Bushing, piece with bushing, or method of producing

a technology of bushings and pieces, applied in the direction of shaft assemblies, mechanical equipment, rotary machine parts, etc., can solve the problems of not being adapted to the creation, requiring dies and tooling, and the dovetails of adjacent surfaces cannot slide into each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]For the purposes of promoting and understanding the invention and principles disclosed herein, reference is now made to the preferred embodiments illustrated in the drawings, and specific language is used to describe the same. It is nevertheless understood that no limitation of the scope of the invention is thereby intended. Such alterations and further modifications in the illustrated devices and such further applications of the principles disclosed as illustrated herein are contemplated as would normally occur to one skilled in the art to which this disclosure relates.

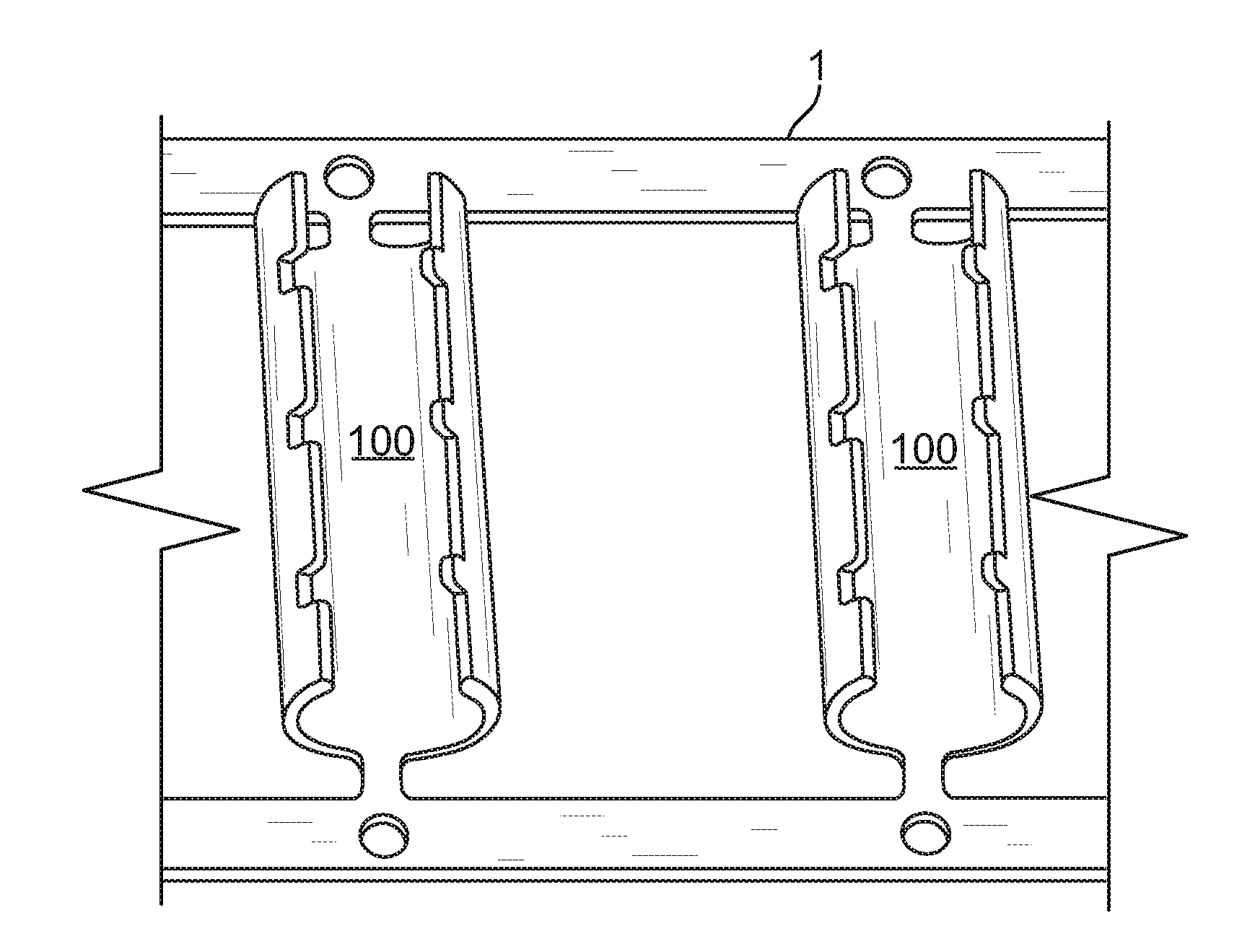

[0025]Progressive die stamping is a metal working method where a long strip of metal also described as a carrying web 1 illustrated at 7A is slid and guided over a series of stations or steps where different operations are performed on a portion of the carrying web. In one embodiment the carrying web 1 is made of a C1050 heat treated to RC 43-48 Zinc per GMW3044 6U48 / 0 0.00025″ Clear Chromate fed into a machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com