Angle measurement error compensation method based on wind speed and position influence

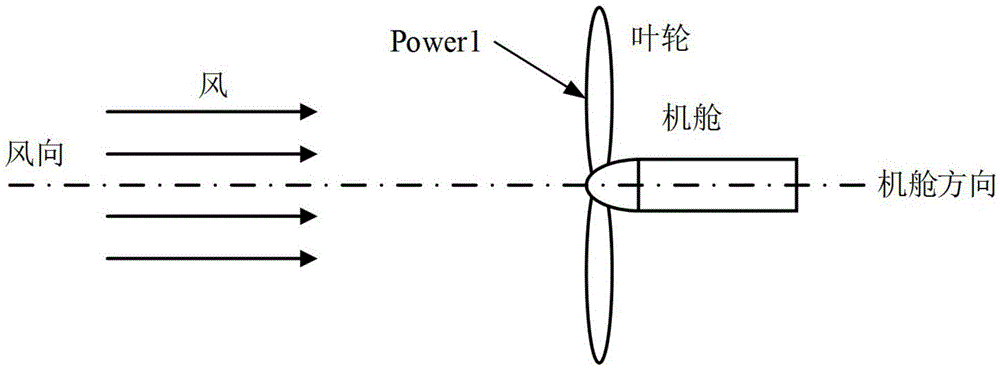

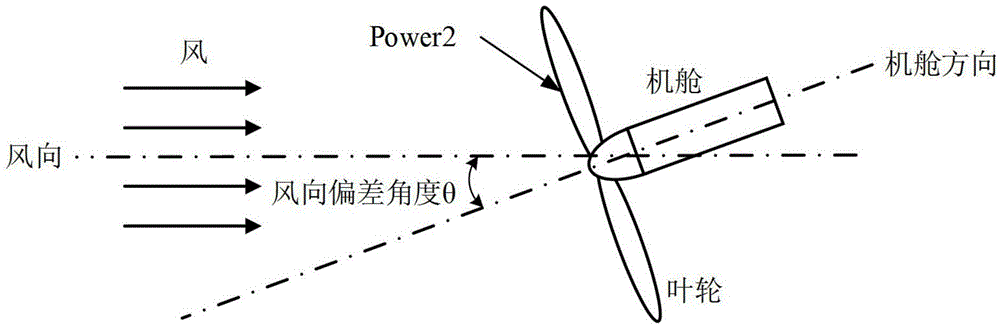

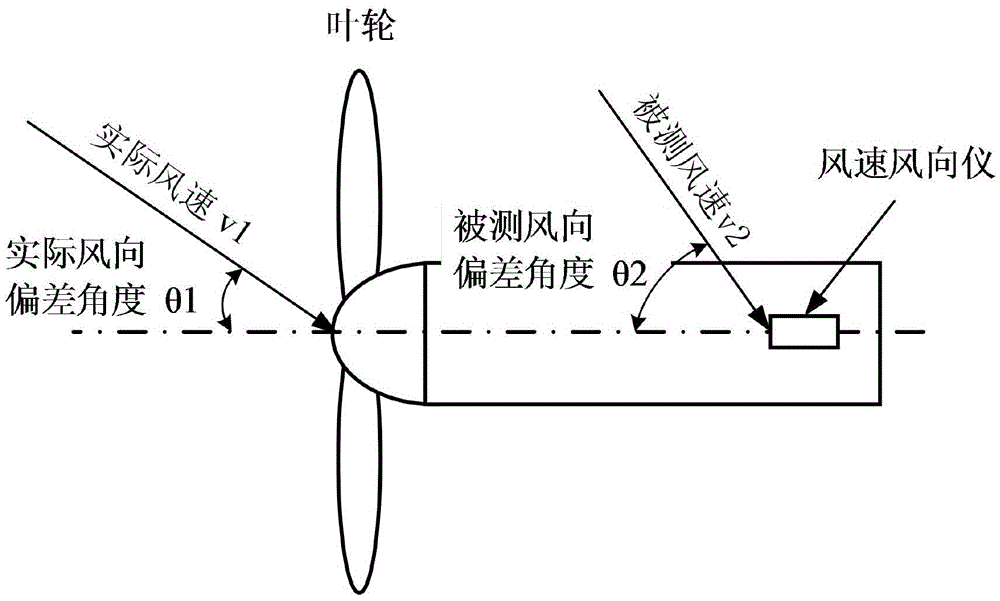

A technology of angle measurement and wind speed, which is applied in the control of wind turbines, the monitoring of wind turbines, and wind power generation. It can solve the problems of not being able to compensate the angle measurement error of the anemometer, and achieve the effect of improving power generation efficiency and wind accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] Such as Figure 4 As shown, a wind turbine A in a wind farm in Hebei is in Figure 4 The micro-site selection situation in , that is, there are four other wind turbines B1, B2, B3, and B4 in the northwest, northeast, southwest, and southeast directions, and there is a hill C in the west.

[0040] In order to represent the micro-site selection difference of wind turbine A in different directions, such as Figure 5 As shown, the fan A is divided into eight areas P1, P2, . . .

[0041] After entering the learning cycle, the anemometer classifies the collected data according to the position and orientation of the cabin, and obtains the angle measurement error curve of each cabin position in turn, as shown in Image 6 As shown, eight angle measurement error curves are finally obtained.

[0042] During the operation cycle of the anemometer, according to the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com