High-strength lightweight aggregate concrete and preparation process thereof

A technology of lightweight aggregate concrete and concrete, which is applied in the field of construction engineering, can solve the problems of unsuitable strength requirements and low strength of lightweight concrete, and achieve the effects of improving surface bonding, easy implementation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

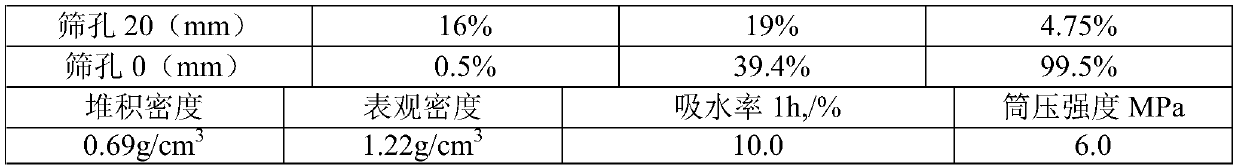

Image

Examples

Embodiment 1

[0060] A preparation method of high-strength lightweight aggregate concrete comprises the following steps:

[0061] Soak the ceramsite in water for 50 minutes, remove the ceramsite, and drain the surface water;

[0062] Put 429kg of ceramsite, 121kg of crushed stone and 85.5kg of water after draining into the mixer, and stir for 15s to obtain the first mixture;

[0063] Then 411kg of cement, 36kg of slag, 39kg of coal gangue powder, 50kg of floating beads and 615kg of pottery sand were put into the mixer and mixed with the first mixture, and stirred for 30 seconds to obtain the second mixture;

[0064] Finally, put 85.5kg of water and 11.5kg of retarder polycarboxylate superplasticizer into the mixer, mix with the second mixture, and stir for 110s to obtain the concrete mixture; pour the concrete mixture into shape, and maintain , to produce high-strength lightweight aggregate concrete.

Embodiment 2

[0066] A preparation method of high-strength lightweight aggregate concrete comprises the following steps:

[0067] Soak the ceramsite in water for 60 minutes, remove the ceramsite, and drain the surface water;

[0068] Put 492kg of ceramsite, 153kg of gravel and 90kg of water drained into the mixer, and stir for 25s to obtain the first mixture; then mix 414kg of cement, 48kg of silica fume, 40kg of coal gangue powder, 55kg of floating beads and 621kg of volcanic slag Continue to put into the blender and mix with the first mixture, stir for 40s to obtain the second mixture;

[0069] Finally, 90kg of water and 11.9kg of retarder polycarboxylate superplasticizer are put into the mixer, mixed with the second mixture, and stirred for 130s to obtain the concrete mixture; the concrete mixture is poured into shape, maintained, High-strength lightweight aggregate concrete can be produced.

Embodiment 3

[0071] A preparation method of high-strength lightweight aggregate concrete comprises the following steps:

[0072] Soak the ceramsite in water for 70 minutes, remove the ceramsite, and drain the surface water;

[0073] Put 625.6kg of ceramsite, 54.4kg of gravel and 88kg of water drained into the mixer, and stir for 20 seconds to obtain the first mixture;

[0074] Then 417kg cement, 39kg fly ash, 44kg slag, 60kg floating beads and 627kg coal slag were put into the mixer and mixed with the first mixture, and stirred for 50s to obtain the second mixture;

[0075] Finally, put 88kg of water and 12.3kg of retarder polycarboxylate superplasticizer into the mixer, mix with the second mixture, and stir for 120s to obtain the concrete mixture; the concrete mixture is poured into shape, maintained, High-strength lightweight aggregate concrete can be produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com