Brand new high-universality maintenance-free high-speed constant-tension yarn winder

A versatile, maintenance-free technology that can be used in the transportation of filamentous materials, thin material handling, transportation and packaging. The effect of high stability, high winding precision and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

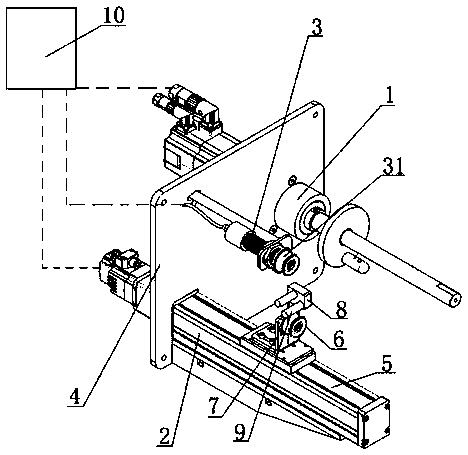

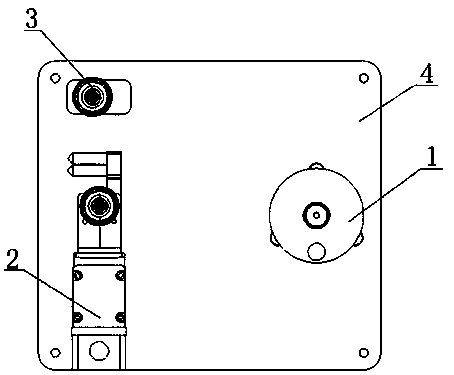

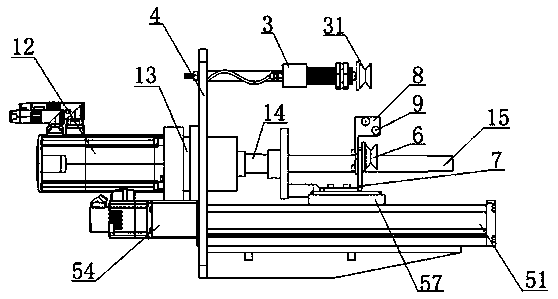

[0036] Refer to attached Figure 1-6 , a brand-new maintenance-free high-speed constant tension yarn winding machine with high versatility, which includes a winding head mechanism 1, a winding arm mechanism 2 and an online tension meter 3, and the winding arm mechanism 2 is installed on the fixed plate 4 In the lower left corner position, the online tensiometer 3 is installed on the upper left corner of the fixed plate 4 and above the winding arm mechanism 2, and the winding head mechanism 1 is installed in the middle position on the right side of the fixed plate 4, and the winding arm mechanism 2 includes Sliding mechanism 5, runner 6, L-shaped fixed plate 7, guide roller support 8, guide roller 9, the lower end of L-shaped fixed plate 7 is installed on the sliding mechanism 5, and runner 6 is installed on one side of L-shaped fixed plate 7, The inner side of the upper end of the L-shaped fixed plate 7 is designed with a guide roller support 8, and two guide rollers 9 are rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com