Patents

Literature

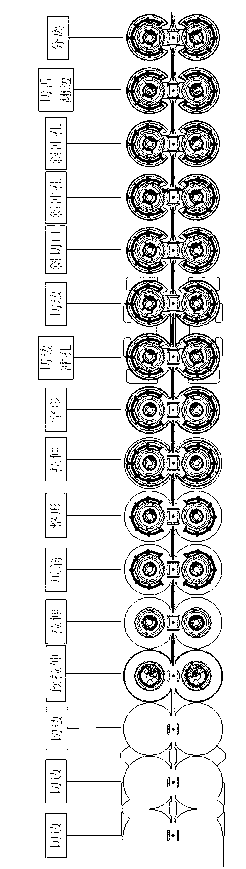

66 results about "Progressive stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

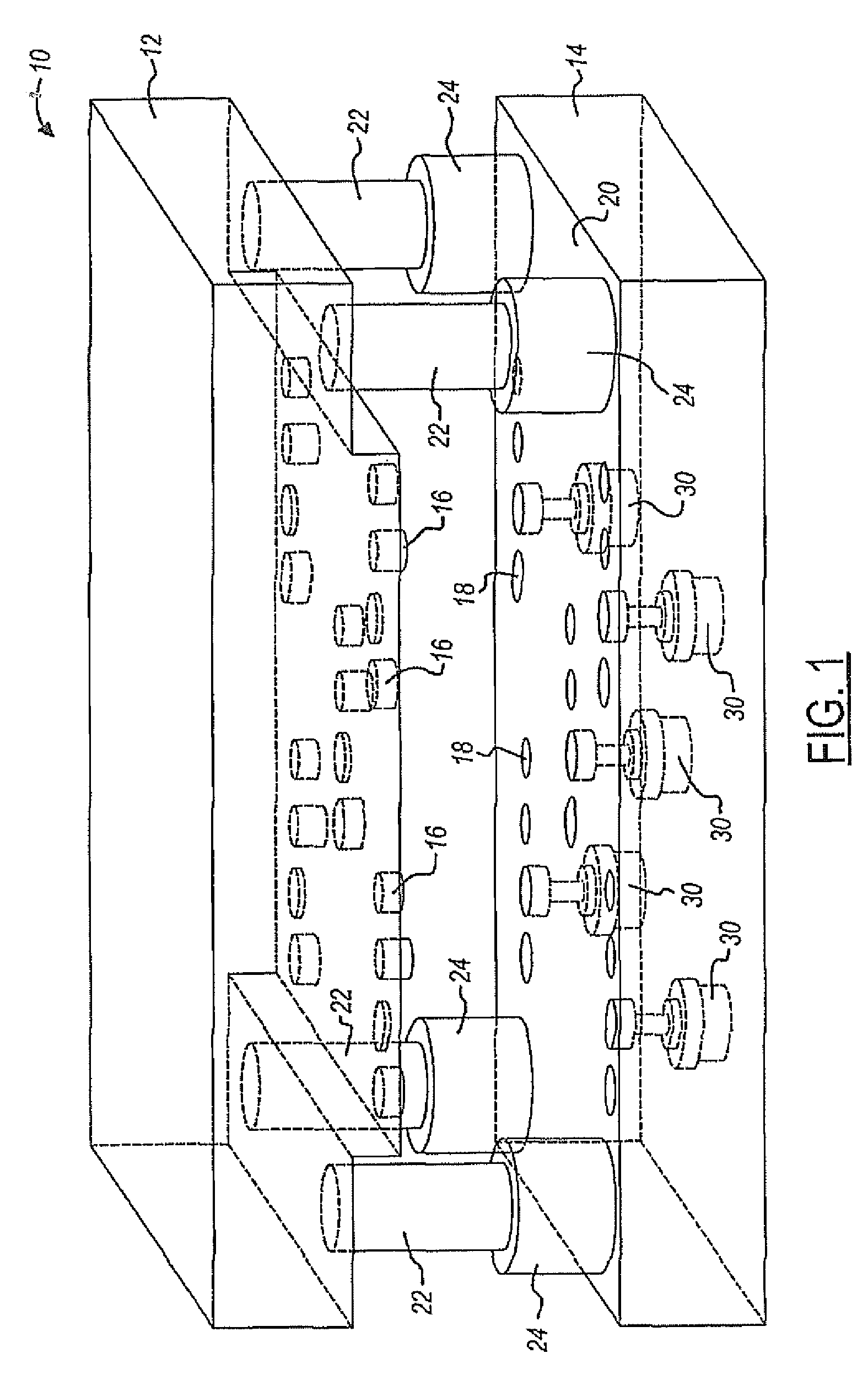

Progressive stamping is a metalworking method that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an automatic feeding system. The feeding system pushes a strip of metal (as it unrolls from a coil) through all of the stations of a progressive stamping die. Each station performs one or more operations until a finished part is made. The final station is a cutoff operation, which separates the finished part from the carrying web. The carrying web, along with metal that is punched away in previous operations, is treated as scrap metal. Both are cut away, knocked down (or out of the dies) and then ejected from the die set, and in mass production are often transferred to scrap bins via underground scrap material conveyor belts.

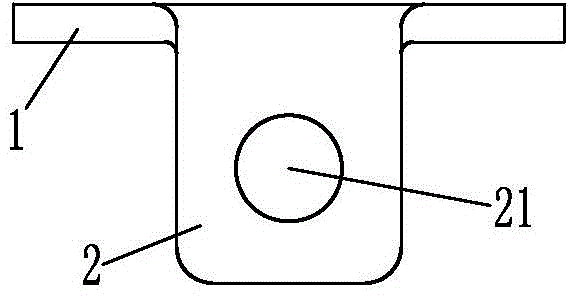

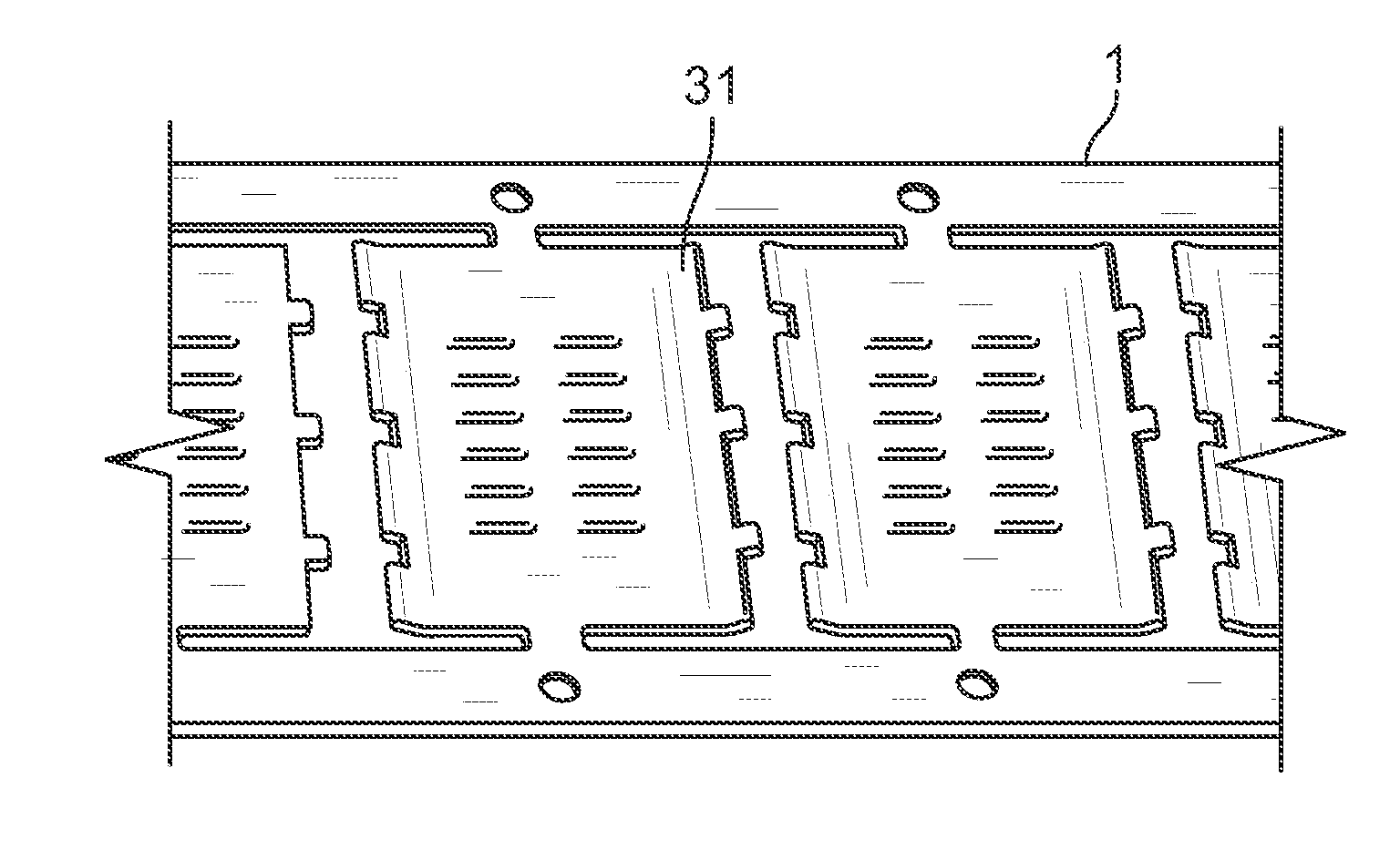

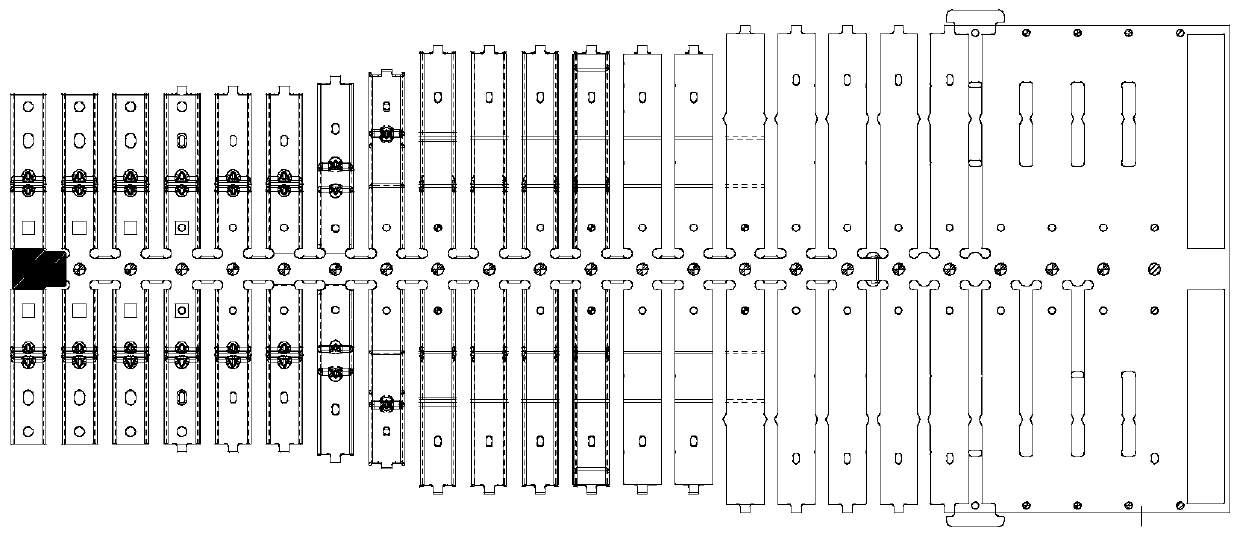

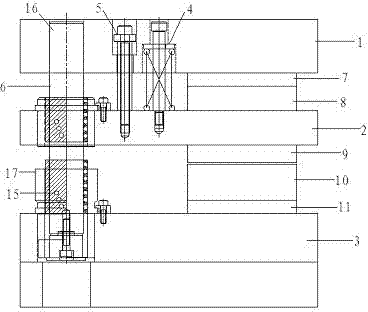

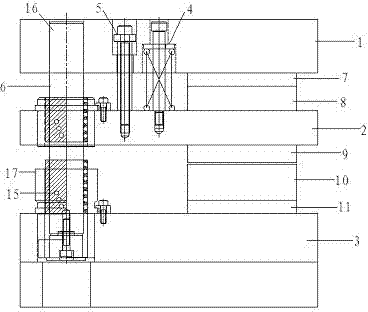

Wiring terminal progressive stamping die

ActiveCN104014659AIncrease productivityBlanking is accurateShaping toolsContact member manufacturingPunchingEngineering

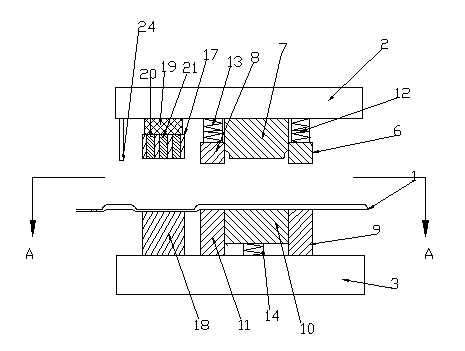

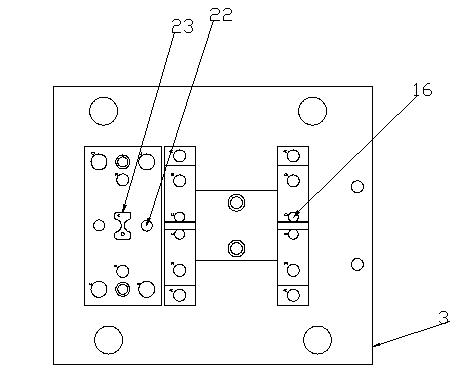

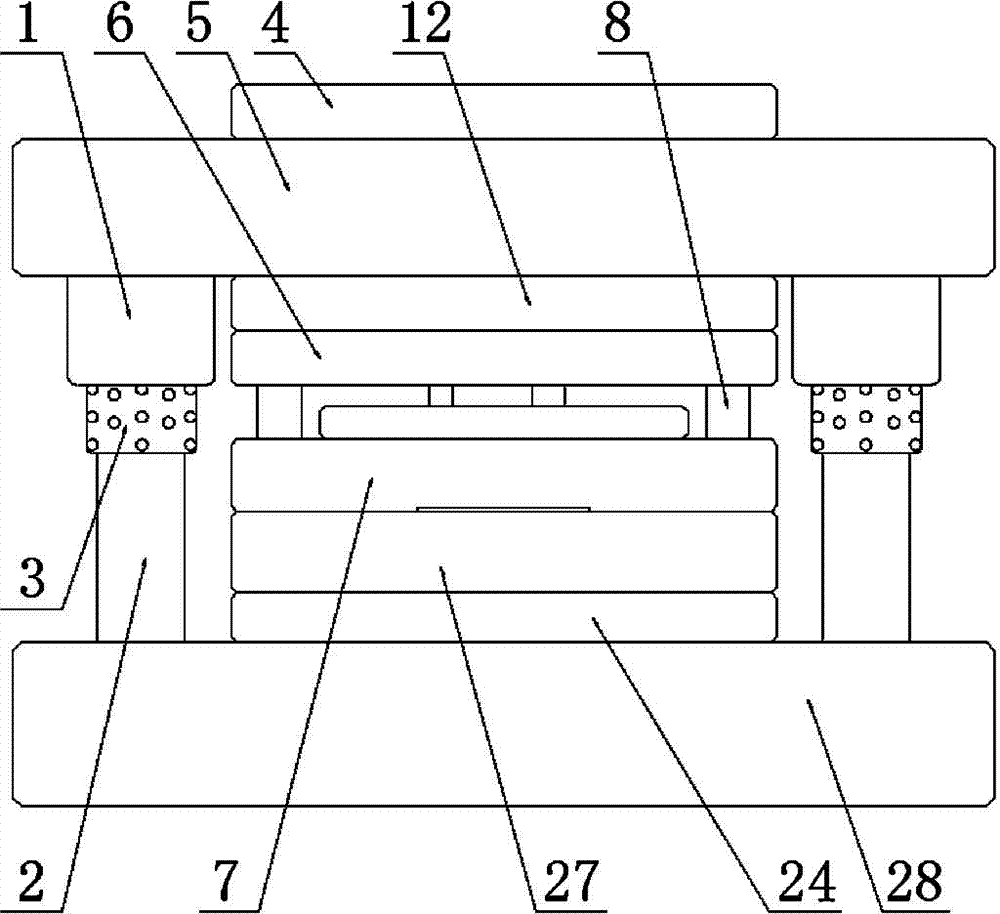

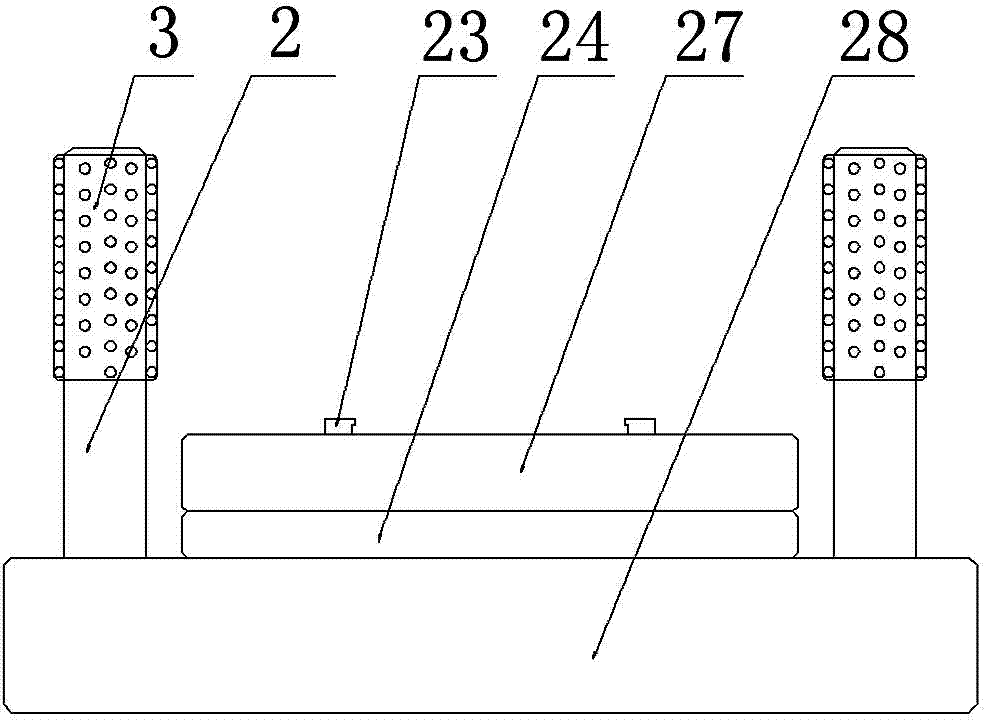

The invention relates to a wiring terminal progressive stamping die. According to the wiring terminal progressive stamping die, a wiring terminal is manufactured through copper tubes, the die comprises an upper die plate, a lower die plate and a guide pillar and guide sleeve structure arranged between the upper die plate and the lower die plate; a leveling station and a punching cutting station are sequentially arranged between the upper die plate and the lower die plate in the horizontal direction, the lower end face of an upper die plate part of the leveling station is sequentially provided with a first upper movable die, a first upper stamping die and a second upper movable die from front to back, and correspondingly, the upper end face of a lower die plate part is sequentially provided with a first lower stamping die, a lower movable die and a second lower stamping die from front to back; the lower end face of an upper die plate part of the punching cutting station are sequentially provided with a third upper movable die, and correspondingly, a third lower stamping die is arranged on the upper end face of the lower die plate. The wiring terminal progressive stamping die has the advantages that operation on the leveling station and operation on the punching cutting station are completed synchronously, only one time of stamping is needed, the production efficiency of products is improved, and raw materials can be saved.

Owner:江苏华兴通讯科技有限公司

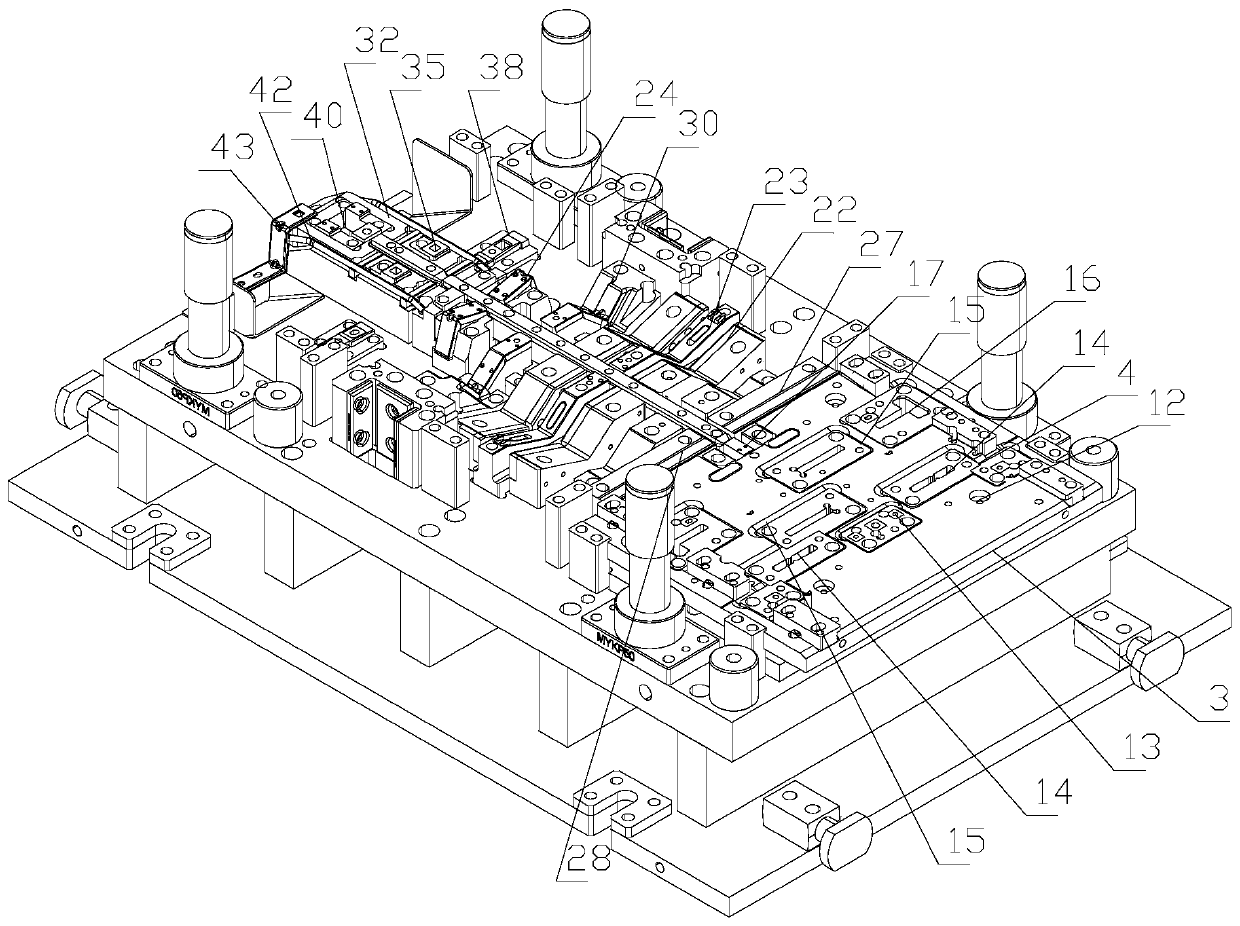

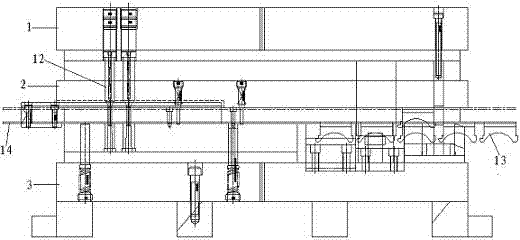

Continuous die for brake wheel covers

InactiveCN102909263ASimple structureIncrease productivityShaping toolsMechanical engineeringProgressive stamping

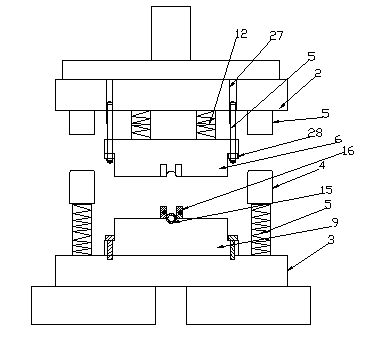

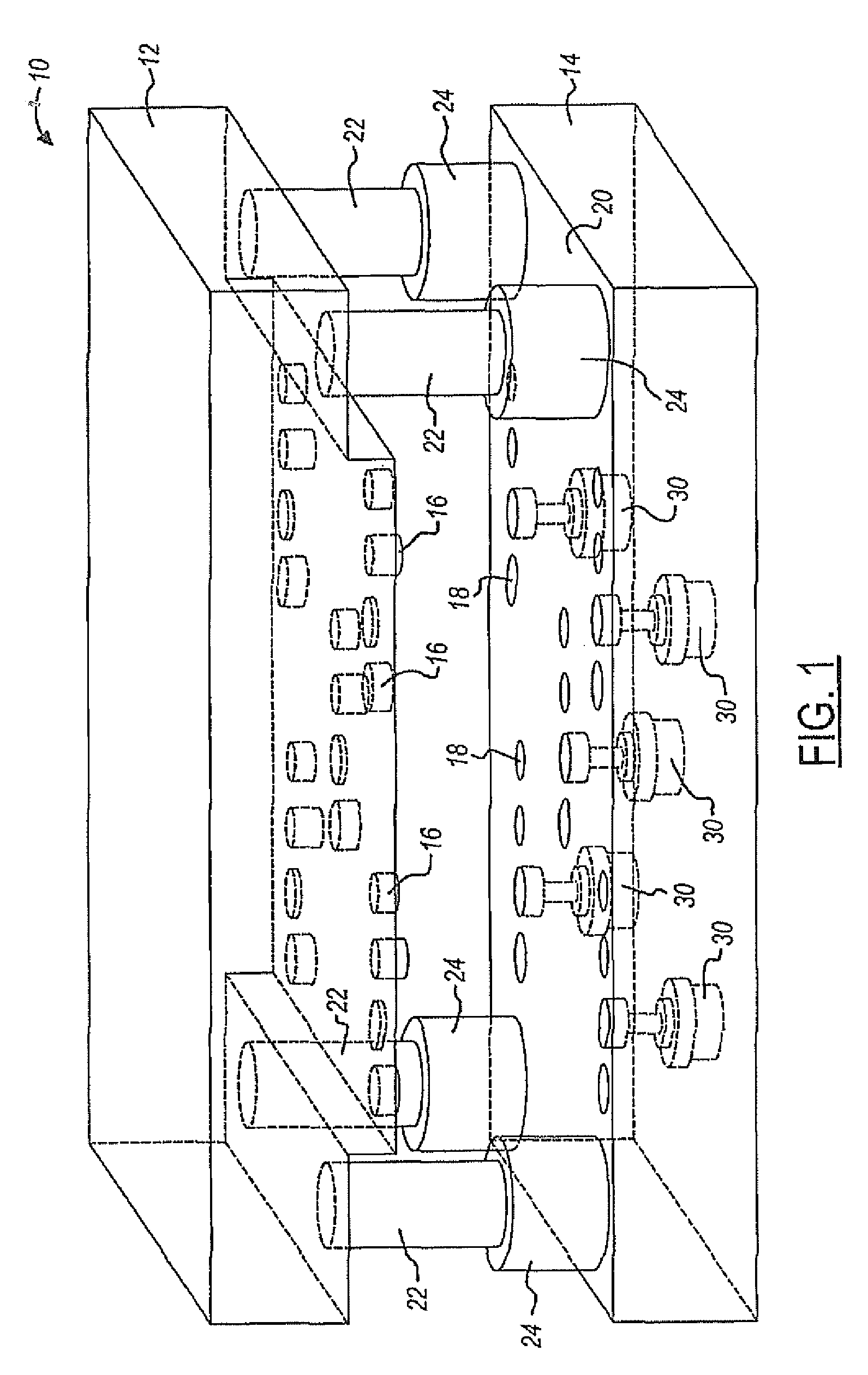

The invention discloses a continuous die for brake wheel covers. The continuous die comprises an upper die holder and a lower die holder. The upper die holder and the lower die holder are used for fixing a continuous multi-station progressive stamping die, the stamping die comprises upper female dies and lower male dies which are matched with one another, the upper female dies are arranged on the lower portion of the upper die holder, the lower male dies are arranged on the upper portion of the lower die holder, and the upper female dies and the lower male dies are sequentially arrayed according to a stamping procedure. The continuous die is simple in structure, multi-station continuous stamping can be realized, the brake wheel cover production efficiency is improved, the machining cycle is shortened, the quality and the precision of a product are guaranteed, and labor cost and production cost are reduced.

