Patents

Literature

71results about How to "Shorten winding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

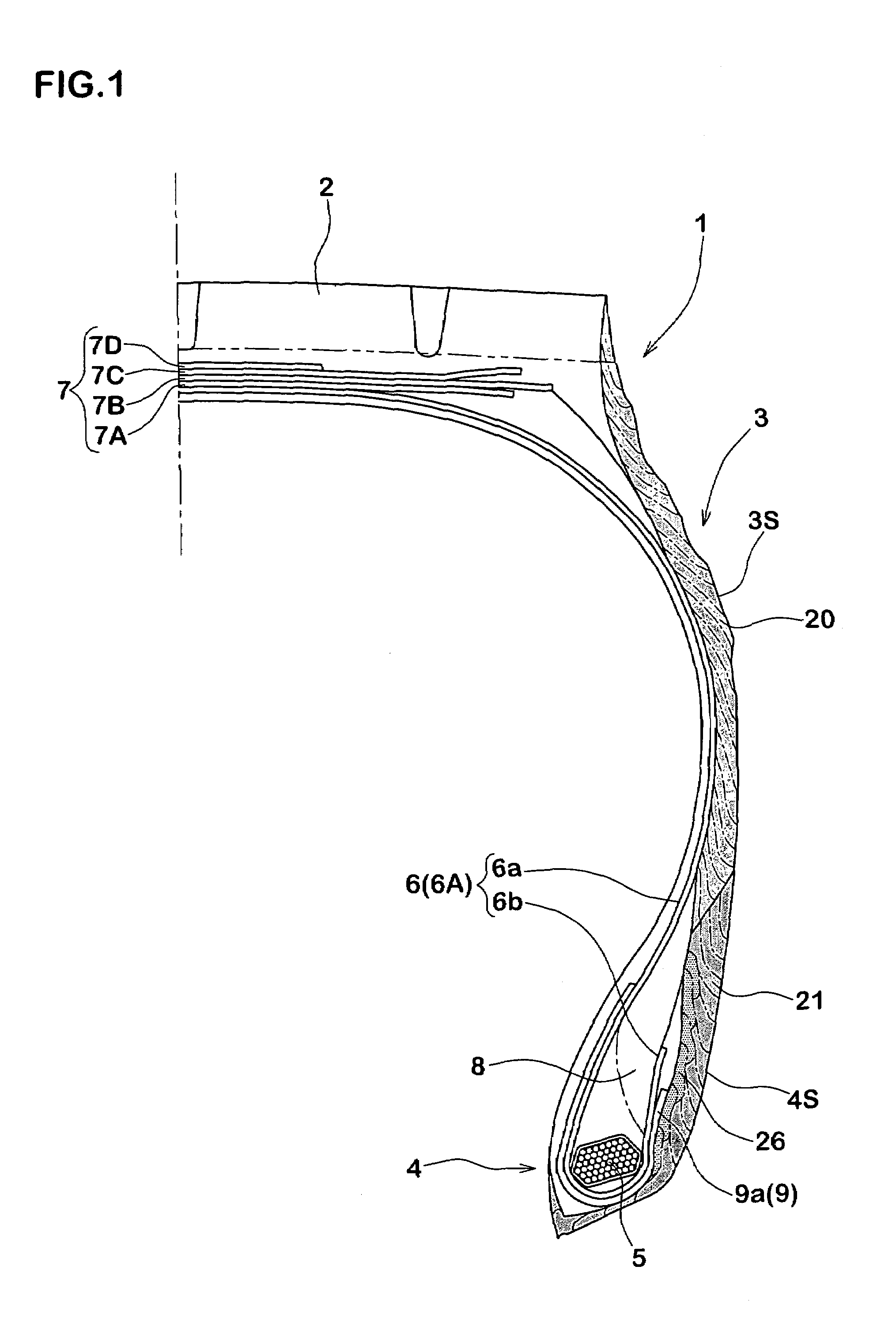

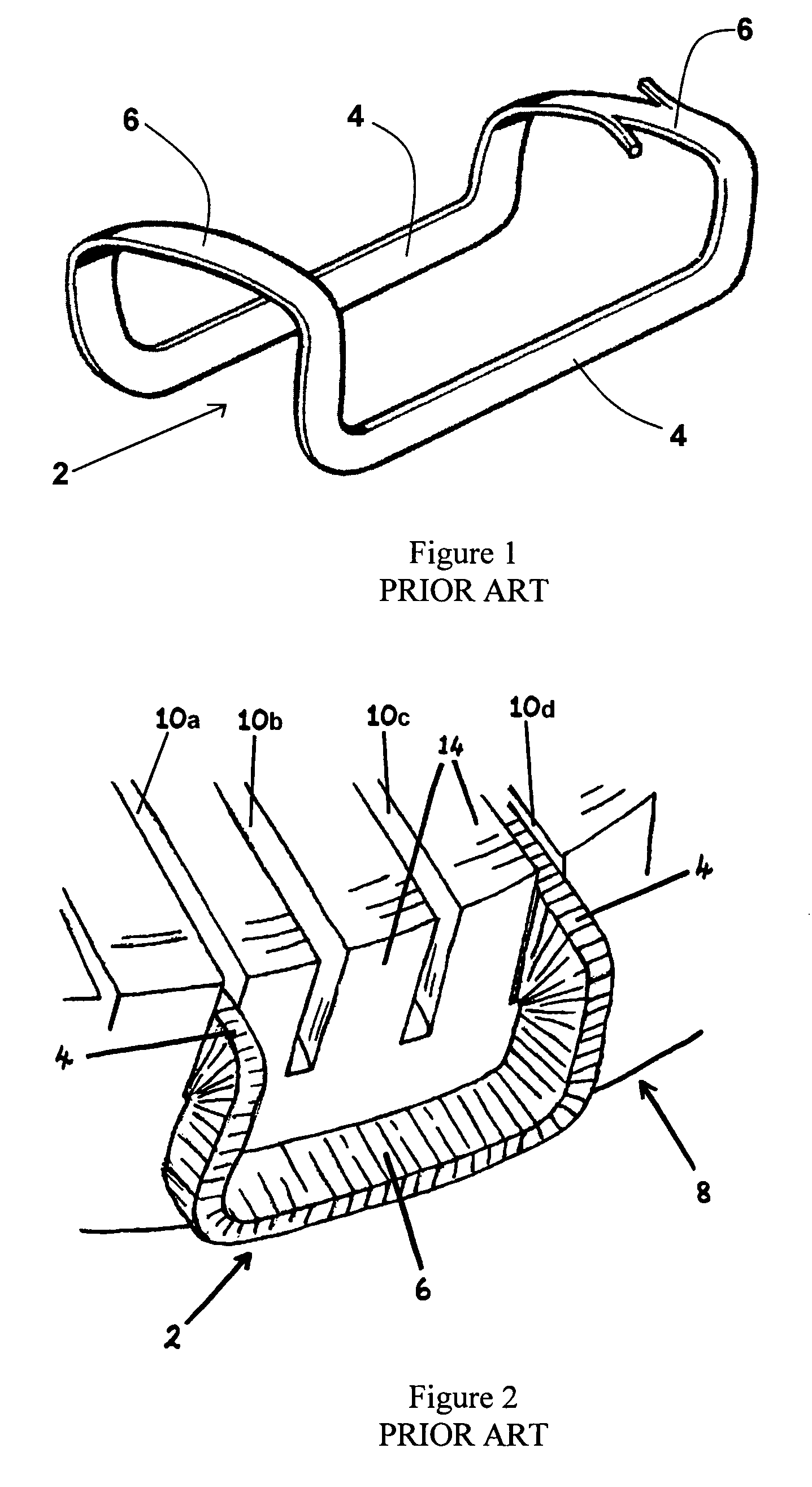

Rubber strip material

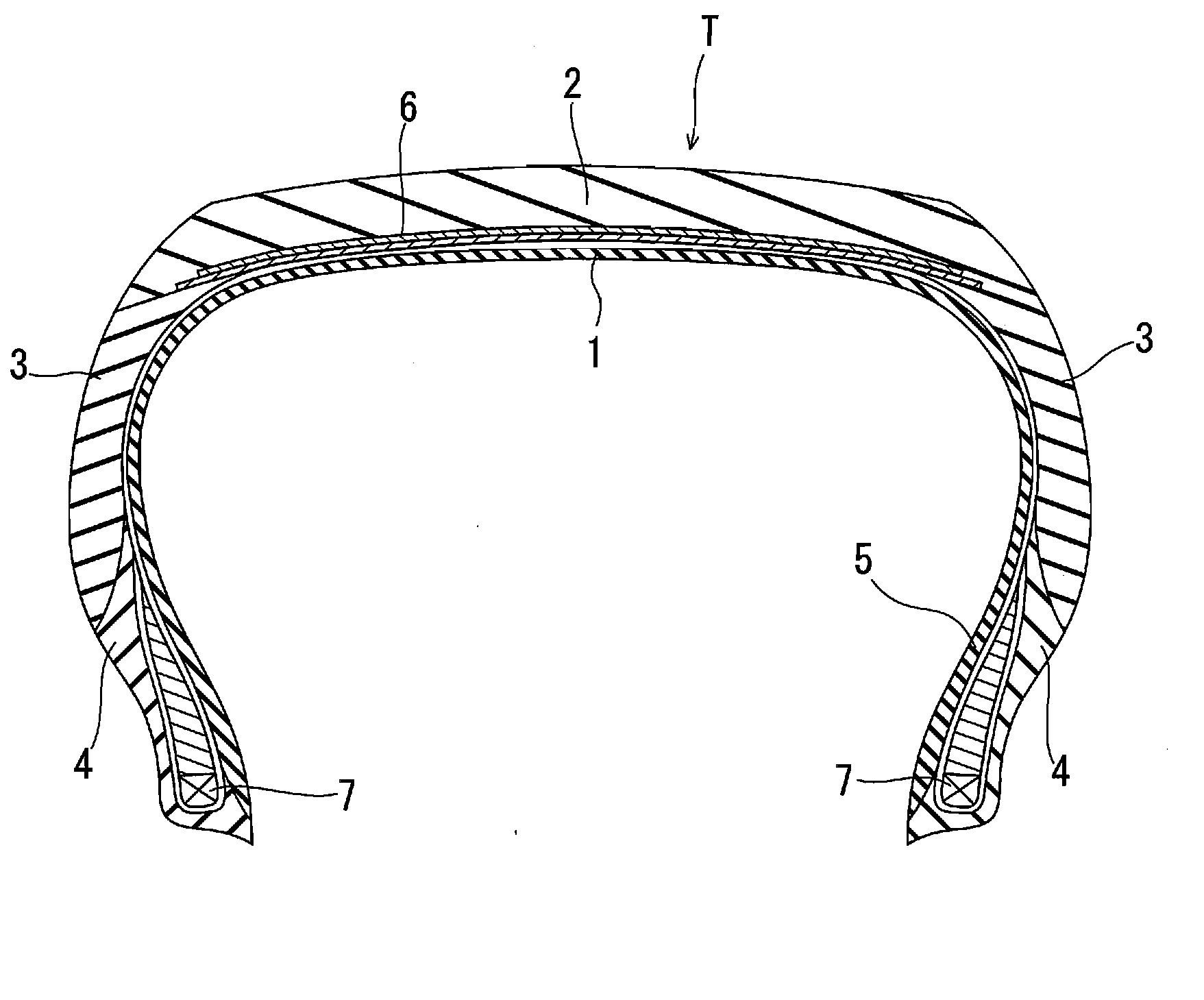

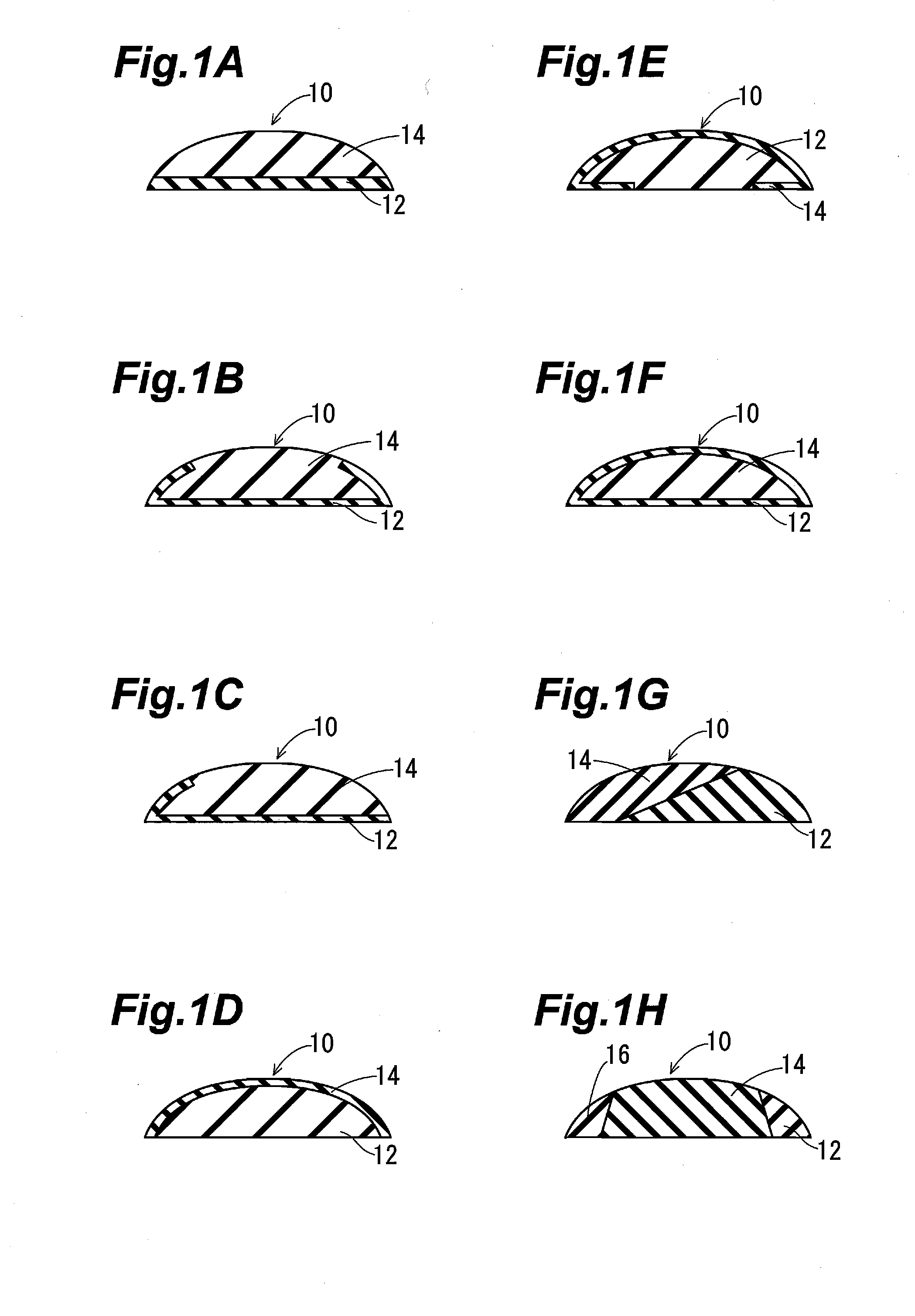

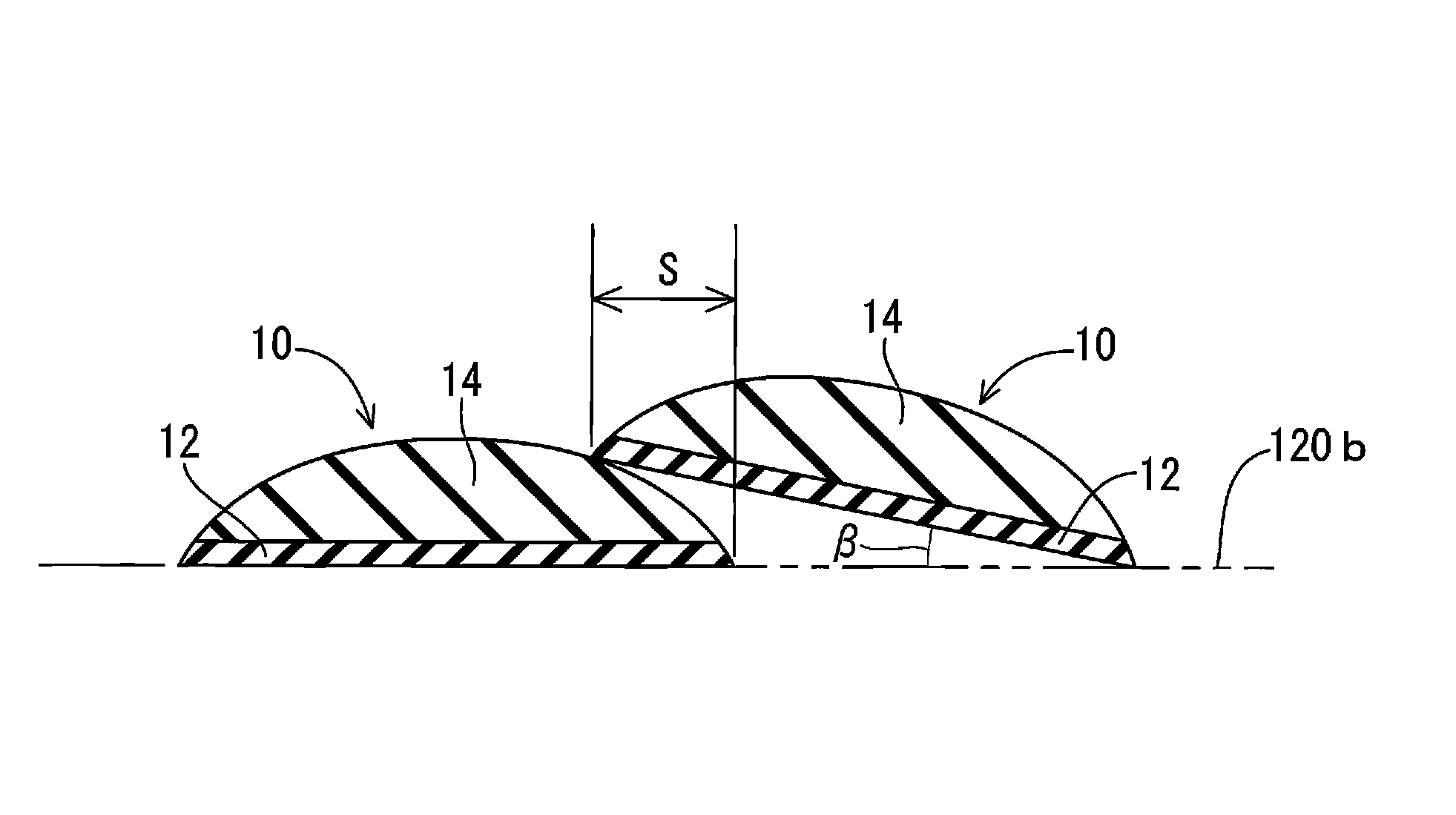

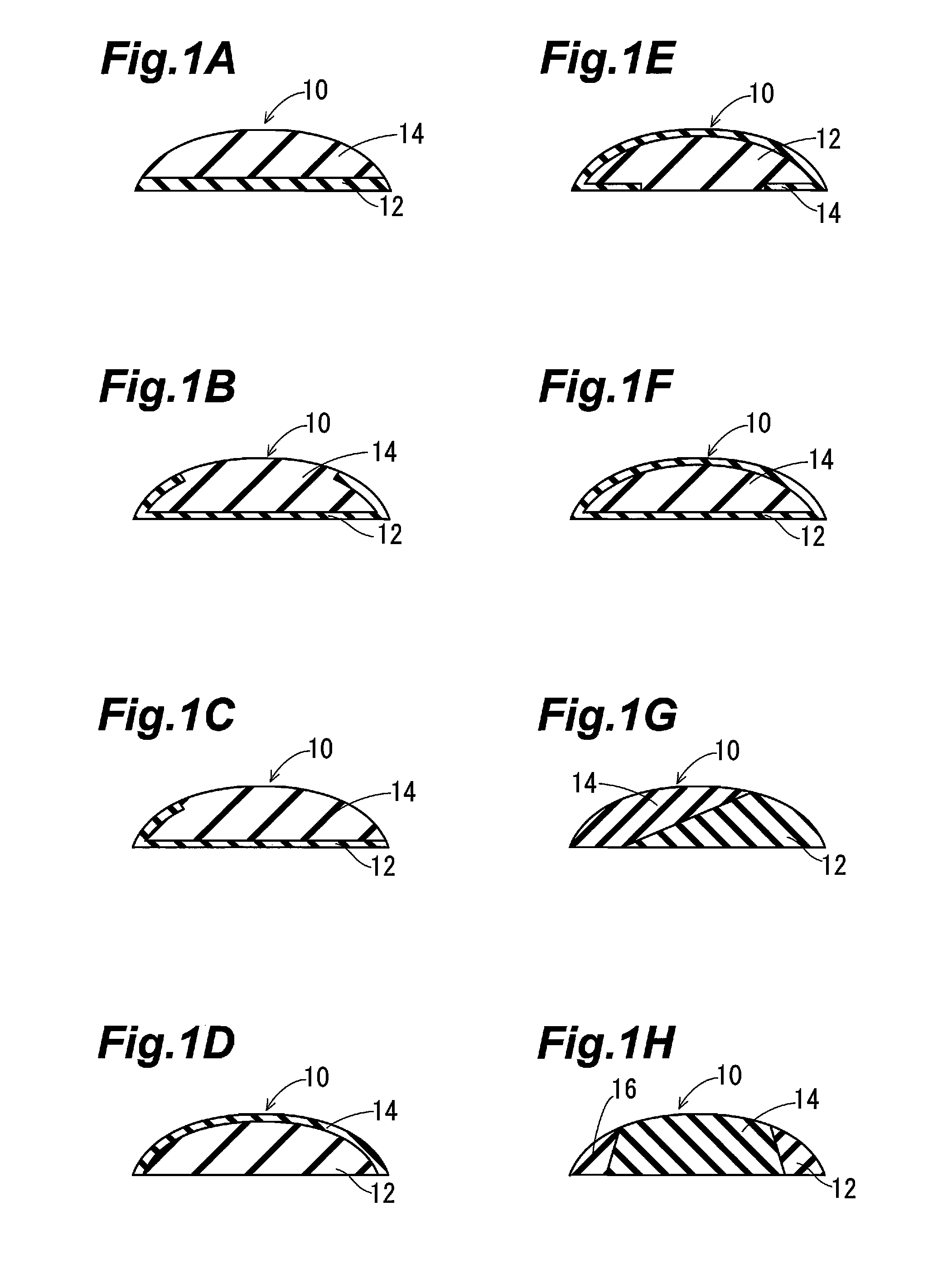

ActiveUS20090320985A1Reduced number of time of windingFabrication can be reducedWithout separate inflatable insertsWith separate inflatable insertsBand shapeEngineering

When forming a rubber member which is made up of a combination of a plurality of rubber compounds by winding spirally a ribbon-shaped unvulcanized rubber strip material in an overlapping fashion, the number of times of winding is reduced so as to shorten a fabrication cycle time of the rubber member to thereby increase the productivity thereof. As a means therefore, a rubber strip material whose cross section is divided into two or more regions which are made up of different rubber compounds is wound spirally on to a drum in an overlapping fashion so as to build a green tire or a tire rubber member.

