Patents

Literature

220results about How to "Little investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatization catalyst, its preparation method and application

ActiveCN1651141ALipophilicHigh aromatization activityMolecular sieve catalystsHydrocarbonsMolecular sieveAdhesive

An aromatizing catalyst for molifying poor gasoline to prepare high-octane gaseline component or arylhydrocarbon is prepared from the Zn, P and RE metal modified HZSM-5 molecular sieve, Y-type molecular sieve, carrier and adhesive proportionally.

Owner:CHINA PETROCHEMICAL CORP +1

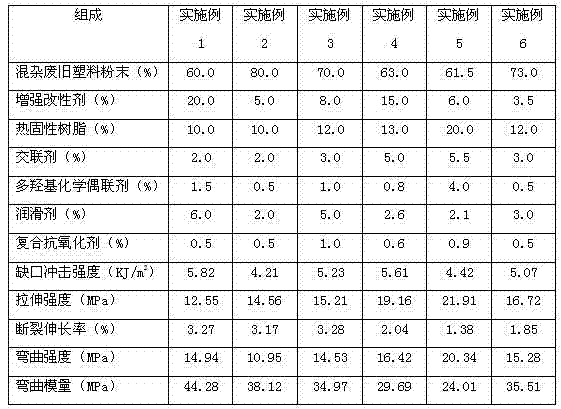

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

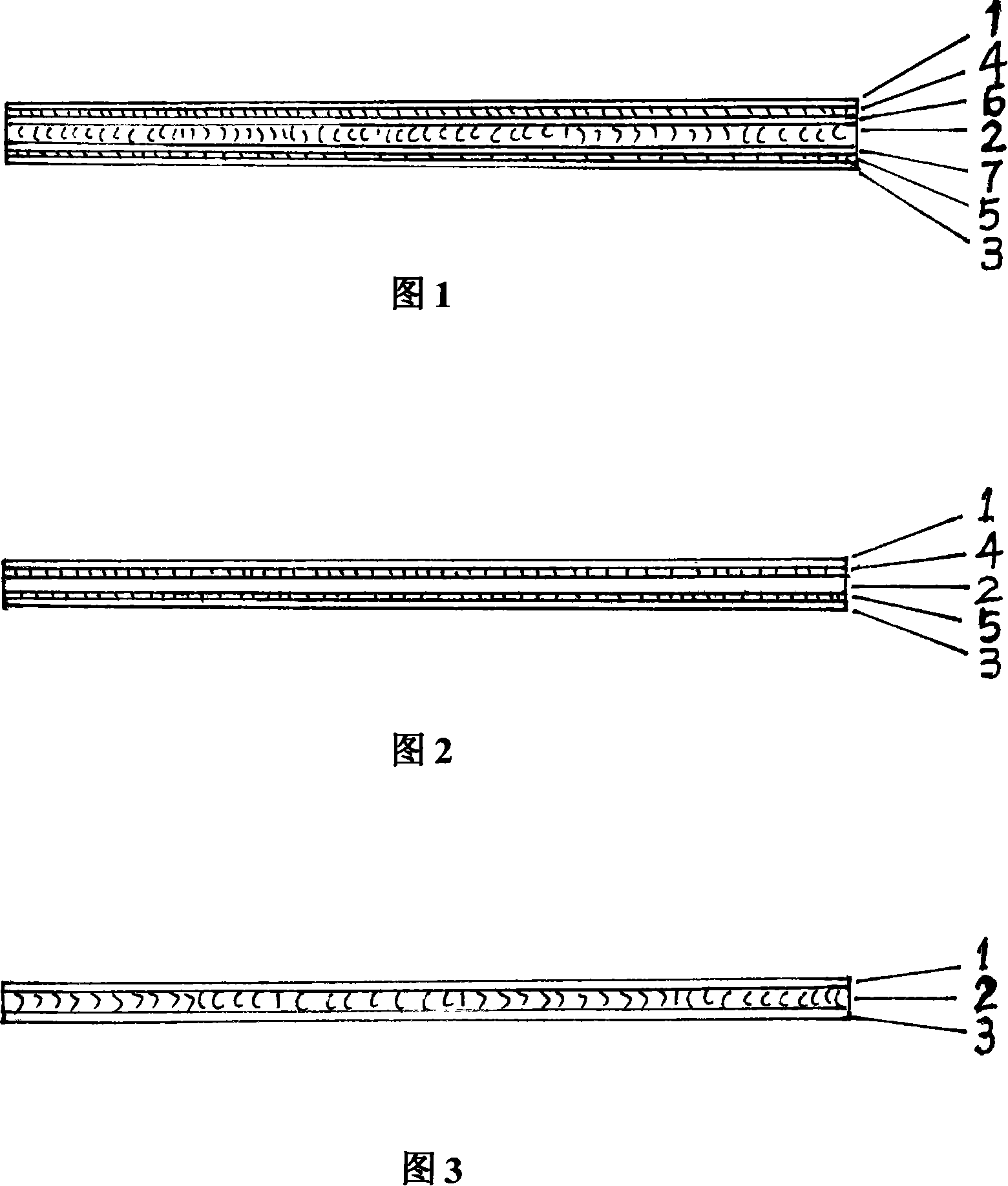

Wood multi-layer floor composed of cut-plate and veneer and method for making same

InactiveCN101139864ASave woodImprove product qualityWood working apparatusFlooringSolid woodSurface layer

The invention relates to a real-wood composite floor panel, which adopts a sheet-cut board with a sheet-cutting method as a core layer, a shave-cut single plate with a shave-cutting method as a surface layer, a rotary cut single plate with a rotary cutting method as a base layer, as well as all the other intermediate layers. The invention belongs to a real-wood composite floor panel, which is an artificial board in the industry of wood materials. The invention is characterized in that the core layer of the real-wood composite floor panel is a sheet-cut board that is produced with a sheet-cutting method; the surface layer of the real-wood composite floor panel is a shave-cut single-plate that is processed with a shave-cutting method; the base layer and all the other intermediate layers of the real-wood composite floor panel are rotary-cut single-plates produced with a rotary cutting method. The fabrication method is that the core layer of the real-wood composite floor panel is produced in a one-through mode covering adhesive coating, blank combination and glueing. The invention has advantages of perfect product quality, small deformation, needing no too much investment, saving wood materials, comprehensive utilization of wood materials and low cost. Except for pruducing real-wood composite floor panels, the invention can also be used to make such base material products as fine woodwork boards, real-wood doors and sheet-type furniture.

Owner:吴立忠

Low-frequency electromagnetic wave magnetic shielding composite paint and its preparation method

InactiveCN1412254ALow priceReduce energy consumptionElectrically-conductive paintsReflecting/signal paintsFiberElectromagnetic environment

The present invention relates to a low-frequency electromagnetic wave magnetic shield composite material and its preparation method. It is characterized by that it adopts magnetic powder, magnetic fibre and amorphous magnetic powder as magnetic conductive filling material, uses macromolecualr resin as film-forming matter, and makes them and coupling agent and solvent undergo the processes of blending, mixing, grinding and filtering at normal temp. so as to obtain the invented composite material whose magnetic shield effect can be up to 14-15 dB, so that it possesses extensive application.

Owner:SICHUAN UNIV

Method for cultivating black fungus with high yield

A method for culturing Auricularia auricula with high output includes such steps as preparing mother seed, preparing stock, stock inoculating, preparing the seed to be cultured, laying the culturing bags on ground or beds, loading said seeds to be cultured in said culturing bags, and culturing while managing. A process for laying the culturing bags is also disclosed.

