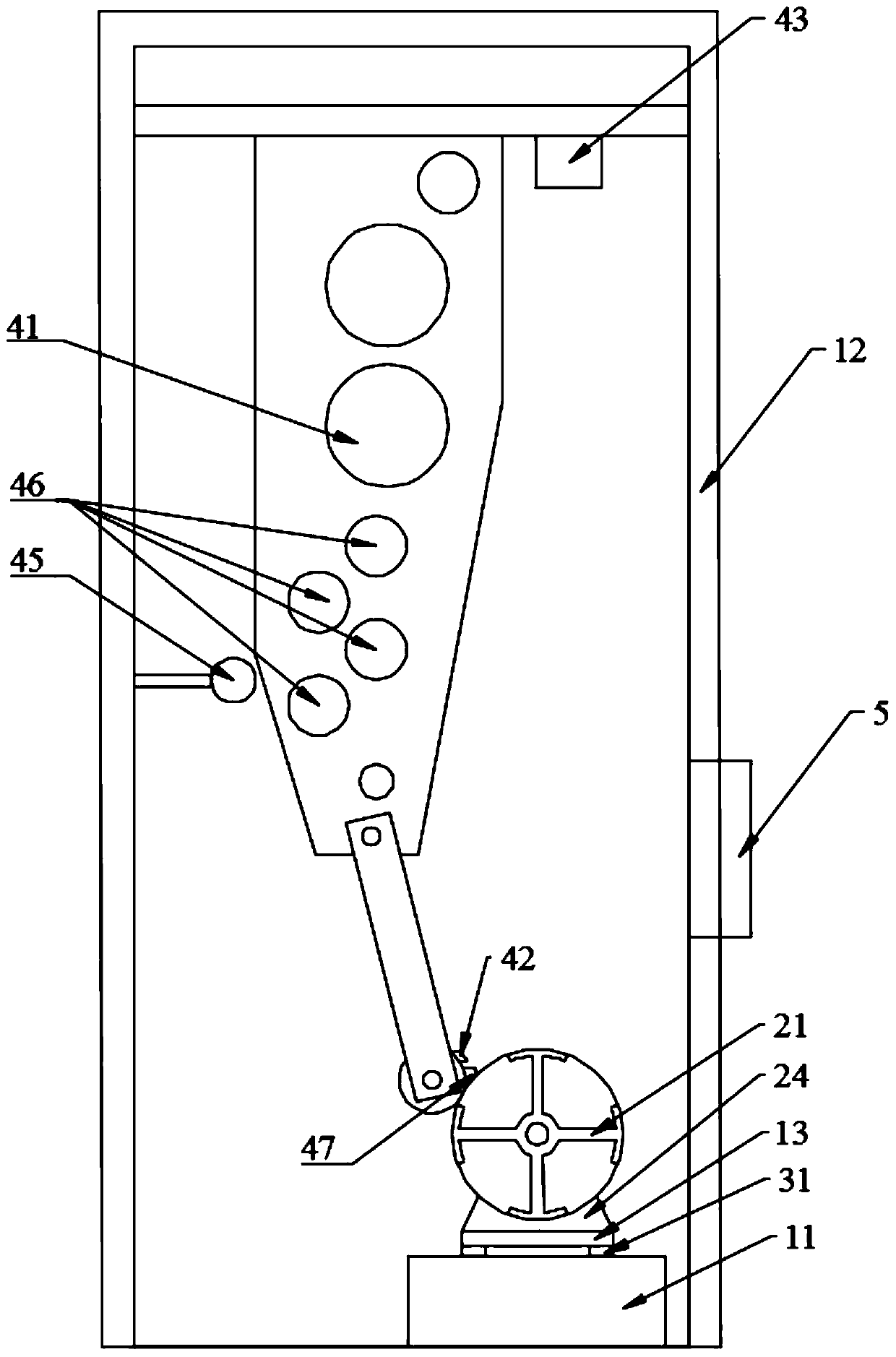

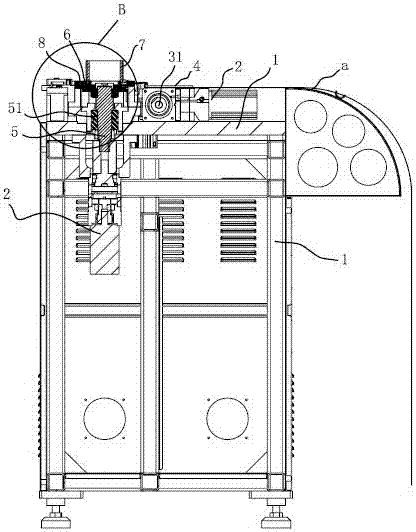

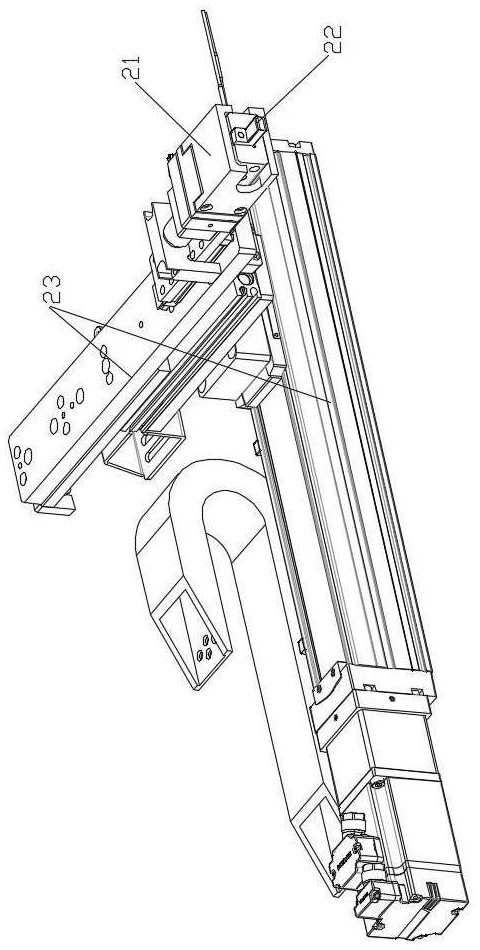

Brand new high-universality maintenance-free high-speed constant-tension yarn winder

The invention relates to a brand new high-universality maintenance-free high-speed constant-tension yarn winder. The yarn winder comprises a winding head mechanism, a winding arm mechanism and an online tension meter. The winding arm mechanism is mounted at the lower left corner of a fixing plate, the online tension meter is mounted at the upper left corner of the fixing plate, and the winding head mechanism is mounted in the middle of the right side of the fixing plate. The winding arm mechanism comprises a sliding mechanism, a rotary wheel, an L-shaped fixing plate, a guide roller support and guide rollers; the lower end of the L-shaped fixing plate is mounted on the sliding mechanism; one side of the L-shaped fixing plate is provided with the rotary wheel; the inner side of the upper end of the L-shaped fixing plate is provided with the guide roller support; the guide roller support is provided with the two guide rollers; the rear end of the sliding mechanism is mounted on the fixing plate; the front end of the online tension meter is provided with the rotary wheel; and an expansion shaft mechanism for mounting a paper tube or a yarn disc is designed at the front end of the winding head mechanism. The yarn winder has the advantages of being reasonable in design, convenient to use, capable of meeting the requirement for universality of parallel and cross winding, stable in operation and high in winding precision.

Owner:SHANGHAI GLOBALINK REINFORCEMENT SCI & TECH +2

Sheet-fed printing material cold-waving membrane-saving unit, cold-waving method thereof and sheet-fed printing material cold-waving membrane-saving device

InactiveCN105818529ALow costSave cold filmFunction indicatorsBronze printingControl systemEngineering

The invention discloses a sheet-fed printing material cold-waving membrane-saving unit, a cold-waving method thereof and a sheet-fed printing material cold-waving membrane-saving device. The sheet-fed printing material cold-waving membrane-saving unit comprises an unwinding mechanism, a winding mechanism and a control system. The unwinding mechanism comprises an unwinding roller used for unwinding at least two rolls of cold-waving membranes, and at least two first traction mechanisms used for traction of corresponding rolls of cold-waving membranes. The winding mechanism comprises a winding roller used for winding at least two rolls of cold-waving membranes. The unwinding roller and the winding roller are both slip frequency shafts. The unwinding mechanism, the winding mechanism and the first traction mechanisms are electrically connected with the control system. By means of the sheet-fed printing material cold-waving membrane-saving unit, the cold-waving method of the sheet-fed printing material cold-waving membrane-saving unit and the sheet-fed printing material cold-waving membrane-saving device, an existing whole-breadth cold-waving membrane which is used can be divided into multiple rolls of independent cold-waving membranes, each roll is independently driven, the cold-waving membranes can be effectively saved, aluminum resources can be effectively saved, and the material cost is reduced.

Owner:ZRP PRINTING GRP CO LTD +1

Binding tape reciprocating type coiling machine and using method thereof

The invention relates to a binding tape reciprocating type coiling machine and a using method thereof. The binding tape reciprocating type coiling machine comprises a machine base and a rack, whereina horizontal coiling wheel is arranged on the machine base, the coiling wheel is driven by a driving motor for driving the coiling wheel to rotate to rotate, and the rotating direction of the drivingmotor is controlled by an encoder. One end of the coiling wheel is arranged on a coiling wheel case, and the coiling wheel case is fixed to a bottom plate. The bottom plate is provided with a screw rod which can axially and horizontally move, and the screw rod is fixedly arranged on the machine base. The screw rod is controlled by a servo motor for controlling the screw rod to axially move, the rack is provided with a guide mechanism, and the guide mechanism is composed of reels with different diameters. The binding tape reciprocating type coiling machine further comprises an electrical equipment control box containing a logical program, and the electrical equipment control box is electrically connected with the encoder and the servo motor. The horizontal movable binding tape reciprocatingtype coiling machine is high in coiling precision, continuous automatic production can be achieved, the coiling edge of a binding tape is neat, and the tightness is moderate.

