Process of bending laminated metal sheet

a technology of laminated metal and bending process, which is applied in the field of shaping or bending laminated metal webs or blanks, can solve the problems of unreliable or even unacceptable, unreliable sheet metal stamping or progressive die press, and unexpectedly difficult sheet metal shaping or bending, so as to eliminate the sliding of laminate sheets, reduce the thickness of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

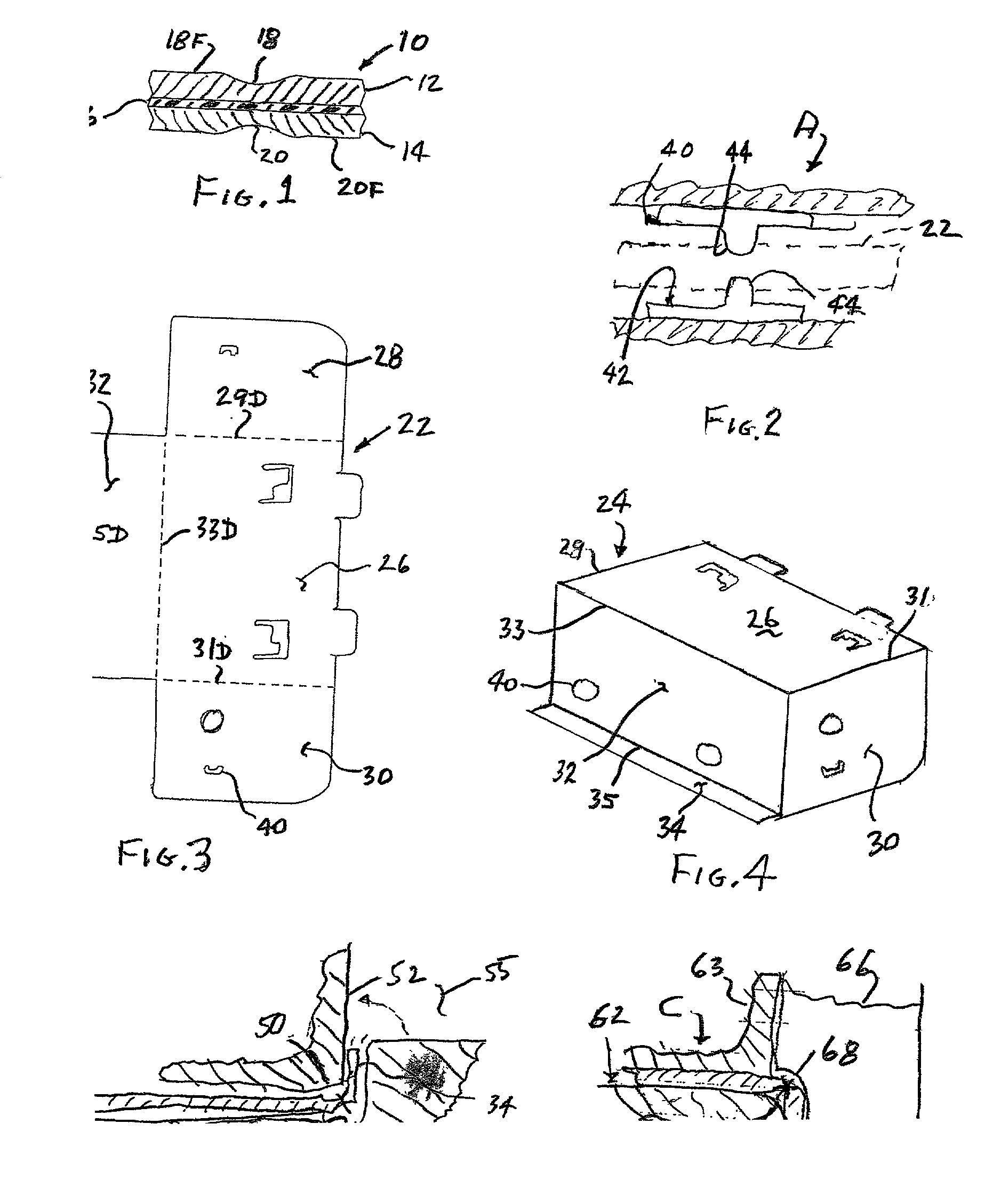

[0019] FIG. 1 shows a sectional view of a piece 10 of laminated metal, being comprised of two metal sheets 12, 14 that sandwich and are held separated but relative to one another by a core 16 of a bonding elastic or vicoelastic material. The figure also shows typical crease regions or depressions 18, 20 formed in the opposite faces 18F, 20F of the laminated metal piece, according to the teachings of this invention.

