Composite treating method for prolonging life of grating machine key components

A composite treatment and chain grate technology, which is used in heat treatment equipment, heat treatment process control, coating and other directions to improve mechanical properties, save resources and energy, and improve fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

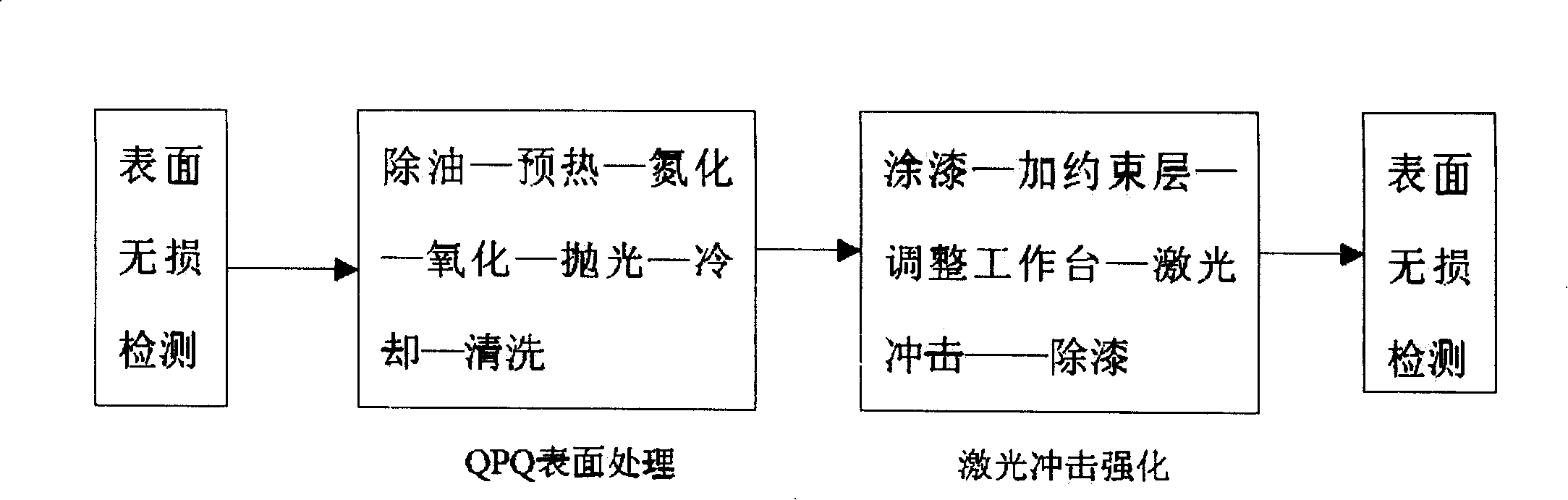

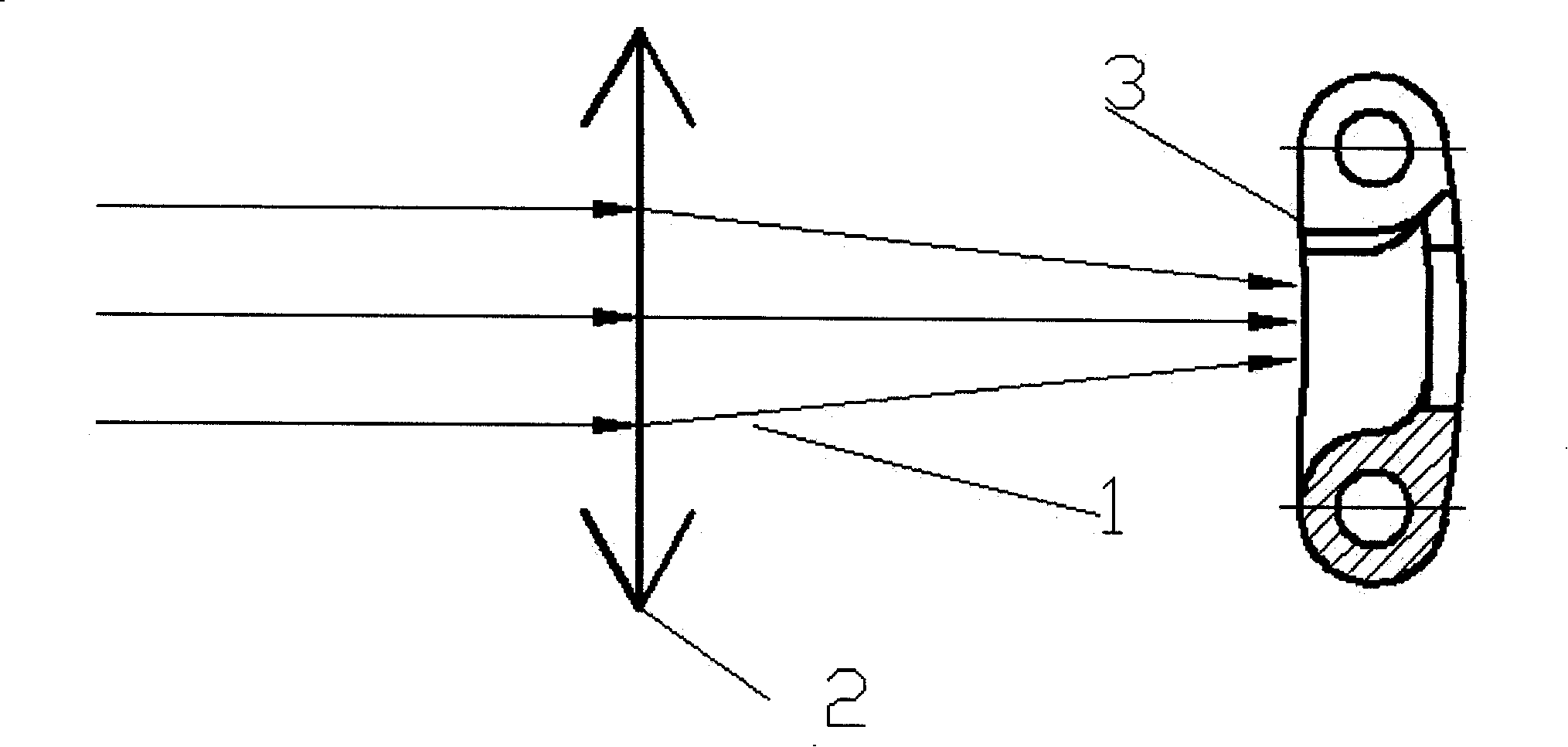

[0023] Embodiment: First, non-destructive testing is carried out on the surface of the chain link of the chain grate, and two eddy current sensors are installed on the surface of the workpiece to be tested, and the weak area of the mechanical performance of the part surface is determined through the detected sensor signal, and the compound treatment position is determined; the QPQ process flow is: Degreasing→preheating (350°C)→QPQ nitriding (520°C)→QPQ oxidation (370°C)→polishing→cooling→cleaning. For the grate material heat-resistant steel 30Cr21Mn8NiSi2NRe, after the QPQ process, the surface wear resistance reaches 23 times that of conventional quenching; after the QPQ process, laser shocks the chain link of the chain grate to improve its thermal fatigue resistance . Such as figure 2 As shown in the process of laser shock strengthening, when the laser output wavelength is 1.054 μm, the pulse width (FWHM) of the output laser is 22.1 ns, and the laser pulse energy is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com