Owner:TOYO TIRE & RUBBER CO LTD

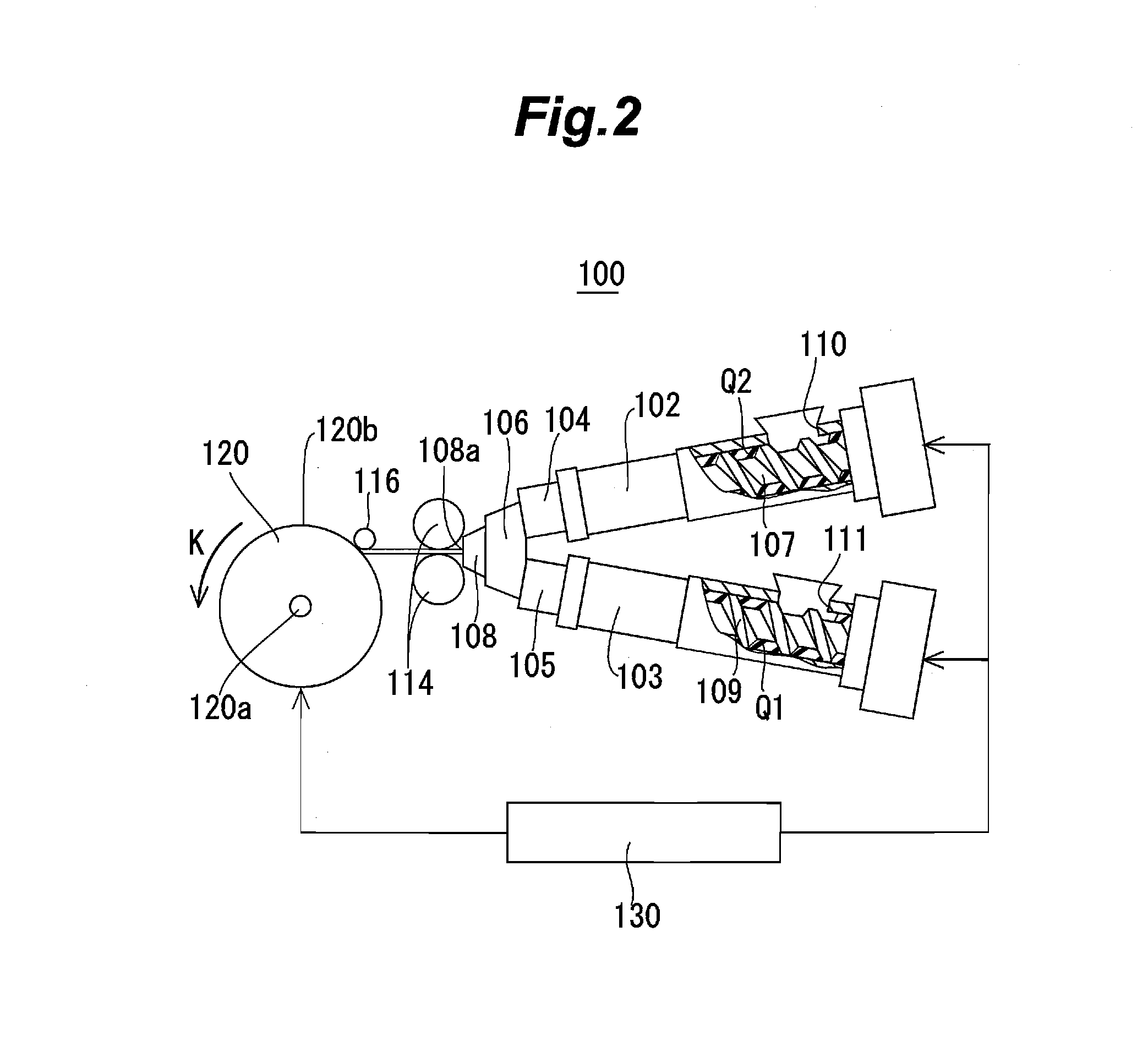

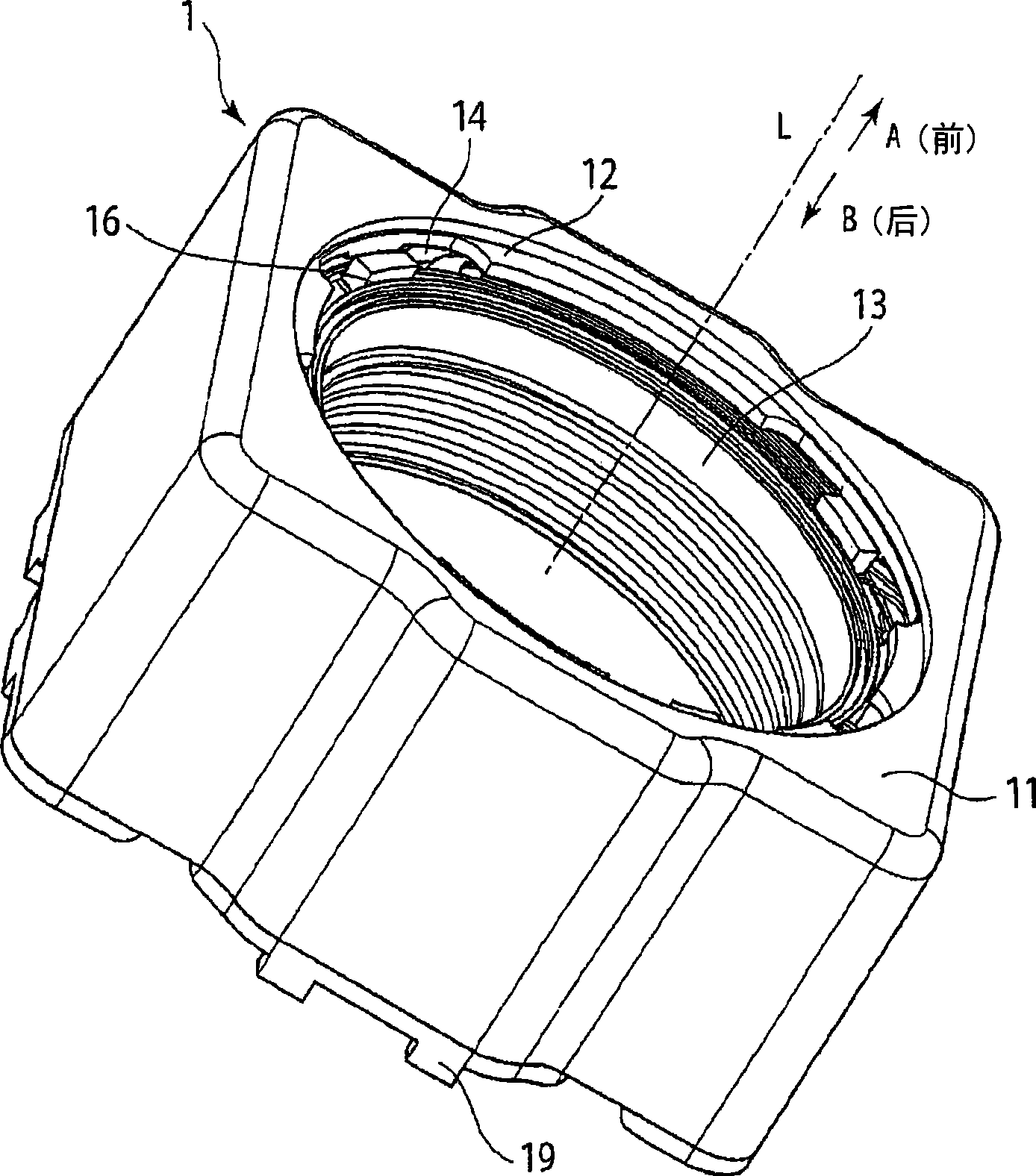

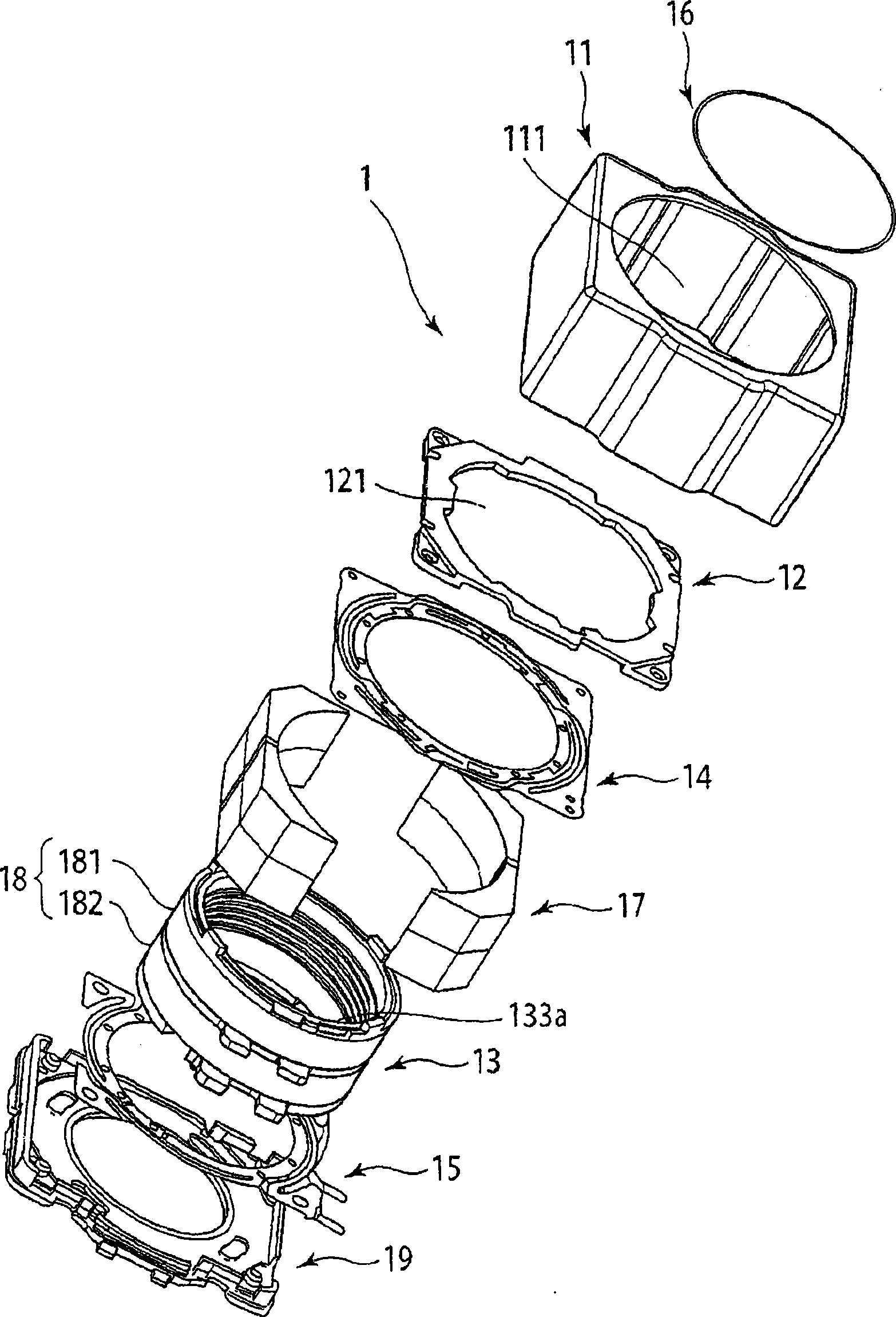

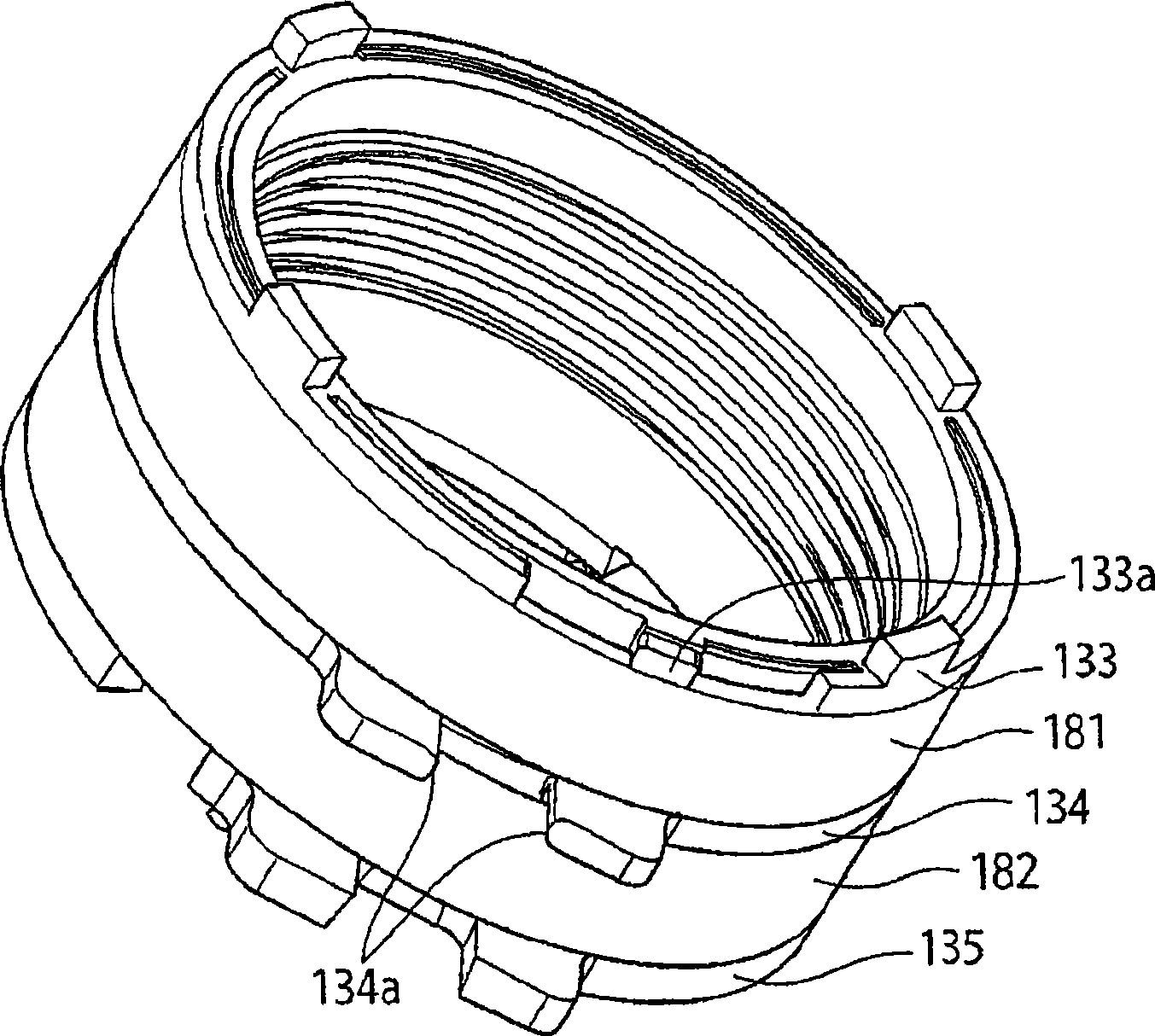

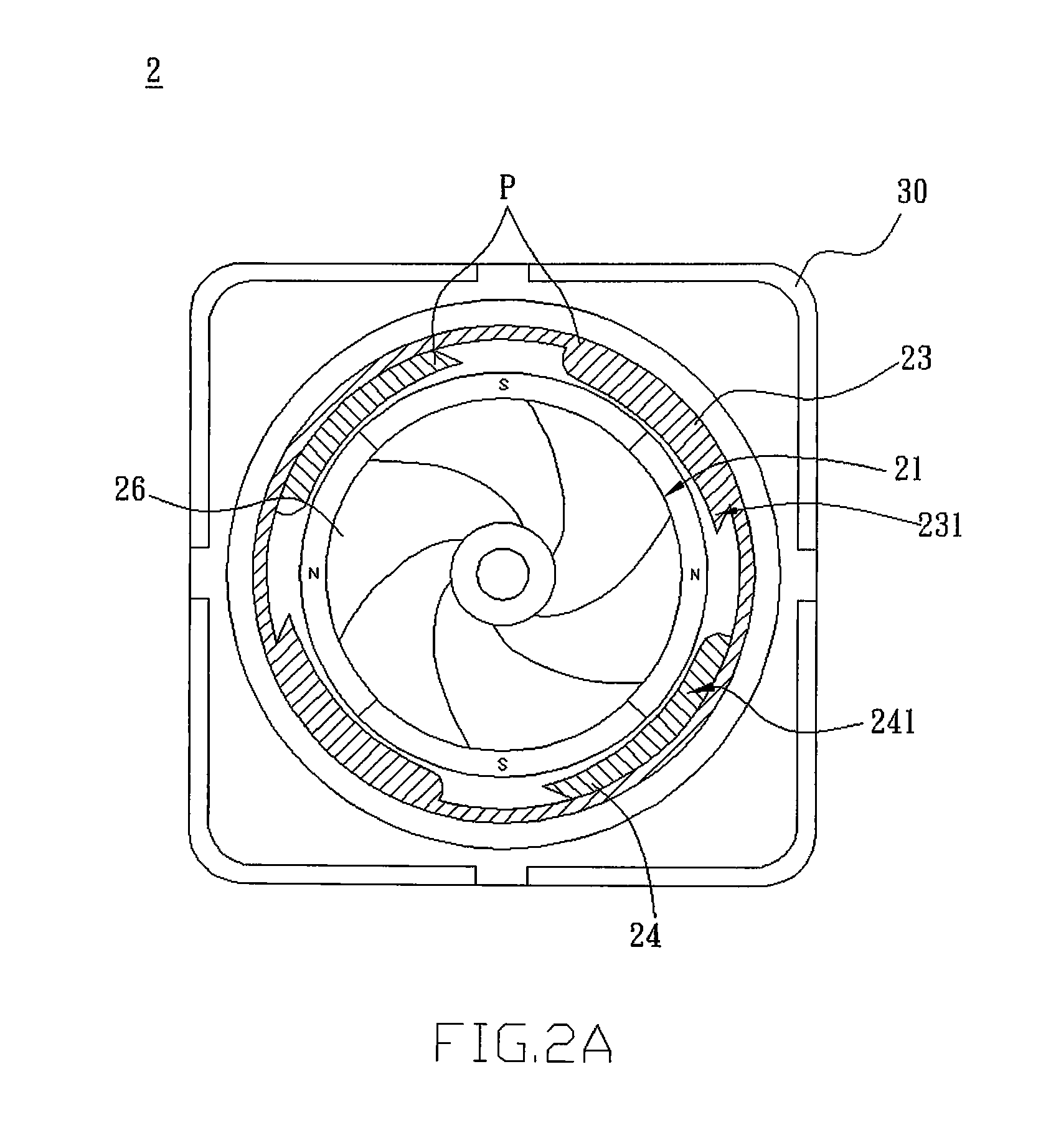

Lens drive device and coil winding method

InactiveCN101435906APrevent looseningShorten winding timeMountingsCoils manufactureEngineeringMagnetic tension force

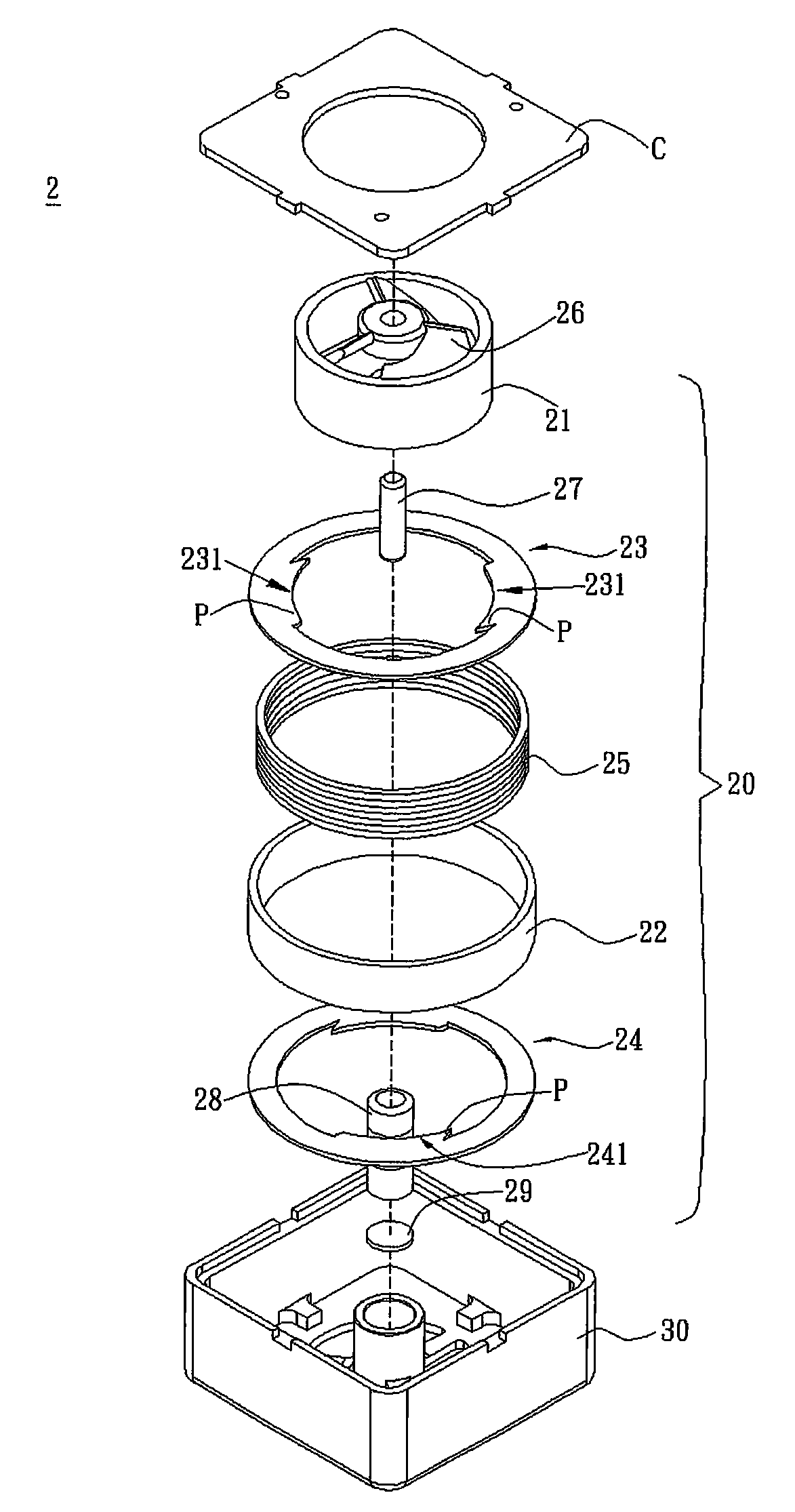

A lens drive device and a coil winding method may prevent loose of the coil. The lens drive device (1) includes a movable body (sleeve 13) movable in an optical axis direction, a support body (maintaining element 19) supporting the movable body through a spring member and a magnetic drive mechanism having a coil (18) and driving the movably body along the optical axis. The movable body includes a coil winding part (131, 132) wherein the coil is winded, an end part and the other end part (a first end part 133, a third end part 135) for restricting a range of the coil winding part and a changing part (133a) formed on at least an end part of the end parts and for changing a drawing direction of the coil (18). The spring member is disposed near the end part except the end part where the changing part (133a) is formed. The winding start and finish ends of the coil (18) are connected electrically.

Owner:NIDEC SANKYO CORP

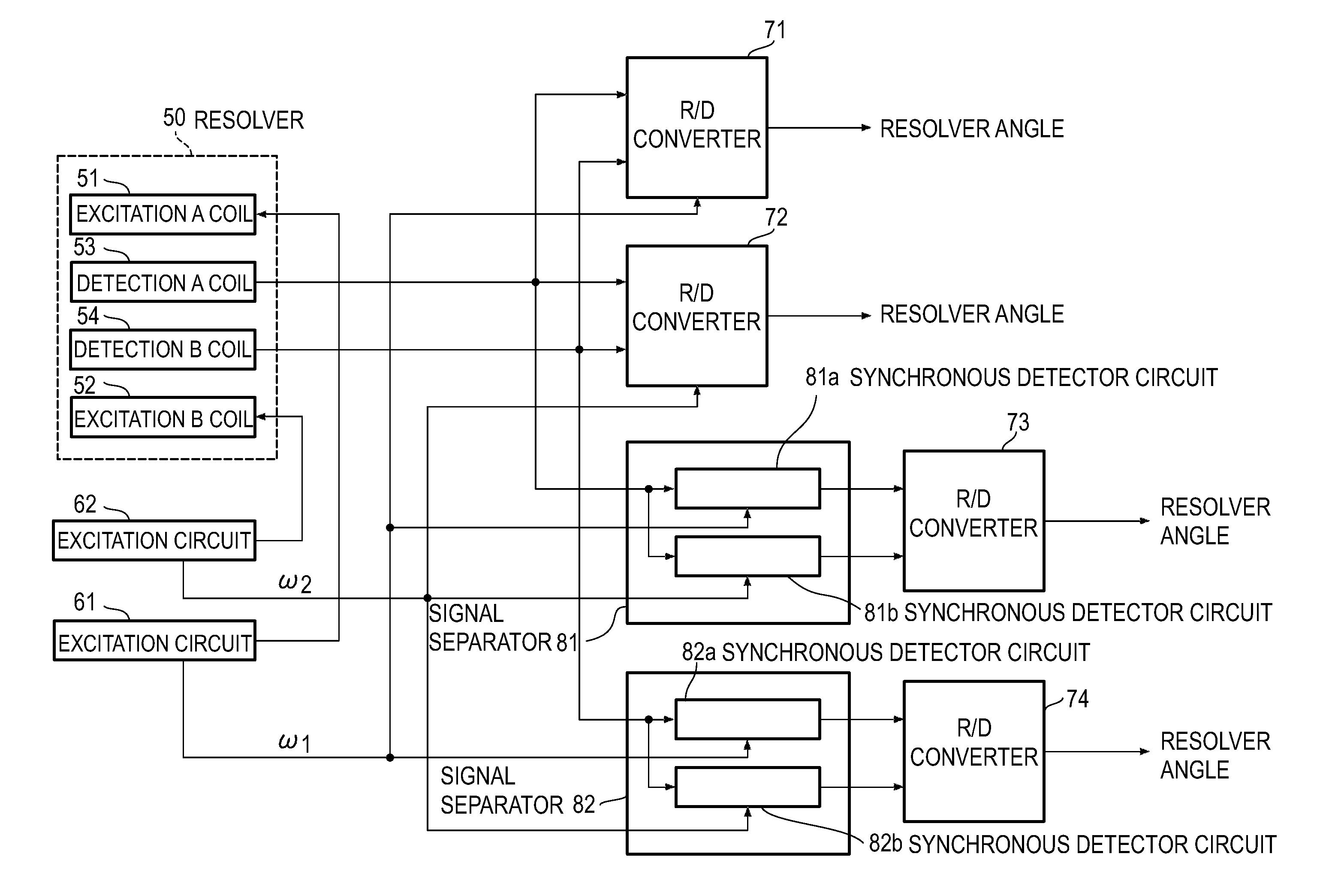

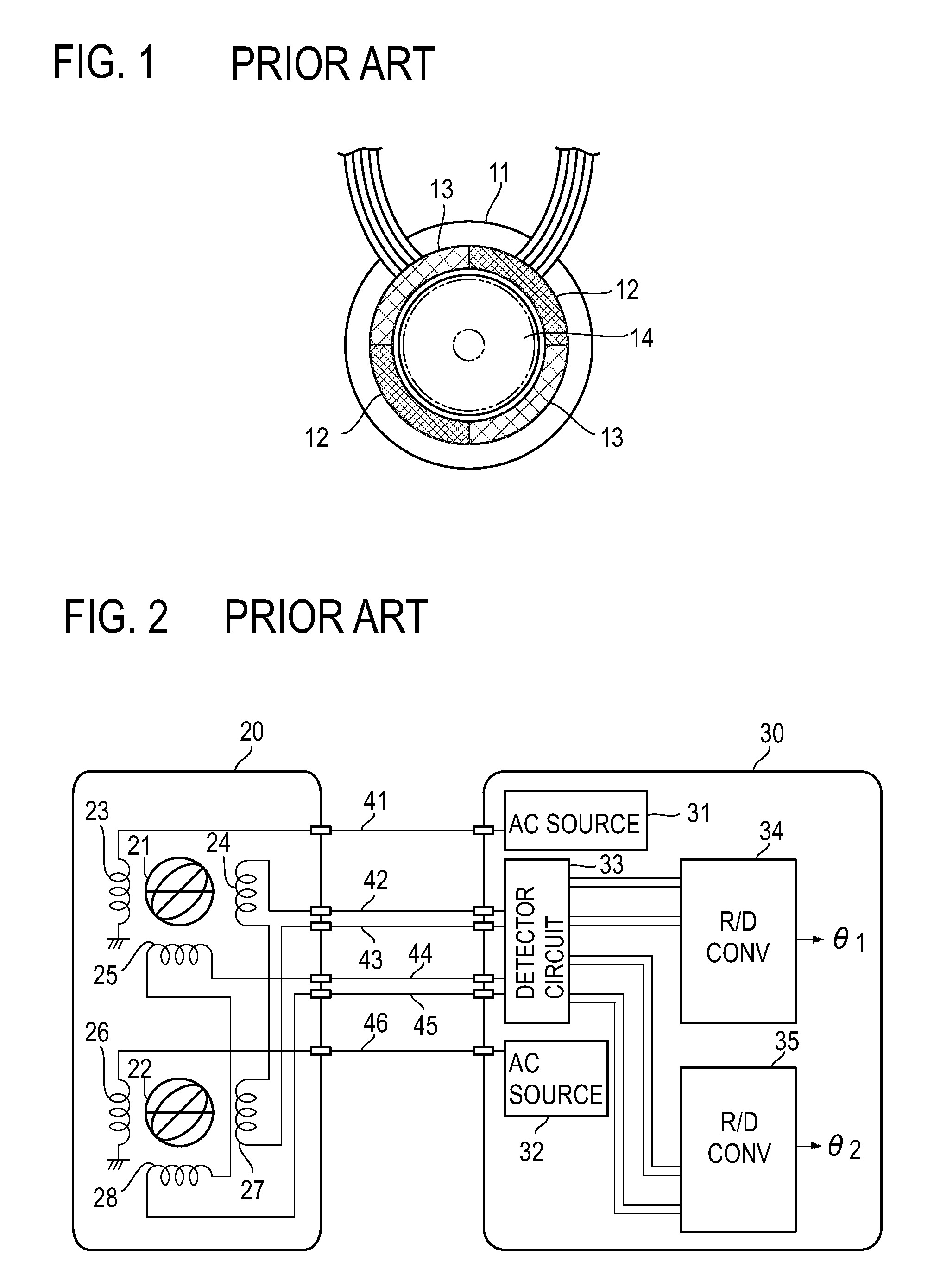

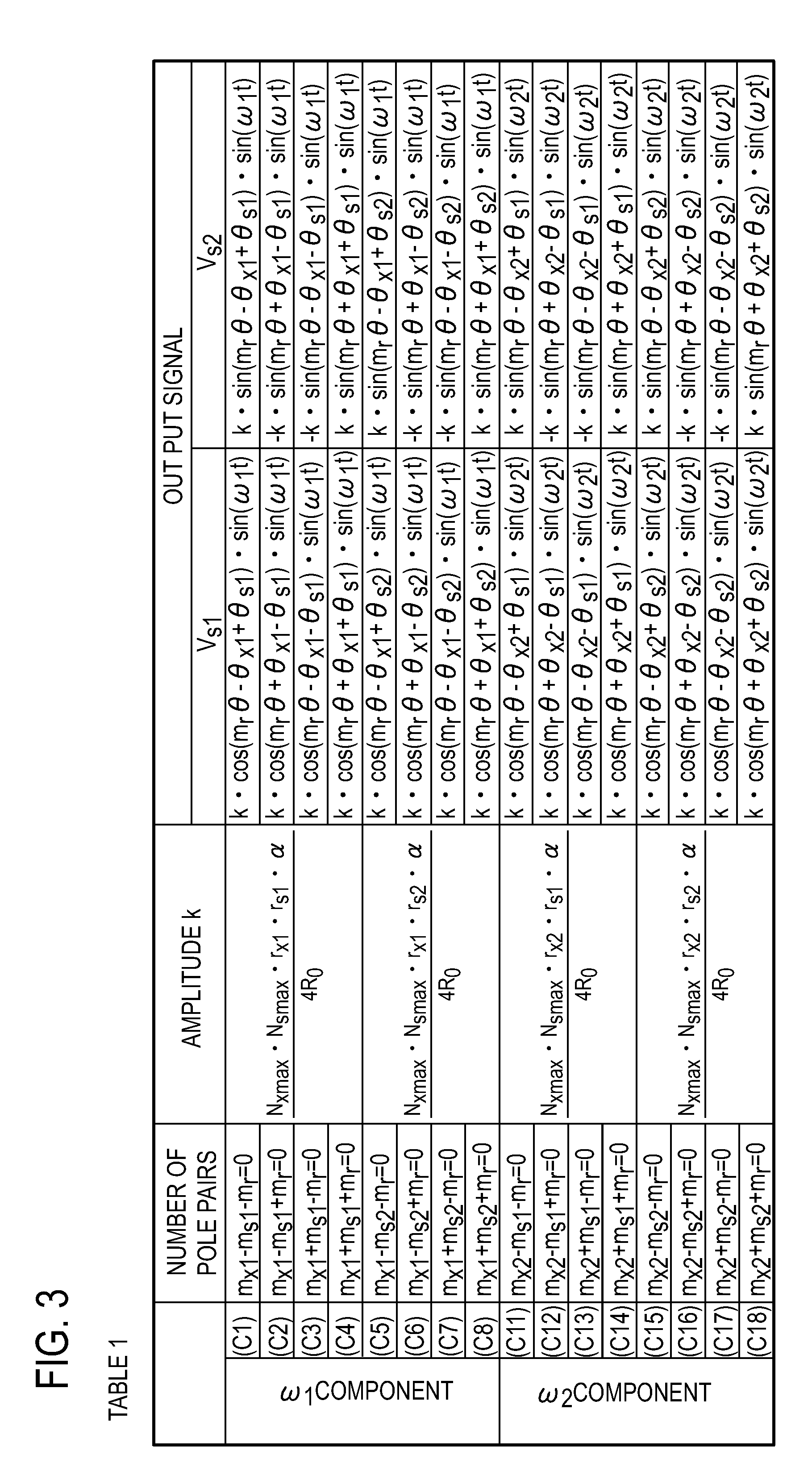

Variable Reluctance Resolver and Rotation Angle Detecting Device

ActiveUS20130060518A1Low costEasy to assembleSynchronous generatorsDigital computer detailsAtomic physicsRotary transformer

Two excitation coils (excitation A coil, excitation B coil) and two detection coils (detection A coil, detection B coil) are provided. The excitation A coil and the excitation B coil are excited at frequencies that are different from each other. The number of turns of the detection A coil and the detection B coil are respectively set with two sine waves using the number ms1 and ms2 of pole pairs. The number ms1 and ms2 of pole pairs, the number mx1 and mx2 of pole pairs of the excitation A coil and the excitation B coil, and the number mr of pole pairs of a rotor are set to have a predetermined relationship. A resolver having redundancy can be realized with small number of coils.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

