Automatic fast winding machine

a fast winding machine and automatic technology, applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of slow winding work of one round of the machine, and the inability to mass produce, so as to shorten the winding time, improve production efficiency, and speed up the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

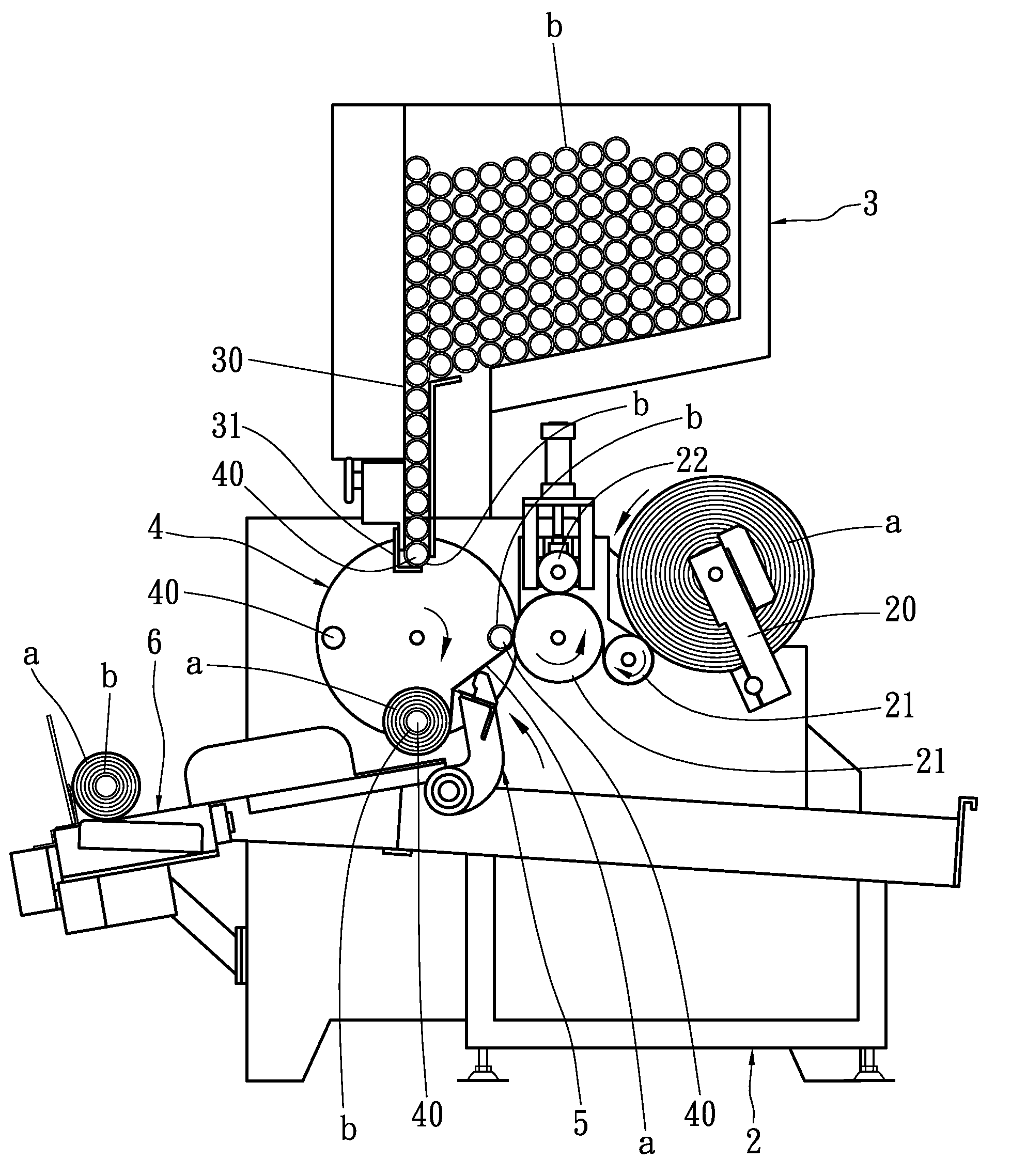

[0012]As shown in FIGS. 3 and 4, an automatic fast winding machine for packing film in the present invention includes a machine table 2, a support frame 20, plural guide rollers 21, a press roller 22, a feeding tank 3, a rotary disk 4, a saw-teeth cut device 5, and a collect frame 6 as main components combined together.

[0013]The support frame 20 is positioned on a right side of the machine table 20 for hanging a large roll of packing film (a).

[0014]The feeding tank 3 is positioned on the upper side of the machine table 2 for storing small cylinders (b) for winding packing film (a) from the large roll to form a small roll of packing film. And a guide hole 30 is formed in a lower portion of the feeding tank 3, with a stop member 31 formed at a lower end of the guide hole 30 and positioned just on the rotary disk 4.

[0015]The rotary disk 4 is just located at the lower end of the guide hole 30 of the feeding tank 3, having four support rods 40 sidewise fixed spaced apart equidistantly ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com