Series excited machine

A series excitation motor and chip technology, applied in the direction of electrical components, electromechanical devices, DC commutators, etc., can solve the problems of reducing enterprise profit space, unstable motor operation, and increasing production costs, and achieve convenient winding space and qualified The effect of improving efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

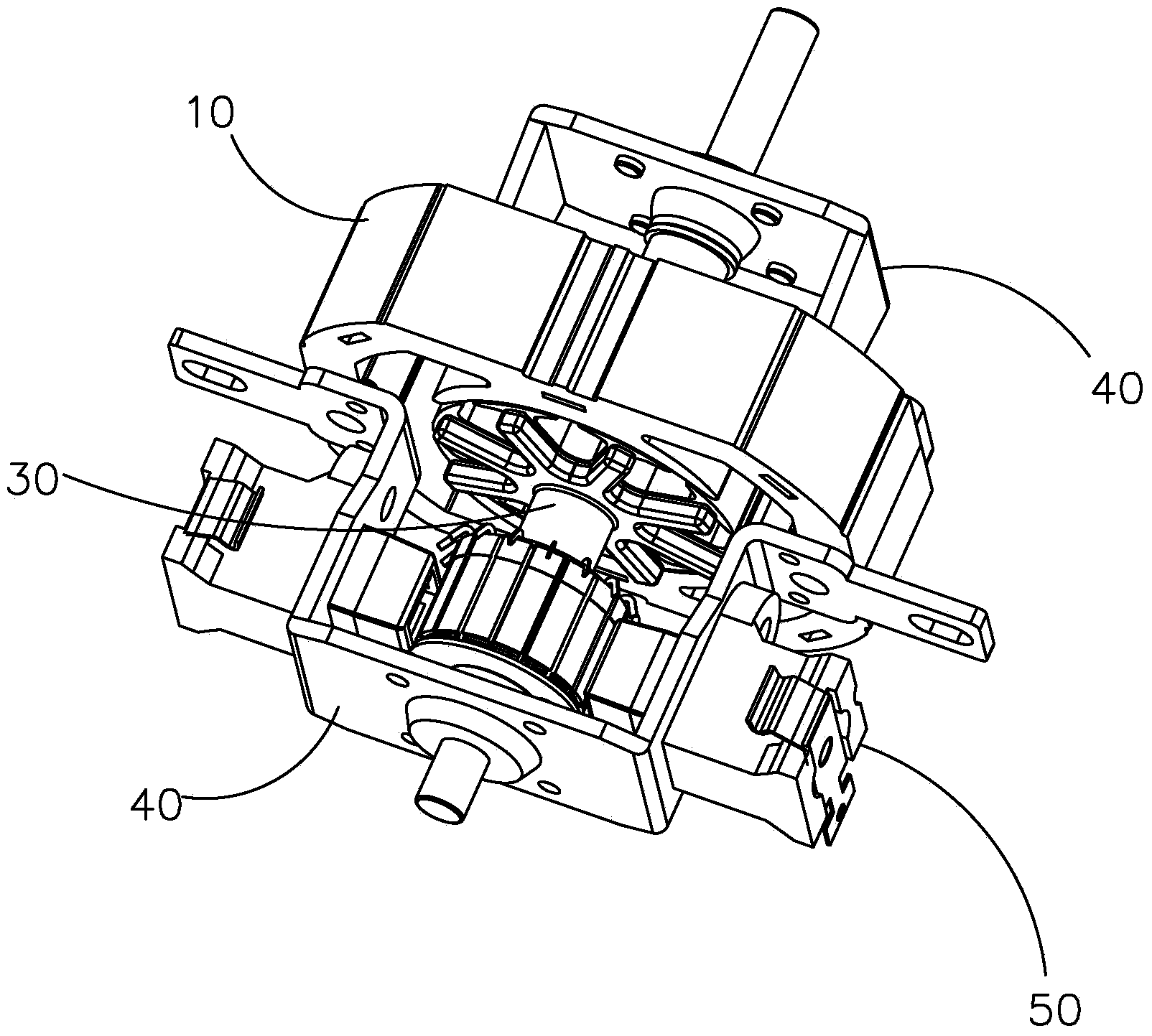

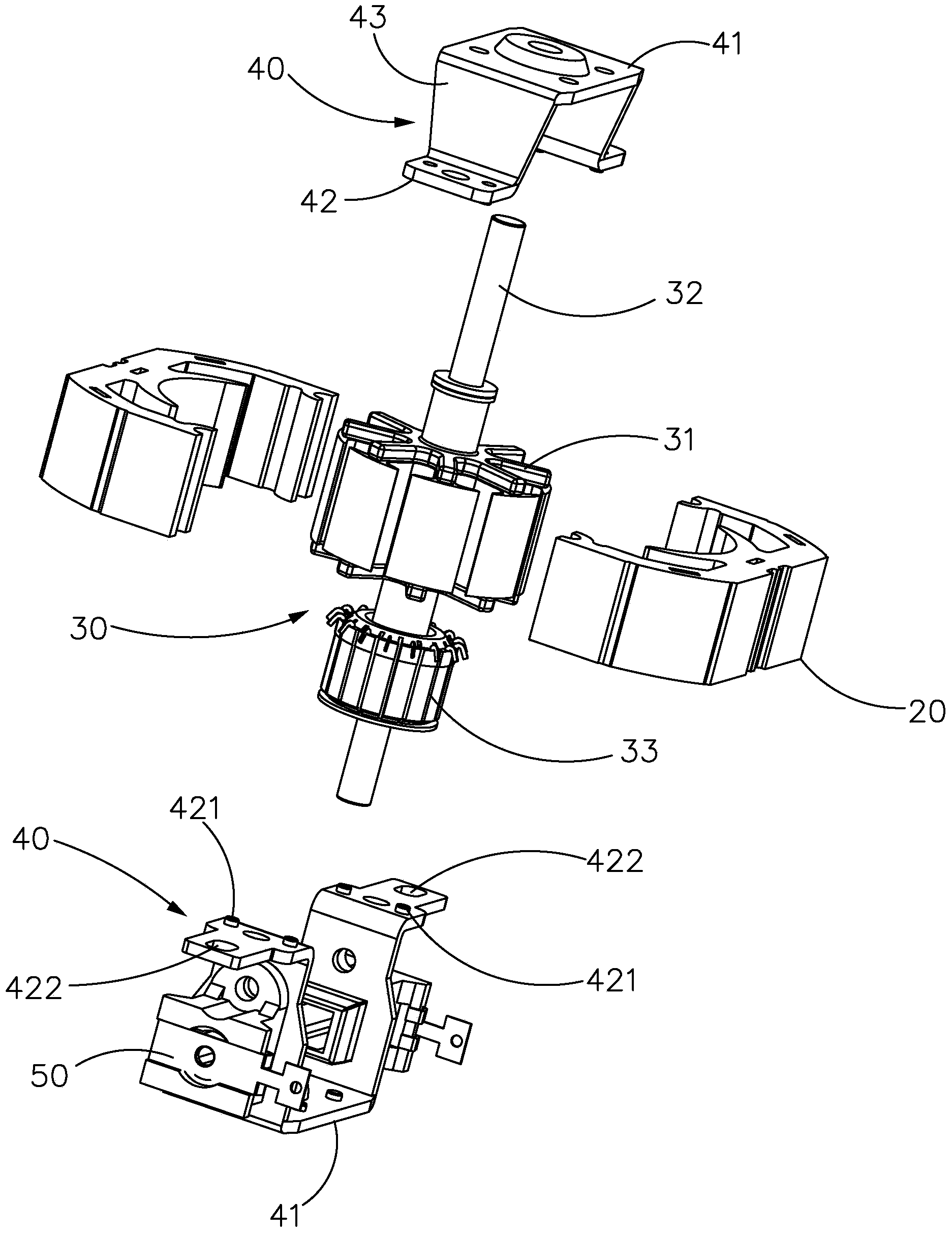

[0022] Such as Figure 1 to Figure 5 As shown, it is a series-excited motor of the present invention, also known as a single-phase series-excited motor. The series motor includes a stator 10, a rotor assembly 30 that can rotate relative to the stator 10, two covers 40 and two carbon brushes 50, the two covers 40 are respectively fixed up and down on the stator 10, and the rotor assembly 30 wears The two carbon brushes 50 are installed on the lower cover body 40 and are in electrical contact with the rotor assembly 30 .