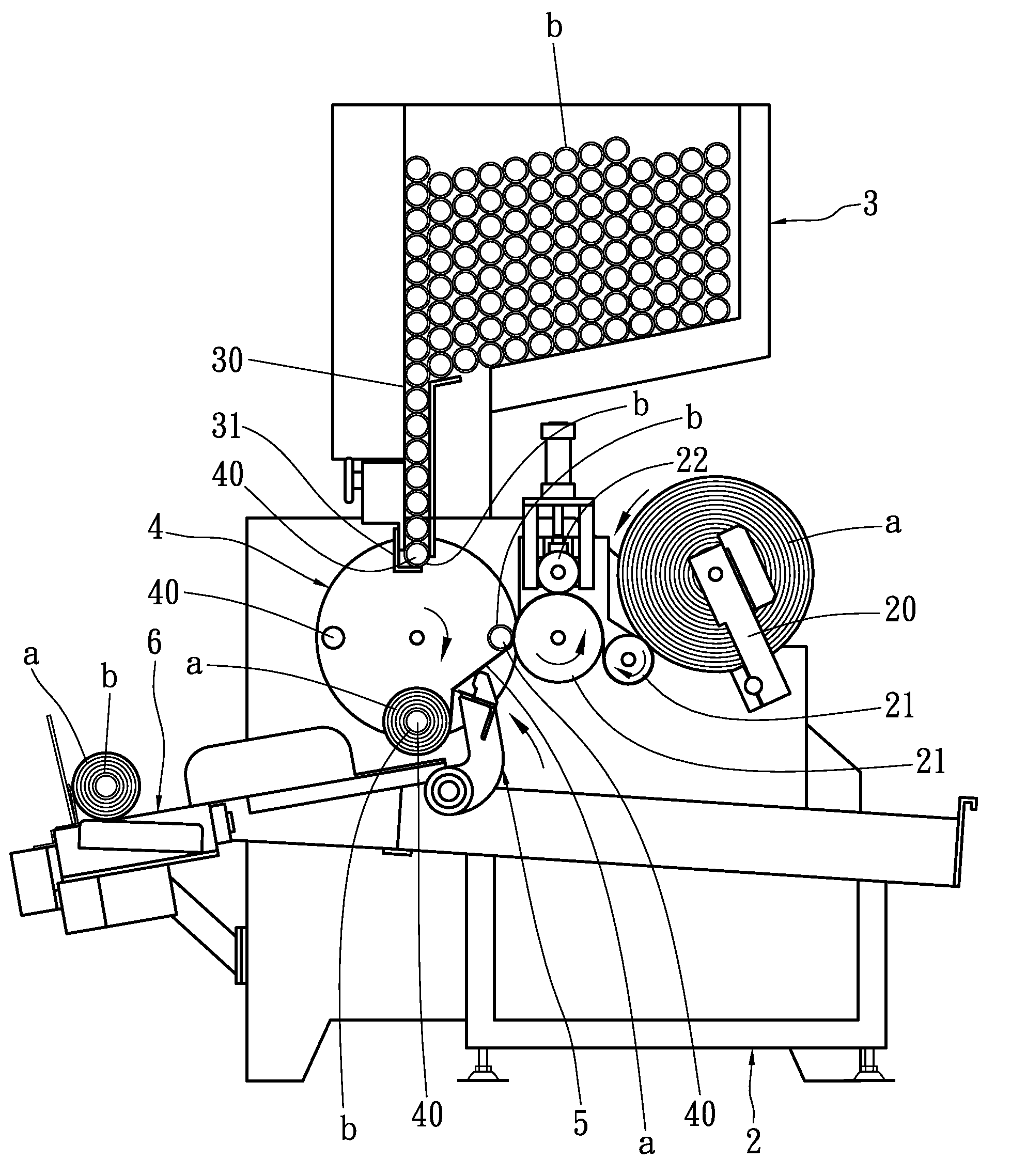

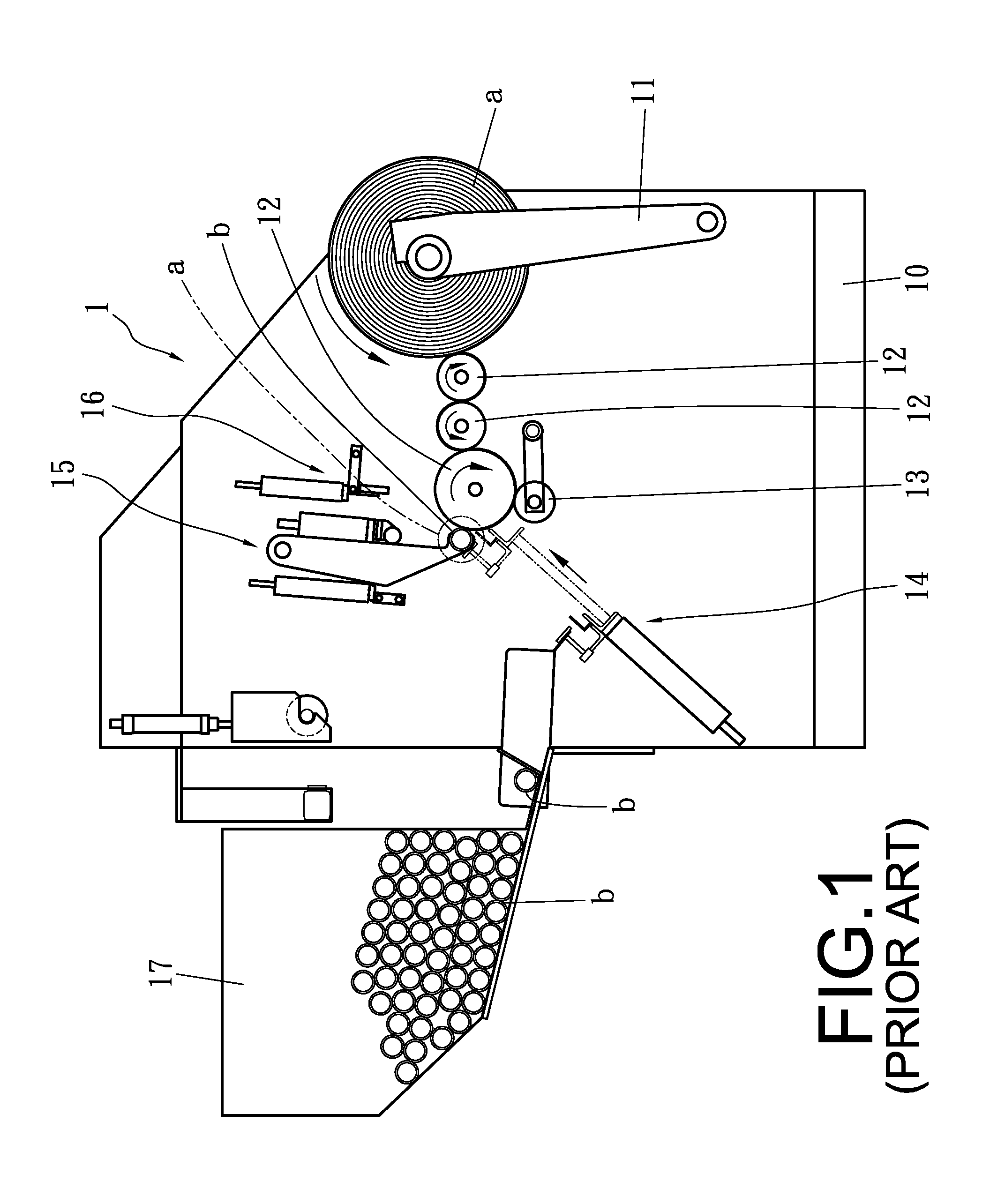

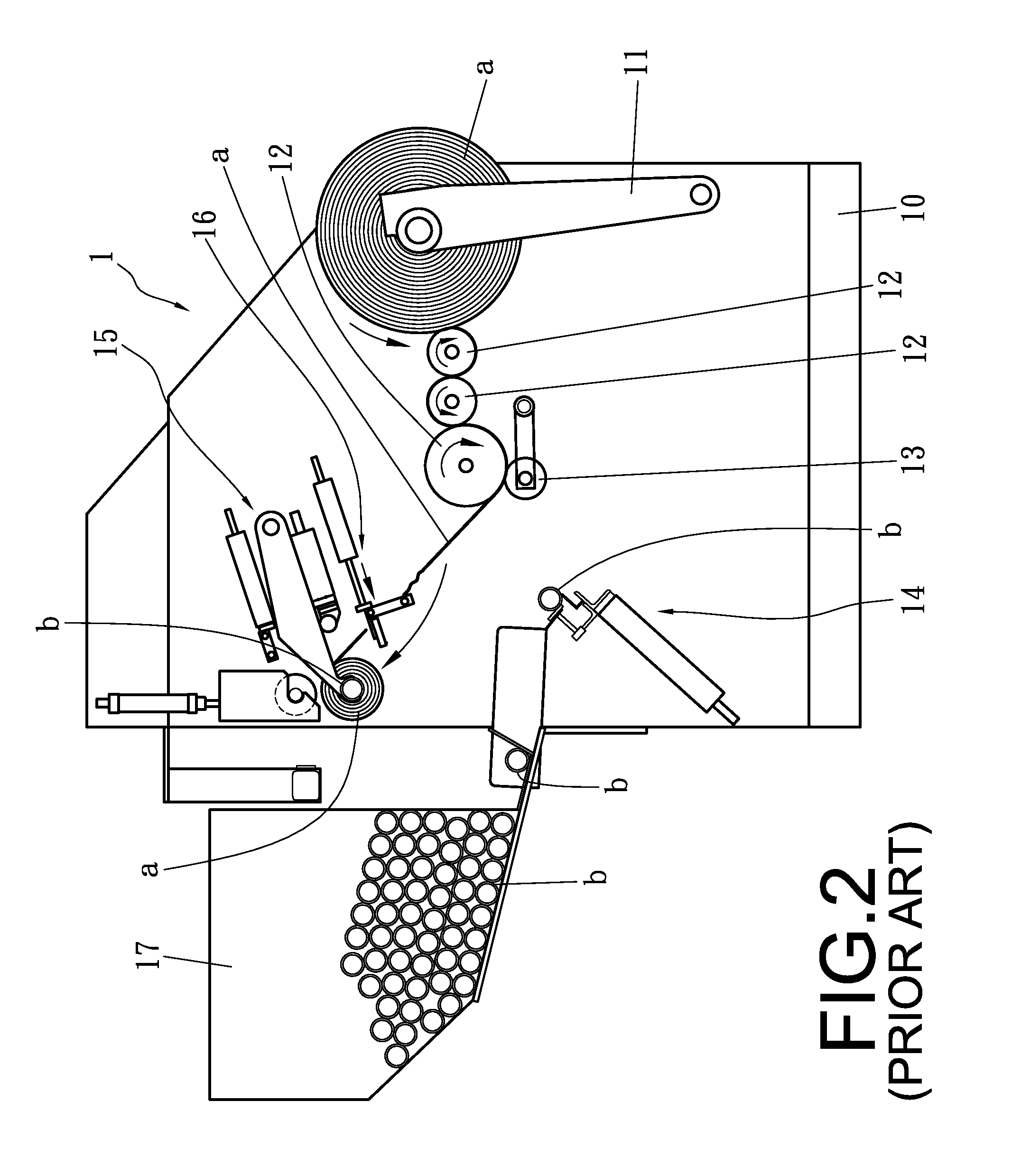

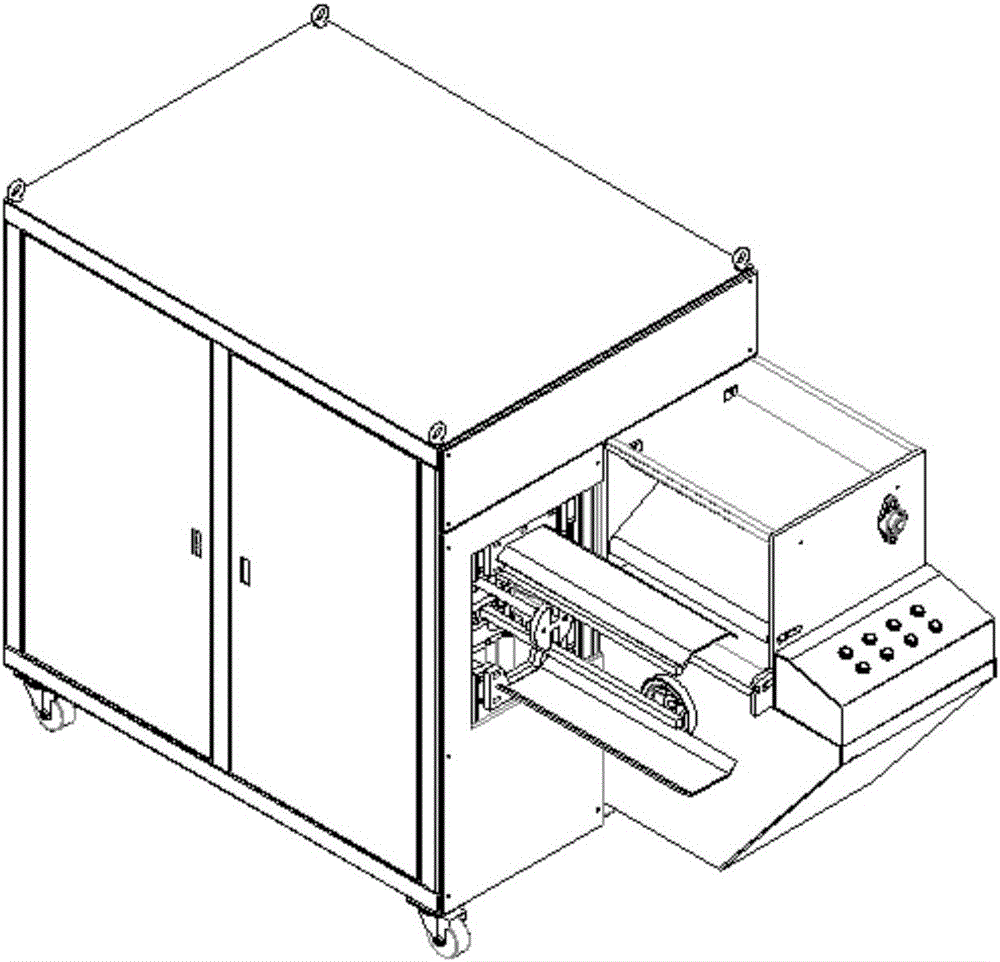

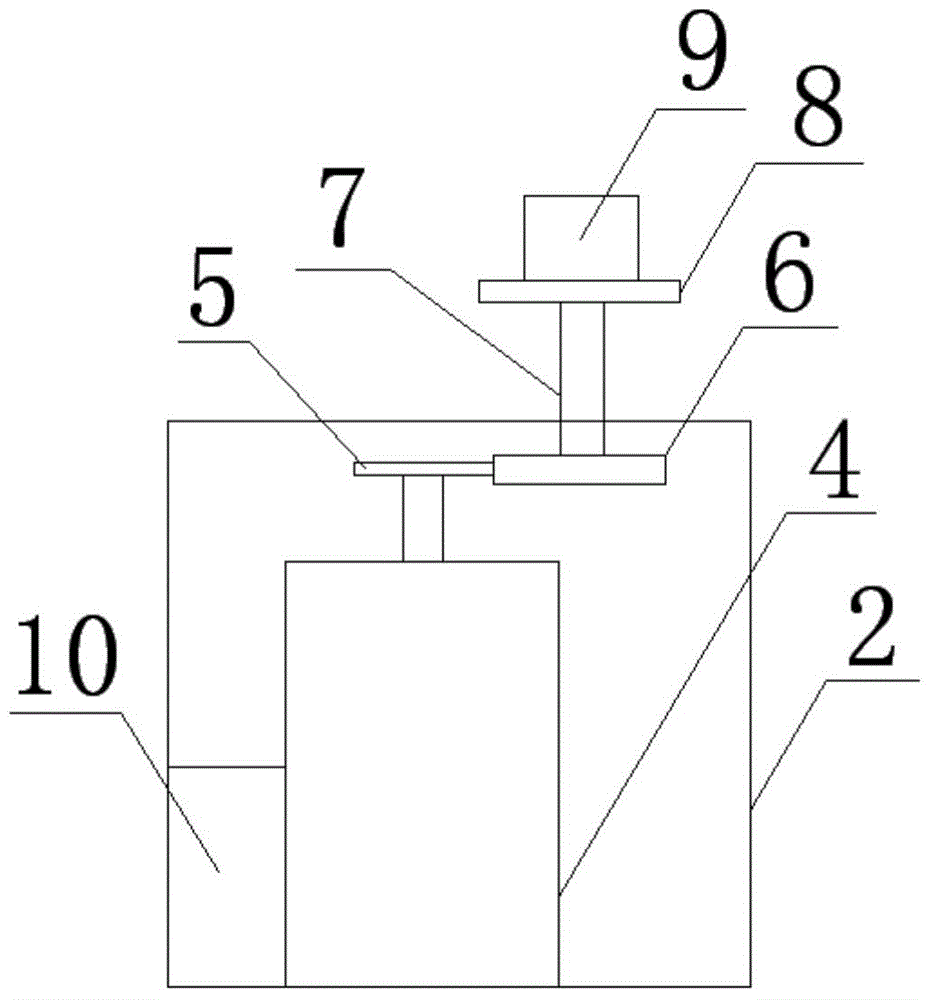

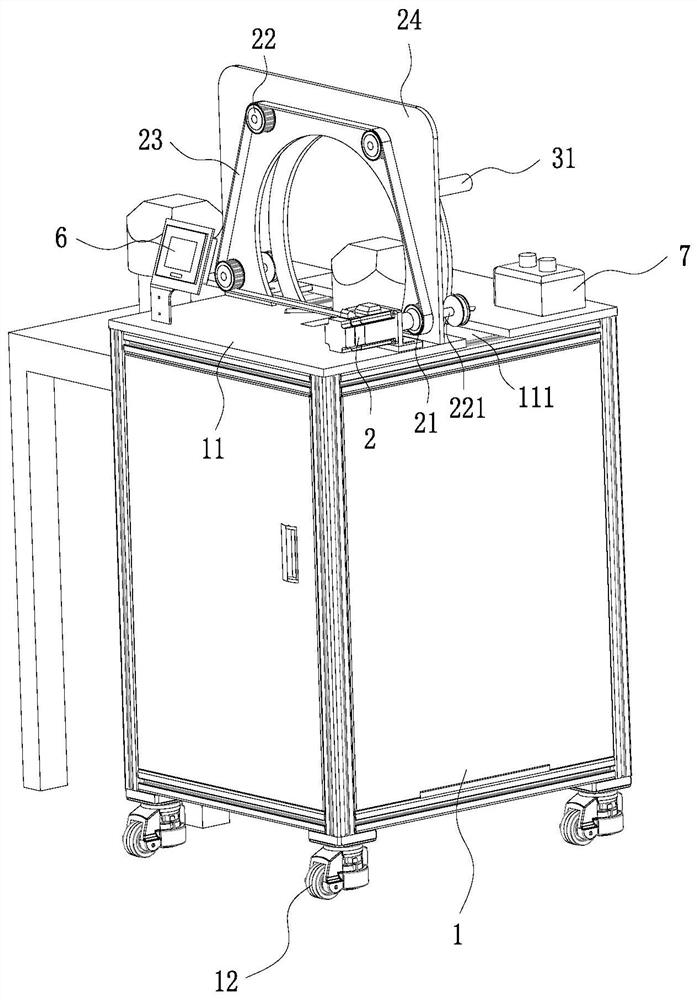

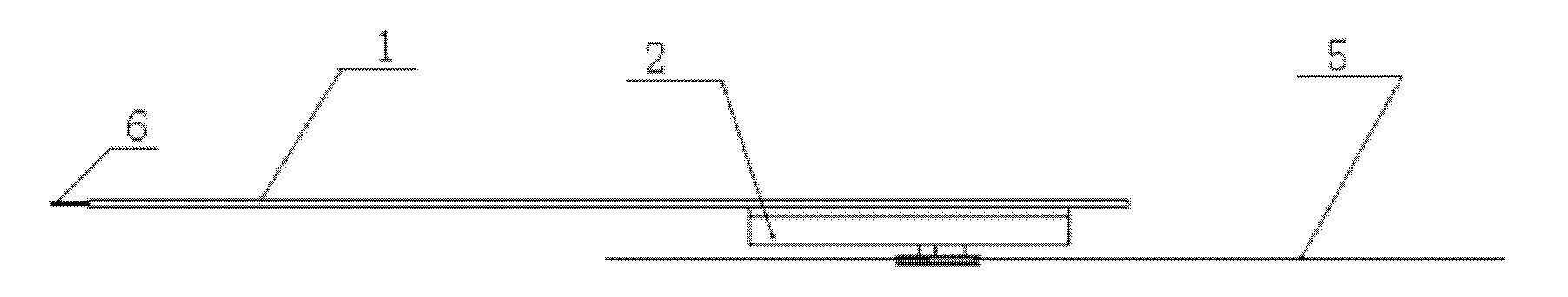

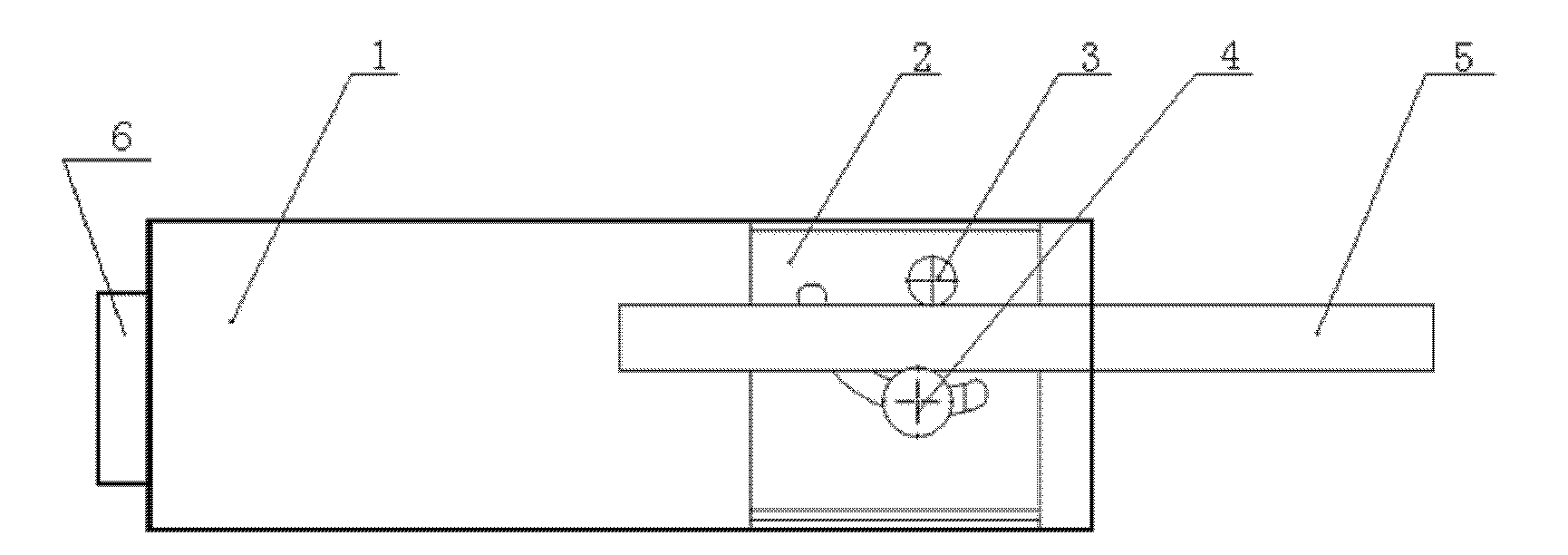

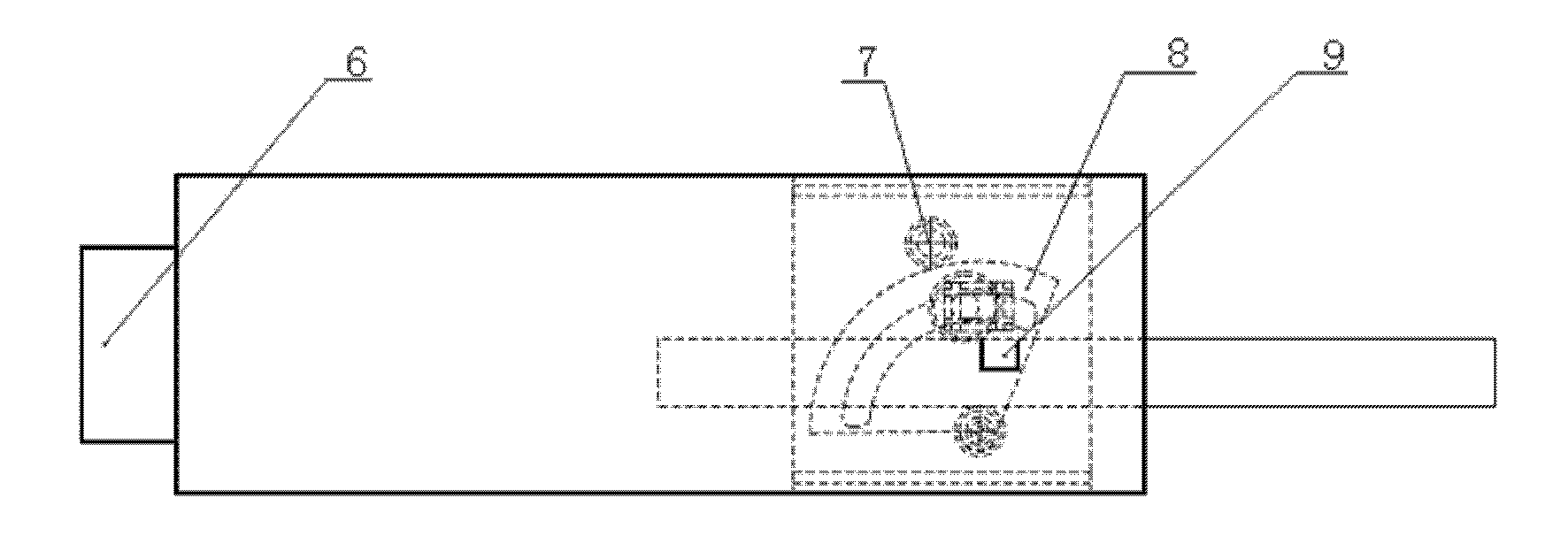

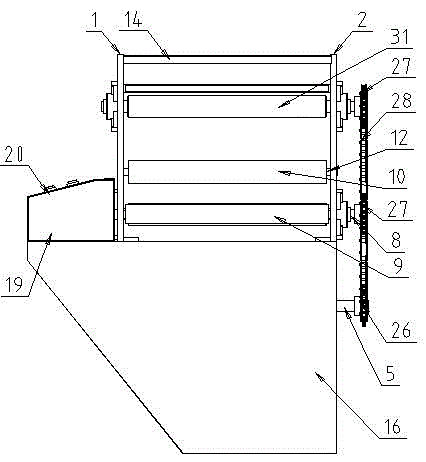

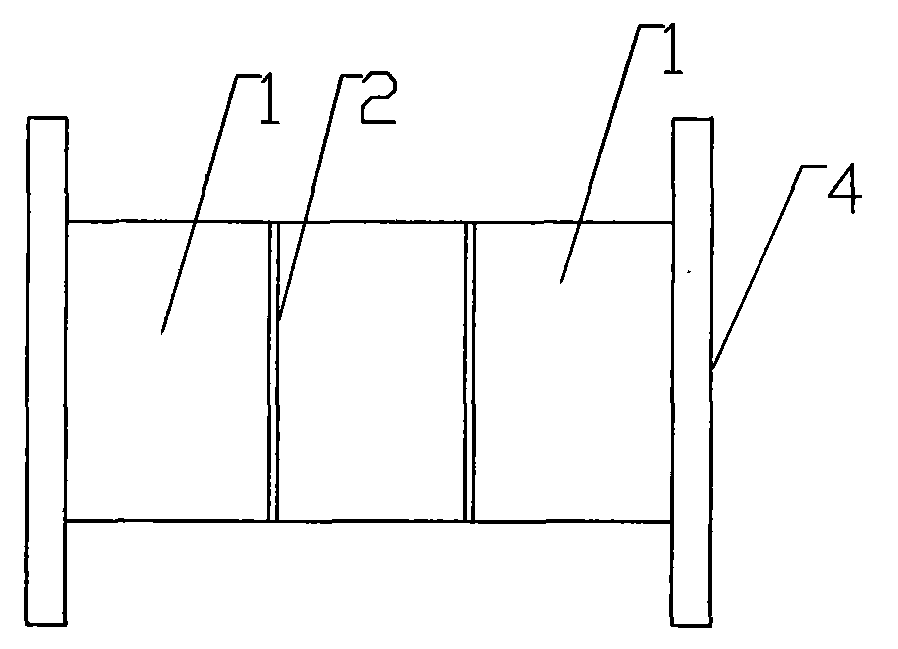

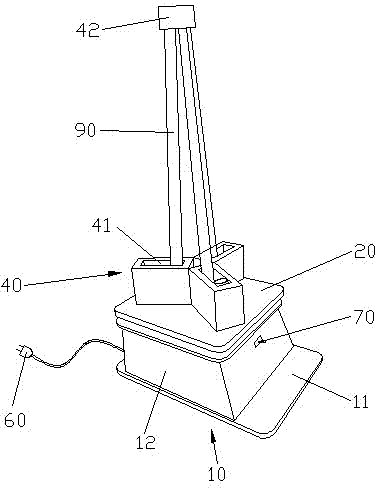

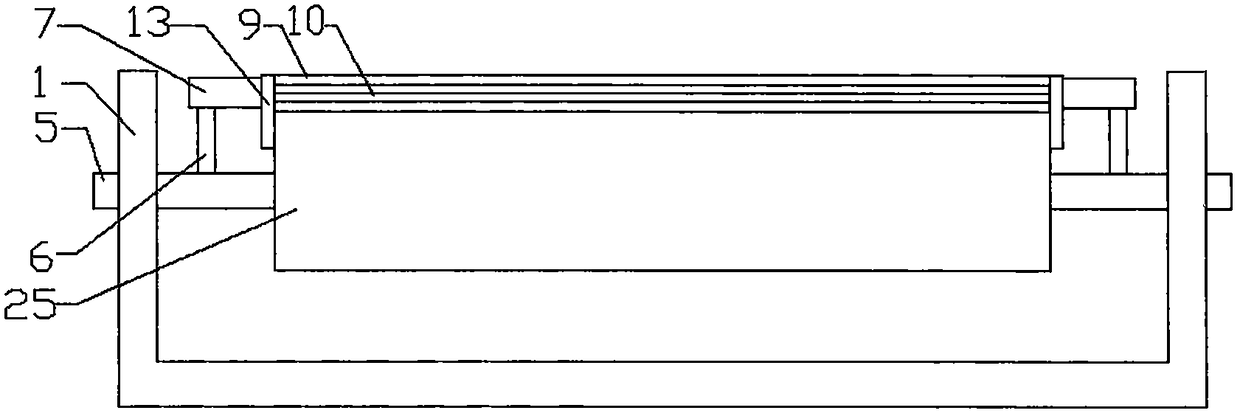

Automatic fast winding machine

InactiveUS20090242683A1High speedShorten winding timeFilament handlingWebs handlingWinding machineEngineering

An automatic fast winding machine includes a machine table, a support frame, a feeding tank, a rotary disk, plural guide rollers, a press roller, a saw-teeth cut device and a collect frame. A large roll of packing film is hung on the support frame. Packing film extends from the large roll, guided by the guide rollers pressed tightly by the press roller, and wound around a cylinder that falls down from the guide hole and supported on one of the support rods, and then the rotary disk turns for 90 degrees once to let the packing film cut by the saw-teeth cut device. Then the cylinder wound with packing film becomes a small roll of packing film to fall down along the collect frame and received and collected therein. All the operations are automatically performed by the machine with fast speed, enhancing production.

