Electronic induction winding device

An electronic induction, retractor technology, applied in belt tensioners, car seat belts, transportation and packaging, etc., can solve the problems of high locking lag cost, difficult control, high noise, etc., to improve the accuracy of retraction degree, reduce the number of parts, reduce the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

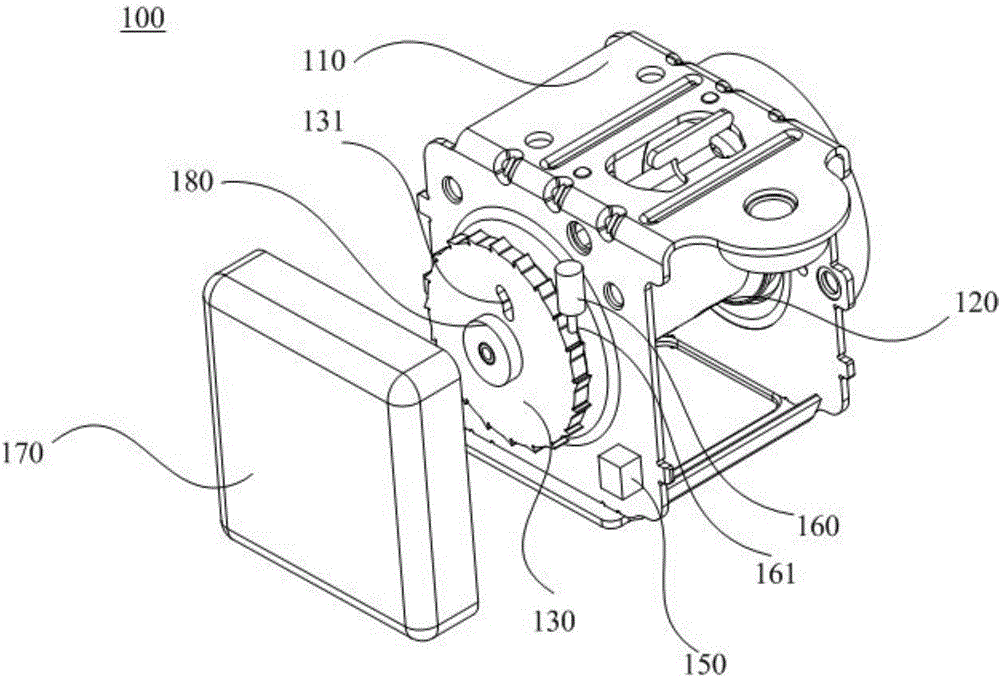

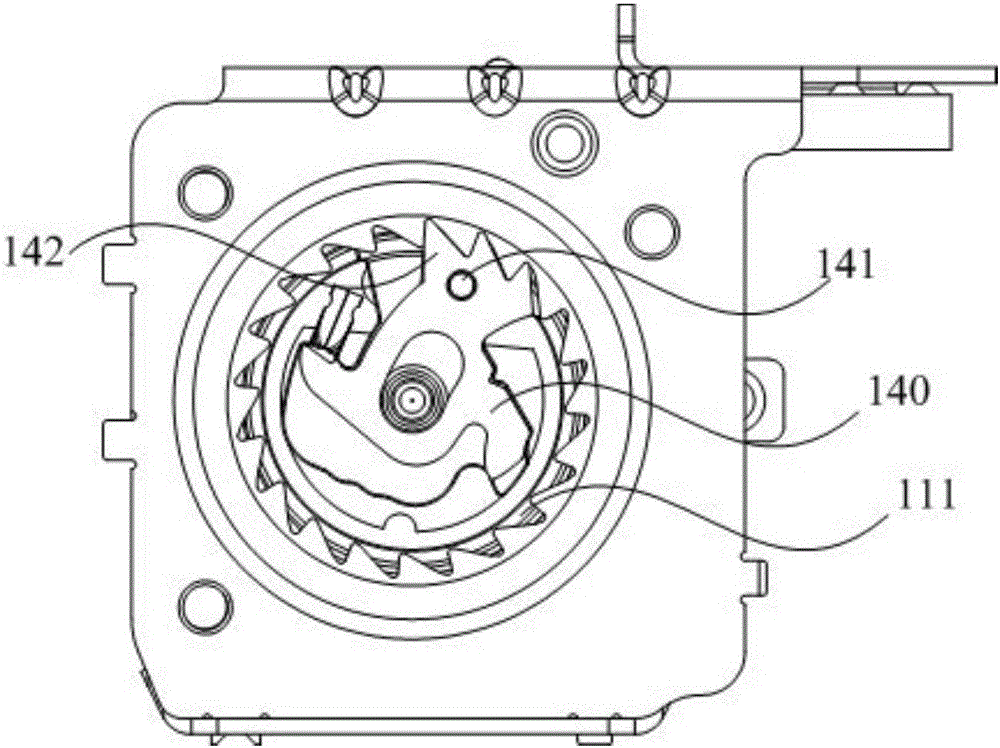

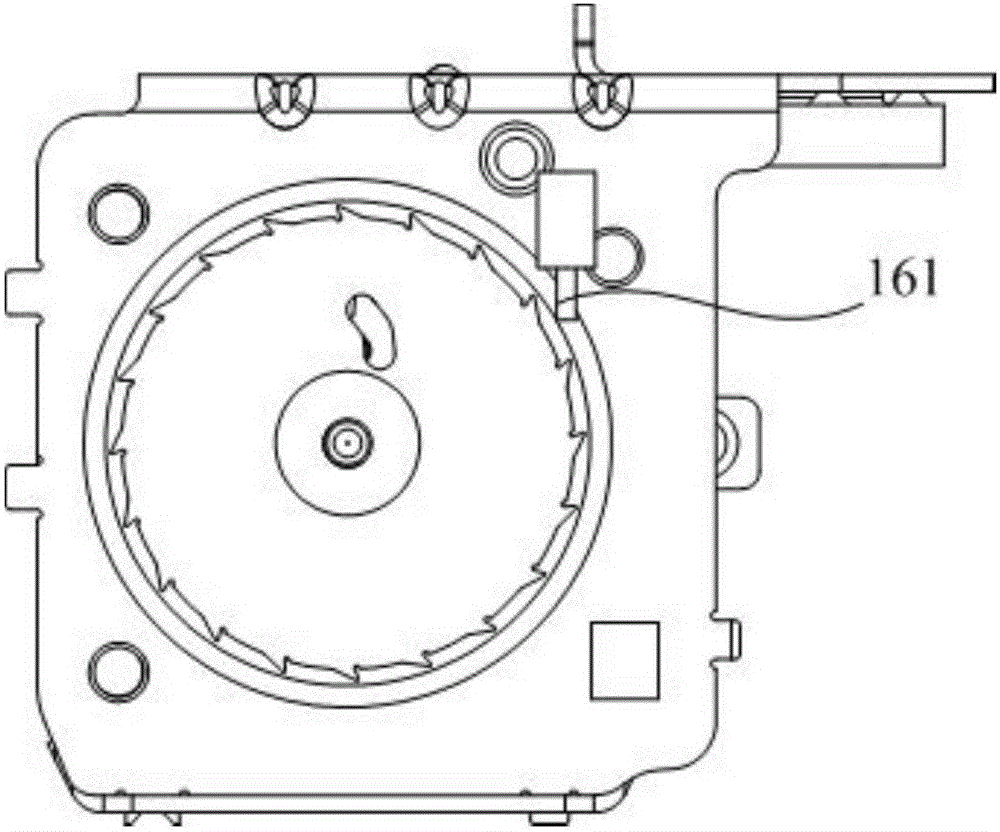

[0030] See figure 1 , figure 2 and Figure 3a , Figure 3b , are respectively a perspective view, a front view and a schematic view of the motion state of the electronic induction retractor 100 of an embodiment. like figure 1 As shown, the electronic induction retractor is used for retracting the safety belt, and the electronic induction retractor includes a frame 110 and a reel 120 . Wherein the frame 110 is used for accommodating the safety belt. The reel 120 is used for winding the safety belt, the reel 120 is arranged in the frame 110 , and one end protrudes from the frame 110 .

[0031] The electronic induction retractor 100 also includes a first induction module 150 , an electromagnetic switch 160 and a control module 170 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com