Processing Technology of Stator Core of Wound Motor

A technology of motor stator and processing technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of winding machine without orthopedic function, affecting the quality of processed products, and serious material belt springback, so as to improve surface quality and feed material Smooth, fast feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

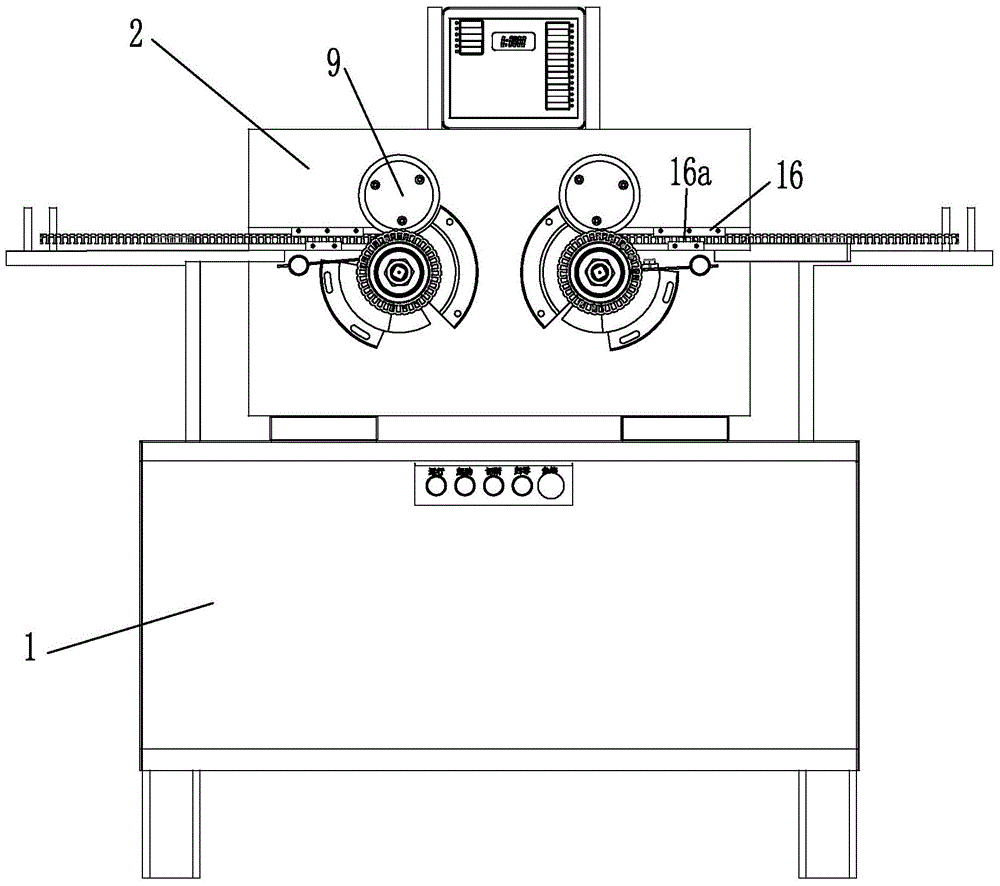

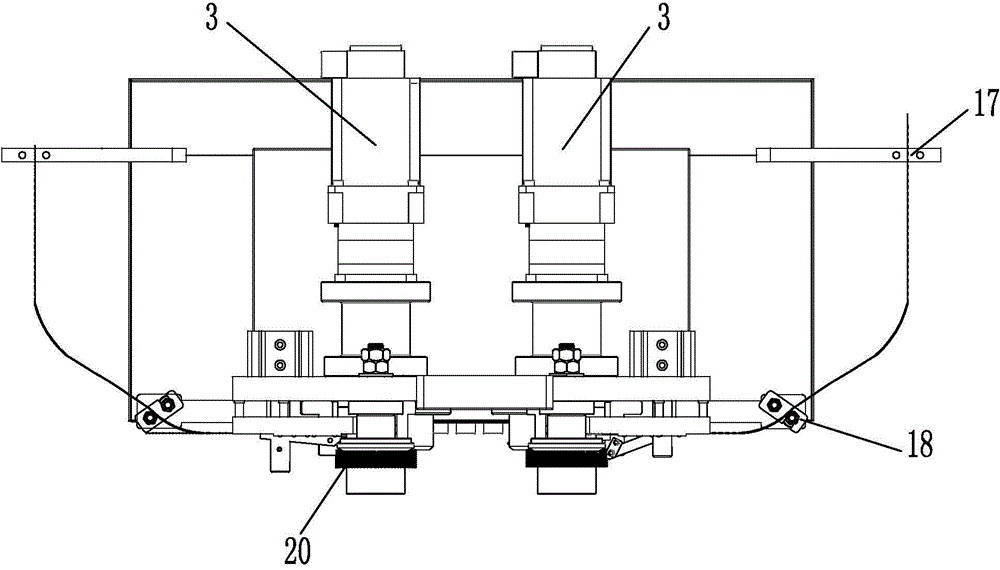

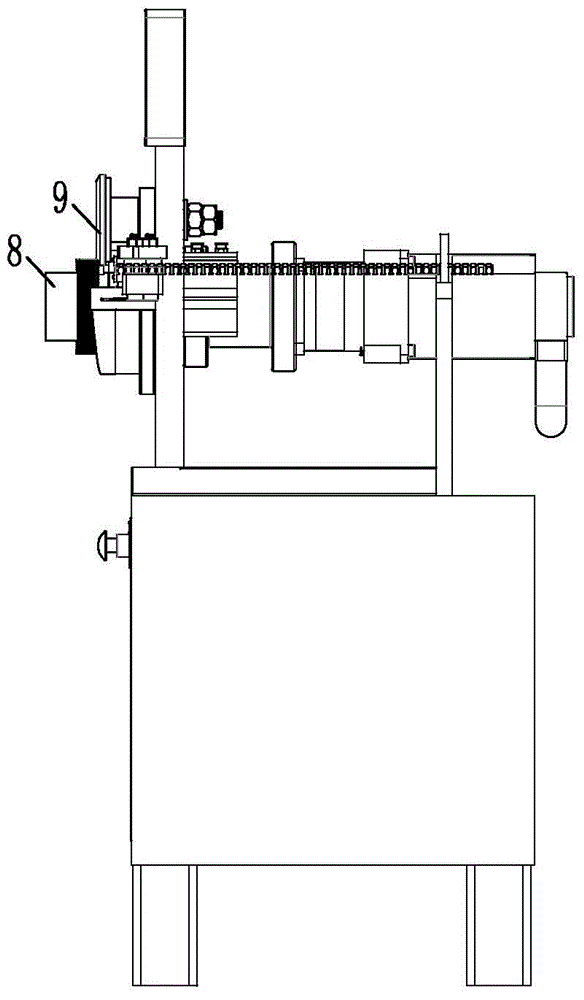

[0040] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0041] A kind of processing technology of the stator iron core of winding type motor, comprises the following steps,

[0042] (A) Uncoiling and leveling the disc-shaped steel strip;

[0043] (B) Stamping: adopt press machine to stamp steel band into linear strip with continuous teeth by stamping die;

[0044] (C) Winding: Feed the linear toothed strip into the winding mechanism, wind it into a circular and spiral loose iron core with a predetermined number of turns, and then pass the strip cutting mechanism from the toothed strip separated from

[0045] (D) Welding: Weld the formed loose iron core on a welding machine to form an integral stator iron core with neat corresponding teeth and a size within the specified range;

[0046] (E) Shaping: put the welded stator core into the shaping mold for pressure shaping;

[0047] (F) San...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com