Owner:CHEN CHUN SHAN

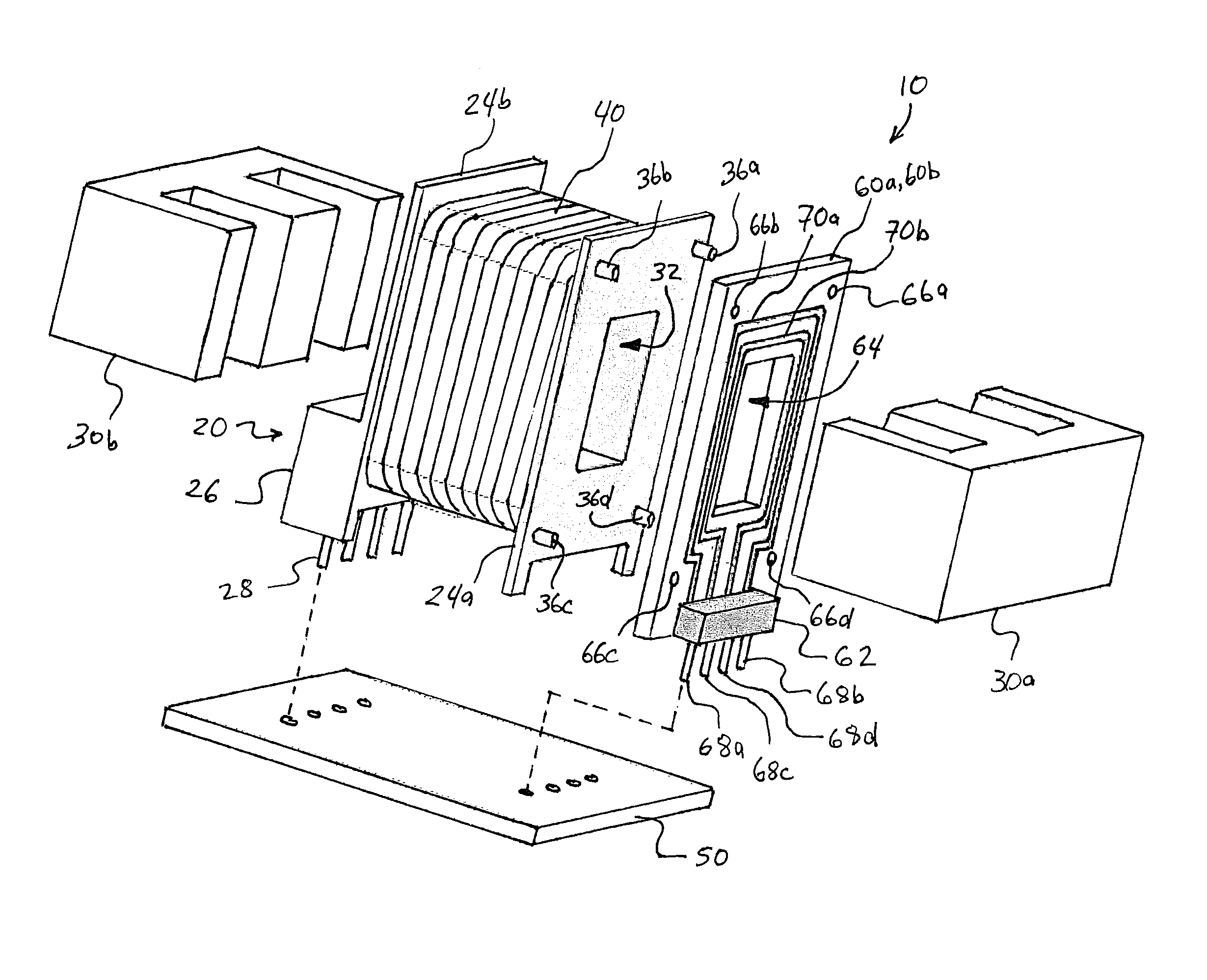

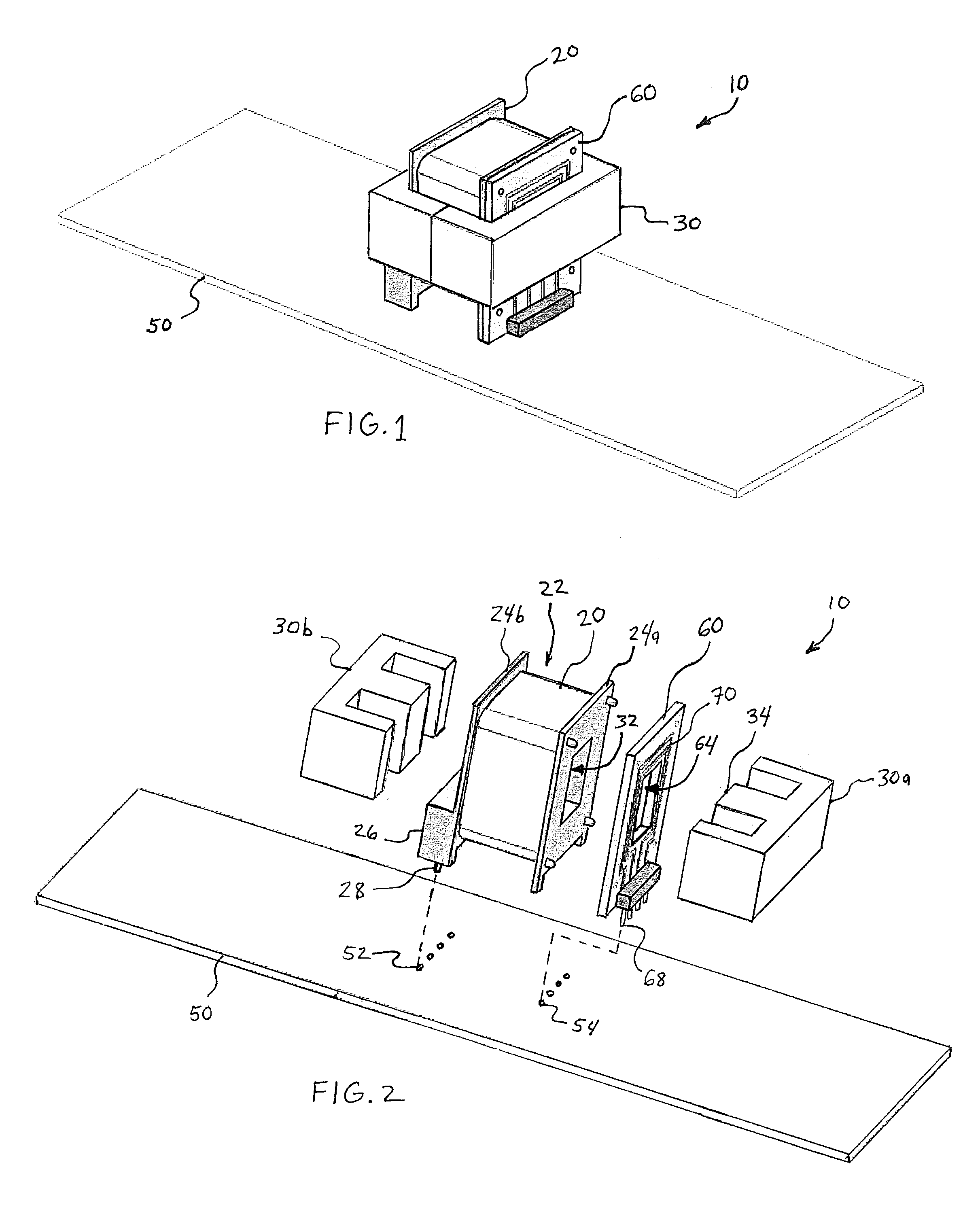

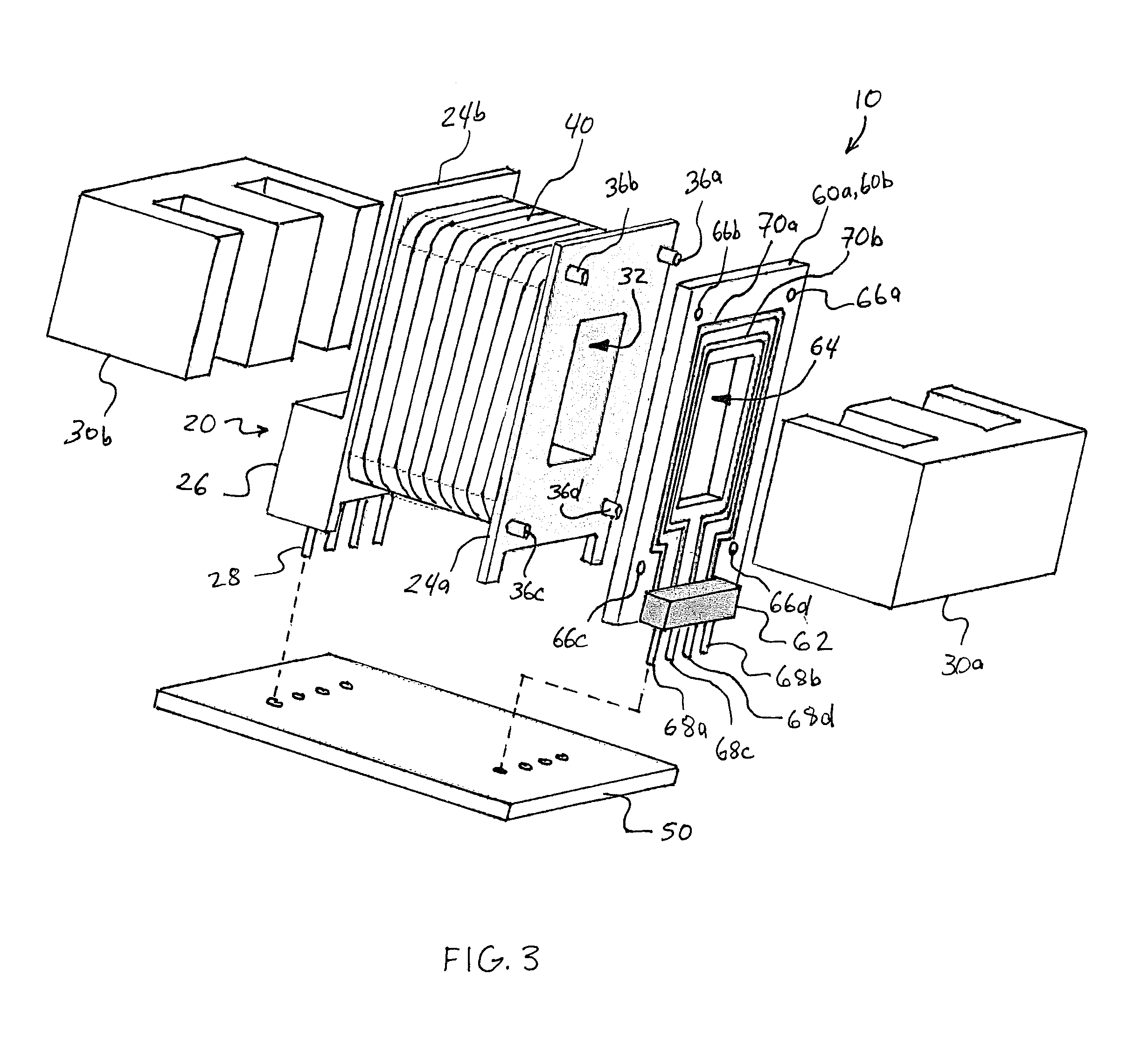

Magnetic component with auxiliary winding circuit board

InactiveUS9396865B1Small sizeShorten winding timeTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsBobbinLow voltage

An auxiliary winding circuit board includes one or more auxiliary conductive windings. The auxiliary winding circuit board is positioned at an axial end of a bobbin, and a core leg extends through an opening in the auxiliary winding circuit board. A main conductive winding is positioned on the bobbin. The auxiliary winding disposed on the auxiliary printed circuit board has enhanced voltage-isolation from the main winding positioned on the bobbin, allowing both a high-voltage main winding and a low-voltage auxiliary winding to be located on one magnetic component. The magnetic component is configured for mounting on a printed circuit board for an electronic device such as a power supply. A modular magnetic component apparatus includes a bobbin with main winding assembly and multiple auxiliary winding circuit boards that may be interchangeably mounted between the bobbin and core for desired applications.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

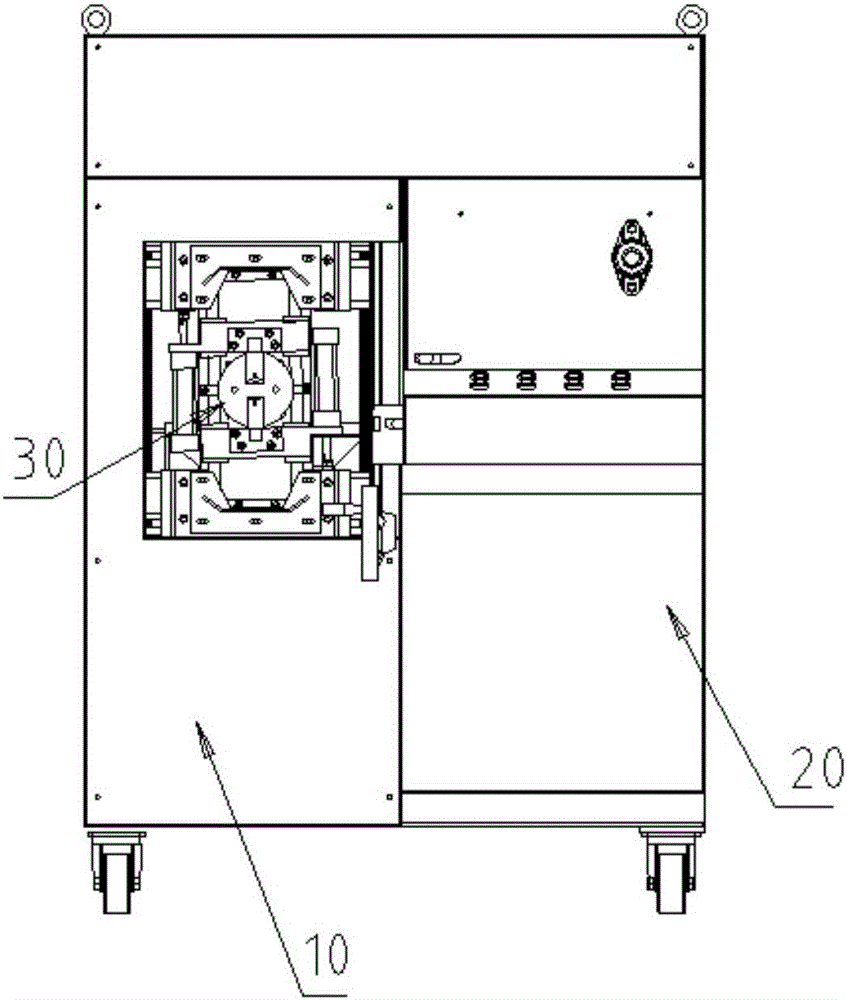

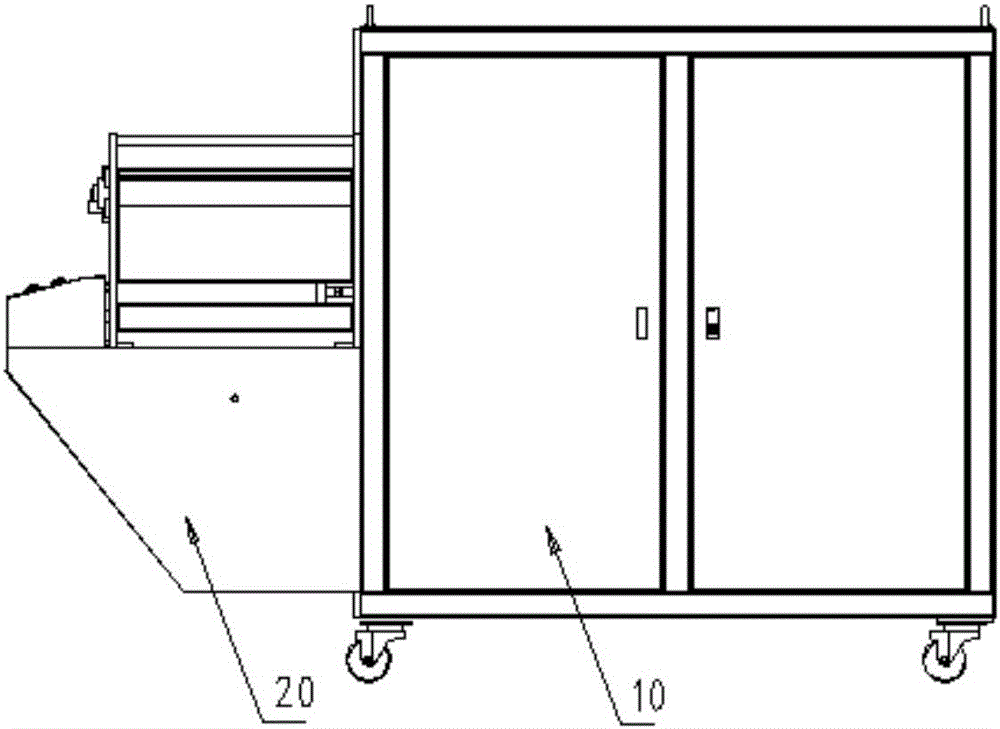

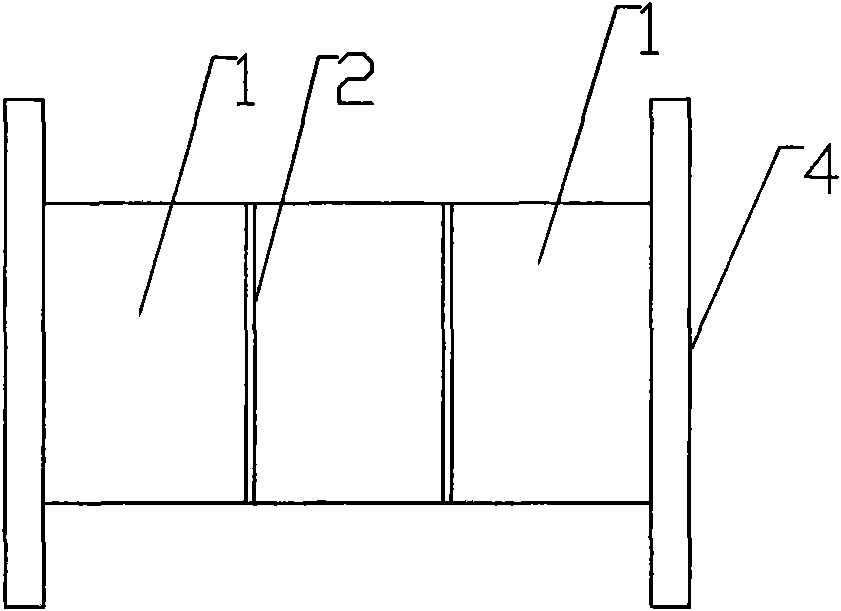

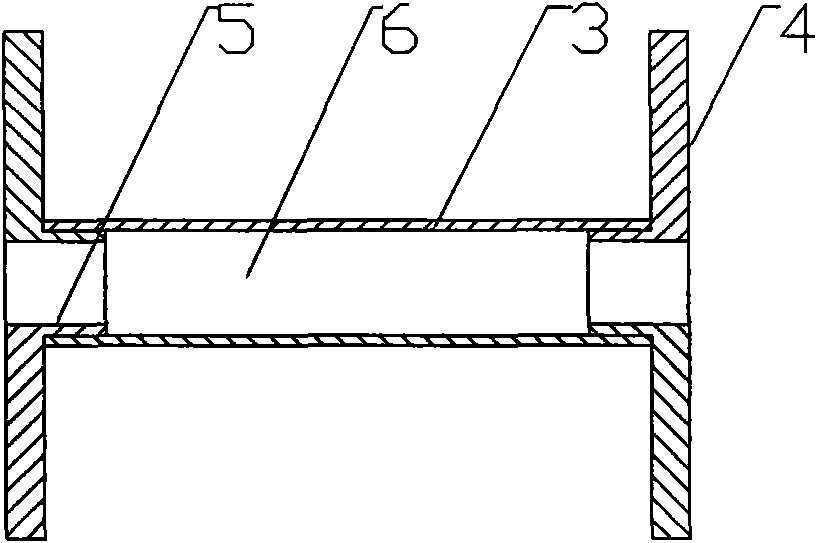

Full-automatic winding machine

ActiveCN105775225AAchieve shrinkageReduce or expand the distancePackagingWinding machineConductor Coil

The invention discloses a full-automatic winding machine. The full-automatic winding machine comprises a rack structure, a feeding device, a winding mechanism and a material pushing device; the feeding device is arranged at the outer side of the front end of the rack structure; the winding mechanism is arranged at the front end in the rack structure; and the material pushing device is arranged at the rear end of the winding mechanism. The rack structure in the full-automatic winding machine can make parts in the machine being fixed or move at relative positions; the feeding device is fixedly connected with the rack structure and used for orderly feeding to-be-packaged wound products; the winding mechanism is used for winding the products conveyed by a conveying belt and making the products meet the packaging requirement; and the material pushing device is used for pushing the products which are wound and meet the packaging requirement into a packaging container. An automatic manner is adopted for the four parts of the full-automatic winding machine to perform the whole winding process, the four parts coordinate with one another, each part completes one regulated operation, and the neat and orderly winding procedure is achieved.

Owner:LANGXI ZHENHAI MACHINERY

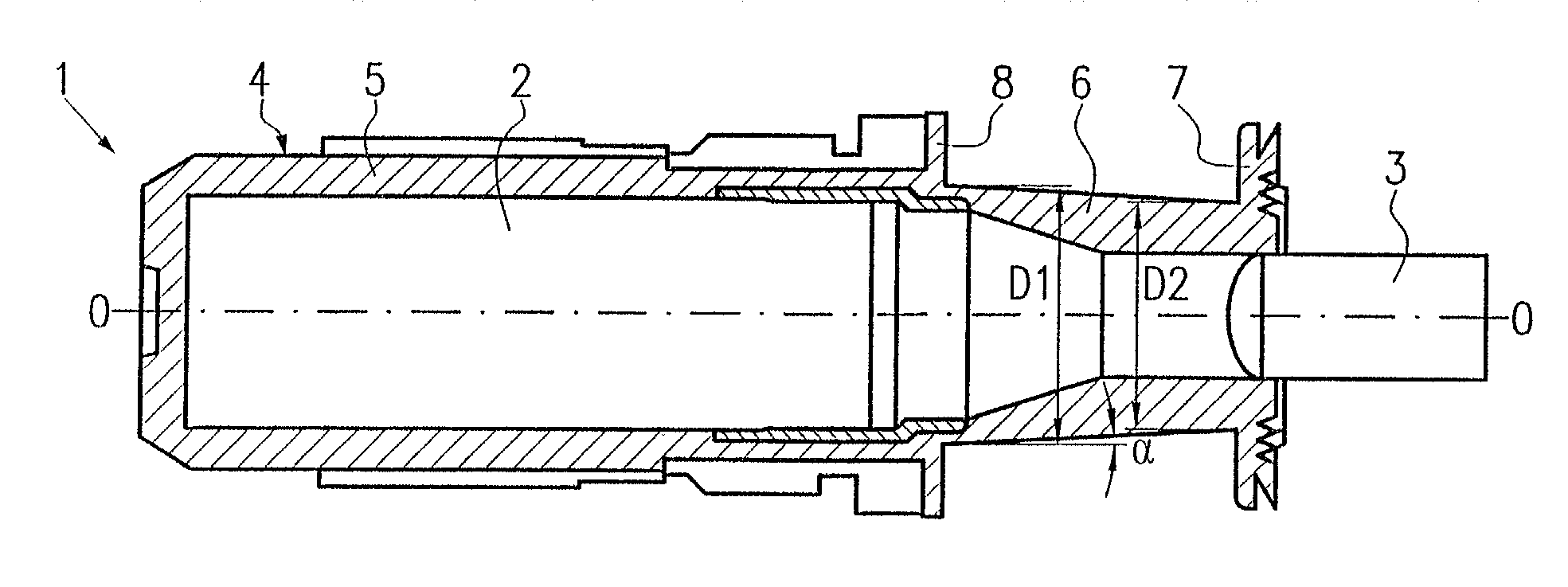

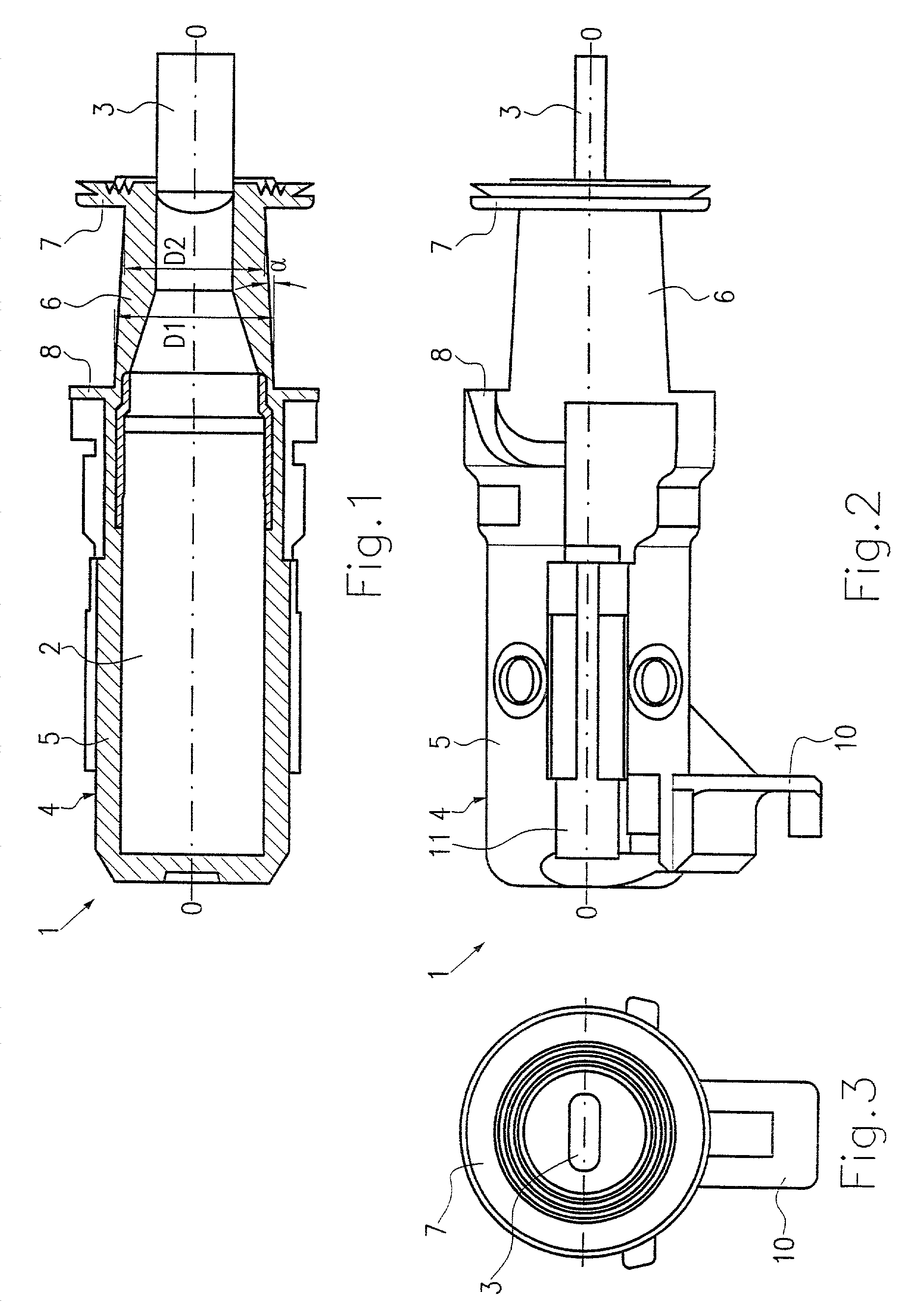

Inductive sensor (speed sensor) with a conical coil base body

InactiveUS7157901B1Reduce in quantityShorten winding timeUsing electrical meansSpeed/acceleration/shock instrument detailsMagnetInductive sensor

In summary, the present invention concerns an inductive sensor, in particular rpm sensor, having a housing (4) with a main housing body (5) and a coil base body (6), whereby a coil is wound around the coil base body (6). The sensor also comprises a magnet (2) that is situated in the housing and has a pole pin (3). The coil base body (6) of the housing (4) is thereby designed entirely conical, in particular slightly conical, in shape.

