Metal forming process and welded coil assembly

A metal forming and coil technology, applied in metal processing, metal processing equipment, welding equipment, etc., can solve problems such as not optimizing applications and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

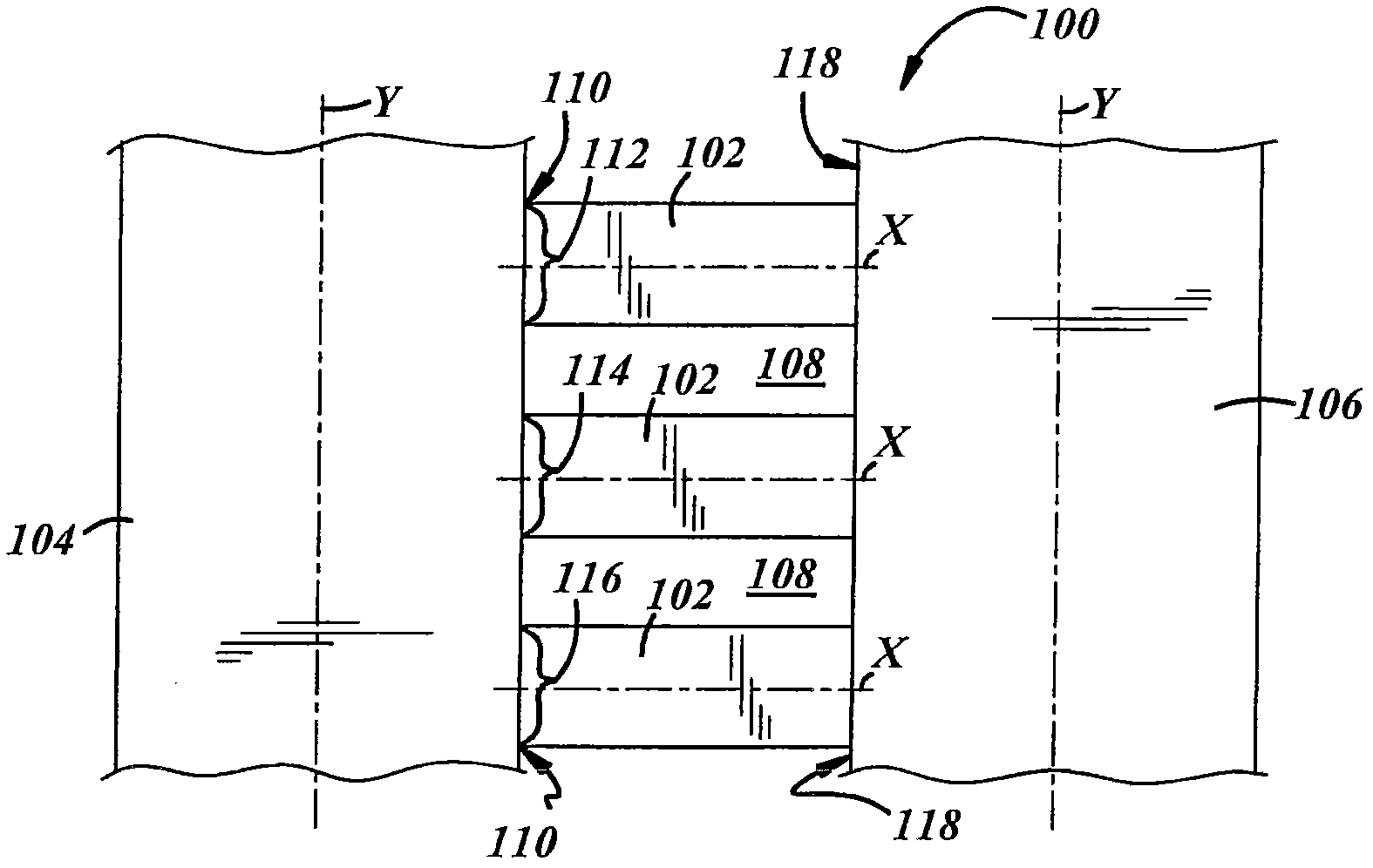

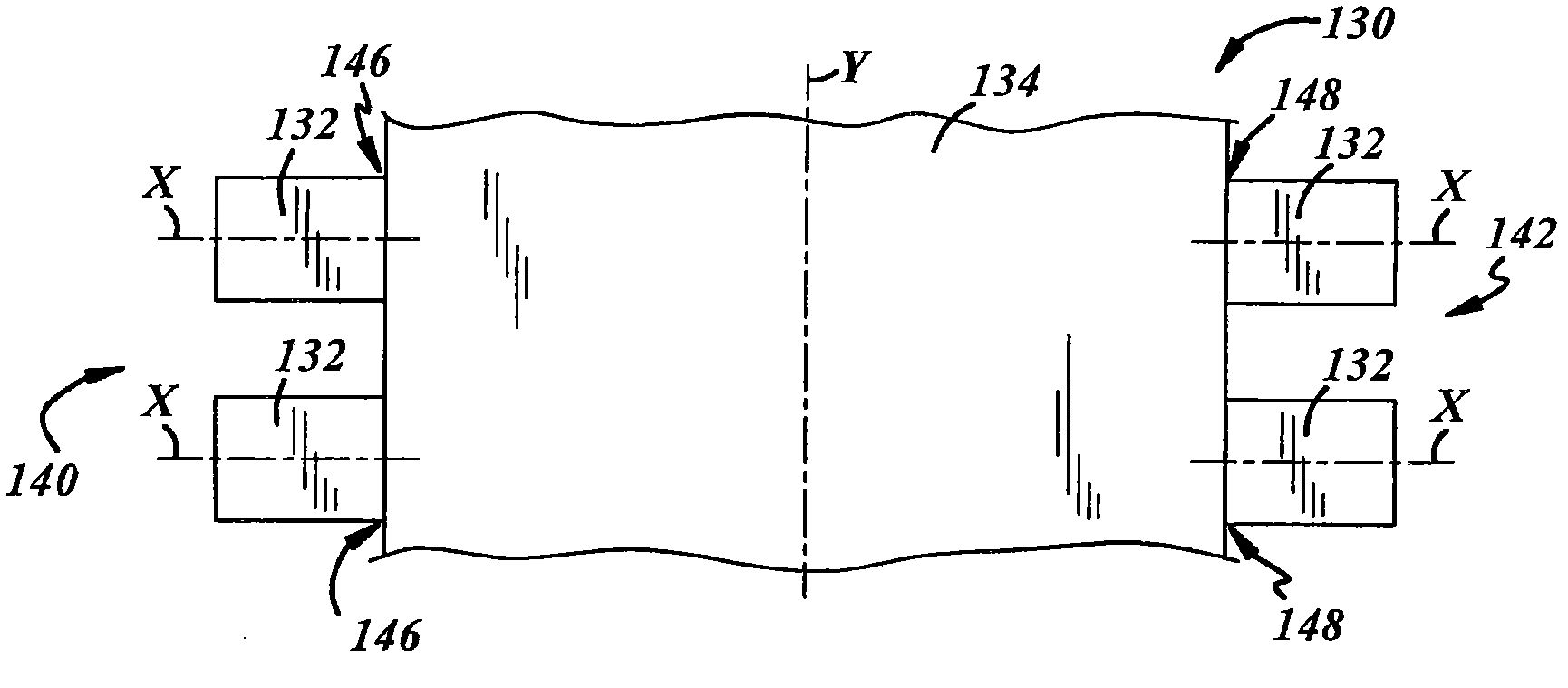

[0016] The metal forming process described herein can be used to form complex metal parts in an effective manner that reduces the amount of scrap metal while maintaining the structural integrity of the complex metal parts. Typically, multiple individual metal blanks are welded to one or more sheet metal coils to produce welded coil assemblies. The welded coil assembly (in coiled or uncoiled form) can then be fed through progressive stamping equipment to form complex metal parts. Although the following description is provided in the context of forming exemplary automobile parts, it should be understood that the metal forming process and welded coil assembly described below may alternatively be used to form non-automotive parts, including for aircraft, boats, ships, Parts of agricultural equipment, RVs, and facilities are not listed here.

