Progressive stamping system for clamping piece of multifunctional electric power meter and stamping process thereof

A technology for power meters and snap-fitting parts, which is applied in the field of progressive stamping systems and stamping processes for snap-fit parts, and can solve problems such as displacement of parts to be stamped, production accidents, and inability to recover in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

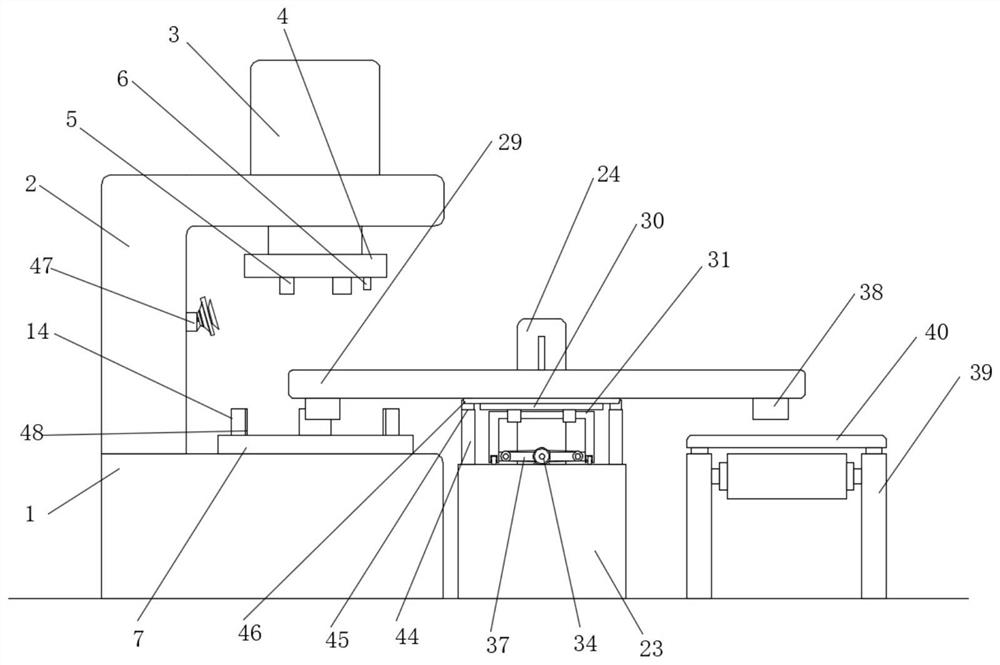

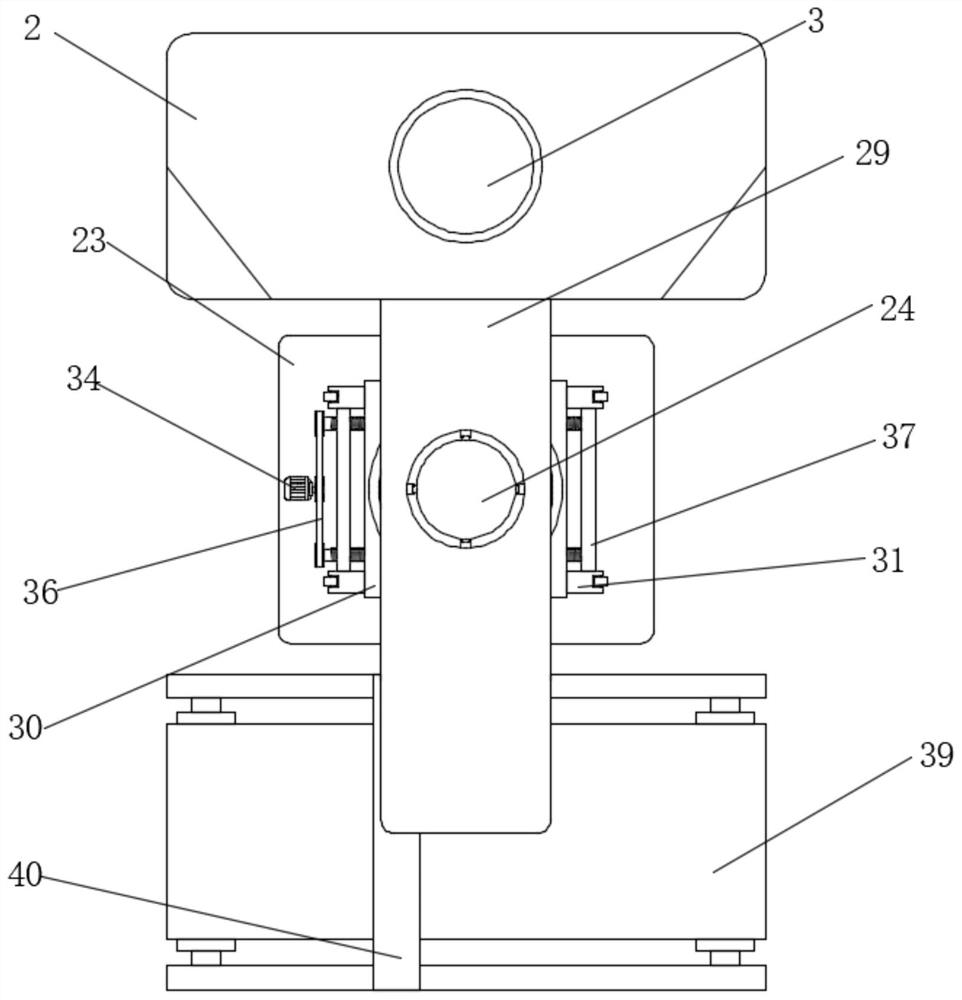

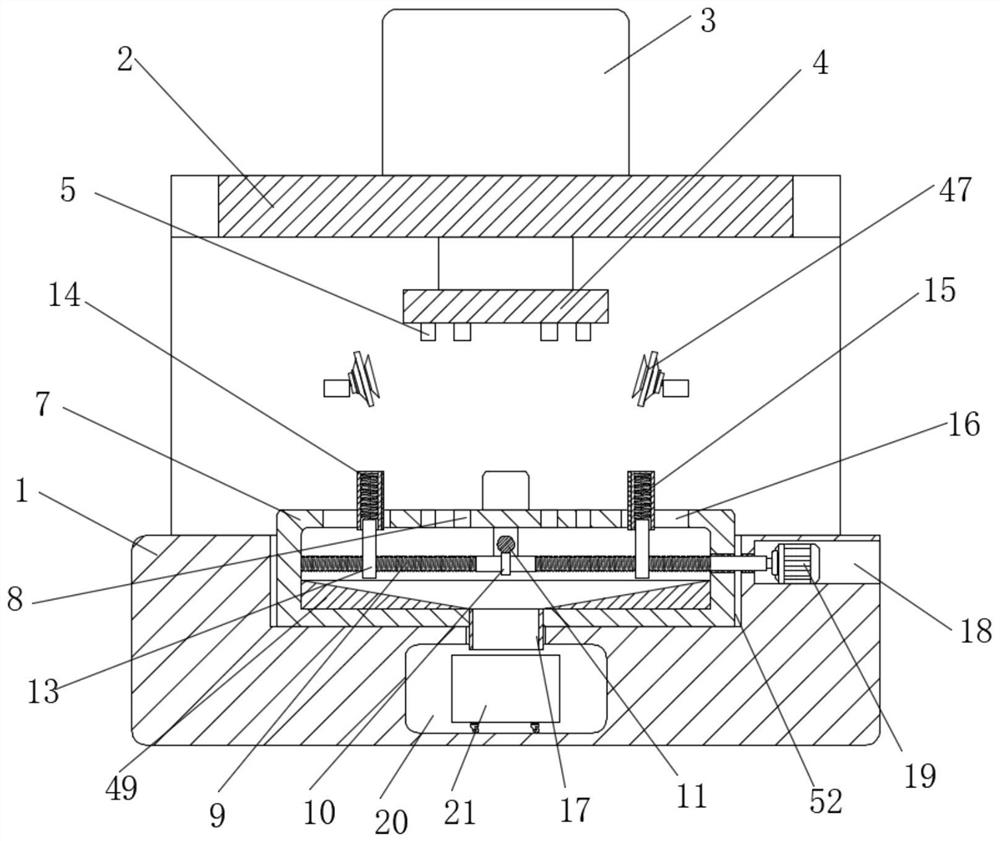

[0048] refer to Figure 1-12 , a progressive stamping system for a multi-functional electrical instrument, comprising a workbench 1, an L-shaped support plate 2 is fixedly connected to the top of the workbench 1, and a hydraulic cylinder 3 is fixedly connected to the top of the L-shaped support plate 2. The piston rod of the cylinder 3 runs through the L-shaped support plate 2 and is fixedly connected with the upper stamping plate 4. The bottom of the upper stamping plate 4 is equidistantly arranged with a plurality of stamping heads 5, and the bottom of the upper stamping plate 4 is fixedly connected with a folding plate 6. , the top of the workbench 1 is provided with a groove 52, the bottom inner wall of the groove 52 is fixedly connected with the lower stamping plate 7, the lower stamping plate 7 is provided with a clamping assembly for clamping the workpiece, and the workbench 1 is provided with a rectangular groove 20, the top inner wall of the rectangular groove 20 is p...

Embodiment 2

[0063] Embodiment two: if Figure 13 As shown in -15, a progressive stamping system for a multi-functional power meter, the difference between this embodiment and Embodiment 1 is that two symmetrical rotating plates 41 are rotatably connected to the two ends of the baffle plate 40, and the conveying Both sides of the top of the band 39 are fixedly connected with fixed blocks 51, and the two fixed blocks 51 are rotatably connected with electric retractable rods 42. The side away from the electric retractable rod 42 is slidingly connected with the rotating plate 41, and the rotation of the rotating plate 41 can be controlled by the fixed block 51, so that the stamped workpieces can fall on the rotating plate 41, which is convenient for collecting the stamped workpieces .

[0064] However, as those skilled in the art know, the working principle and wiring method of the hydraulic cylinder 3, the driving motor 19, the stepper motor 34, the rotating motor 27, the electric retractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com