Owner:ROBERT BOSCH GMBH

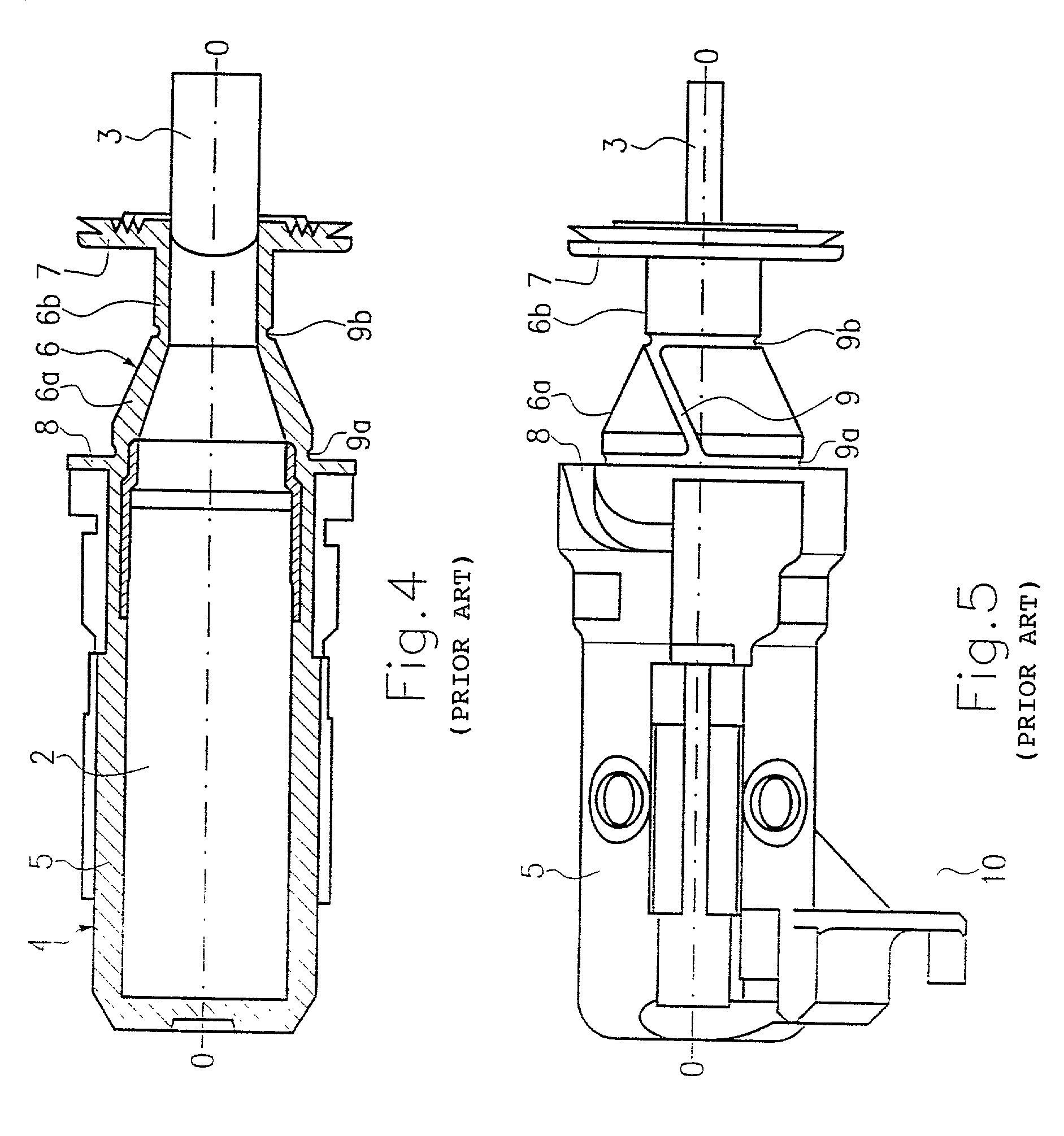

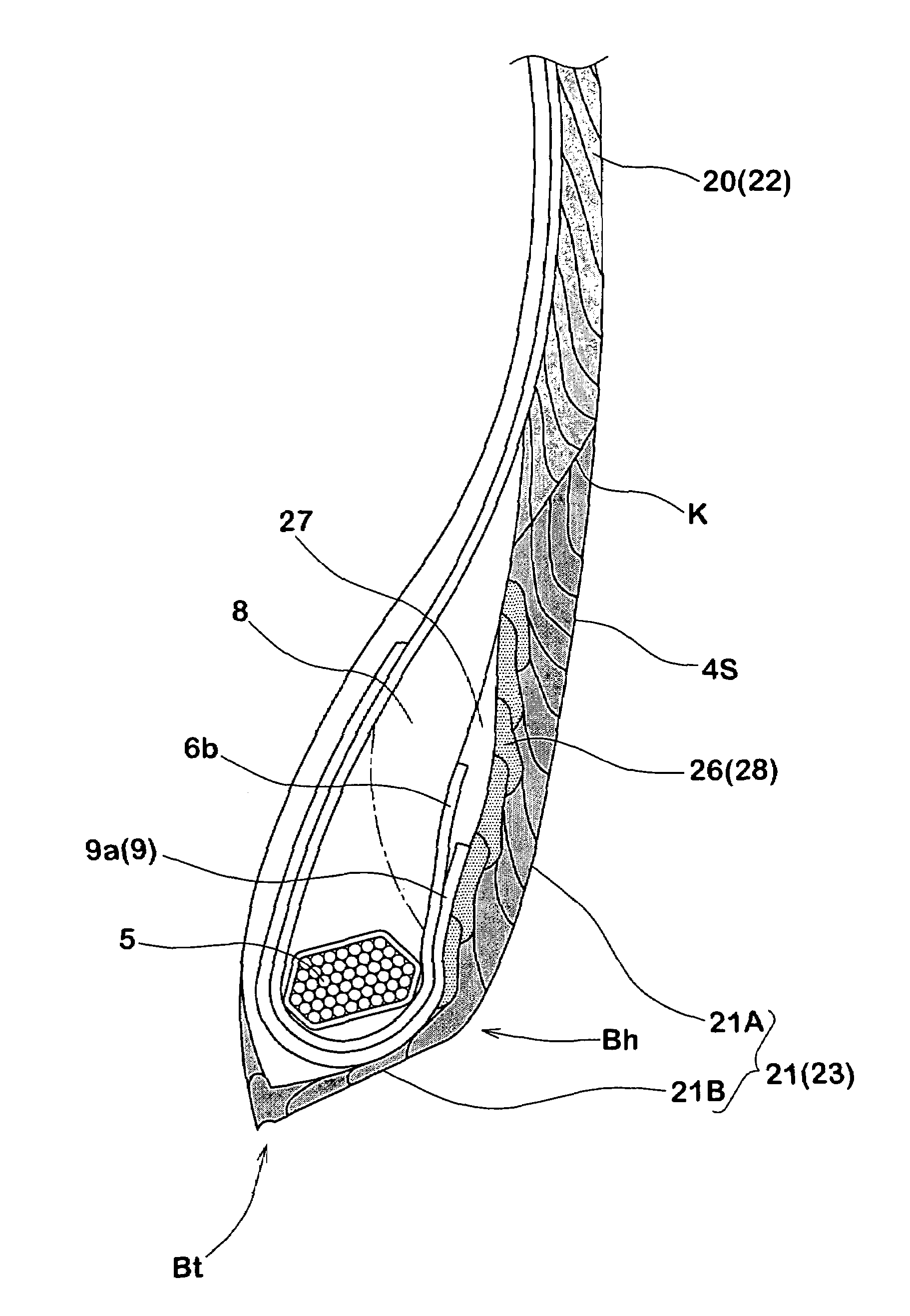

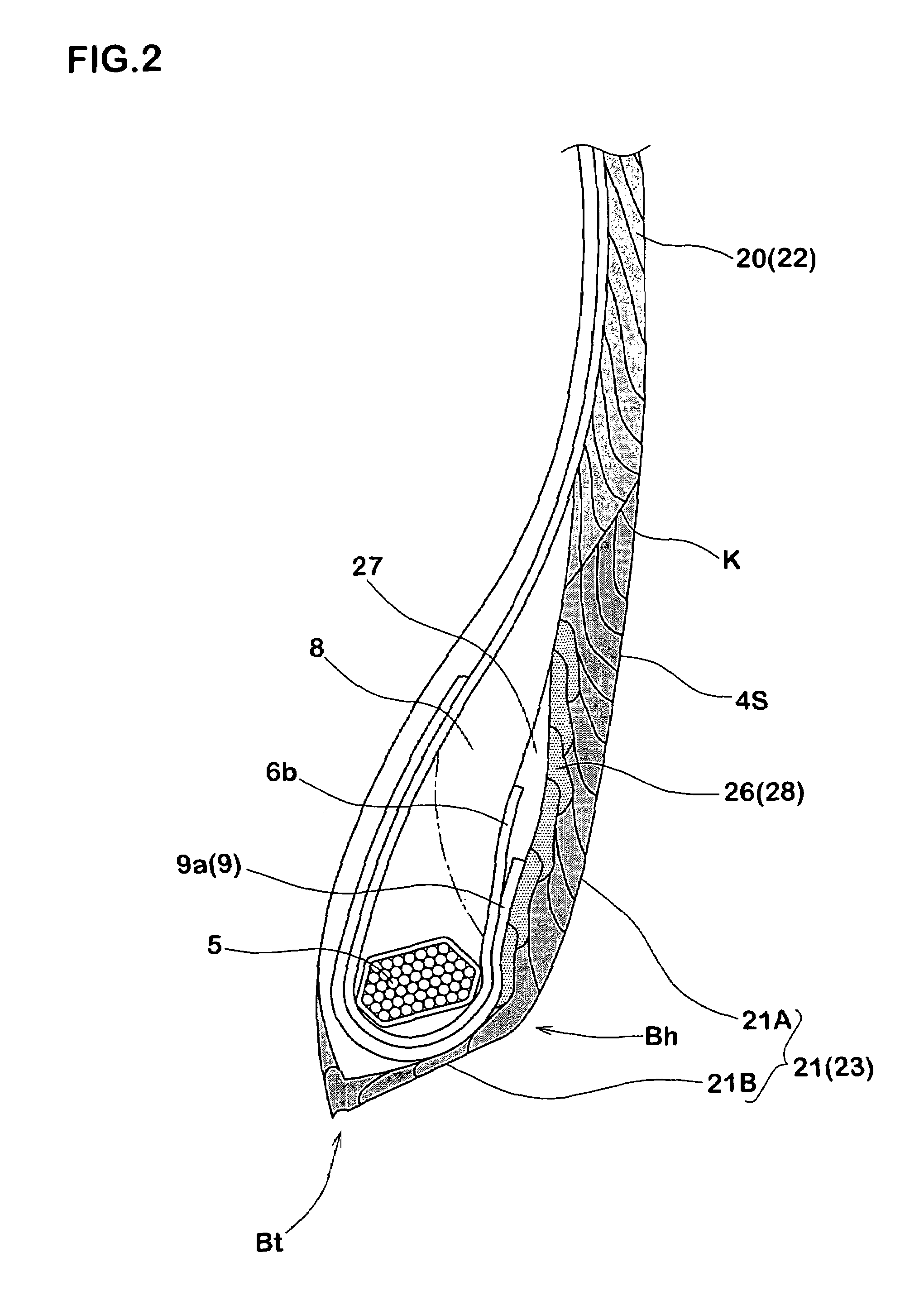

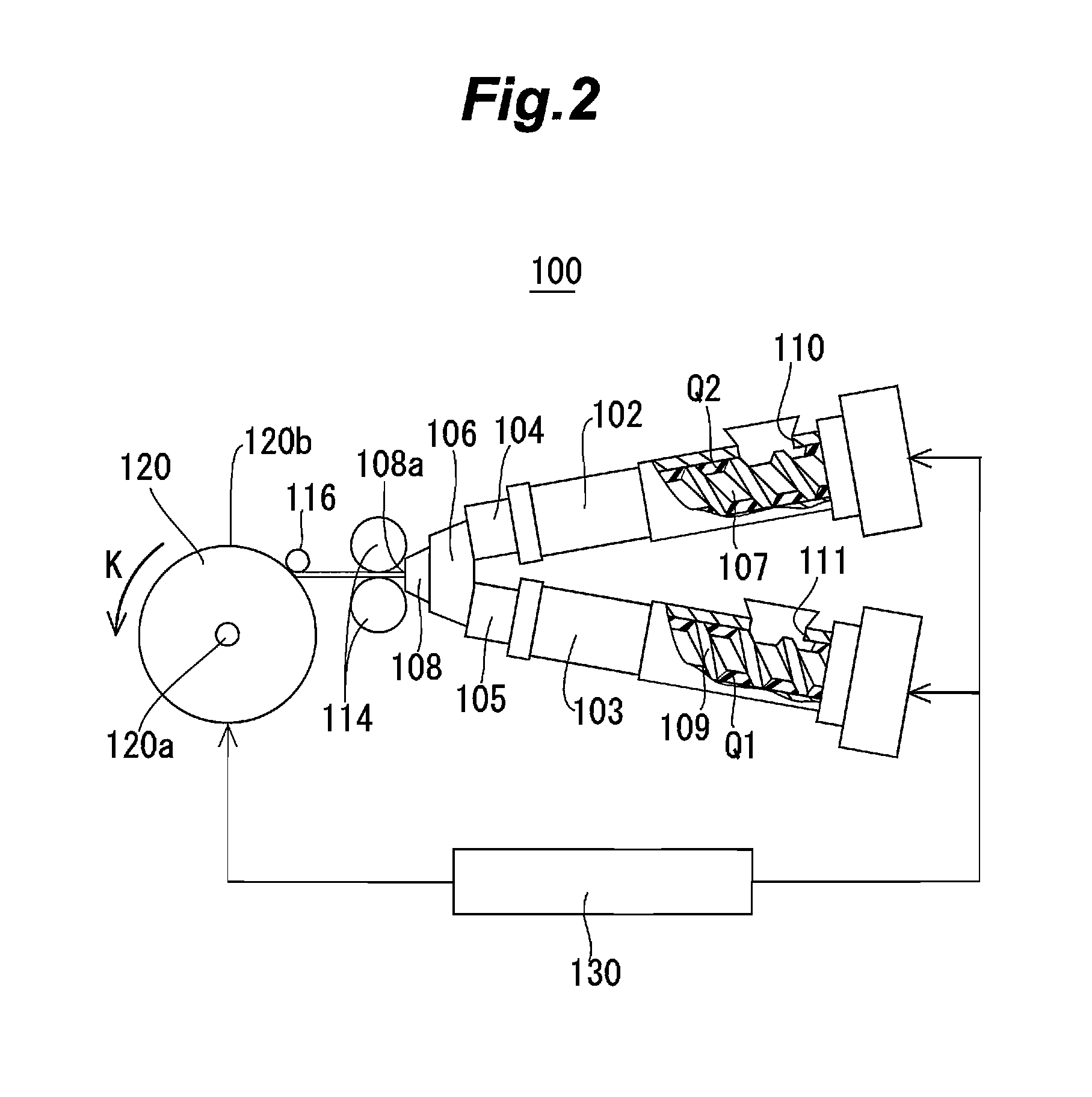

Pneumatic tire and manufacturing method of the same

InactiveUS7628190B2Improve appearance qualityShorten winding timeWithout separate inflatable insertsTyresMechanical engineeringTread

A pneumatic tire comprises a carcass reaching a bead core of a bead portion from a tread portion via a side wall portion; a side wall rubber arranged in an outer side of said carcass and forming an outer side surface of said side wall portion; and a clinch rubber for preventing a rim displacement connected to a lower end of the side wall rubber and forming an outer side surface of said bead portion. The sidewall rubber and the clinch rubber are constituted by a strip wind body formed by winding and overlapping a side wall rubber strip and a clinch rubber strip in a circumferential direction and spirally, and the respective rubber strips are wound in the same direction from the bead portion side toward the tread portion side.

Owner:SUMITOMO RUBBER IND LTD

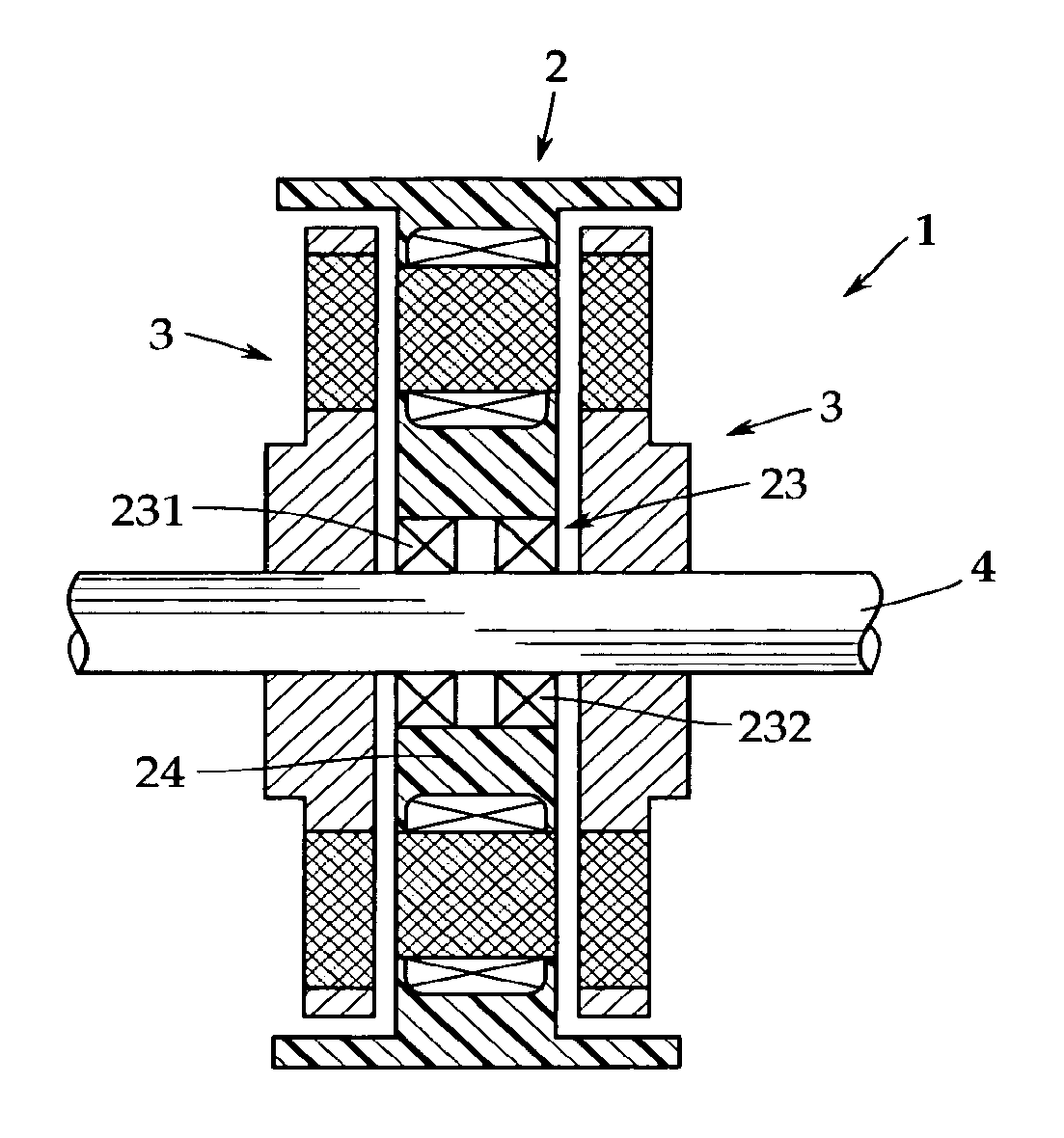

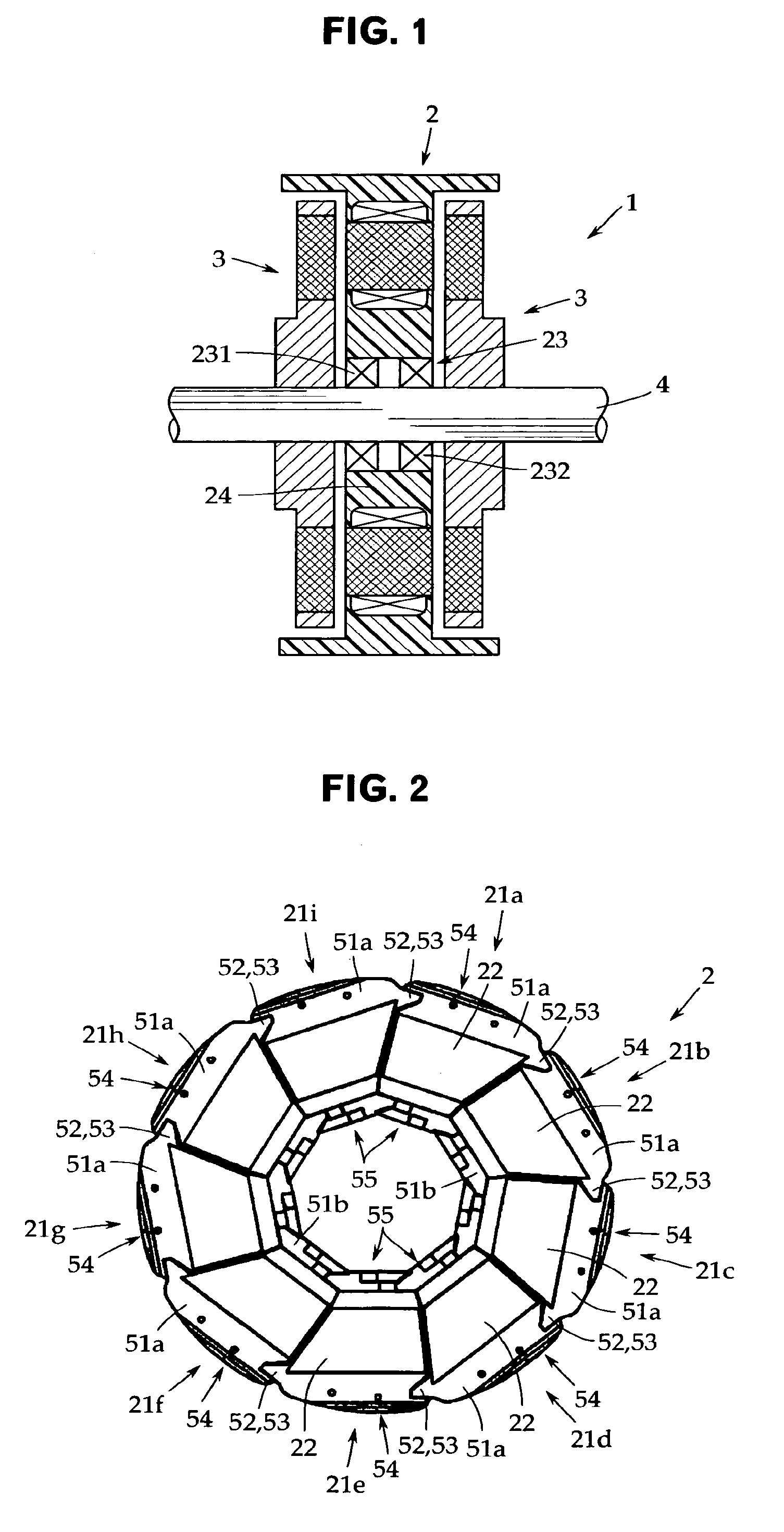

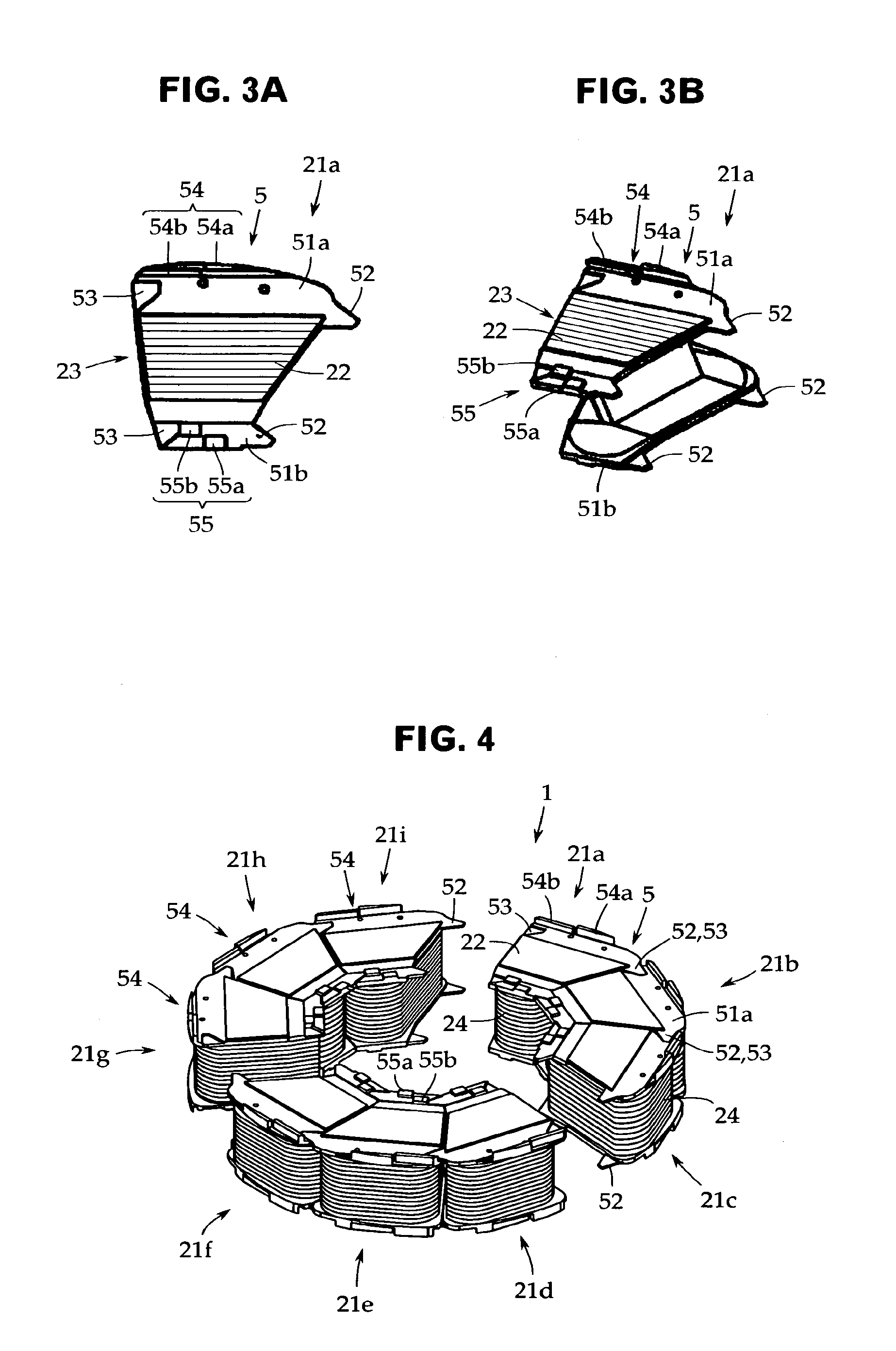

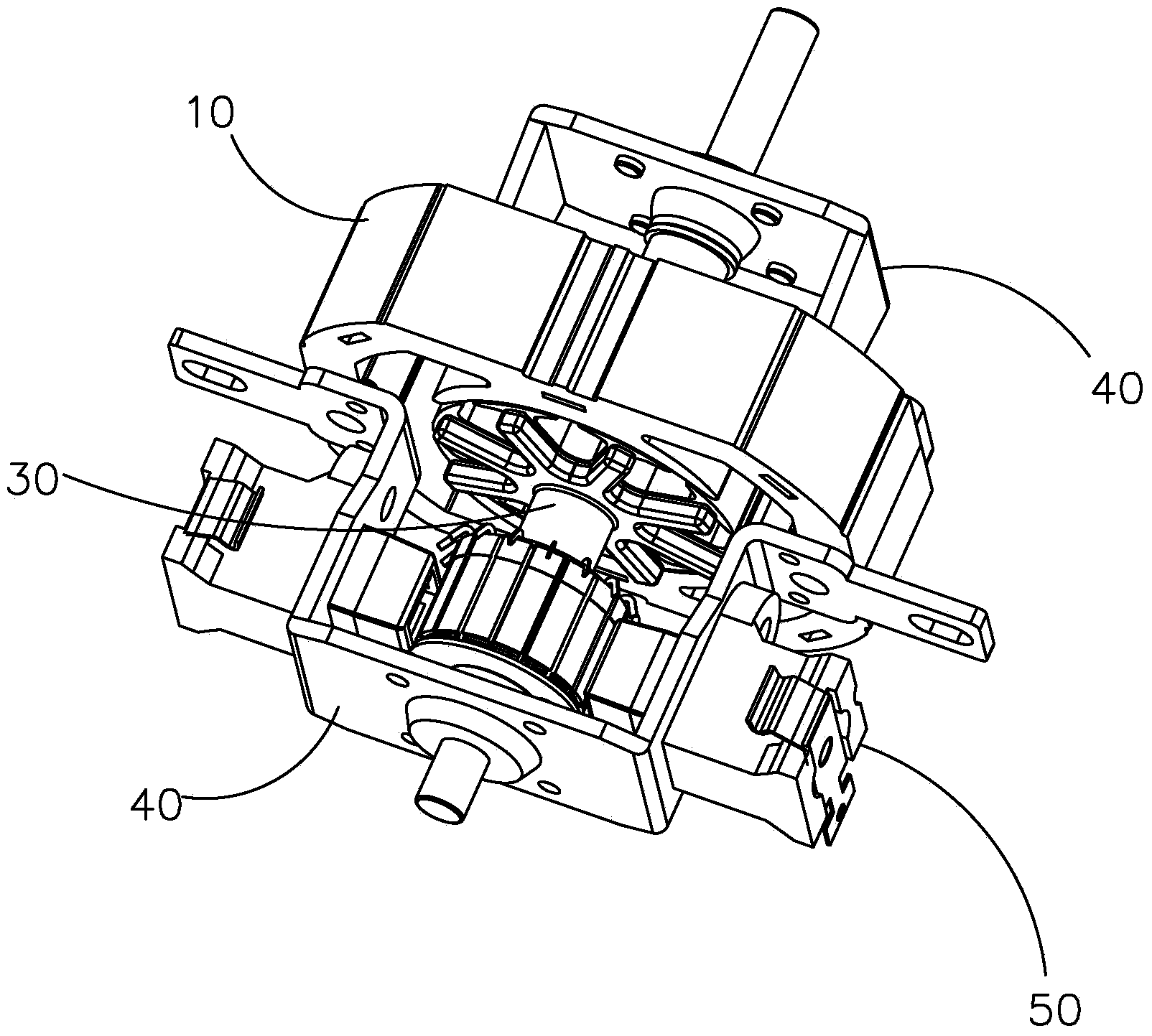

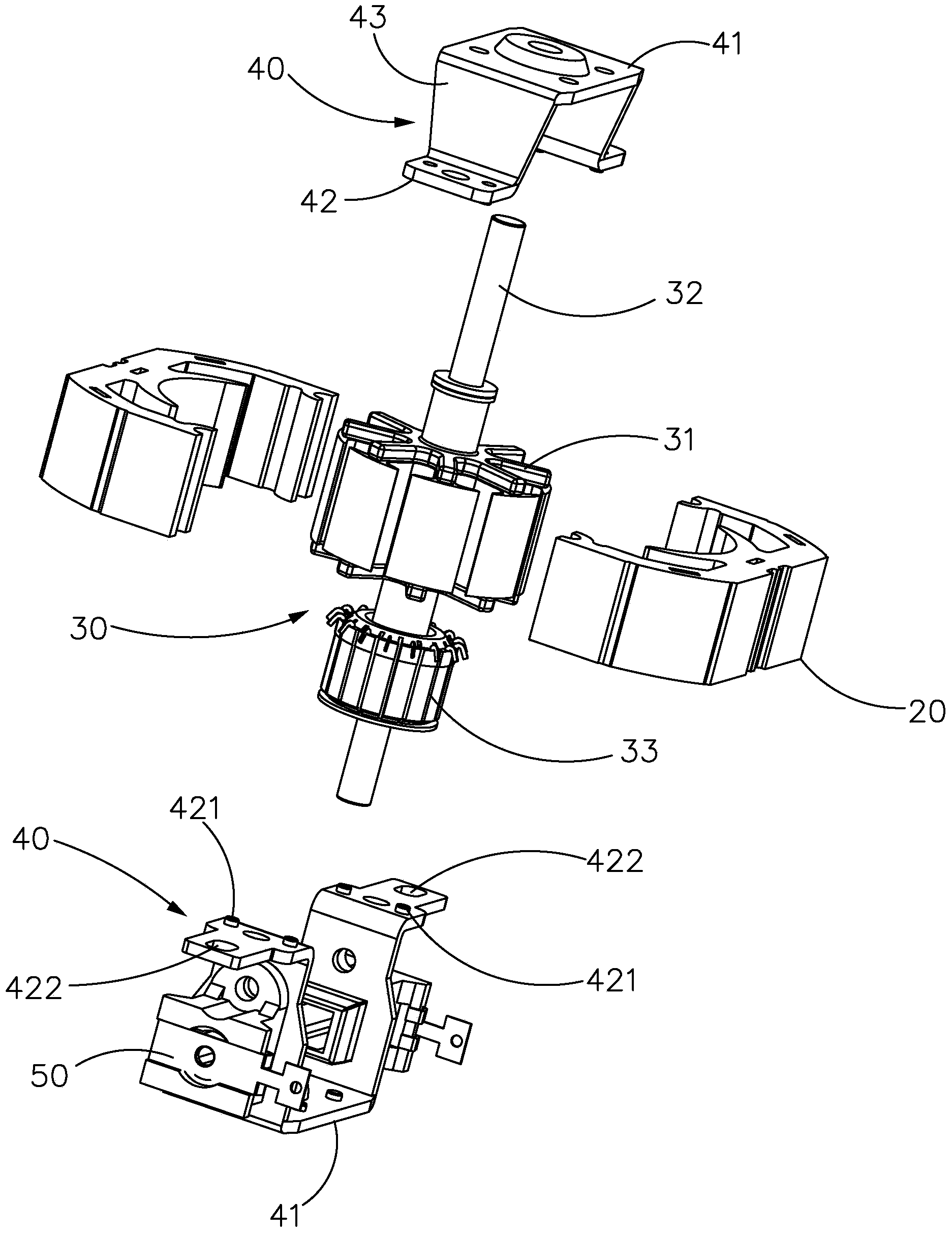

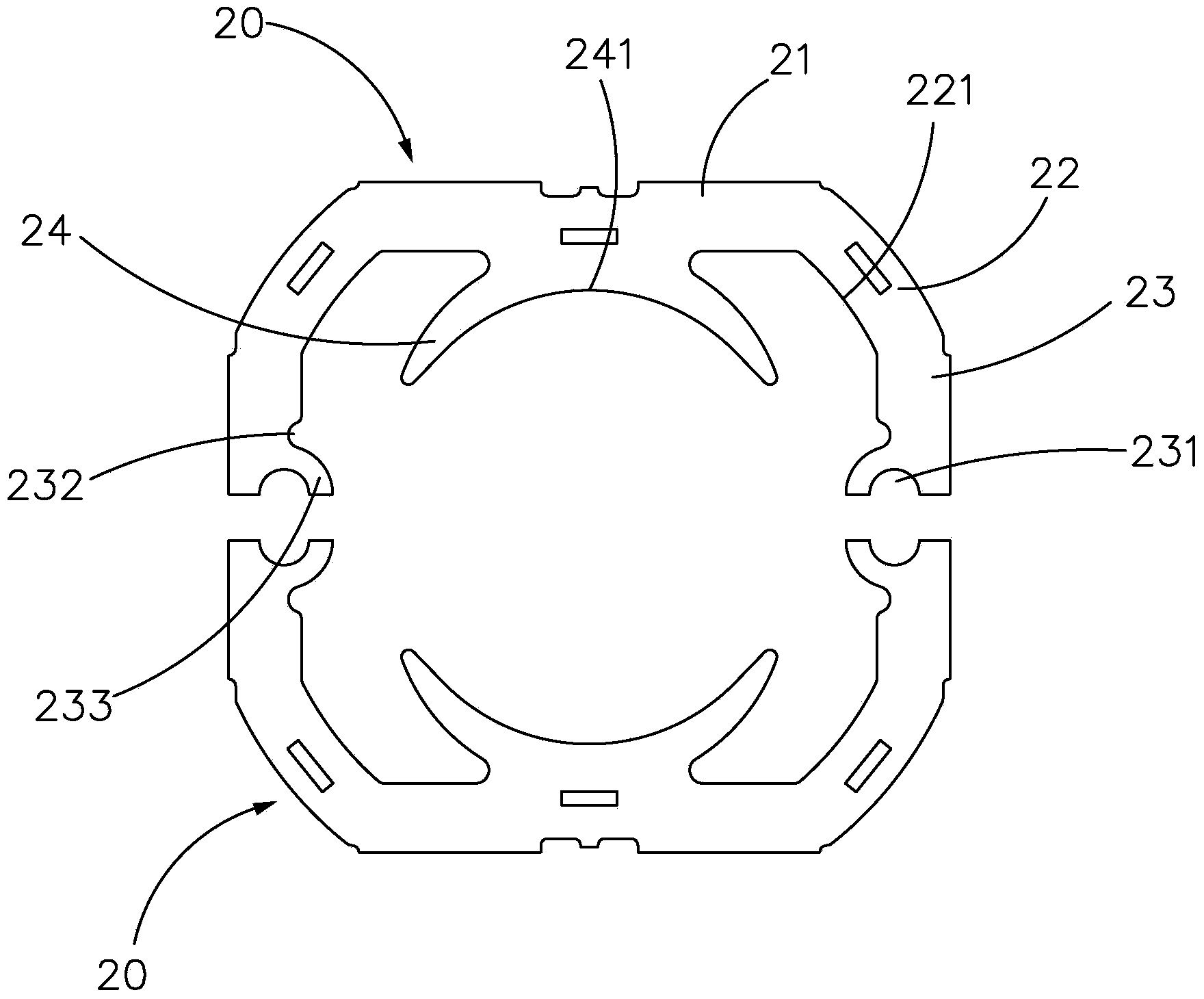

Axial air-gap electronic motor

ActiveUS7531937B2Shorten winding timeReduce assembling manpowerMechanical apparatusMagnetic circuit rotating partsEngineeringConductor Coil

