Side stamping progressive die for automotive annular circular disc part and side stamping process

A disc part and ring technology, which is applied in the field of side punching continuous die and side punching process of automobile annular disc parts, can solve the problems of reduced efficiency, long punching time, product punching deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

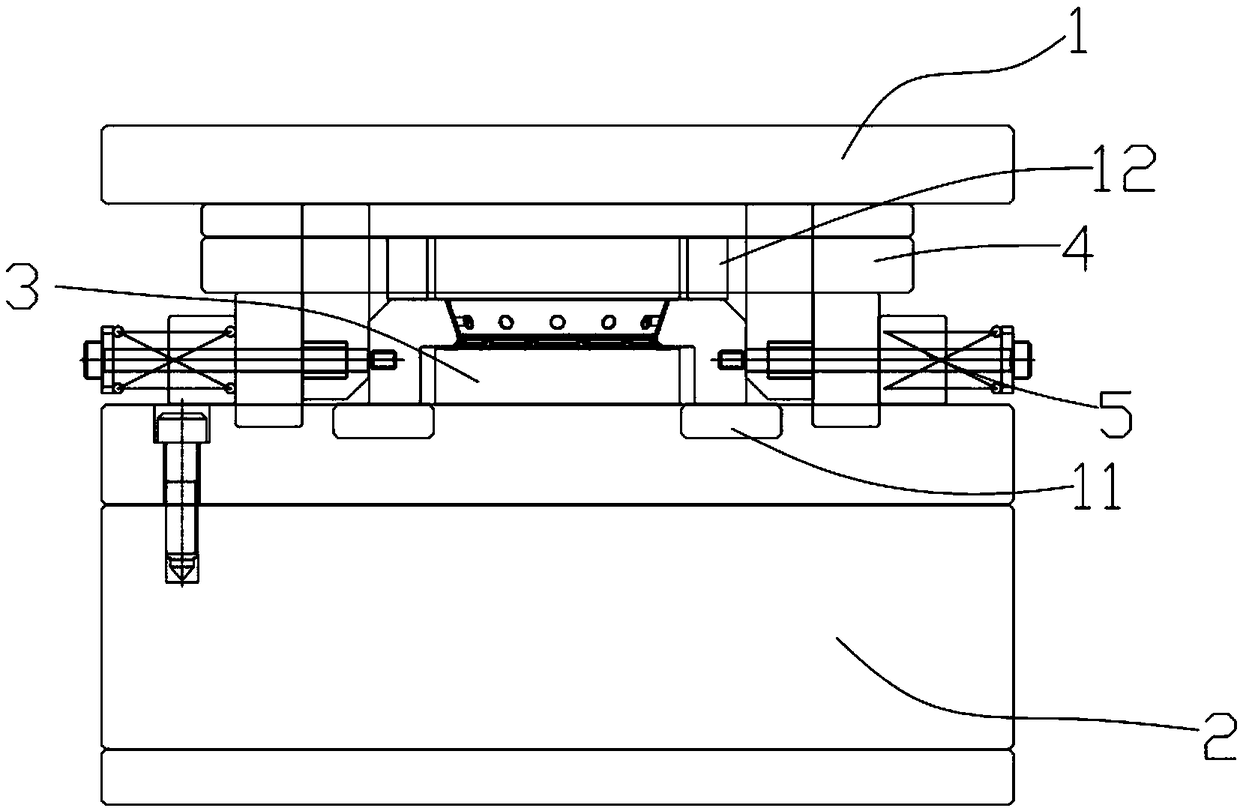

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

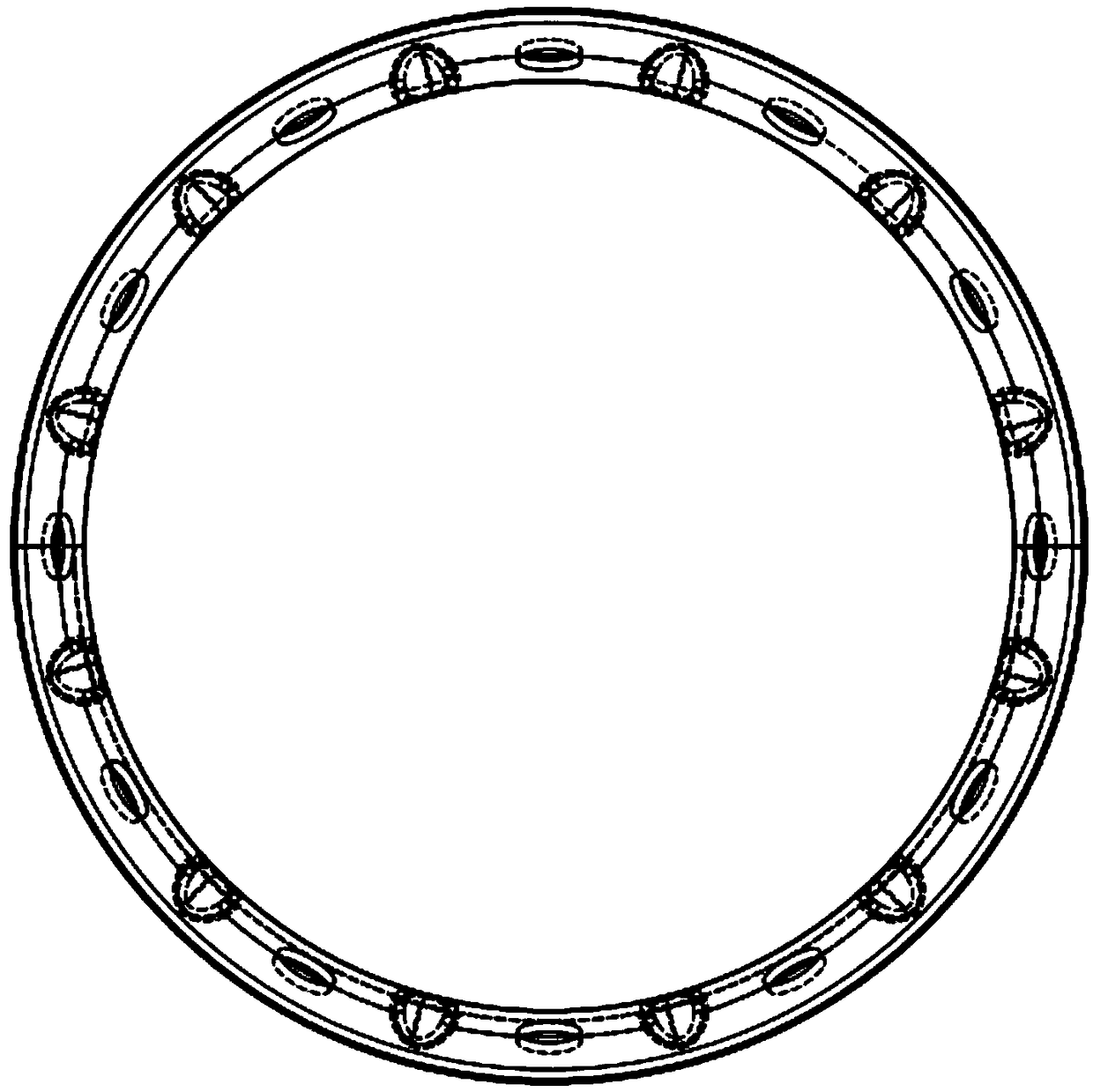

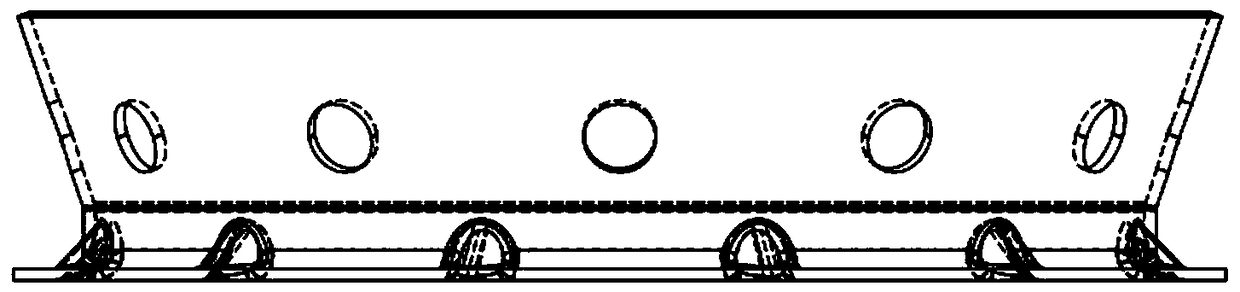

[0027] Such as Figure 3 ~ Figure 8 As shown, the present invention proposes a continuous die for the side punching of an automobile ring disc, including a punching die, a twelve-hole side punching shaping die, and a flanging die arranged in sequence.

[0028] The twelve-hole side punch shaping die includes a first upper template 1 and a first lower template 2, a first placement table 3 is arranged between the first upper template 1 and the first lower template 2, and the first placement The platform 3 is used to place products, the lower part of the first upper template 1 is connected with a positioning platen 4, and the positioning platen 4 is pressed on the first placing platform 3, and the first placing platform 3 is provided with a column shaped body 13, the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com