Owner:陈淑华

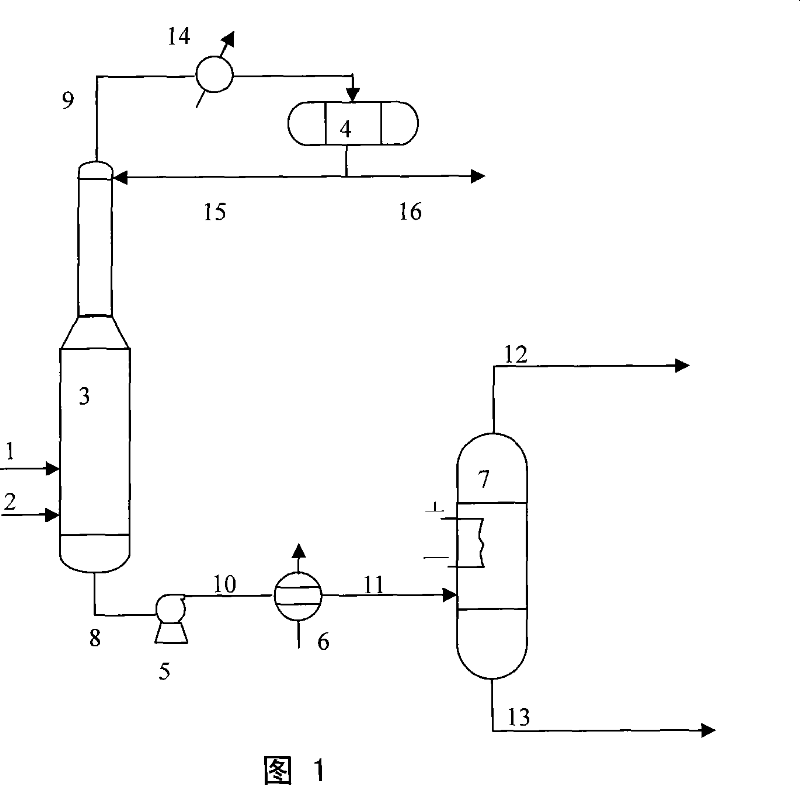

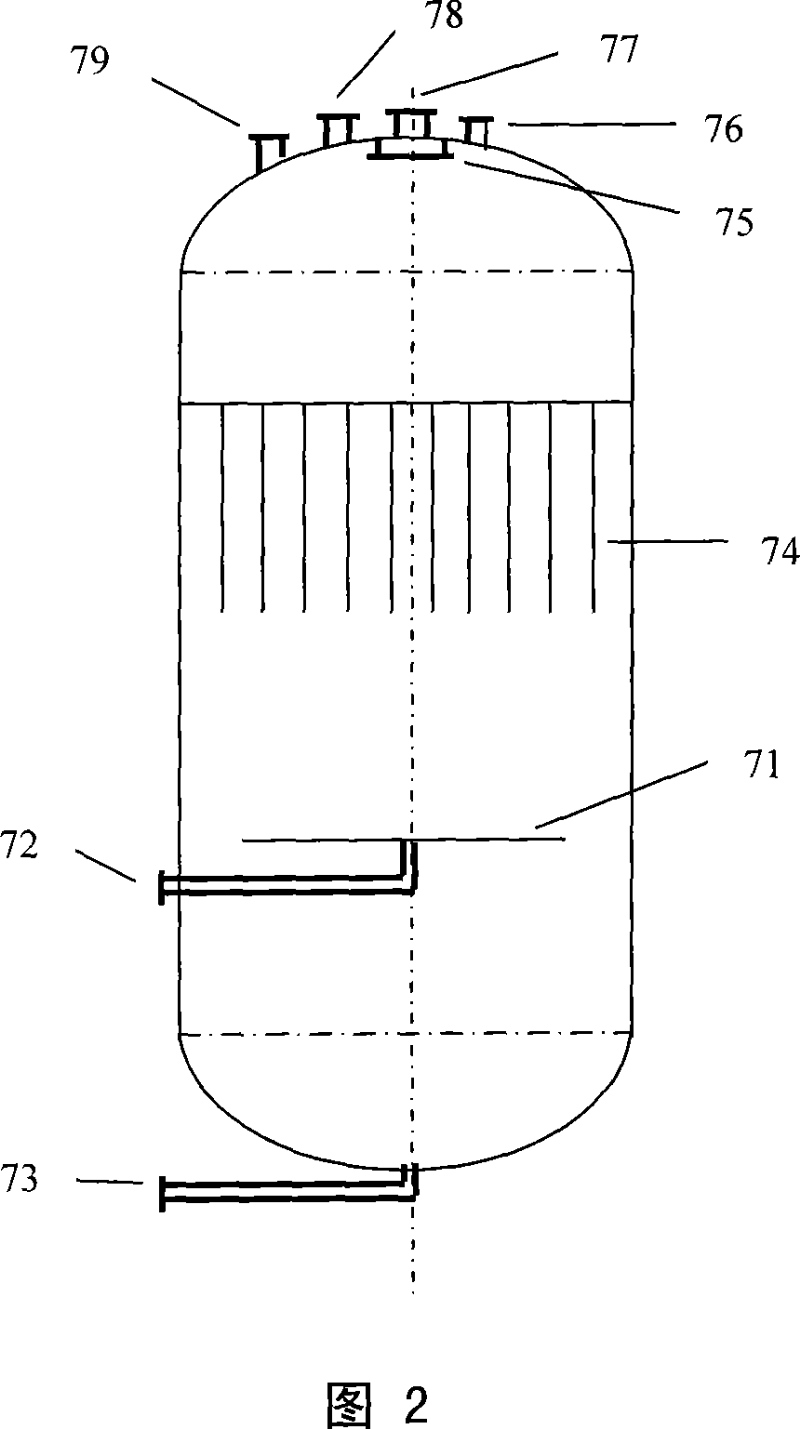

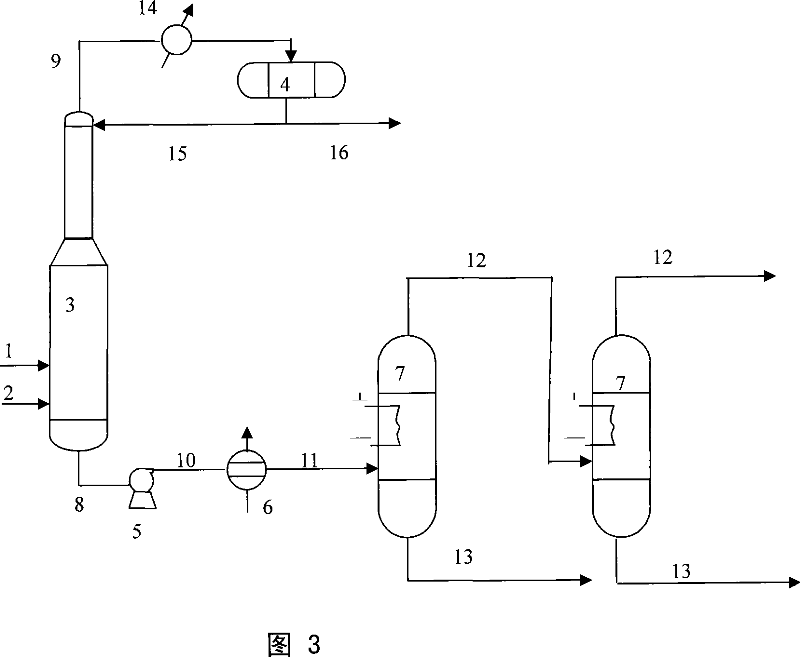

Diesel oil hydrogenation refining fractionation method and device

ActiveCN101037608ASolve the problem of unqualified water contentLess investmentDewatering/demulsification with electric/magnetic meansGasoline stabilisationSteam condensationTower

The invention provides a hydrogenation refining fractionation method for diesel oil, which includes a stripping fractional distillation process for reaction generation oil steam and a dewatering process for refined diesel oil. Concrete technical project of the method is: hydrogenation refining reaction generation oil from low pressure separator enters feed inlet of fractionating tower with certain temperature; the fractionating tower employs steam stripping fractional distillation, superheating stripping steam is charged in tower bottom, tower top oil gas enters reflux pot on tower top after cooling, refined diesel oil at tower bottom enters one or more than one series connected vertical ionization dehydration pot after supercharging by pressure pump, heat exchanging and cooling; micro steam condensation water in the refined diesel oil aggregates to larger drip by high-voltage electric field in the ionization dehydration pot, sedimentates at pot bottom and is removed by dehydration pipeline; refined diesel oil without water comes from top of the ionization dehydration pot is the eligible final product. The invention also provides a device for realizing the method.

