Arrangement for winding a web of material

A material strip and winding body technology, applied in the field of winding material strip devices, can solve the problems of low life and achieve reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

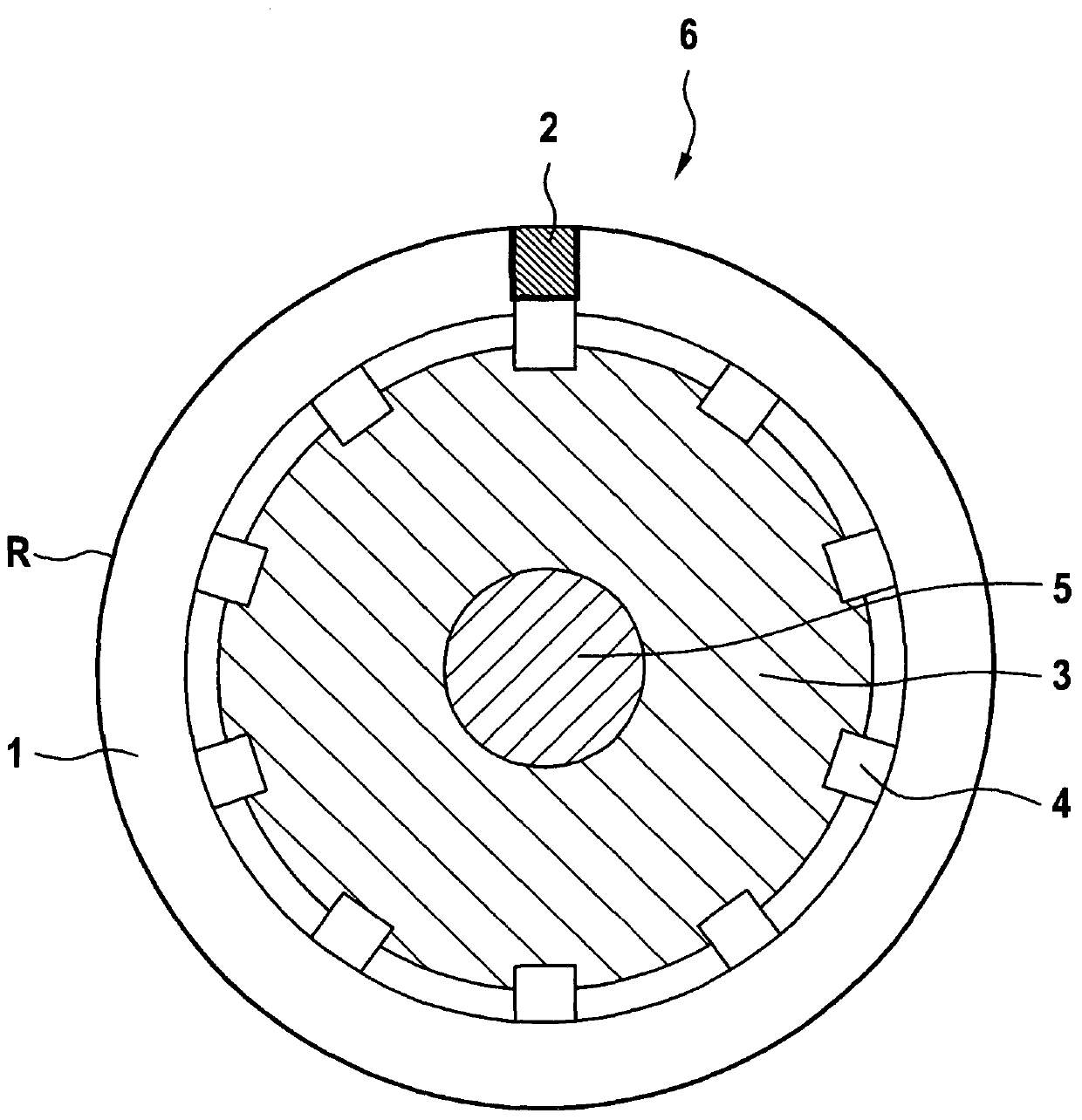

[0030] figure 1 The device shown shows an expanding clamping shaft, referenced 3 , which is connected around its central axis to drive means, such as a Benninger adapter, by a suitable coupling. The expansion clamping shaft 3 can here be connected to a drive with a torque of 500 Nm in the present embodiment and a winding speed of up to 200 m / min. The diameter of the expansion clamping shaft is 148mm, and the clamping range is between 148.5mm and 154mm. Its length can be adjusted on site to the existing drive unit, and can also be adjusted to the length of the winding body.

[0031] The expanding clamping shaft 3 is a pneumatic shaft driven at a driving pressure of 6.0 bar and has 10 clamping bars equally spaced around its circumference. The clamping bar is clamped on the figure 1 Rolling body of recycled paper or other paper type with an outer layer of parchment paper and / or other paper type formed in the form of a glued sleeve with a suitable force in the state shown, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com