Owner:奇昊汽车系统(苏州)有限公司

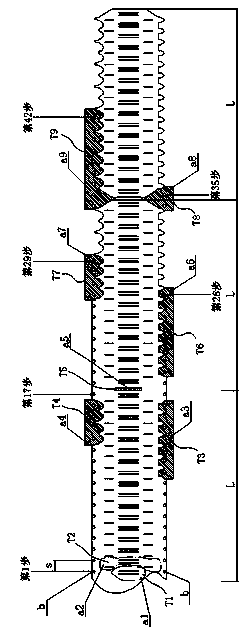

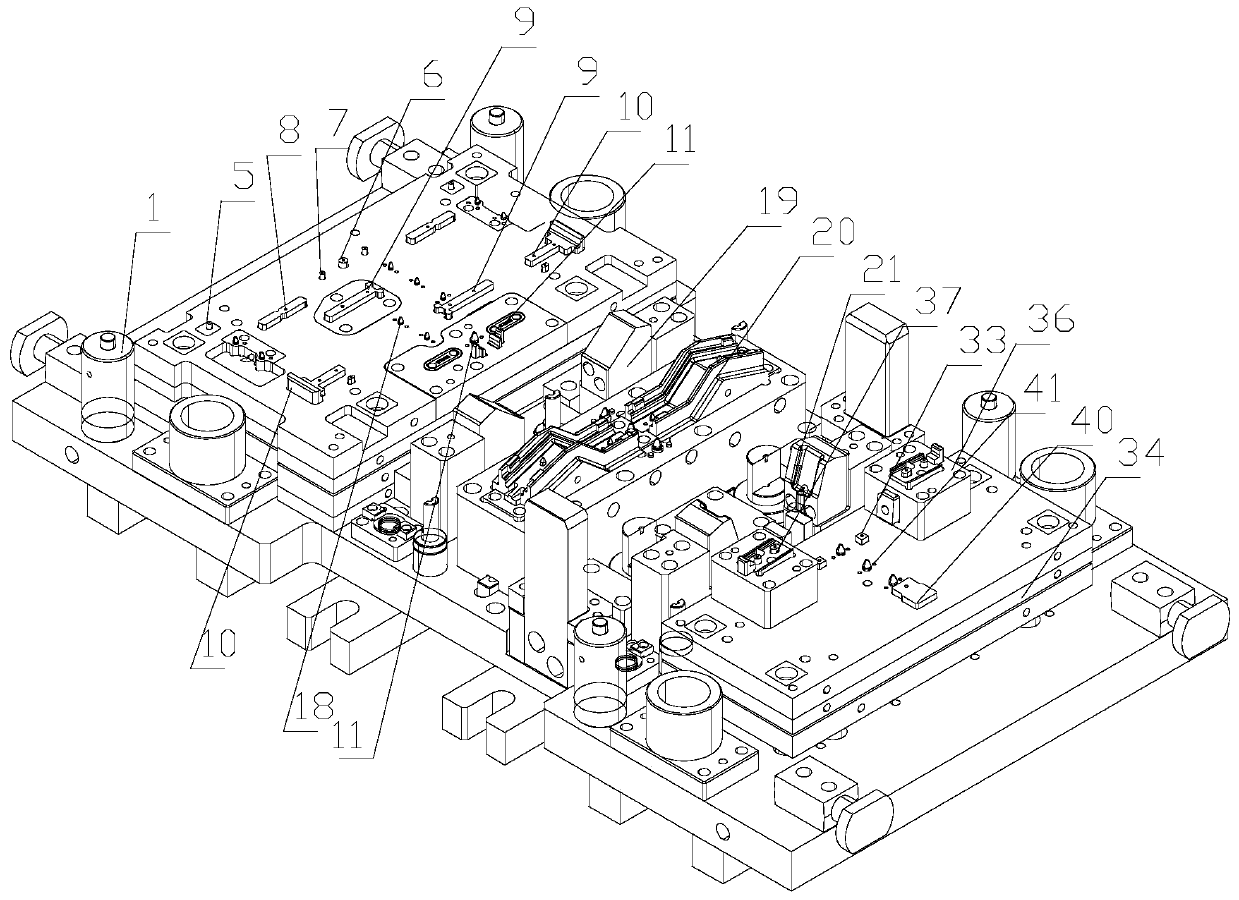

Progressive stamping die of motor rotor

The invention discloses a progressive stamping die of a motor rotor. The progressive stamping die of the motor rotor comprises an upper die body and a lower die body. An upper mounting plate of the upper die body is provided with a first punch column and a second punch column which are arranged in parallel in the feeding direction. Punches in the first punch column and punches in the second punch column are staggered, and the center-to-center distance between the first punch column and the second punch column is smaller than the diameter of the motor rotor. A lower die plate of the lower die body is provided with a first die cavity column and a second die cavity column in the feeding direction. The first die cavity column and the second die cavity column correspond to the first punch column and the second punch column respectively. The progressive stamping die of the motor rotor is high in production efficiency and low in manufacturing cost.

