Real time on-line detection method for progressive stamping belt material pace and detector

A detector and step technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of no versatility, poor sensitivity, single function, etc., and achieve high versatility, high precision, and high detection sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

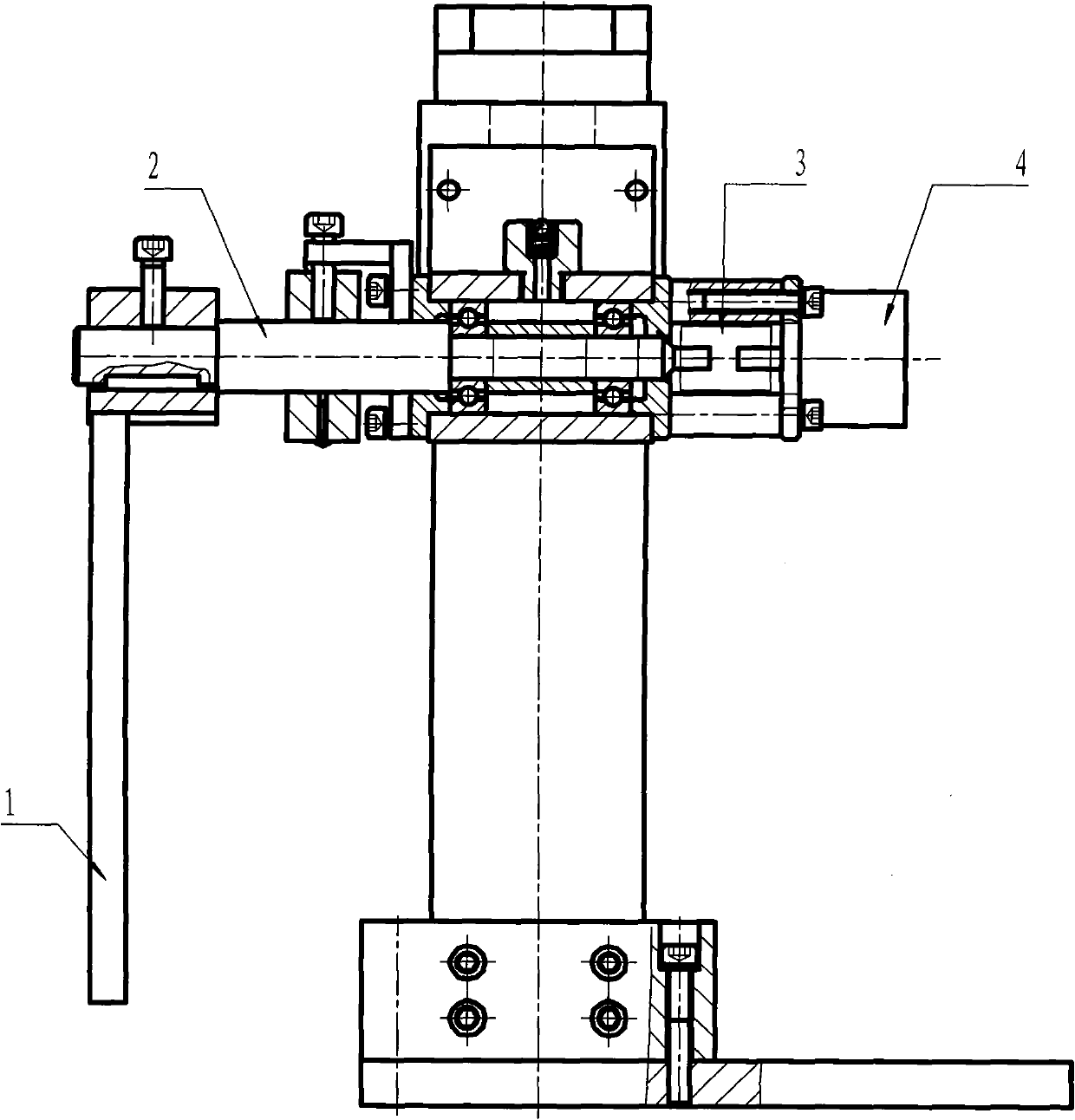

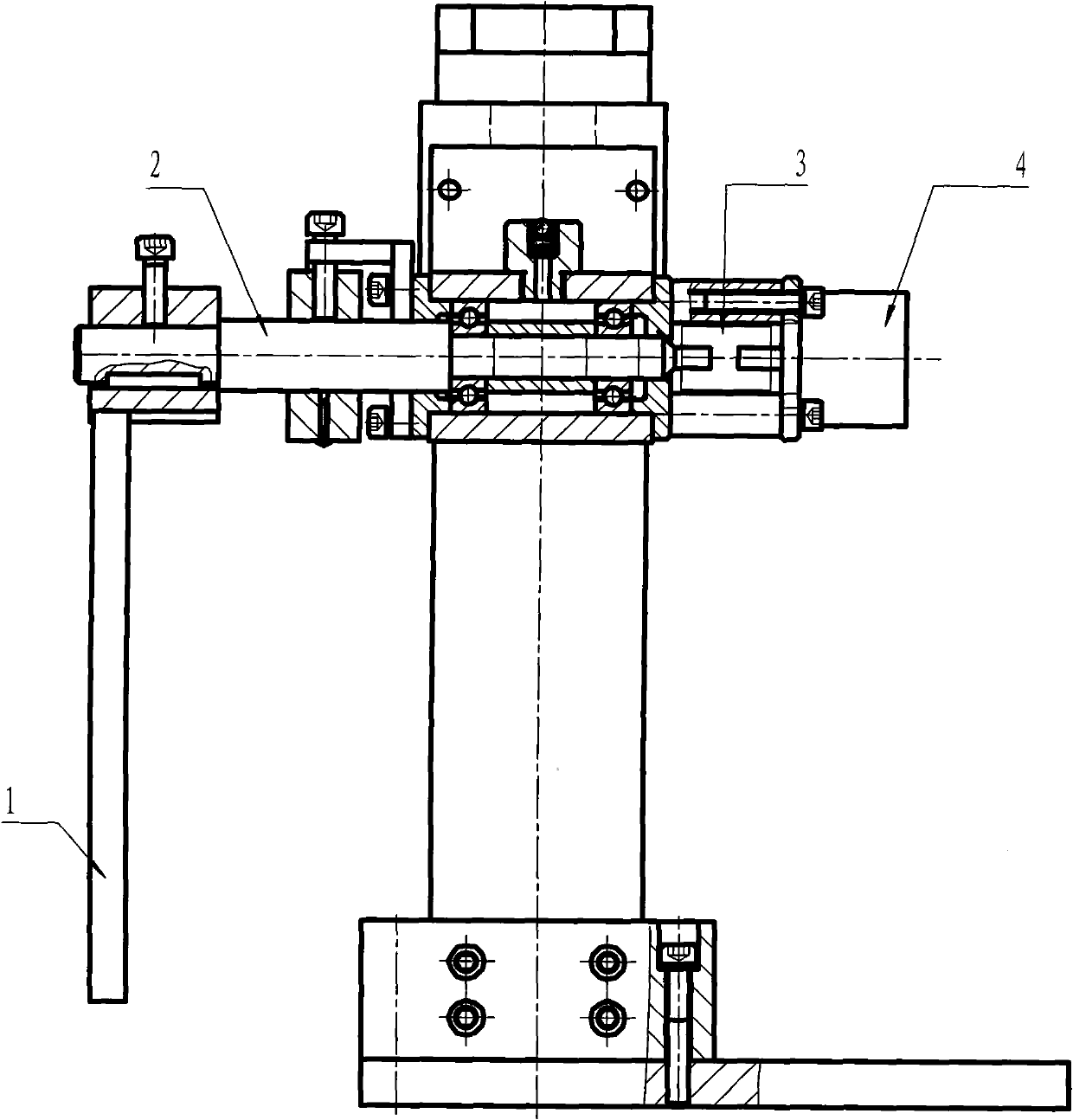

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, it is a structural schematic diagram of a real-time on-line detection device for progressive stamping strips according to the present invention. The device includes a swing rod 1 , a rotating shaft 2 , a coupling 3 and a rotary encoder 4 .

[0012] A general-purpose progressive stamping strip material real-time online detector, the detector includes a swing rod 1, a rotating shaft 2, a coupling 3, a rotary encoder 4, the swing rod 1 is fixed on the front end of the rotating shaft 2, and the The rear end is connected with the rotary encoder 4 through the coupling 3 .

[0013] A general-purpose progressive stamping strip material step distance real-time online detection method, through the feeding of the strip material step distance at the rear end of the mold, it acts on the swing rod 1 of the detector, the swing rod 1 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com