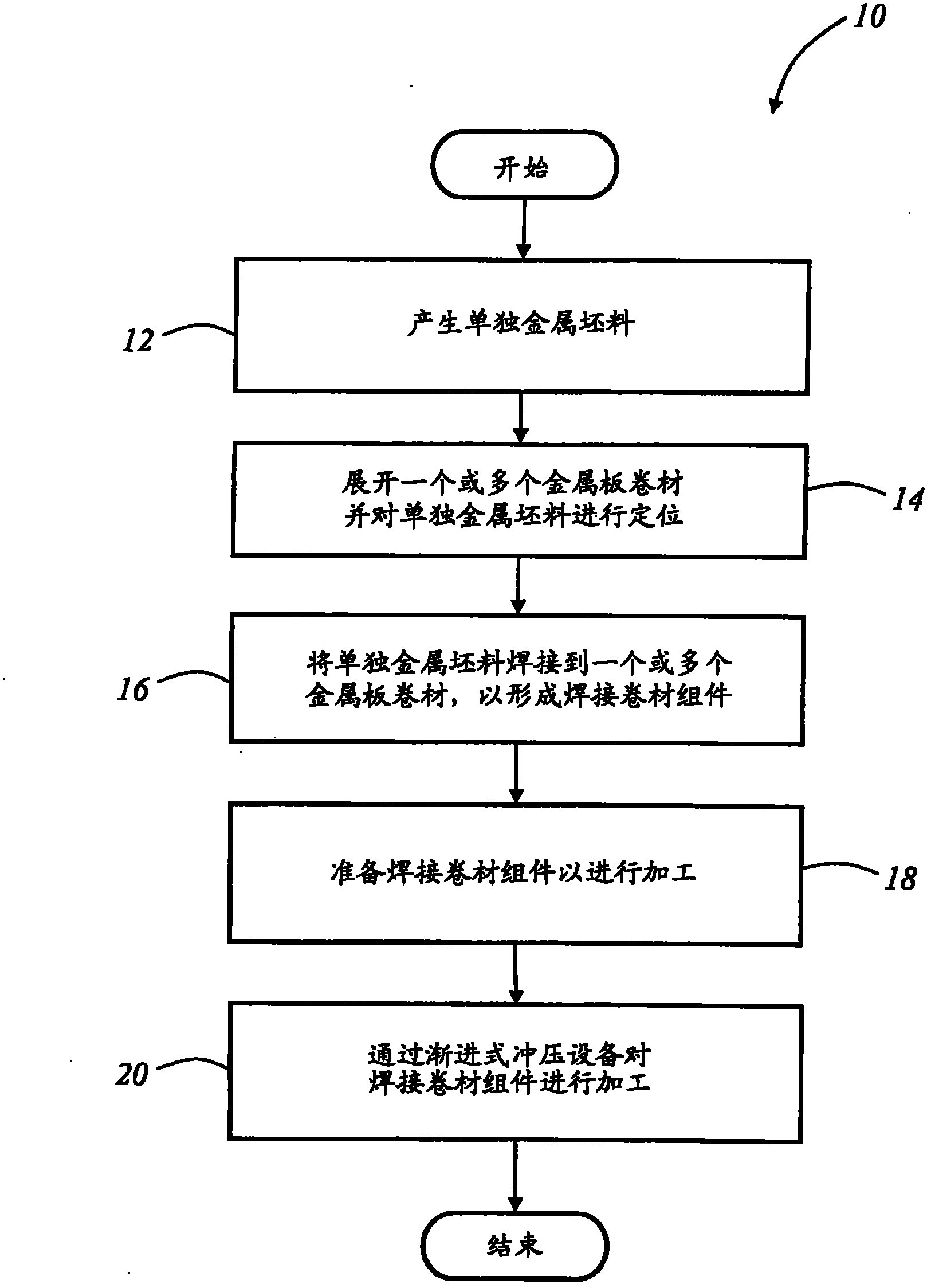

[0017] reference figure 1 , Which shows an exemplary metal forming process 10, which can be used to manufacture automotive parts process, in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com