Production method of multireel reel lithium tape

A production method and lithium ribbon technology are applied in the production field of multi-coil lithium ribbons, which can solve the problems of not being suitable for large-scale automation equipment, multiple shutdowns and reeling time, waste of lithium ribbon heads and tails, etc., so as to save transportation costs, Less boarding and boarding, improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

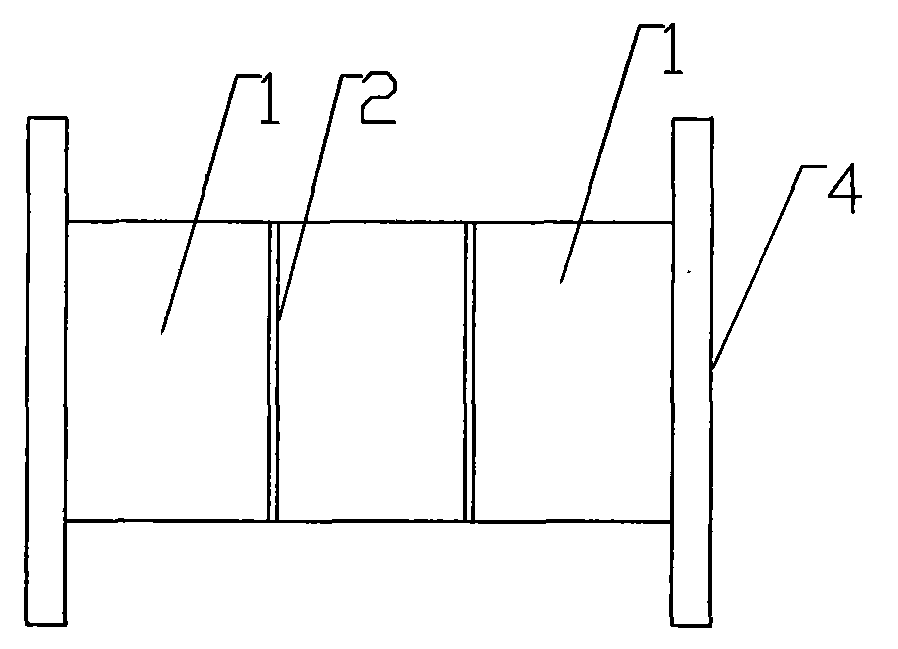

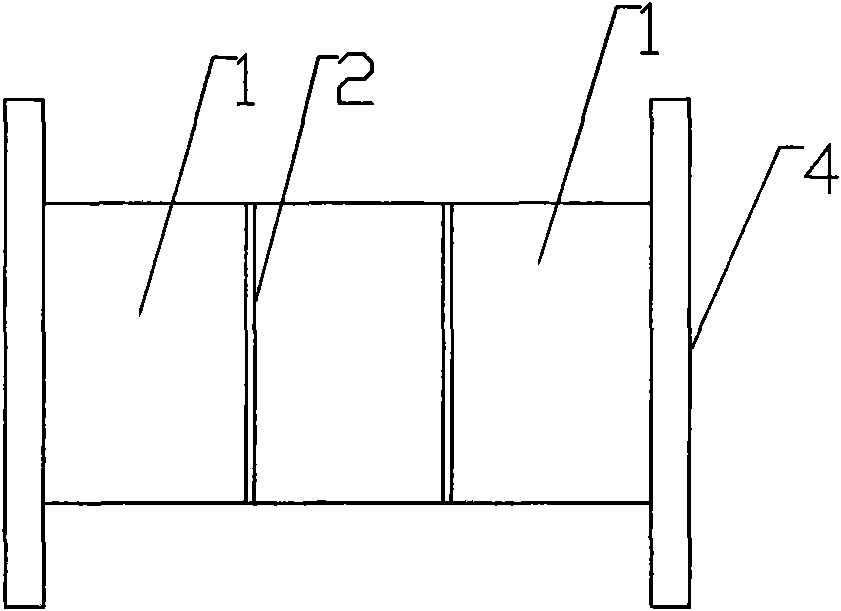

[0032] A production method of a multi-volume reel lithium ribbon, comprising the following process steps:

[0033] a. Install the spool of the reel on the winding machine, connect the extruded lithium ribbon to one end of the spool, start the winding machine, and complete the winding of a roll of lithium ribbon on the spool;

[0034] b. Move the reel on the winding machine to the area to be wound on the reel, connect the extruded lithium ribbon to the area to be wound on the reel, start the winding machine, and complete a roll of lithium ribbon on the reel;

[0035] c. Repeat the previous steps to wind multiple rolls of lithium ribbons on the reel in sequence.

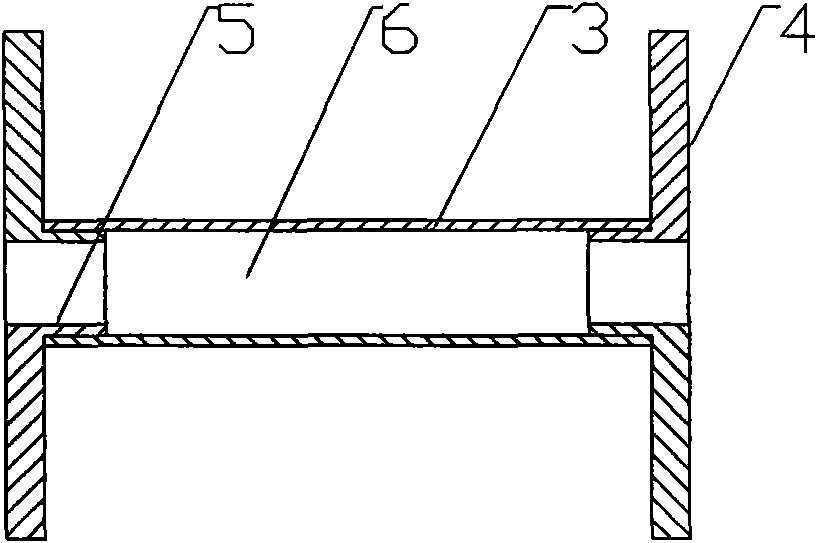

[0036] The present invention also includes step d, the step d is installing protection disks at both ends of the reel, and engaging the protection disk with the reel.

[0037] The present invention also includes step e, the step e is installing a separator between two adjacent rolls of lithium ribbon on the reel.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com