Owner:CHINA PETROLEUM & CHEM CORP

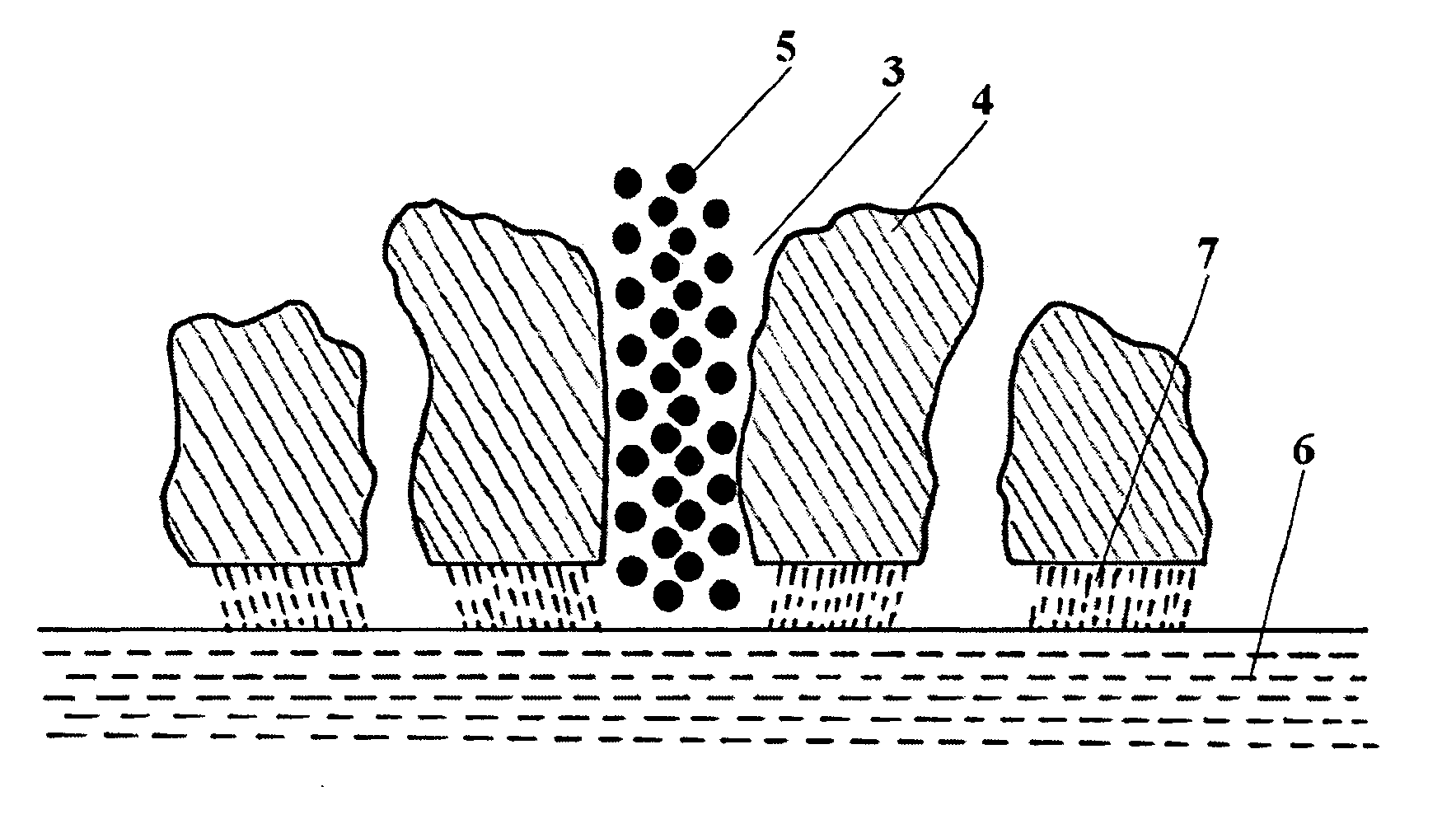

Functional silk non-woven xysma and producing process thereof

InactiveCN1552972AImprove insulation effectIncrease elasticityDe-gumming silkNon-woven fabricsCross-linkEmulsion

Functional silk non-woven wadding is prepared from natural silk, plant resin emulsion and inorganic nano bactericidal. The said emulsion is of self cross-linked anion resin, co-polymerized from acrylic diester, arylonitrile itaconic acid and N hydroxy acrylamide as cross-linking agent. The ratio of emulsion : silk is 100: (1.5-5.0) by dry weight. Silver ion nano bactericidal is also added into the wadding with the ratio of the bactericidal : silk is 100: (0.5-15.0). The product is soft and light, moisture-absorbing and gas permeable, high thermal insulation, elastic, water washing resistance, safety and usable widely.