Owner:广安旗力机电有限公司

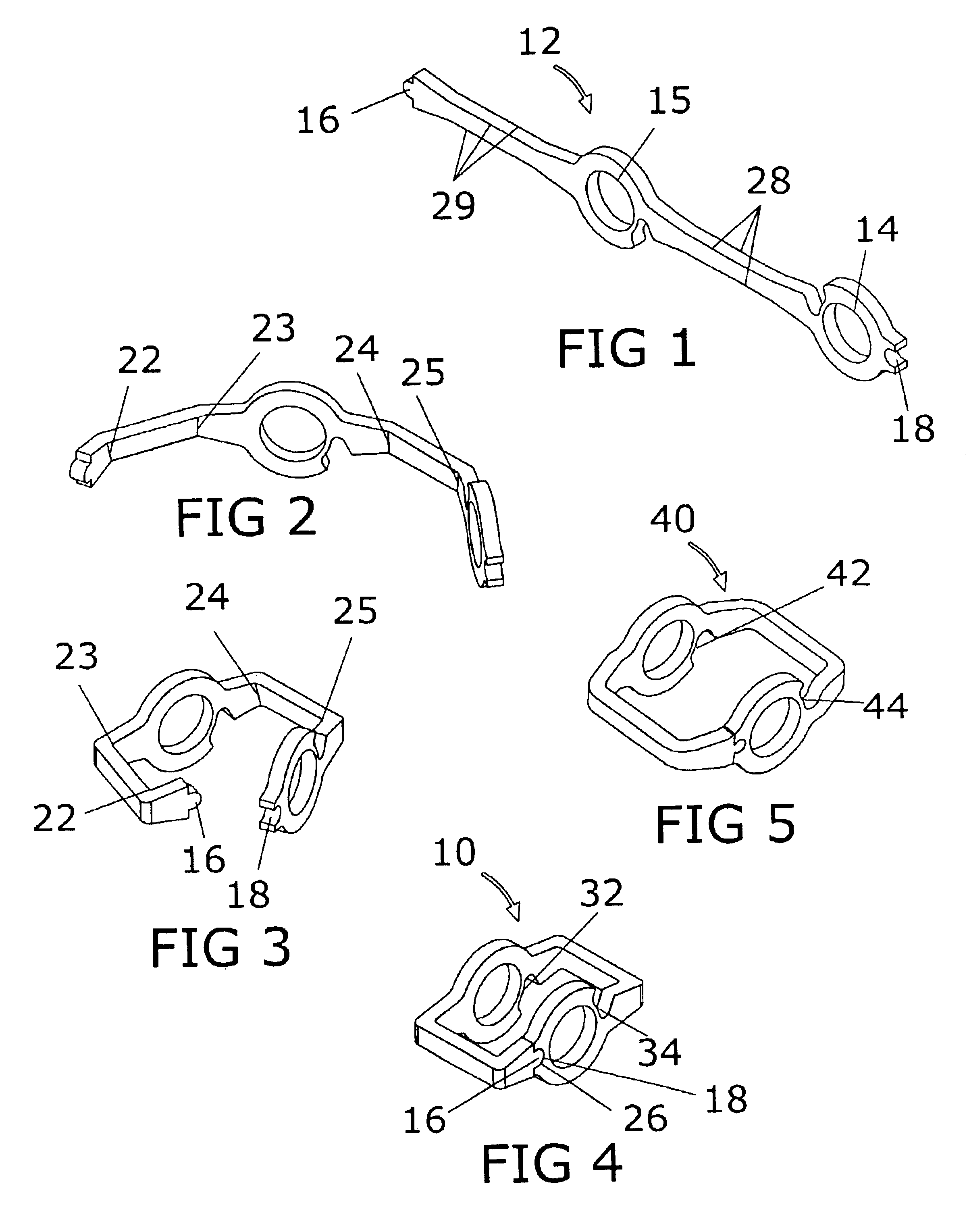

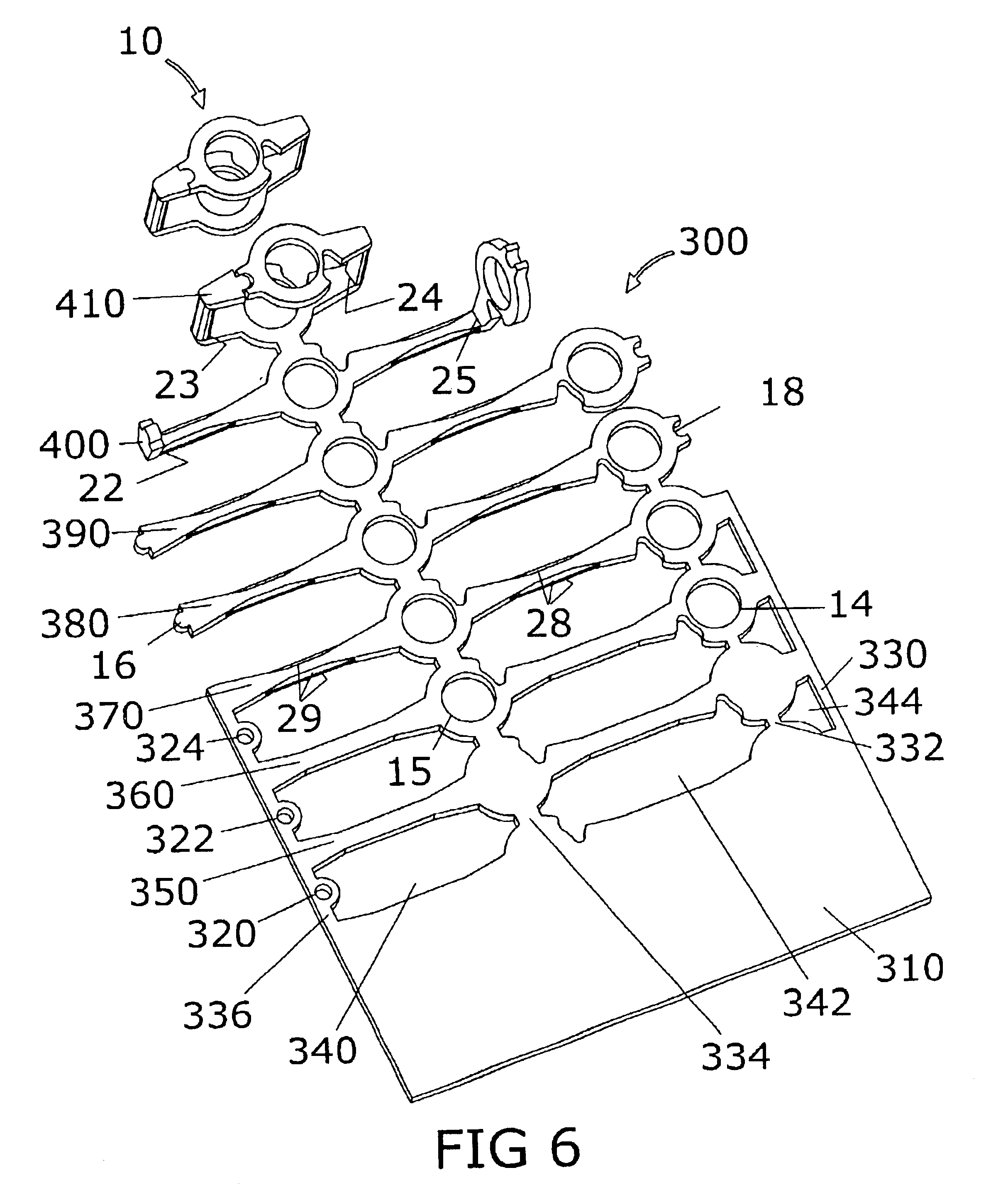

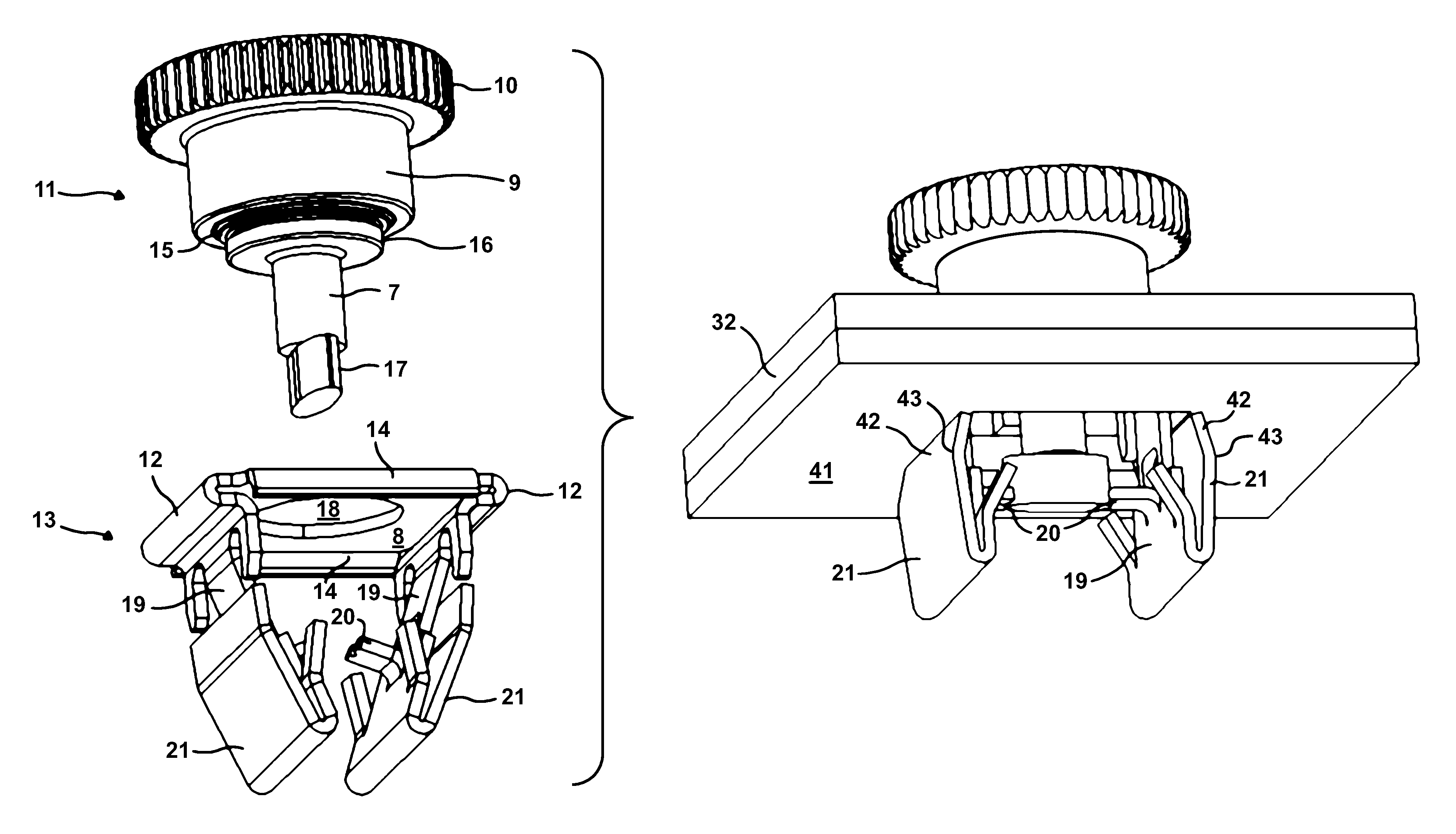

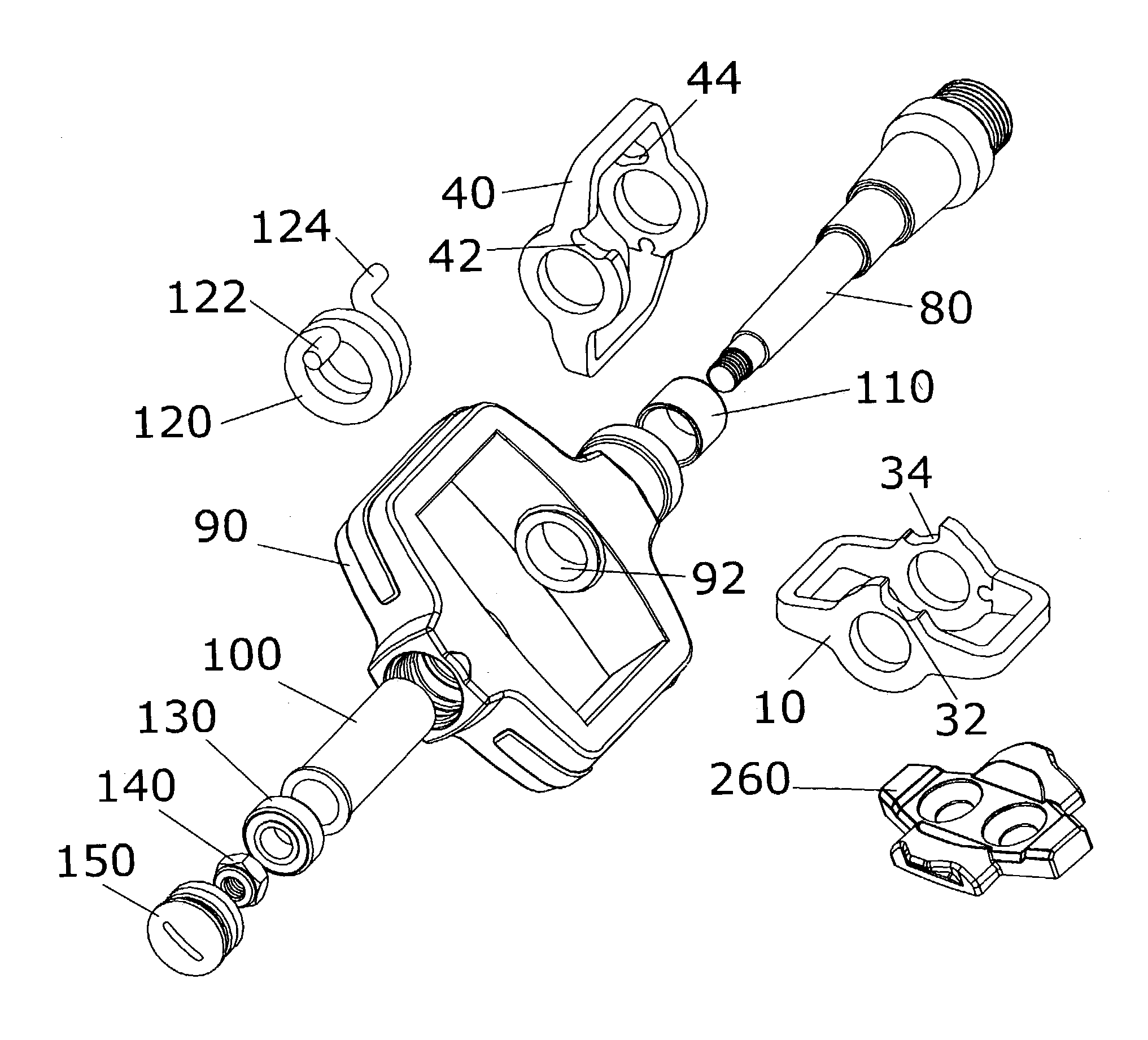

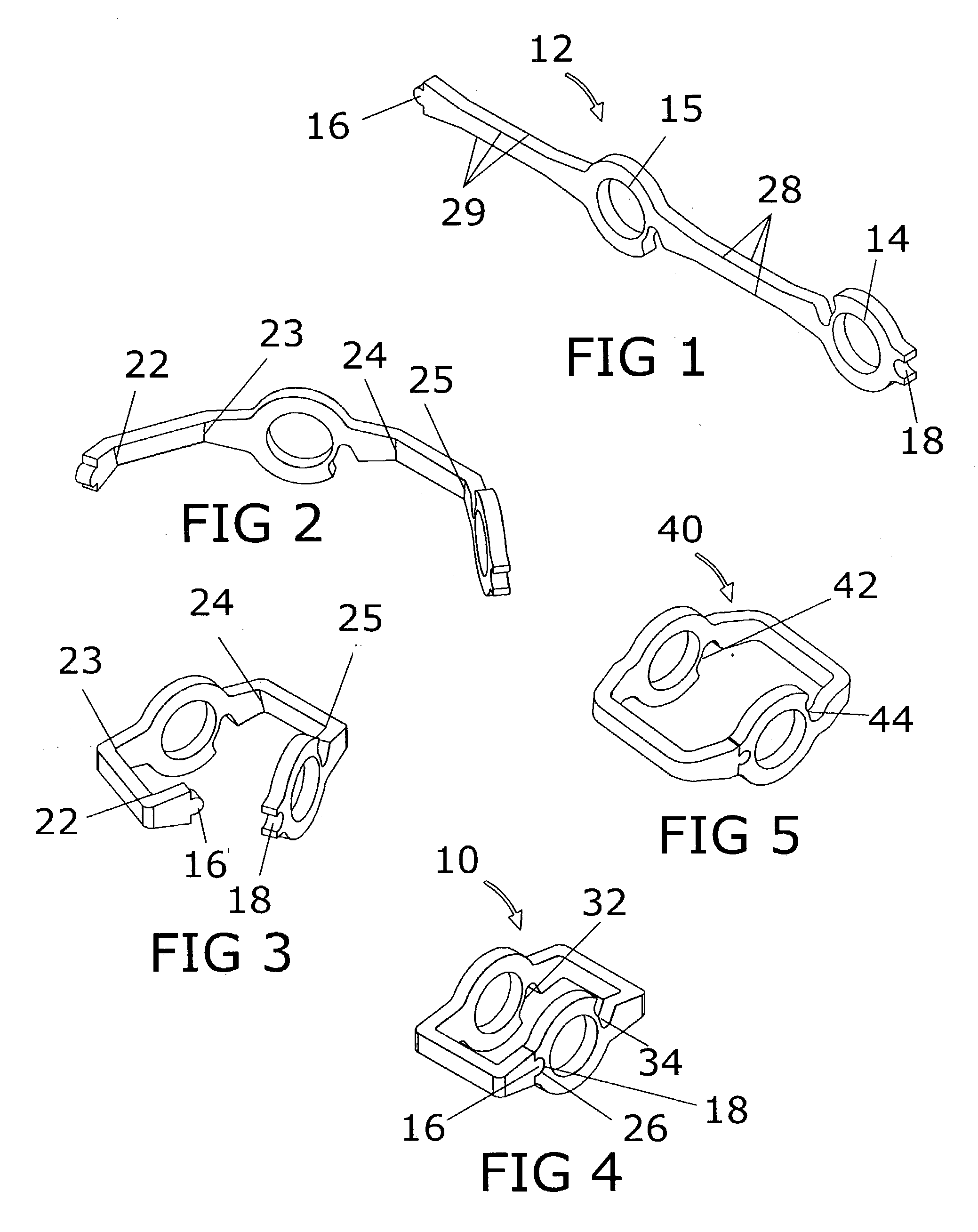

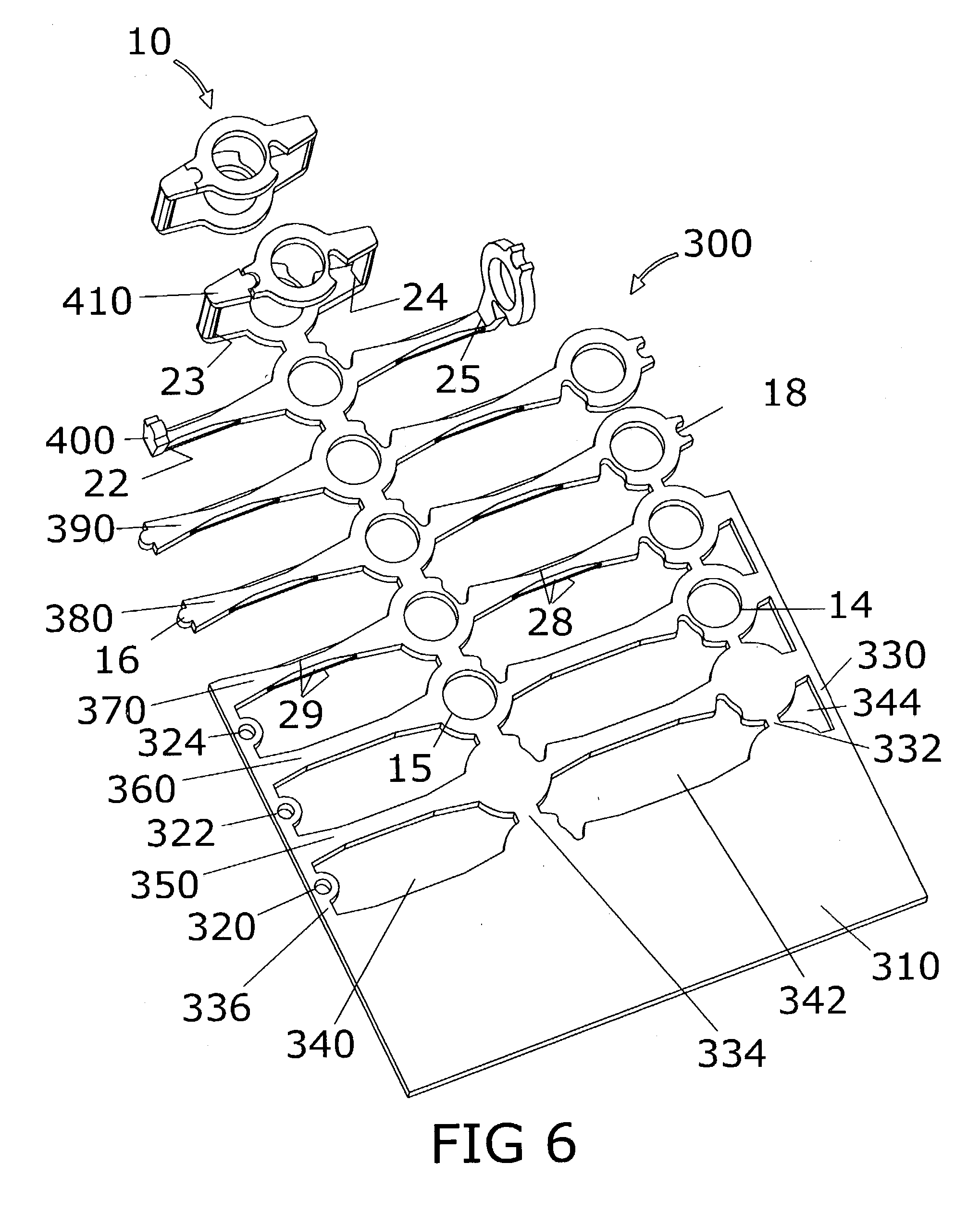

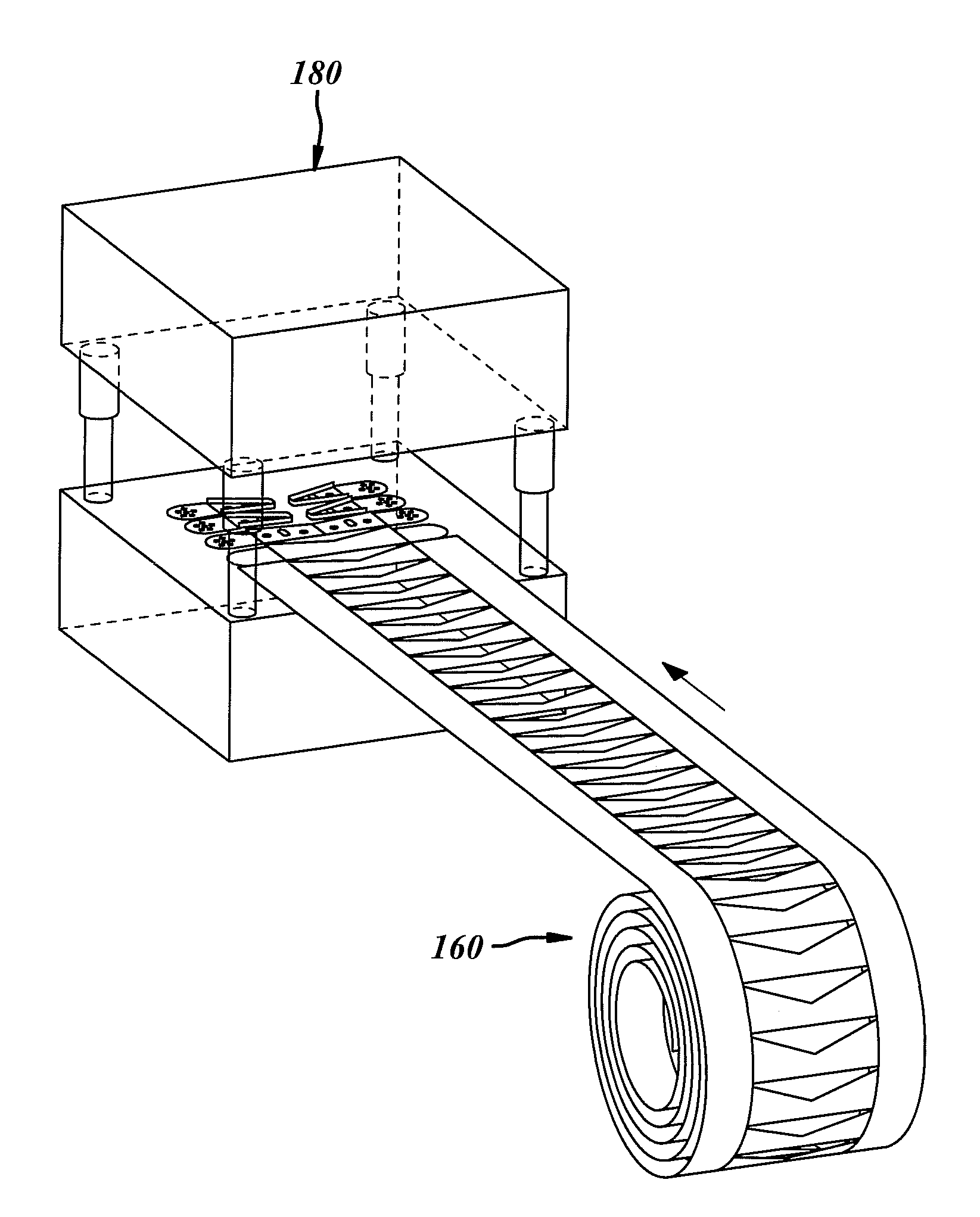

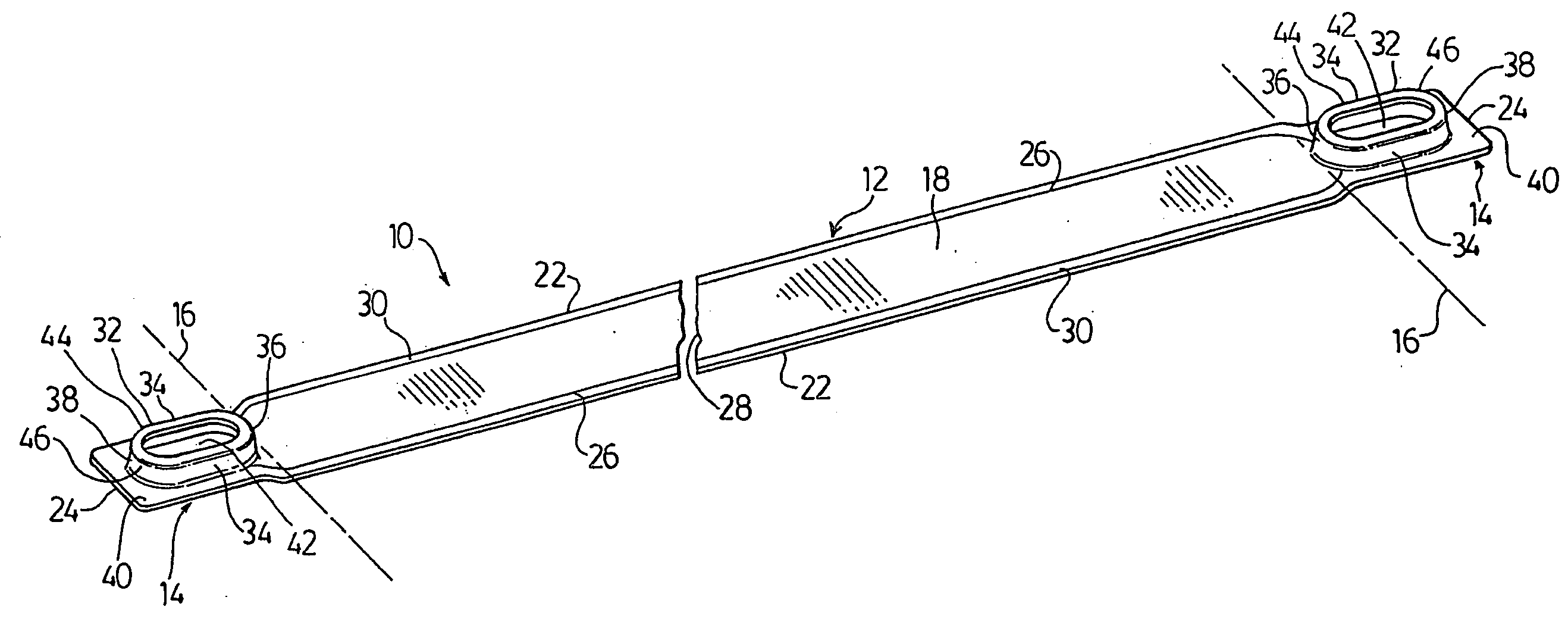

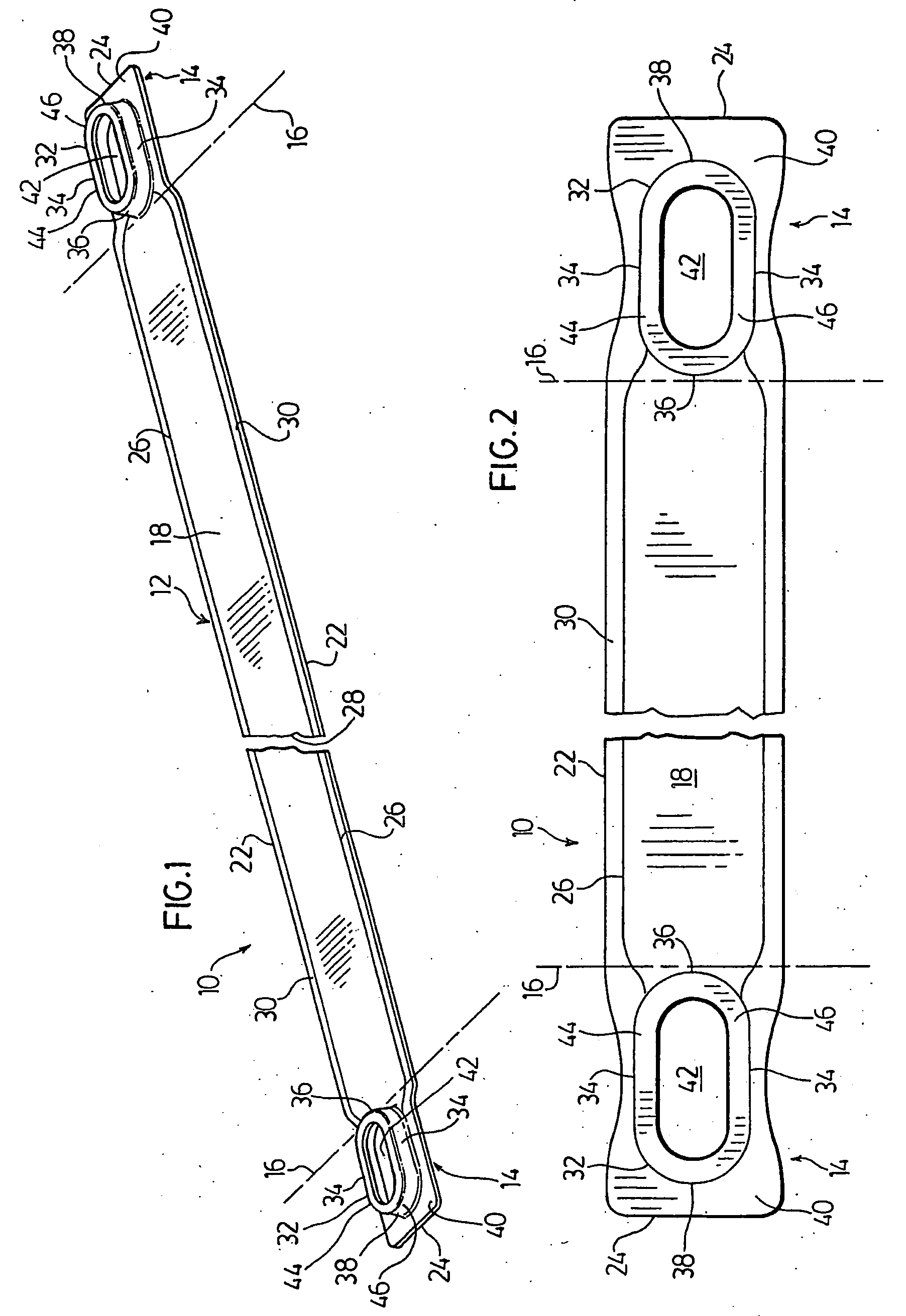

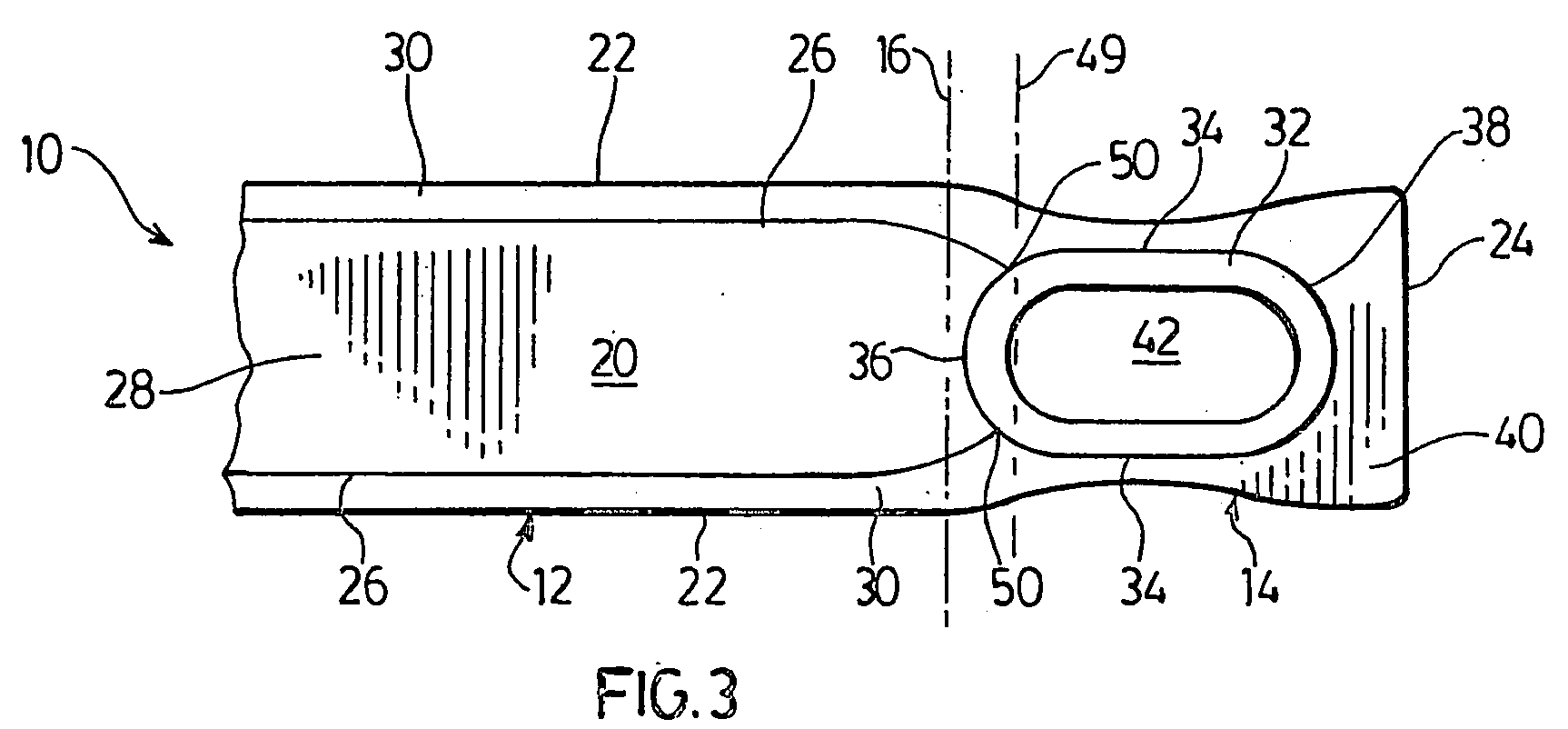

Method of fabricating a clipless bicycle pedal

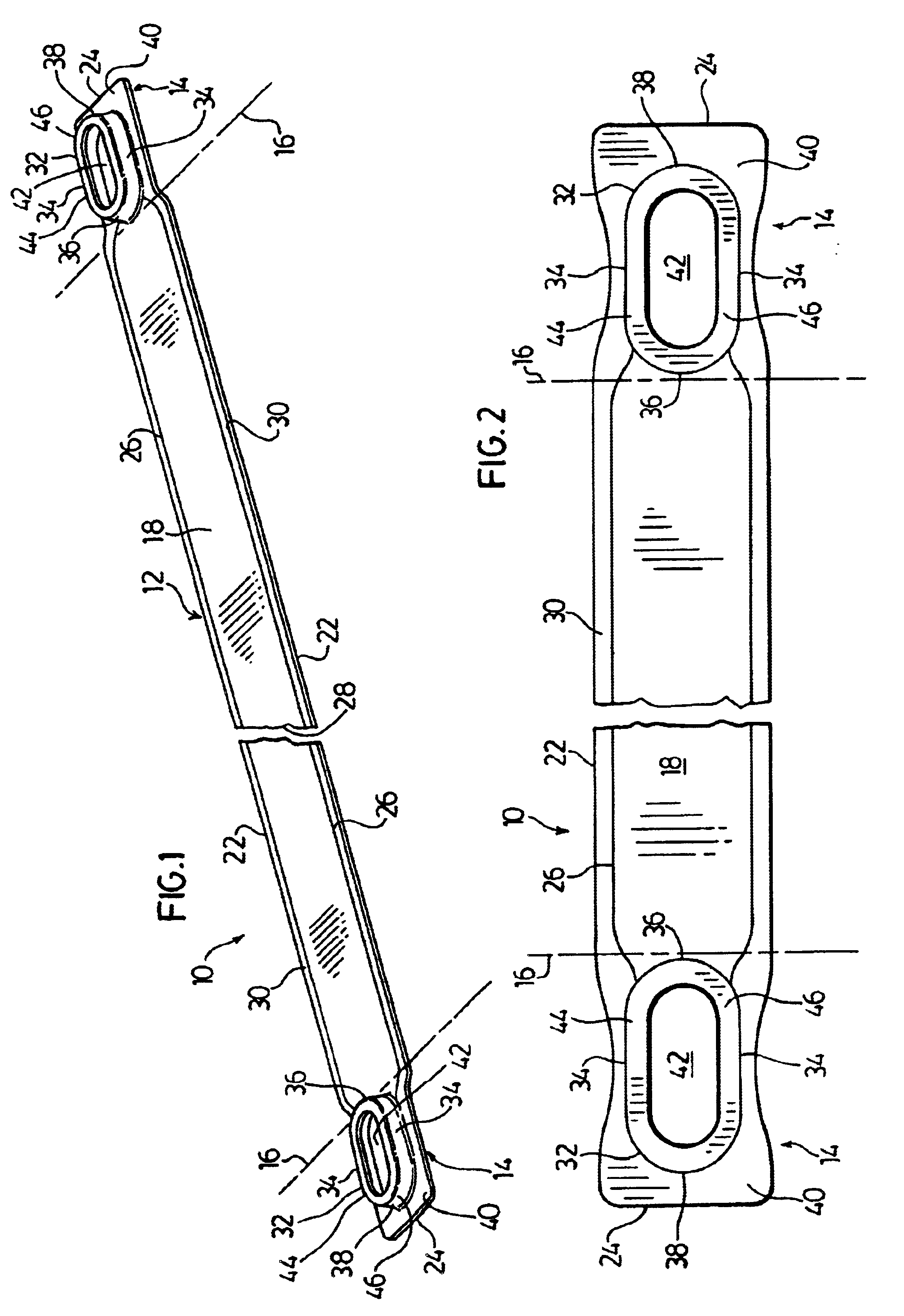

A clipless mechanism for a four-sided clipless bicycle pedal is made by a stamping and welding process. The stamping is preferably a progressive stamping process. The stamped parts include two components, an inner wing and an outer wing. The two stamped components are generally similar in shape to each other, but the inner wing fits within the outer wing. Each part is first stamped as a flat pattern by a progressive die. Each part then has radii stamped into the edges by the second station of the progressive die. Next, each part is partially folded by the third station of the progressive die. Then each part is folded completely by the fourth station of the progressive die. The actual number of steps may vary depending upon the material chosen, the thickness of the material and the design of the stamping tool. Then each part is welded closed and the resulting rectangular wings are assemblied in juxtaposed orthogonal relation to provide four shoe cleat engaging receptacles.

Owner:CRANK BROS INC

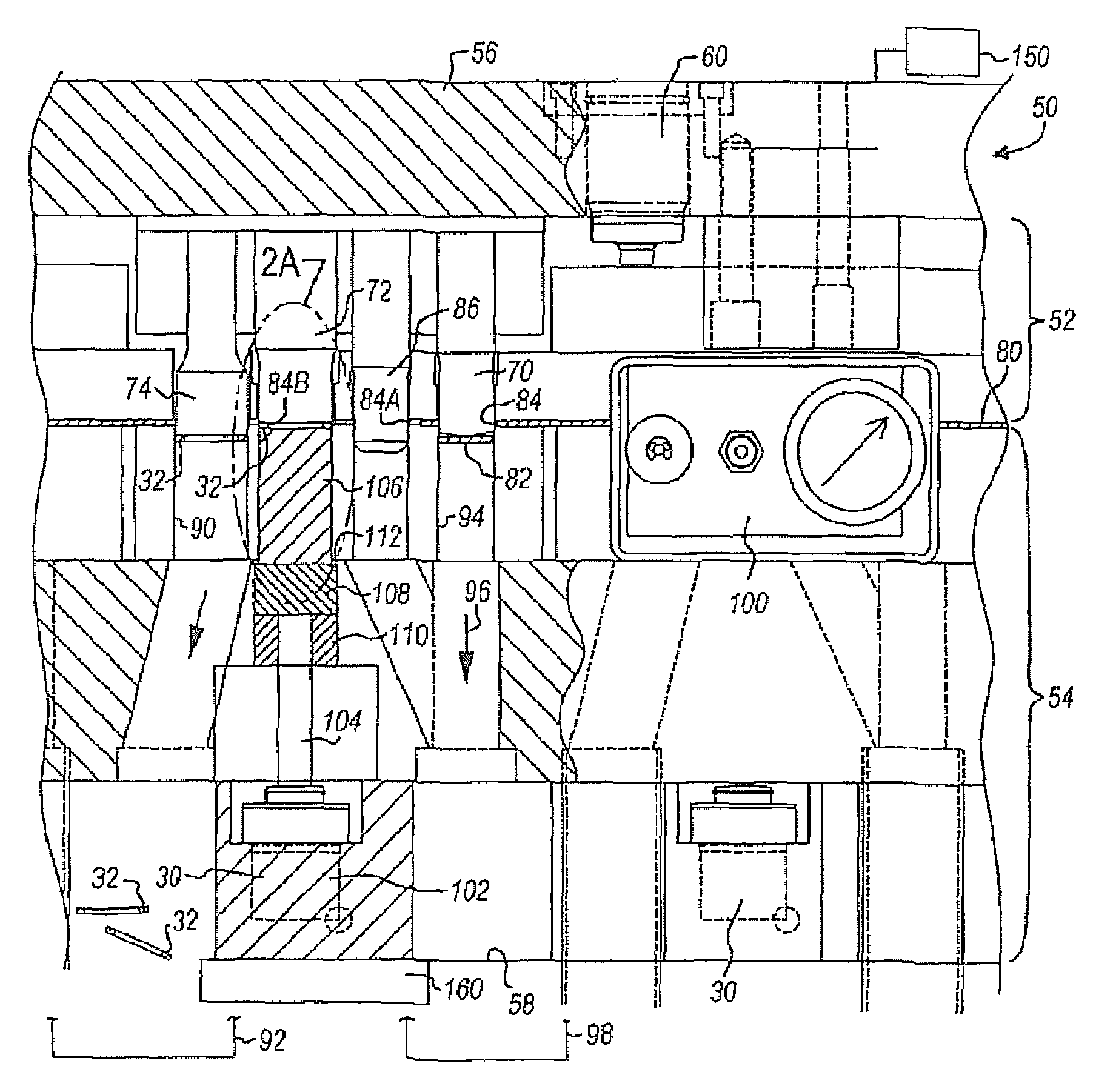

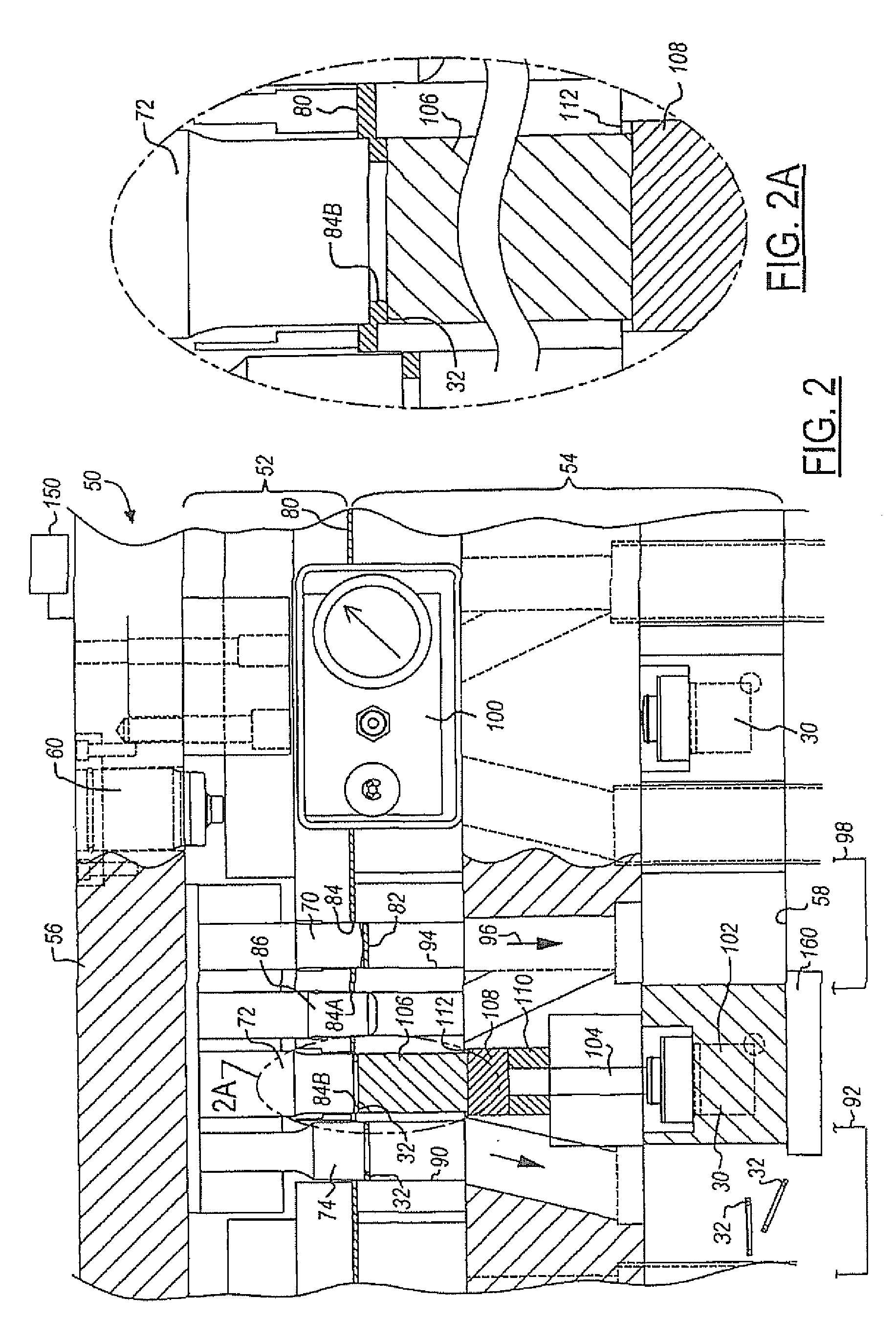

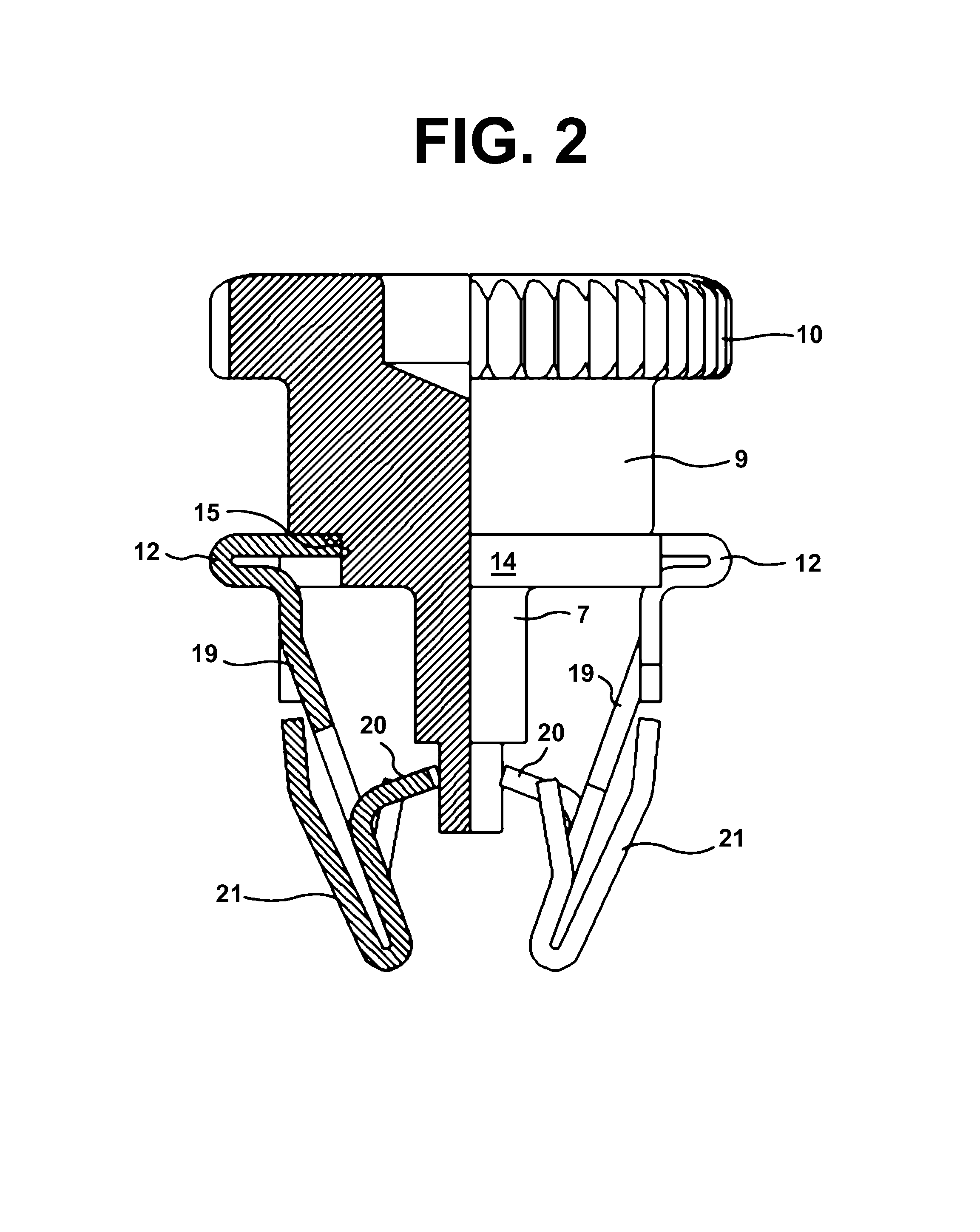

Progressive stamping die

A progressive stamping die system and method of operation providing dimensionally accurate flat stamped parts. A biasing mechanism is provided in actual alignment with a coin punch member in order to accurately control the configuration and planar accuracy of the stamped parts being formed.

Owner:COWIE RALPH

Progressive stamping die for producing thin-wall metal rings

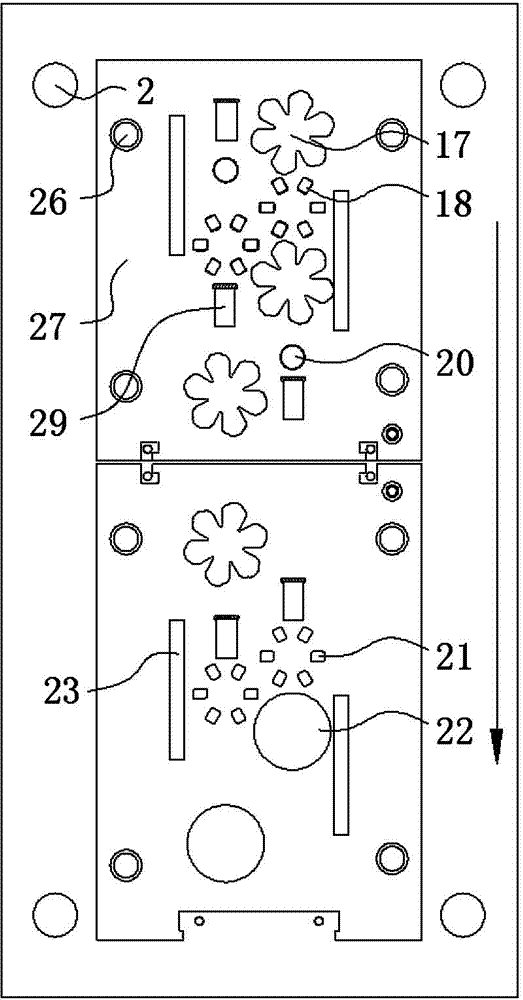

The invention discloses a progressive stamping die for producing thin-wall metal rings, which comprises an upper die portion and a lower die portion. A deep drawing convex die, a punching convex die, a turnup convex die, a reforming convex die and a blanking convex die are installed on the upper die portion in sequence. All the convex dies penetrate through a discharging board, and an annular protrusion portion is arranged on the discharging board at the portion around the reforming convex die. Correspondingly, a deep drawing concave die, a punching concave die, a turnup concave die, a reforming concave die and a blanking concave die are installed on the lower die portion in sequence, and an elastic ejector is respectively arranged in cavities of the deep drawing concave die, the turnup concave die and the reforming concave die. The progressive stamping die for producing thin-wall metal rings solves the technical problems of low processing precision of metal rings with two straight end faces and low production efficiency and is reasonable in structure and widely used in metal ring manufacture industries in electronic industries.

