Hand-push type rapid grain collector for sunning ground

A hand-push, grain harvester technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low efficiency of manual closing work, injury to grain harvesters, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

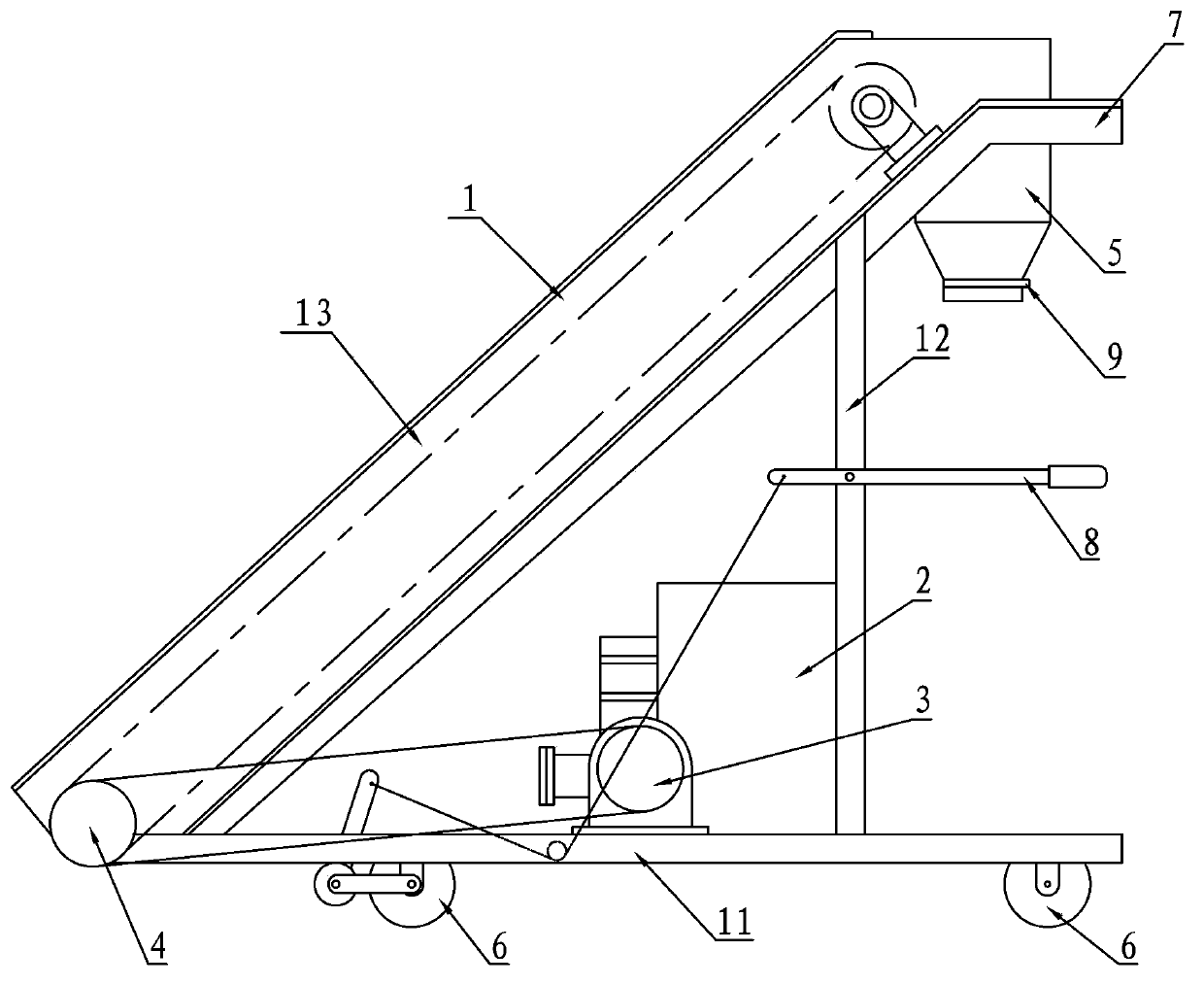

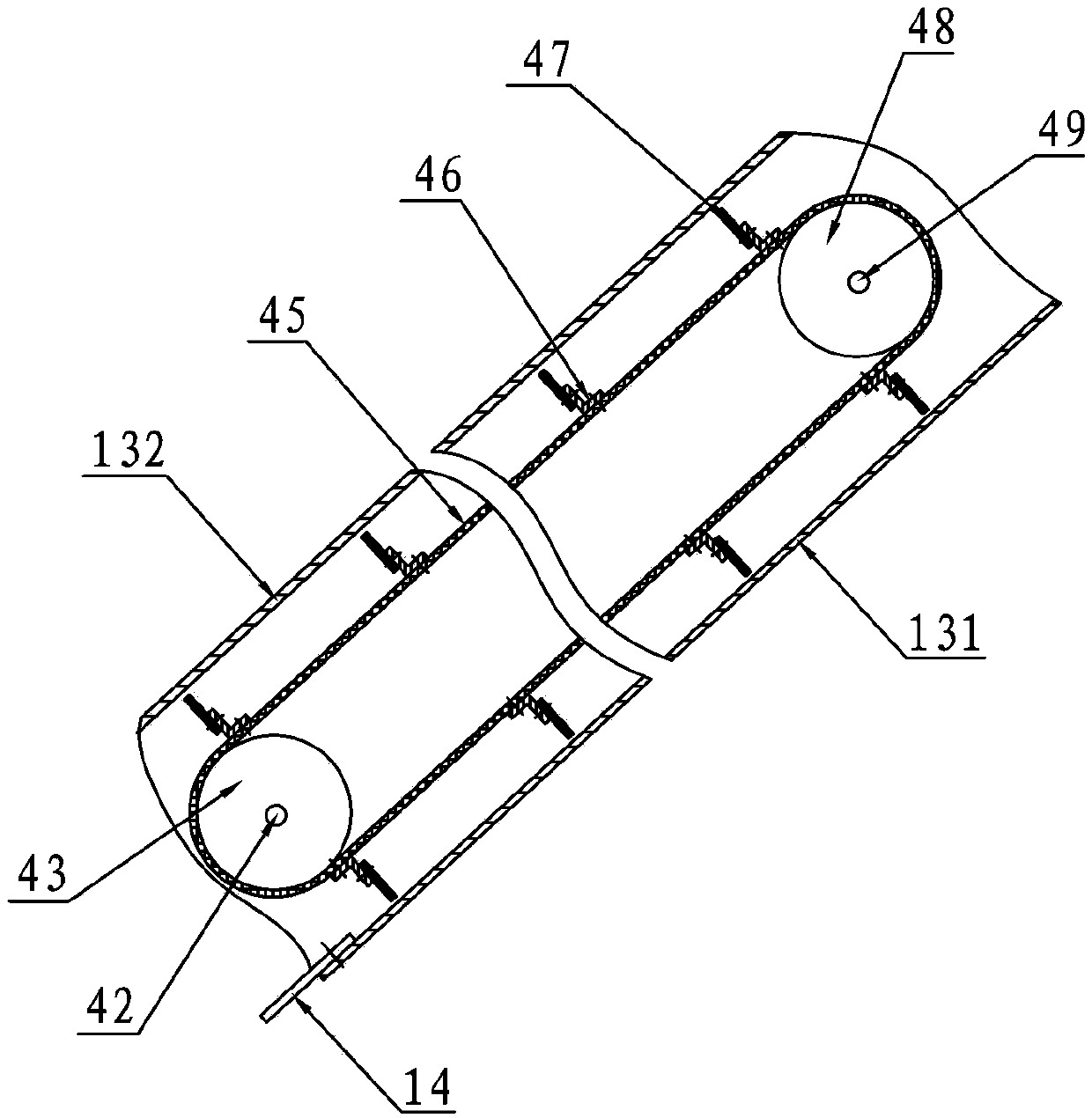

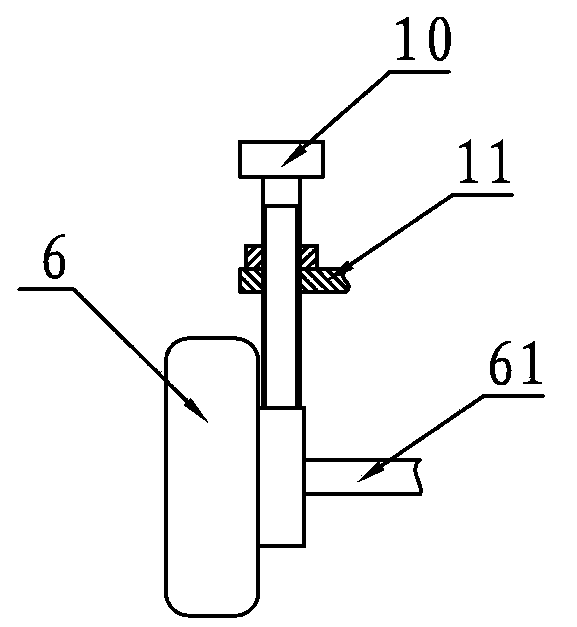

[0023] A hand-push type fast harvesting machine for drying, such as Figure 1 to Figure 6 Shown, comprise frame 1, power machine 2, gearbox 3, circulation harvesting device 4, discharge box 5, moving roller 6 and push rod 7, frame 1 is made up of bottom frame 11, mullion 12 and inclined cabinet 13 The inclined chassis 13 is a hollow cuboid surrounded by a bottom plate 131, a top plate 132 and two side plates 133, and the bottom frame 11, the mullion 12 and the inclined chassis 13 are fixedly connected to form a right-angled triangle frame body, and the bottom frame 11 Set horizontally, the mullion 12 is set vertically, the bottom frame 11 and the mullion 12 are right-angled sides of a right-angled triangle, the bottom plate 131 of the inclined chassis 13 is the hypotenuse of a right-angled triangle, and the power machine 2 and the gearbox 3 are installed on the bottom frame 11 , the gearbox 3 is driven by the power machine 2, and the cyclic grain harvesting device 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com