Owner:丁永华

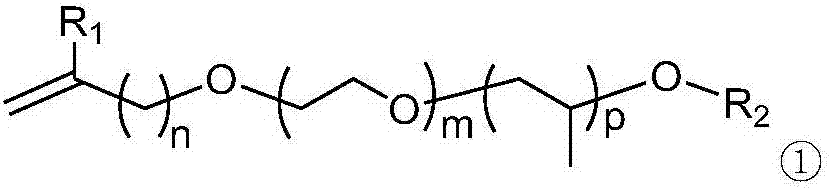

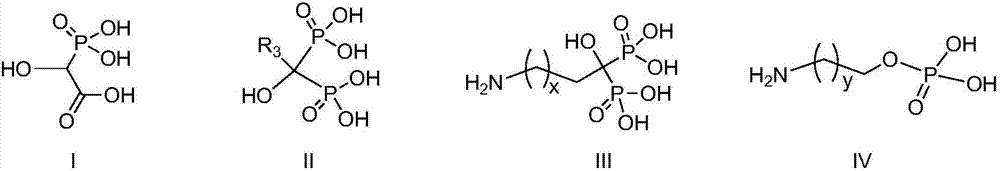

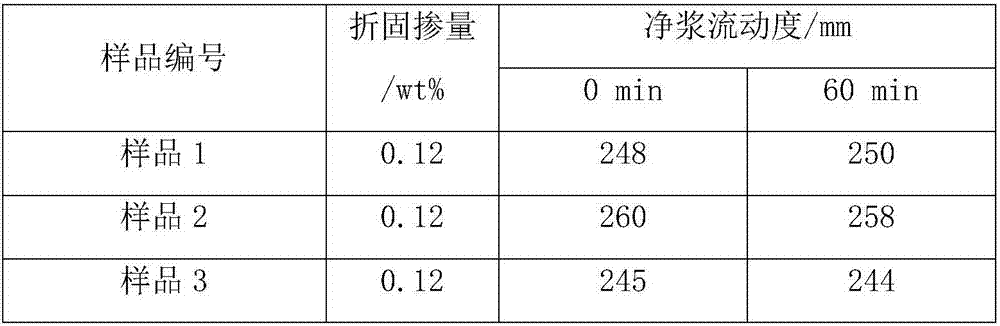

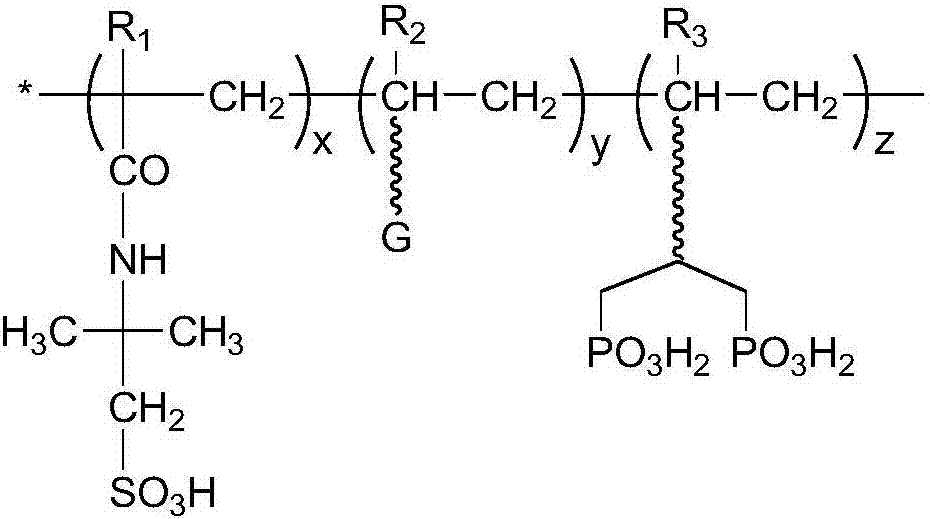

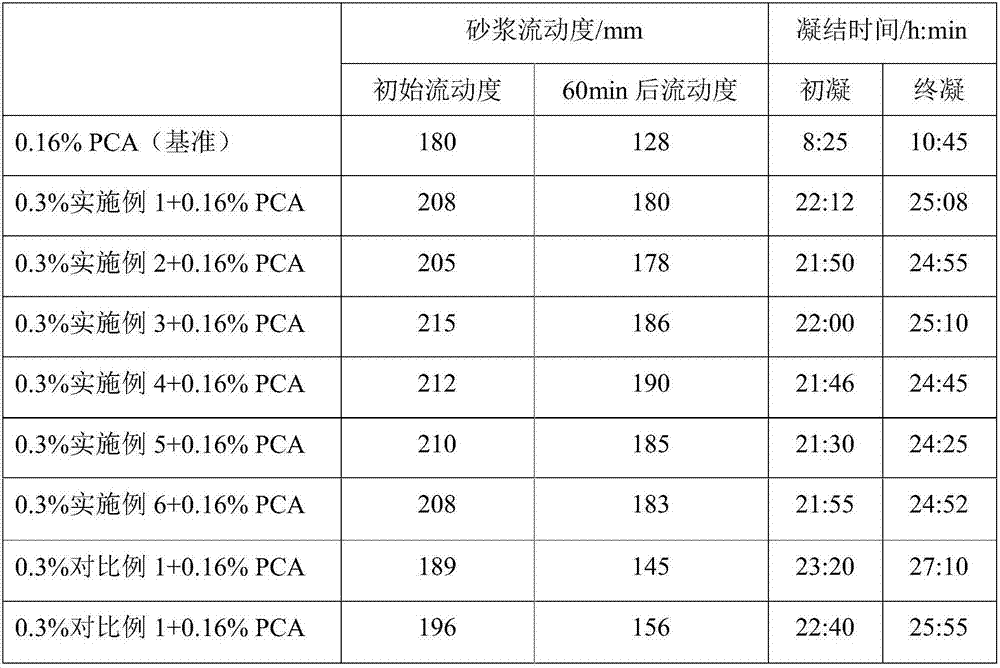

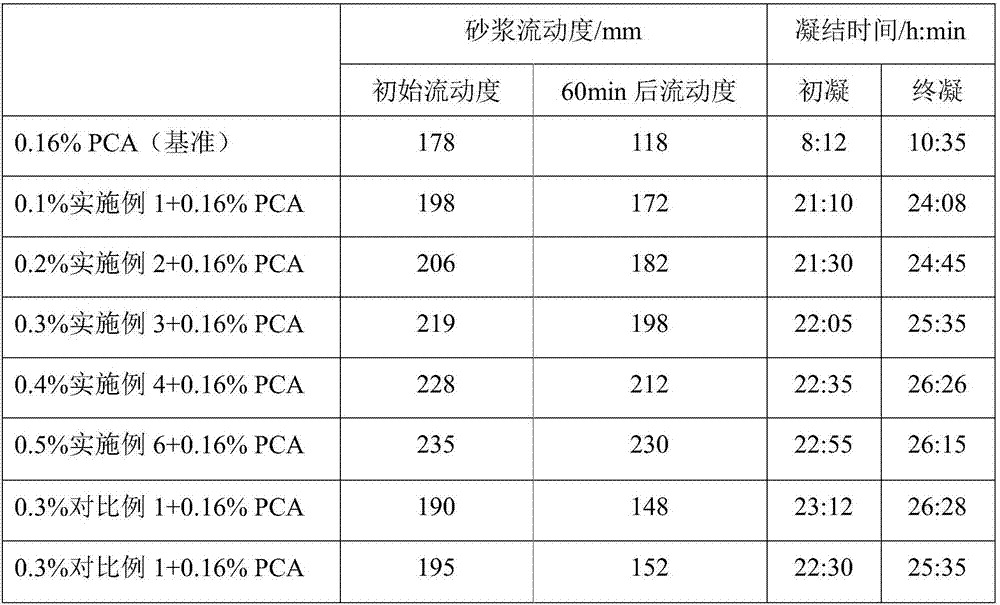

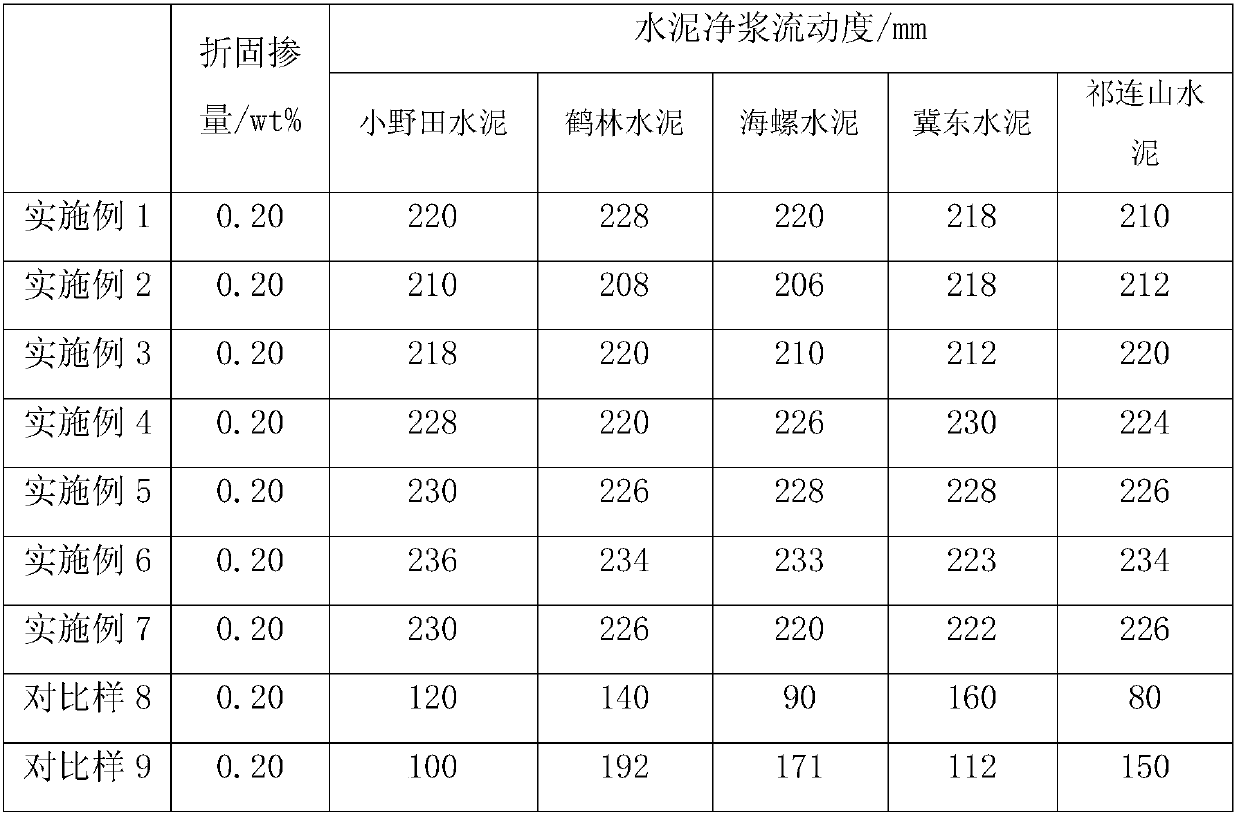

Phosphonate-base polymer with high adaptability and slump retaining properties, and preparation method and application thereof

The invention discloses a phosphonate-base polymer with high adaptability and slump retaining properties, and a preparation method and application thereof. The phosphonate-base polymer has the following structural characteristics: the side chain is an ether type chain segment; and the polymer has two stages of adsorption groups, the primary adsorption group is a phosphonate or phosphite functional group, the secondary adsorption group is carboxyl, and the two functional groups are connected by an ester bond or amido bond. The weight average molecular weight of the phosphonate-base polymer with high adaptability and slump retaining properties is 10000-50000. The phosphonate-base polymer has a novel molecular structure, and thus, has the advantages of low doping amount, high water reducing rate, excellent slump retaining properties, and high sulfate and clay interference resistance. The preparation technique can implement industrialization, and thus, has broad market application space.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

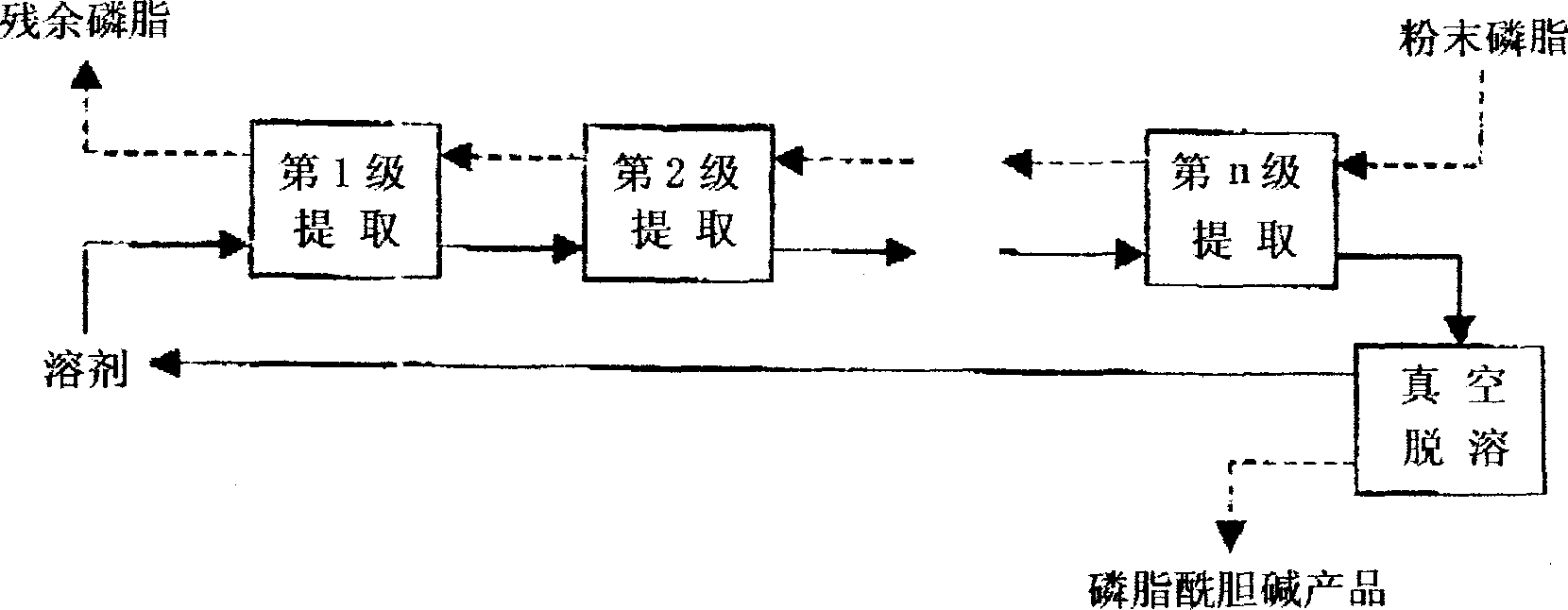

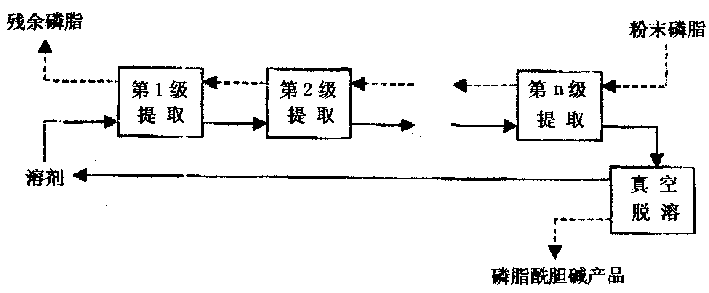

Process for extracting phosphatidecholine from powdered soybean phosphatide

A process for extracting phosphatidylcholine from the powdered soybean phosphatide incldues multi-stage counter-current extracting with the mixed solvent of acetonitrile and low-carbon alcohol, and vacuum removing of solvent. Its advantages are high purity (more than 70%), and high output rate (more than 70%).