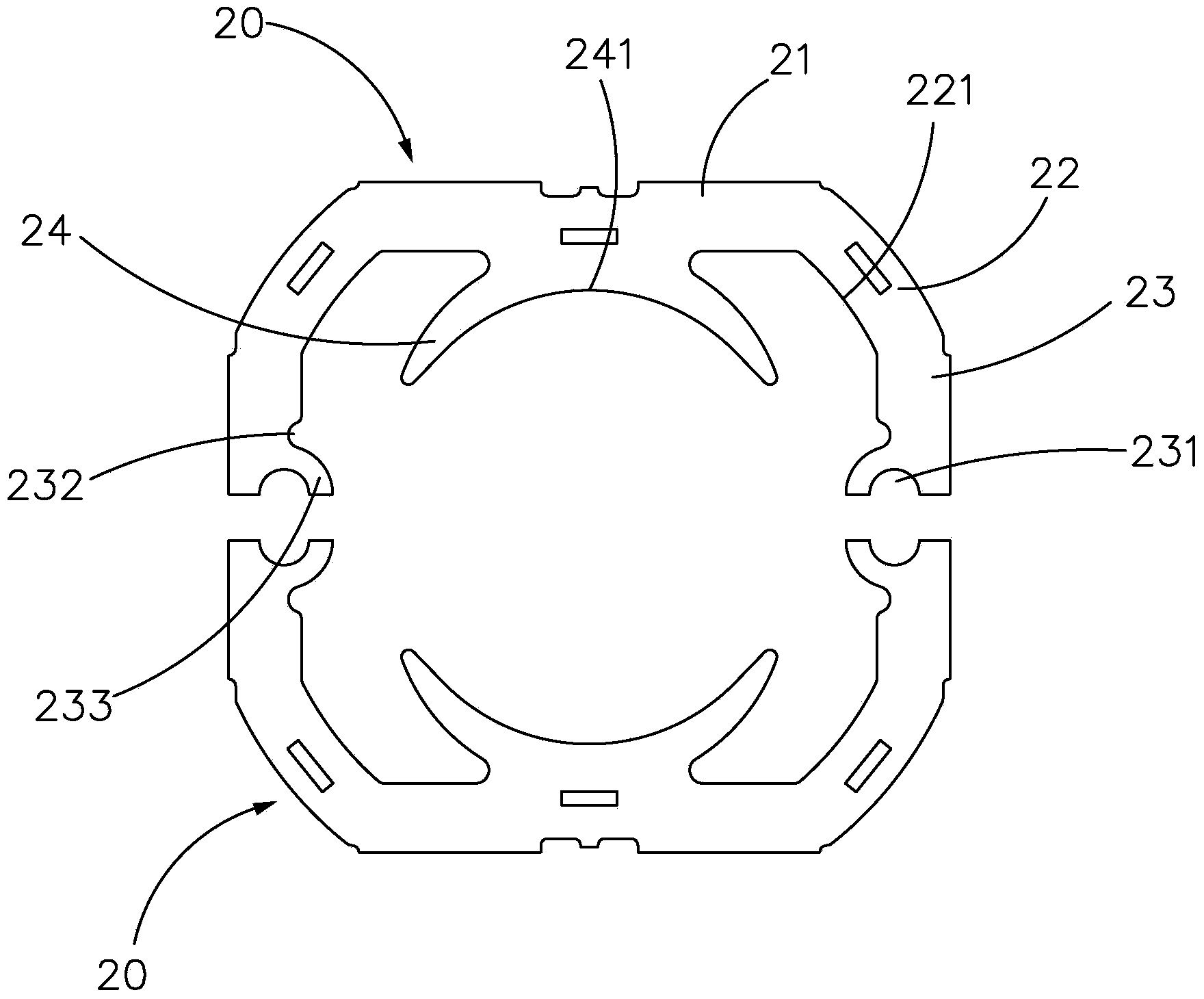

[0023] The stator 10 includes two opposing chip assemblies 20 in a C-shaped structure, the two chip assemblies 20 are arranged at intervals, and each chip assembly 20 is wound with a stator winding (not shown in the figure). In the present invention, the so-calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com