Improvement method for electronic grade glass fiber yarn preparation

A glass fiber yarn and electronic-grade technology, which is applied in the field of electronic fiber cloth processing, can solve problems such as poor coating effect of oiler sizing agent, failure to meet product quality requirements, and failure to meet the needs of multi-point pulling and high-speed production processes. Achieve the effects of reducing the abnormal oil content of the wire cake, reducing the drawing and winding time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An improved method for preparing electronic-grade glass fiber yarn, the specific steps are as follows:

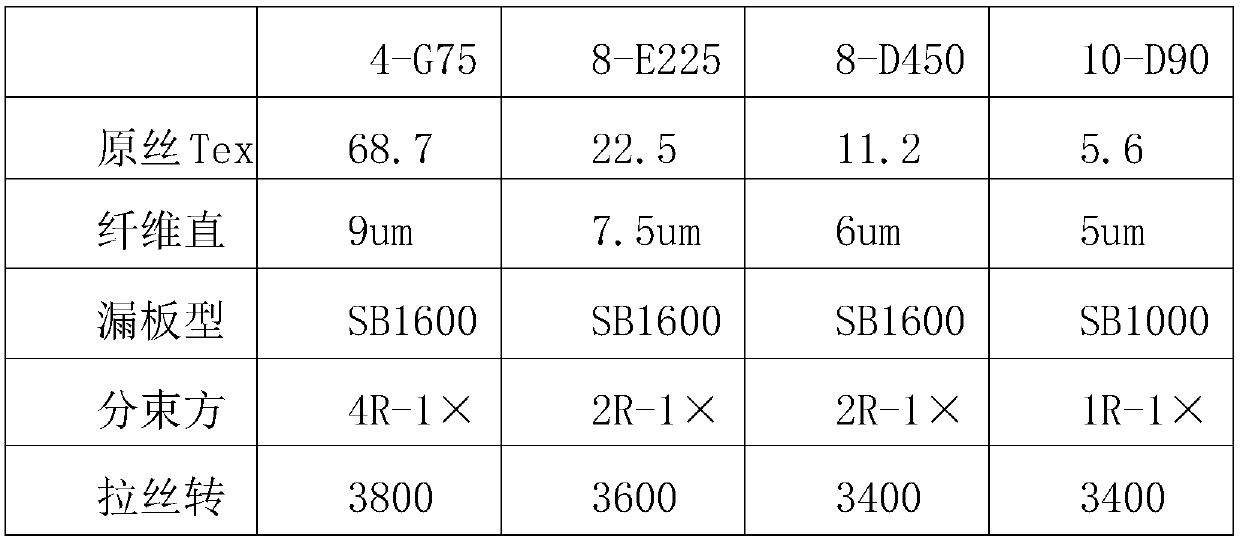

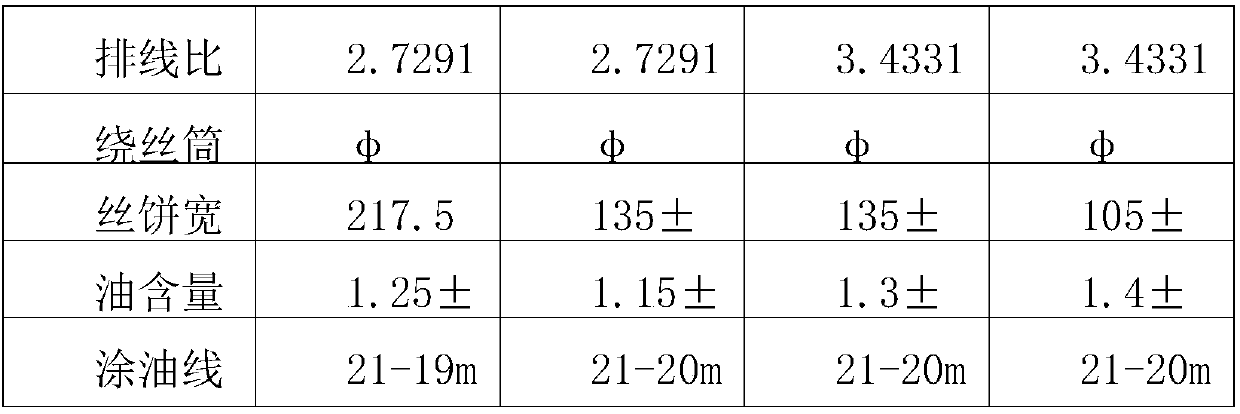

[0039] (1) Improve the design of the existing three-point drawing G75-1200H leaking board to a four-pointing G75-1600H leaking board, adding one partition;

[0040] (2) Adjust the beam splitting method from 4R-1×3 to 4R-1×4, and improve the design of the existing six-point drawing E225-1200H breakout plate / D450-1200H to eight-point pull E225-1600H breakout plate / D450 -1600H breakout plate, add 2 partitions;

[0041] (3) Adjust the beam splitting method from 2R-1×6 to 2R-1×8, improve the design of the existing 8fenla D900-800H leak board to Shifenla D900-1000H leak board, and add 2 partitions;

[0042] (4) Adjust the beam splitting method from 1R-1×8 to 1R-1×10, adjust the process parameter setting after the partition of the leakage plate and the size of the interval change, and check the drawing tension;

[0043] (5) Increase the drawing speed according to the actu...

Embodiment 2

[0055] An improved method for preparing electronic-grade glass fiber yarn, the specific steps are as follows:

[0056] (1) Improve the design of the existing three-point drawing G75-1200H leaking board to a four-pointing G75-1600H leaking board, adding one partition;

[0057] (2) Adjust the beam splitting method from 4R-1×3 to 4R-1×4, and improve the design of the existing six-point drawing E225-1200H breakout plate / D450-1200H to eight-point pull E225-1600H breakout plate / D450 -1600H breakout plate, add 2 partitions;

[0058] (3) Adjust the beam splitting method from 2R-1×6 to 2R-1×8, improve the design of the existing 8fenla D900-800H leak board to Shifenla D900-1000H leak board, and add 2 partitions;

[0059] (4) Adjust the beam splitting method from 1R-1×8 to 1R-1×10, adjust the process parameter setting after the partition of the leakage plate and the size of the interval change, and check the drawing tension;

[0060] (5) Increase the drawing speed according to the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com