Owner:TSINGHUA UNIV

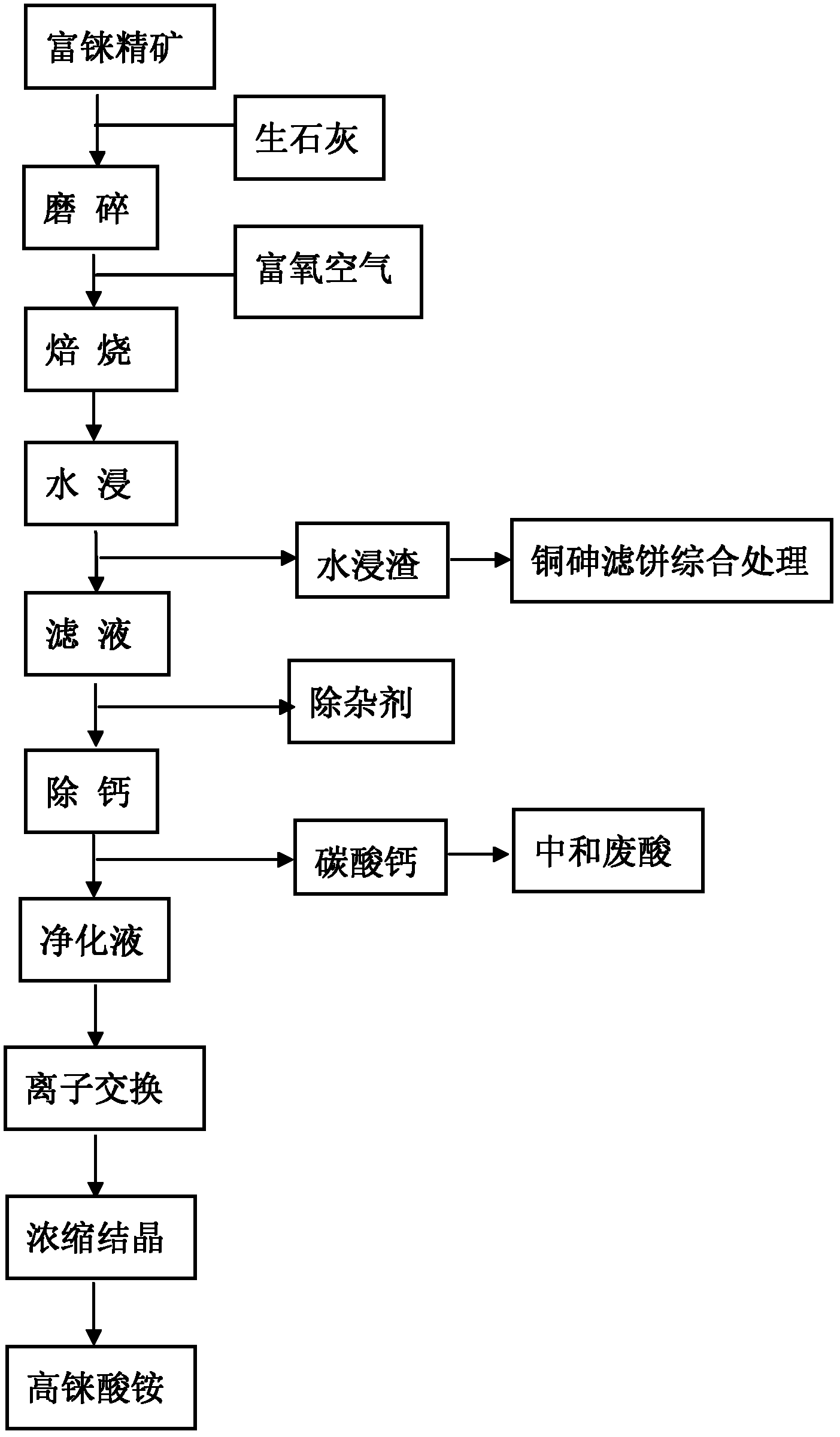

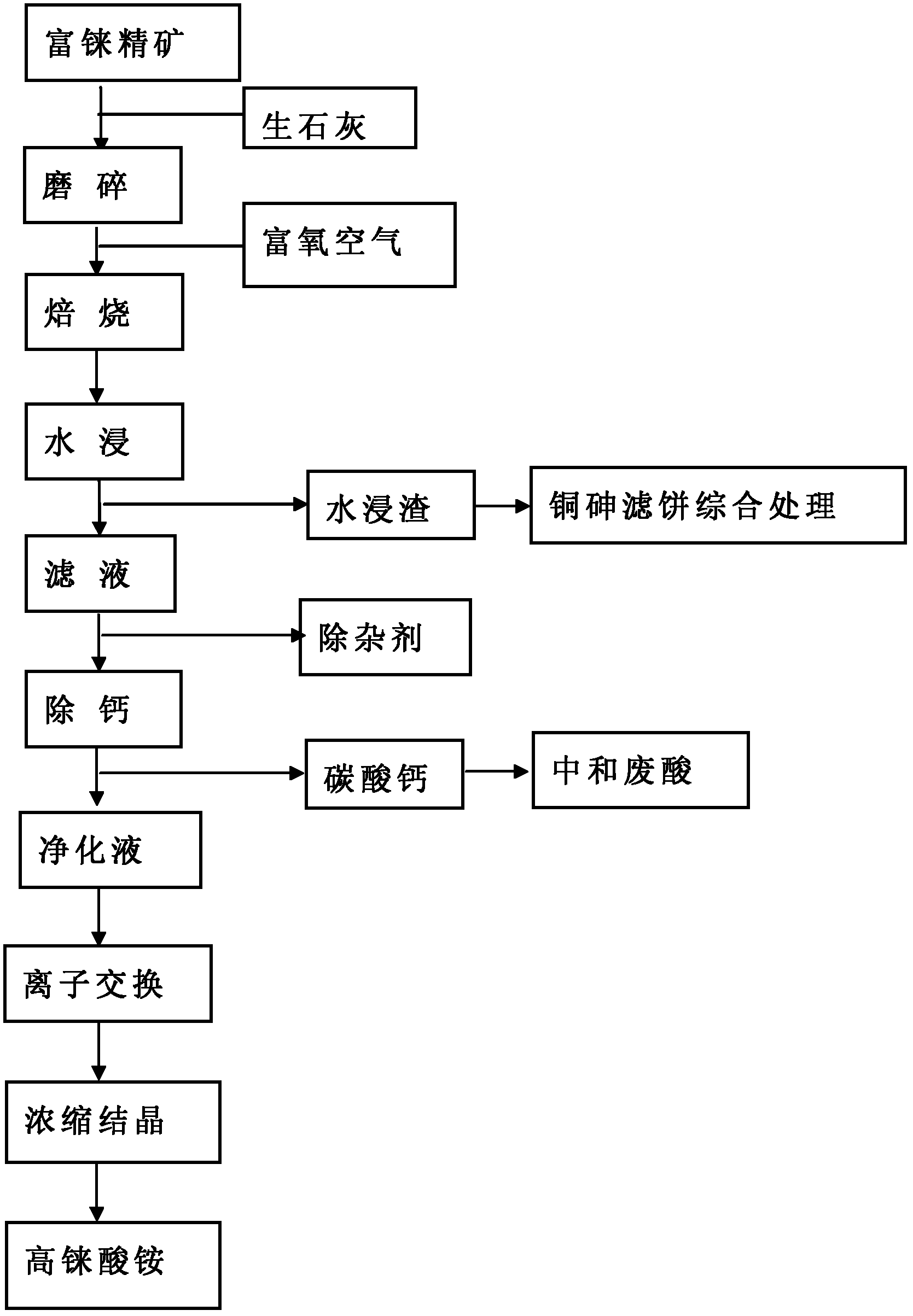

Method for extracting rhenium from rhenium-rich concentrates

ActiveCN102628111AThe effect is thoroughHigh recovery rate of rheniumProcess efficiency improvementIonIon exchange

The invention provides a method for extracting rhenium from rhenium-rich concentrates. The method comprises the following steps of: mixing the rhenium-rich concentrates with quick lime, grinding a mixture, feeding oxygen-enriched air into the mixture, and roasting the mixture at a temperature of 400-900 DEG C; sizing and immersing the roasted mixture by using water, and filtering after the immersion is finished; adding an impurity removing agent into the filtered liquid so as to remove calcium and trace heavy metal ions; filtering after removing impurities; and carrying out ion exchange process on the filtered liquid, which is subjected to impurity removal and filtering, through anion exchange resin, obtaining ammonium rhenate solution after desorption, and obtaining ammonium perrhenate through reconcentration and crystallization. According to the method provided by the invention, quick lime oxygen-enriched roasting and water immersion are used, so that the operations of decoppering, arsenic removal and desulfuration are carried out, therefore rhenium, arsenic and sulfur are oxidized sufficiently under the oxygen enrichment condition; the rhenium, arsenic and sulfur are combined with calcium oxide, so that insoluble substances are generated; the effects of removing copper, arsenic and sulfur are more thorough in the water immersion condition, and the disadvantage that the calcium content is high in the quick lime roasting and water immersion technology is solved through using the impurity removing agent to remove impurities; and the recovery rate of rhenium is high, so that the method provided by the invention is favorable to industrialized application.