Owner:WEIFANG YUYUAN ELECTRONICS CO LTD

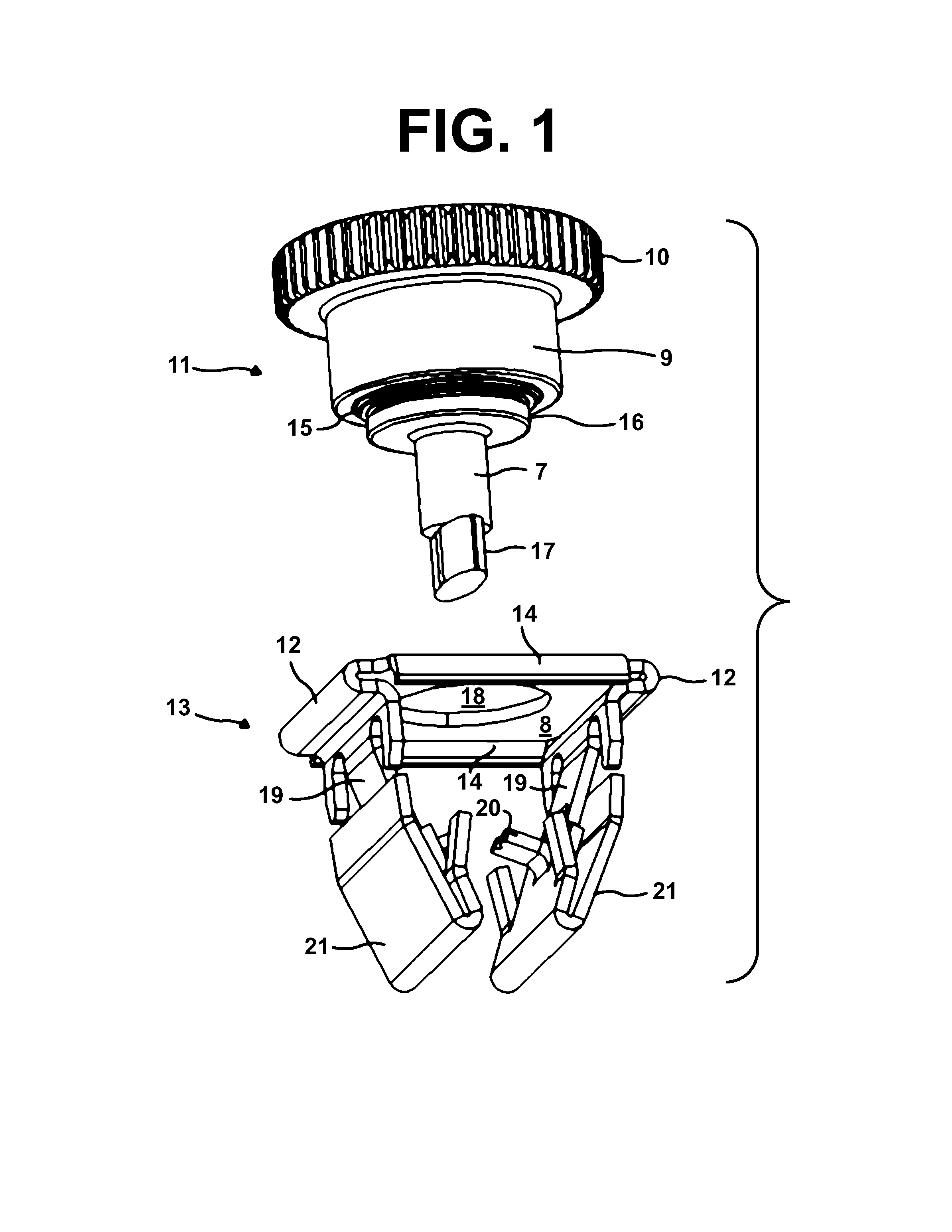

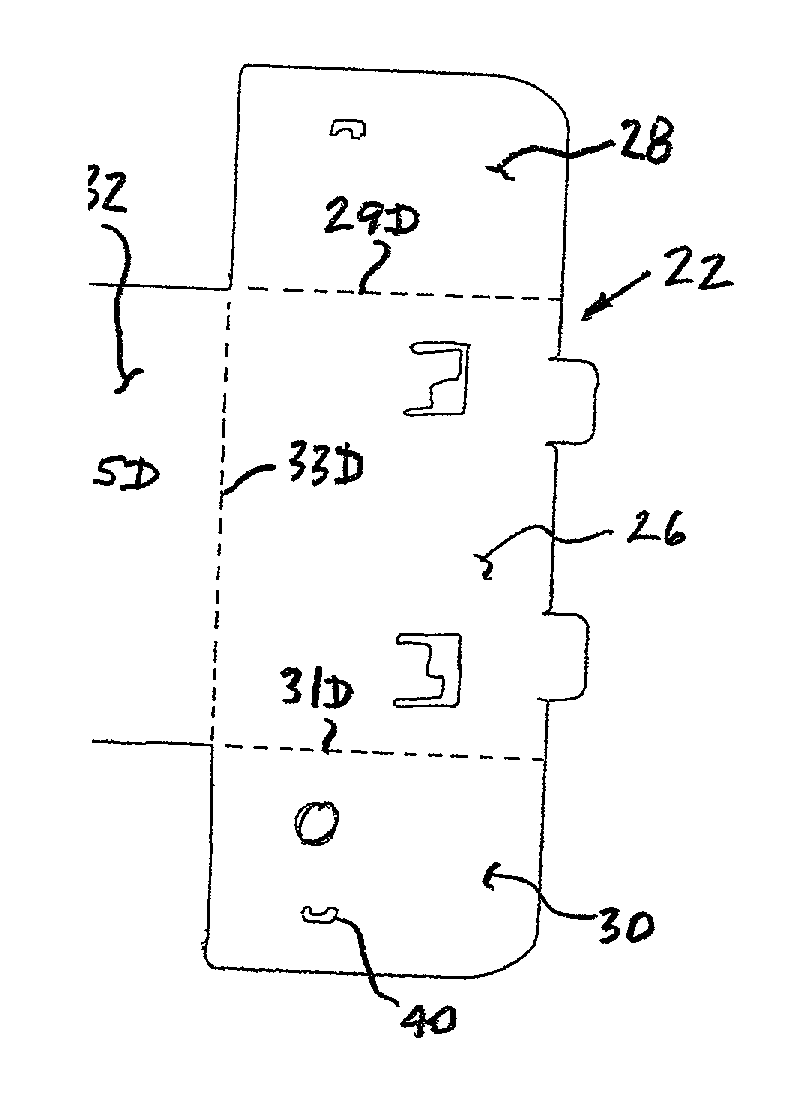

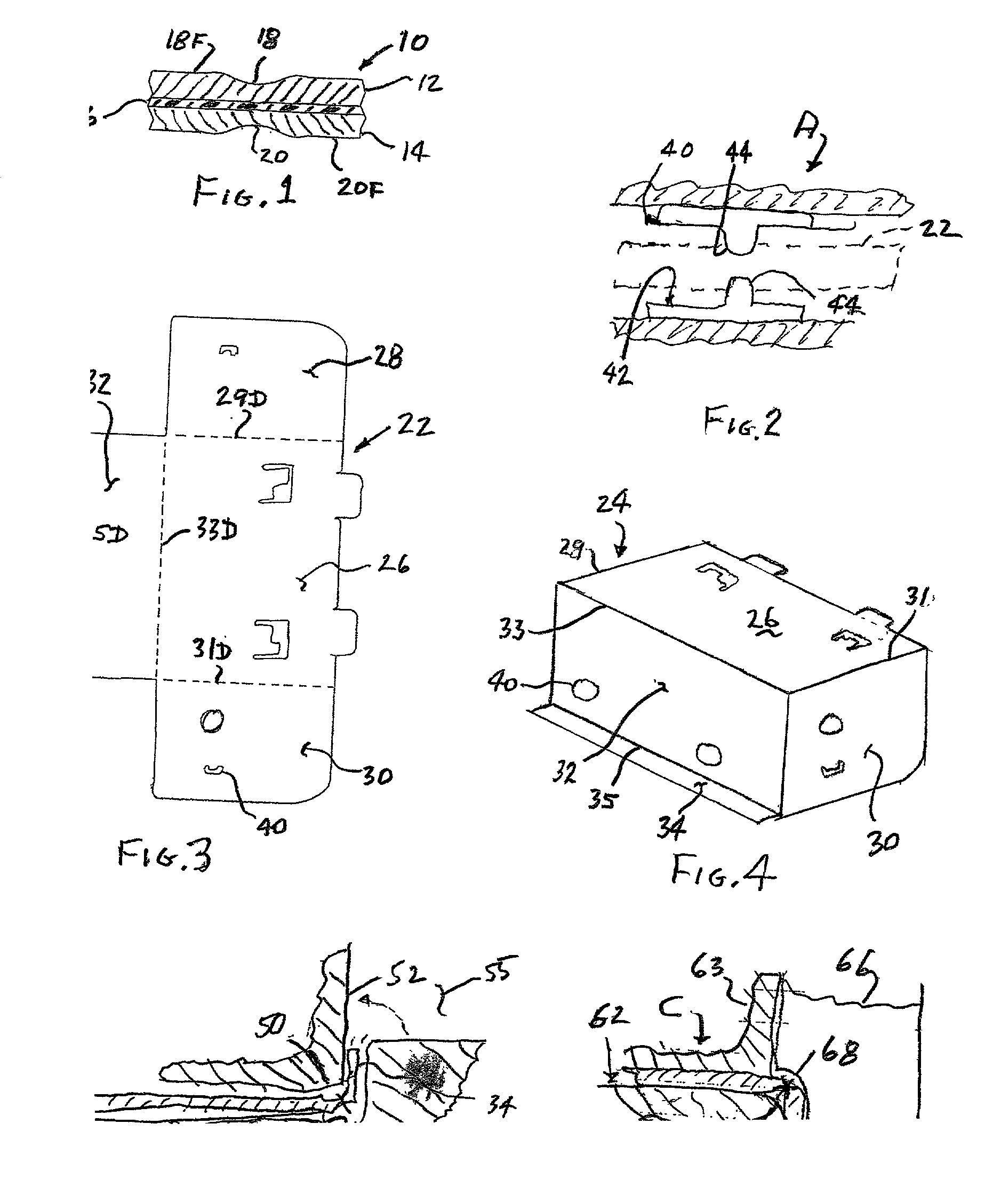

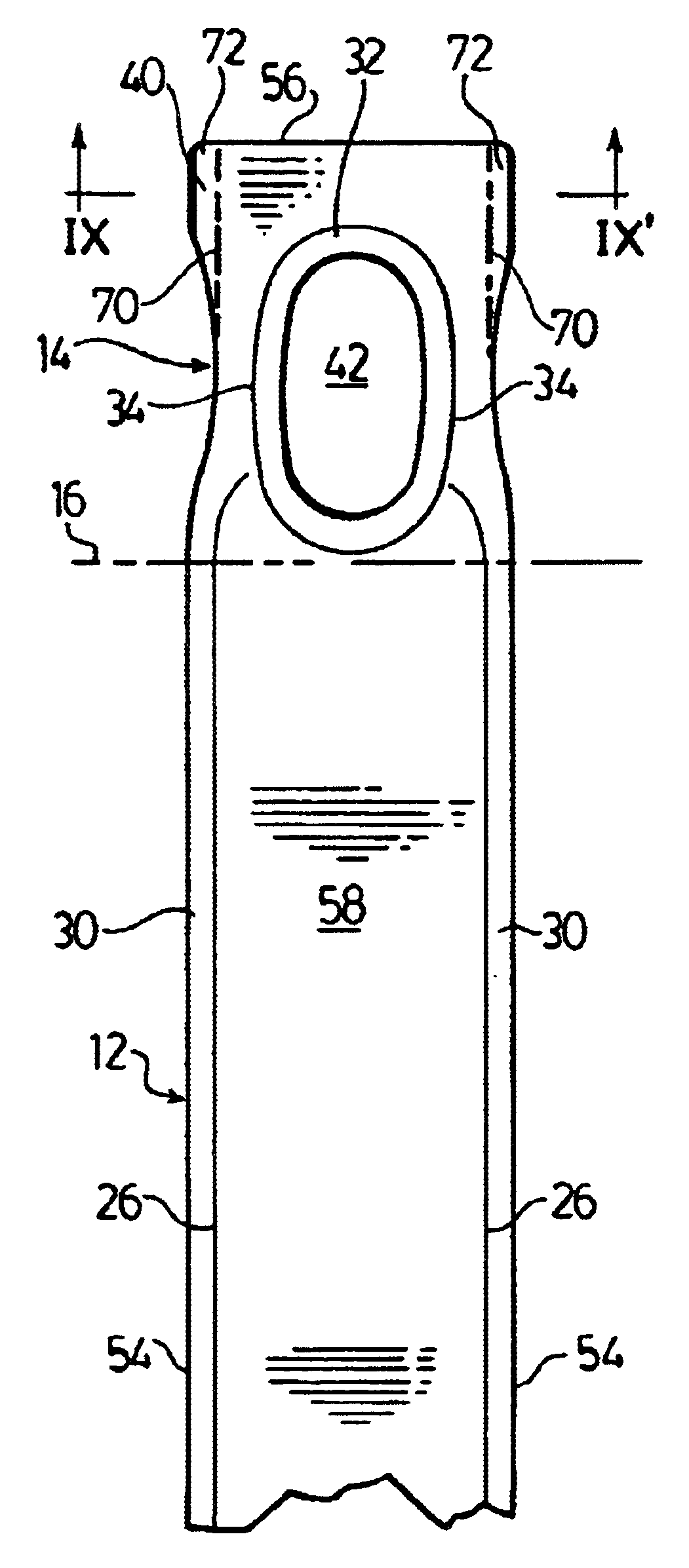

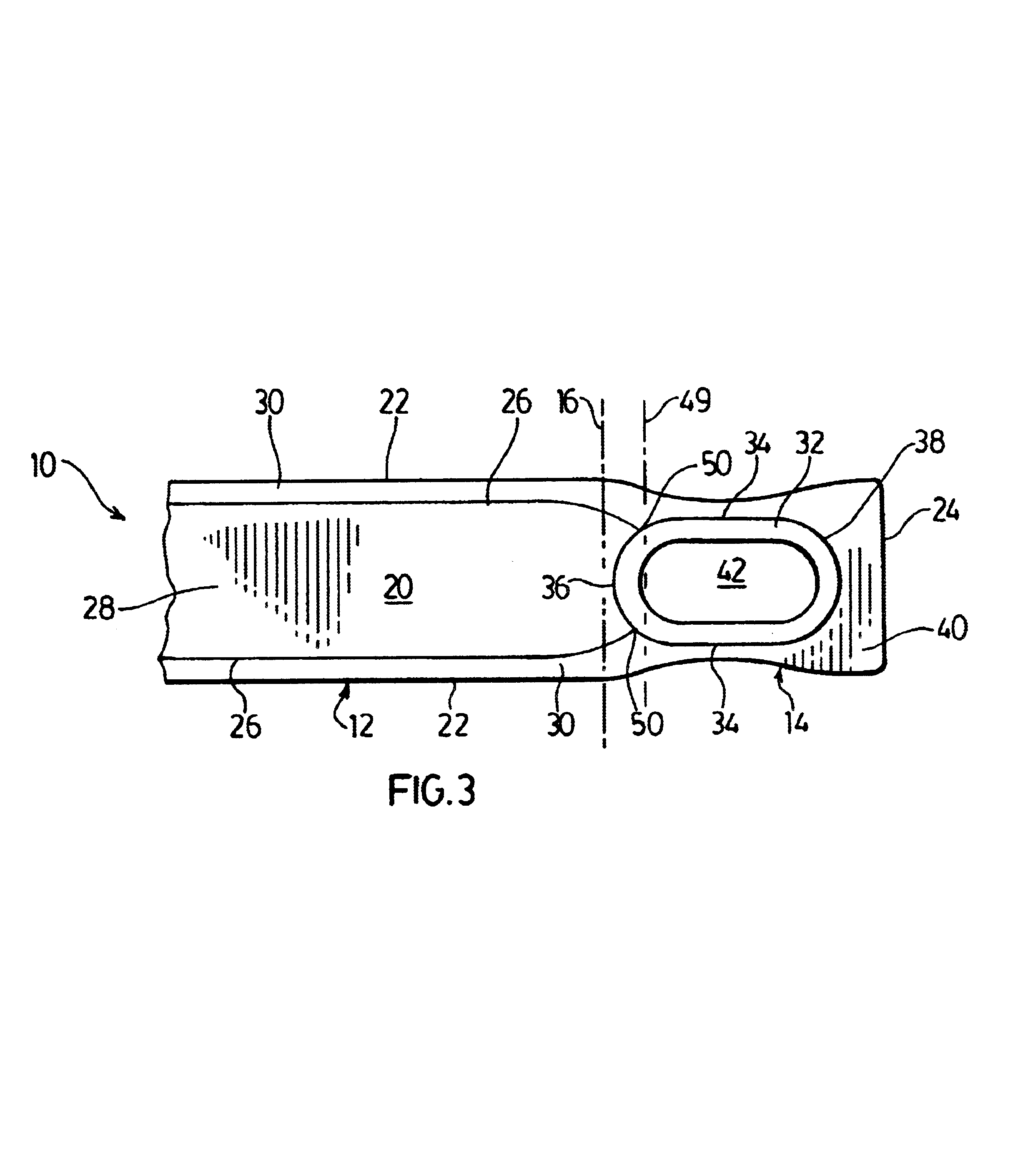

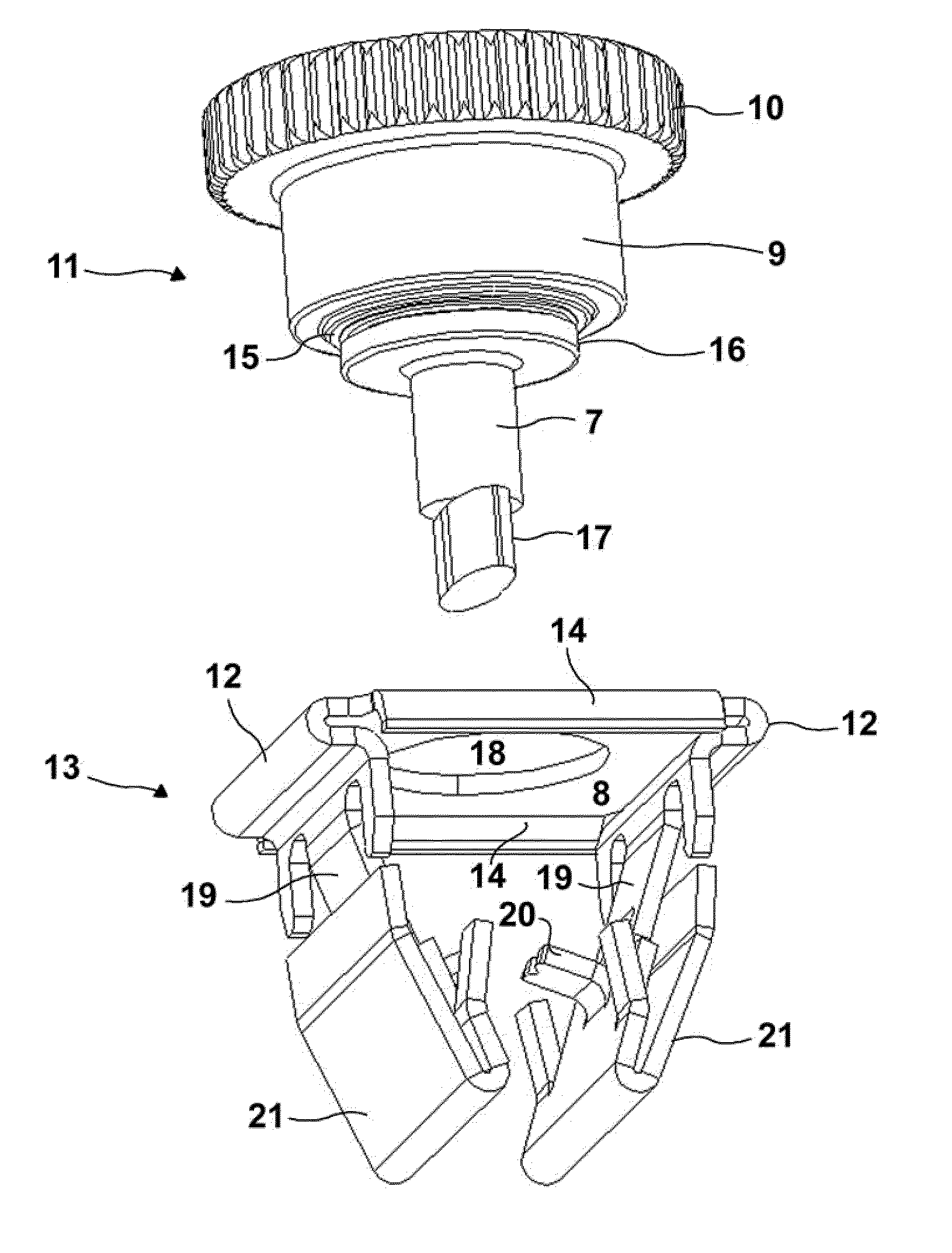

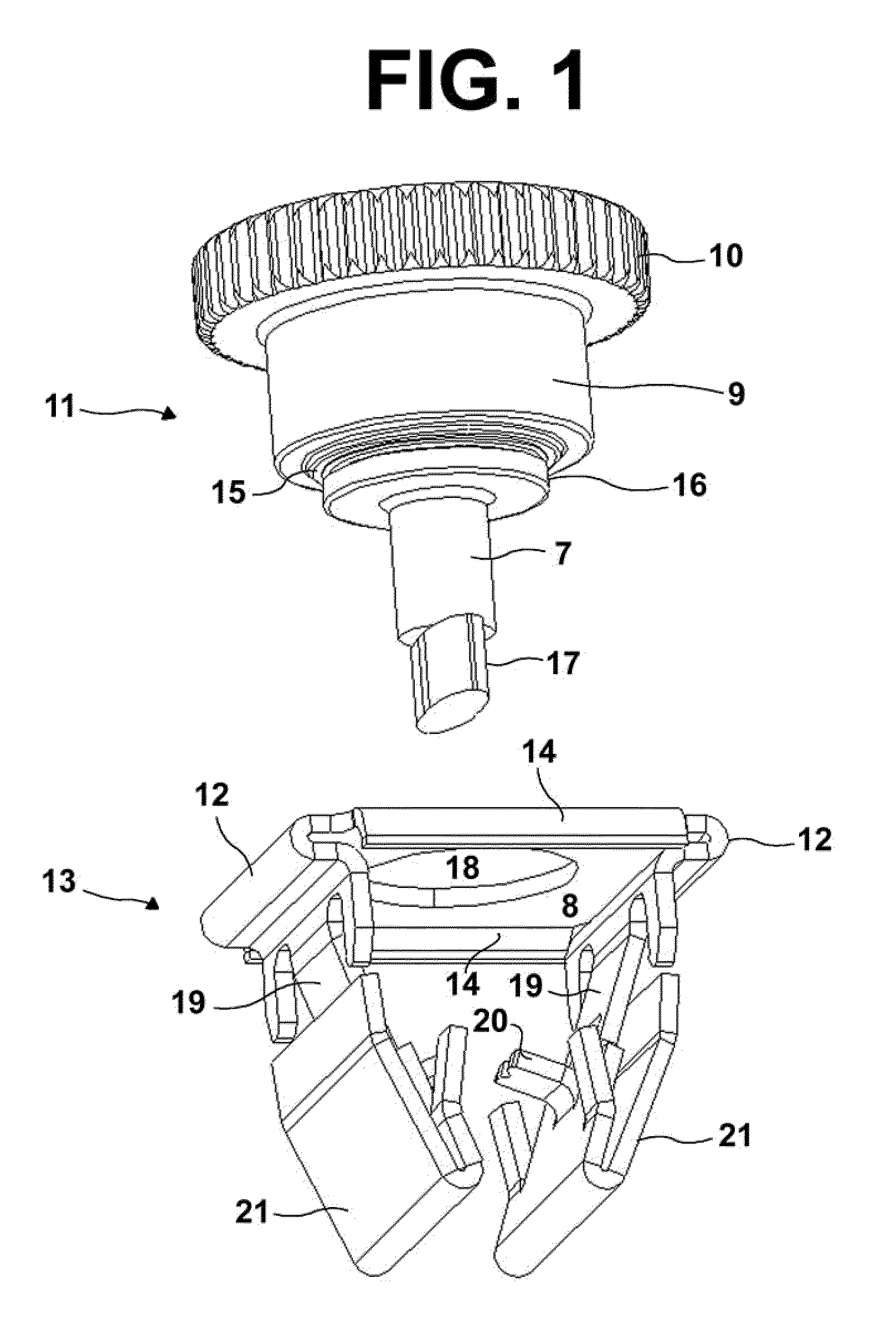

Quick acting panel fastener

A panel fastener is comprised of two separately formed interacting parts: a panel retainer and an actuator pin. The retainer is fashioned from sheet metal using progressive stamping technology. The retainer and pin work together to create a fastener for securing two panels together that can semi-permanently snap into the first panel and then be clamped onto and then selectively removed from the second panel. Attachment to the second panel is obtained by expanding and later released by contracting the legs of the retainer by rotating a cammed expander pin between self-locking positions. A head of the expander pin can be configured for hand actuation, tool-only actuation, or both. The retainer is fashioned from sheet metal using progressive stamping technology.