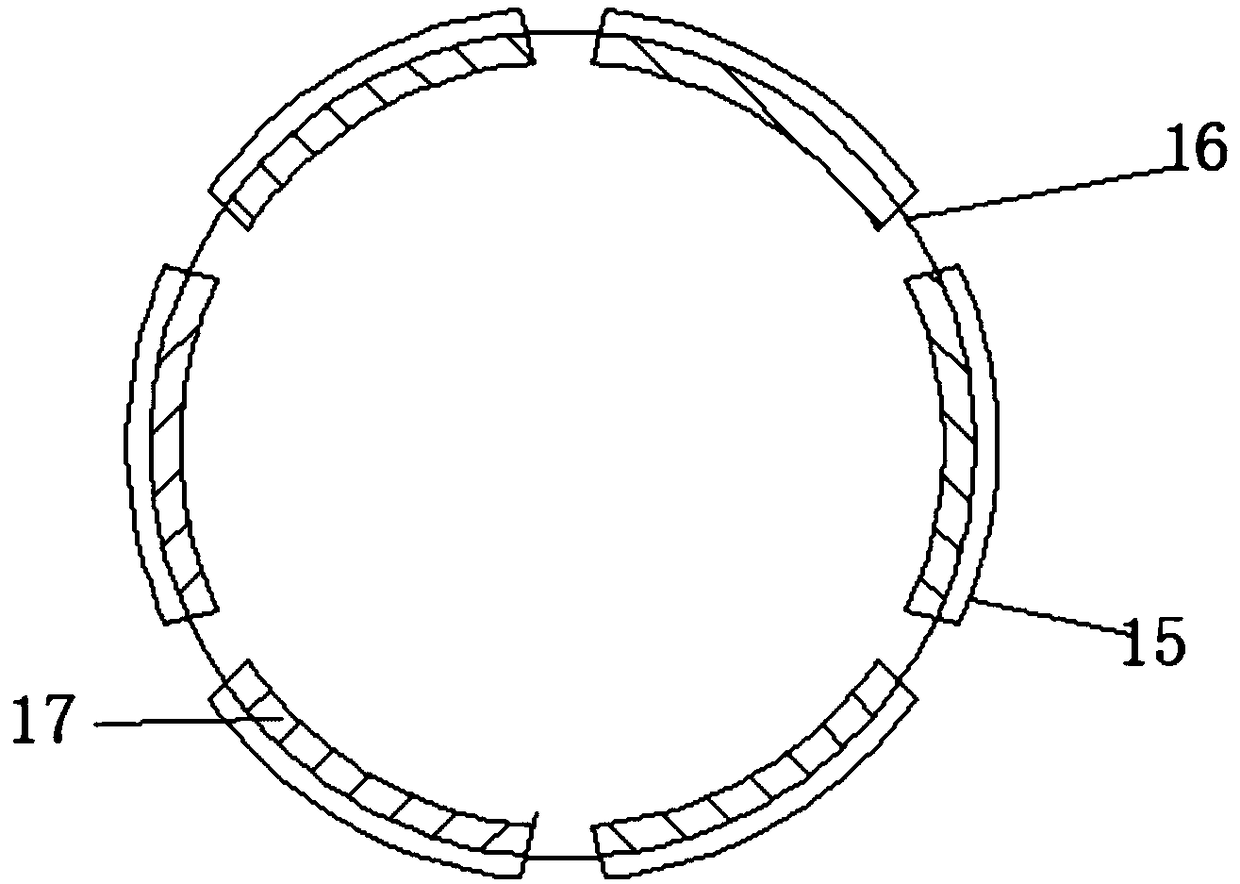

In an axial air-gap electronic motor in which a teeth surface of a stator and a magnet surface of a rotor are arranged opposedly along the axis line direction of an output shaft of the rotor with a predetermined gap being provided therebetween, the stator has a plurality of core members connected in a ring form with the axis line being a center, and each of the core members is provided with a connecting device for connecting the teeth surfaces to each other in an opposed state. In order to shorten the wire winding time and reduce the assembling manpower for the core members, a stator is formed by connecting a plurality of core members in a ring form with the axis line being a center, and locking ribs are provided as connecting devices for connecting the core members to each other in a rod form along the axis line direction.

Owner:FUJITSU GENERAL LTD

Variable reluctance resolver and rotation angle detecting device

ActiveUS9013132B2Low costEasy to assembleElement comparisonAsynchronous induction motorsAtomic physicsRotary transformer

Owner:JAPAN AVIATION ELECTRONICS IND LTD

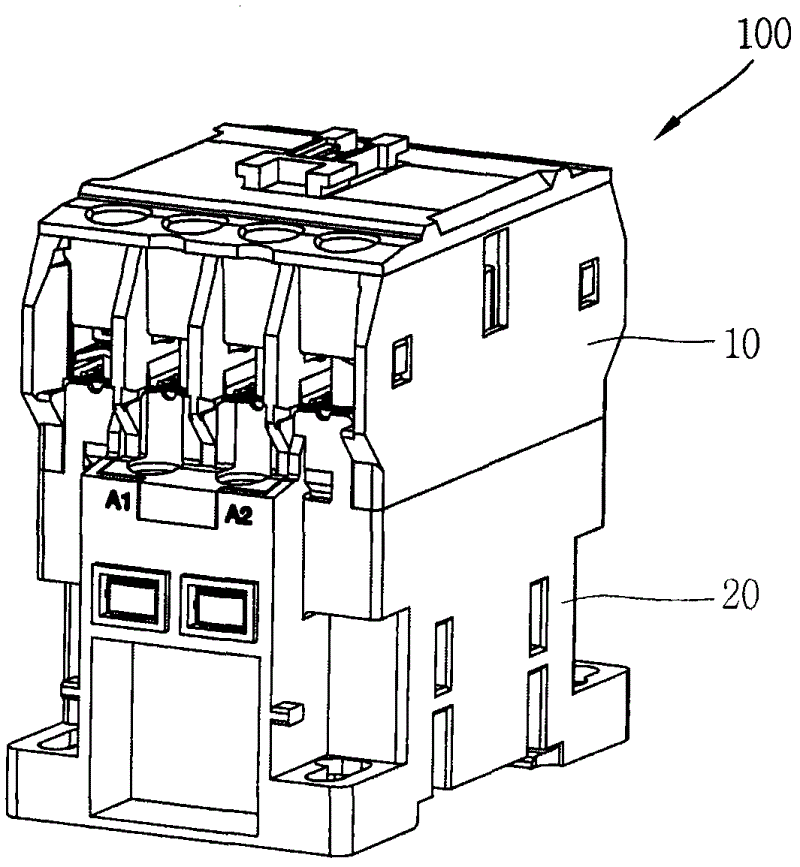

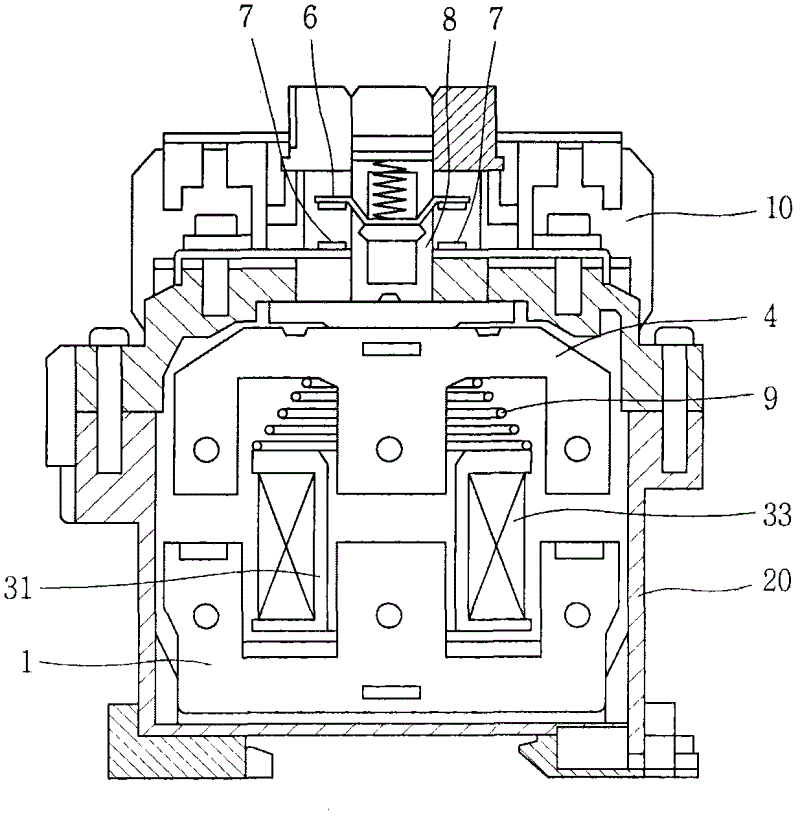

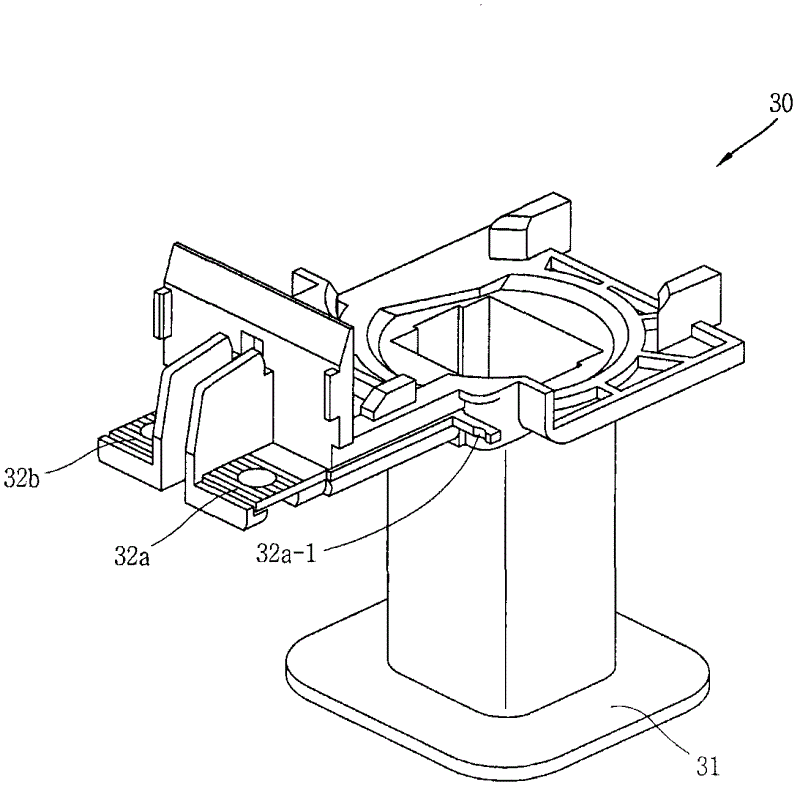

Magnetic coil assembly

InactiveCN102623251AShorten winding timeSuppress disconnectionElectromagnetic relay detailsCoilsBobbin

The present disclosure provides a magnetic coil assembly for suppressing the generation of broken wire in a coil as well as reducing a winding time, the magnetic coil assembly according to the present disclosure comprise a bobbin; a magnetic coil wound around the bobbin; a pair of terminals fixedly installed at the bobbin; a first coil fixing protrusion portion extended from the terminal to fix a starting end portion of a first coil half which is a half of the entire length of the magnetic coil; a second coil fixing protrusion portion extended from the bobbin to fix a starting end portion of a second coil half which is the remaining half of the magnetic coil, and fix an terminals end portion of the first coil half; and a third coil fixing protrusion portion extended from the terminal to fix a terminal end portion of the second coil half.

Owner:LSIS CO LTD

Series excited machine

ActiveCN103944339ANo-load speed dropsFast windingDC commutatorHigh volume manufacturingEconomic benefits

A series excited machine comprises a stator, a rotor component and two covers. The two covers are fixed on the stator in an up and down mode, and the rotor component comprises an iron core, a rotation shaft arranged on the iron core in a penetrating mode, and a rotor winding wound on the iron core. The two ends of the rotation shaft are vertically arranged on the two covers respectively in a penetrating mode, the stator comprises two opposite horizontal chip assemblies, and each chip assembly is formed by vertically stacking a plurality of chips made of magnetic conductive materials; the iron core also is formed by vertically stacking a plurality of chips made of the magnetic conductive materials, the thickness of the iron core is larger than the thickness of each chip assembly, and the number of the chips on the iron core is 2-8 more than that of the chips on the chip assemblies. The iron core is thickened, the no-load speed of the motor is obviously lowered, but the load speed is not changed, in batch production, the product percent of pass is improved by 20%, and economic benefits of enterprises are improved.

Owner:重庆市开州区联峰电机有限公司

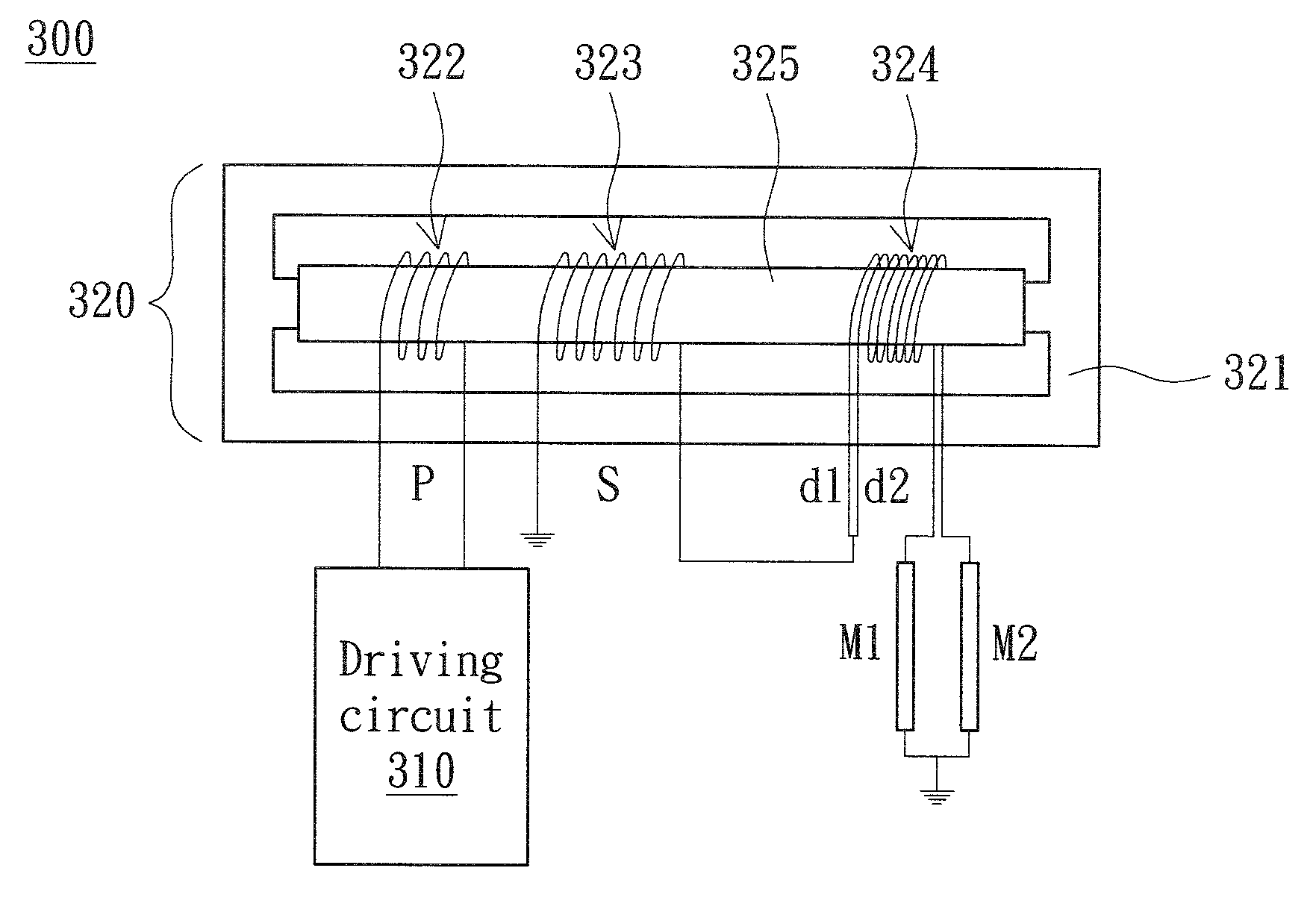

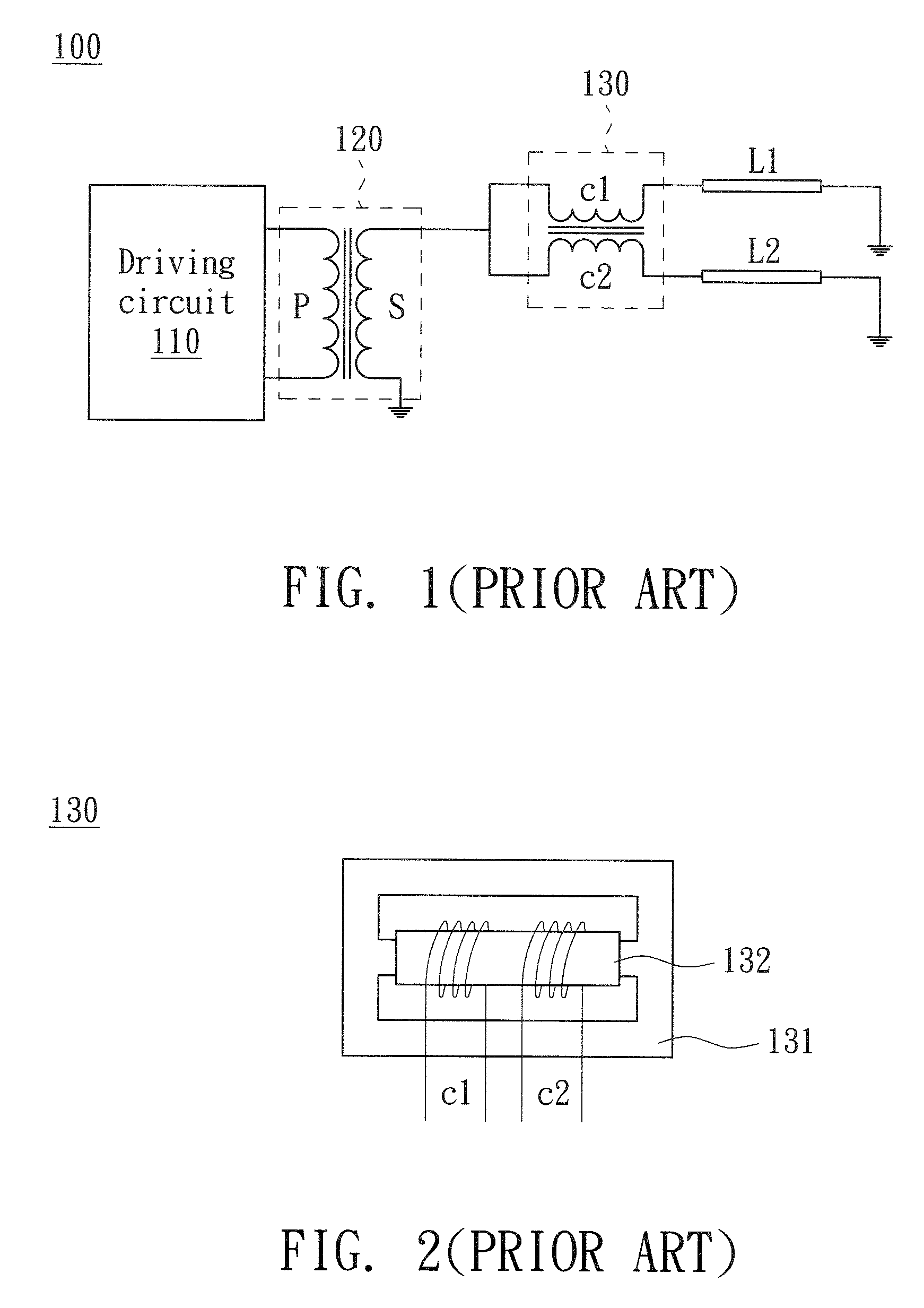

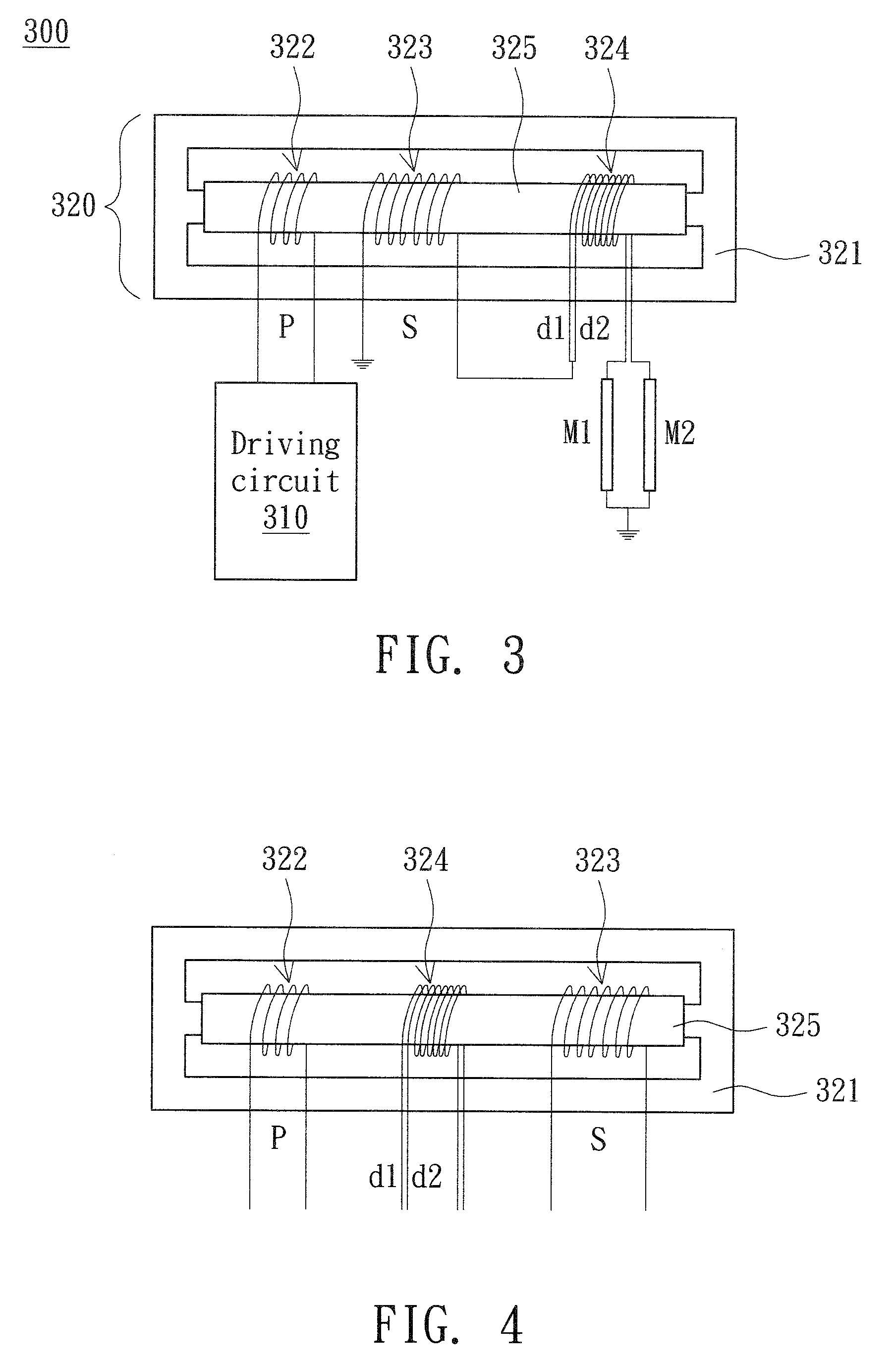

Transformer and multi-lamp driving circuit using the same

InactiveUS7459863B2Reduce manufacturing costShorten winding timeTransformers/inductances coils/windings/connectionsElectric light circuit arrangementTransformerFlux loop

A transformer for driving multiple lamps includes a core, a primary winding set, a secondary winding set and a balancing winding set. The primary winding set winds around the core and includes a first primary coil. The secondary winding set winds around the core and includes a first secondary coil. The balancing winding set winds around the core and includes a first balancing coil and a second balancing coil which wind around the core in a combinative way. The primary winding set, the secondary winding set and the balancing winding set have the same magnetic-flux loop in the core.

