Angle measurement error compensation method for adding main control system data transfer error correction

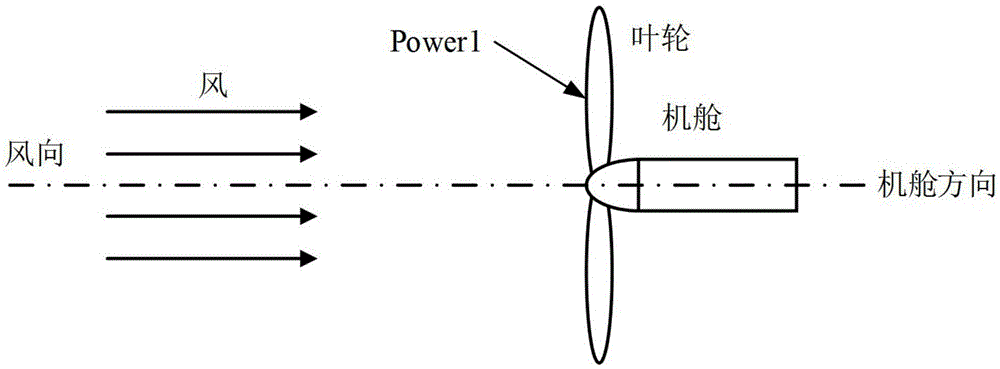

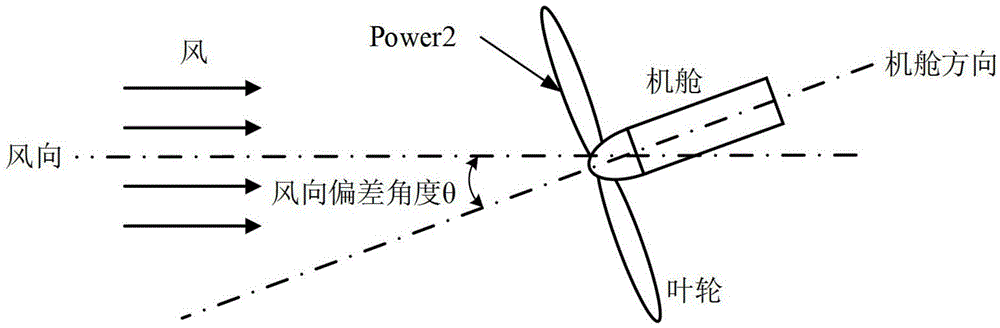

A main control system and transmission error technology, applied in the direction of engine control, wind turbine control, wind turbine monitoring, etc., can solve the problems of unable to compensate the angle transmission error of the main control system, reduce power generation efficiency, etc., and reduce the loss of power generation , improve power generation efficiency, and improve the effect of obtaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

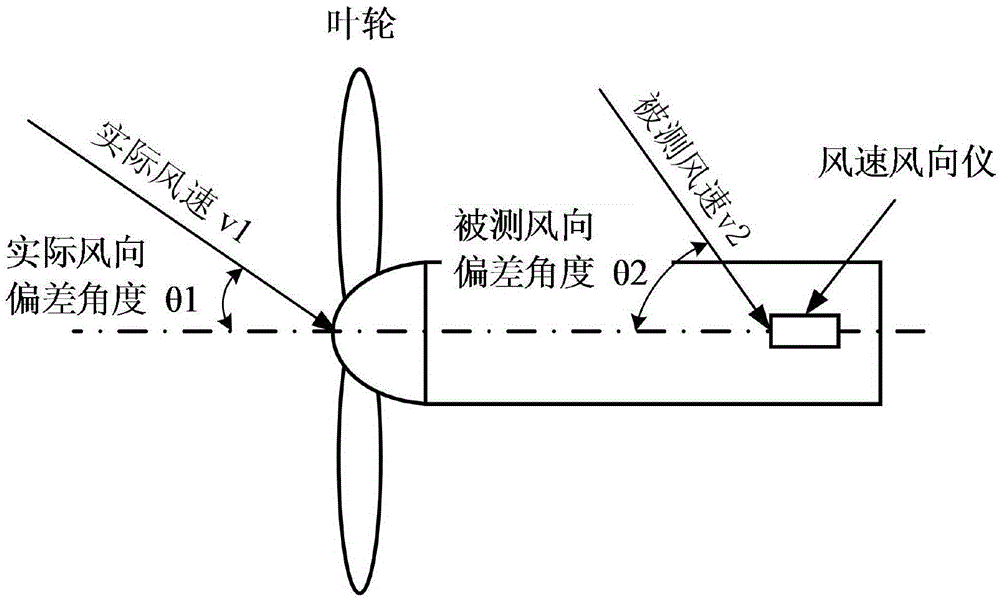

[0038] In the present invention, before analyzing the angle transmission error between the anemometer and the main control system, the angle measurement error δ of the anemometer is firstly analyzed. 1 Compensate, that is, get δ 1 =0.

[0039] In eliminating angle measurement error δ 1 After that, the wind direction deviation angle θ at the fan impeller 1 The wind direction deviation angle θ obtained by the main control system 3 There is only an angular transfer error δ between 2 . The anemometer can actively collect the wind direction deviation angle θ collected by the main control system of the target fan 3 , and count the wind direction deviation angle θ 3 The density distribution histogram of , if the angle transfer error between the anemometer and the main control system δ 2 = 0, then the wind direction deviation angle θ 3 The distribution law of Figure 5 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com