Owner:PEM MANAGEMENT INC

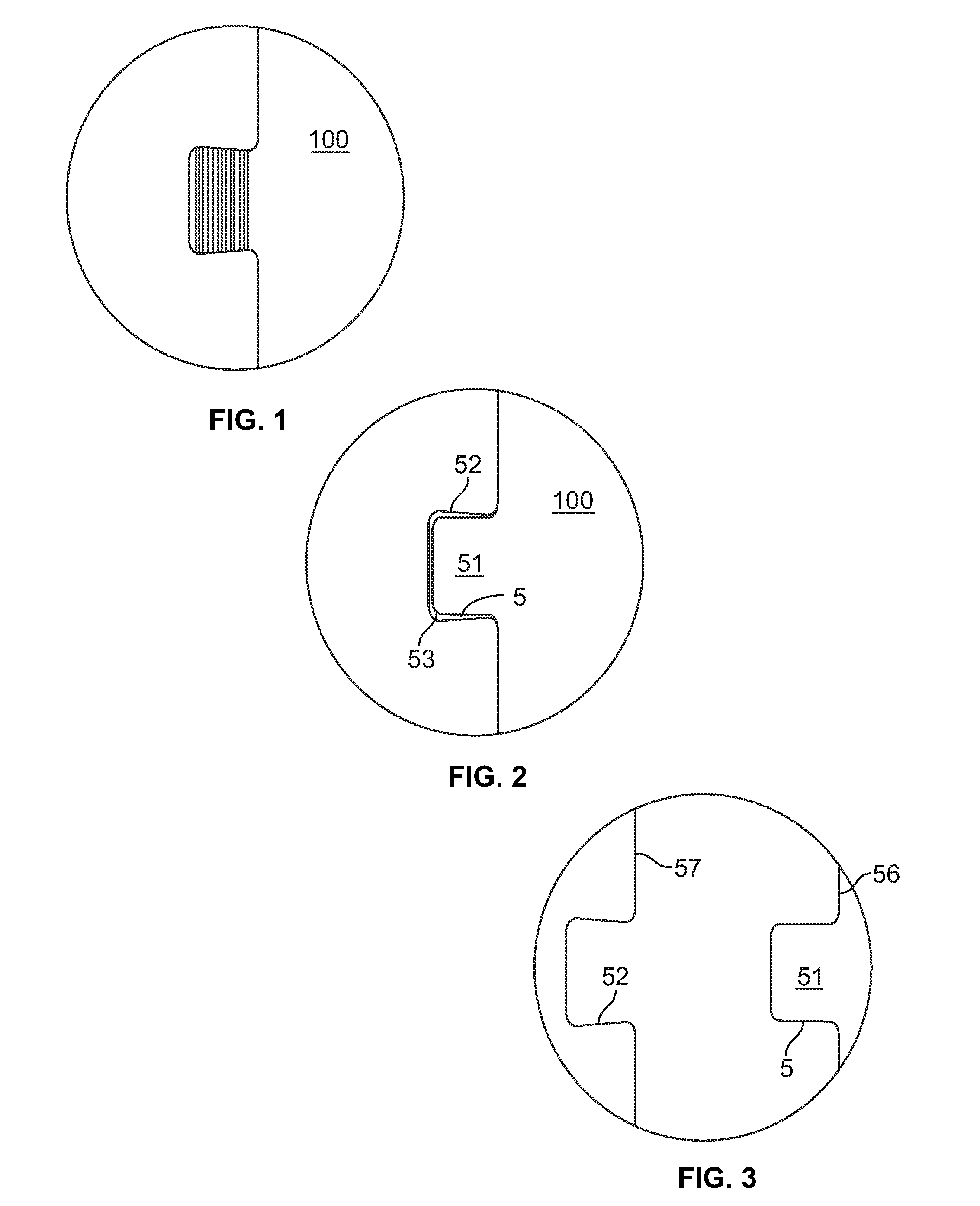

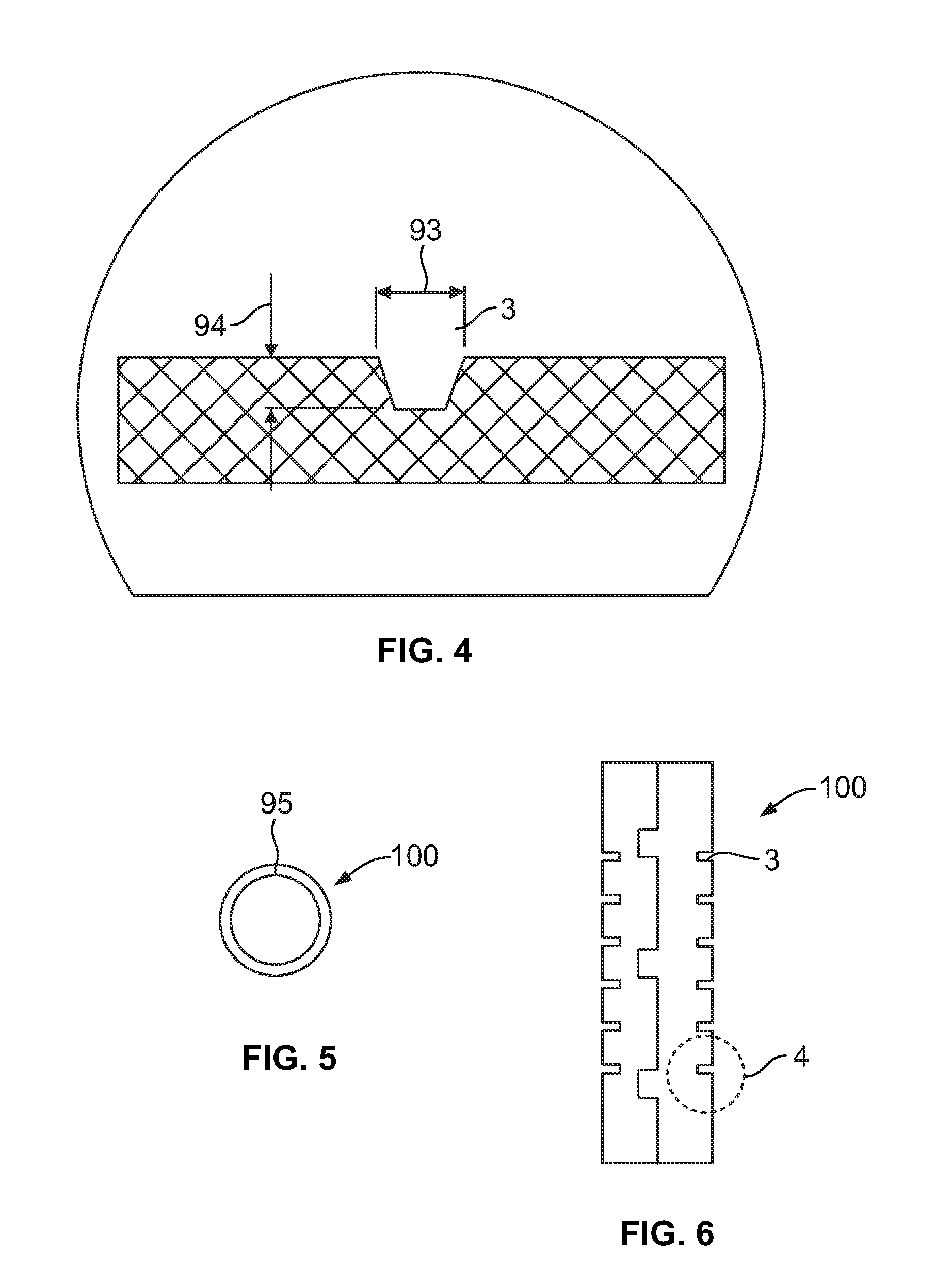

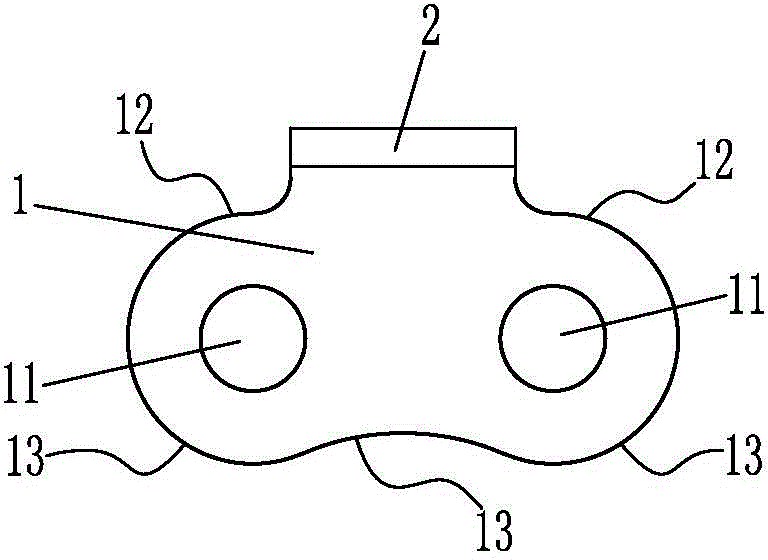

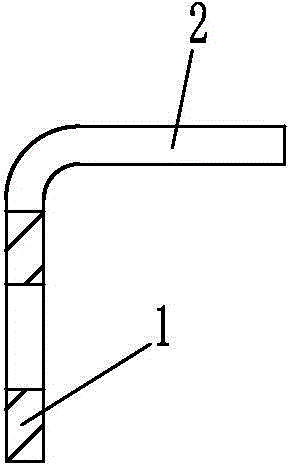

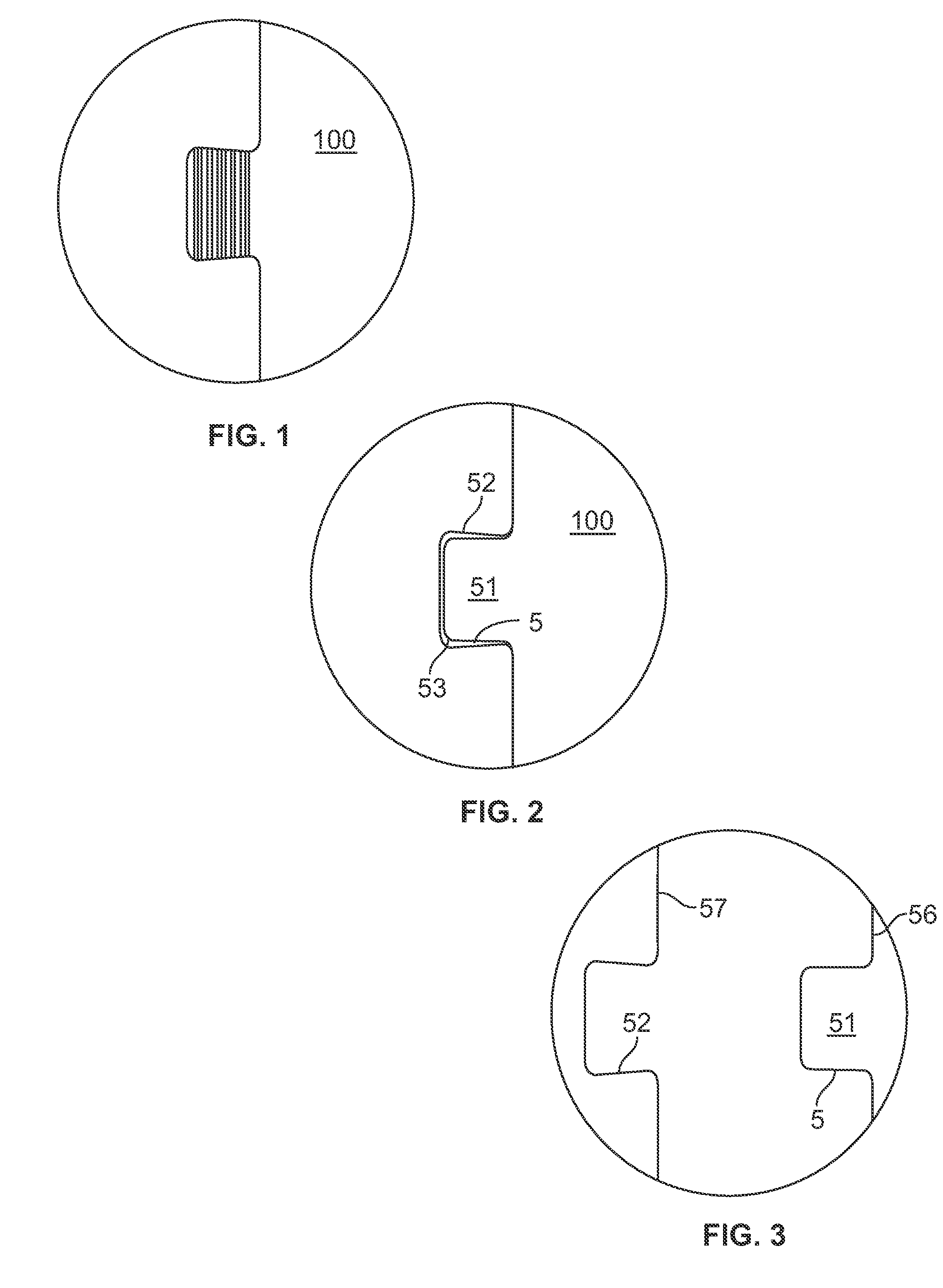

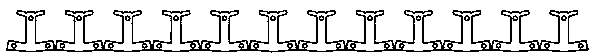

Bushing, piece with bushing, or method of producing

This disclosure relates to bushings produced with adapted dovetails for production on a carrying web of a progressive stamping machine at a plurality of stations. The bushing includes a regular shape male dovetail inserted into an irregular shape crenellated female opening at the conclusion of a plurality of operations at stations on a progressive stamping machine. Once the bushing is bent in shape, in a subsequent step, the regular shape male dovetail is punched to lock in place into the irregular shape crenellated female opening.

Owner:DIAL TOOL IND

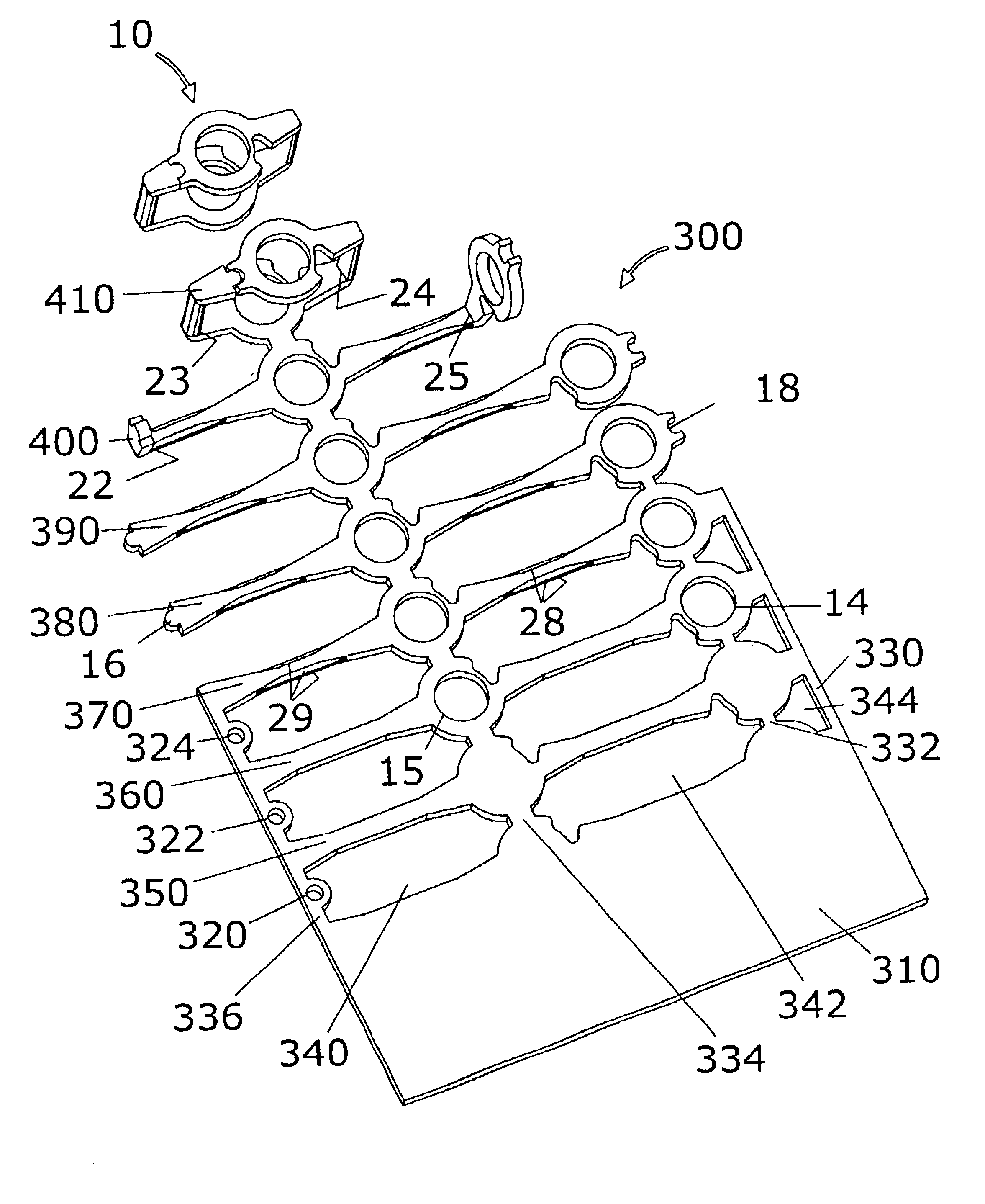

Method of fabricating a cliples bicycle pedal

InactiveUS20040168542A1Short timeA large amountControlling membersMechanical apparatusSlide plateEngineering

A clipless mechanism for a four-sided clipless bicycle pedal is made by a stamping and welding process. The stamping is preferably a progressive stamping process. The stamped parts include two components, an inner wing and an outer wing. The two stamped components are generally similar in shape to each other, but the inner wing fits within the outer wing. Each part is first stamped as a flat pattern by a progressive die. Each part then has radii stamped into the edges by the second station of the progressive die. Next, each part is partially folded by the third station of the progressive die. Then each part is folded completely by the fourth station of the progressive die. The actual number of steps may vary depending upon the material chosen, the thickness of the material and the design of the stamping tool. Then each part is welded closed and the resulting rectangular wings are assemblied in juxtaposed orthogonal relation to provide four shoe cleat engaging receptacles.

Owner:CRANK BROS INC

Automatic stamping forming technology for K-shaped accessory plates and chain plates of chain and for combination of K-shaped accessory plates and chain plates of chain

The invention discloses a chain, K-shaped accessory plates of the chain and chain plates of the chain, and particularly discloses an automatic stamping forming technology for the combination of the K-shaped accessory plates and the chain plates of the chain. A continuous multi-station stamping die is used for conducting progressive stamping forming machining of the K-shaped accessory plates and the chain plates on a steel belt, the two chain plates are inserted into the gap between the two K-shaped accessory plates, and accordingly the combined stock layout of the K-shaped accessory plates and the chain plates is formed. The continuous multi-station stamping die is sequentially provided with a pre-stamping chain plate hole station, a fine stamping chain plate hole station and a chain plate blanking station in the progressive conveying direction of the steel belt. The continuous multi-station stamping die is sequentially provided with a pre-stamping accessory plate pin hole station, a fine stamping accessory plate pin hole station, a stamping accessory plate platform hole station, an accessory plate edge cutting station, a 45-degree accessory plate bending station, a 90-degree accessory plate bending station and a blanking accessory plate station in the progressive conveying direction of the steel belt. According to the scheme, stamping forming machining of the two K-shaped accessory plates and blanking machining of the two chain plates of the chain can be automatically completed in multiple steps on one punch press, and therefore the production efficiency of products is improved.

Owner:HANGZHOU DONGHUA CHAIN GRP

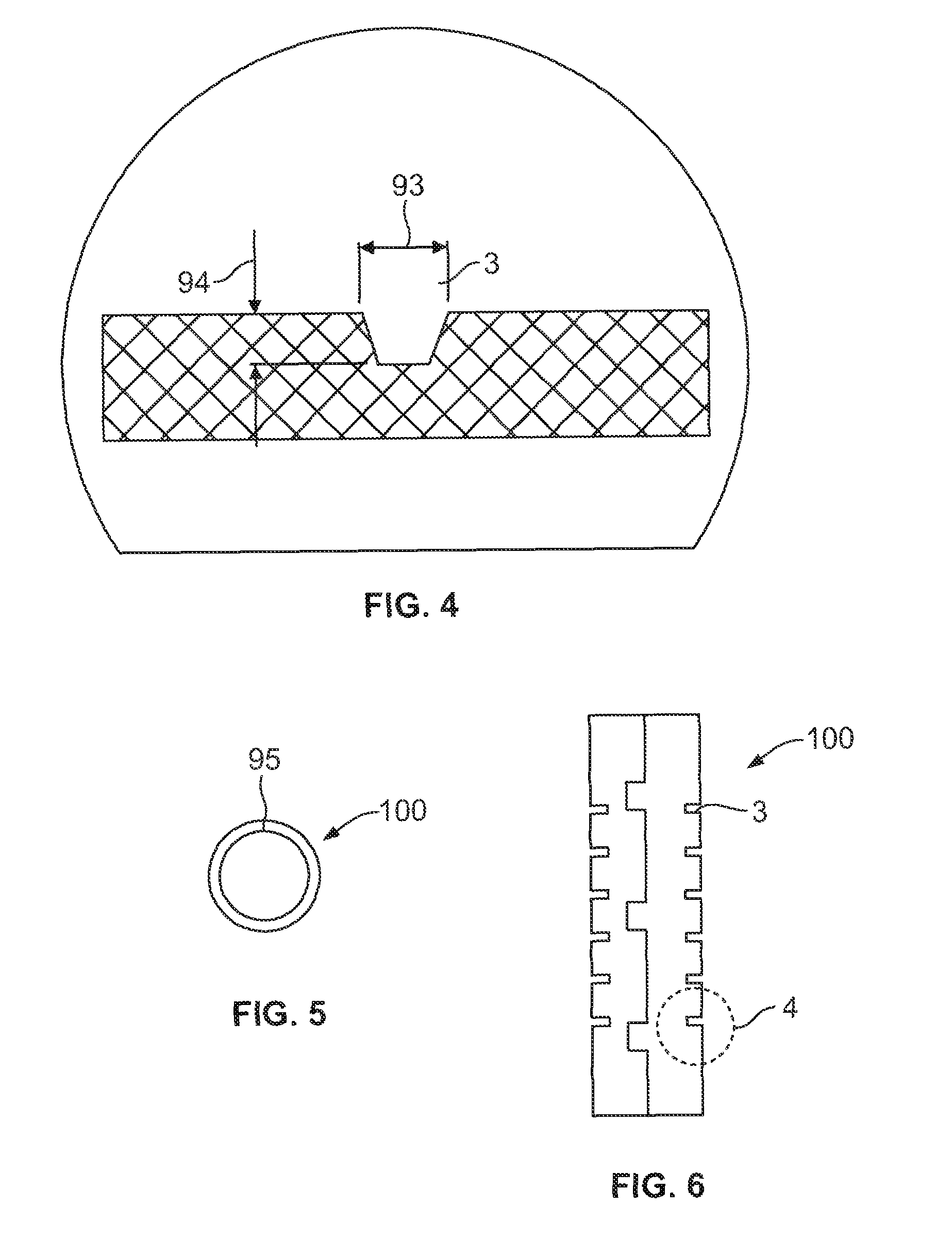

Process of bending laminated metal sheet

InactiveUS20020148273A1Reduce sheet thicknessEliminates laminate sheet slidingEngineeringMetal sheet

This invention improves on the process of bending in a conventional progressive stamping press a flat laminated metal sheet around a corner edge of a die block to form a generally straight piece-part corner, and comprises the steps of forming extended concavely rounded depressions in the opposite sheet faces at the sheet locations of the intended corner, then locating and clamping the sheet with the depressed regions aligned along a die block corner, and then mechanically bending the sheet with said depressed sheet regions aligned over the die block corner edge. The sheet depressions can be aligned essentially opposite one another, being rounded concavely and of a high width-to-depth ratio and of a depth to reduce the sheet to between 80-30% of its original thickness. The sheet depressions might occur at one stamping press station by opposing press tools each having a convex rounded working edge elongated along the length of the intended corner, with the blank bending occurring at a subsequent stamping press station.

Owner:BUHRKE IND

Progressive stamping die

InactiveUS20060021414A1Simple methodMaintain alignmentShaping toolsForging hammersEngineeringMechanical engineering

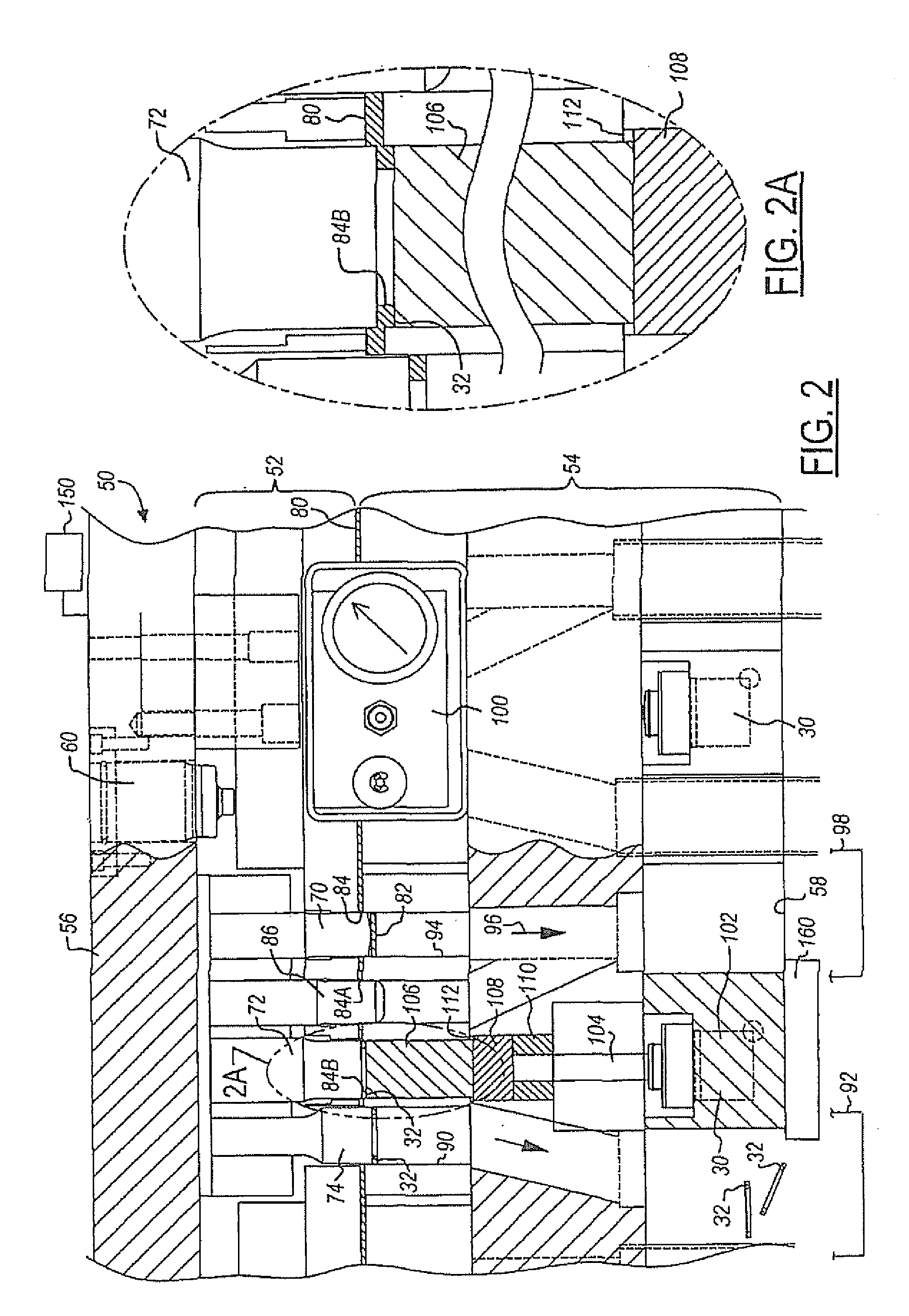

A progressive stamping die system and method of operation providing dimensionally accurate flat stamped parts. A biasing mechanism is provided in actual alignment with a coin punch member in order to accurately control the configuration and planar accuracy of the stamped parts being formed.

Owner:COWIE RALPH

Heat exchanger plates and manufacturing method

InactiveUS6837305B2Great longitudinal dimensionMetal-working apparatusStationary conduit assembliesEngineeringHeat exchanger

A method for forming heat exchanger plates comprises formation of a fluid flow channel along the edges of a sheet metal strip or blank, and formation of a pair of raised end bosses. The raised end bosses are elongated in the longitudinal dimension and are formed within the final width dimension of the plate so as to avoid the need for trimming of excess material along the edges of the plate. The method generates less scrap than prior art processes using progressive stamping, and also permits variation of the plate lengths.