Owner:DARFON ELECTRONICS CORP

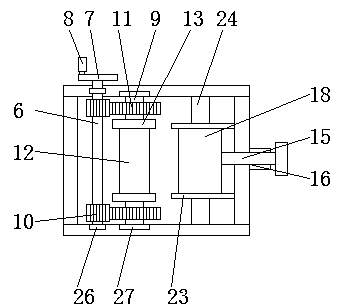

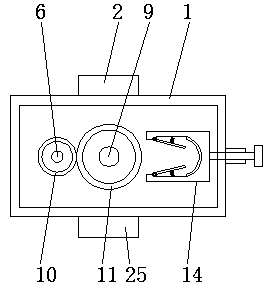

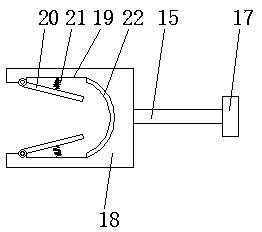

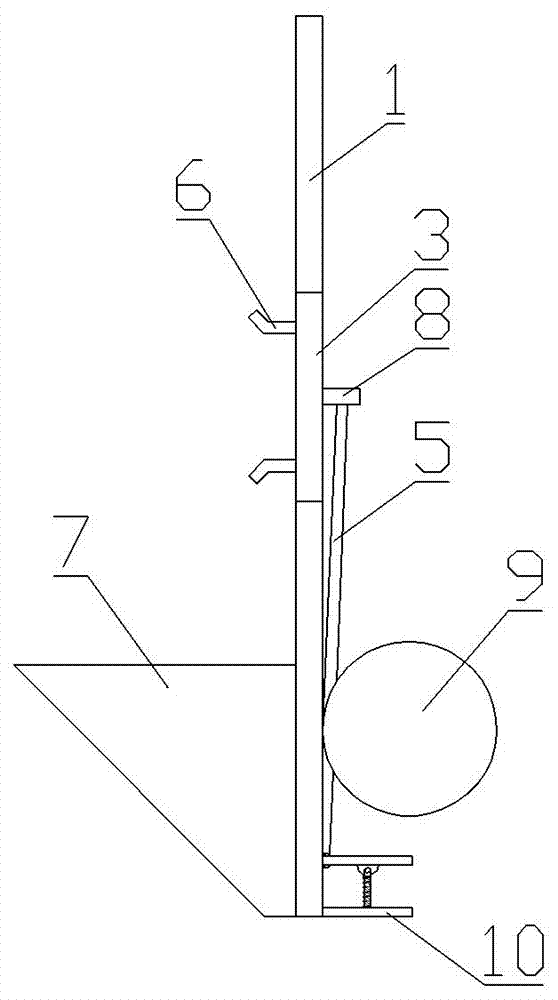

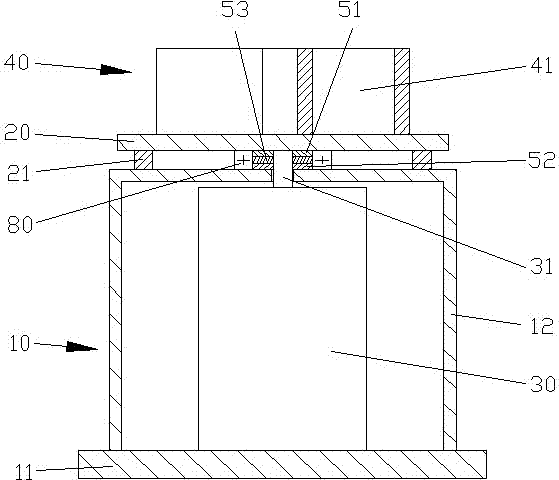

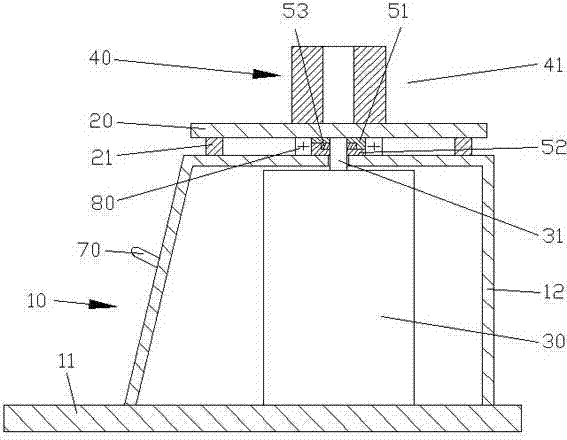

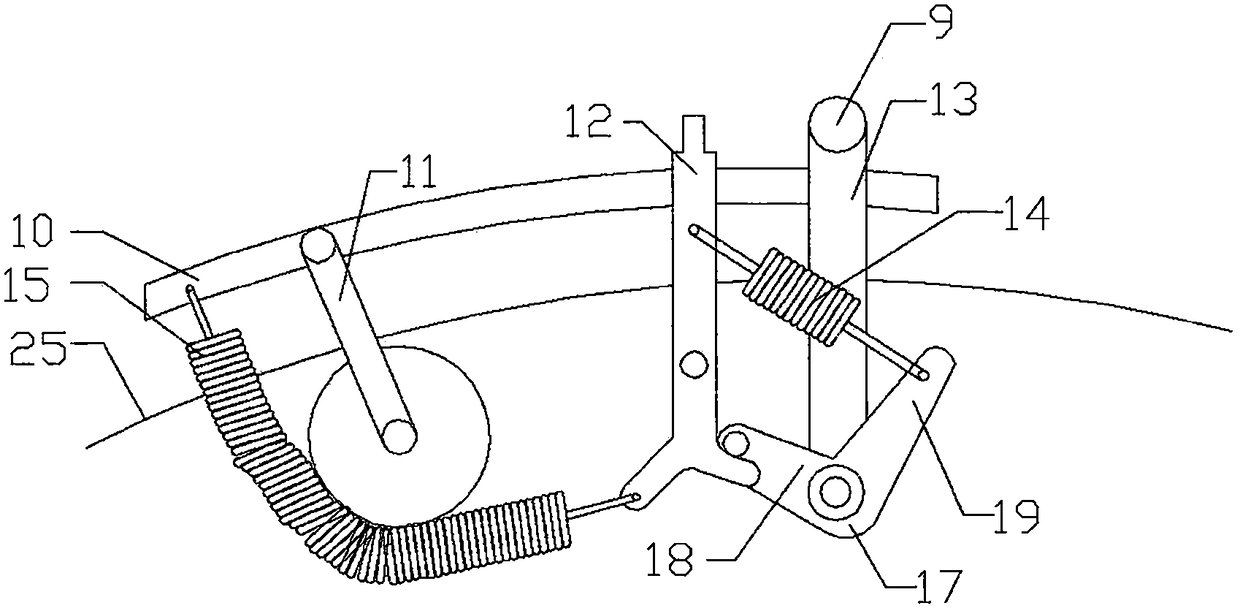

Winding device for fire hose

The invention discloses a winding device for a fire hose. The winding device comprises a shell. An inlet is formed in the top of the shell and internally provided with a flattening mechanism. A firstrotation rod is arranged in the shell. A second rotation rod is arranged on one side of the first rotation rod. The two ends of the first rotation rod are sleeved with drive gear rings. The two ends of the second rotation rod are provided with driven gear rings engaged with the drive gear rings. The outer side of the second rotation rod is sleeved with a belt winding barrel. Limiting stop discs are arranged at the two ends of the belt winding barrel. The side, away from the first rotation rod, of the second rotation rod is provided with a tight holding mechanism. The tight holding mechanism comprises a screw, a rotation disc and a U-shaped tight holding body. Grooves are formed in the inner walls of the two sides of the U-shaped tight holding body. Tight holding plates embedded in the grooves are hinged to the front ends of the grooves. Springs are arranged between the tight holding plates and the grooves. An outlet is formed in the bottom of the shell. The winding device is convenientand fast to operate, the winding efficiency and the winding effect are improved, and roll loosening and disengaging are prevented.

Owner:山东九泽换热系统有限公司

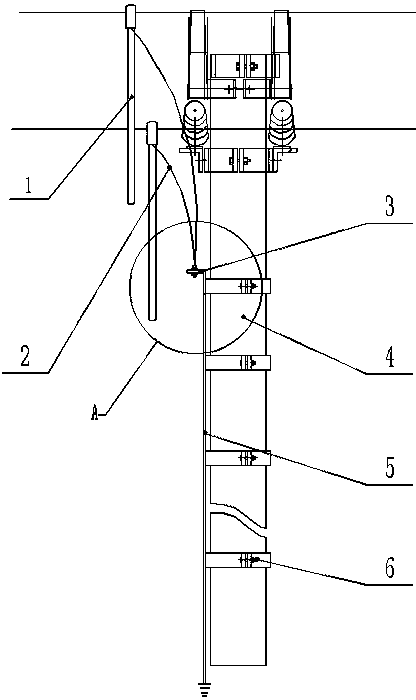

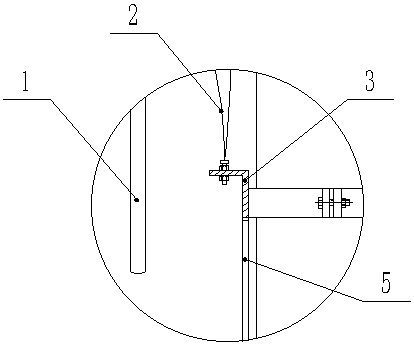

Grounding wire winding device

InactiveCN104670981AReduce investmentImprove work efficiencyFilament handlingStationary caseGear wheel

Owner:STATE GRID CORP OF CHINA +2

Rubber strip material

ActiveUS8304056B2Fabrication can be reducedShorten winding timeWithout separate inflatable insertsWith separate inflatable insertsEngineeringCycle time

When forming a rubber member which is made up of a combination of a plurality of rubber compounds by winding spirally a ribbon-shaped unvulcanized rubber strip material in an overlapping fashion, the number of times of winding is reduced so as to shorten a fabrication cycle time of the rubber member to thereby increase the productivity thereof. As a means therefore, a rubber strip material whose cross section is divided into two or more regions which are made up of different rubber compounds is wound spirally on to a drum in an overlapping fashion so as to build a green tire or a tire rubber member.

Owner:TOYO TIRE & RUBBER CO LTD

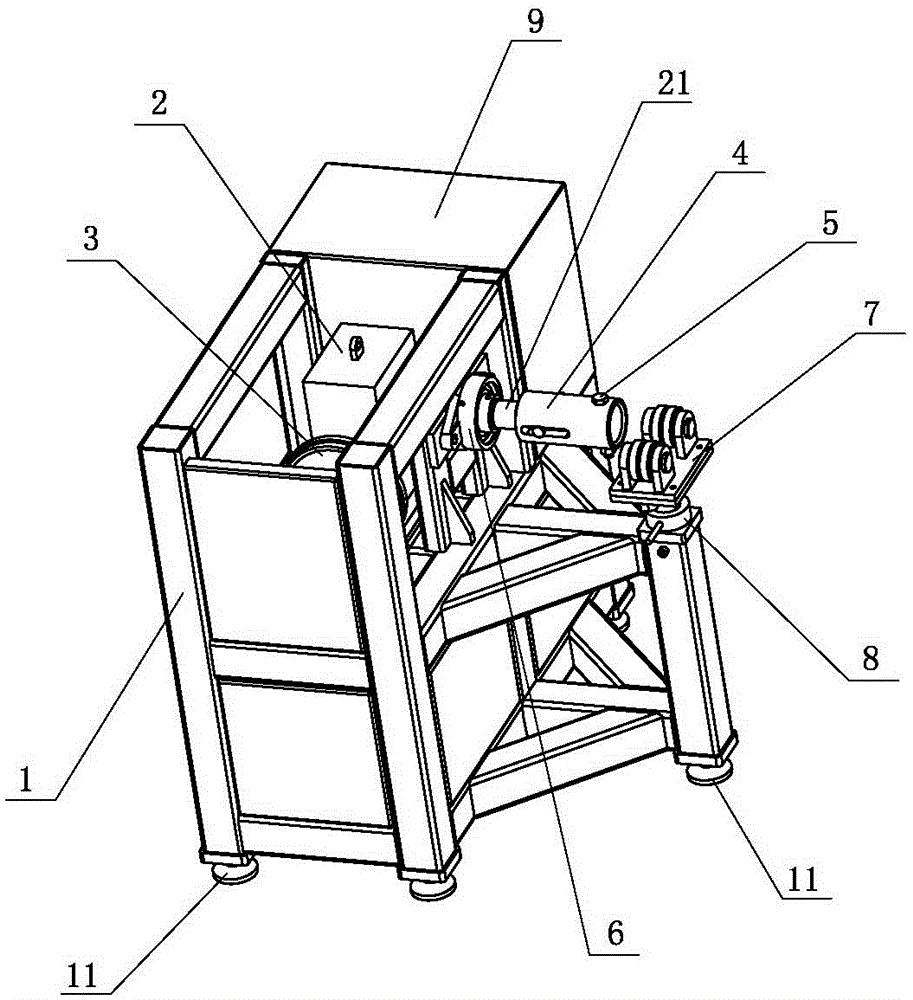

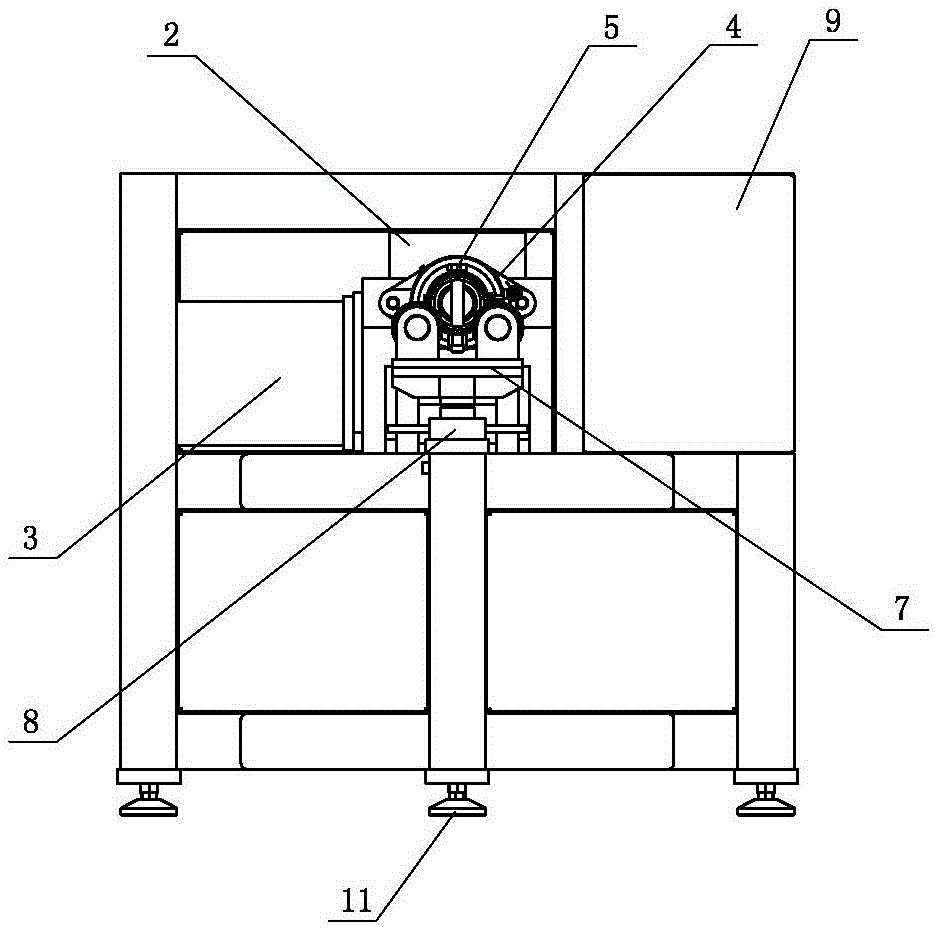

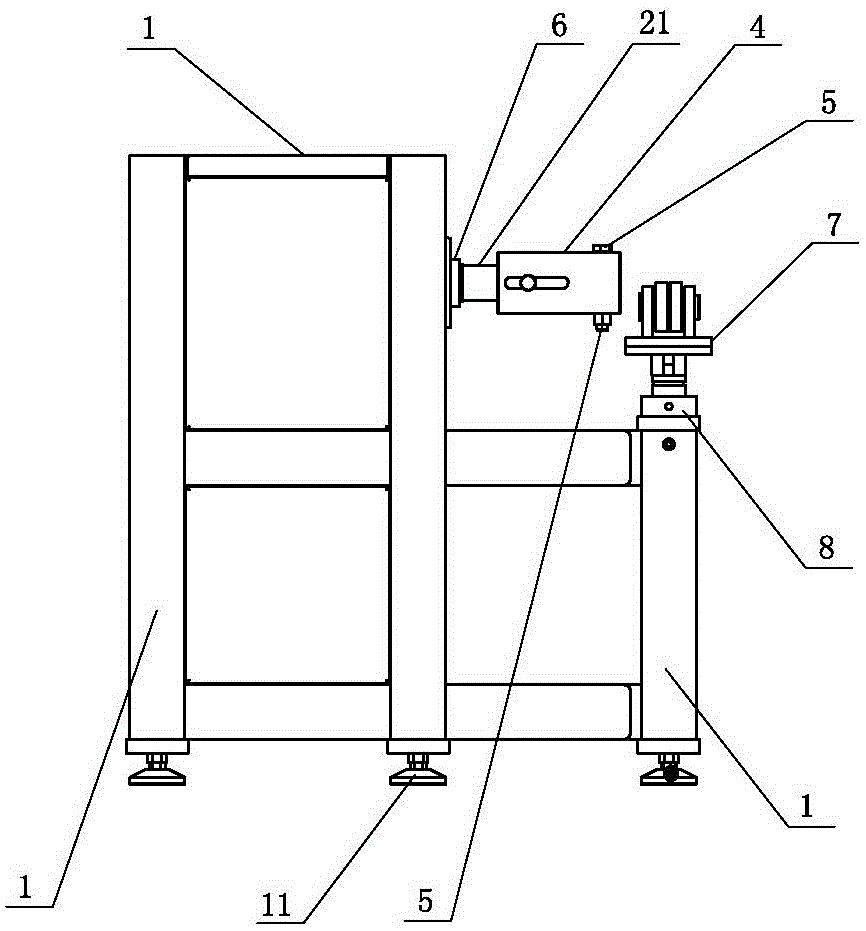

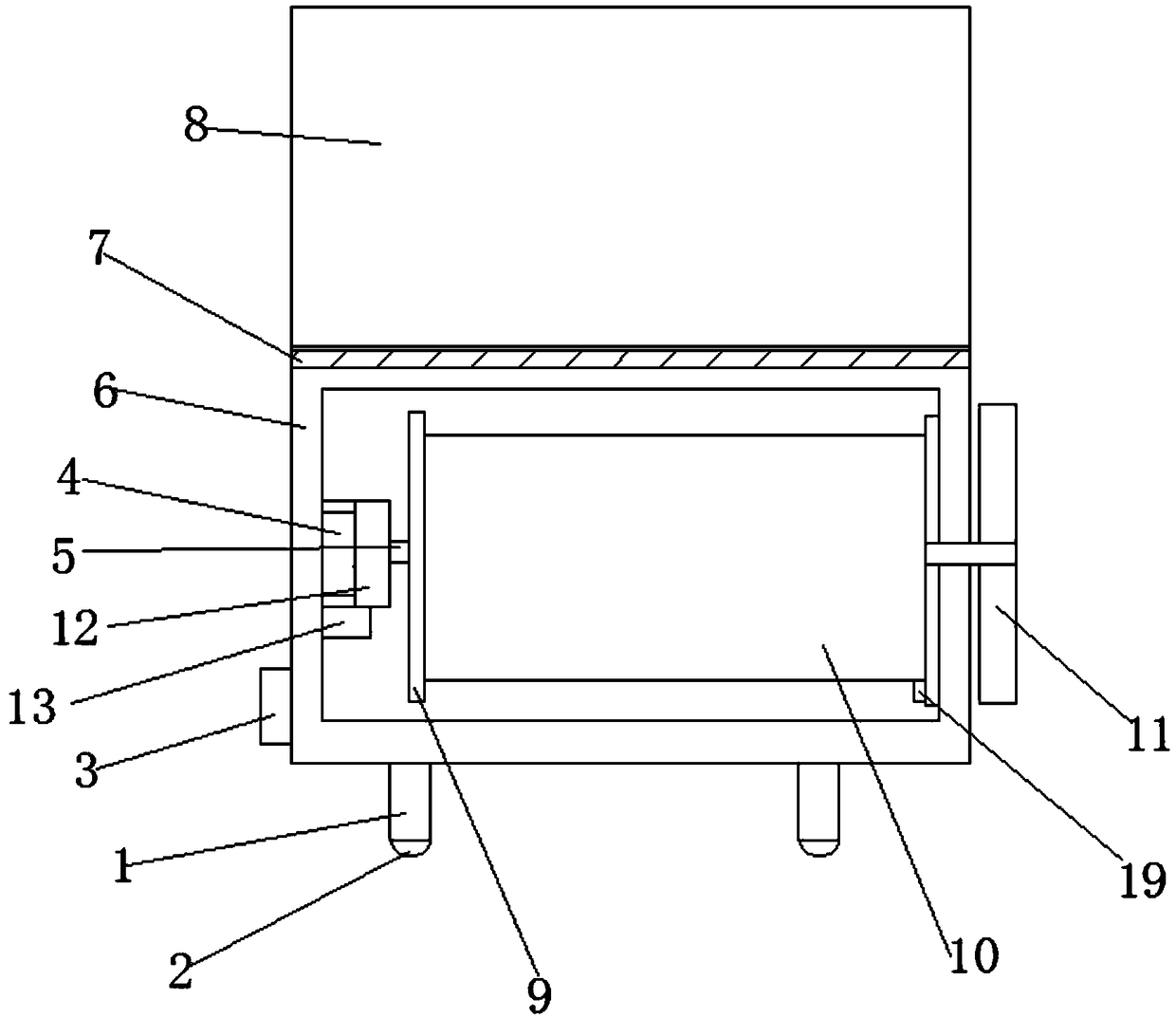

Winding machine for anode tube of wet-type electrostatic dust collection device

InactiveCN105149390AIncrease productivityHigh degree of automationElectrode constructionsWinding machineAutomatic control

The invention discloses a winding machine for an anode tube of a wet-type electrostatic dust collection device and belongs to the technical field of environment protection equipment. The winding machine comprises a machine frame and an adjusting base arranged on the bottom of the machine frame, wherein a speed reducer is installed in the middle of the machine frame, and a motor is electrically connected to one side of the speed reducer; the front portion of an output shaft of the speed reducer is sleeved with a connecting sleeve, and a connecting pin is installed on the connecting sleeve; a bearing is arranged on the machine frame and located in front of the speed reducer, and the bearing is used for supporting the output shaft; a supporting base is arranged on the front portion of the machine frame and located below the connecting sleeve, and an adjusting nut is arranged below the supporting base; a control cabinet is arranged on the machine frame and is electrically connected with the speed reducer and the motor. Compared with the prior art, the winding machine has the advantages that automatic control is adopted, rotation, sudden stop, offline rotation and 60-degree precise positioning of a die can be achieved, automation degree is high, the requirement for manpower during production is lowered, winding time is shortened, production cost is reduced greatly, and anode tube production efficiency is improved.

Owner:青岛恒科智能装备有限公司

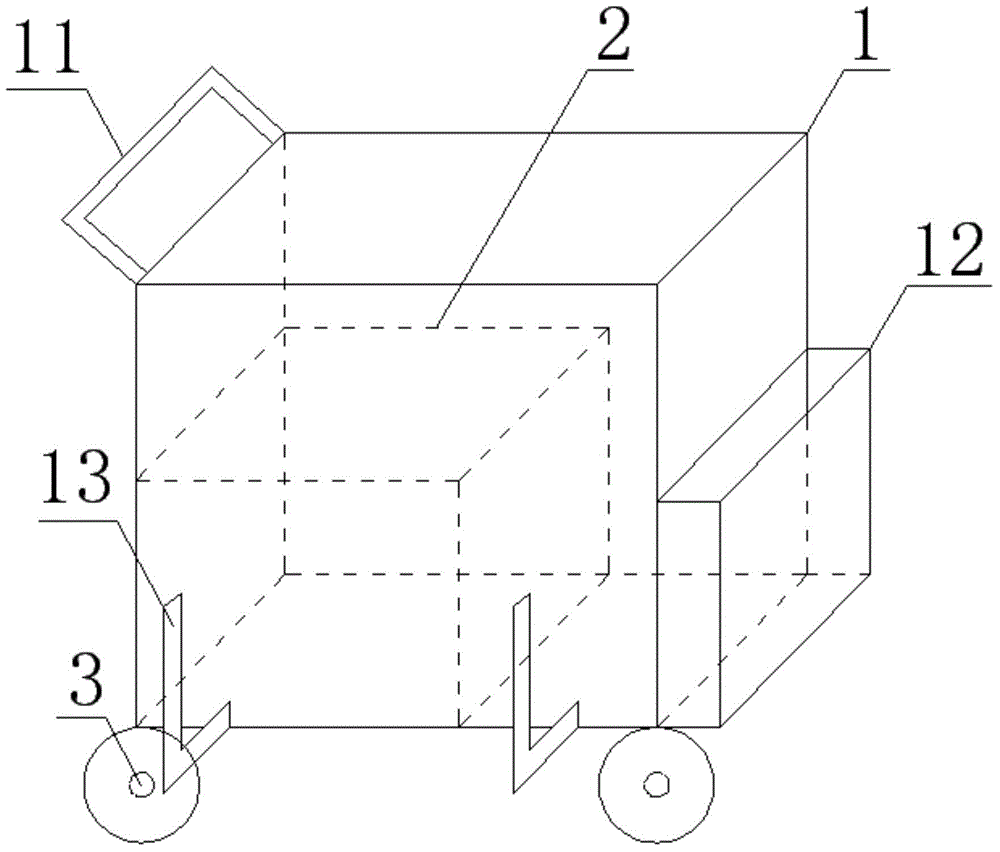

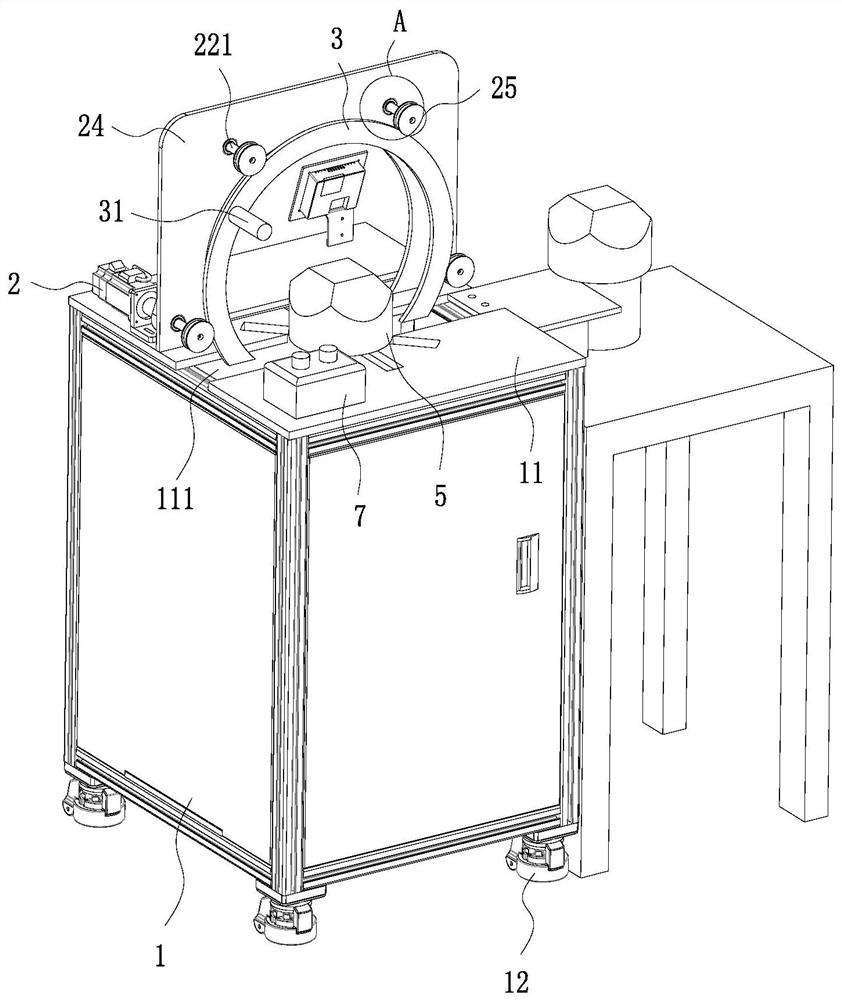

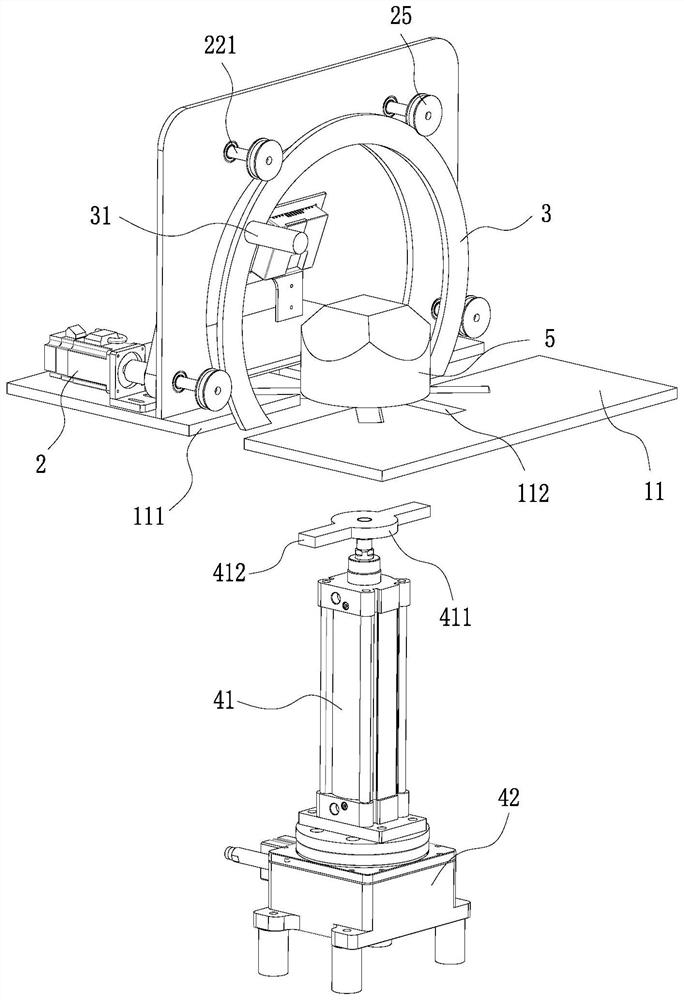

Packing device for comprehensively winding heavy object

ActiveCN114194442AShorten winding timeReduce in quantityWeb rotation wrappingWrapping with article rotationClassical mechanicsEngineering

The packaging device comprises a winding mechanism, a rotating mechanism and a fixing seat, the winding mechanism comprises a driving assembly and a winding assembly, the winding assembly comprises a rotating ring and a winding rod used for storing a winding film, and the fixing seat is provided with a placing plate used for placing a workpiece. The placing plate is provided with an avoiding groove used for avoiding a winding film, the driving assembly controls the winding assembly to rotate, the winding rod winds the winding film to a workpiece, the rotating mechanism is used for controlling the workpiece to rotate in the horizontal direction, and the device can automatically and comprehensively package the workpiece.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

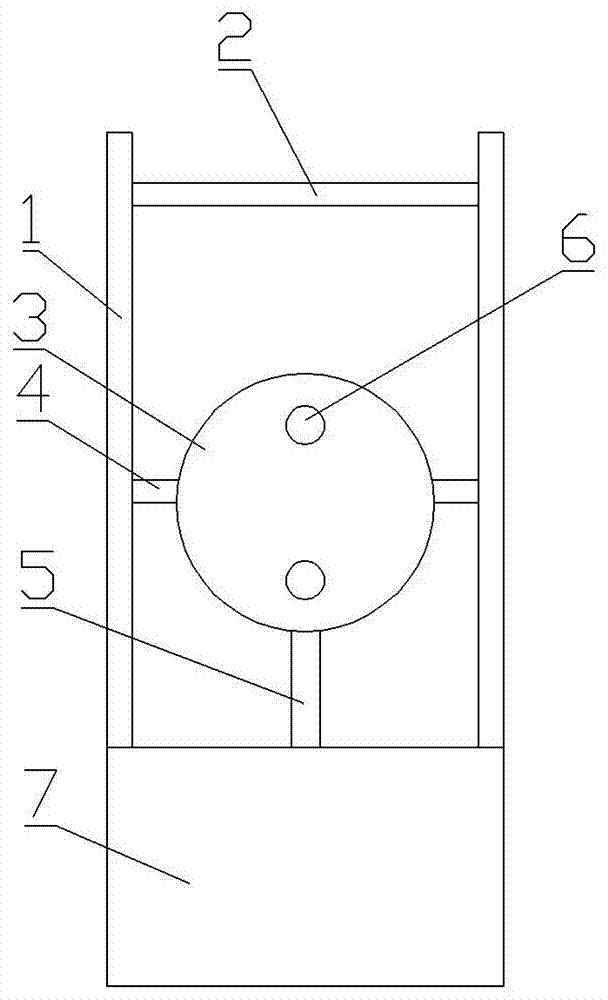

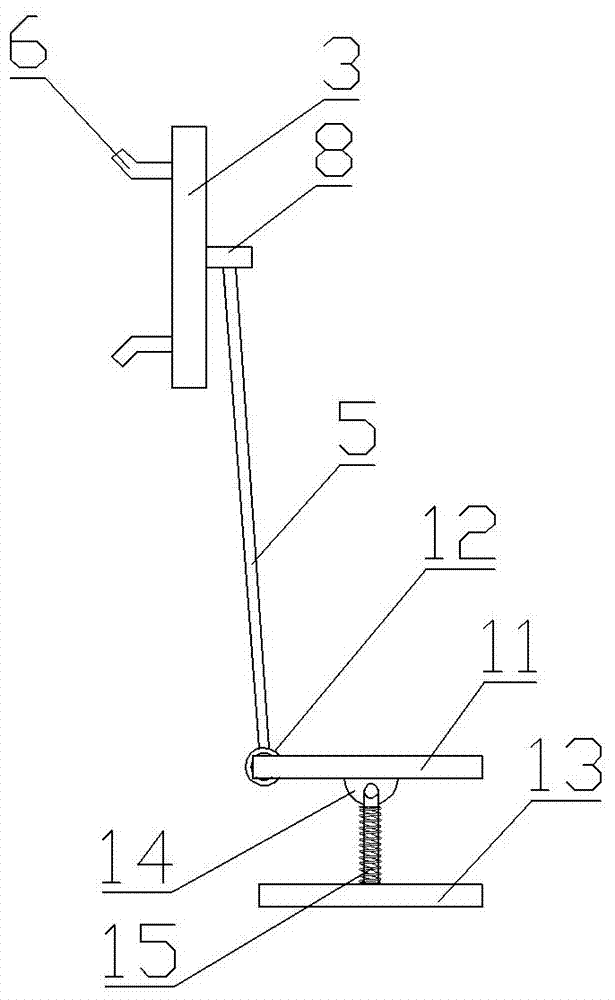

Grounding wire winding frame

The invention discloses a grounding wire winding frame, which comprises a vertical frame, a rotating shaft rotatably connected to the vertical frame, a turntable rotatably connected to the rotating shaft, a horizontal bar located above the rotating shaft, a grounding wire bin located below the rotating shaft, an eccentric Two winding posts arranged on the front surface of the turntable, a central shaft fixedly arranged on the back of the turntable, and a stepping mechanism arranged on the vertical frame and located at the back of the ground wire warehouse; ring; the stepping mechanism is connected with the central shaft. The invention can adapt to the requirements of any site, and greatly facilitates the suspension, removal and transportation of the grounding wire. The invention can greatly reduce the labor load and transportation physical strength of the staff, and at the same time enable the staff to carry articles such as girdles during the transportation. When winding the grounding wire, the grounding wire can be placed in the warehouse to avoid damage to the wire, reduce the winding time by two-thirds, and have low cost, and can be used for a long time after one investment.

