Lead wire looping machine

A looping machine and wire technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of wasting labor, low production efficiency, and restricting the development of enterprises, so as to promote the degree of automation and improve Productivity and versatility-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

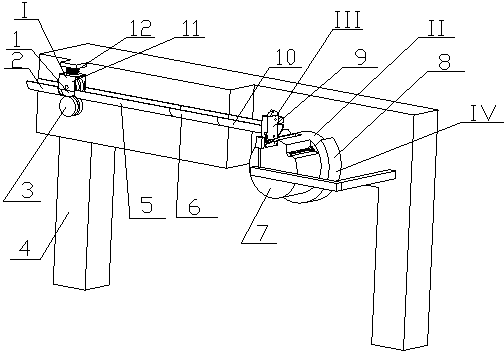

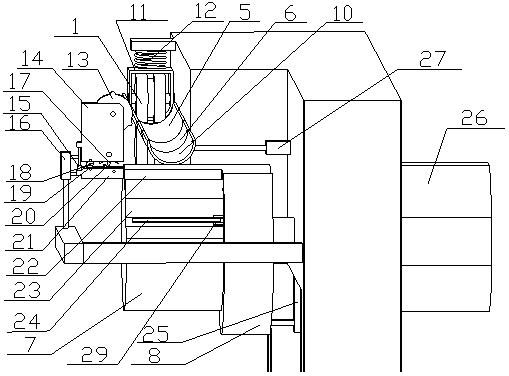

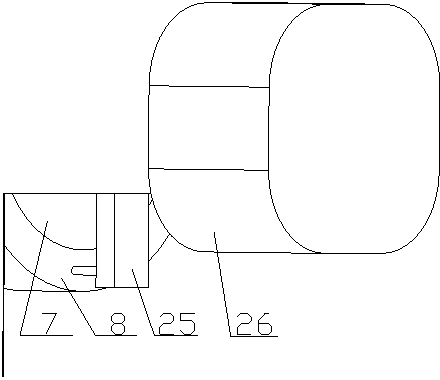

[0029] In this example, see Figure 1 to Figure 8 , the wire looping machine, comprising a frame 4 equipped with wire feeding device I, winding device II, tape wrapping device III and wire pushing device IV, wire feeding device I is installed on the front end of frame 4, winding device II Installed on the rear end of the frame 4, the output end of the wire feeding guide rail in the wire feeding device I is connected to a reel 7 in the winding device II; the tape wrapping device III is installed on one side of the winding device II, so that A tape winding mechanism 9 in the tape winding device III moves up and down with the reel 7 as the midpoint; a wire pushing device IV is installed on the other side of the winding device II, so that one of the wire pushing devices IV is placed on the reel 7 The push wire ring 8 moves back and forth along the axis of the reel.

Embodiment 2

[0031] In this example, see Figure 1 to Figure 8 , a wire looping machine, mainly composed of a frame 4, a wire feeding device, a wire winding device, a tape wrapping device and a wire pushing device, the wire feeding device includes a front fixed guide rail 2, a middle fixed guide rail 5, a rear fixed guide rail 6, The movable guide rail 10, the driving guide wheel 3 and the driven guide wheel 1, the front fixed guide rail 2, the middle fixed guide rail 5 and the rear fixed guide rail 6 are connected in series in a straight line and fixedly connected with the frame 4, and the movable guide rail 10 and the cylinder 27 The piston rod ends are fixedly connected, the cylinder 27 is fixed on the frame 4, the driving guide wheel 3 is connected with the motor in the frame 4 cabinet, and the driven guide wheel 1 is elastically connected with the frame 4 through the spring 12; the winding device includes a motor Component 26, reel 7 and wire crimping rod set, reel 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com