Continuous die for brake wheel covers

A brake wheel cover, continuous technology, applied in the field of stamping molds, can solve the problems of unfavorable product stamping, complex mold structure, low production efficiency, etc., and achieve the effects of improving production efficiency, reducing production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

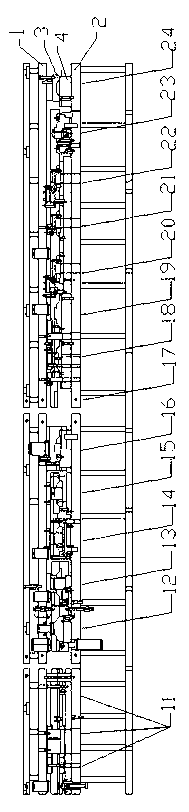

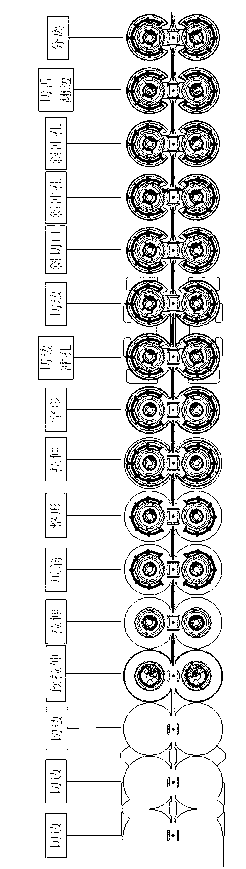

[0013] A kind of brake wheel housing continuous mold of the present embodiment, as Figure 1 ~ Figure 2 As shown, it includes an upper die base 1 and a lower die base 2 for fixing a continuous multi-station progressive stamping die, and the stamping die includes an upper die 3 and a lower punch 4 that cooperate with each other, and the lower part of the upper die base 1 is provided with There is an upper die 3, and the upper part of the lower die base 2 is provided with a lower punch 4, and the upper die 3 and the lower punch 4 are arranged in sequence according to the stamping process. The stamping die is automatic feeding, and the feeding height of the stamping die is equal. The stamping die comprises three trimming dies 11, one pre-stretching die 12, one stretching die 13, one beading die 14, one shaping die 15, one stretching die 16, and one empty step die 17 according to the stamping process. One side trimming punching die 18, one side trimming die 19, one oblique notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com