Owner:JIANGSU JU HONG BUNDLE BRING MFG

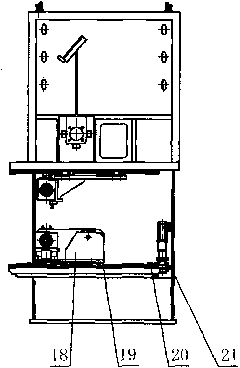

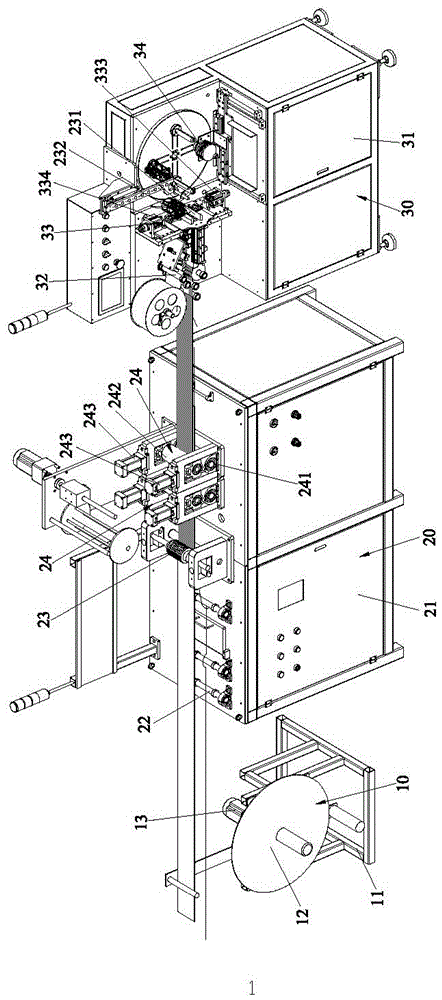

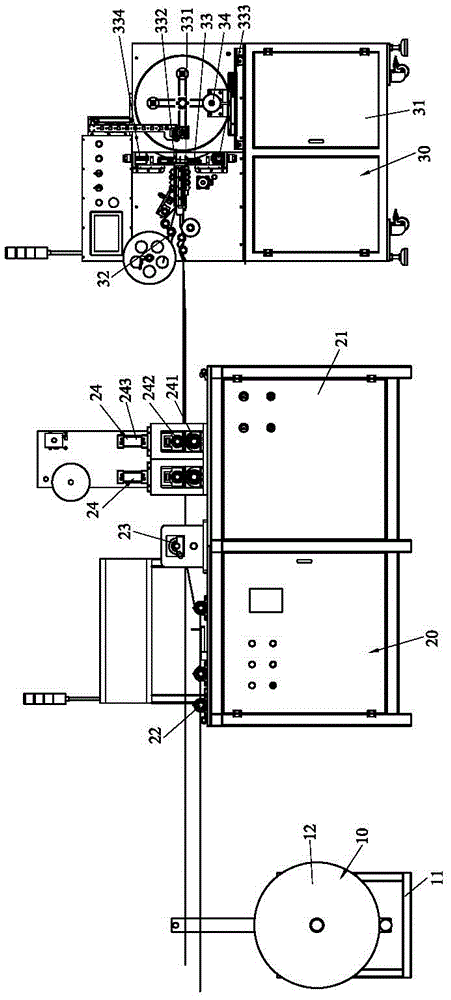

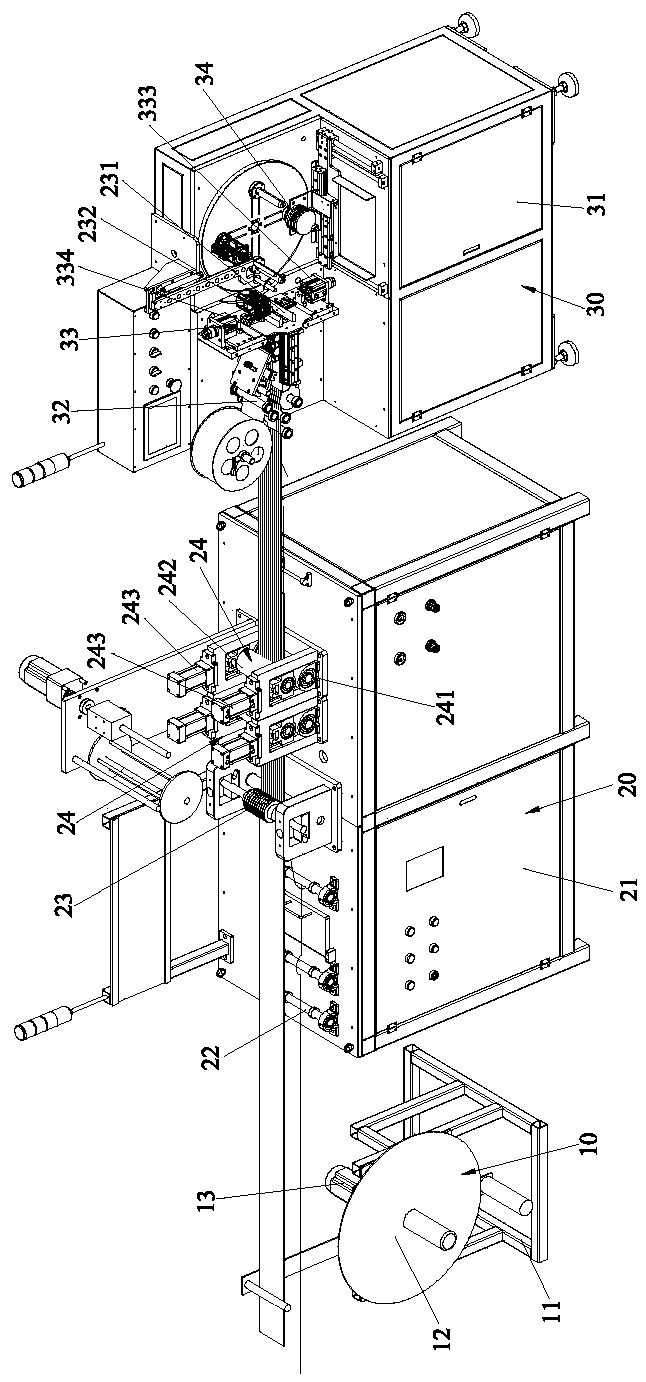

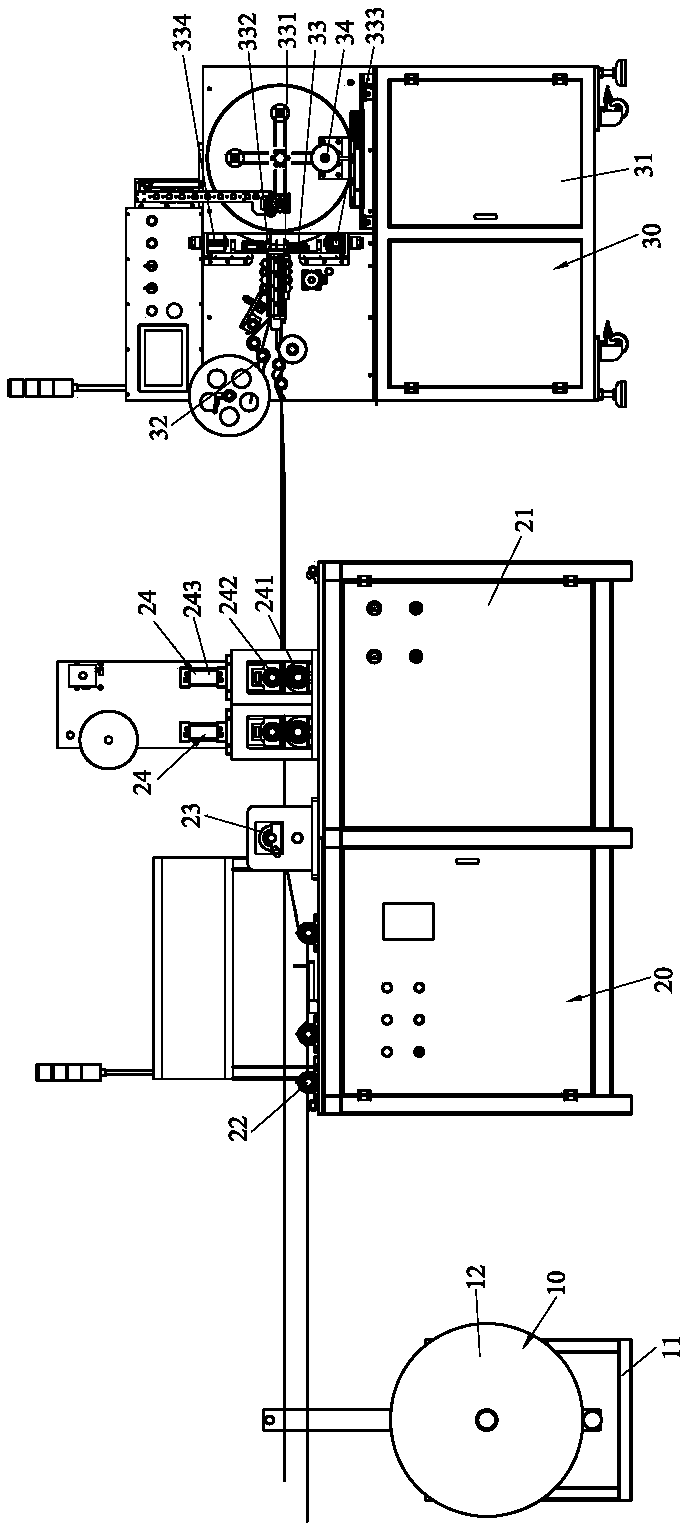

Velcro automatic winding machine

ActiveCN105565033ARealize automatic winding operationPracticalWebs handlingWinding machineEngineering

The invention discloses a Velcro automatic winding machine. The Velcro automatic winding machine comprises a feeding device, a tape rewinding and cropping device and a slitting and rolling device, wherein the feeding device, the tape rewinding and cropping device and the slitting and rolling device are sequentially arranged side by side; the tape rewinding and cropping device comprises a first machine frame, a guiding mechanism, a tape rewinding mechanism and cropping mechanisms, wherein the guiding mechanism, the tape rewinding mechanism and the cropping mechanisms are sequentially arranged side by side on the first machine frame; the slitting and rolling device comprises a second machine frame, a scroll mechanism, a slitting mechanism and a rolling mechanism, wherein the scroll mechanism, the slitting mechanism and the rolling mechanism are sequentially arranged side by side on the second machine frame. The feeding device, the tape rewinding and cropping device and the slitting and rolling device are matched for movement, and the automatic winding work can be realized. The Velcro automatic winding machine is high in practicability, wide in application range of products, simple in operation, high in stability, high in winding precision, and good in consistency of the products, and the production efficiency can be greatly improved.

Owner:东莞百宏实业有限公司

Automatic winding device of motor stator iron core

ActiveCN104810991AImprove winding accuracyReduce defective rateManufacturing stator/rotor bodiesDrive motorManipulator

The invention discloses an automatic winding device of a motor stator iron core. The automatic winding device comprises a worktable, a driving motor is arranged on the worktable, and a drawing belt enters a guide-in channel under drive of a transmission gear and the driving motor and then is further dragged into a winding and forming mechanism. A winding spindle of the winding and forming mechanism is vertically arranged on the worktable by a bearing assembly, the lower end of the winding spindle is connected with a winding motor, an operating end of the winding spindle extends out of the worktable, and the port of the winding spindle is connected with a reel by a connector, a forming mold is arranged at the outer ring of the connector, and the internal channel formed between internal grooves of the forming mold relative to the connector is a circumferential deformation space for the drawing belt. The drawing belt winds on the reel with ribs after extending out of the deformation space and is cut off to form helical stator packs after winding preset turns. The automatic winding device adopts double power sources, formed products are always kept winding on the reel, materials are taken by manipulators, production efficiency is improved and labor cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

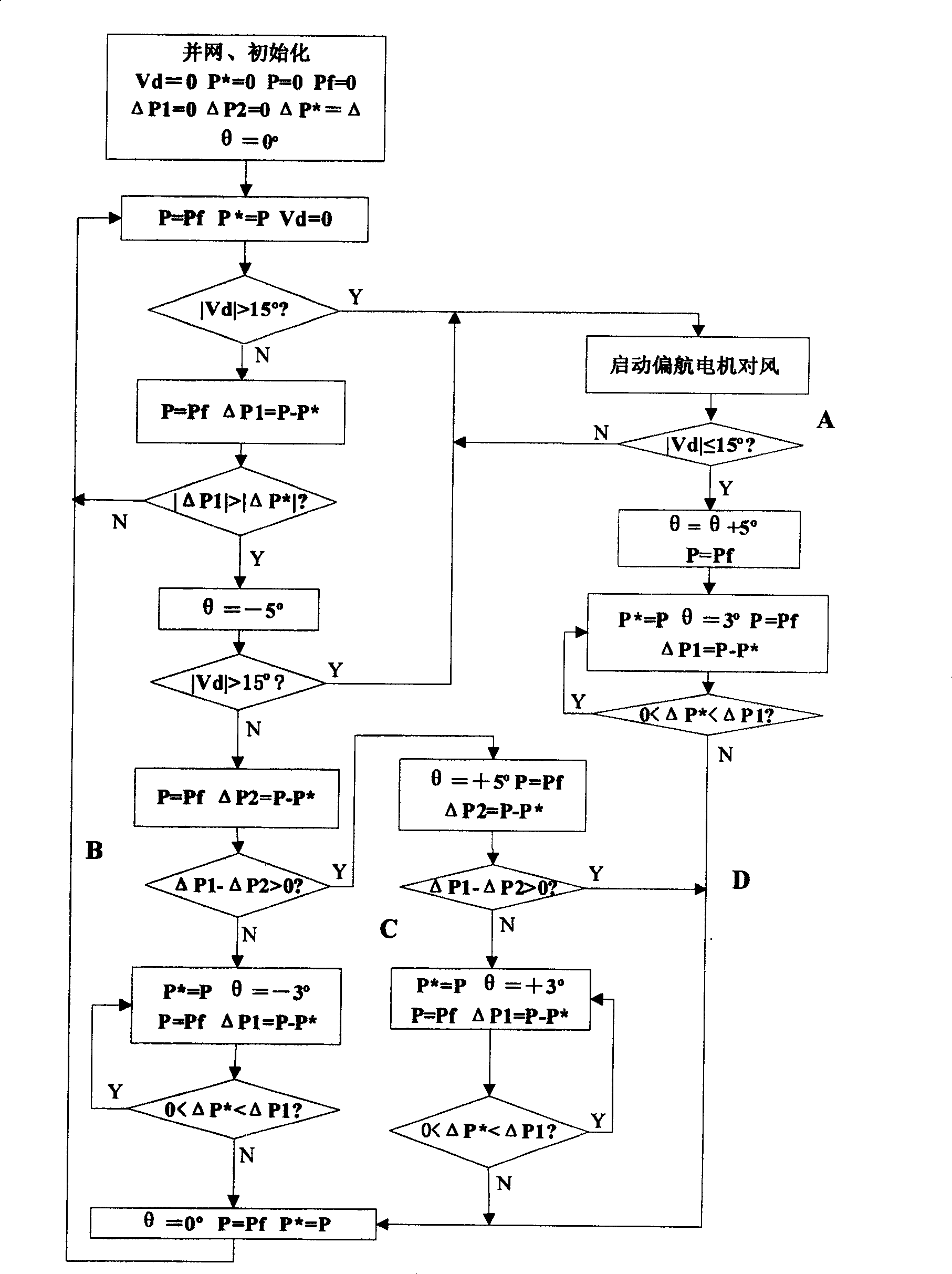

Wind mill leeway control method based on wind vane and output power

InactiveCN100460669CShorten winding timeImprove winding accuracyWind motor controlMachines/enginesSignal onEngineering

The invention relates to a drift control method of wind mill based on wind vane and output power. When the absolute wind change value is higher than 15degree, the invention uses wind vane control method, and when the absolute wind change value is not higher than 15degree, the invention uses power control method. Since the wind direction and speed changes will change the output power of generator, the power checker can check the output power of motor, the invention only processes drift control when the wind direction changes, while the wind change is used as interference signal on the power control method. The power control method is divided into anti-clockwise rotation, clockwise rotation, and original position stop conditions. The invention can shorten the align time, improve accuracy and energy utilization.