Owner:STATE GRID CORP OF CHINA +2

Method for forming coil with flat coiling machine

The invention relates to a method for forming a coil with a flat coiling machine, and the method comprises the following steps: setting the length-width dimensions of a to-be-coiled coil, the number of turns and the width of a copper sheet, setting the stroke of a sliding table and the rotation angle of a rounded angle roller wheel according to the width of the coil, setting the distance from the center of the rounded angle roller wheel to the center of a R-angle guide wheel through a caster servo motor according to the width of the copper sheet, controlling the movement of the sliding table on a sliding table base through a sliding table servo motor, and allowing an external gear to drive a gear to enable the rounded angle roller wheel to rotate around the center of the center of the R-angle guide wheel to form the R-angle of the coil. The flat coiling machine used in the method has simple structure and small floor area and is easy to operate; and since the servo motor control system is adopted, a coil with a tower shape, an elliptic shape or an irregular shape can be coiled by only setting the specification and the shape parameters of the coil. The method provided by the invention has the advantages of high dimensional precision of the formed coil, short coiling time, and high production efficiency.

Owner:株洲南方机电制造有限公司

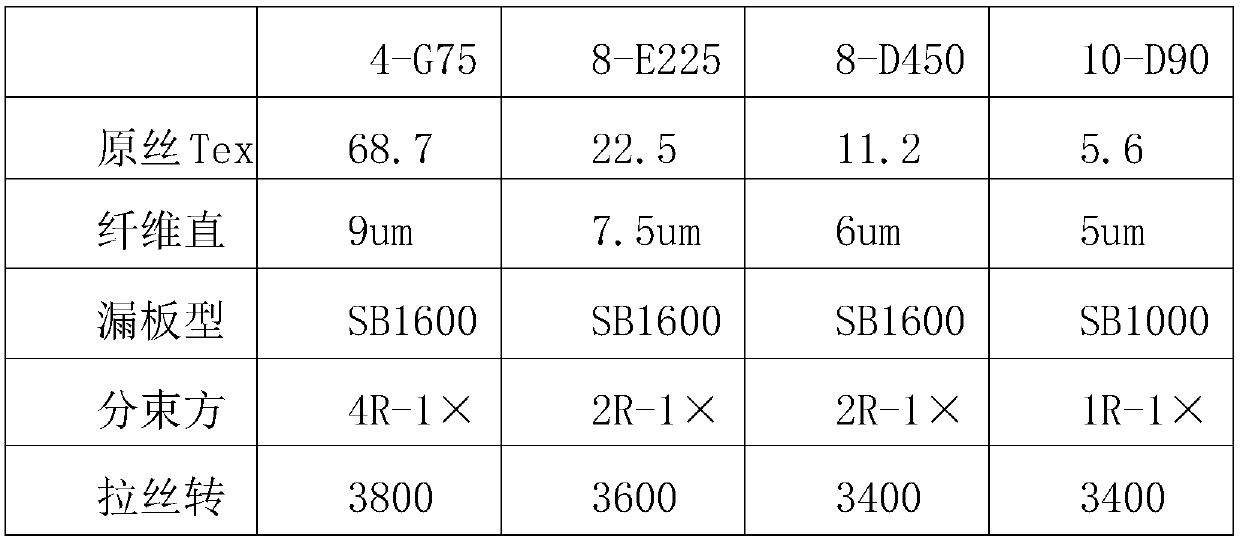

Improvement method for electronic grade glass fiber yarn preparation

InactiveCN109574493AIncrease glass flowIncrease productivityGlass making apparatusGlass productionMolten glassOil content

The invention discloses an improvement method for electronic grade glass fiber yarn preparation. According to the method, an existing three-point G75-1200H bushing plate is improved into a four-pointG75-1200H bushing plate, one partition is increased, a beam splitting mode is adjusted into 4R-1*4 from 4R-1*3, an existing six-point E225-1200 bushing plate / D450-1200H bushing plate is improved intoan eight-point E225-1600H bushing plate / D450-1600H bushing plate, two partitions are increased, a beam splitting mode is adjusted into 2R-1*8 from 2R-1*6, an eight-point D900-800H bushing plate is improved into a ten-point D900-1000H bushing plate, and two partitions are increased. According to the method, molten glass flow can be improved within unit time, production efficiency is improved, the rotating speed of a wire drawing machine is improved, wire drawing and winding time is reduced, production energy consumption is saved, wire arrangement ratio is adjusted, wire cake forming is improved, the width of a wire cake is reduced, so that the total width of the wire cake is matched with a wire drawing machine head, an oil sprayer is improved, oil spraying rotating speed is adjusted, and quality exception such as abnormal oil content caused by poor oil spraying effect is reduced.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

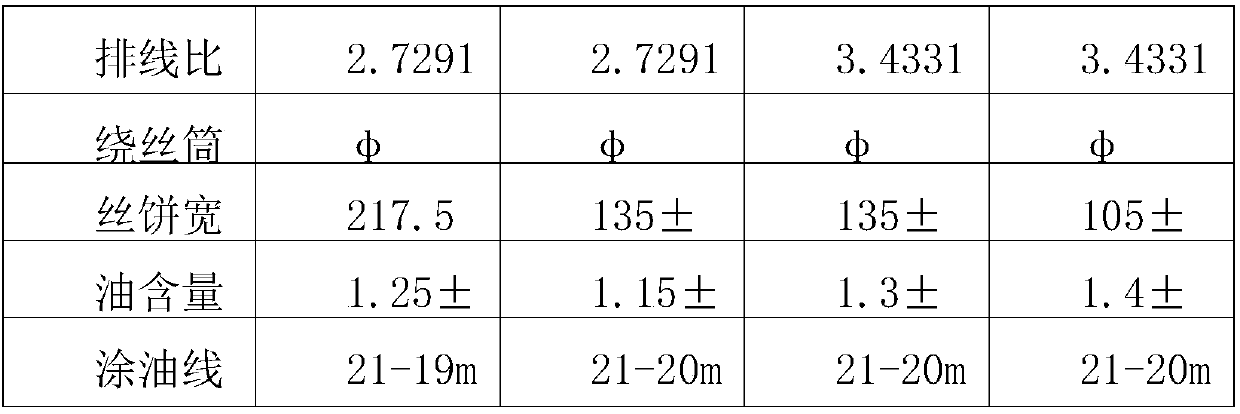

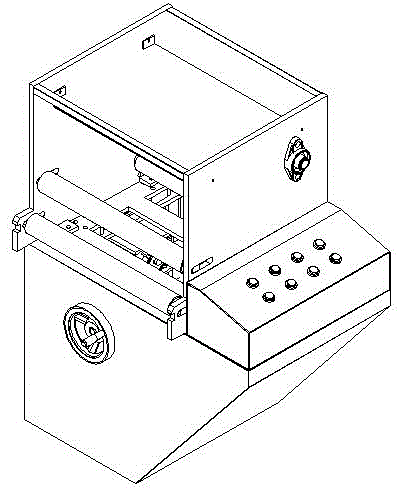

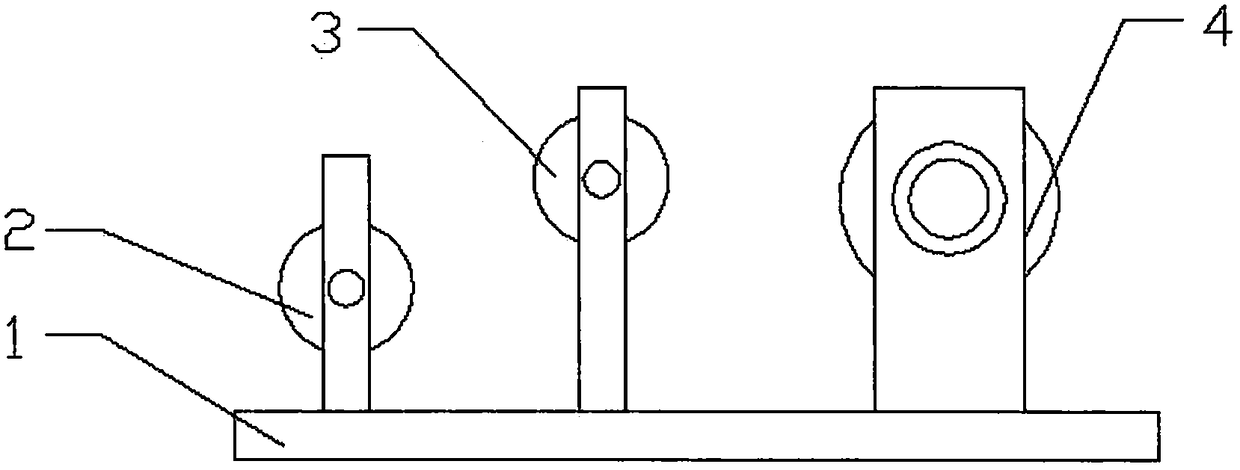

Novel feeding device for winding machine

The invention discloses a novel feeding device for a winding machine. The novel feeding device comprises a support base, the front end face of the support base is provided with an electric appliance box, the back end face of the support base is provided with a material conveying feeding device, and the material conveying feeding device comprises a transmission mechanism, a regulating mechanism, a conveying mechanism, a control mechanism and a feeding box; the feeding box is arranged on the support base, the transmission mechanism is arranged in the support base, the conveying mechanism is in transmission connection with the transmission mechanism, the conveying mechanism is arranged in the feeding box, and the regulating mechanism is arranged over the transmission mechanism. The feeding device is a mechanism which can perform automatic feeding after manual packaging is changed into automatic packaging, and the mechanism can perform feeding in a conveying mode, perform smoothing operation on products to be packaged through a horizontal conveyor belt and an inclined conveyor belt and enable the products to be packaged to have the smooth shape before being wound.

Owner:LANGXI ZHENHAI MACHINERY

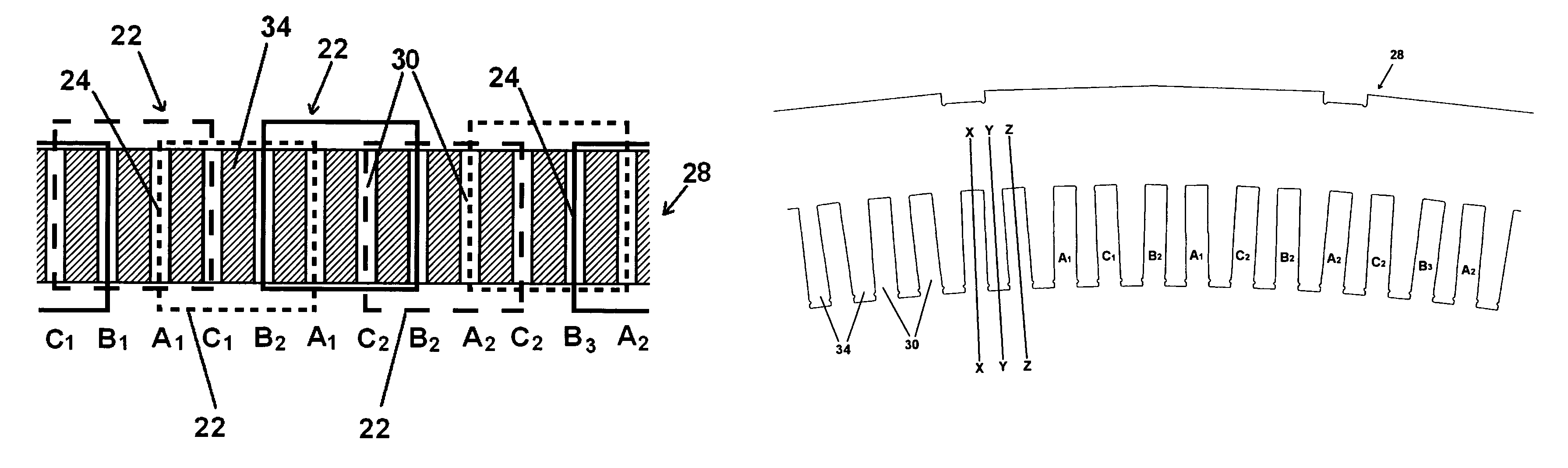

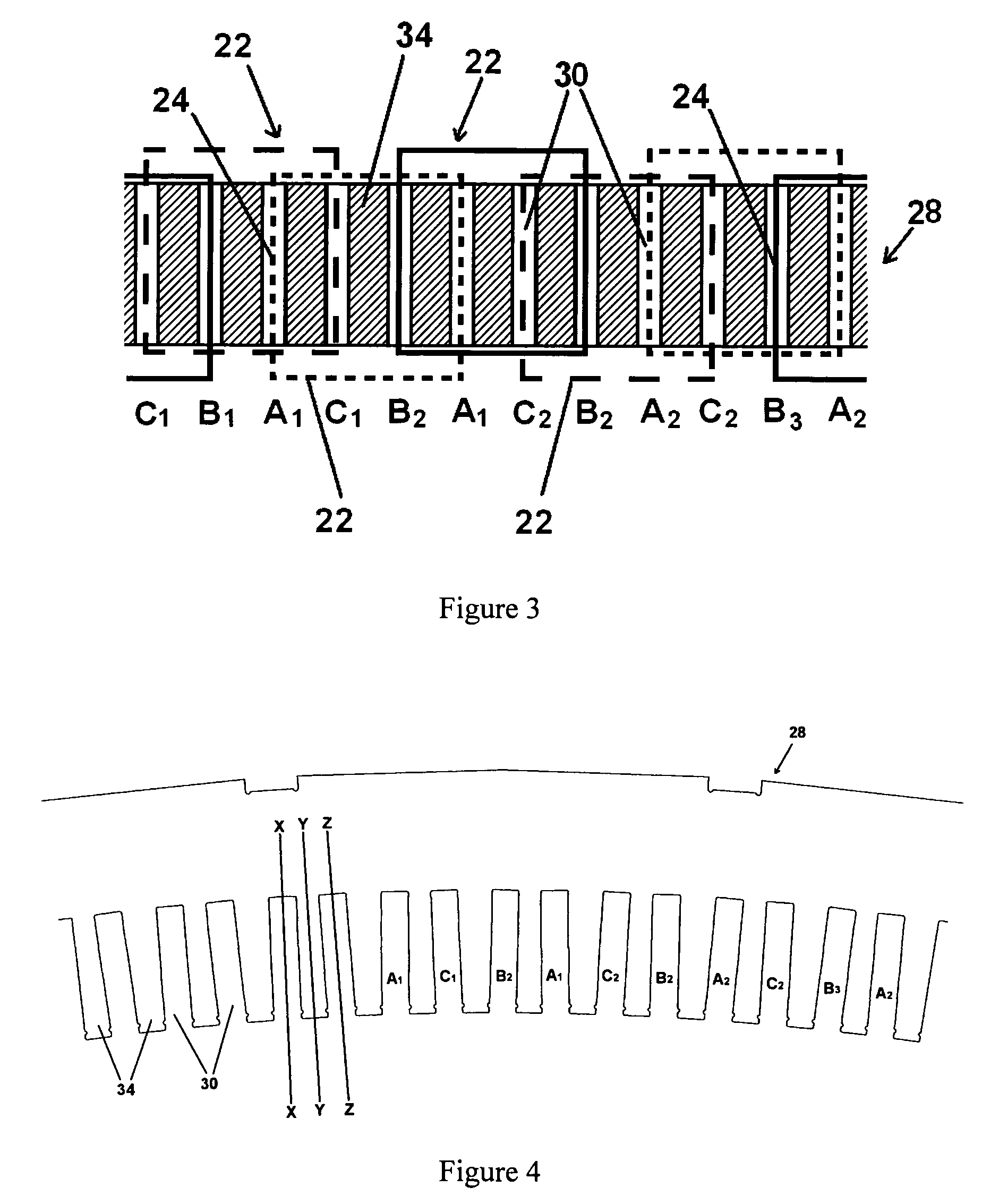

Stators for electrical machines

ActiveUS7990014B2Shorten winding timeAngular separationMagnetic circuit rotating partsMagnetic circuit stationary partsConductor CoilElectrical and Electronics engineering

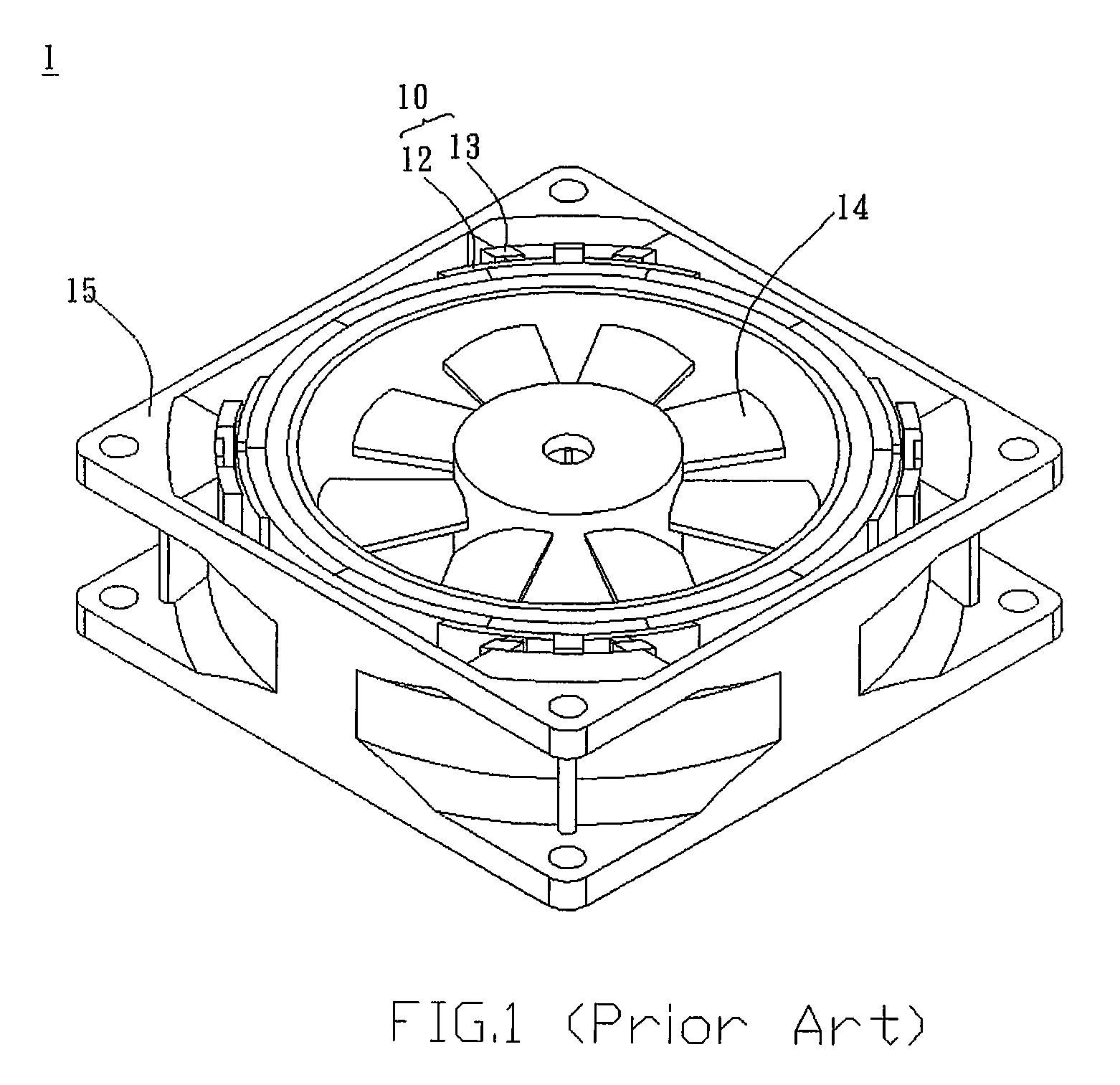

An improved stator (28) for rotating electrical machines with single-layer stator windings consisting of a plurality of pre-formed coils (22) of equal angular pitch. The stator (28) has a first cylindrical surface in which a plurality of circumferentially spaced winding slots (30) are formed and in which the axially-extending winding runs (24) of the pre-formed coils (22) are positioned. The two winding runs (24) of each coil (22) will each be positioned in a winding slot (30) and the two winding slots (30) that receive the coil (22) define a winding slot pair. The improvement arises from the fact that the winding slots (30) of each winding slot pair extend into the stator (28) in substantially parallel directions. This means that the axially-extending winding runs (24) of each pre-formed coil (22) may also be substantially parallel and need not be angled towards each other. This enables the stator (28) to be easily wound as each pre-formed coil (22) may be simply and easily slotted into a parallel winding slot pair.

Owner:GE POWER CONVERSION

Production method of multireel reel lithium tape

The invention discloses a production method of a multireel reel lithium tape, which comprises the process steps of: a. installing a scroll of a real on a winding machine, connecting an extruded lithium tape with one end of the scroll, starting the winding machine and finishing the winding of one coil of the lithium tape; b. moving the scroll to the area to be wound of the scroll on the winding machine, connecting the extruded lithium tape with the area to be wound of the scroll, starting the winding machine and finishing the winding of one coil of the lithium tape; and c. repeating such steps and winding a plurality of coils of lithium tapes on the scroll. The invention is suitable for large automation equipment, has advantages of less machine starting and shutdown numbers, little jointing waste and convenient packaging, can save transport cost, shorten shutdown and charging time and reduce jointing waste; besides, the lithium tape on the reel can be used both separately and integrally, which is suitable to the simultaneous production of multiple production lines, thereby improving the working efficiency; and moreover, the load of the lithium tape winding machine can be decreased, thereby realizing more stable winding and reducing lithium tape winding error.

Owner:成都顿威新型金属材料有限公司

Production technique for suspension springs

InactiveCN106734779AShorten winding timeExcellent stress relaxation resistanceAnalysing solids using sonic/ultrasonic/infrasonic wavesWire springsSand blastingStress relief

The invention discloses a production technique for suspension springs. The production technique for the suspension springs comprises the following steps of winding, specifically, winding of suspension spring main bodies is conducted according to the preset heights, outer diameters and turn numbers of the springs, one-time drawing formation of hook rings at the two ends and the suspension spring main bodies is conducted at the same time, and thus primary finished suspension springs are obtained; tempering stress relief, specifically, the primary finished suspension springs are placed in a tempering furnace for tempering stress relief; flaw detection, specifically, flaw detection is conducted on the primary finished suspension springs subject to tempering stress relief; surface treatment, specifically, primary sand blasting is conducted on the primary finished suspension springs subjected to flaw detection, and secondary sand blasting is conducted on the primary finished suspension springs subjected to primary sand blasting; sorting, specifically, machined finished suspension springs are conveyed one by one through spring conveying equipment, and stacking and sorting of the finished suspension springs are achieved; and packaging, specifically, the sorted suspension springs are placed in storage bags so as to be packaged. In this way, by adoption of the production technique for the suspension springs, the winding time of the suspension springs can be shortened, the stress relaxation resistance of the suspension springs is effectively improved, and the fatigue life of the springs is prolonged.

Owner:WUXI FENGLI SPRING

Cable fixing device for mechanical equipment

InactiveCN109436946AExtended service lifeShorten winding timeFilament handlingElectric machineryEngineering

The invention discloses a cable fixing device for mechanical equipment. The cable fixing device comprises a box body, wherein the box body comprises a top cover and a box body matched with the top cover, a rotary motor is arranged in the middle of the inner side wall of the box body, a transmission rod is arranged at one end of the rotary motor, the transmission rod penetrates through the interiorof a winding cylinder and is connected with a rotary table, baffles are arranged at the two ends of the winding cylinder, a wire inlet hole is formed in the outer wall of the box body, the wire inlethole is divided into a plurality of segmentation bodies by a radial segmentation line, through holes are formed in the segmentation bodies, an annular elastic rope is arranged in the through hole, and all the segmentation bodies are connected into a whole through an elastic rope. The cable fixing device has the beneficial effects that the structure is simple, the use is convenient, the cable canbe conveniently wound by workers, the situation that the wound cable is not knotted and adhered to other objects can be guaranteed, the cable fixing device is convenient to dismount and mount, and theoverall use efficiency is improved.

Owner:郑州骏弘机电科技有限公司

Fan and motor thereof

ActiveUS8251681B2Increase the areaImprove cooling efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesElectric motor

A motor includes a rotor magnetic ring, a stator core, a first magnetic conducting sheet and a second magnetic conducting sheet. The stator core is disposed around and out of the rotor magnetic ring. The first magnetic conducting sheet has a ring shape with a protruding portion serving as a first magnetic pole. The second magnetic conducting sheet has a ring shape with a protruding portion serving as a second magnetic pole. The first magnetic conducting sheet is disposed at the upper side of the stator core, and the second magnetic conducting sheet is disposed at the lower side of the stator core. The projections of the first and second magnetic poles alternate with each other. A fan including the motor is also disclosed.

Owner:DELTA ELECTRONICS INC

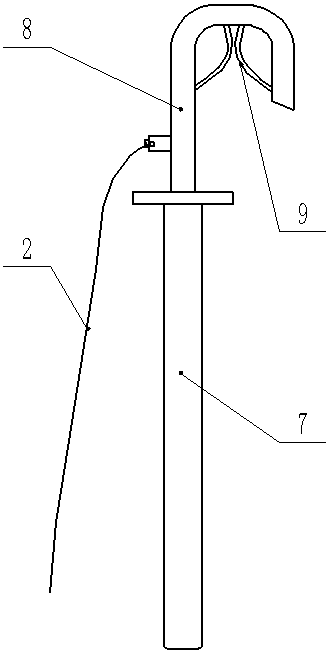

High voltage line safety grounding device

InactiveCN107785686AEliminate difficult entryEliminate unpluggingElectric connection structural associationsConnection contact member materialEngineeringHigh pressure

The invention discloses a high-voltage line safety grounding device, which includes a movable part and a fixed part, the movable part includes a hanger insulation rod and a grounding wire; Fixing frame; the wire-hanging insulating rod includes an insulating rod and a wire-hanging hook, the upper end of the grounding wire is installed on the wire-hanging hook, the lower end of the grounding wire is connected to the upper end of the grounding lead through a wire joint, and the grounding wire The lead wires are fixed on the electric pole through a plurality of fixing frames, and the lower ends of the grounding lead wires are directly introduced into the ground. The lower end of the grounding wire of the safety grounding device is installed on the next base tower on the load side of the vacuum switch of the 10kV line, and is used for the operation grounding wire of the 10kV line for maintenance.

Owner:史军

High-voltage earth wire winder

InactiveCN102208773AQuality assuranceShorten winding timeCable installation apparatusEngineeringHigh pressure

The invention discloses a high-voltage earth wire winder, comprising a shell, a tray above the shell, a motor which is arranged in the shell, connected with the tray and used for driving the tray to rotate and a power plug which is electrically connected with the motor and extends out of the shell, wherein a fixed device is arranged on the tray as well as connected and fixed with an earth wire insulating rod. By adopting the technical scheme, after the portable earth wire winder is used, the earth wire is wound in accordance with the overall specification, thus ensuring the quality of the earth wire. The time to wind the earth wire is reduced obviously, and only one person is required to wind the earth wire as compared with the prior art in which two persons are required, thus reducing the labor force, improving the working efficiency of operators, and ensuring blackout and power supply for clients on time.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

Silk blank winding device

The invention discloses a silk blank winding device, and relates to the technical field of textile equipment. The device comprises a sliding resisting component and a rack, the sliding resisting component comprises a rotary shaft, limiting sheets arranged above the rotary shaft, two fixing rods symmetrically arranged at the two ends of the rotary shaft, stirring rods and pressing rods, the bottomsof the pressing rods are hinged to the end of the rotary shaft, a connecting rod is arranged between the tops of the pressing rods, each of the bottoms of the pressing rods is provided with a V-shaped wedge block, the two stirring rods are arranged on one sides of the pressing rods, the middles of the pressing rods are hinged to the end of the rotary shaft, when the stirring rods are stirred to move clockwisely, the connecting rods are pushed by the pressing rods to allow the limiting sheets to be released from the lower portion of the connecting rod, the fixing rods are arranged on the othersides of the stirring rods, the fixing rods are hinged to the end of the rotary shaft, the limiting sheets are fixed to the tops of the fixing rods, the bottoms of one ends of the limiting sheets areconnected with one ends of second springs, the other ends of the second springs are connected with the bottoms of the stirring rods, and the other ends of the limiting sheets are arranged below the connecting rods. By means of the device, the sliding between silks and the rotary shaft is effectively prevented to winding time and allow silk winding to be solid.

Owner:射阳县华宏丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com