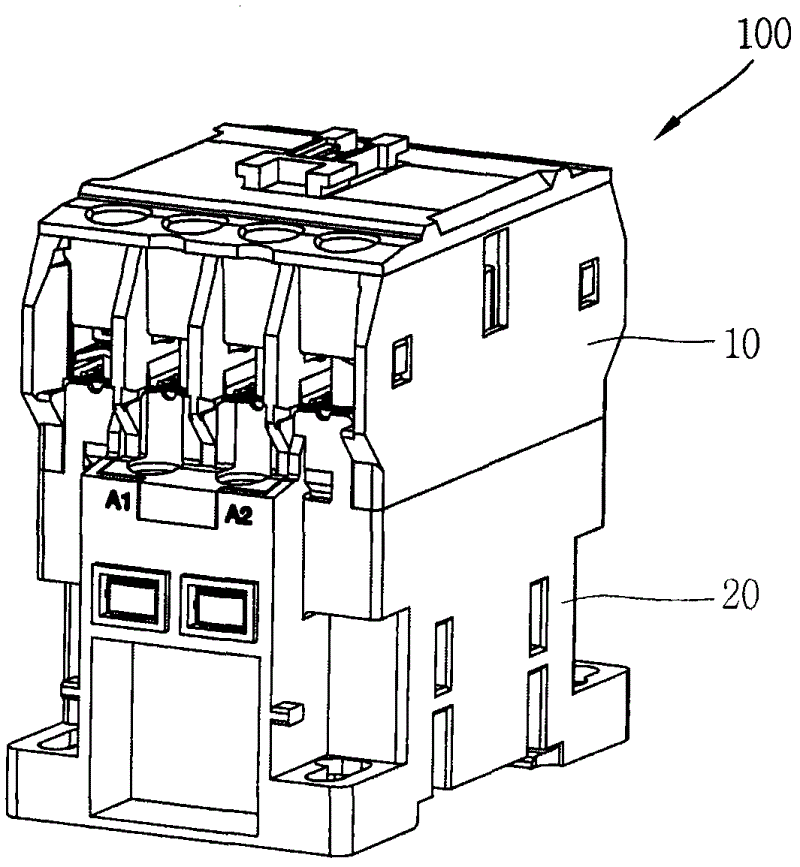

Magnetic coil assembly

A technology of magnetic coils and components, applied in the direction of coils, electrical components, electromagnetic relays, etc., can solve the problems of winding coils and wire disconnection at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

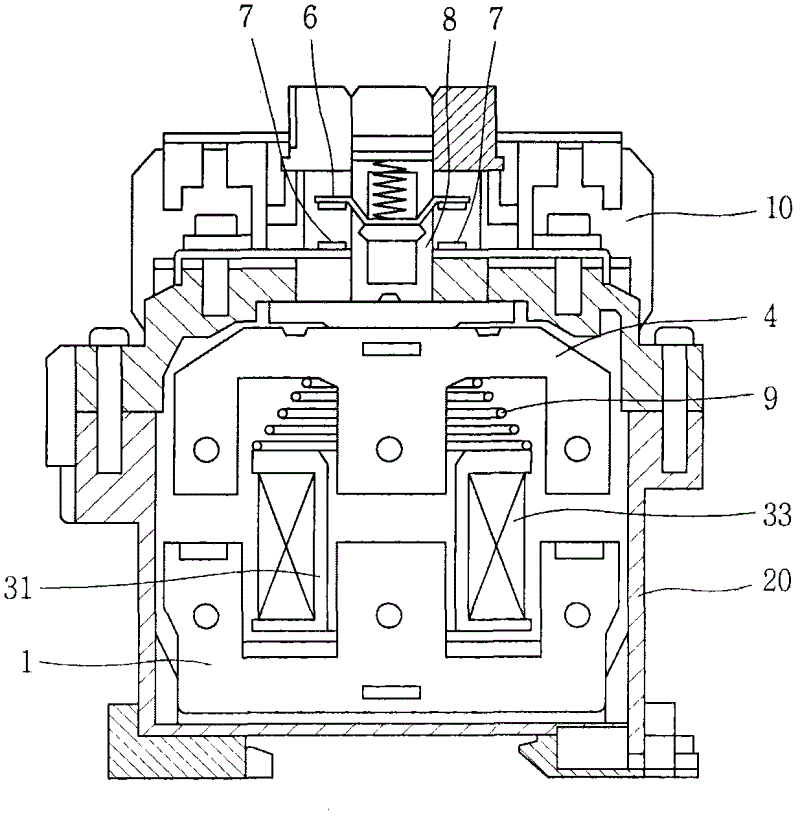

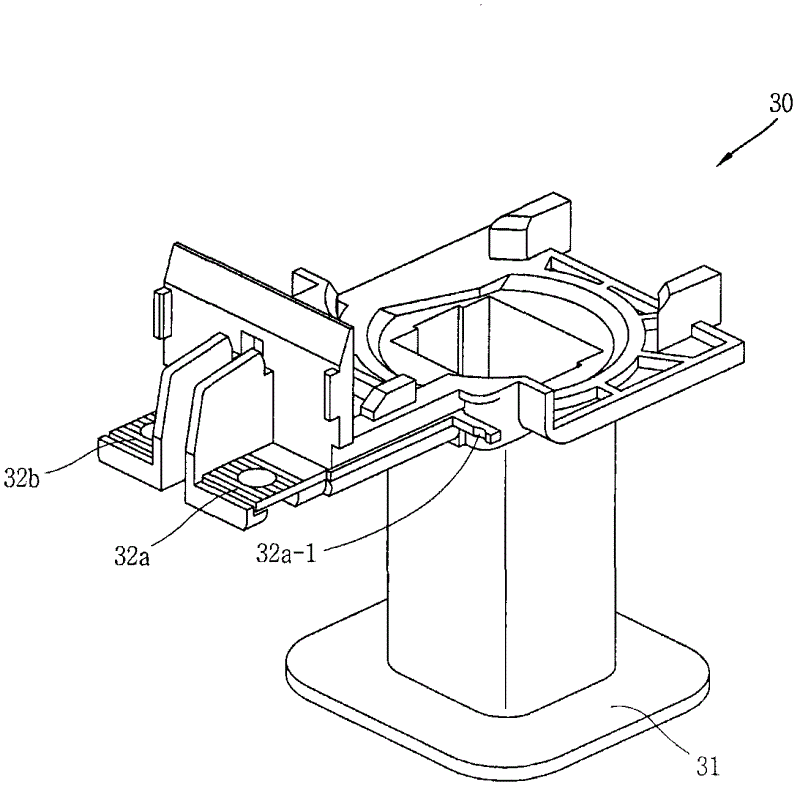

[0034] From the following description of preferred embodiments of the present disclosure with reference to the accompanying drawings, objects of the present disclosure, configurations for achieving the above objects, and working effects thereof will be clearly understood.

[0035] refer to Figure 5 to Figure 7 , the magnetic coil assembly 30-1 according to the preferred embodiment of the present disclosure includes a bobbin 31, a magnetic coil 33, a pair of terminals 32a, 32b, a first coil fixing protrusion 32a-1, a second coil fixing protrusion 31a, and the third coil fixing protrusion 32b-1.

[0036] The bobbin 31 is made of an electrically insulating material such as synthetic resin, and may typically include a square columnar body portion having an inner hollow and flange portions formed on both end portions in the length direction of the body portion. The upper flange portion of the flange portion includes: a pair of extensions extending longitudinally in one direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com