Owner:SHANGHAI JIAO TONG UNIV

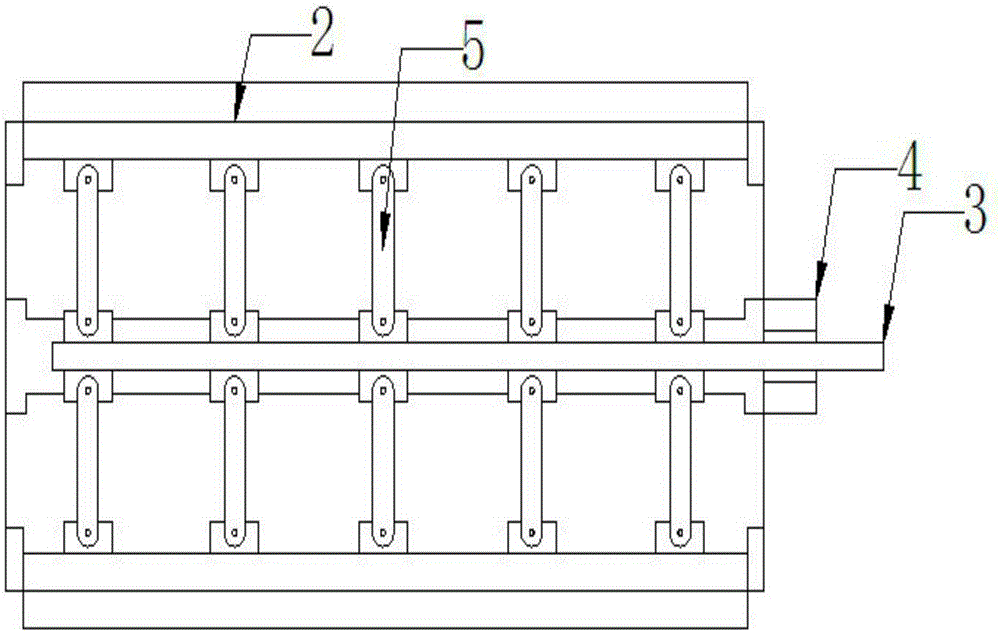

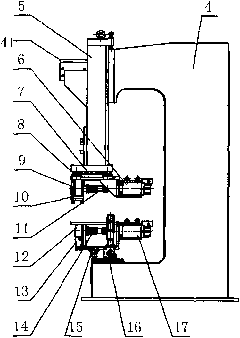

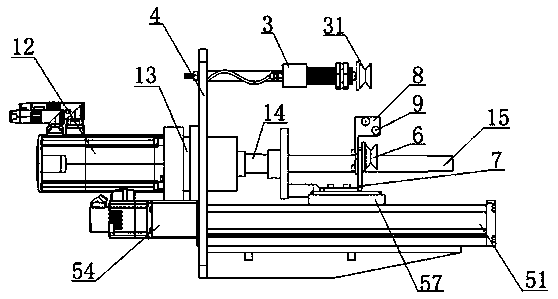

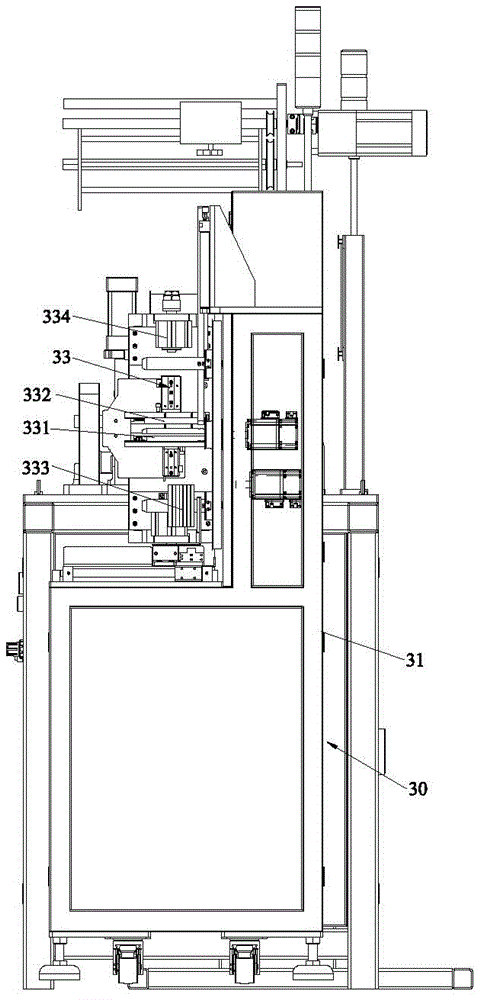

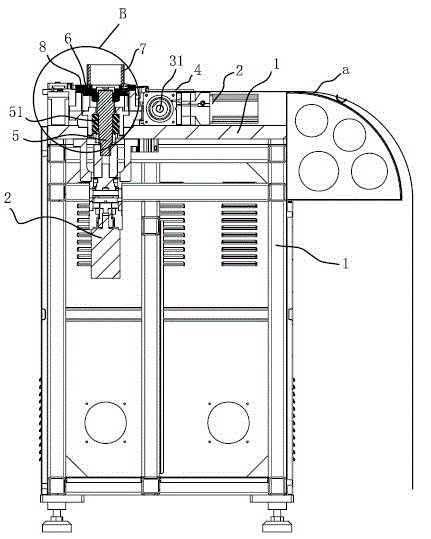

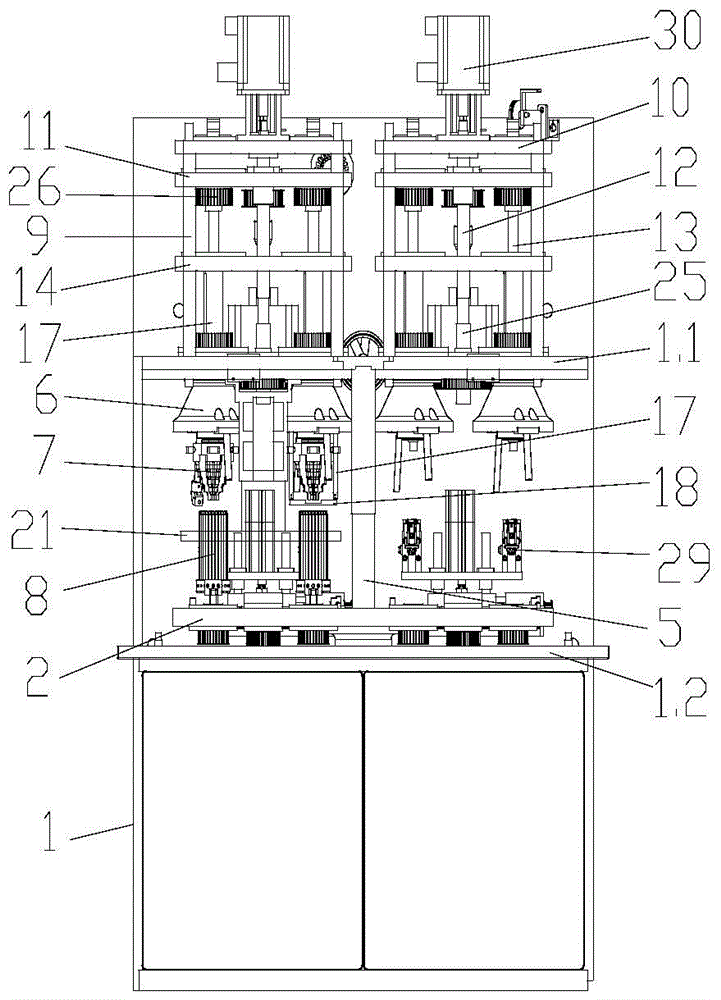

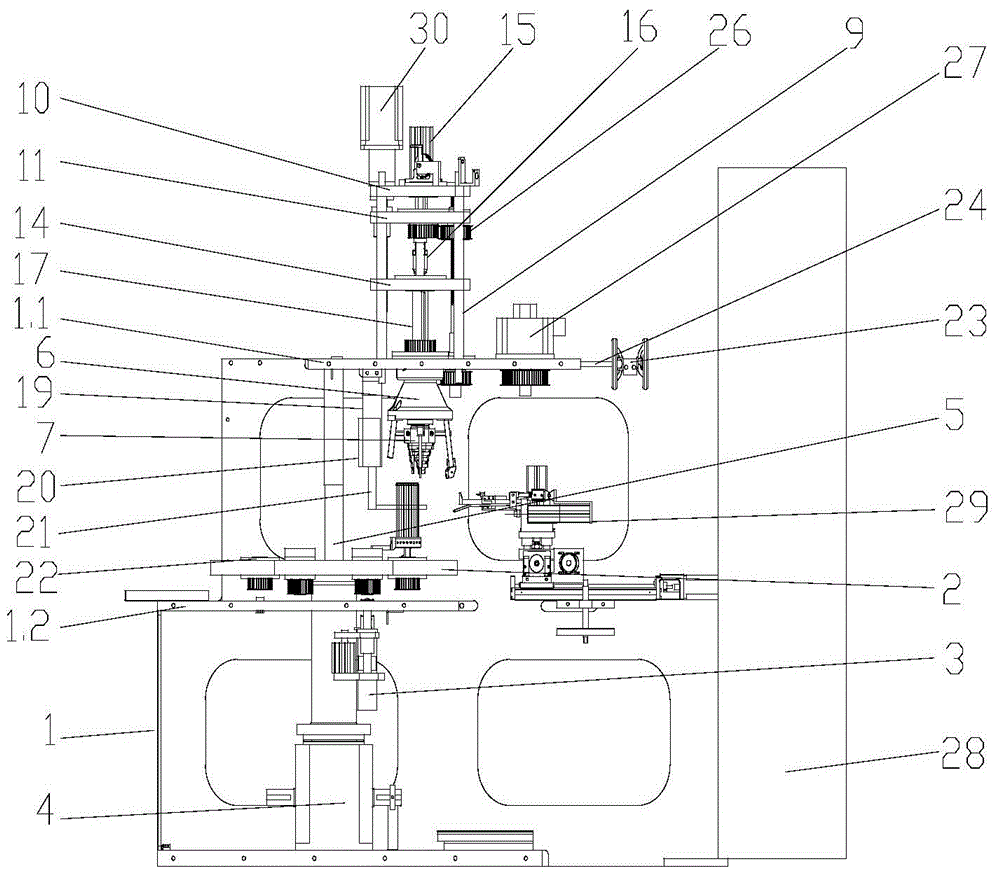

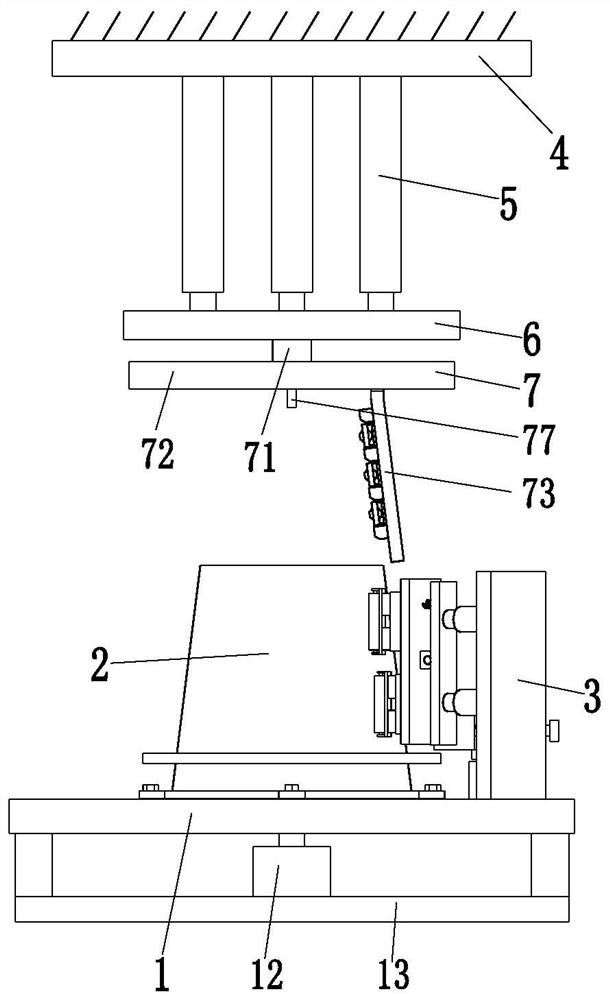

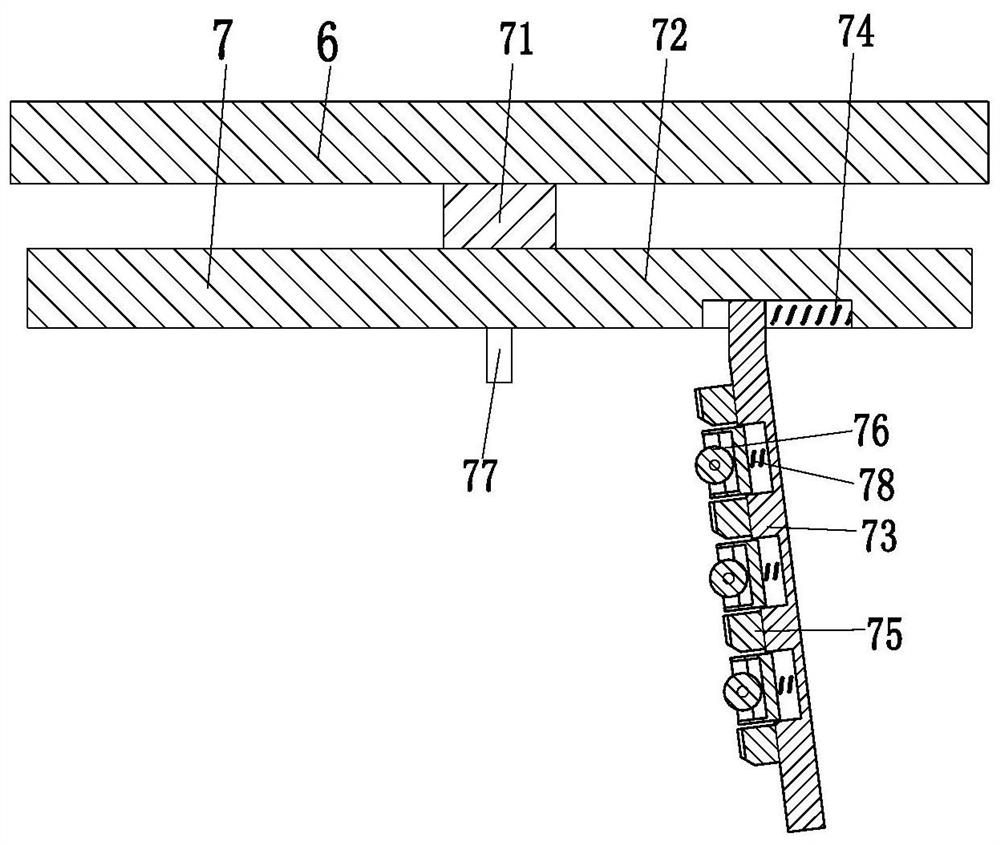

