Progressive stamping die

A progressive stamping and stamping die technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of slow production efficiency, poor precision, high scrap rate, etc., and achieve the effect of speeding up production efficiency and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

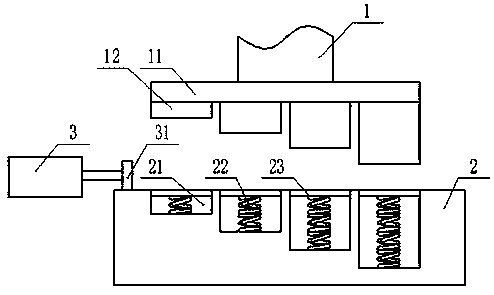

[0016] See figure 1 , The embodiment of the present invention includes:

[0017] A progressive stamping die, comprising: a stamping die 1 and a bottom die 2, the stamping die 1 is located directly above the bottom die 2;

[0018] A punching plate 11 is fixedly installed under the punching die 1, and a plurality of punches 12 are fixedly installed under the punching plate 11, and the length of each punch 12 increases from left to right;

[0019] The upper surface of the bottom mold 2 is provided with a plurality of stamping cavities 21, the depth of each stamping cavity 21 increases from left to right, and the bottom of each stamping ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com