Parting and paving device

A paving and winding device technology, applied in the field of paving devices, can solve the problems of waste of PVC film and inability to guarantee the sealing of molded parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

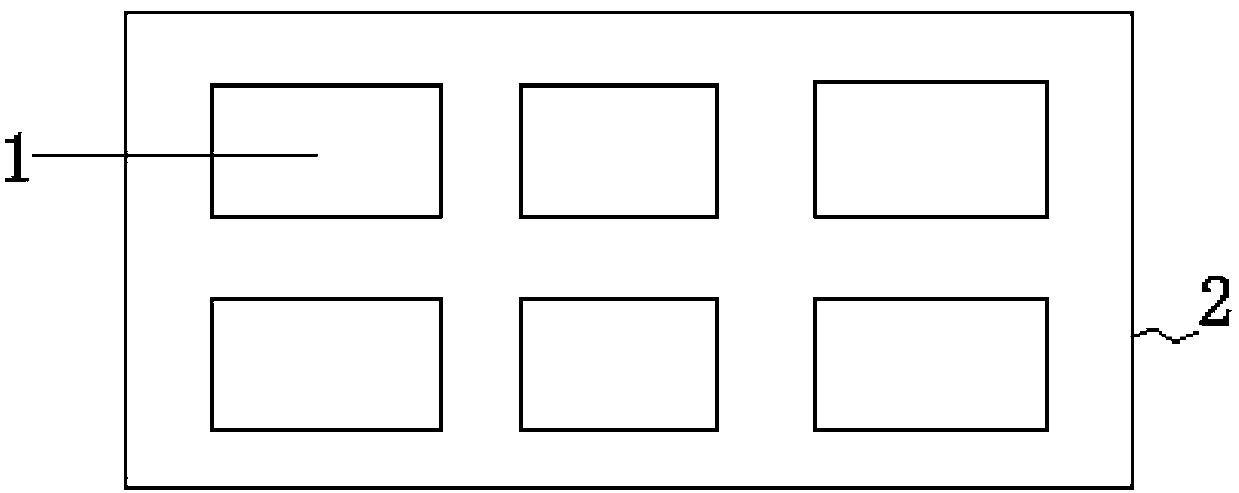

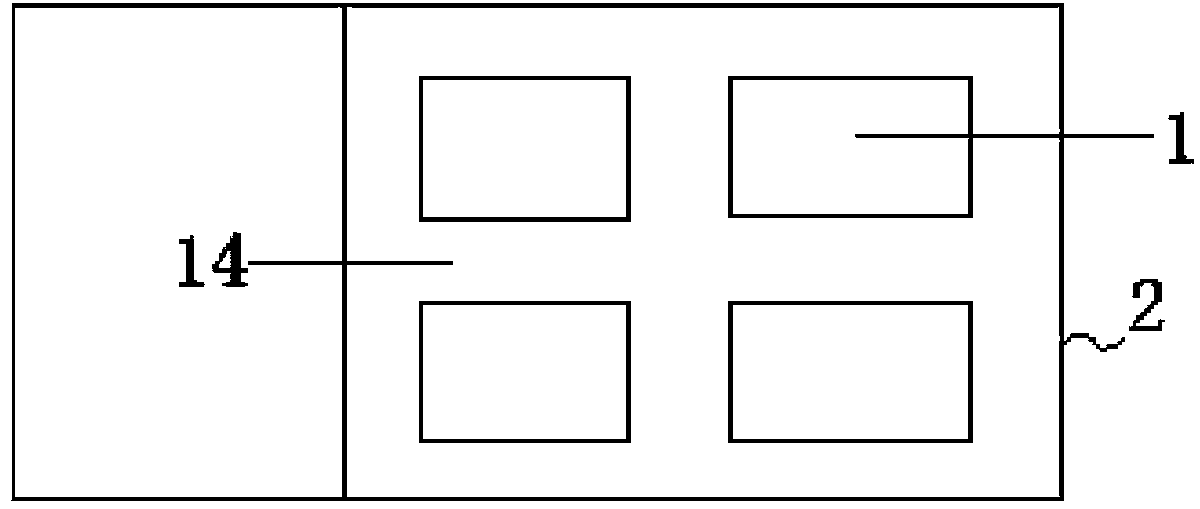

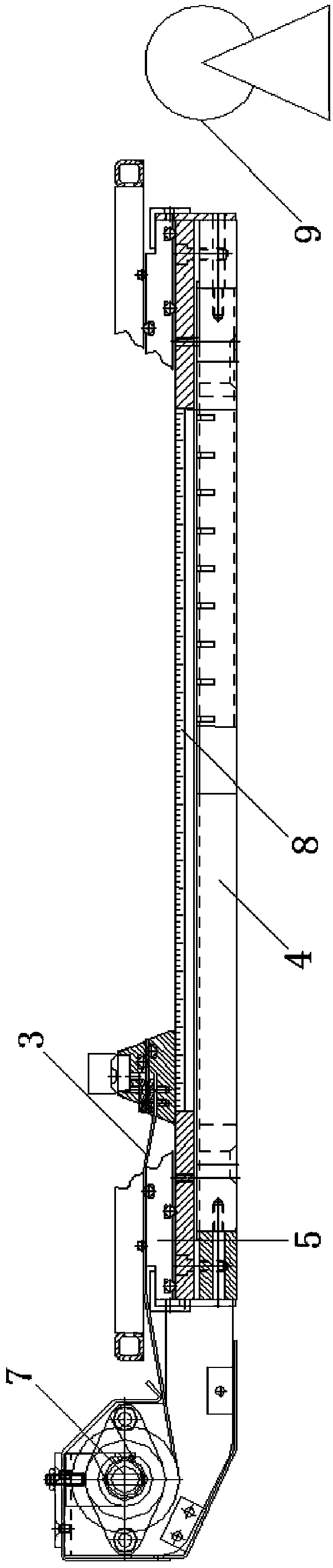

[0016] Such as image 3 and Figure 4 As shown, the divided paving device of the present invention includes a base 4 on which a discharge frame 5 is fixed, and the discharge frame 5 is used to place workpieces that need to be veneered. A movable partition bar 6 is placed in the discharge frame 5 , and the length of the partition bar 6 is adapted to the width of the discharge frame 5 in order to ensure the airtightness after the partition bar 6 is separated. A silica gel membrane 3 is fixed on the separation bar 6, and the other end of the silica gel membrane 3 is wound on an automatic winding device.

[0017] Further, such as Figure 5 As shown, the automatic winding device includes a rotating shaft 10, an air motor 11 and a cylinder 12, the silicone film 3 is wound on the rotating shaft 10, a protrusion 13 is fixed at one end of the rotating shaft 10, and the pneumatic The front end of the motor 11 is provided with a slot corresponding to the protrusion, and the air motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com