Raw tire forming method and raw tier forming apparatus

A technology for raw tires and carcasses, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of clamping and fixing the carcass cord a, deformation of the winding part, and inability to stand up, and achieves the path of the carcass cord. Stabilization, reduction in miniaturization, and realization of the effect of device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

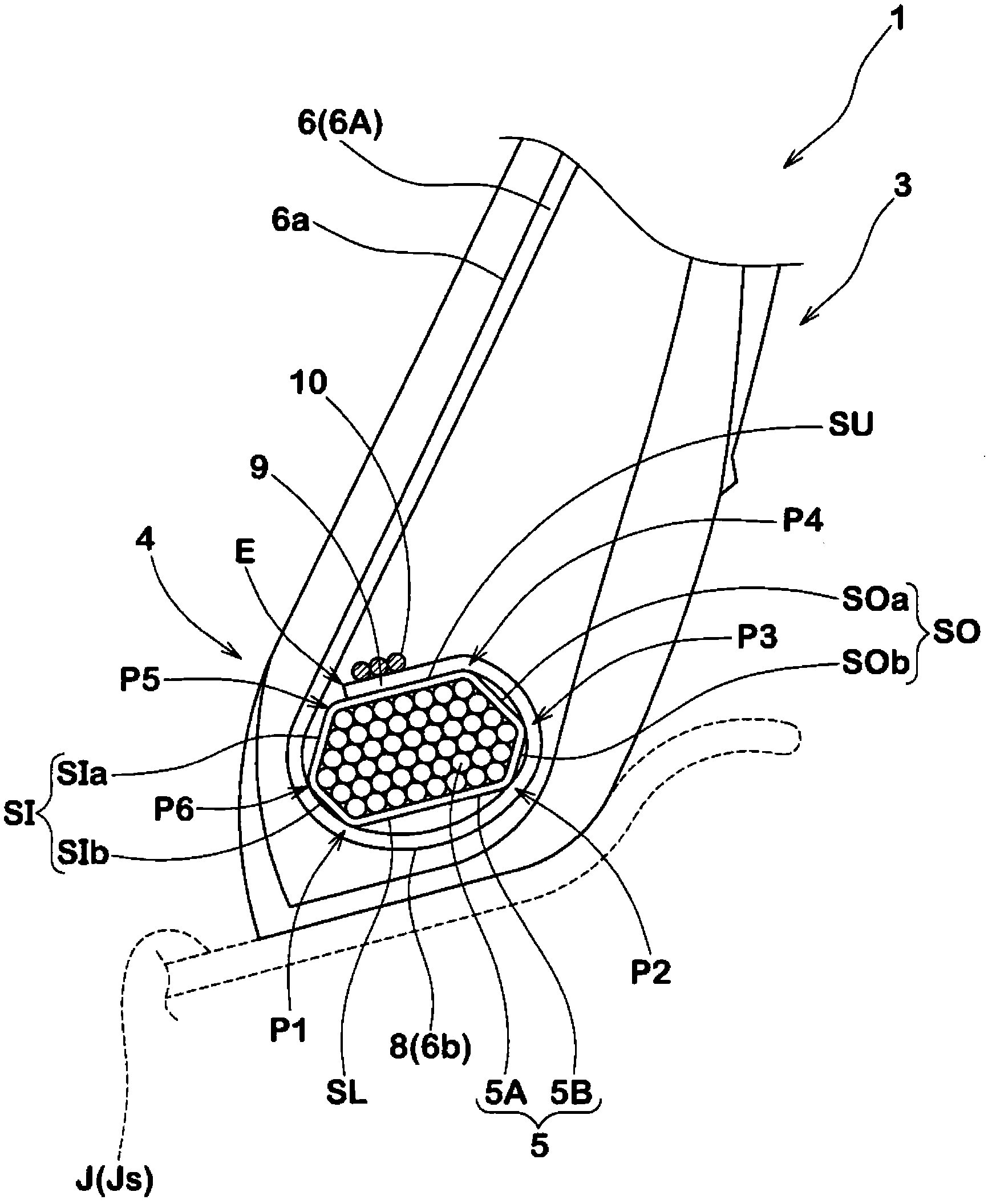

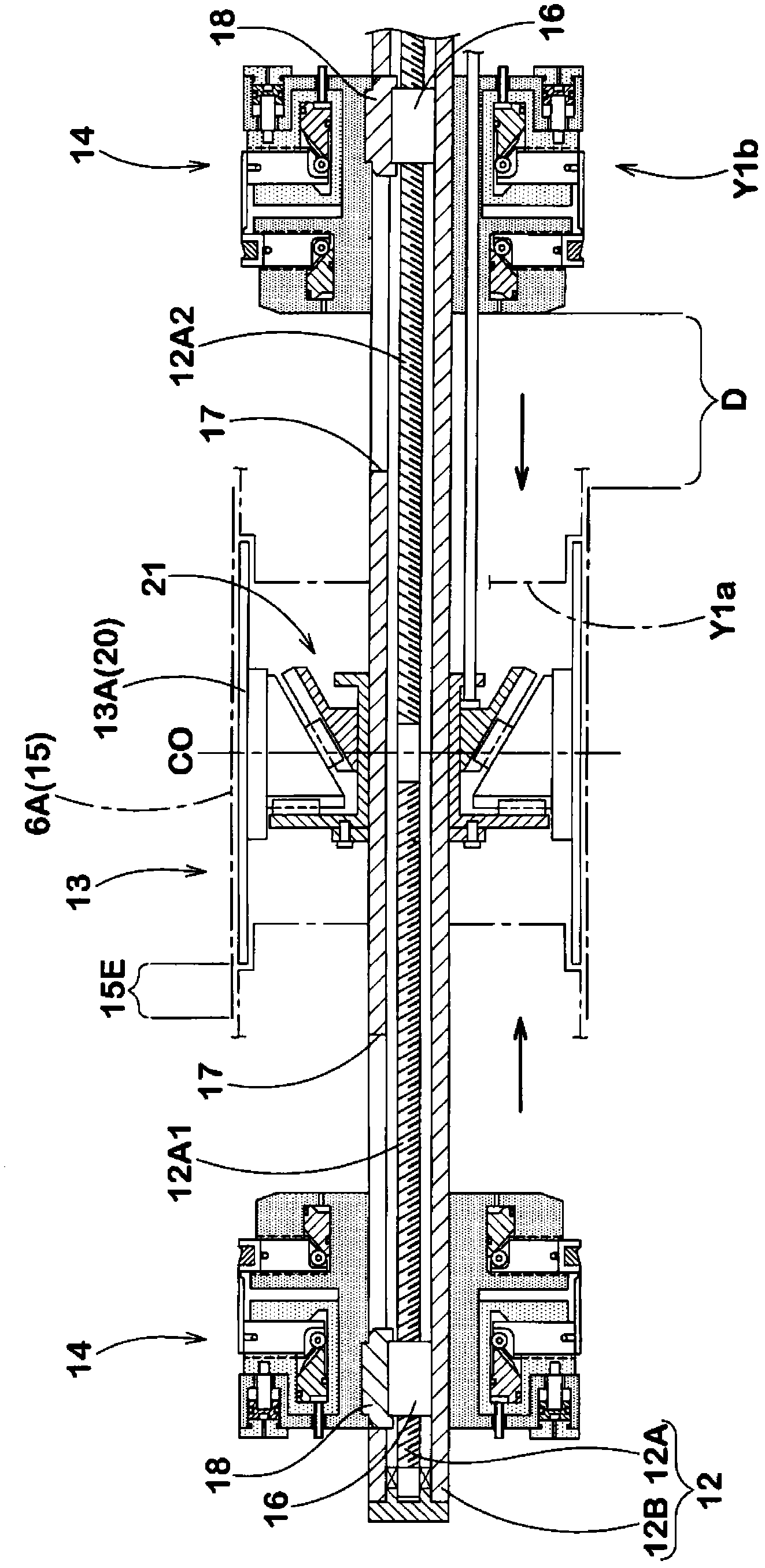

