Lubricant formulation for high temperature metal forming processes

a technology of high temperature metal forming and lubricant formulation, which is applied in the direction of metal rolling arrangement, manufacturing tools, shaping tools, etc., can solve the problems of ineffective petrochemical based lubricants, and achieve the effect of improving lubricity and good adhesion to the surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]For ease of reference and understanding, the following description is set forth with respect to a simplified exemplary metal formation process. Importantly, it is to be understood that the lubrication system of the present invention is in no way limited to such a formation process. Rather, it is contemplated and intended that the lubrication system will be broadly applicable to any number of elevated temperature metal formation practices.

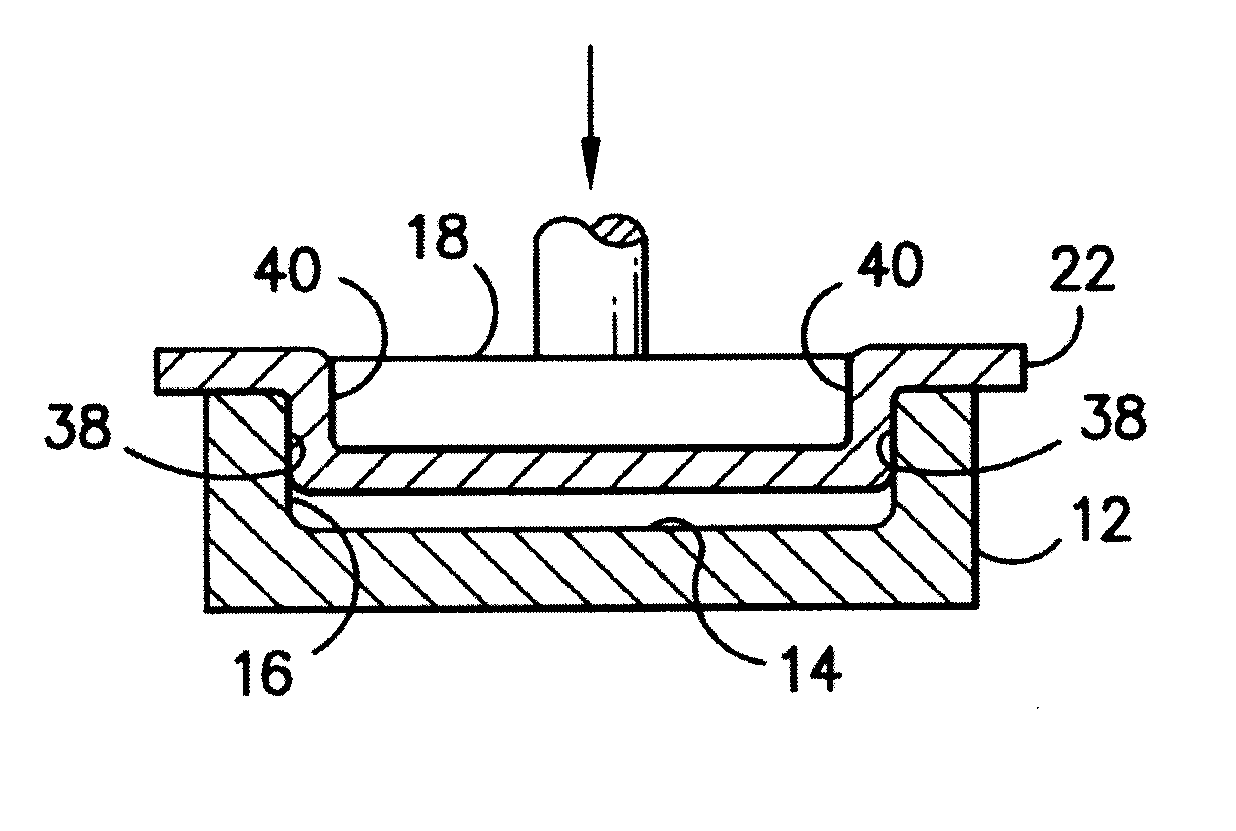

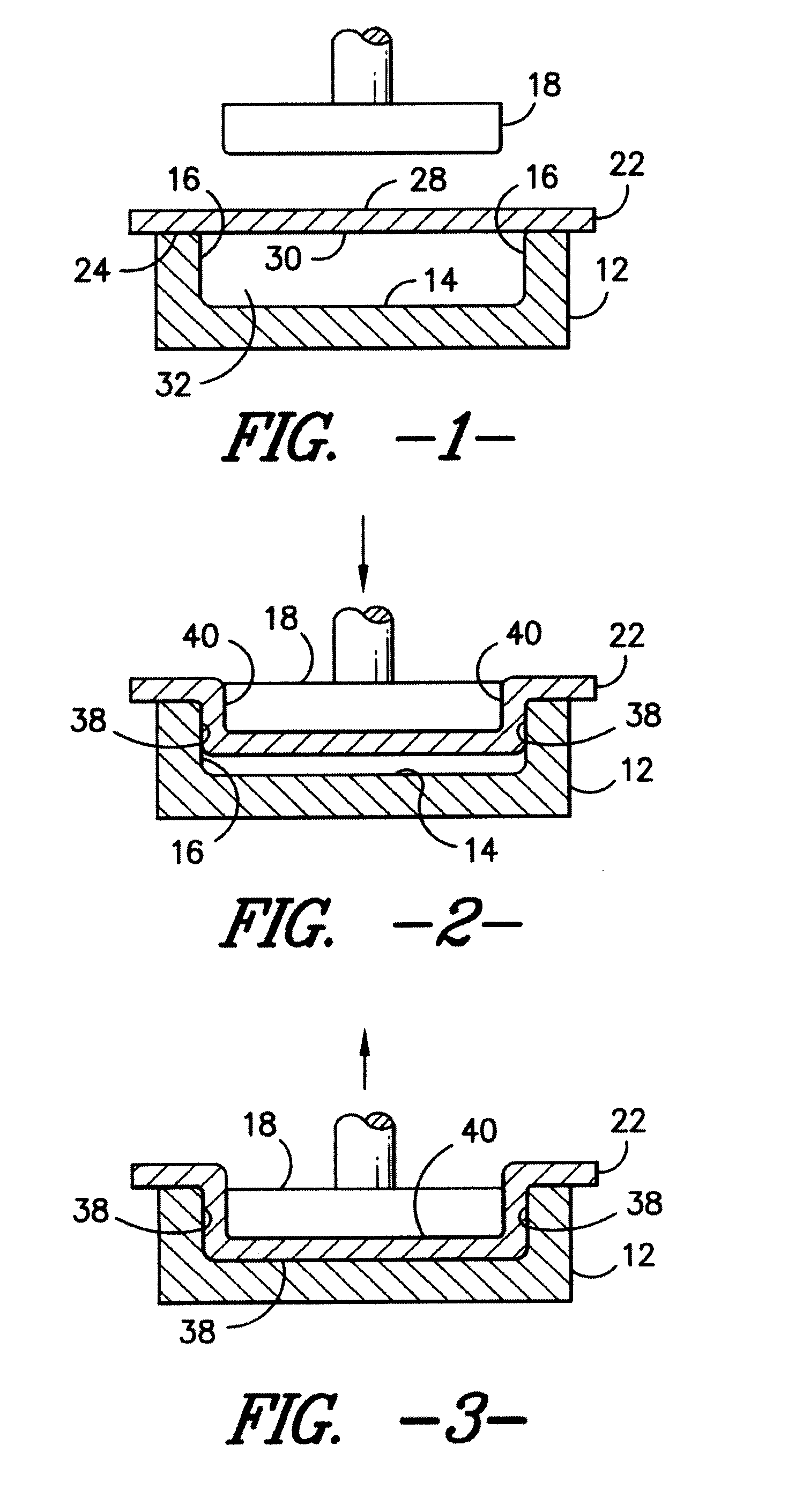

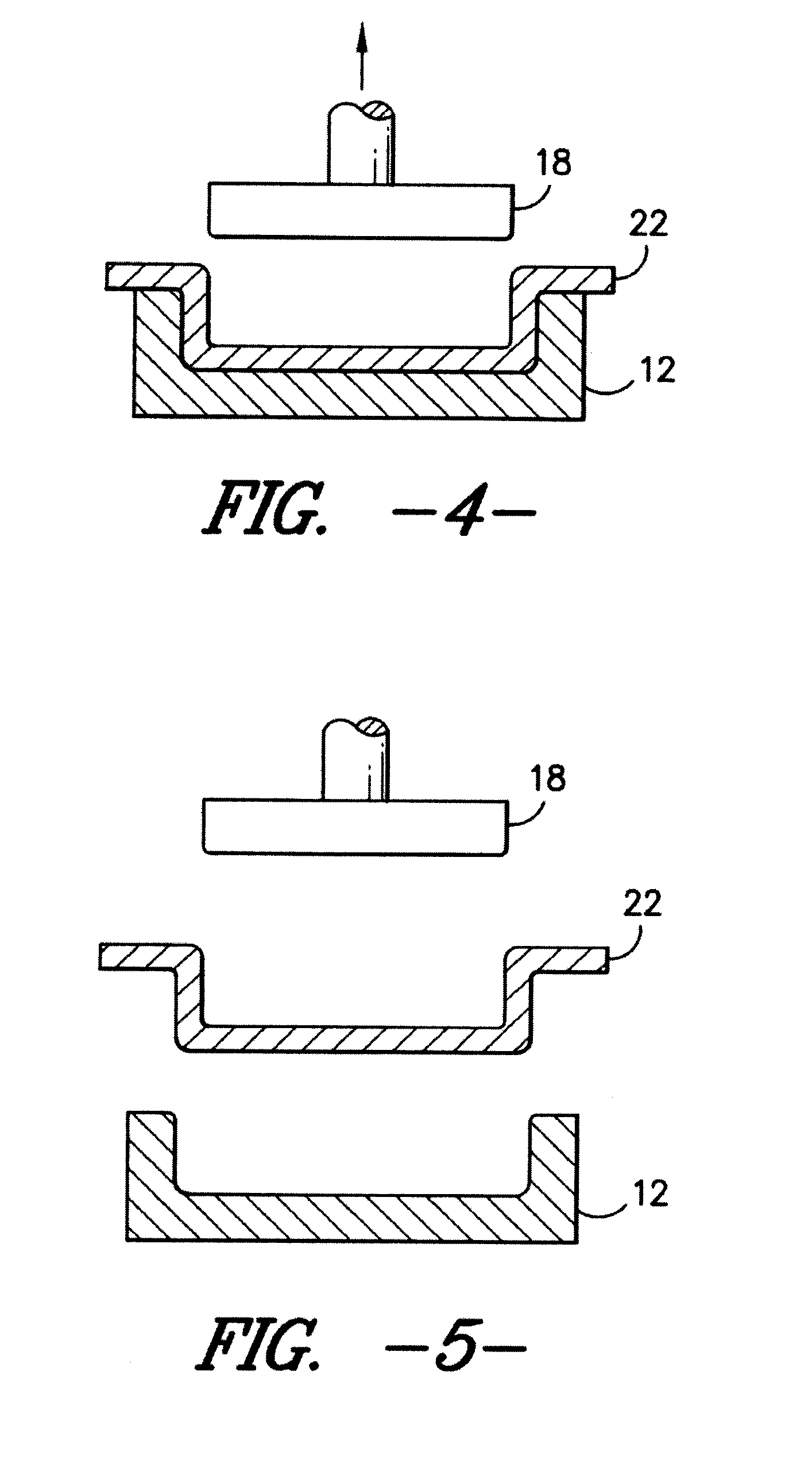

[0013]Reference will now be made to the various drawings wherein to the extent possible, like elements are designated by corresponding reference numerals in the various views. FIGS. 1-5 illustrate schematically a simplified exemplary so called “warm forming” practice utilizing male and female formation tool members. In the illustrated practice a female member 12 includes a mold cavity 32, bottom surface 14, and two opposing wall surfaces 16. A metal blank 22 is placed on top of the female member such that a portion of the bottom surface 30 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| plastic | aaaaa | aaaaa |

| coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com