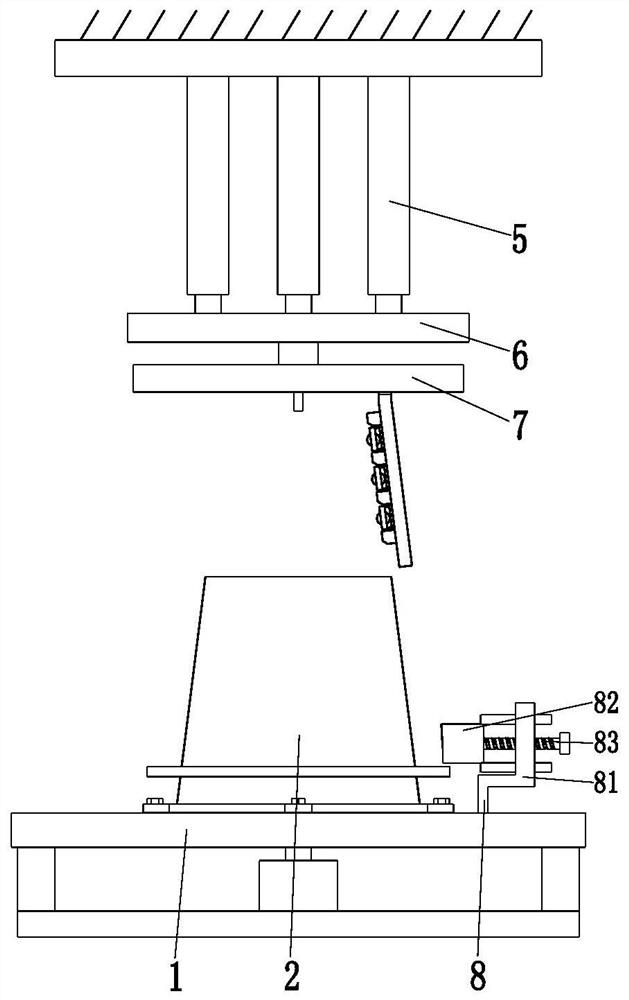

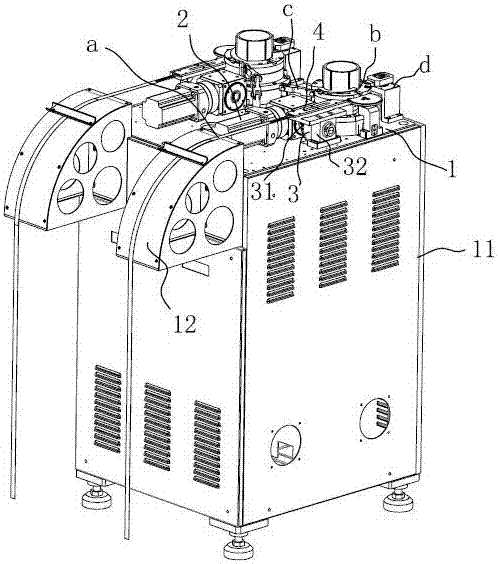

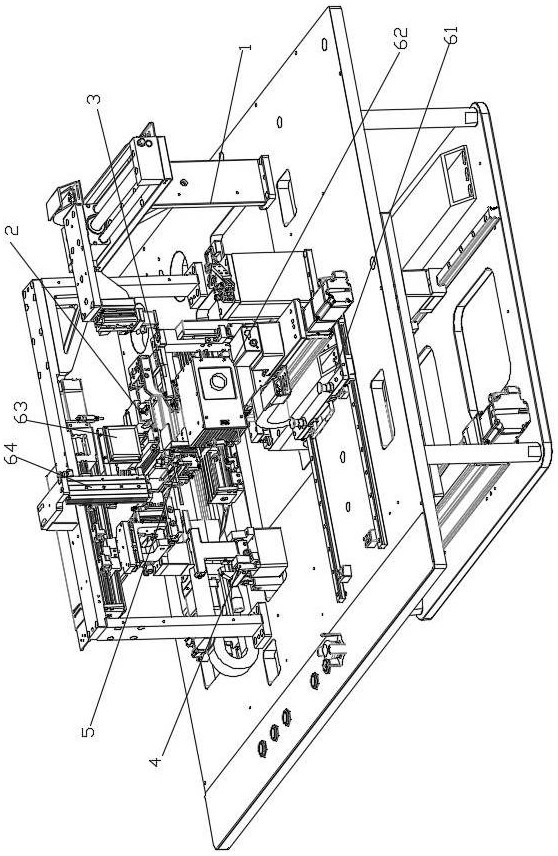

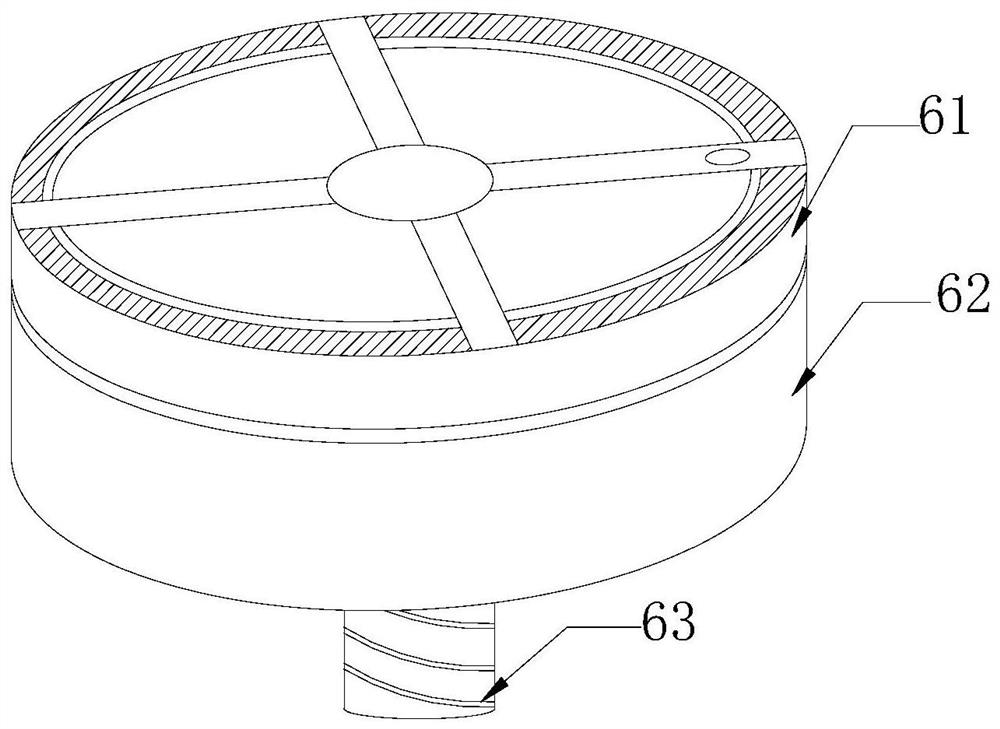

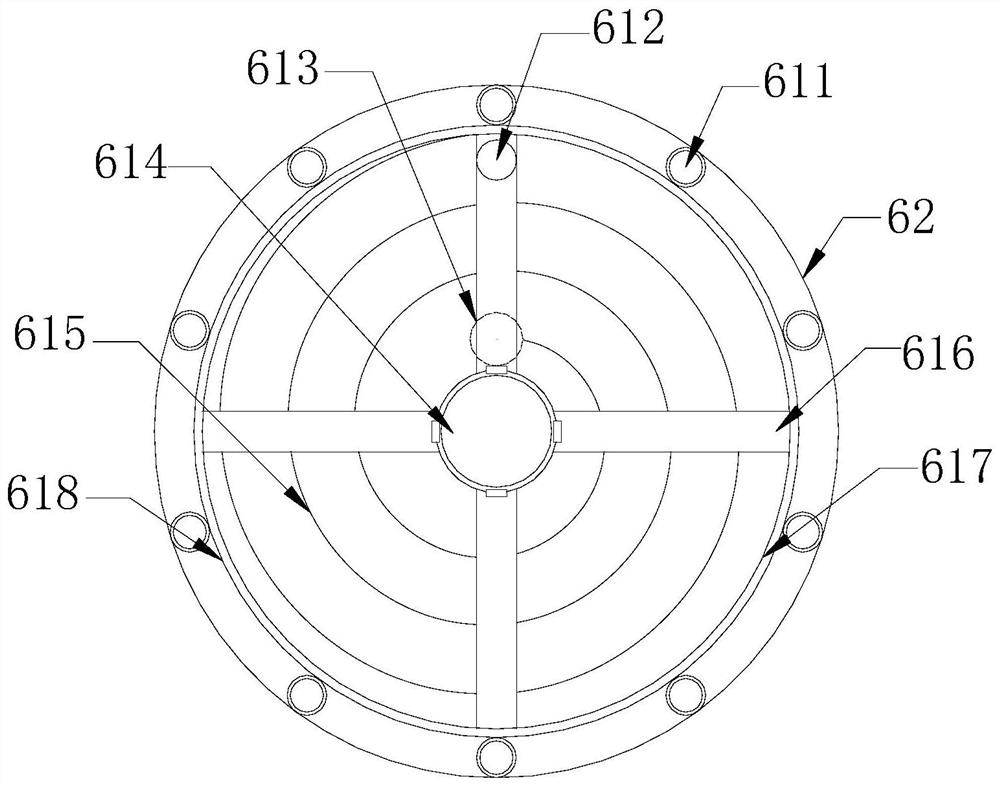

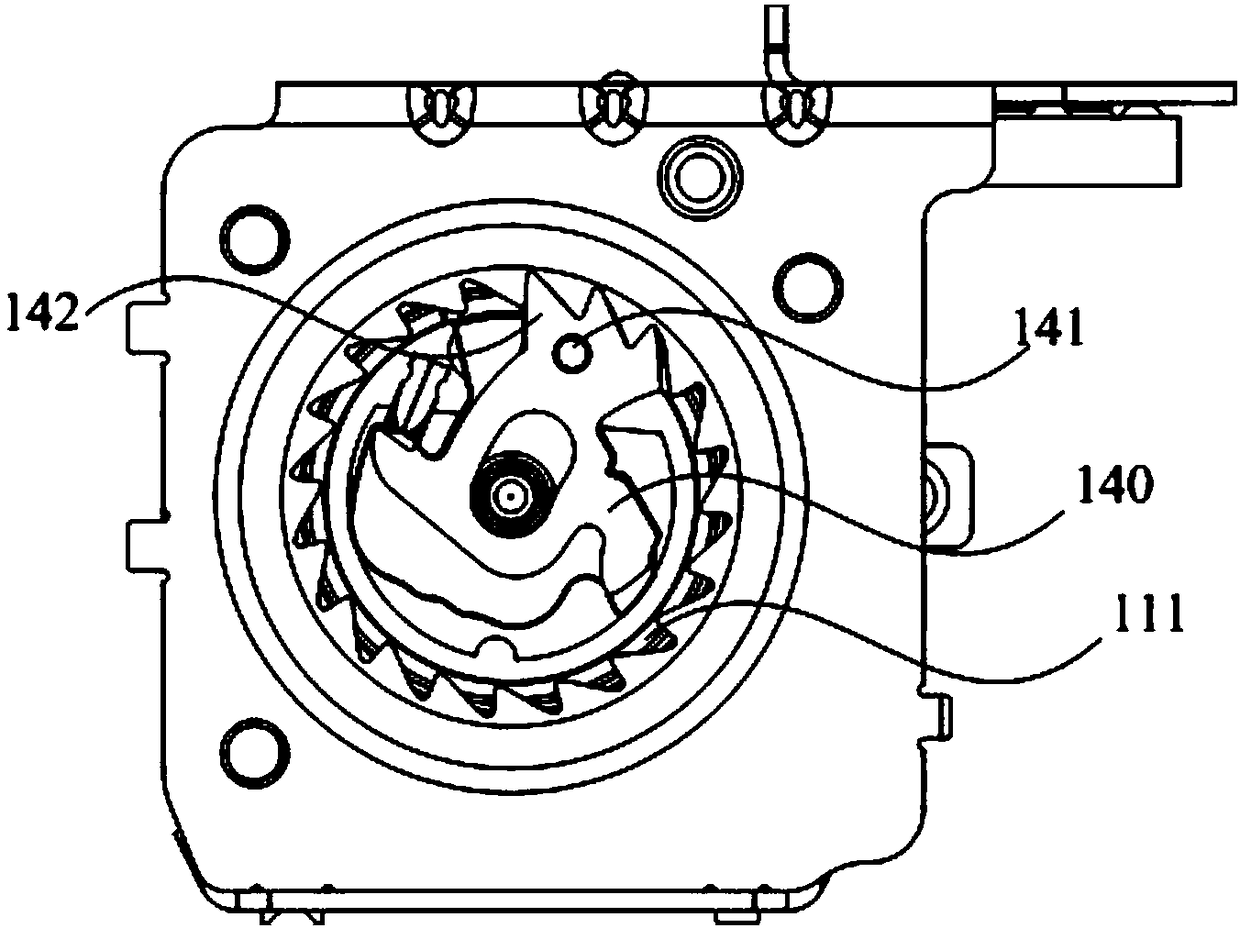

A finely adjustable four-head eight-station winding machine

ActiveCN104538171BQuality improvementImprove winding accuracyCoils manufactureWinding machineConductor Coil

