High-speed reeling machine

A high-speed coil and reel technology, applied in the field of rolling mill supporting equipment, can solve the problems of difficult alignment of edges, low winding precision, and uneven layers at both ends of the strip coil, so as to reduce the number of roll changes, high winding precision, The effect of large winding diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

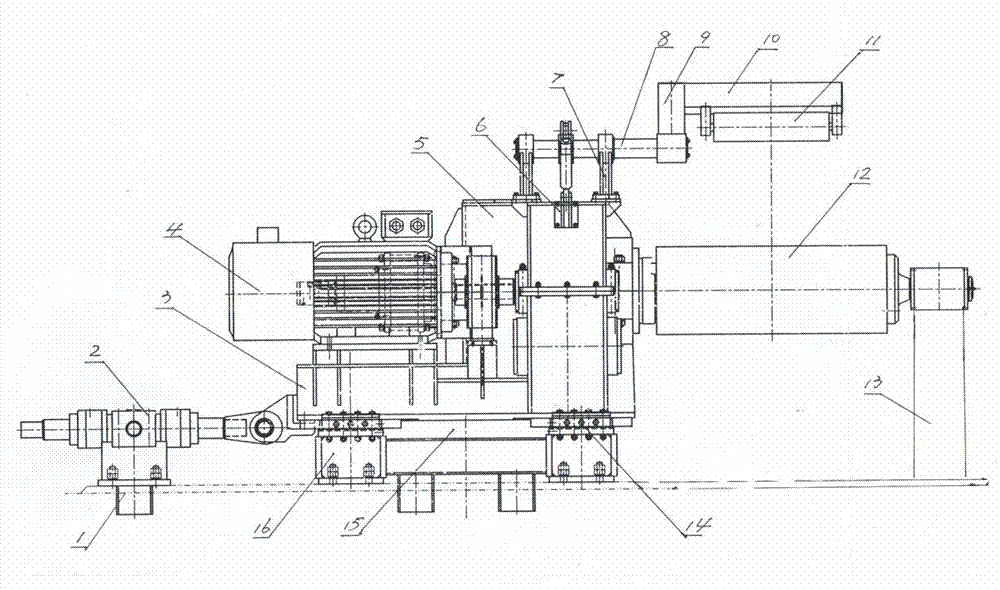

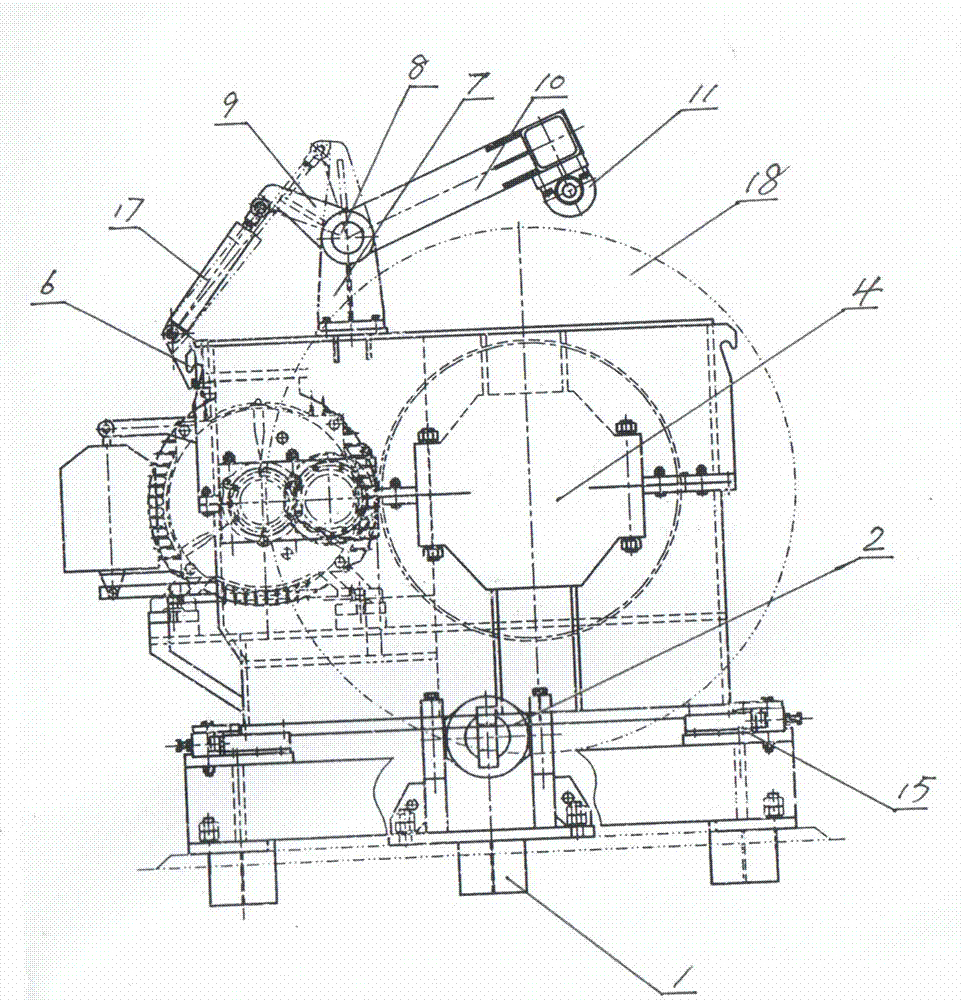

[0012] Such as figure 1 and figure 2 As shown, the high-speed coiler of the present invention includes a base 16, the base 16 is rectangular, two guide rails 15 are arranged on the top of the base 16, and the two guide rails 15 are parallel and arranged along the longitudinal sides of the base 16. A frame 3 is arranged on the base 16, and the frame is rectangular. The bottom of the frame 3 is equipped with two rows of rollers 14 by means of a wheel seat and a wheel shaft, and the two rows of rollers 14 are respectively placed in the corresponding tracks 15 on the top of the base 16 and can roll along the longitudinal direction of the tracks 15 . The frame 3 is provided with a motor 4, a reduction box 5 and a reel 12, the output shaft of the motor 4 is connected with the input shaft of the reduction case 5, and the output shaft of the reduction case 5 is connected with one end of the reel 12. A first support 13 is provided below the outer end of the reel 12 , and the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com