Owner:DANA CANADA CORP

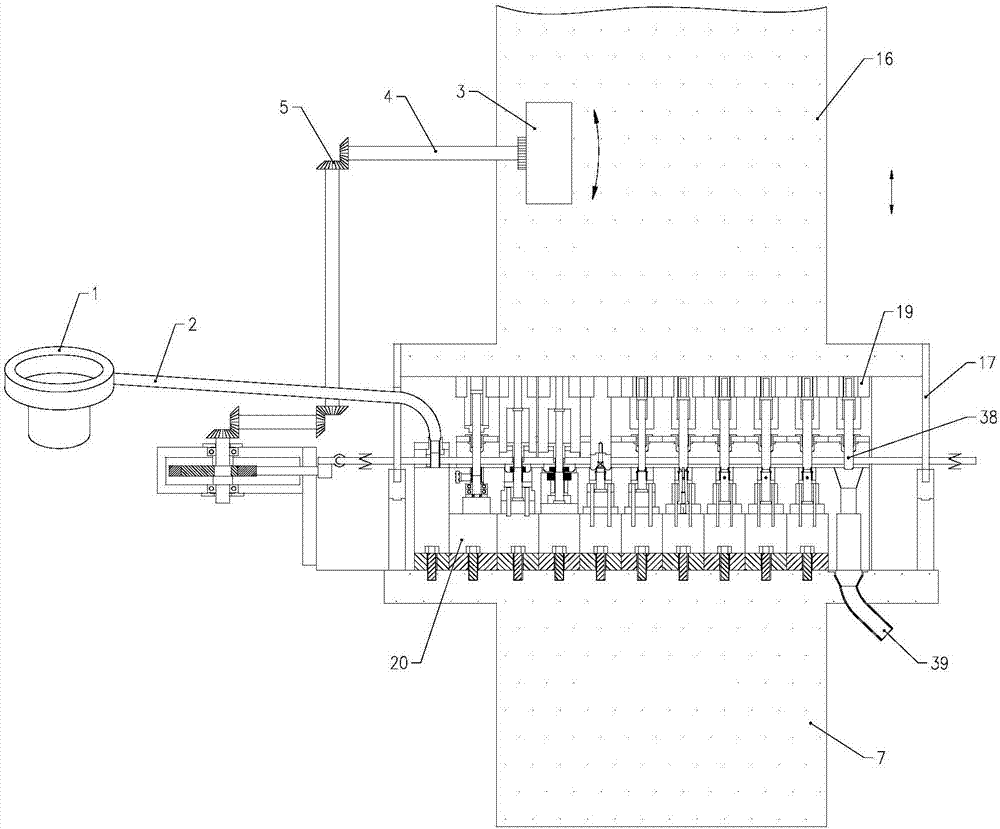

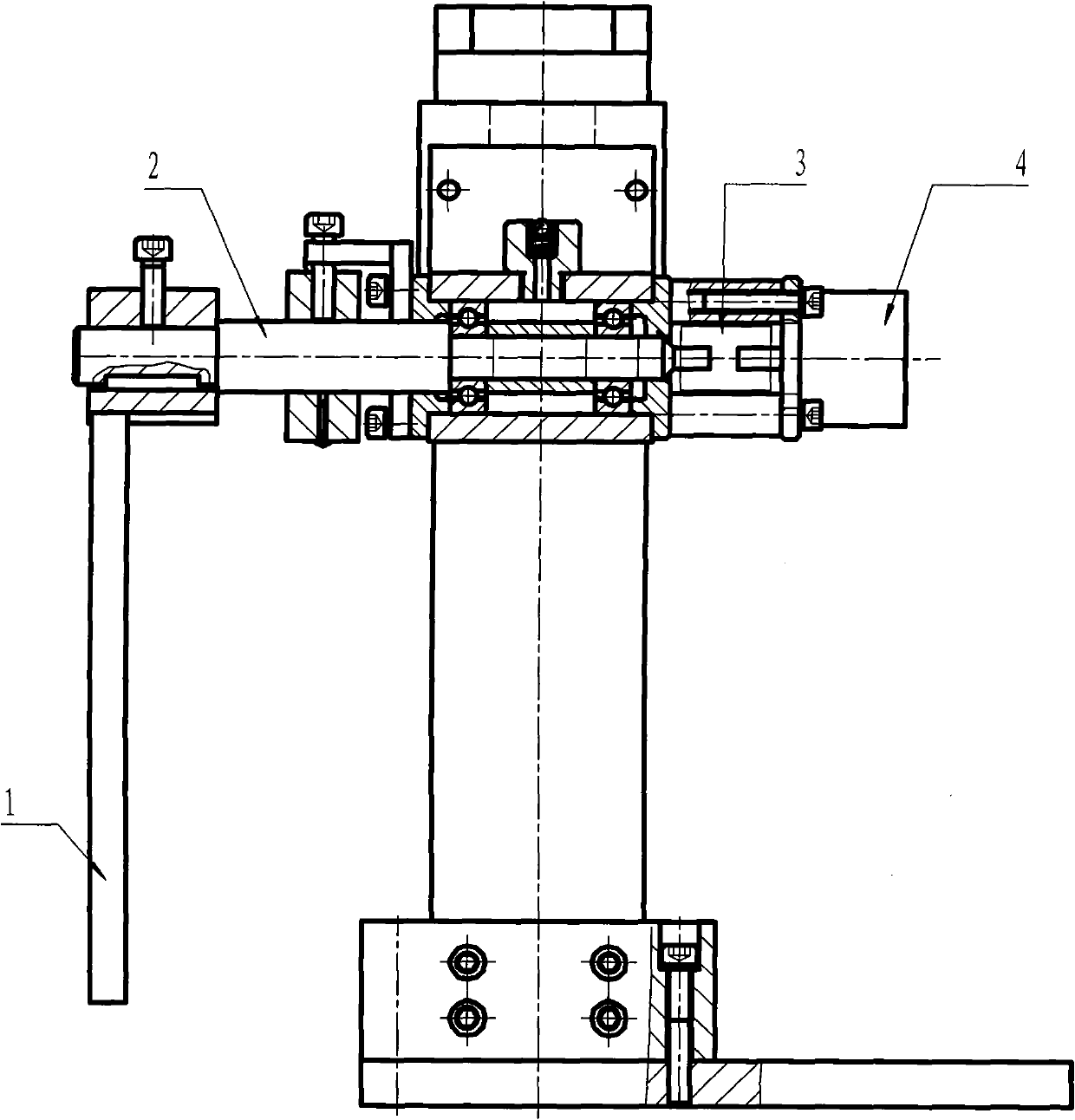

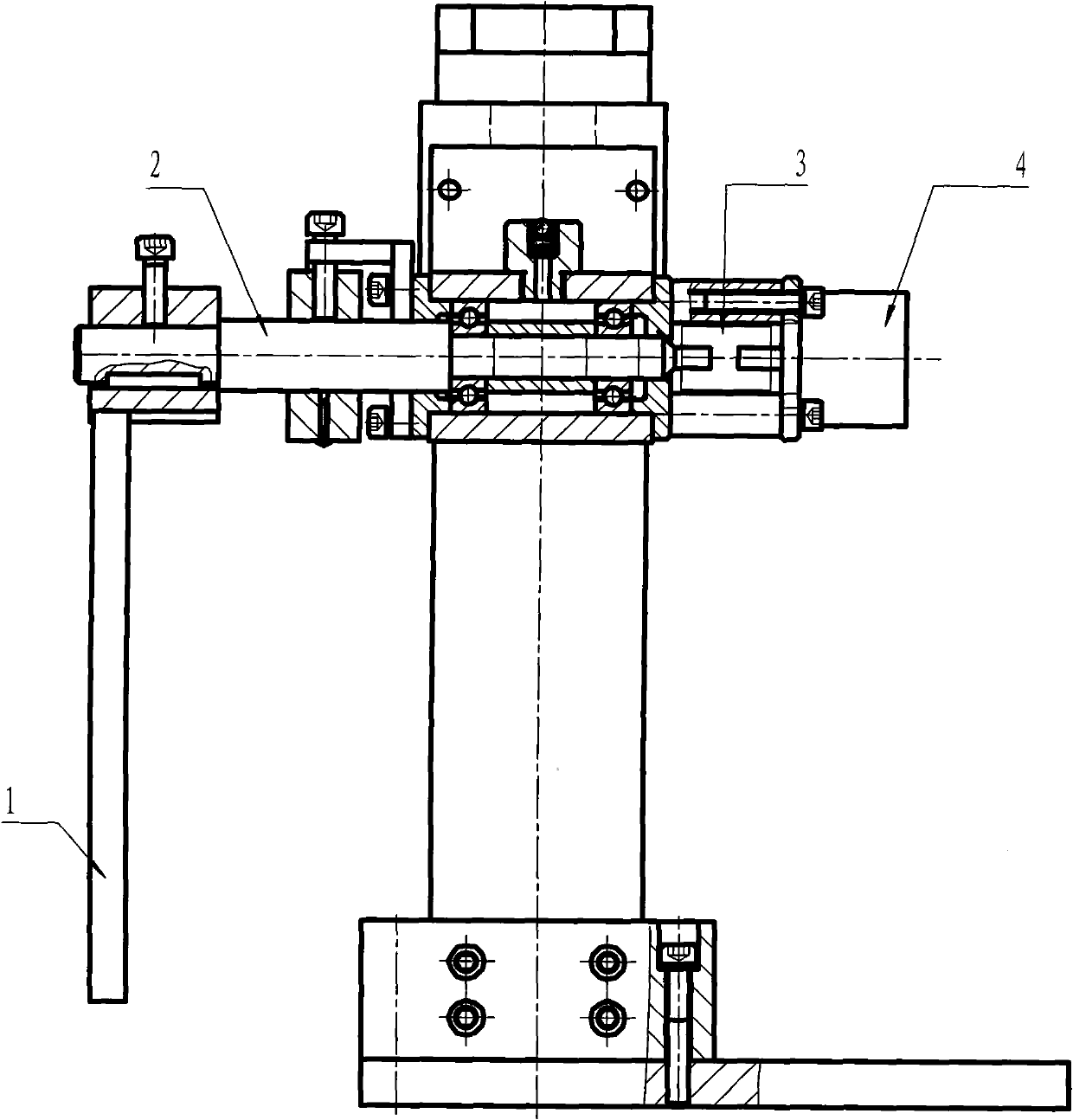

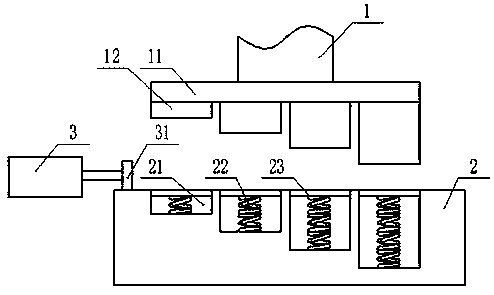

Progressive mould of composite tool

The invention relates to the technical field of pipe material processing dies, and discloses a progressive die for composite tooling, including a feeding device, a feeding device between processes, a discharging device, and a progressive stamping die with multiple process dies; The stamping die includes an upper die and a lower die, the upper die is fixed on the upper part of the punch press, the lower die is fixed on the lower part of the punch press; the inter-process feeding device is arranged on the upper die, the lower die Between the molds, the pipe fittings provided by the feeding device are used to sequentially send the pipe fittings provided by the progressive stamping die from one process die station to the next process die station; the discharge device is used to send out the processed pipe fittings. The products produced by various types of equipment processes are integrated into a pair of molds to complete the whole process of automatic feeding, feeding, multi-process simultaneous production, and automatic output, which solves the problem of low efficiency and production problems in the processing of pipe fittings. The time process is long and the labor required is too much.

Owner:姚修兵

Quick acting panel fastener

ActiveUS20110020092A1Super low costEasy to operateSnap-action fastenersRail fastenersEngineeringSelf locking

A panel fastener is comprised of two separately formed interacting parts: a panel retainer and an actuator pin. The retainer is fashioned from sheet metal using progressive stamping technology. The retainer and pin work together to create a fastener for securing two panels together that can semi-permanently snap into the first panel and then be clamped onto and then selectively removed from the second panel. Attachment to the second panel is obtained by expanding and later released by contracting the legs of the retainer by rotating a cammed expander pin between self-locking positions. A head of the expander pin can be configured for hand actuation, tool-only actuation, or both. The retainer is fashioned from sheet metal using progressive stamping technology.

Owner:PEM MANAGEMENT INC

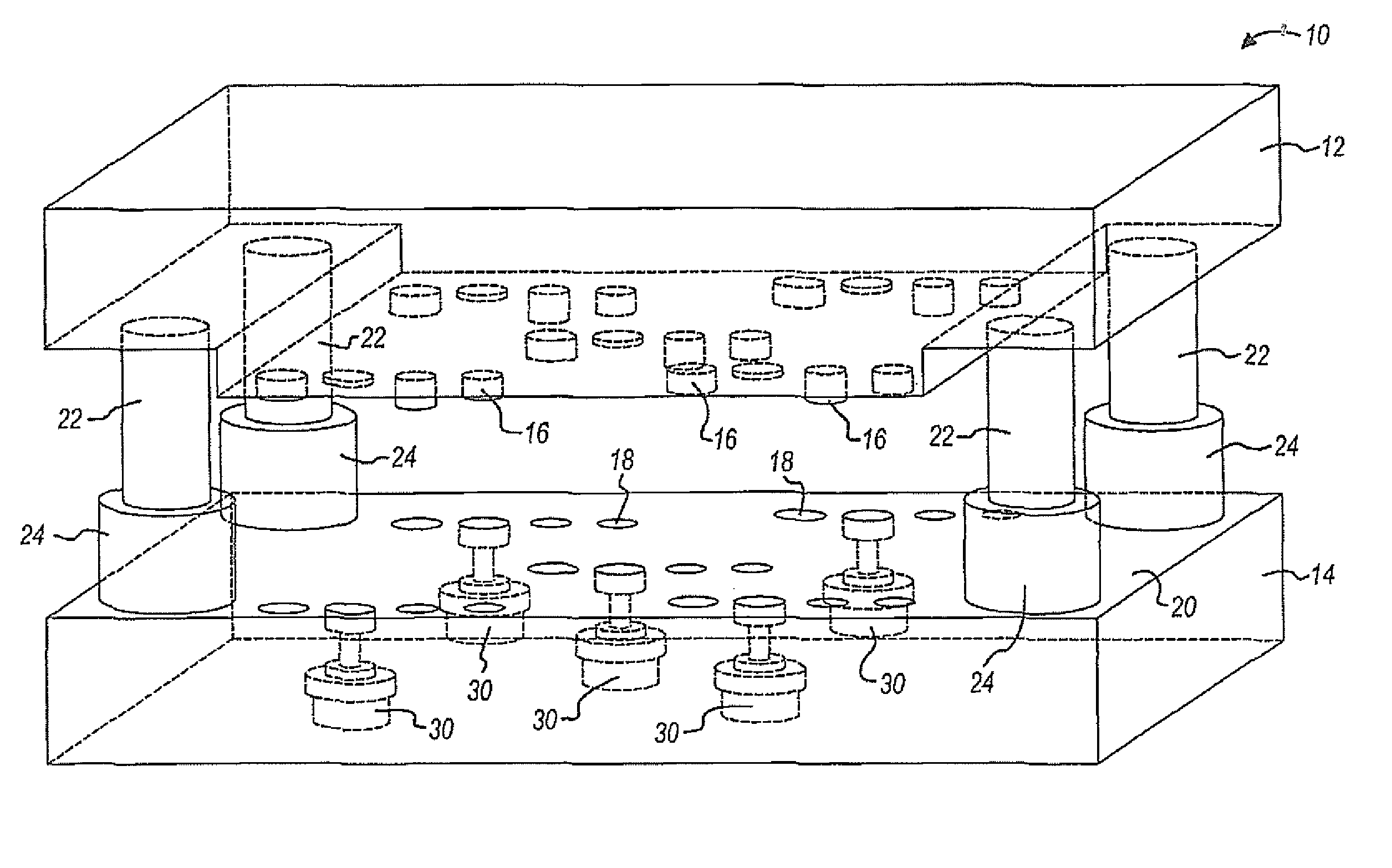

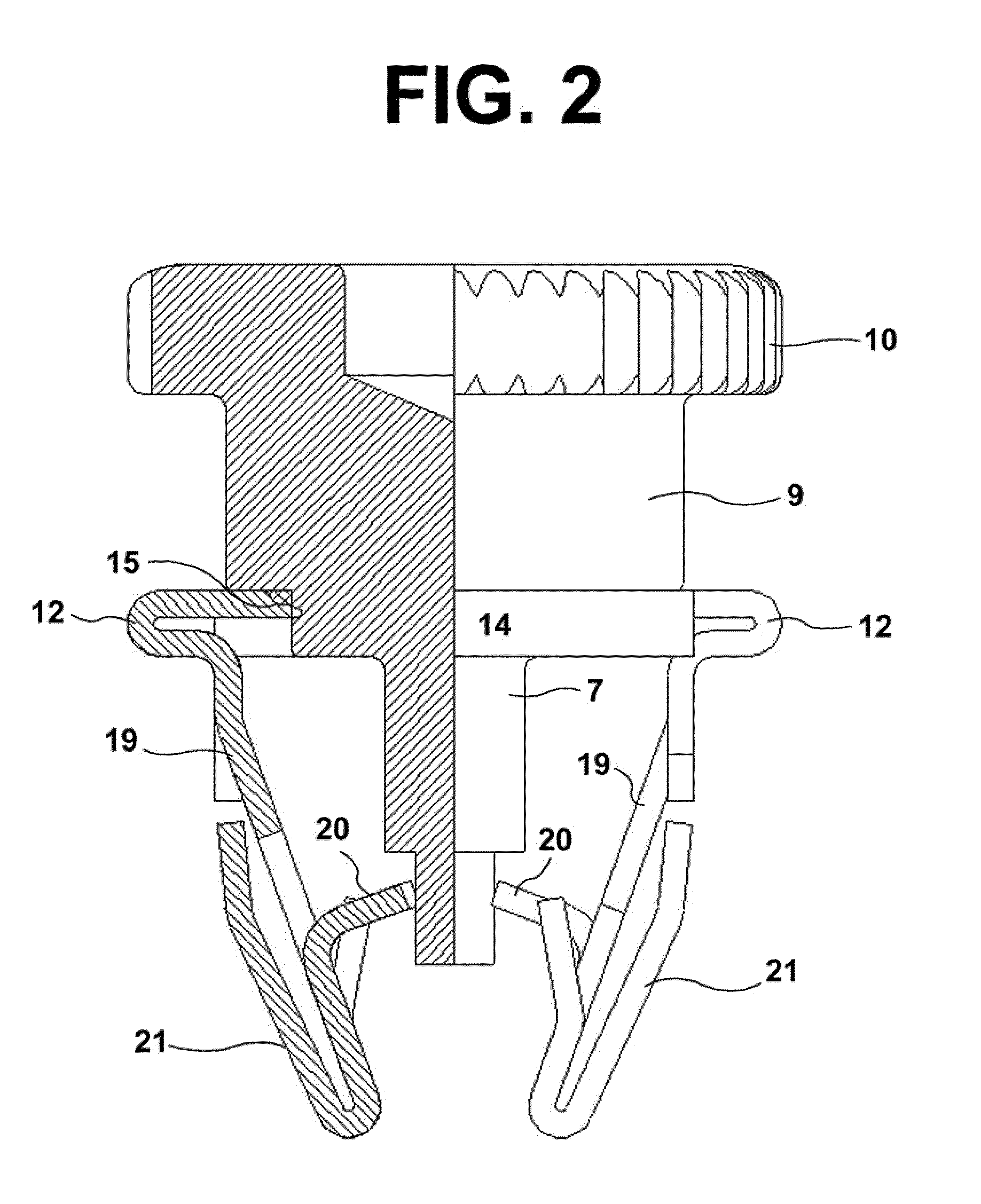

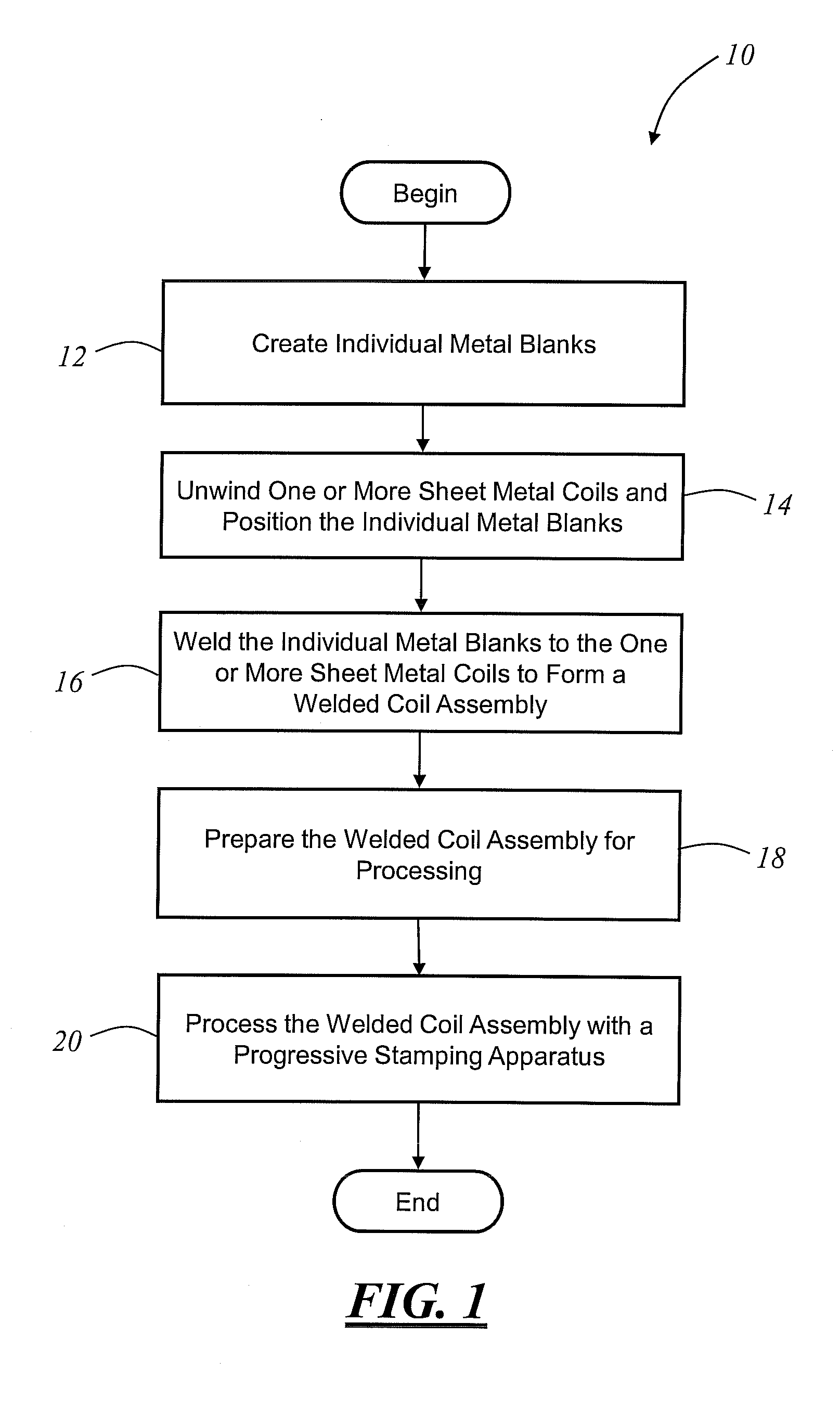

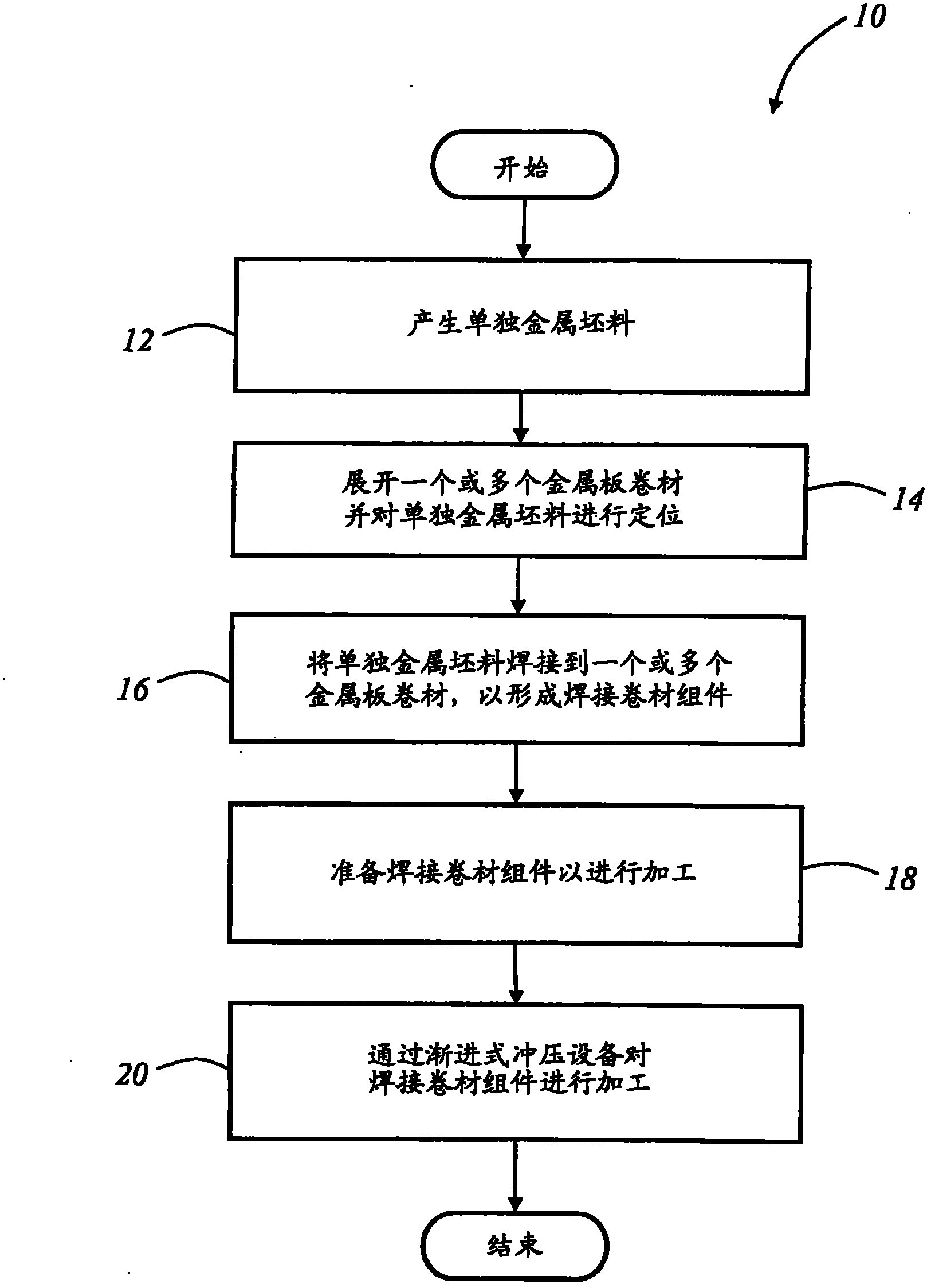

Metal forming process and welded coil assembly

InactiveUS20110151271A1Semiconductor/solid-state device detailsSolid-state devicesMetal forming processMetal

A metal forming process and welded coil assembly that may be used to form complex metal components in a manner that is efficient, reduces scrap material, and maintains the structural integrity of the components. Generally, a number of individual metal blanks are welded to one or more sheet metal coils in order to produce a welded coil assembly. The metal blanks may be welded along the length of the inner sides of two sheet metal coils, or the metal blanks may be welded along the length of the outer sides of a single sheet metal coil, to cite a couple of possibilities. The welded coil assembly can then be fed through a progressive stamping apparatus or other machine to create a complex metal part.

Owner:SHILOH IND INC

Method of producing bushing and piece with bushing

This disclosure relates to bushings produced with adapted dovetails for production on a carrying web of a progressive stamping machine at a plurality of stations. The bushing includes a regular shape male dovetail inserted into an irregular shape crenellated female opening at the conclusion of a plurality of operations at stations on a progressive stamping machine. Once the bushing is bent in shape, in a subsequent step, the regular shape male dovetail is punched to lock in place into the irregular shape crenellated female opening.