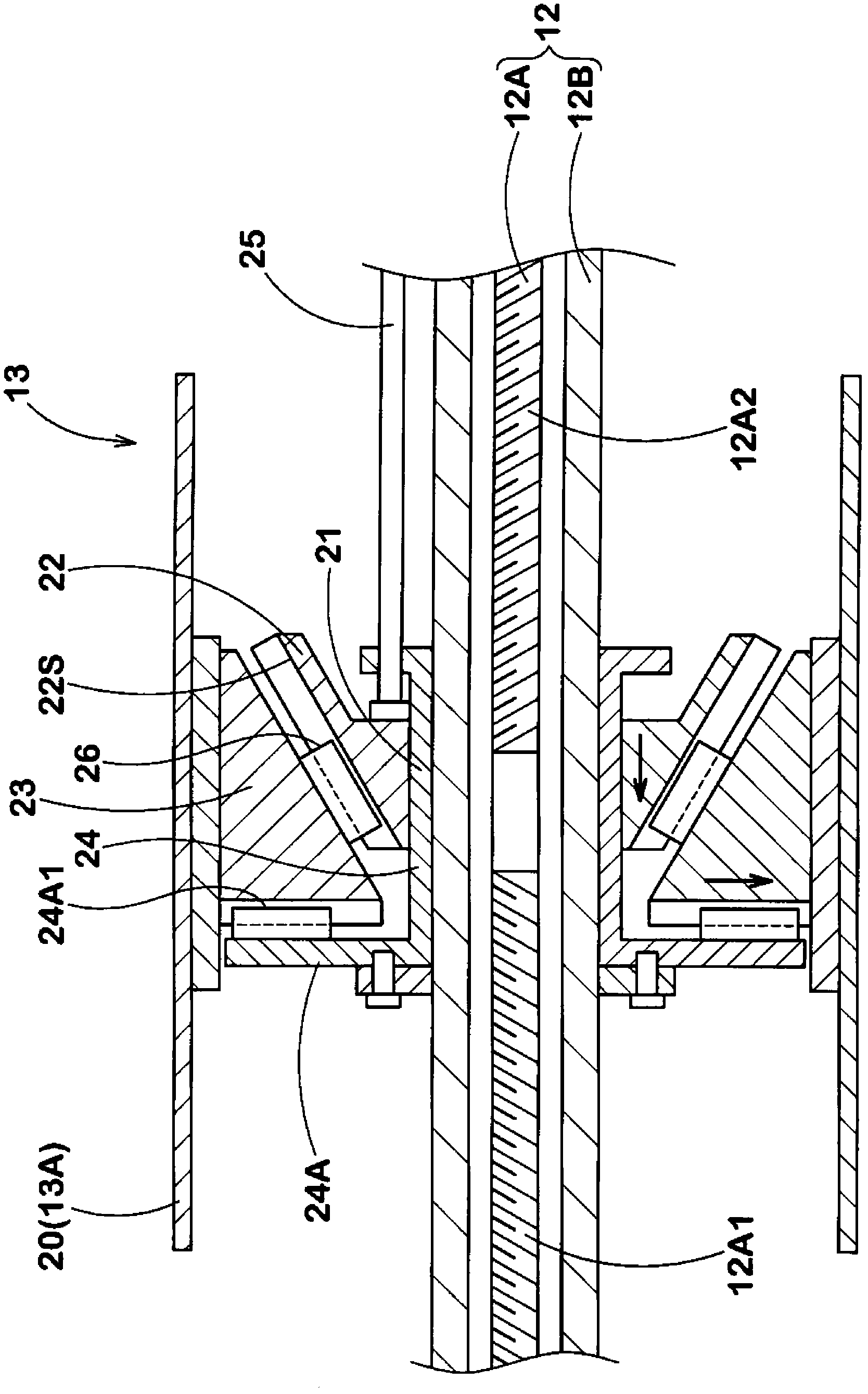

[0050] Next, embodiments of the present invention will be described in detail. figure 1 The radial cross section of the bead portion 4 in the case where the tire 1 having a bead strip structure is a radial tire for trucks. The tire 1 includes at least a carcass 6 extending from the tread portion having a contact surface through the sidewall portion 3 The bead core 5 of the bead portion 4 is provided with a well-known belt layer for tread reinforcement on the outside in the radial direction of the carcass 6 and inside the tread portion.

[0051] The above-mentioned carcass 6 is composed of a carcass cord 6A, which is formed by wrapping the carcass cords (steel cords) in parallel with the cord arrangement body after the rubber is applied. In the case of a tire, the carcass cords are arranged at an angle of 75 to 90 degrees with respect to the tire circumferential direction.

[0052] In addition, the carcass cord 6A continuously has carcass turn-up portions 6b on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com