Flame-retardant reinforced ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

A technology of ABS material and brominated flame retardant, which is applied in the field of flame retardant reinforced ABS material and its preparation, can solve the problems of not having high strength and high flame retardant performance at the same time, and high cost, so as to improve the surface bonding force and ensure the strength Performance requirements, the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

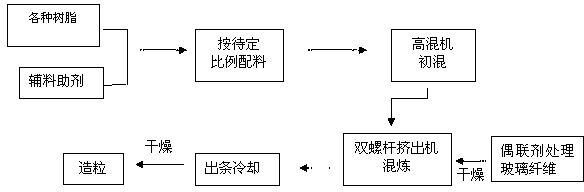

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, unit: kg

[0039] 40 parts of acrylonitrile-styrene (SAN), 10 parts of ABS high rubber powder, 29 parts of glass fiber, 5 parts of styrene-maleic anhydride (SMA), 12 parts of decabromodiphenylethane as brominated flame retardant, 3 parts of antimony trioxide, 0.10 part of polytetrafluoroethylene as anti-dripping agent, 0.3 part of antioxidant 1010, 0.4 part of vinyl bisstearamide (EBS) as lubricant, and 0.2 part of coupling agent KH550.

Embodiment 2

[0040] Embodiment 2, unit: kg

[0041]Acrylonitrile-styrene (SAN) 35 parts, ABS high rubber powder 14 parts, glass fiber 30 parts, styrene-maleic anhydride (SMA) 5 parts, brominated flame retardant 12 parts, antimony trioxide 3 parts, The anti-dripping agent is 0.15 parts of polytetrafluoroethylene, 0.3 parts of antioxidant 168, 0.40 parts of lubricant zinc stearate, and 0.15 parts of coupling agent KH560.

Embodiment 3

[0042] Embodiment 3, unit: kg

[0043] Acrylonitrile-styrene (SAN) 45 parts, ABS high rubber powder 12 parts, glass fiber 20 parts, styrene-maleic anhydride (SMA) 5 parts, brominated flame retardant 15 parts, antimony trioxide 3, antimony The dripping agent is 0.15 parts of polytetrafluoroethylene, 0.3 parts of antioxidant, 0.5 parts of lubricant calcium stearate, and 0.2 parts of coupling agent KH550.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com