Owner:YANGGU XIANGGUANG COPPER

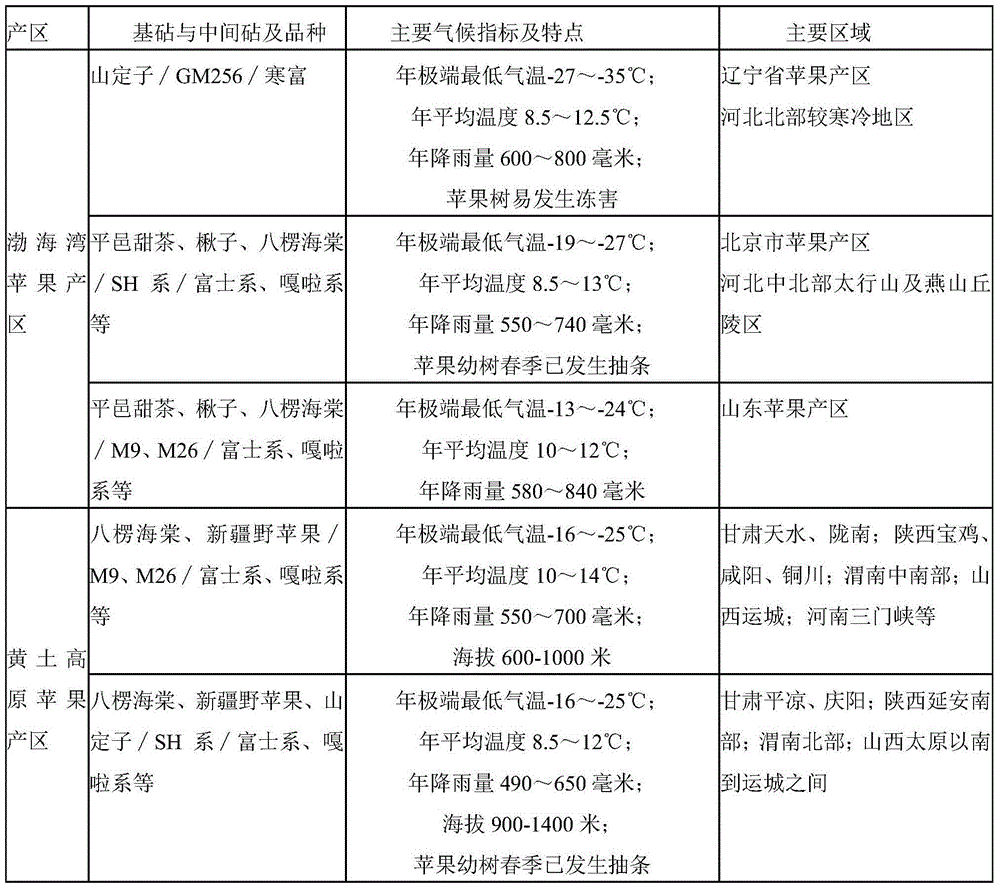

Intensive high-efficiency dwarf stock cultivation method for apple trees

InactiveCN104429641AIncrease productionImprove efficiencyGraftingCultivating equipmentsRootstockOrchard

The invention discloses an intensive high-efficiency dwarf stock cultivation method for apple trees, and provides a garden building method including nursery stock selection, wide-row close planting, middle-stock burying and planting, trellis cultivation, shaping and pruning and the like. For different climatic conditions of different areas, different dwarf stocks are provided, and it is important to select suitable dwarf stocks in each area. The lengths of middle stocks of selected nursery stocks are kept uniform during garden building, the middle stocks are buried with soil during planting until the top ends of the middle stocks are exposed out of the ground by 1-10cm, and the burying depths of the middle stocks are uniform. The burying depths of the dwarf middle stocks relate closely to the sizes of crowns, and particularly, are of a great significance in building of gardens with high uniformity in crown size. The intensive high-efficiency dwarf stock cultivation method is suitable for the situation of China, and the built apple gardens have the advantages of low investment, early fruiting, high yield, high benefit and convenience in management.

