Method for machining overlong concentric ladder through hole on ordinary boring machine through lengthening boring cutter rod

A technology of stepped through hole and boring bar, applied in boring bars, boring/drilling, metal processing equipment, etc., can solve the problems of large size and shape tolerance deviation, unguaranteed machining accuracy, and increased machining cost, etc. Achieve the effect of ensuring the processing size and shape and position tolerance, reducing the difficulty of finding the correct card and processing, and reducing the processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] The method for processing super-long concentric stepped through-holes on a common boring machine by using an extended boring bar according to the present invention comprises the following steps:

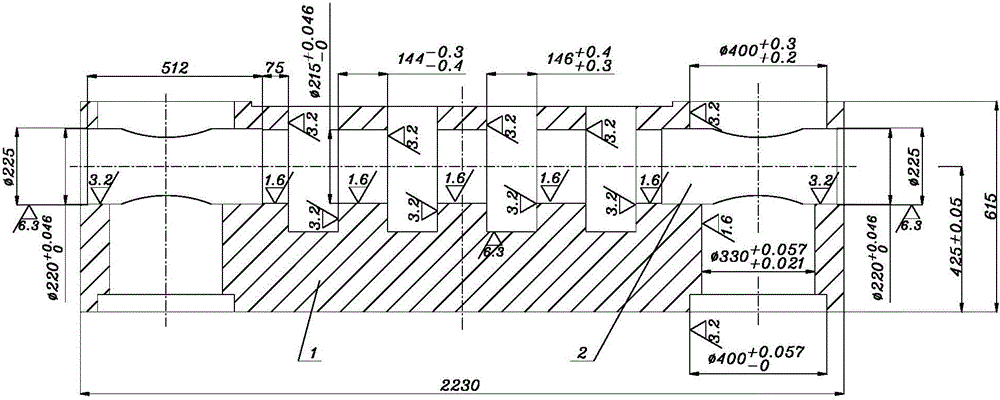

[0031] 1) Roughly process each part of the workpiece, leaving a margin of 4 to 6mm on one side, and then finish machining the surrounding area with a CNC machine tool to ensure that the size and shape tolerance is ≤0.05mm;

[0032] 2) The concentric stepped through hole is in the same direction as the main shaft, and the workpiece is aligned and clamped with the finished part as the reference, and the alignment accuracy is ≤0.02mm;

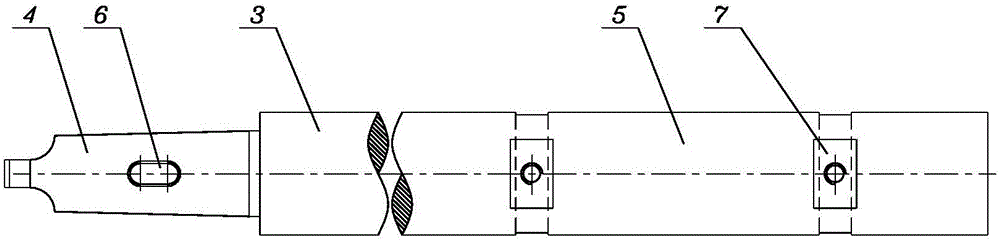

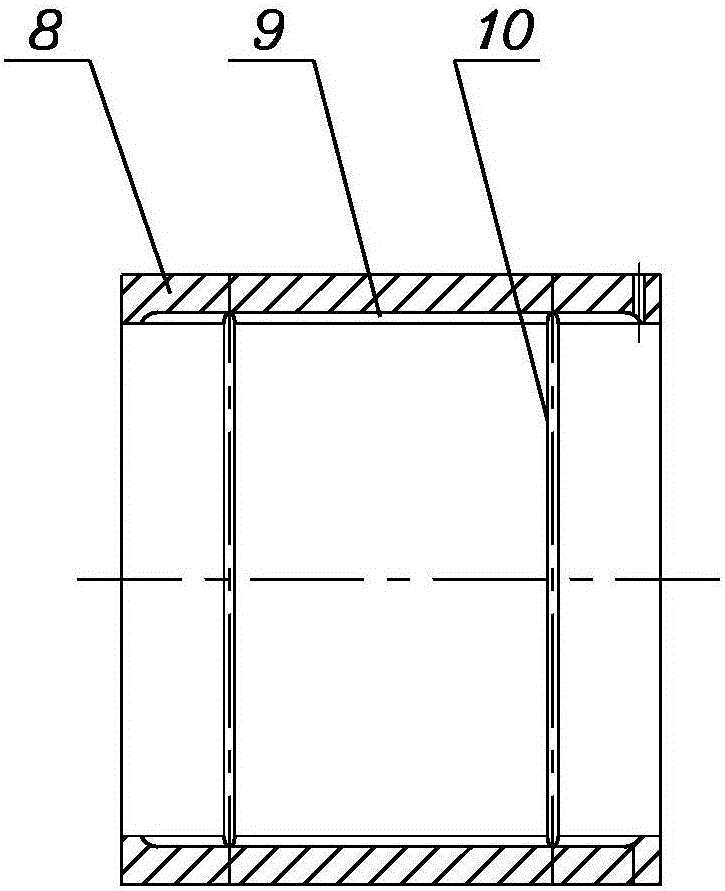

[0033] 3) The extended boring bar is composed of a tapered shank section and an optical axis section. The shaft end is equipped with a sliding sleeve, and the optical shaft section can rotate freely in the sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com