The invention belongs to the technical field of a winding machine, in particular to a four-head eight-station winding machine capable of carrying out fine tuning. The four-head eight-station winding machine comprises a bracket, a transposition indexing mechanism, a workbench, a workbench positioning mechanism, a winding mechanism and a trimming and wire pulling mechanism, wherein the workbench positioning mechanism and the transposition indexing mechanism are fixedly arranged on the lower part of the bracket; the transposition indexing mechanism is connected with the workbench positioning mechanism through a transmission mechanism; the winding mechanism and the trimming and wire pulling mechanism are correspondingly arranged on the middle of the bracket; the winding mechanism comprises four parallel winding pots, wherein the winding pots are arranged on the bottom of an upper plate of the bracket; a winding former is arranged in each winding pot; the upper part, which corresponds to the winding mechanism, of the bracket is provided with a former sinking mechanism and a wire pushing mechanism, wherein the former sinking mechanism and the wire pushing mechanism are used for controlling the winding former to vertically move; the middle of the bracket is also provided with a wire protecting mechanism corresponding to the winding mechanism; the workbench is provided with two groups of wire hanging cup installation seats which are symmetrically distributed so as to bring convenience for alignment, and therefore, a coil is good in winding quality and high in precision.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

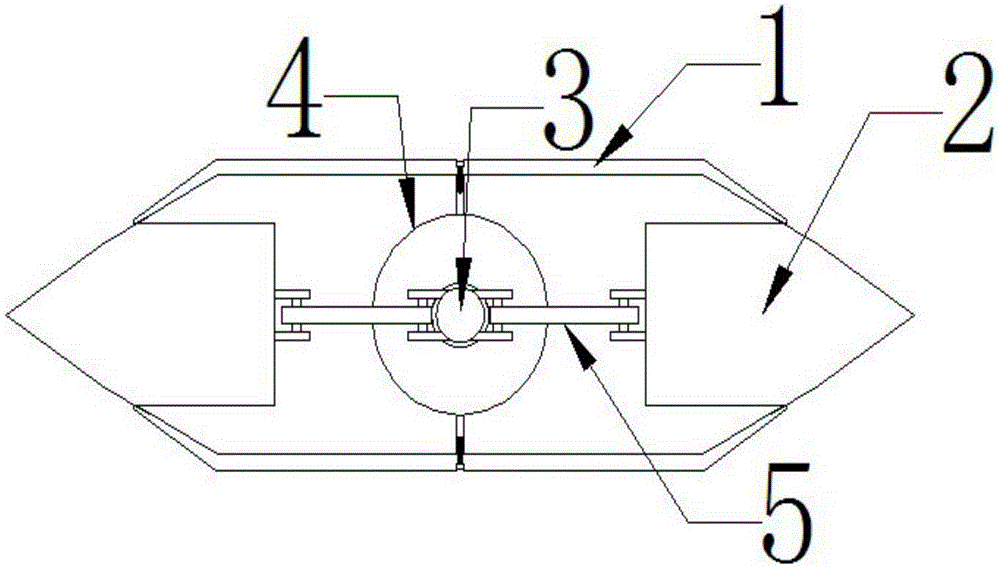

A winding device for a cylindrical packaging box

ActiveCN110774662BImprove winding forming effectImprove winding accuracyBox making operationsPaper-makingClassical mechanicsLocking plate

The invention relates to a winding device for a cylindrical packaging box, which includes a bottom plate, a shaping seat, a rolling mechanism, a connecting plate, a locking push rod, a locking plate and a pressing mechanism. A circular groove is arranged in the middle of the bottom plate. The circular groove of the bottom plate is connected with a sliding seat through a sliding fit. There are several groups of threaded holes symmetrically arranged in the middle of the sliding seat. The threaded holes set in the middle of the sliding seat are equipped with a shaping seat through bolts. The rolling mechanism is located in the shaping seat. The rolling mechanism is installed on the top of the bottom plate, the connecting plate is located directly above the shaping seat, the connecting plate is installed on the free end such as the external wall, and the locking plate is installed on the bottom of the connecting plate through a locking push rod. , The compression mechanism is installed on the bottom of the locking plate. The invention can solve the problem that the box wall of the box wall in the existing box winding molding is easy to be indented or wrinkled by manual winding, and the packaging box winding and sticking will have a certain position deviation, resulting in poor packaging box forming effect.