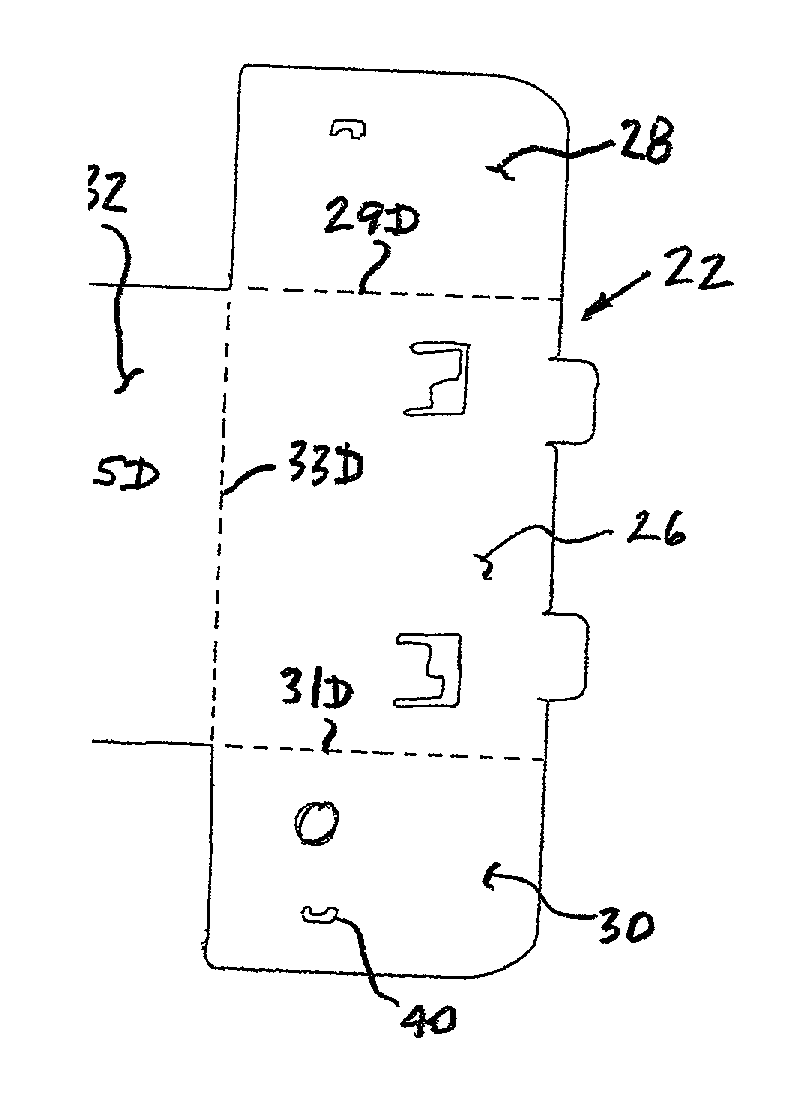

[0020] More specifically, FIG. 3 shows in plan view a blank 22 which might be folded to three-dimensional piece-part 24 illustrated in FIG. 4. The piece part 24 has main panel 26, and opposed side panels 28, 30 (30 being shown only in FIG. 4), and side panel 32 folded 90 degrees from the main panel across corners 29, 31, 33 respectively; and further has flange panel 34 folded 90 degrees from the side panel 32 across corner 35.

[0021] The invention provides that prior to bending the fold panels 28, 30, 32, 34 relative to its adjacent hinged panel, crease regions or depressio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com