Owner:DIAL TOOL IND

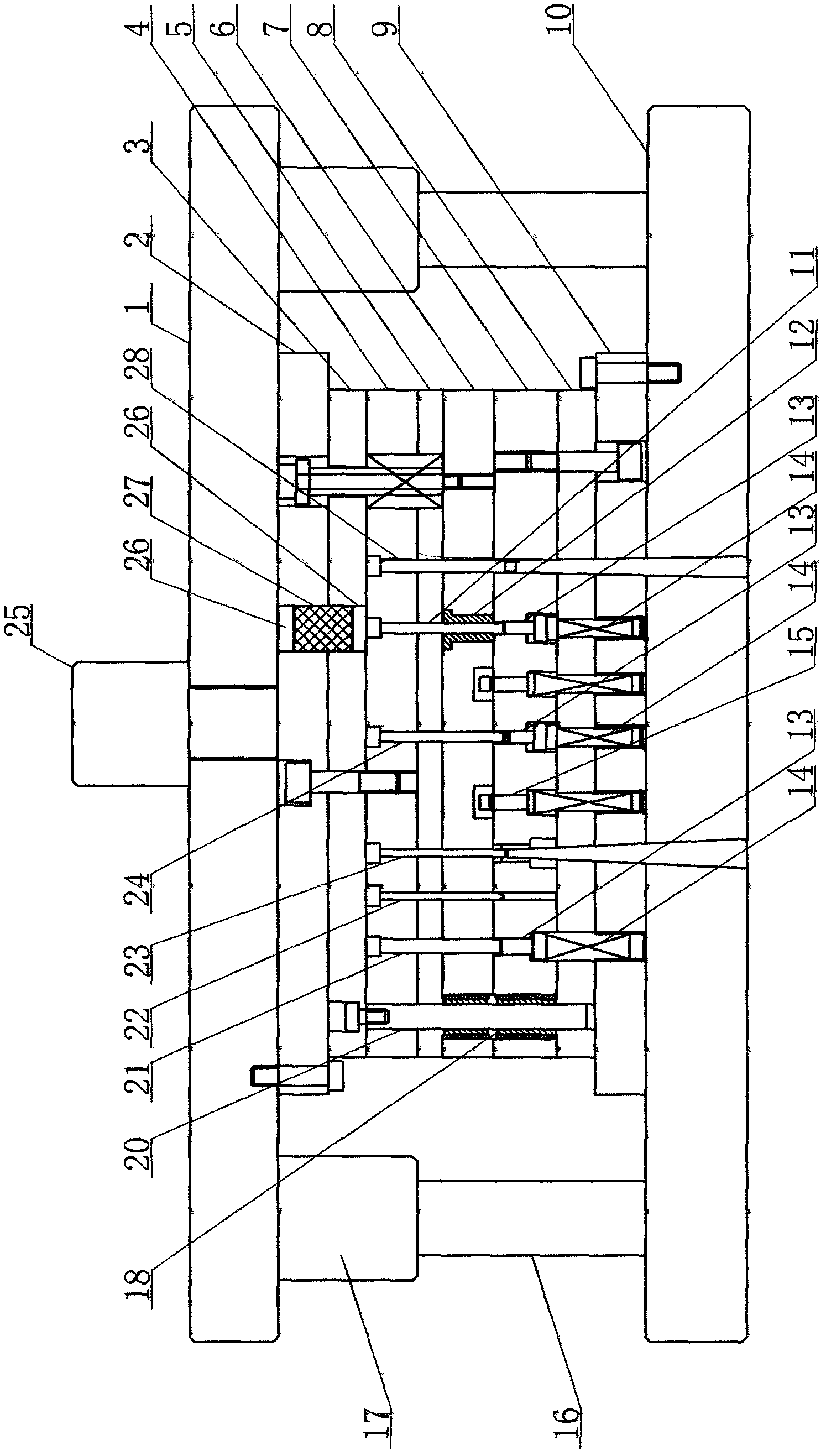

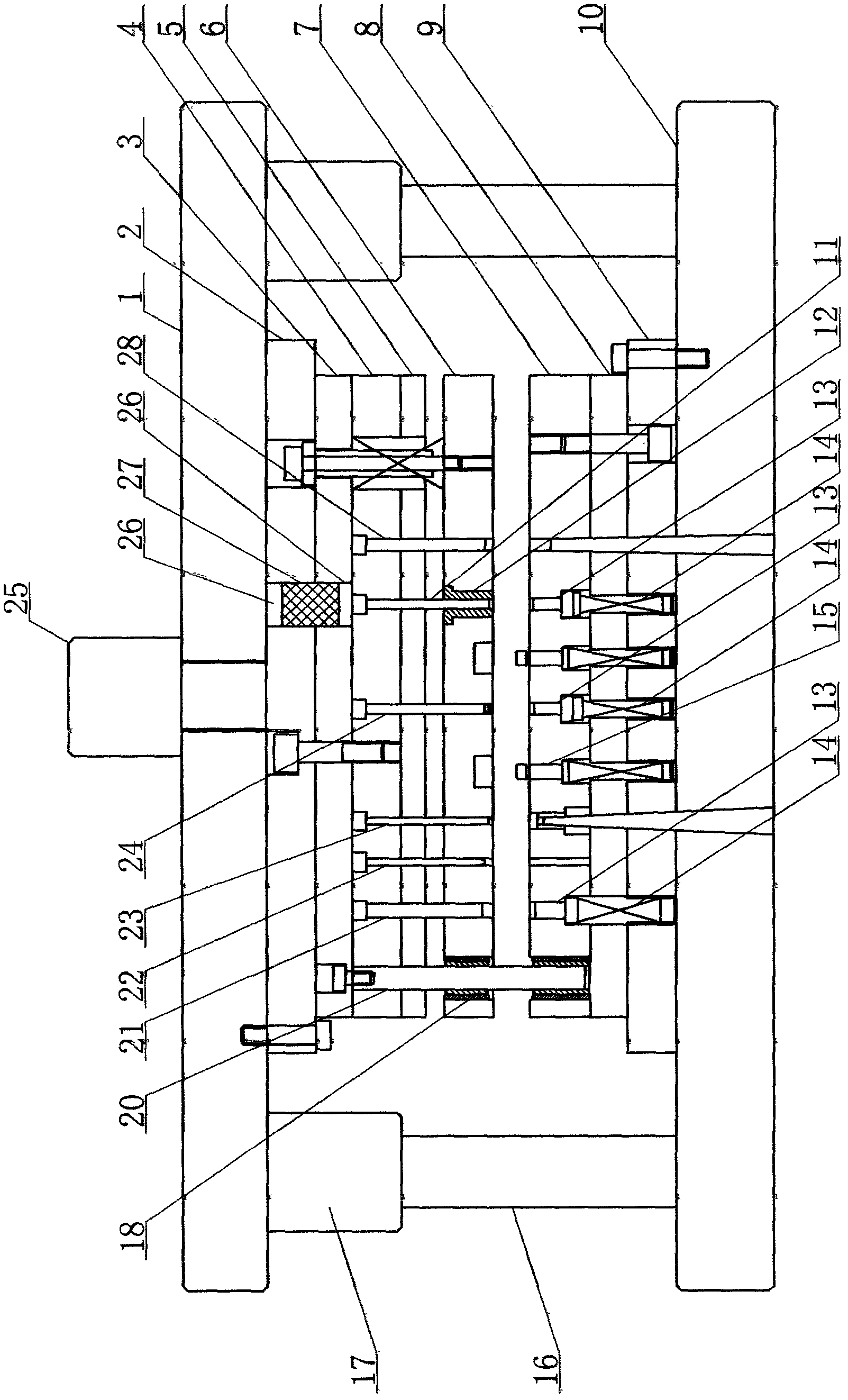

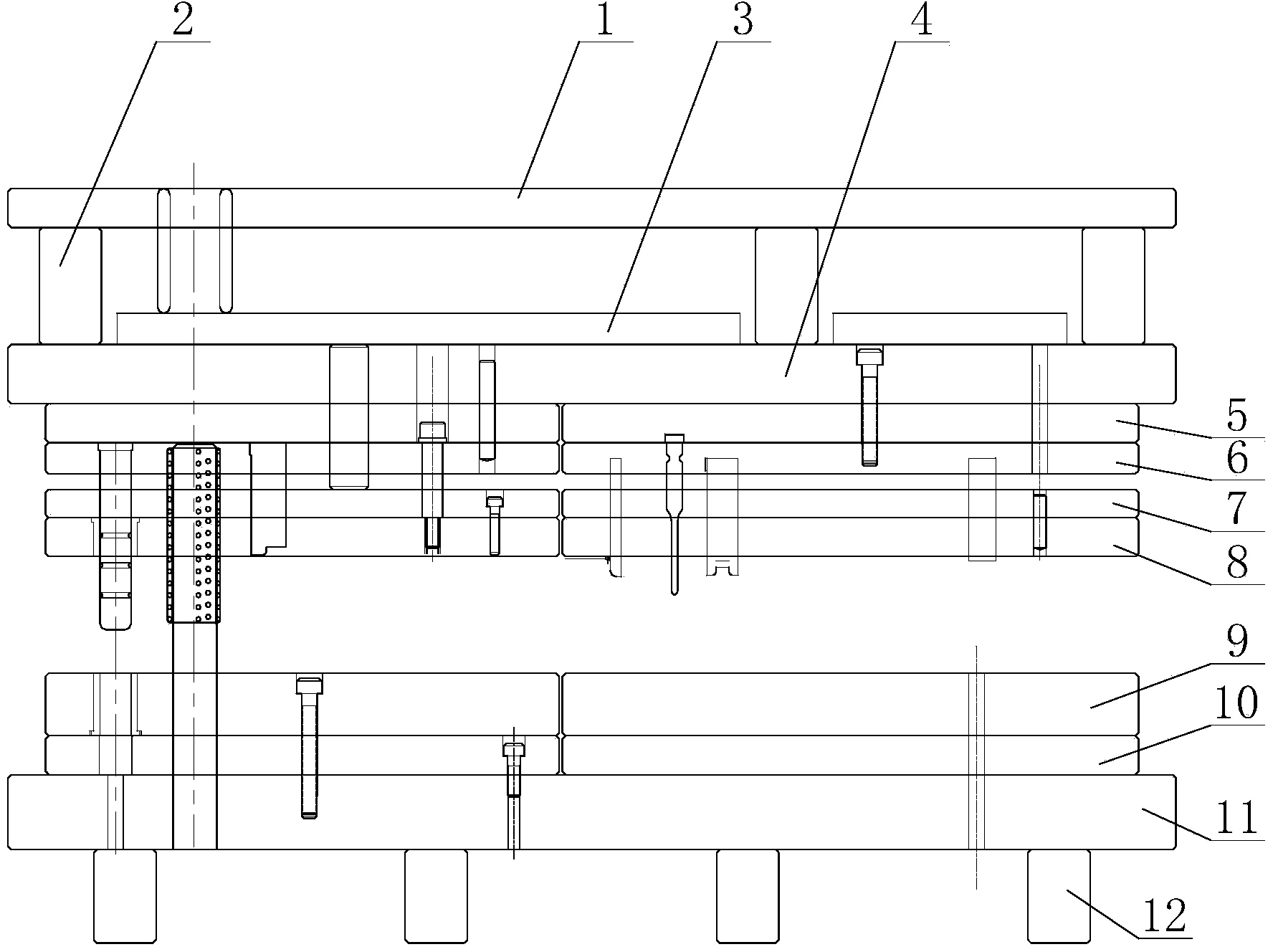

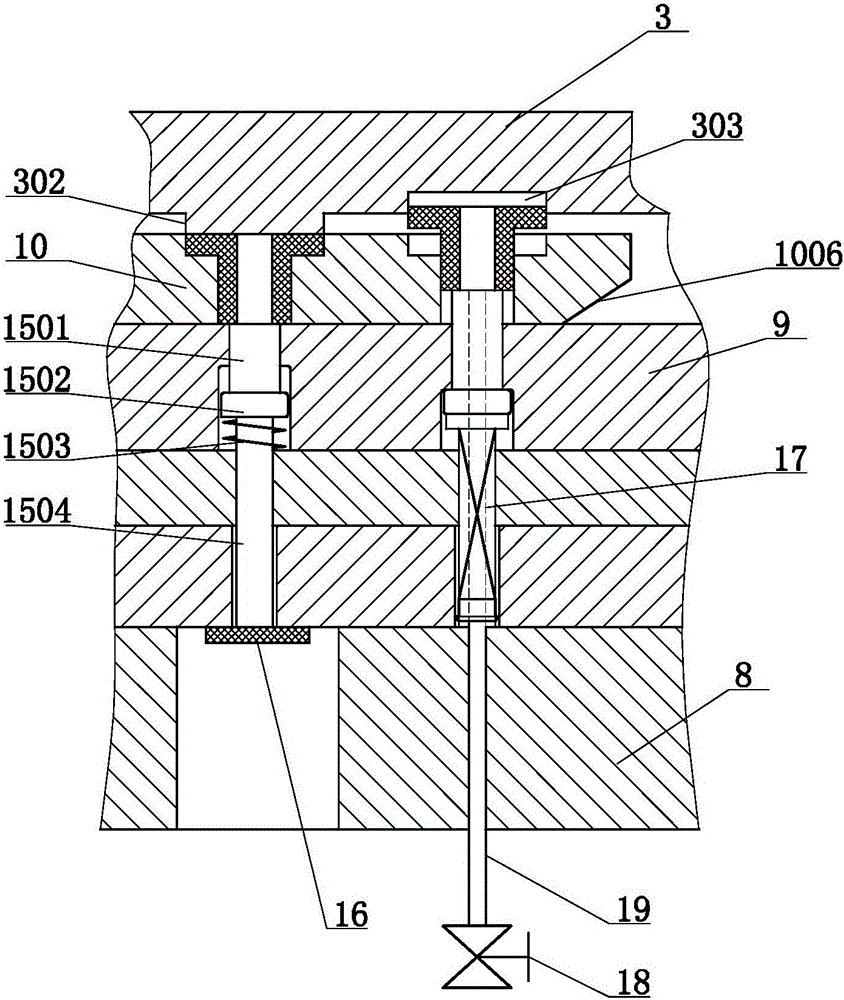

Progressive stamping die for round float valve and stamping technology

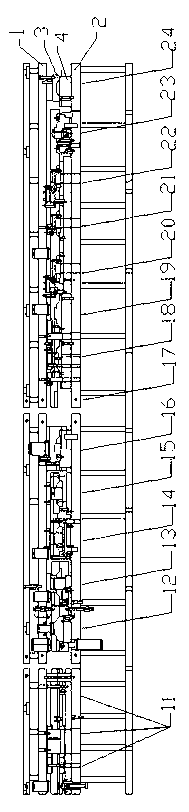

The invention discloses a progressive stamping die for a round float valve. The die comprises an upper die body and a lower die body, wherein the upper die body comprises an upper die base, an upper base plate, an upper clamping plate, a stop plate and a stripper plate, the lower die comprises a lower die base, a lower base plate and a lower die plate, an air port puncturing male die body, a primary punching male die body, a trimming male die body, a secondary punching male die body, a composite male die body, a valve leg puncturing male die body, a valve leg forming male die body, an edge forming male die body, an upper valve leg forming male die body and a cut-forming male die body are fixed on the upper clamping plate, and an air port punching female die body, a primary punching female die body, a trimming female die body, a secondary punching female die body, a composite female die body, a valve leg puncturing female die body, a valve leg forming female die body, an edge forming female die body, an upper valve leg forming female die body and a cut-forming male die body are fixed on the lower die plate. The invention further discloses a round float valve stamping technology. According to the technology, a steel belt is conveyed into the progressive stamping die for the round float valve in a step-by-step mode to conduct progressive stamping. According to the progressive stamping die for the round float valve and the stamping technology, round float valve production efficiency is high and cost is low.

Owner:WUXI HUACHENG PETROCHEM EQUIP

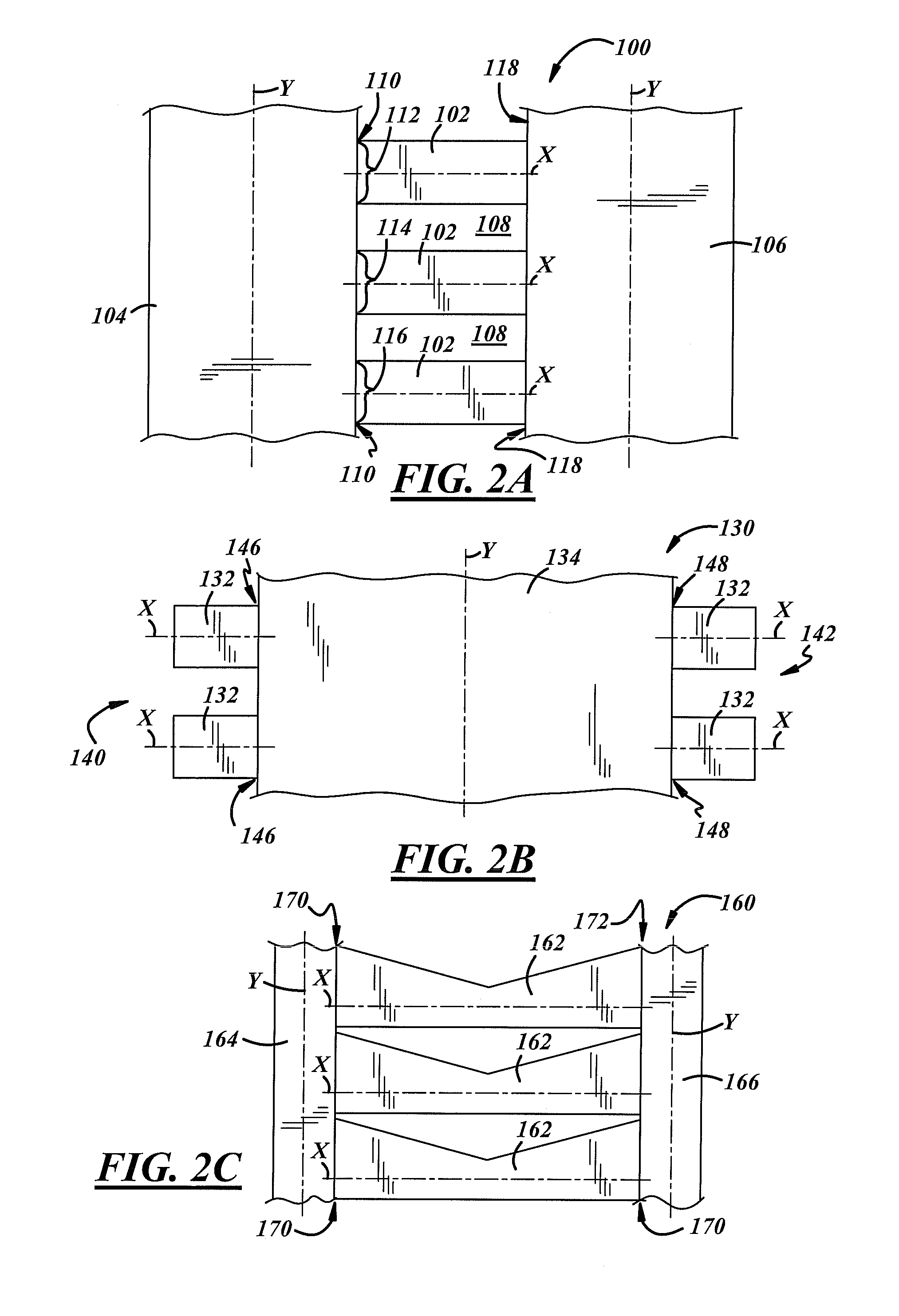

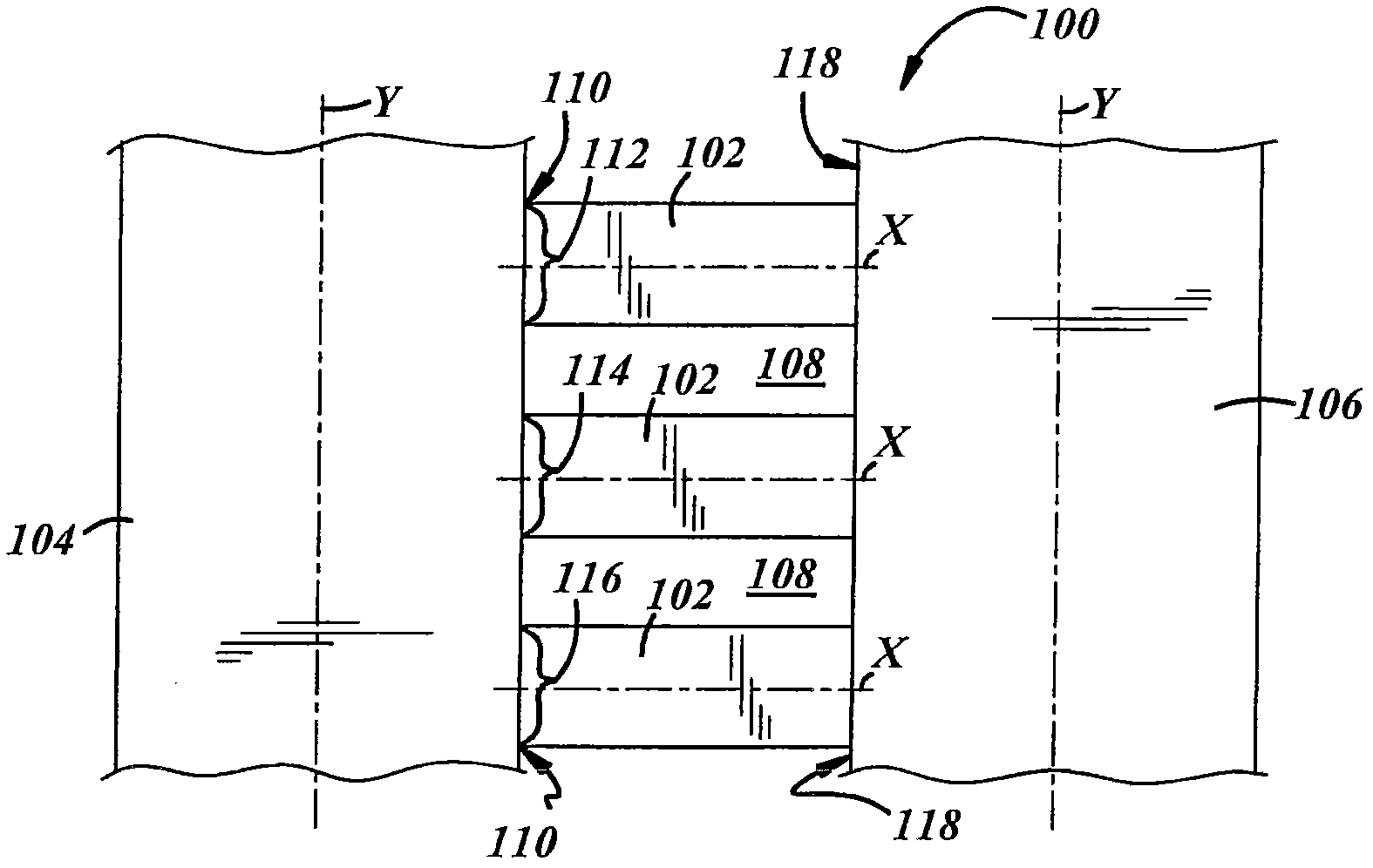

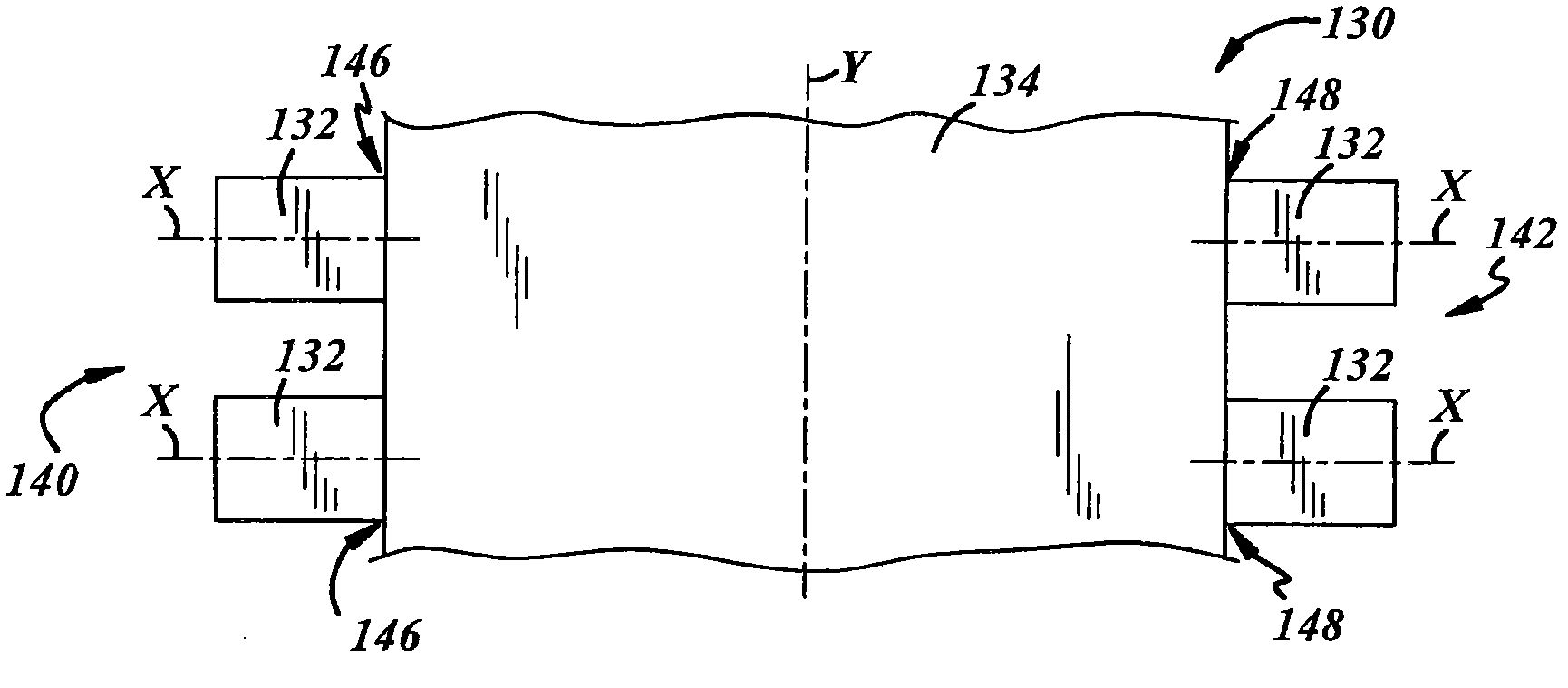

Metal forming process and welded coil assembly

InactiveCN102131597AWelding with roller electrodesWelding/soldering/cutting articlesMetal forming processMetal

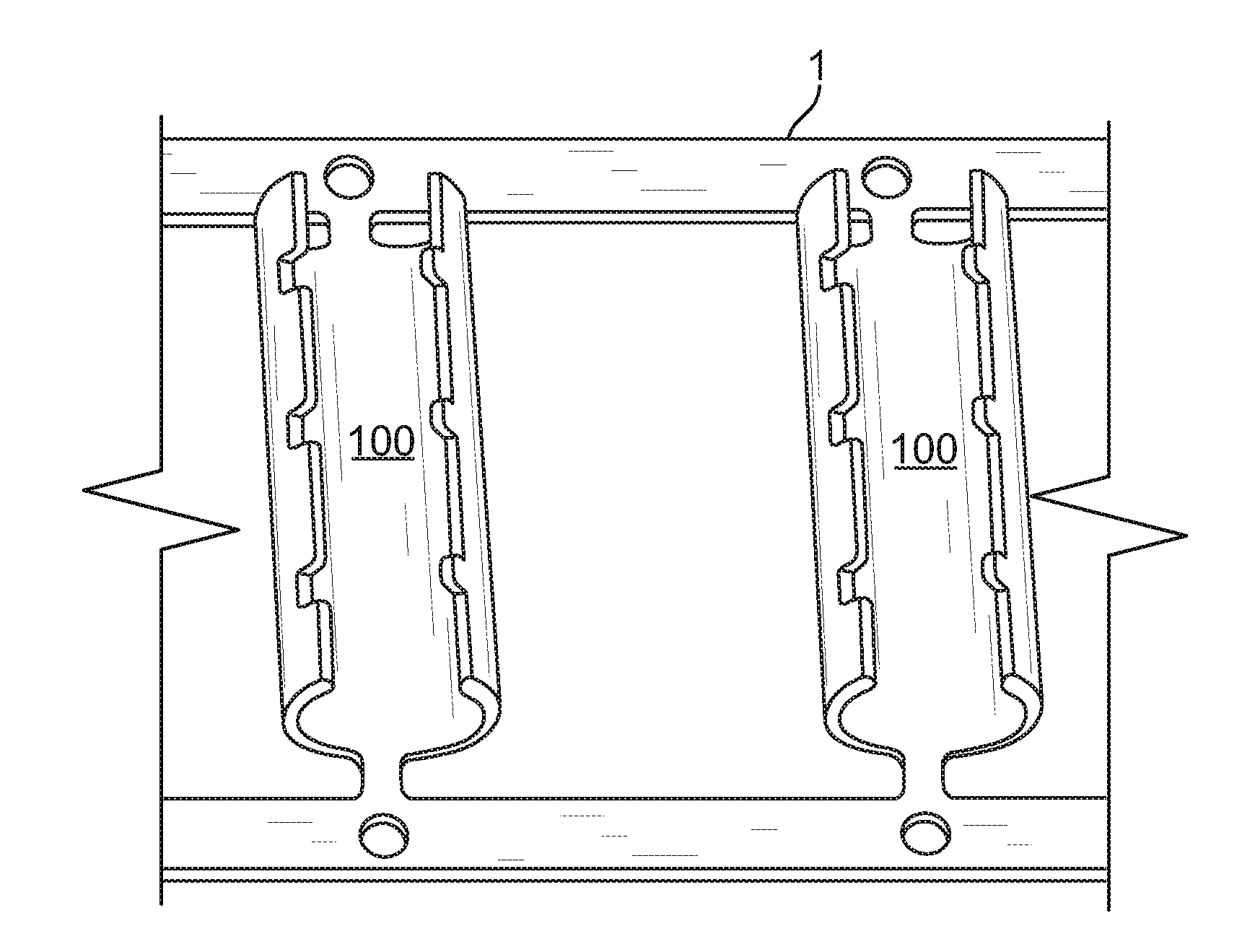

A metal forming process and welded coil assembly (100, 130, 160) that may be used to form complex metal components in a manner that is efficient, reduces scrap material, and maintains the structural integrity of the components. Generally, a number of individual metal blanks (102, 132, 162) are welded to one or more sheet metal coils (104, 106, 134, 164, 166) in order to produce a welded coil assembly. The metal blanks may be welded along the length of the inner sides of two sheet metal coils, or the metal blanks may be welded along the length of the outer sides of a single sheet metal coil, to cite a couple of possibilities. The welded coil assembly can then be fed through a progressive stamping apparatus (180) or other machine to create a complex metal part (188, 190, 198, 200).

Owner:SHILOH IND INC

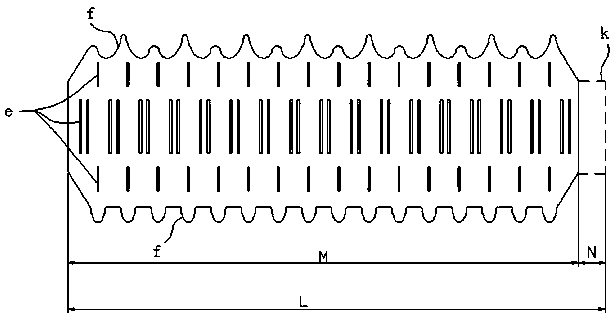

Method for stamping multi-station progressive die

InactiveCN103357761AReduce manufacturing difficultyReduce manufacturing costShaping toolsElectric controlStamping process

The invention discloses a method for stamping a multi-station progressive die. Structure waste materials, process waste materials and various forming which need to be removed of a strip of a product to be stamped are divided into multiple characteristic units according to a stamping process, the length of the characteristic unit with the most occurrence number in the characteristic units in a feeding direction is set as a step pitch, multi-station progressive stamping is carried out on strip feeding through the step pitch, the processing of other characteristic units are controlled and stamped through electric control stamping pins arranged at different process positions, when the strip is sent to a certain process position, the electric control stamping pin corresponding to the process position carries out stamping, and therefore when feeding is carried out through the set step pitch, the characteristic units of the strip are gradually processed, the strip is cut off finally, and stamping is completed to obtain the product. Through the adoption of the die designed through the method, the total length of the die can be controlled around 1m, die materials are saved, the manufacturing difficulty, the manufacturing cost and the manufacturing period of the die are reduced, and the manufacturing precision of the product is improved.

Owner:HUNAN COMM POLYTECHNIC

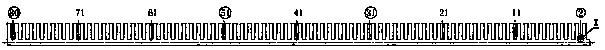

Real time on-line detection method for progressive stamping belt material pace and detector

InactiveCN102553972AAct as active safety protectionHigh detection sensitivityMetal working apparatusCouplingProgrammable logic controller

The invention discloses a general real time on-line detection method for a progressive stamping belt material pace and a detector. Belt material pace feeding acts on a swing rod of the detector, the swing rod is fixed at the front end of a rotating shaft, the rear end of the rotating shaft is connected with a rotating coder through a coupler, and linear movement of the belt material pace feeding is converted into the circumferential movement of the rotating coder. The rotating coder sends a signal to a programmable logic controller (PLC) which displays a value on a touch screen in real time. A measured value is compared with a set value simultaneously: when the measured value is larger than the set value, a machine tool is controlled to stop, and when the measured value is not larger than the set value, the device is normally operated. Under the conditions of large principal vectors and high speed production, the detector can display and detect the belt material pace in real time and enable the machine tool to be automatically stopped under abnormal conditions so as to avoid the condition of mould damage caused by out of tolerance of the pace. The application of the real time on-line detection method for the progressive stamping belt material pace and the detector can enable detection sensitivity and accuracy to be high and enable generality to be strong.