Owner:贵州永吉盛珑包装有限公司

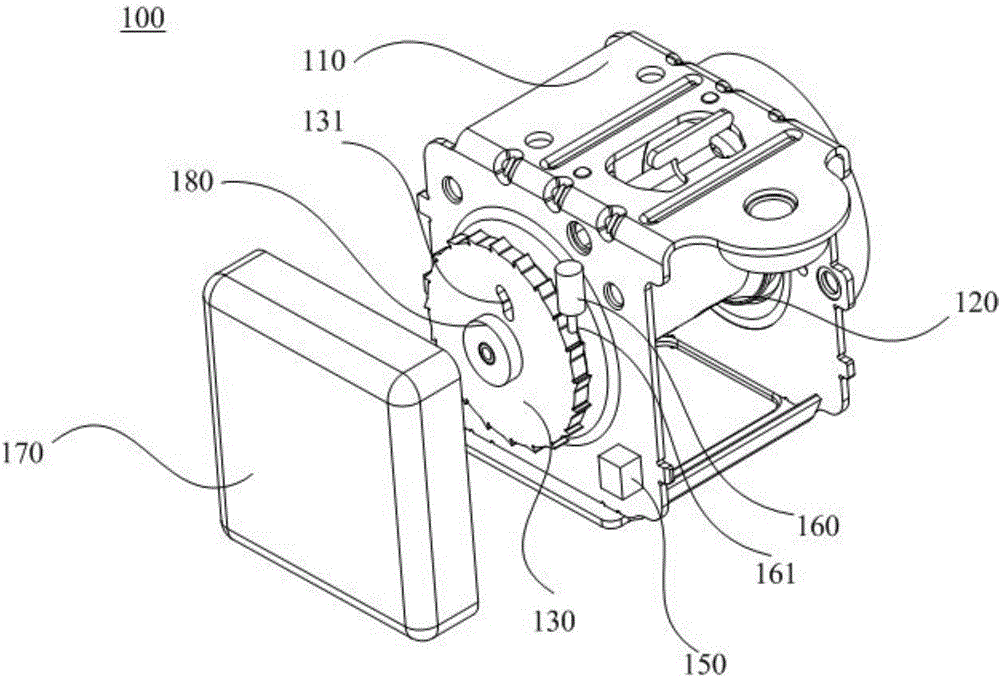

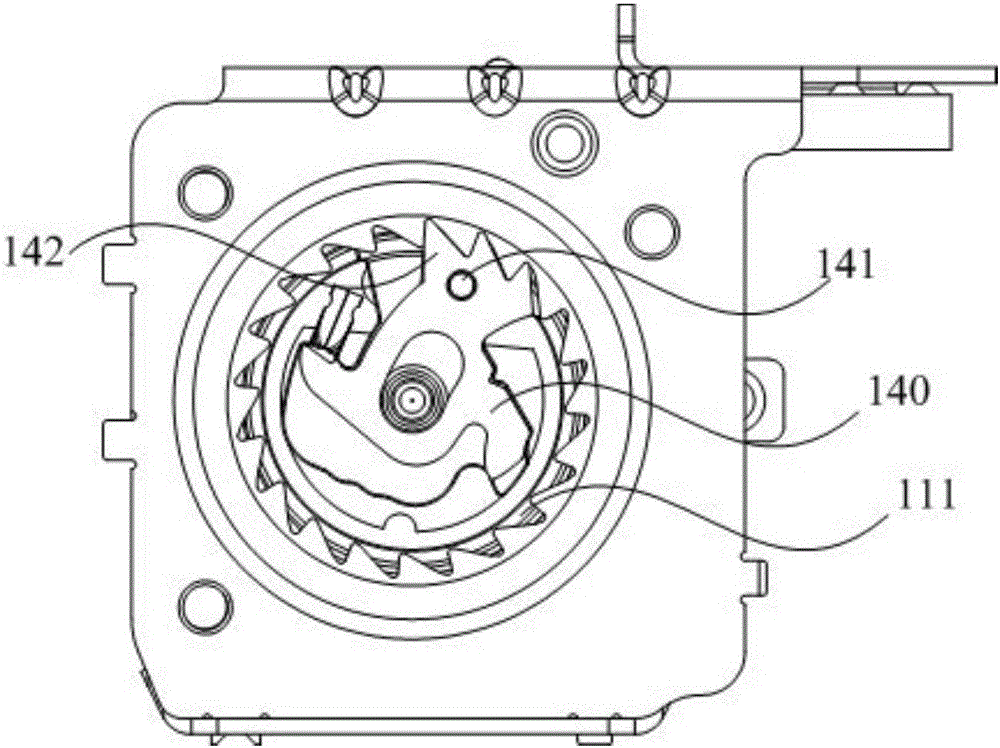

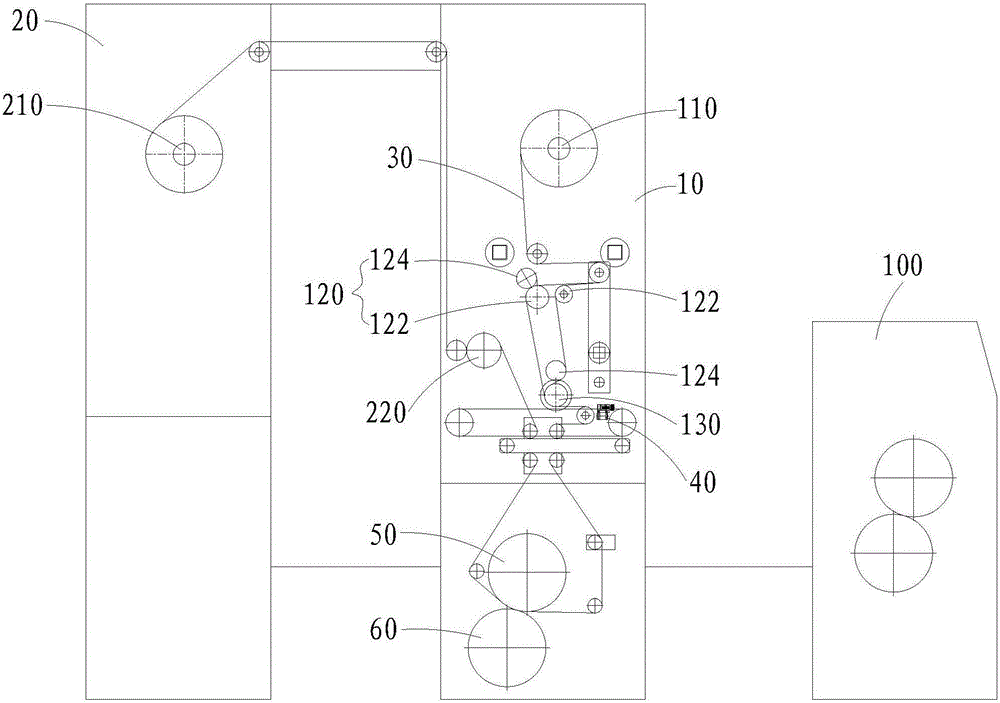

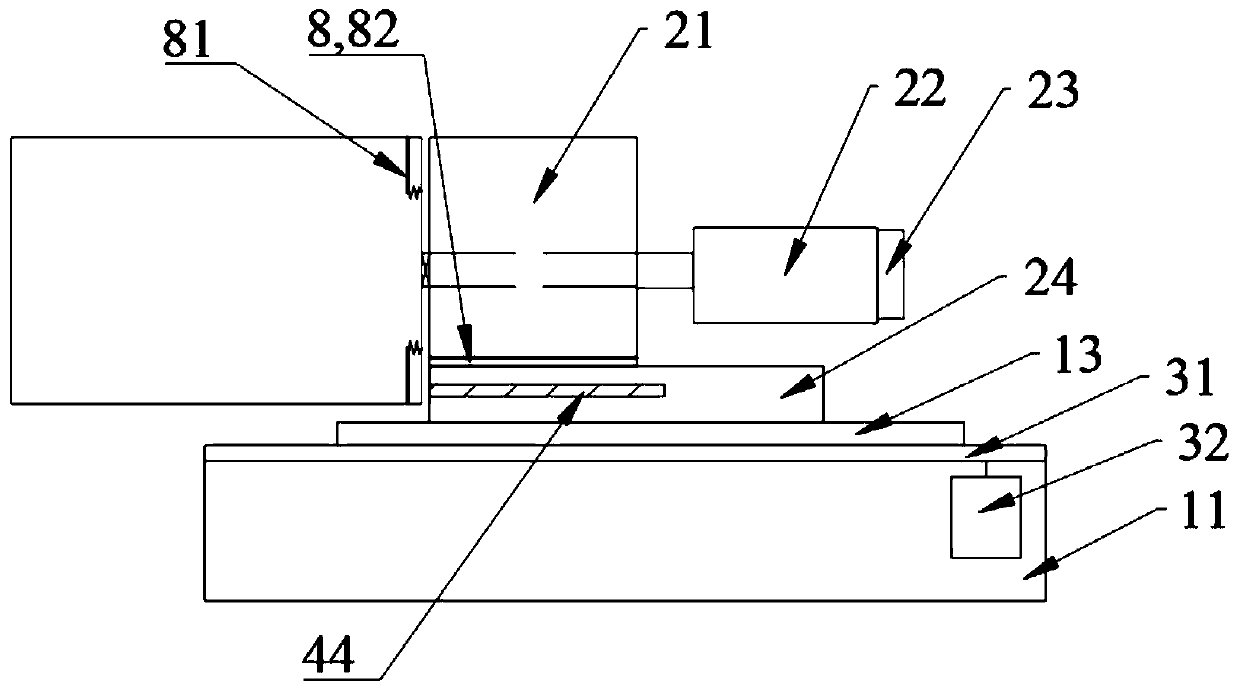

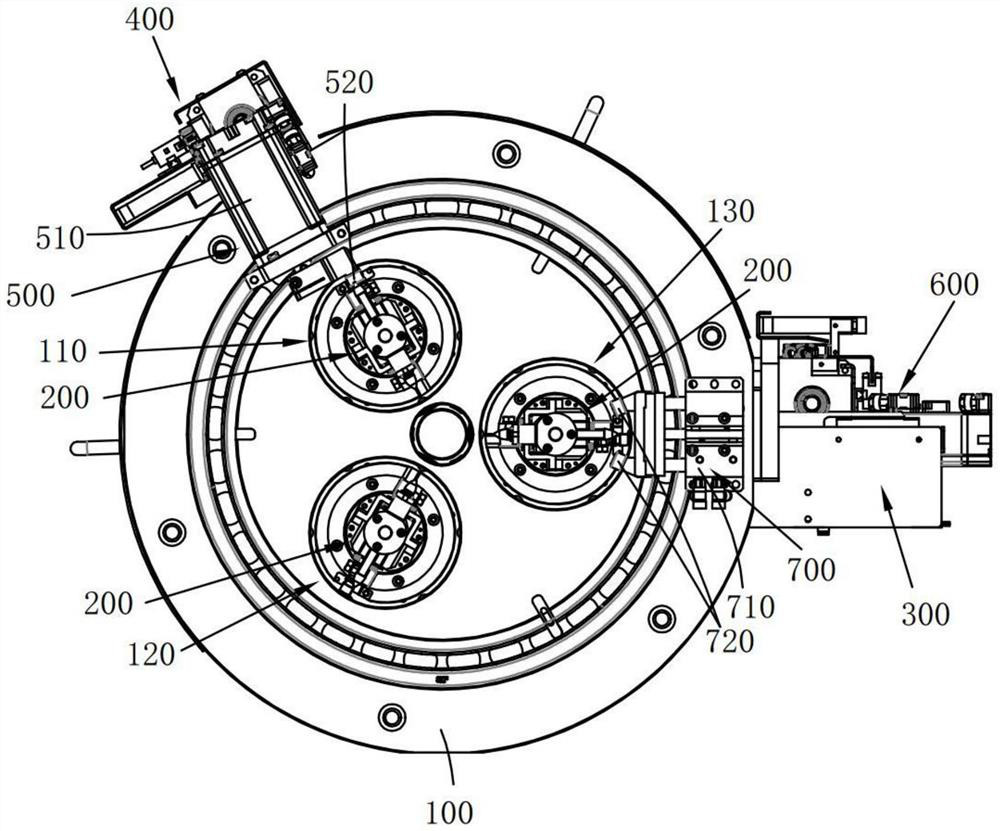

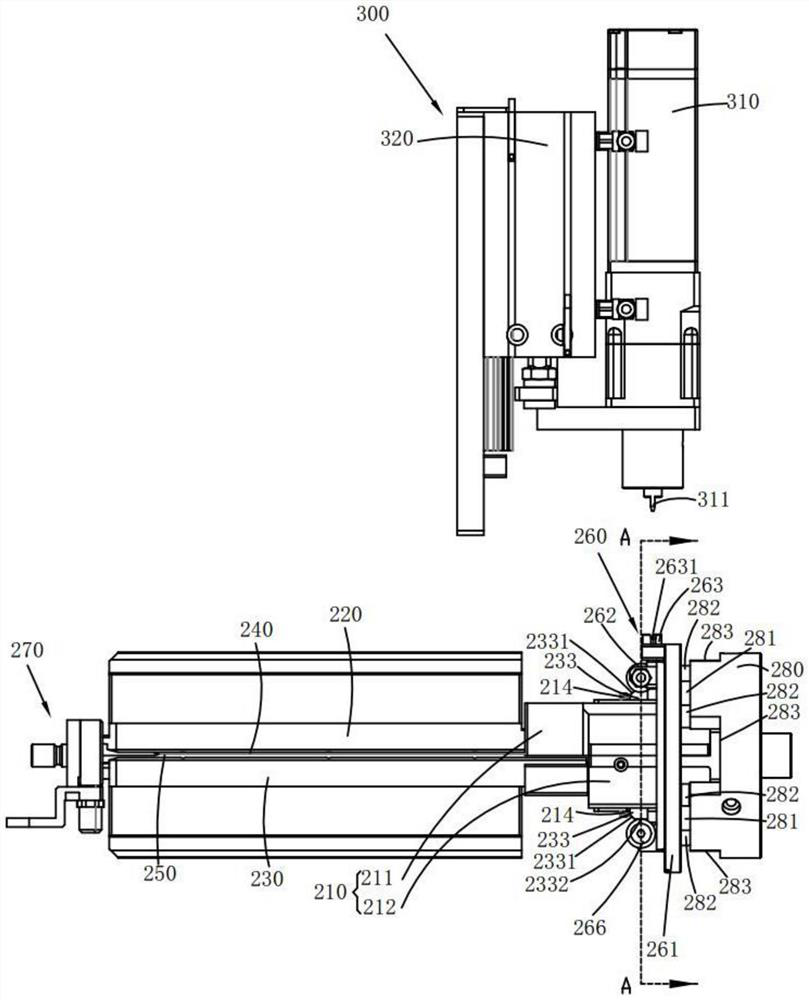

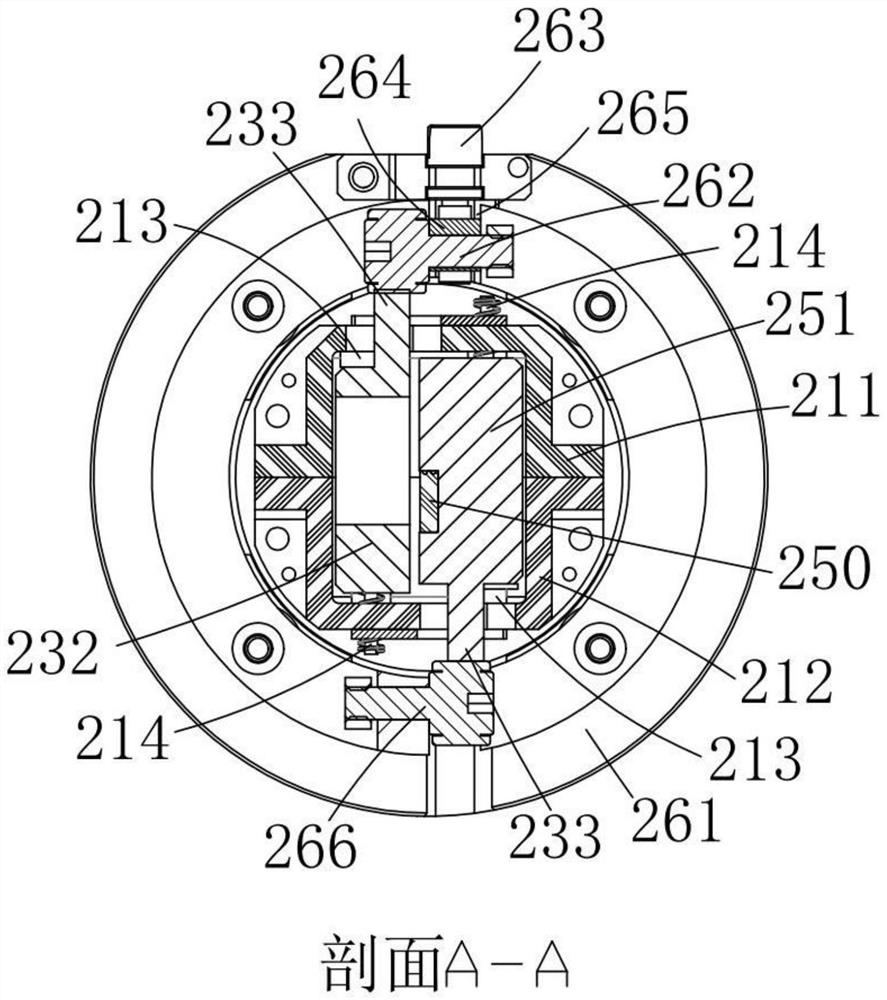

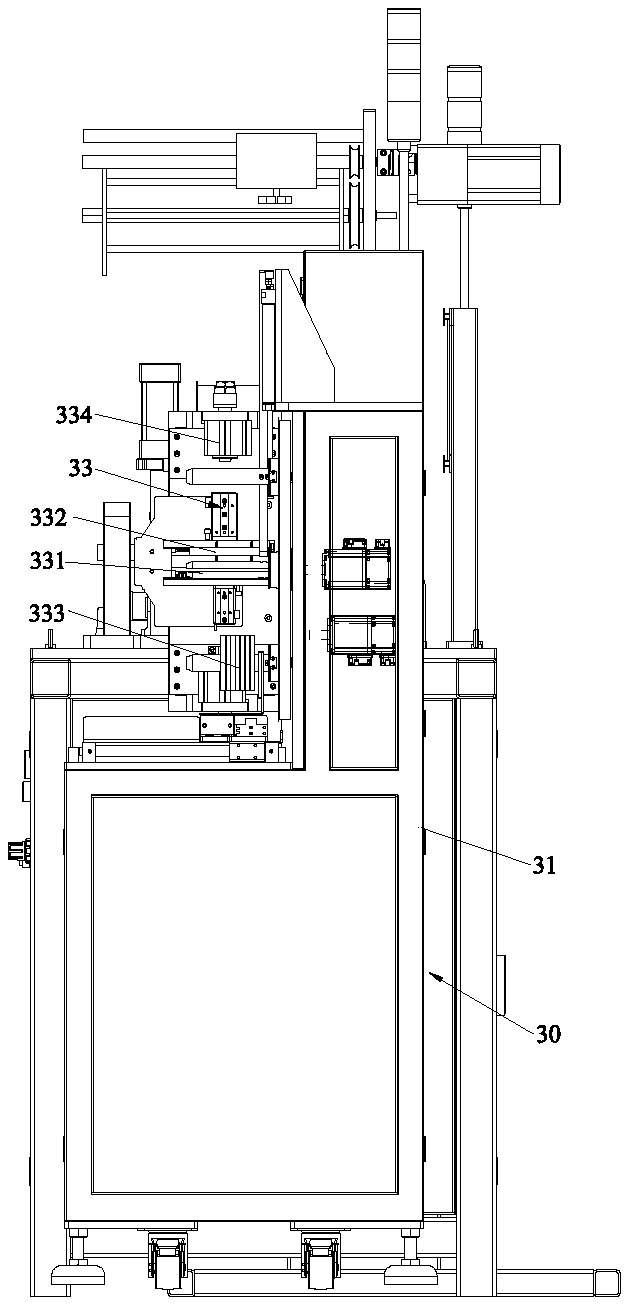

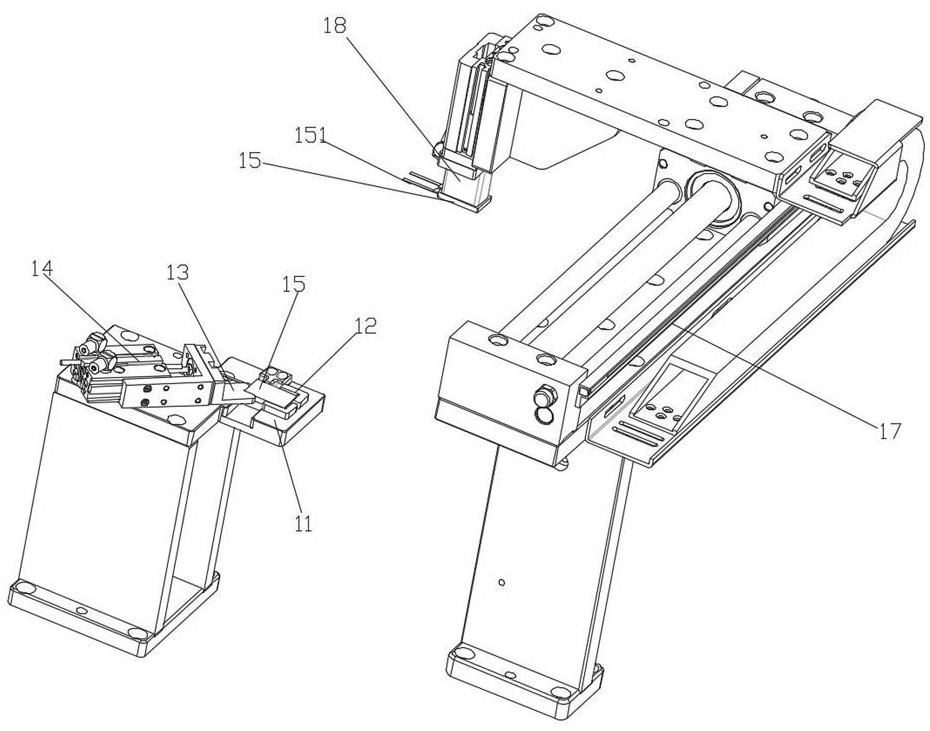

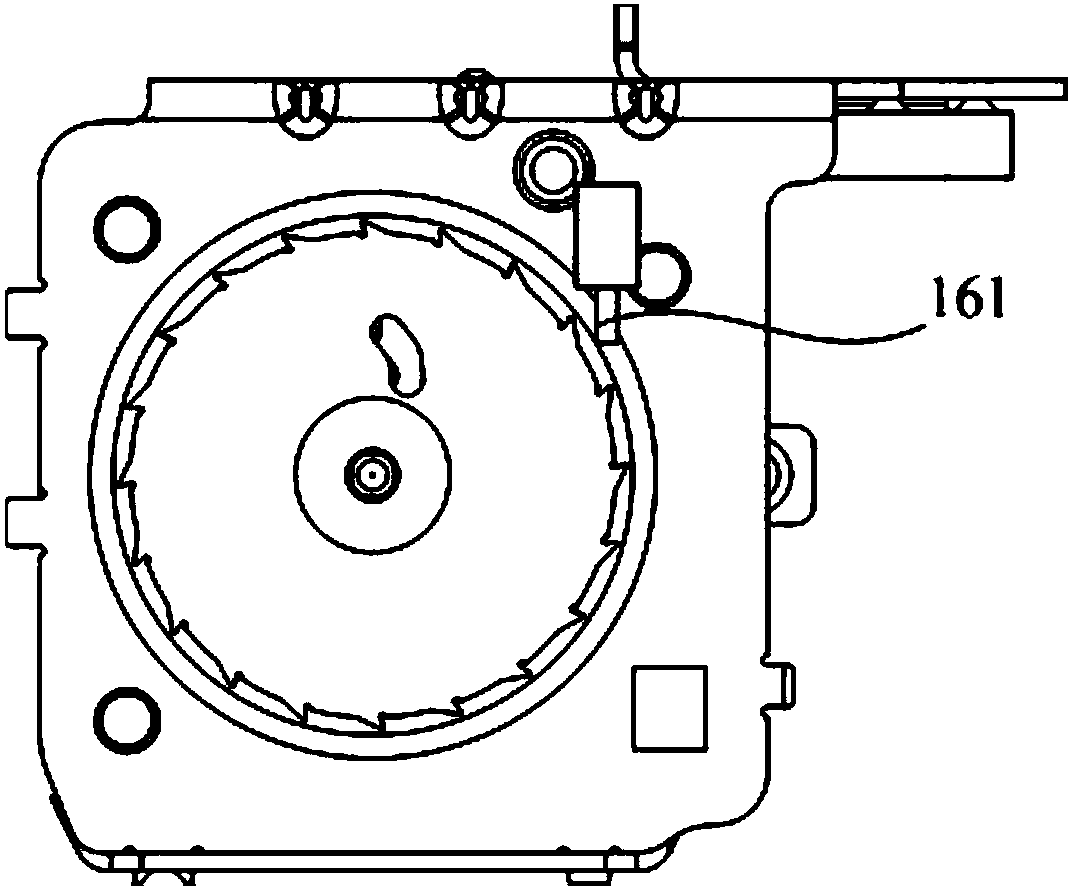

Winding device and winding method

PendingCN114744277AImprove winding accuracyImprove work efficiencyFinal product manufactureLi-accumulatorsElectric machineryElectrical and Electronics engineering

The invention discloses a winding device and a winding method. The winding mechanism comprises a rotating tower, three winding needle mechanisms are arranged on the rotating tower and correspond to a winding station, a rubberizing station and a discharging station respectively, and a motor needle opening assembly, a needle closing assembly and a needle opening and closing adjusting assembly are further arranged on the rotating tower. The motor needle opening assembly is arranged at a winding station and drives the winding needle mechanism to clamp a material belt; the needle closing assembly is arranged on the discharging station and drives the winding needle mechanism to loosen the material belt. A first adjusting assembly matched with the opening and closing needle adjusting assembly is arranged on the outer surface of the winding needle mechanism, and the opening and closing needle adjusting assembly is arranged on the discharging station and matched with the first adjusting assembly to adjust the perimeter of the winding needle mechanism. According to the winding device and the winding method, the winding precision of the battery cell can be improved while the working efficiency is ensured.