Owner:NORTHWEST A & F UNIV

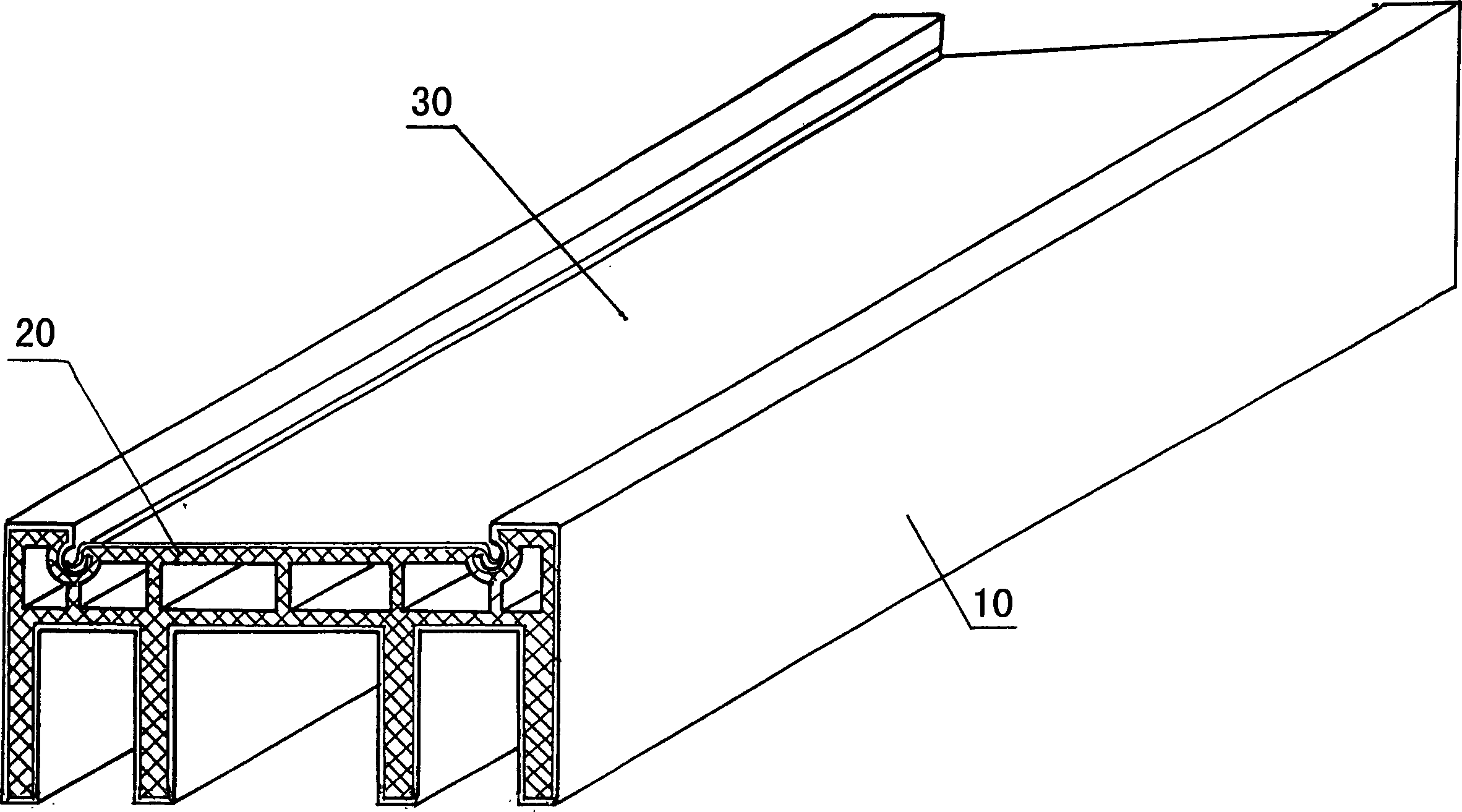

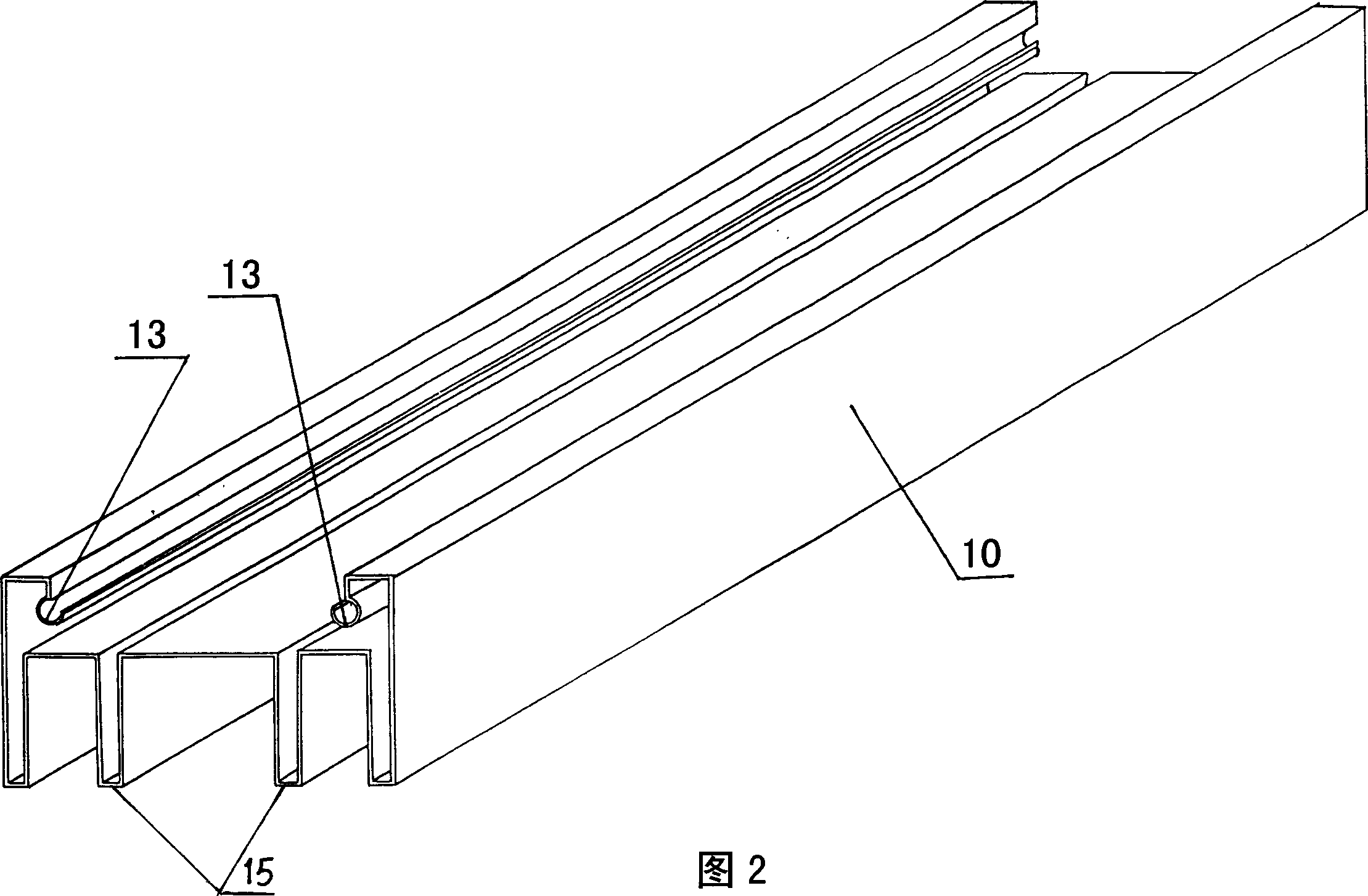

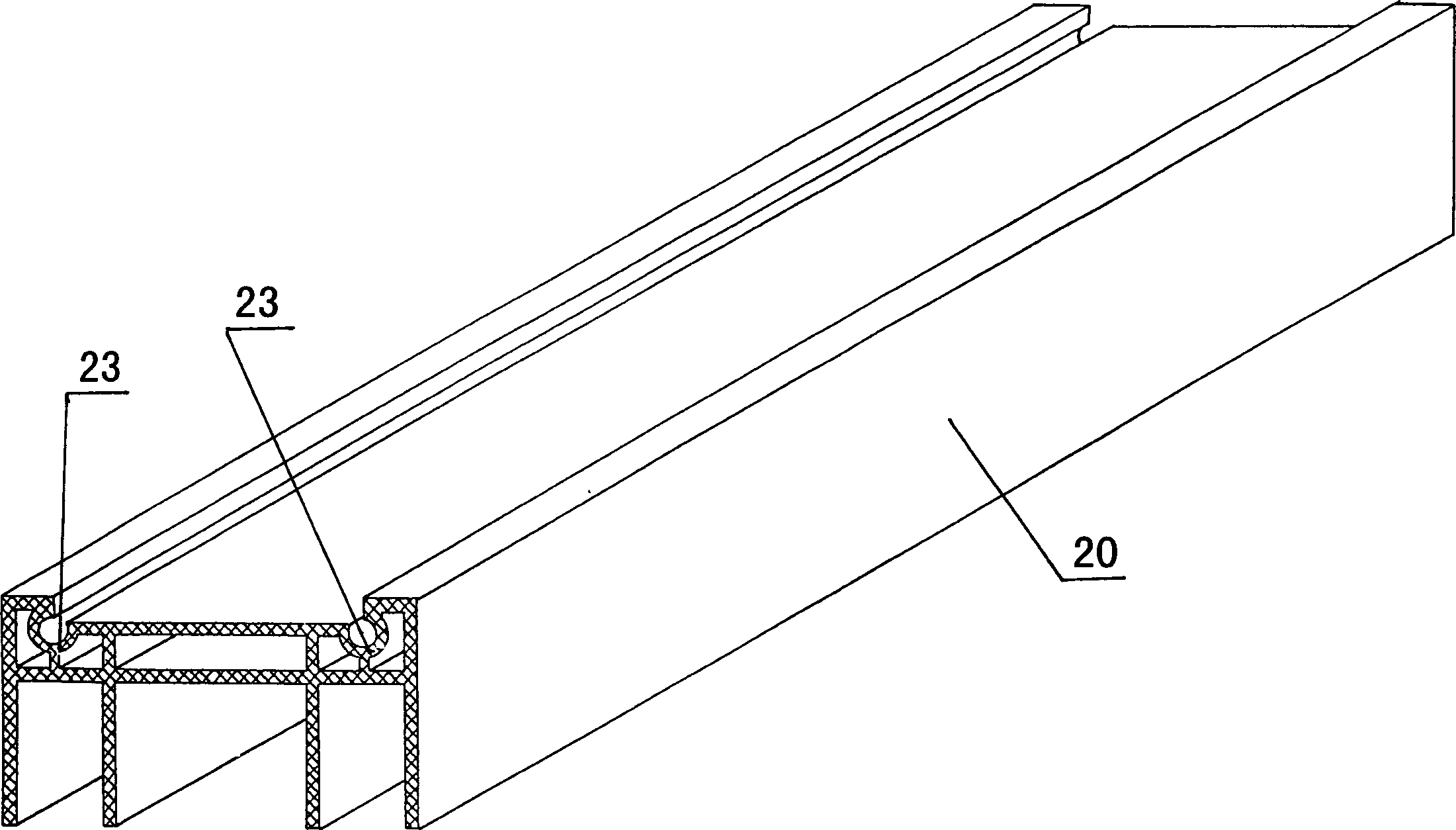

Stainless steel door and window section material with plastic lining frame and its manufacturing method

The present invention relates to a stainless steel door and window profile material with inside-linked with plastics and its manufacturing method. Its main body is stainless steel profile cavity inside-lined with plastic skeleton, and the gap between them is filled with adhesive. The stainless steel profile cavity and seal plate are made up from cold-bent and rolled stainless steel belt, the inside-linked plastic skeleton is made up by extrusion of hard and high-strength thermo-plastic flame-retardant plastics. These construction elements are then combined and lock jointed into shape, solidified, sized to obtain product. It possesses the advantages of beautiful appearance, and corrosion resistant of stainless steel, and light-weight, heat-and sound-insulating and low cost of plastics.