Owner:JIANGSU SUNWAY GROUP

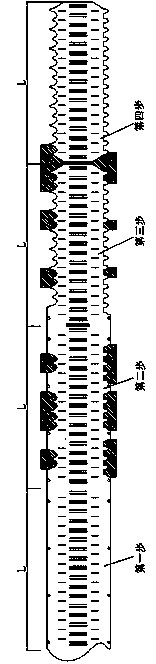

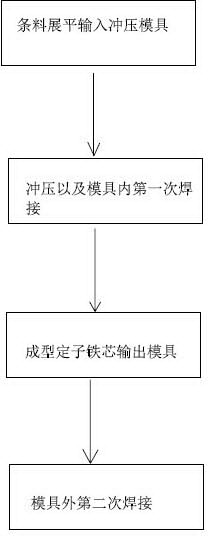

Process for manufacturing straight-bar stator cores

ActiveCN104348312AEasy to separate from each otherReduce processManufacturing stator/rotor bodiesSingle plateEngineering

The invention discloses a process for manufacturing straight-bar stator cores. The process comprises the following steps of stamping a bar material into required stamped plates by using a progressive stamping die, and simultaneously welding the stamped plates into an iron core with certain thickness through laser in the die; welding the rest soldering points on the exterior of the die; finally forming the required products. Pre-welding is realized in the stamping die for the first time, and procedures are effectively reduced; in the stamping procedure, a welding groove gap of the (N+1)th plate is particularly stamped, so that the size of the welding groove of the plate is greater than the size of a welding groove of a conventional stator single plate, and the (N+1)th plate cannot be welded in the welding process in the die, so that stator cores welded in the die can be easily separated from each other, setting on laser welding equipment is not required, the welding yield is greatly improved and the cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

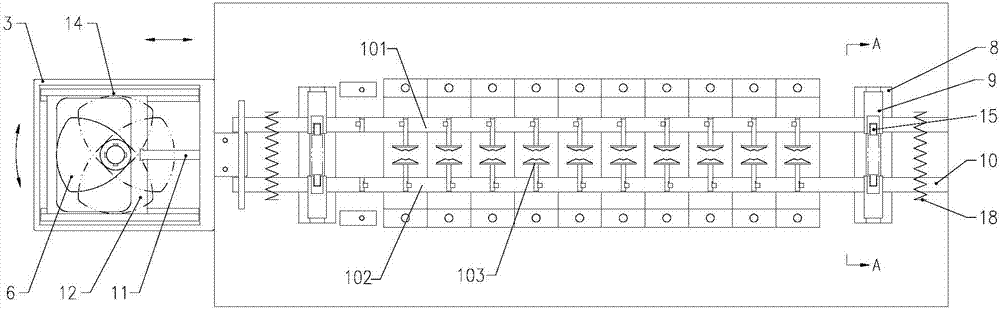

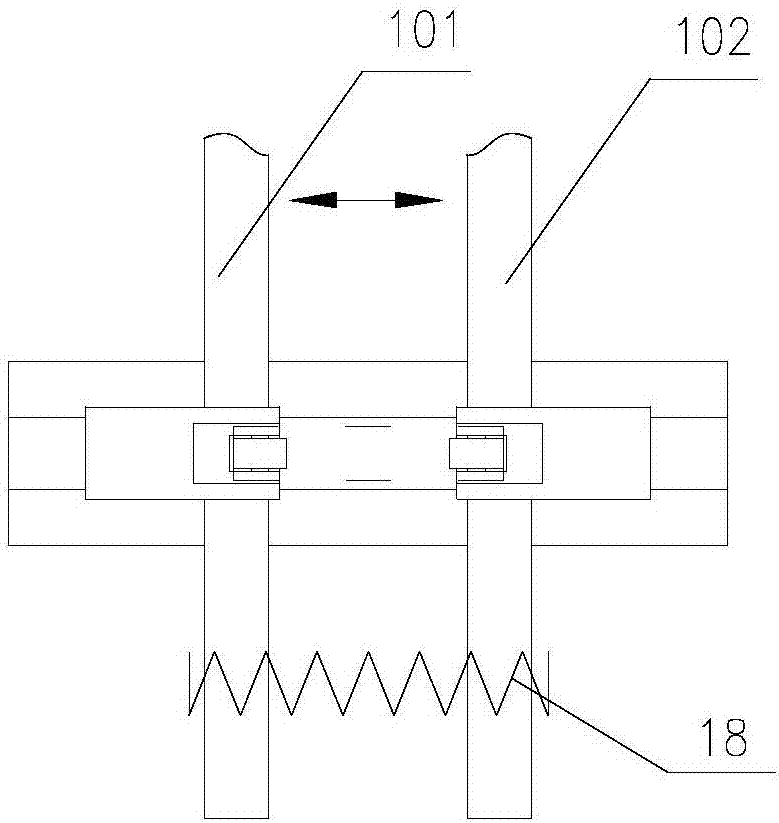

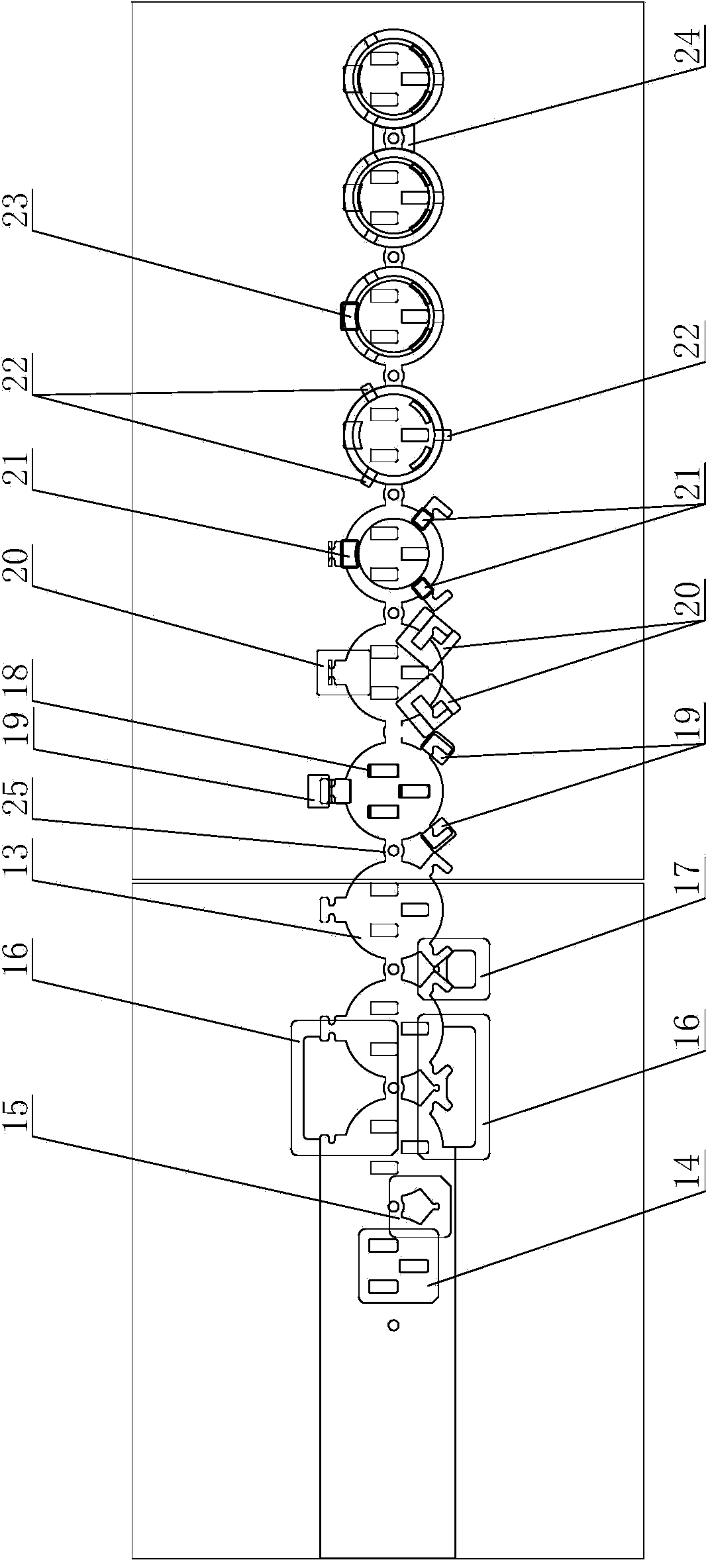

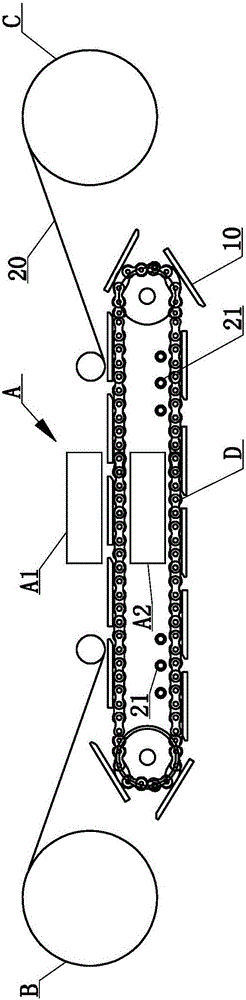

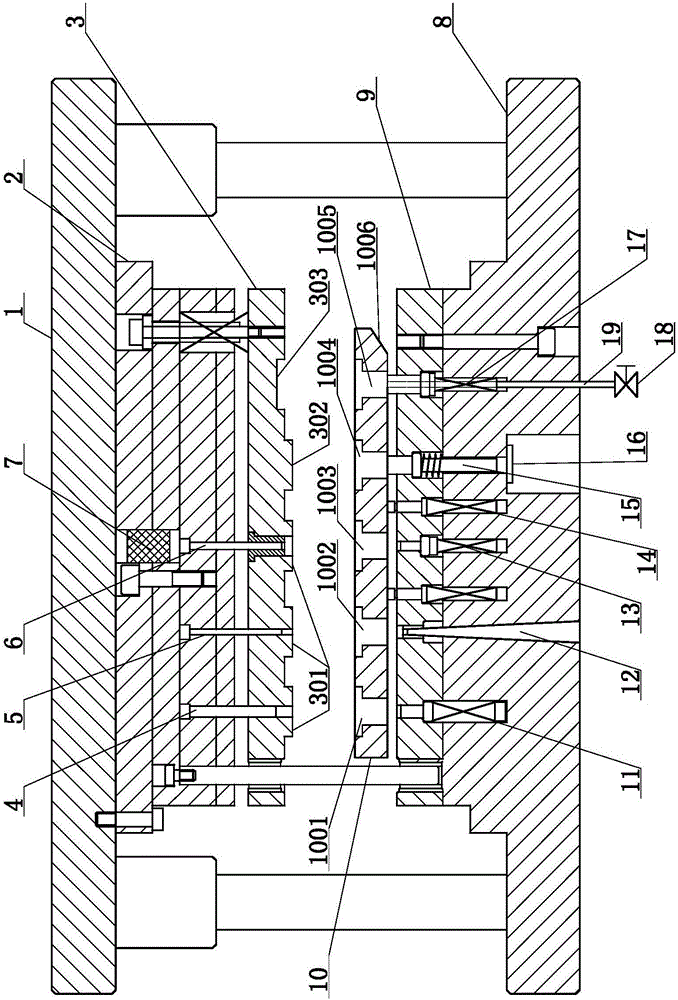

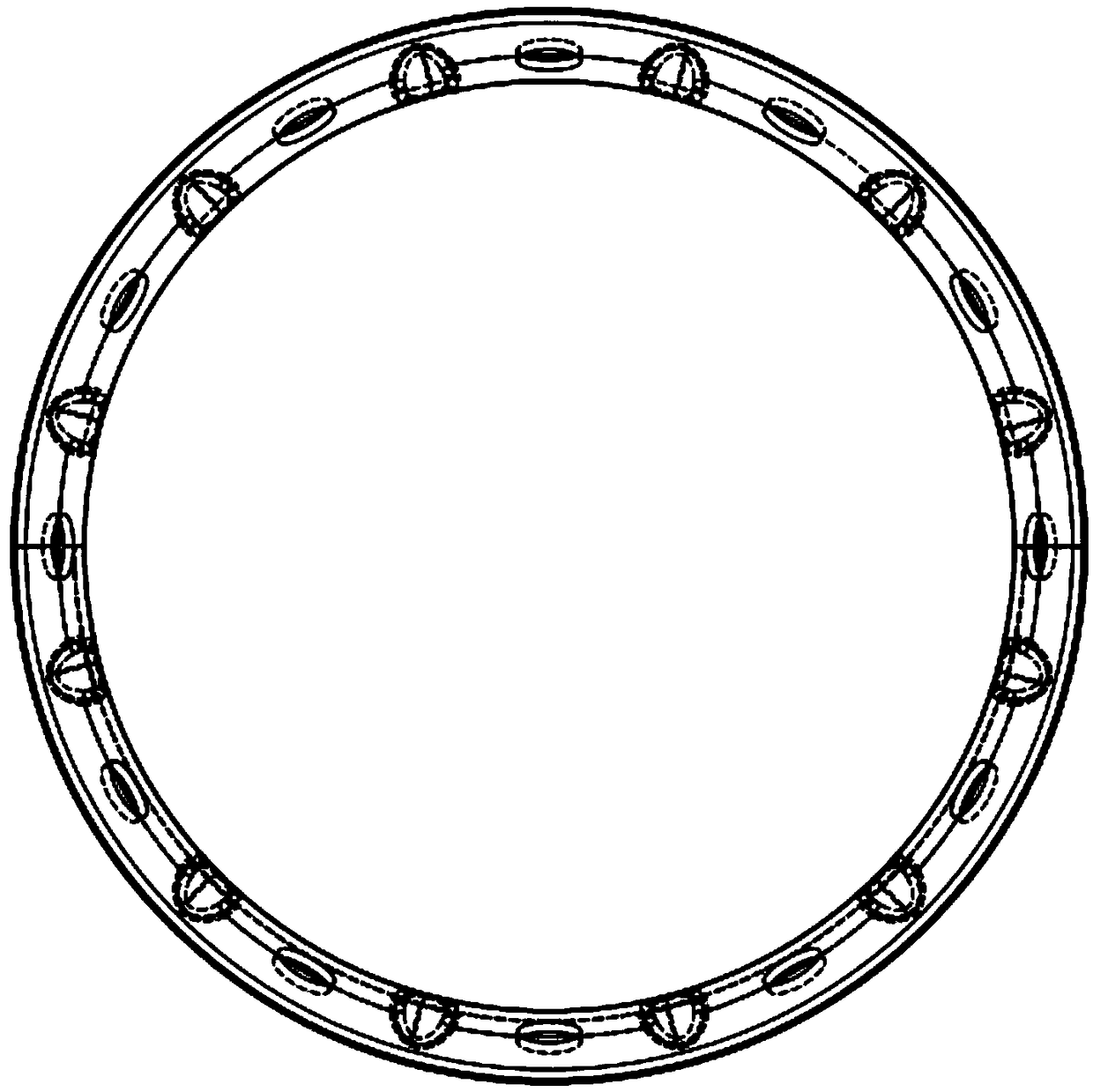

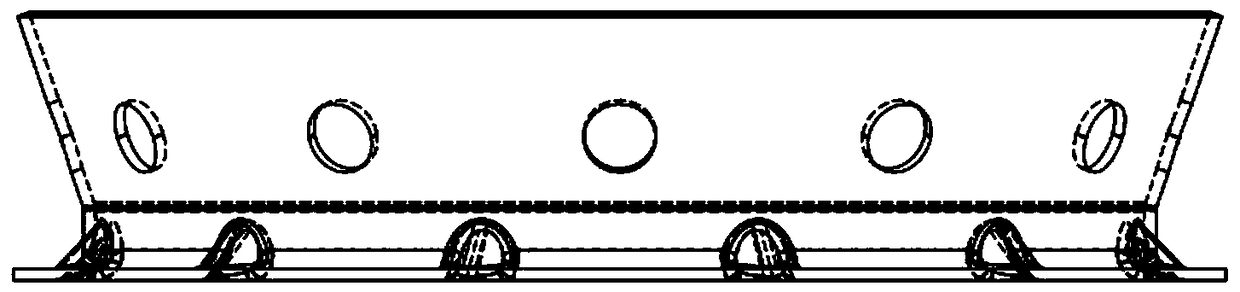

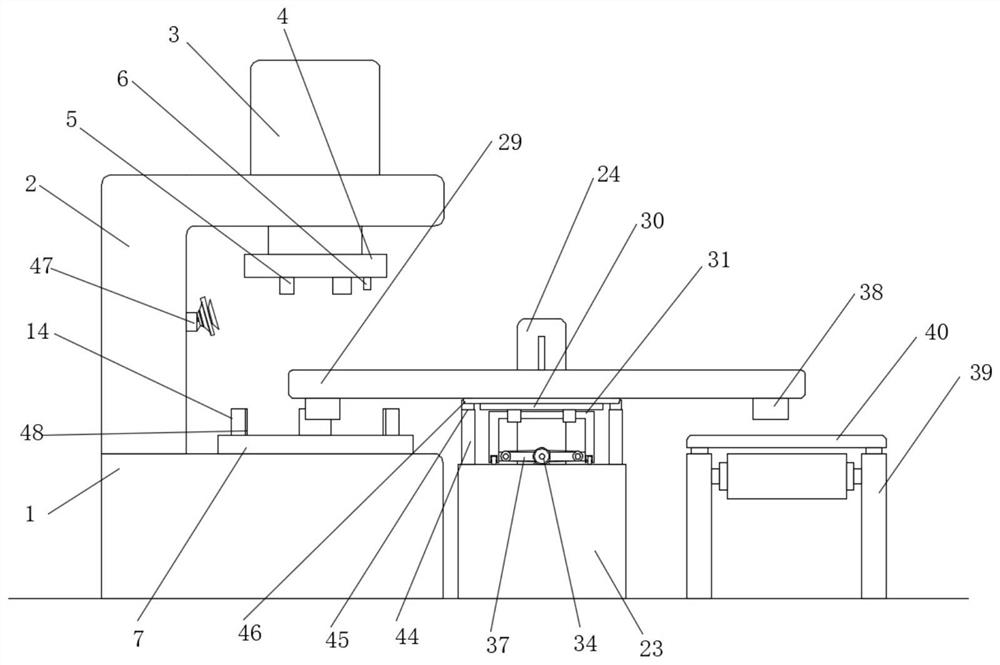

Automatic stamping equipment for thin-walled annular workpieces

ActiveCN105921612AImprove continuityRealize processingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses automatic stamping equipment for thin-walled annular workpieces and belongs to the technical field of stamping dies. The automatic stamping equipment comprises a stamping die, wherein the stamping die comprises an upper die part and a lower die part, the upper die part comprises an upper die holder, a connecting plate and a stamping plate, and the lower die part comprises a lower die holder and a lower die plate which are fixed and mounted together; a drawing male die, a punching male die and a shaping male die are sequentially mounted on the connecting plate of the upper die part, stamping convex rings surrounding all of the drawing male die, the punching male die and the shaping male die are arranged on the stamping plate, and a drawing elastic ejector, a blanking hole and a shaping elastic ejector are sequentially and correspondingly arranged on the lower die plate of the lower die part; and a molding die plate mounted on a circulating chain is arranged between the stamping plate and the lower die plate, and a drawing female die, a blanking female die and a shaping female die are sequentially arranged on the molding die plate. The automatic stamping equipment can realize the processing of the annular workpieces with different cross areas on the progressive stamping die, improves the production efficiency and the finished product rate and is widely applied to the manufacture of the annular workpieces with different cross areas.

Owner:河北昊天滤清器制造有限公司

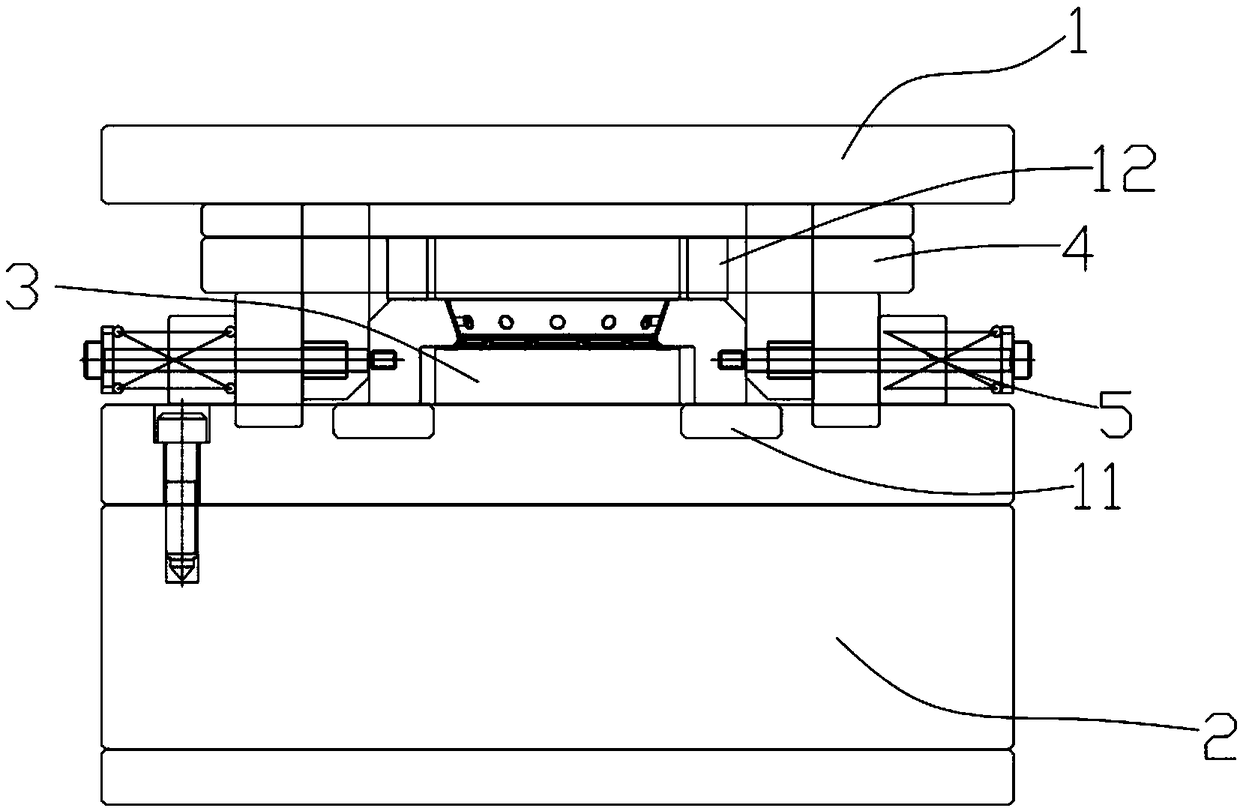

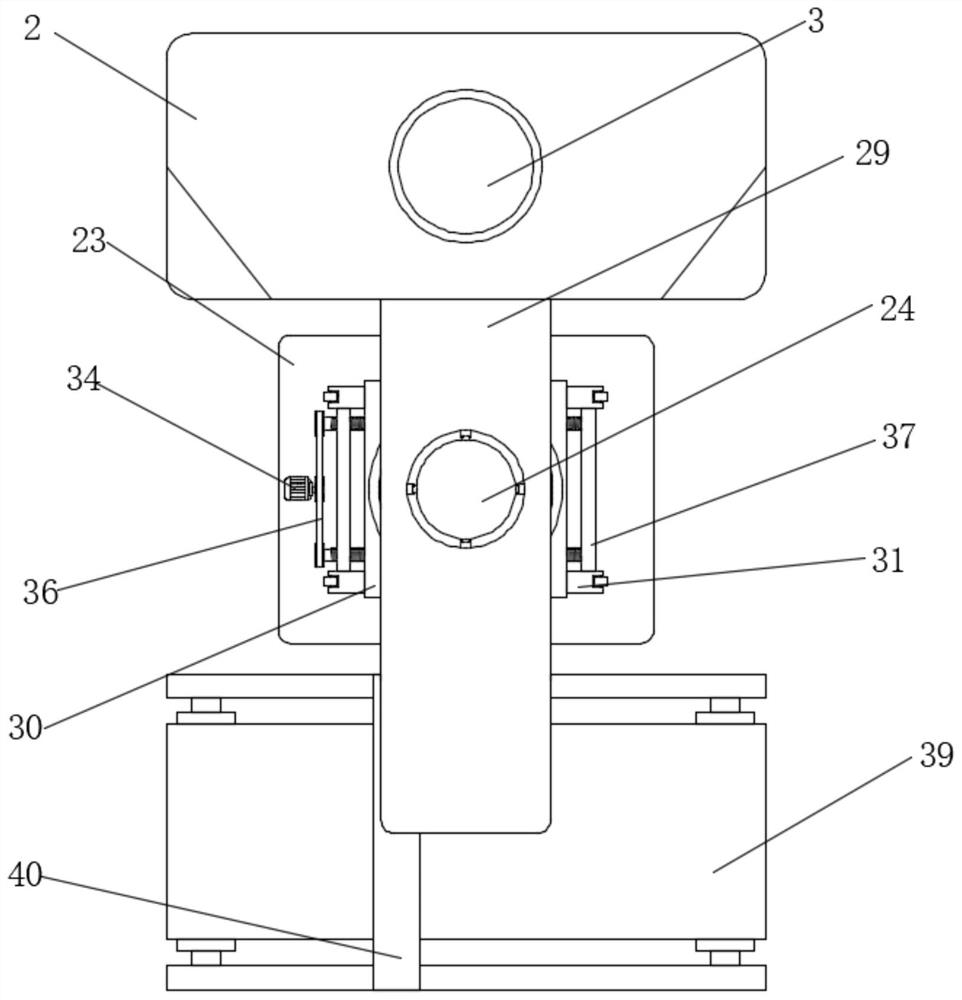

Side stamping progressive die for automotive annular circular disc part and side stamping process

ActiveCN108994174AWill not deformImprove efficiencyShaping toolsVehicle componentsCircular discPunching

The invention provides a side stamping progressive die for an automotive annular circular disc part. The side stamping progressive die comprises a stamping die, a twelve-hole side stamping sizing dieand a flanging die which are arranged in sequence. The invention further discloses a side stamping process of the side stamping progressive die for the automotive annular circular disc part. The sidestamping process comprises the following steps: S1, raw material stamping: taking a strip-shaped metal plate, and stamping the strip-shaped metal plate to form a circular disc-shaped sheet through a stamping machine; and S2, stretching punching: stamping through a stamping shaping part of a progressive stamping die, punching the center of the circular sheet, and forming a middle cylindrical bulgepart and an annular part at the bottom of the bulge part. The side stamping progressive die is provided with the twelve-hole side stamping sizing die used for simultaneously punching 12 holes, so thatthe side stamping progressive die can simultaneously punch 12 holes in the side wall of a thin workpiece, and therefore the efficiency is improved. Meanwhile, the side stamping progressive die applies force simultaneously to the surroundings of the workpiece, so that the workpiece cannot deform. As the mechanism capable of sizing at the same time is arranged, the side stamping progressive die canensure that one stamping realizes the simultaneous completion of punching and preliminary sizing, and therefore the working efficiency is improved.

Owner:苏州万荣汽配科技有限公司

Heat exchanger plates and methods for manufacturing heat exchanger plates

InactiveUS20060169444A1Stationary conduit assembliesHeat exchange apparatusEngineeringHeat exchanger

Owner:DANA CANADA CORP

Progressive stamping die

The invention discloses a progressive stamping die. The stamping die comprises a stamping die body and a bottom die body; the stamping die body is located over the bottom die body; a stamping plate isfixedly arranged on the lower portion of the stamping die body, and a plurality of punches are fixedly installed on the lower portion of the stamping plate; the lengths of the punches are increased from left to right; a plurality of stamping cavities are formed in the upper surface of the bottom die body, and the depths of the stamping cavities are increased sequentially from left to right; a reset spring is fixedly arranged at the bottom of each stamping cavity, and the top of each reset spring is connected with a stamping die plate. In this way, progressive stamping forming of products canbe completed, so that the stamping precision is favorably improved, and the production efficiency is improved.

Owner:SUZHOU HUICHENG PRECISION MOLD

Progressive stamping die for radiator support

ActiveCN111014451AGuaranteed machining accuracyNo height dimensional instabilityShaping toolsStructural engineeringIndustrial engineering

The invention discloses a progressive stamping die for a radiator support, wherein the progressive stamping die is stable in part flanging size and high in yield. According to the die, workpieces aresymmetrically punched and formed from a raw material plate until a product is cut off and sent out at a last work station; due to the fact that an upper pressing plate is provided with a plurality ofpositioning pins which are used for positioning workpieces and matched with positioning punches in position, and a discharging base is provided with a plurality of positioning pins which are used forpositioning the workpieces and matched with the positioning punches in position, a plate can be accurately positioned on all work stations, and thus the processing precision of all the work stations is guaranteed. Besides, ribbing and line pressing inserts are additionally arranged on an upper die and a lower die in the previous procedure of bending, ribbing and reinforcing are conducted on the product in advance, the situation that the height of the product is not stable in the later procedure of bending and flanging is avoided, and the processing efficiency and the product quality are greatly improved.

Owner:长沙金鸿顺汽车部件有限公司

Method for manufacturing progressive type decorative machine plates via punching

InactiveCN102950865AAvoid crackingAvoid deformationLaminationLamination apparatusPunchingEngineering

Provided is a method for manufacturing progressive type decorative machine plates via punching. The method comprises the following steps: forming an optical solid film upon the substrate; printing patterns upon the optical solid film via flexible and transparent pressing die; and using a radiation source to solidify the optical solid film. Then both the substrate and the optical solid film receive punching processing. The instant stress of processing deformation of the optical solid film and the substrate can be gradually released by two times of the punching of different dies and two-segment type punching of the same die as well as two times of stroke punching / continuous progressive punching processing of the same die, thereby completely avoiding the chapping / deformation of the optical solid film during the processing process, maintaining the completement of the pattern on the surface of the finished products, and ensuring the pattern to be firmly attached to the substrate.

Owner:JIIN MING IND

Three-plate high-speed progressive stamping die

InactiveCN102294405AHigh precisionHigh precision requirementsShaping toolsPetroleum engineeringProgressive stamping

The present invention disclosed a three -board high -speed stamping mold, including: upper board, middle board, lower board, multiple other high structures, multiple spring pre -pressure structures, and multiple balls. There is a compressive plate, the lower template and the lower pad, and the upper plate and the middle plate are set with a fixed plate and upper pad. Due to the use of the mid -to -board and ball -beaded columns, the present invention can improve the accuracy of the stamped workpiece.

Owner:JIANGSU ZEEN TOOLING

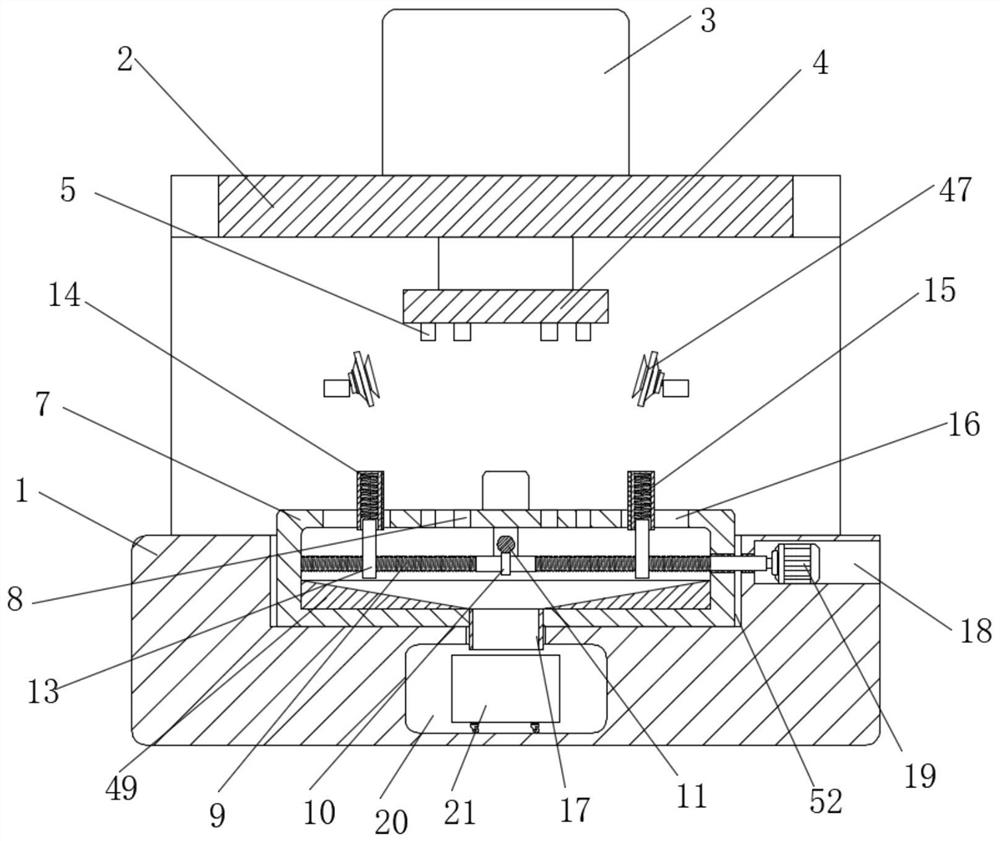

Progressive stamping system for clamping piece of multifunctional electric power meter and stamping process thereof

ActiveCN112845851AAvoid affecting the machining accuracyAvoid displacementMetal-working feeding devicesPositioning devicesHydraulic cylinderElectric machine

The invention belongs to the technical field of electric power meter machining, in particular to a progressive stamping system for a clamping piece of a multifunctional electric power meter and a stamping process thereof, and provides the following scheme. The progressive stamping system comprises a workbench, an L-shaped supporting plate is fixedly connected to the top of the workbench, and a hydraulic cylinder is fixedly connected to the top of the L-shaped supporting plate; and a piston rod of the hydraulic cylinder penetrates through the L-shaped supporting plate and is fixedly connected with an upper stamping plate, and a plurality of stamping heads are distributed at the bottom of the upper stamping plate at equal intervals. The stamping system is simple in structure and convenient to operate, a driving motor is started to drive a first bidirectional lead screw and a second bidirectional lead screw to rotate, then clamping blocks can be driven to move, a workpiece is fixed, the workpiece is prevented from moving during stamping, a collecting box is arranged in the workbench so that leftover materials can be recycled conveniently, in addition, manual operation is not needed in the feeding and discharging process, the probability of production accidents is reduced, and the machining efficiency can be improved.

Owner:中电装备山东电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com