Winding machine for anode tube of wet-type electrostatic dust collection device

A wet electrostatic precipitator and anode tube technology, applied in electrode structure, electrostatic separation, etc., can solve the problems that the use effect cannot reach the expected situation, the function of the winding machine is single, and the mold cannot be stopped, so as to reduce the labor demand, shorten the winding time, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

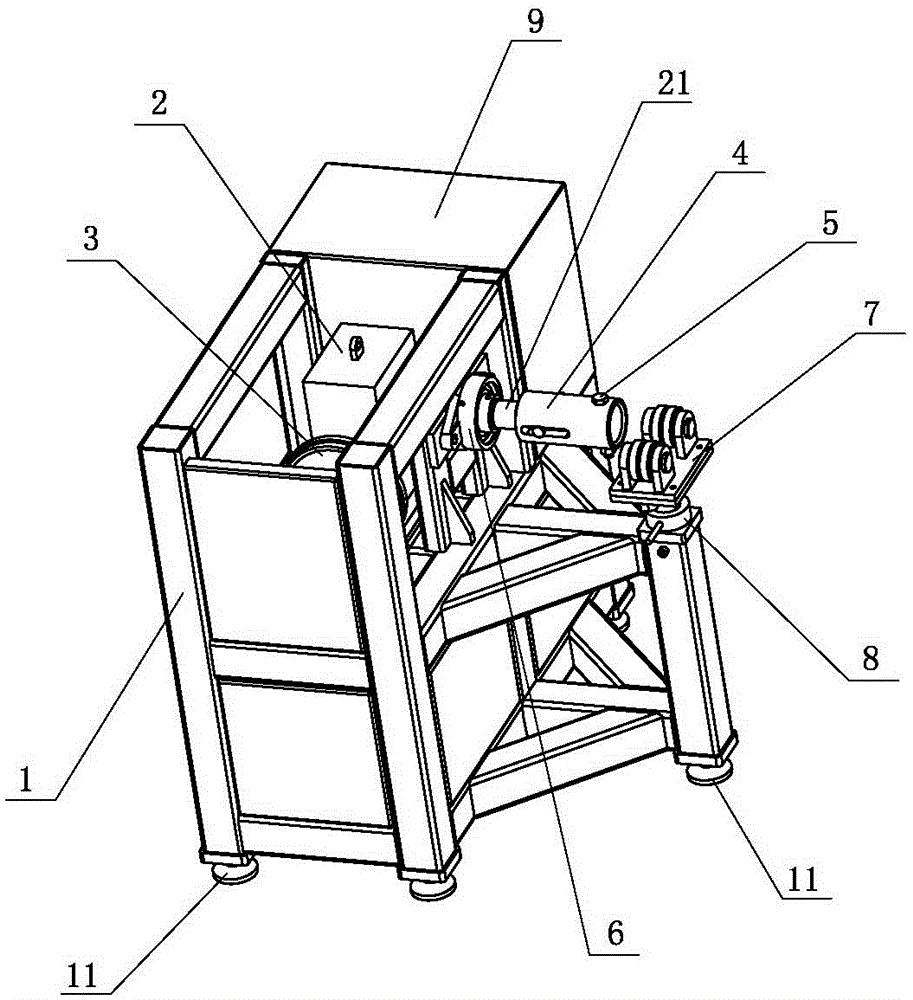

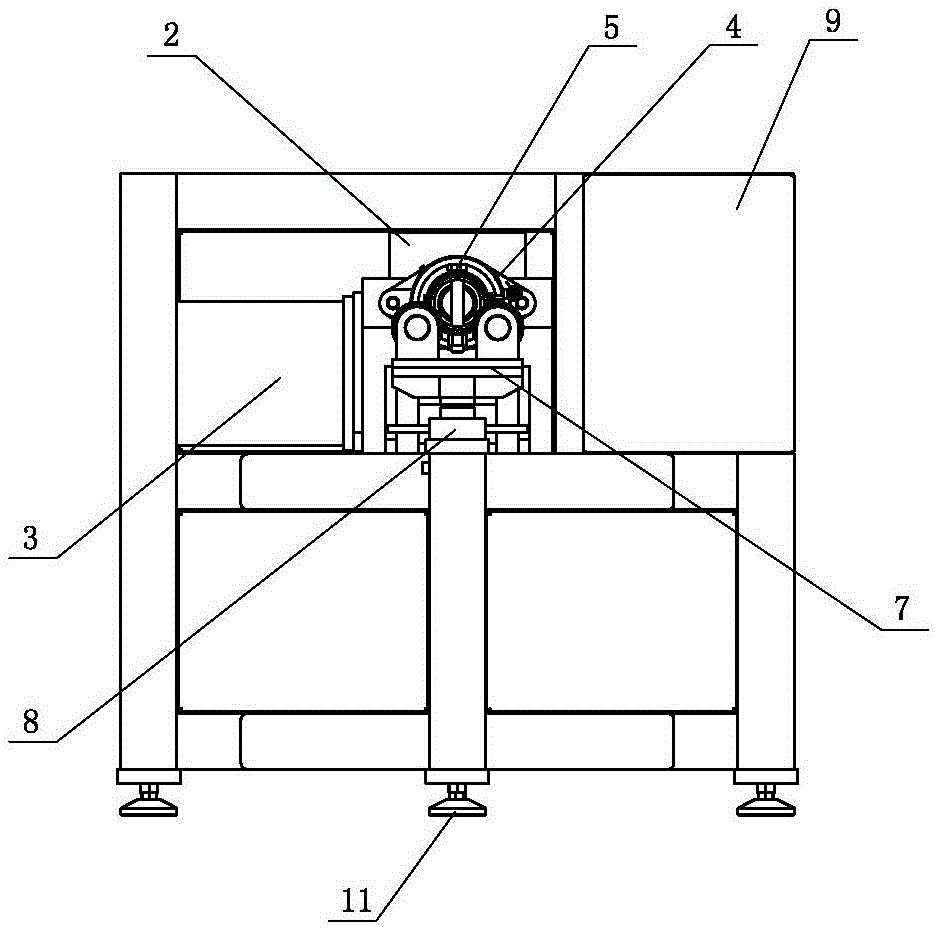

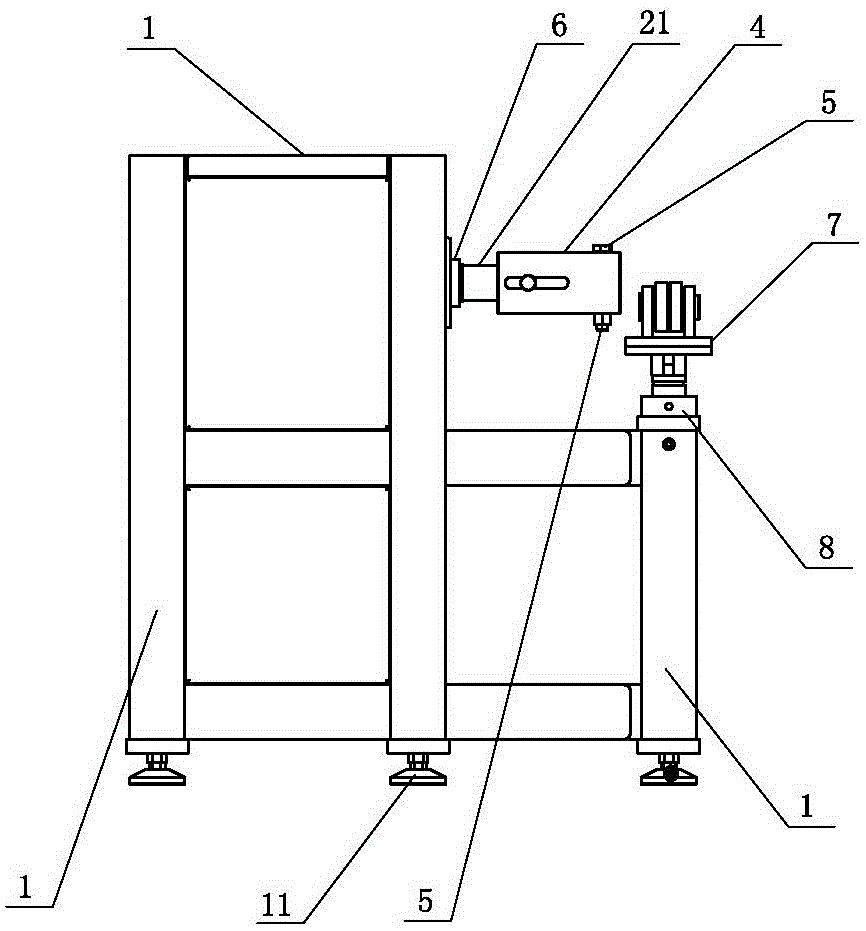

[0020] Such as figure 1 , 2 , 3, a wet electrostatic precipitator anode tube winding machine, including a frame 1, the bottom of the frame 1 is installed with an adjustment base 11; It is electrically connected with the motor 3; the front part of the output shaft 21 of the reducer 2 is sleeved with a connecting sleeve 4, which can rotate and slide relative to the output shaft 21, and the connecting sleeve 4 is drilled from top to bottom, and installed in the hole Connecting pin 5; bearing 6 is set on the front of reducer 2 and frame 1, and the bearing 6 is used to support output shaft 21; the front part of frame 1, below connecting sleeve 4, is provided with support seat 7, and the lower part of support seat 7 is set and adjusted Nut 8. A control cabinet 9 is arranged on the frame 1, and the control cabinet 9 is electrically connected to the reducer 2 and the motor 3.

[0021] Working principle and working process of the present invention are as follows:

[0022] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com