Owner:SUZHOU JIERUISI INTELLIGENT TECH CO LTD

A Velcro automatic winding machine

ActiveCN105565033BRealize automatic winding operationPracticalWebs handlingWinding machineEngineering

The invention discloses a Velcro automatic winding machine. The Velcro automatic winding machine comprises a feeding device, a tape rewinding and cropping device and a slitting and rolling device, wherein the feeding device, the tape rewinding and cropping device and the slitting and rolling device are sequentially arranged side by side; the tape rewinding and cropping device comprises a first machine frame, a guiding mechanism, a tape rewinding mechanism and cropping mechanisms, wherein the guiding mechanism, the tape rewinding mechanism and the cropping mechanisms are sequentially arranged side by side on the first machine frame; the slitting and rolling device comprises a second machine frame, a scroll mechanism, a slitting mechanism and a rolling mechanism, wherein the scroll mechanism, the slitting mechanism and the rolling mechanism are sequentially arranged side by side on the second machine frame. The feeding device, the tape rewinding and cropping device and the slitting and rolling device are matched for movement, and the automatic winding work can be realized. The Velcro automatic winding machine is high in practicability, wide in application range of products, simple in operation, high in stability, high in winding precision, and good in consistency of the products, and the production efficiency can be greatly improved.

Owner:东莞百宏实业有限公司

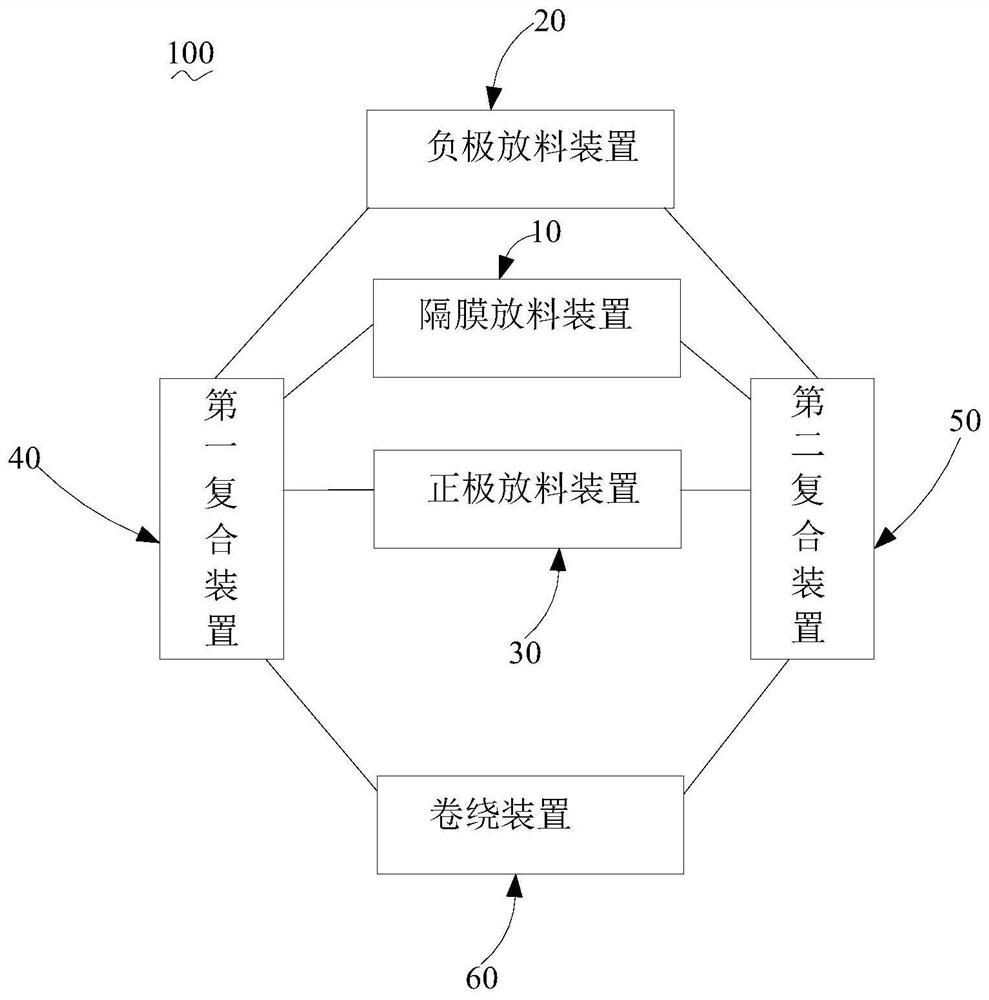

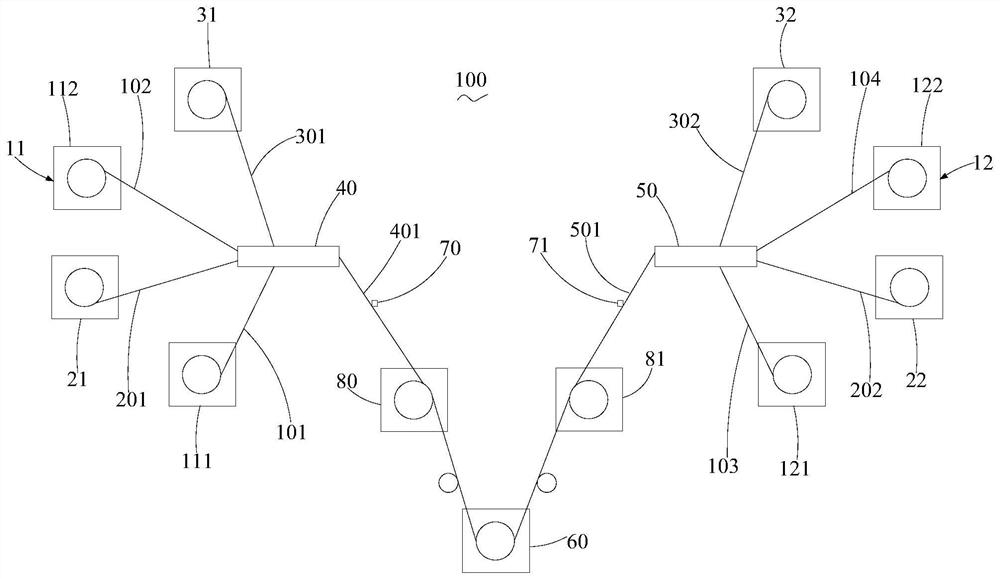

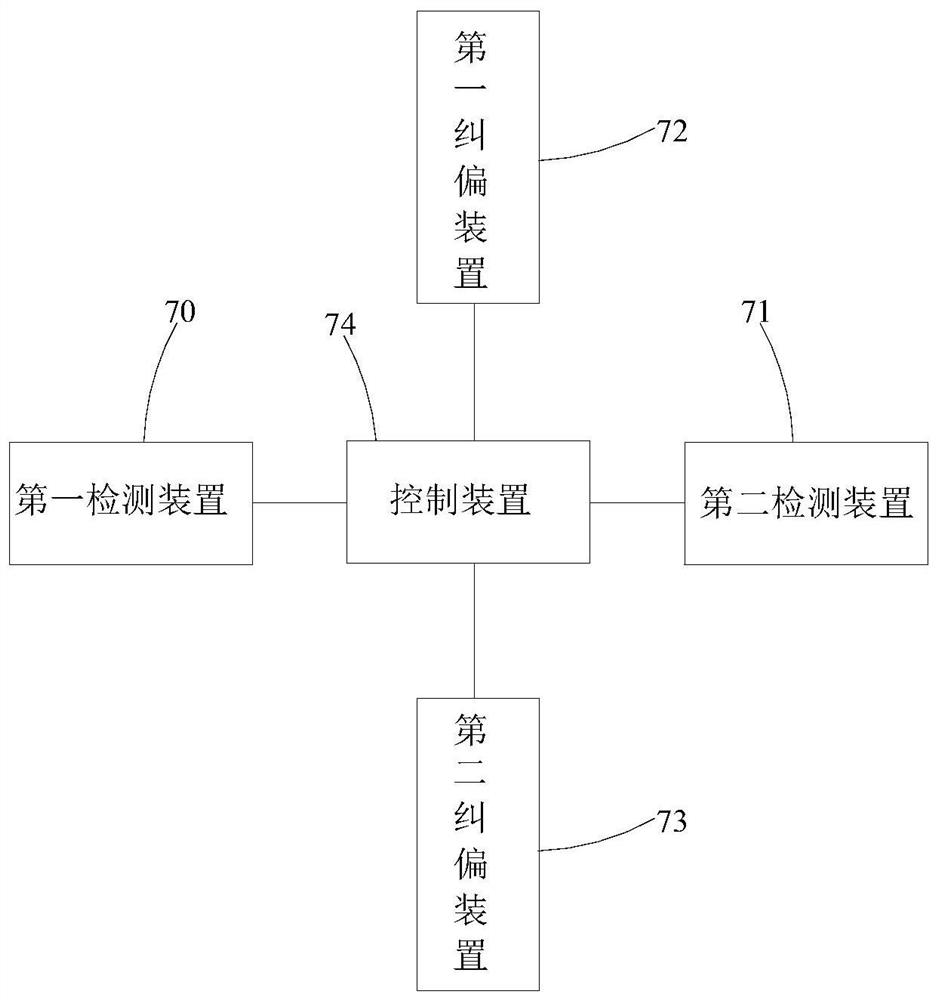

Battery cell winding equipment and preparation method of battery cell

PendingCN112768786AImprove work efficiencyReduce discountAssembling battery machinesFinal product manufactureBattery cellAnalytical chemistry

