Variable-speed moving mechanism of rack of coiling machine

A technology of moving mechanism and spring machine, which is used in the manufacture of springs, mechanical equipment, transmission devices, etc. from wires, can solve the problems of uncertain wire feeding speed, less effective wire feeding time, low production efficiency, etc., and achieves a large proportion of working time. , The effect of high spring winding precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

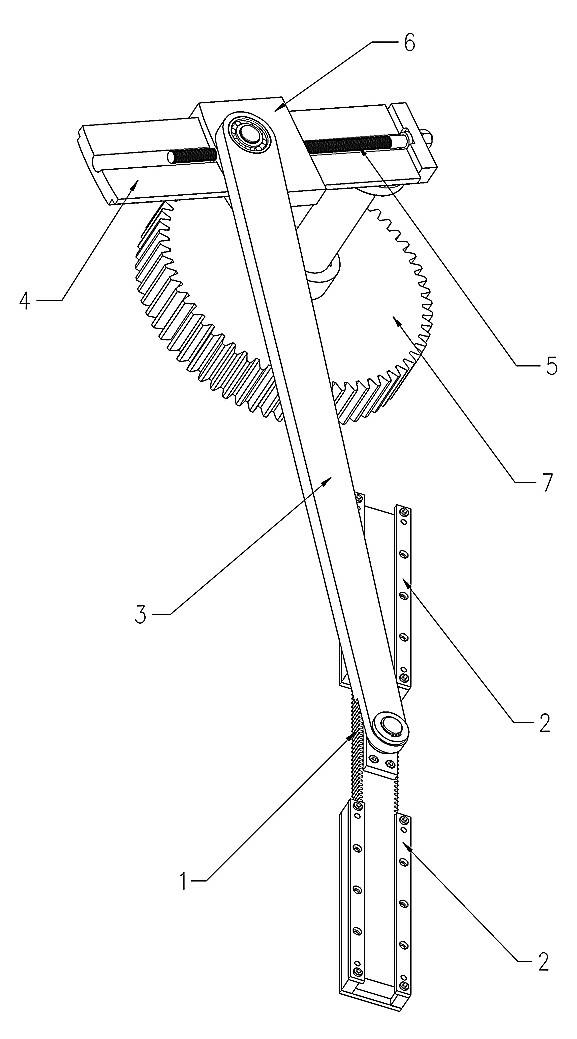

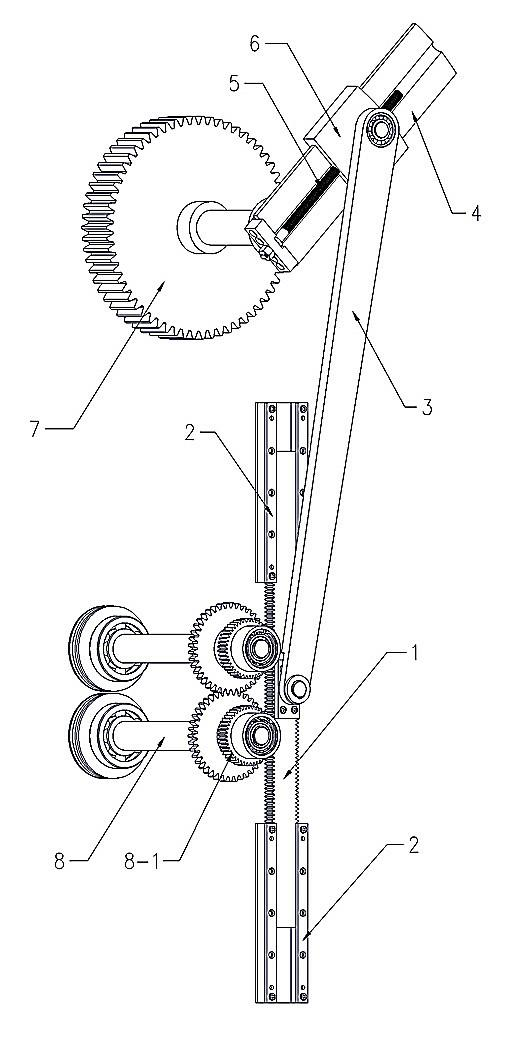

[0030] The structure of the present invention is as Figure 1 to Figure 4 As shown, it mainly includes a rack 1, a sliding seat 2, a connecting rod 3, a screw seat 4, a screw 5, a slider nut 6, and a gear 7.

[0031] The left side of the rack 1 meshes with the two clutch gears of the wire feeding wheel transmission 8, and the rotating shaft in the middle of the rack 1 is connected with the pin shaft at one end of the connecting rod 3 through a bearing; the rack 1 is slidably connected in the two sliding seats 2 , the slider 2 is fixed on the frame;

[0032] The other end of the connecting rod 3 is pinned to the slider nut 6;

[0033] The gear 7 is fixed on the frame through bearings, the gear 7 and the screw base 4 are fixed at both ends of the same rotating shaft; the screw 5 is connected to the screw base 4 through the bearing, and the slider nut 6 is connected to the screw base by sliding tenon 4, the slider nut 6 is threadedly connected with the screw mandrel 5, and when...

Embodiment 2

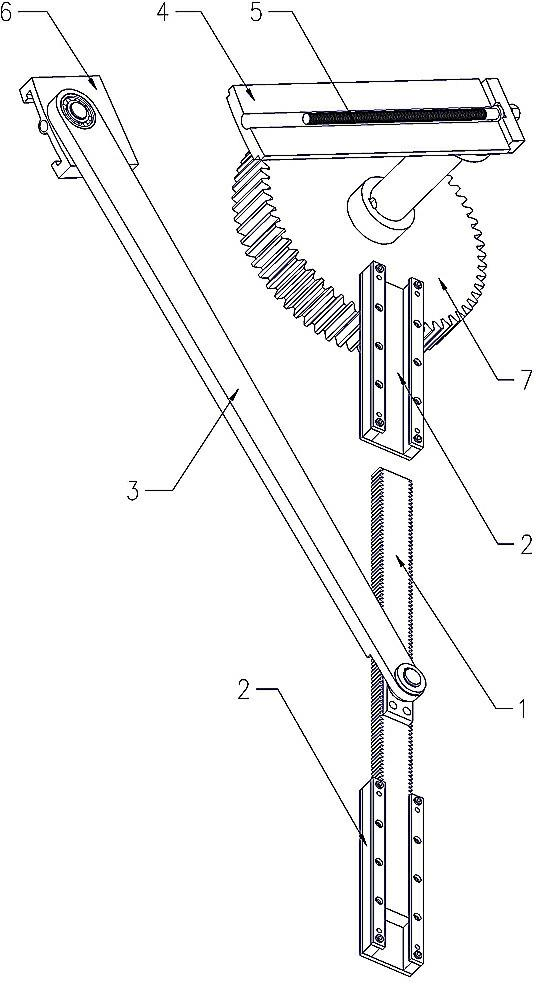

[0040] see Figure 5 , the basic structure of this embodiment is the same as that of Embodiment 1, only the rack 1 is installed horizontally, and the wire feeding in the vertical direction can be realized.

Embodiment 3

[0042] see Figure 6 , the basic structure of this embodiment is the same as that of Embodiment 1, the rack 1 has teeth on both sides, only a pair of wire feeding wheel transmissions are added on the other side of the rack, but the clutch direction of the overrunning clutch is opposite, that is, overrunning The clutch direction of the clutch should meet the following principles: the clutch directions of the diagonal clutches are consistent. Make wire feeding more powerful and reliable, suitable for conveying thick steel wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com