The invention relates to battery cell winding equipment and a preparation method of a battery cell. A diaphragm discharging device of the battery cell winding equipment is used for outputting a first diaphragm, a second diaphragm, a third diaphragm and a fourth diaphragm respectively; a negative electrode discharging device is used for outputting a first negative electrode plate and a second negative electrode plate; a positive electrode discharging device is used for outputting a first positive electrode plate and a second positive electrode plate; a first compounding device is arranged at the downstream of the diaphragm discharging device, the negative electrode discharging device and the positive electrode discharging device; the first compounding device is used for compounding and connecting the first diaphragm, the first negative electrode plate, the second diaphragm and the first positive electrode plate to form a first compound plate body; a second compounding device is arranged at the downstream of the diaphragm discharging device, the negative electrode discharging device and the positive electrode discharging device, and is used for compounding and connecting the third diaphragm, the second negative electrode plate, the fourth diaphragm and the second positive electrode plate to manufacture a second composite plate body; and a winding device is used for winding the first composite plate body and the second composite plate body to manufacture a battery cell.

Owner:深圳市万德自动化科技有限公司

Processing Technology of Stator Core of Wound Motor

InactiveCN103683719BImprove winding accuracyReduce reboundManufacturing stator/rotor bodiesElectrophoresisEngineering

The invention discloses a process for processing a stator iron core of a winding type motor. The process comprises the steps of disc-shaped steel band uncoiling and leveling, stamping, winding, welding, reshaping, sand blowing and electrophoresis, wherein an automatic winding and shearing machine integrated with a winding mechanism and a shearing mechanism is adopted in the winding step, the smooth band feeding is ensured, the feeding speed is high, stamping stress of bands can be also eliminated, and the winding accuracy is improved. Furthermore, a newly-designed welding machine is adopted in the welding step, and the surface quality of welded products is improved.

Owner:CHONGQING LINZHENG MACHINERY

Motor stator core automatic winding equipment

ActiveCN104810991BImprove winding accuracyReduce defective rateManufacturing stator/rotor bodiesRe introductionDrive motor

The invention discloses an automatic winding device for motor stator iron core, which includes a working platform, on which a driving motor is arranged, and the punching belt enters the introduction channel driven by the transmission gear and the driving motor, and then is brought into the winding forming mechanism ; The winding main shaft of the winding forming mechanism is vertically arranged on the working platform through the bearing assembly, the winding motor is connected to the lower end of the winding main shaft, the working end of the winding main shaft extends out of the working platform and its port is connected with the connecting block Reel connection, a forming die is set on the outer ring of the connecting block, and the internal channel formed between the forming die and the inner groove opposite to the connecting block is the circumferential deformation space of the punching belt; the punching belt comes out of the deformation space and is wound on the ribbed After the predetermined number of turns on the reel is completed, the punching belt is cut to form a spiral stator lamination. The present invention adopts dual power sources, and the formed product remains wound on the reel, and the manipulator is used to pick up the material, improving the production efficiency and reducing the labor cost.

Owner:CHANGYING XINZHI TECH CO LTD

Battery film winding process and equipment

ActiveCN114194445AAvoid wrinklesQuality assuranceFinal product manufactureCell component detailsEngineeringMechanical engineering

The invention relates to the technical field of battery processing, and relates to a battery film winding process and equipment. One end of the protective film is hot-pressed on the starting end of the first side surface of the battery, the protective film is sequentially wound on each side surface of the battery by driving the battery to rotate, and the protective film is gradually wound on the battery by utilizing a segmented and multi-time high-temperature hot-pressing technology, so that wrinkles of the protective film are effectively avoided; the film is wound by driving the battery to rotate without repeated pressing in the later period, so that the quality of the protective film is ensured; and meanwhile, the central lines of the battery and the protective film in the length direction are overlapped and wound, so that the condition that the central lines of the battery and the protective film in the length direction deviate in the film winding process is effectively avoided, the film winding precision is improved, and the film winding quality is ensured.

Owner:荣旗工业科技(苏州)股份有限公司

Numerical control four-roller veneer reeling machine

PendingCN111195664AAdjust the degree of bendingImprove efficiencyShaping toolsNumerical controlEngineering

The invention discloses a numerical control four-roller veneer reeling machine. The numerical control four-roller veneer reeling machine comprises a machine frame, wherein supporting legs are installed at the bottom of the machine frame, four rolling cylinders are installed on the machine frame and include the first rolling cylinder, the second rolling cylinder, the third rolling cylinder and thefourth rolling cylinder; the first rolling cylinder is installed on the upper portion of the machine frame, the second rolling cylinder and the third rolling cylinder are installed on the two sides below the first rolling cylinder in parallel, the fourth rolling cylinder is installed on the lower portion of the machine frame and is parallel to the first rolling cylinder, the two ends of the firstrolling cylinder are fixed to a first lifting assembly, and the two ends of the fourth rolling cylinder are fixed to a second lifting assembly; and a controller is installed on the machine frame. Thenumerical control four-roller veneer reeling machine is novel in structural design, good in overall structural stability and simple in working principle, and the distance between the rolling cylinderscan be adjusted according to needs, the bending degree of a rolled plate is further adjusted, and the plate rolling efficiency is further improved.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

Split paving device

The invention relates to a paving device, and in particular provides the paving device which saves the dosage of a PVC (polyvinyl chloride) film. The paving device comprises a base, wherein a material containing frame is fixed on the base, a movable partition bar is arranged in the material containing frame, the length of the partition bar is adaptive to the width of the material containing frame; a silica film is fixed on the partition bar, and the other end of the silica film is winded on an automatic winding device. Due to the adoption of the structure, a workpiece is arranged in the material containing frame, and is covered rightly by the PVC film, then the partition bar is moved to be beside the workpiece, the space without workpiece of the material containing frame is sealed by the silica film, and finally, the whole base is moved to a molding press to press. In addition, the partition bar is winded automatically by the automatic winding device after the mould pressing is finished; the partitioning and paving device has high automation degree and high winding precision, and effectively saves the dosage of the PVC film.

Owner:WEMHOENER CHANGZHOU MACHINERY MFG

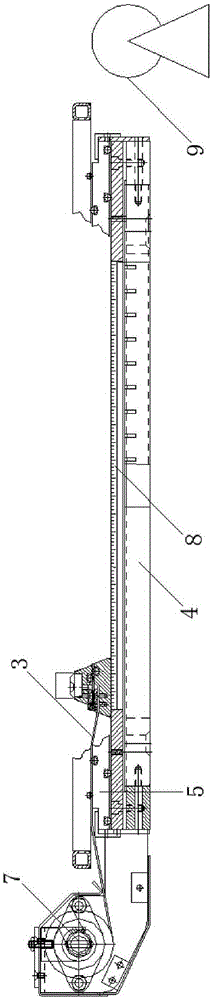

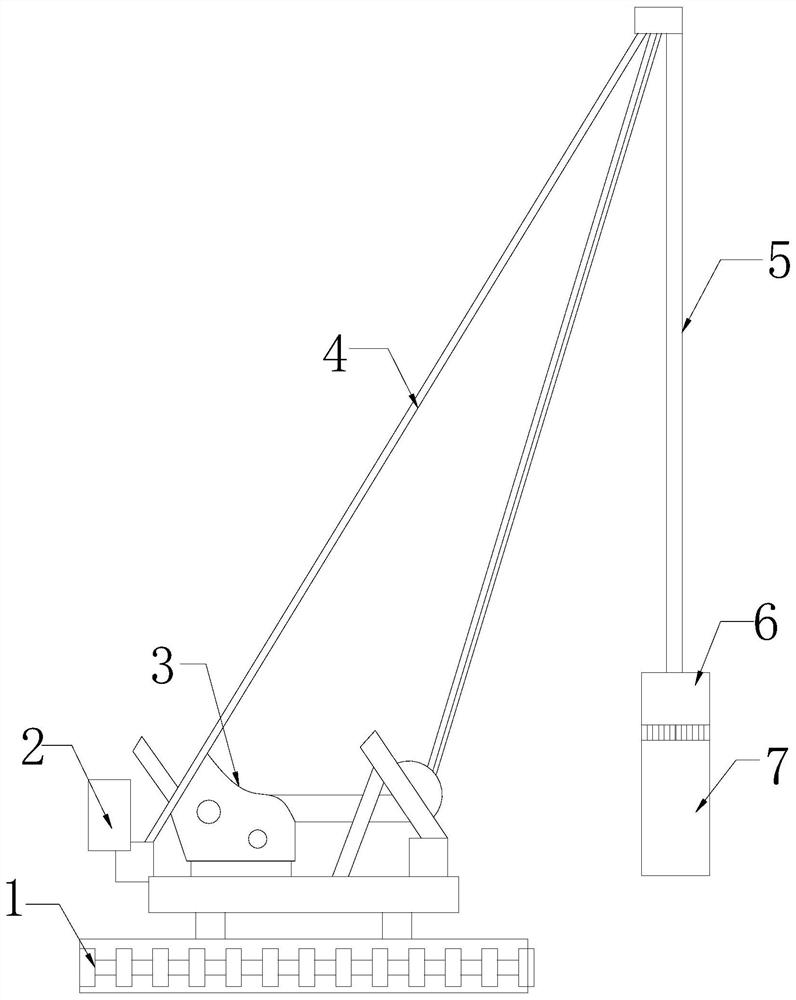

Vibration pile driver for bridge construction

InactiveCN112726609ARealize continuous operationRealize one-time soil guideBulkheads/pilesSoil scienceStructural engineering

The invention discloses a vibration pile driver for bridge construction. The vibration pile driver structurally comprises a walking base, an operation room, a driving table, a traction inhaul cable, a lifting plate, a pile hammer and a pile frame, wherein the operation room controls the driving table, the operation room and the driving table are installed on the walking base, the driving table is connected to the lifting plate through the traction inhaul cable, the pile hammer and the pile frame are movably connected to the lifting plate, and the pile hammer is mechanically connected with the pile frame; and the pile hammer comprises a soil guide device, a soil collecting cavity and a drill bit, the soil guide device is installed on the soil collecting cavity, the drill bit is arranged at the bottom of the soil collecting cavity, and the drill bit is arranged in the pile frame in a matched mode. The soil guide device is matched with the soil collecting cavity, a guide-out opening and a soil inlet formed in the soil guide device are connected with a soil guide pipe, the soil inlet is matched with the soil collecting cavity, soil in the soil collecting cavity is discharged out of the guide-out opening through the soil guide pipe via the soil inlet, the guide-out opening is connected to the exterior of the pile frame, continuous operation of soil guide of the pile hammer is achieved, one-time soil guide is achieved, and the pile driving efficiency is improved.

Owner:洪雯娜

Parting and paving device

The invention relates to a paving device, and in particular provides the paving device which saves the dosage of a PVC (polyvinyl chloride) film. The paving device comprises a base, wherein a material containing frame is fixed on the base, a movable partition bar is arranged in the material containing frame, the length of the partition bar is adaptive to the width of the material containing frame; a silica film is fixed on the partition bar, and the other end of the silica film is winded on an automatic winding device. Due to the adoption of the structure, a workpiece is arranged in the material containing frame, and is covered rightly by the PVC film, then the partition bar is moved to be beside the workpiece, the space without workpiece of the material containing frame is sealed by the silica film, and finally, the whole base is moved to a molding press to press. In addition, the partition bar is winded automatically by the automatic winding device after the mould pressing is finished; the partitioning and paving device has high automation degree and high winding precision, and effectively saves the dosage of the PVC film.

Owner:WEMHOENER CHANGZHOU MACHINERY MFG

Electronic induction retractor

ActiveCN105946785BImprove winding accuracyHigh volume controllabilityBelt retractorsEngineeringConductor Coil

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com