Owner:占金弟

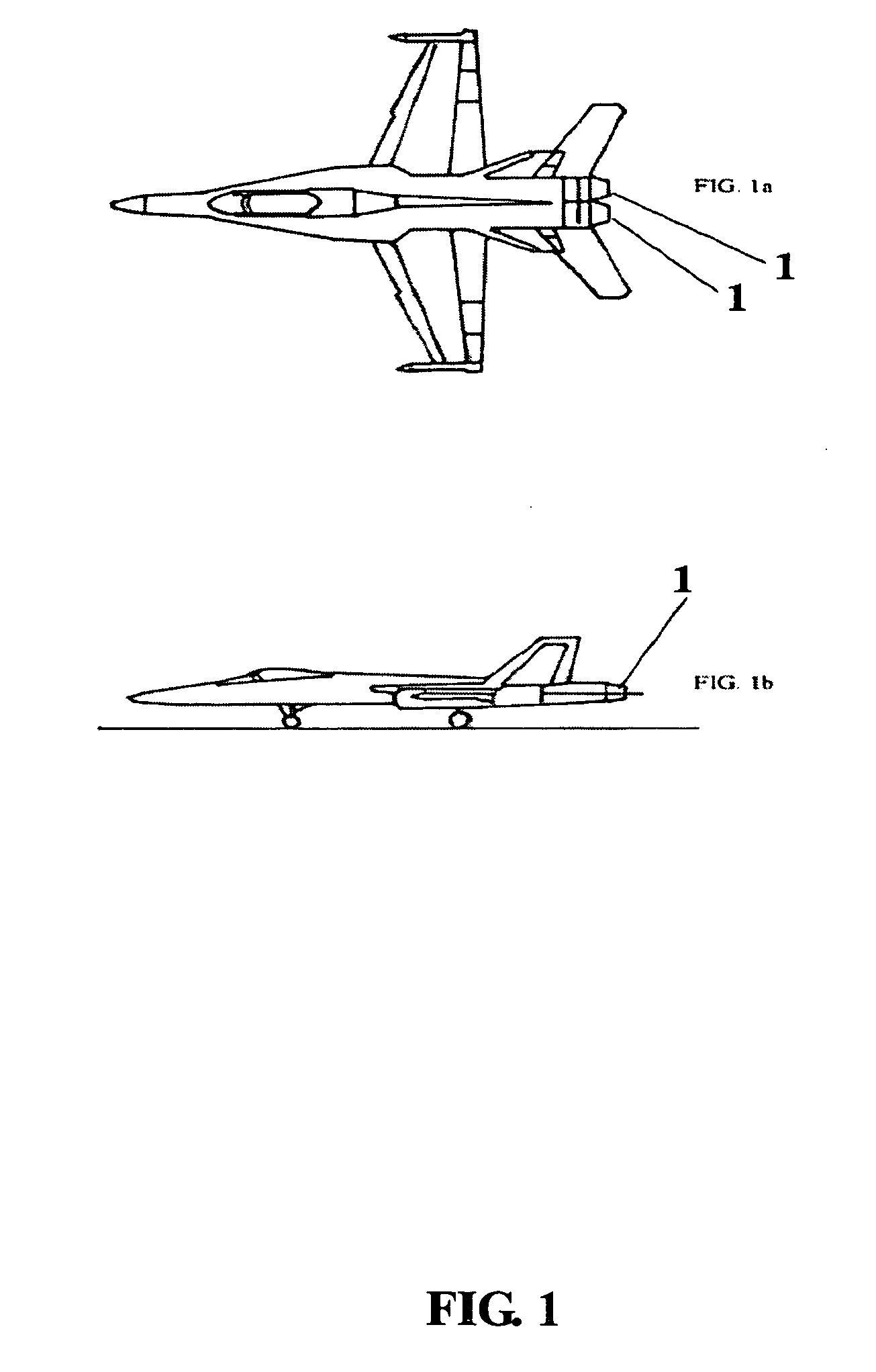

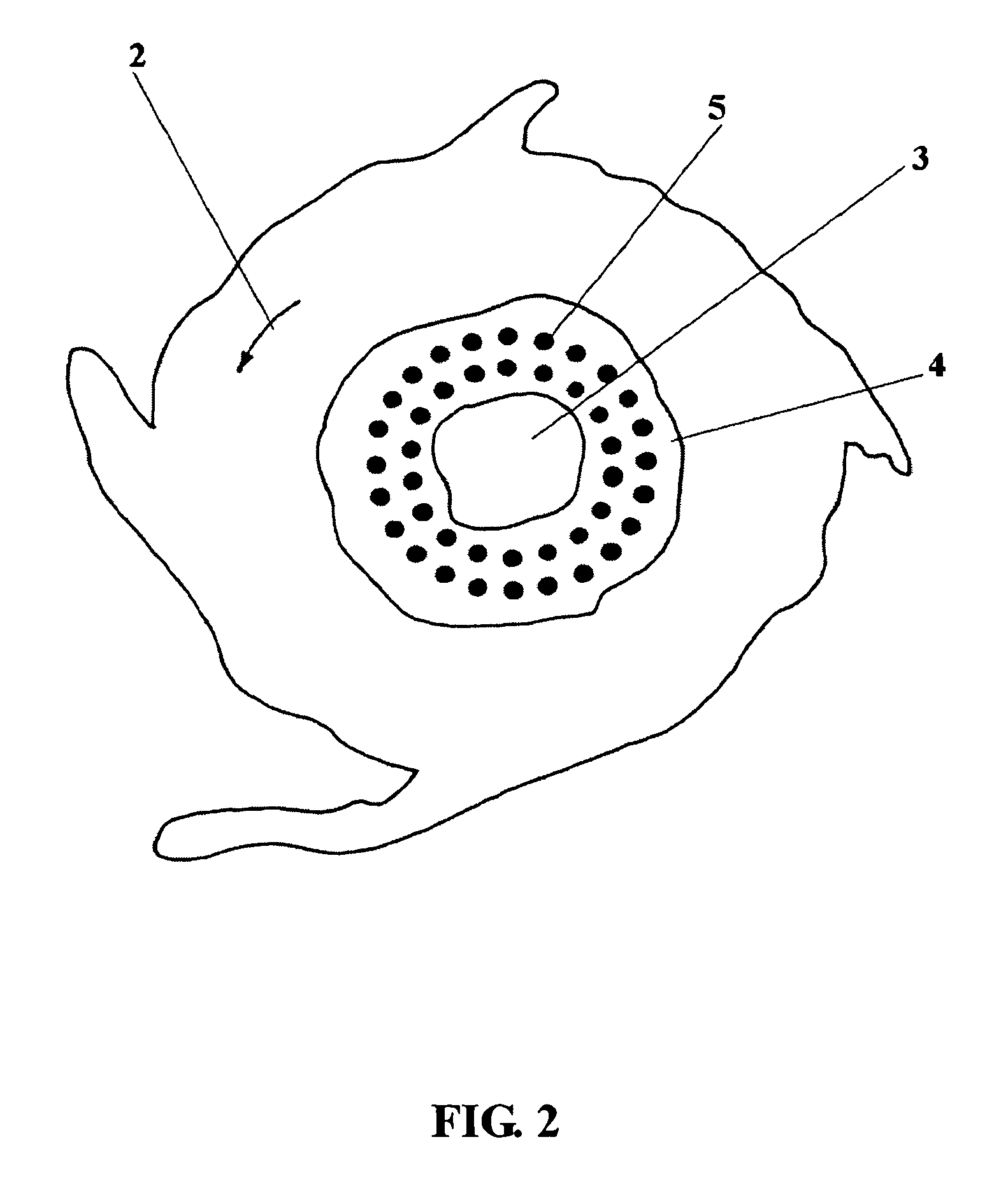

Method for controlling hurricanes

InactiveUS20100072297A1Little investmentFog dispersionWeather influencing devicesAirplaneEngineering

A method for controlling hurricanes by raising temperature in the eye and / or in the outflow. Air temperature within the eye and in the outflow of a hurricane is raised by flying scores of jet planes with afterburners in the structure. Small changes in temperature on a large scale bring in large changes in other variables on the smaller scale to change the direction and intensity of the hurricane.

Owner:SAVLA MANILAL J +1

Method for processing non-autoclaved foam concrete building blocks in producing phosphogypsum through microwave high temperature

InactiveCN102218766AProcessing speedUniform qualitySolid waste managementCeramic shaping apparatusFoam concreteBrick

The invention discloses a method for processing non-autoclaved foam concrete building blocks in producing phosphogypsum through microwave high temperature, which comprises the steps as follows: solid waste phosphogypsum in the phosphate fertilizer industry is arranged in a microwave tunnel furnace and is heated to 200-770 DEG C for 3-5min to lead a plurality of impurities in the phosphogypsum like phosphoric acid, calcium fluoride, iron aluminum oxide, acid-insoluble matters, organic matters and the like to volatilize or convert into inert materials during the heating process, thereby obtaining beta-type semihydrated gypsum or beta II-type anhydrous gypsum; then the beta-type semihydrated gypsum or beta II-type anhydrous gypsum, fly ashes, cements, quicklime and modified additive are mixed and levigated, then are stirred with water and gypsum waterproofing agent, and finally are uniformly mixed with foams of foaming agent and poured into a building brick die. The method disclosed by the invention has the following advantages: the method has simple technique, low equipment investment and lower manufacture cost and avoids secondary pollution; the microwave high temperature method has quick processing speed and uniform quality; the utilization amount of phosphogypsum waste residues is large and the utilization rate is as high as 60-70 percent; moreover, the building blocks belong to obturator structures and has good insulating effect, high strength and good waterproof performance.

Owner:许祯玮 +3

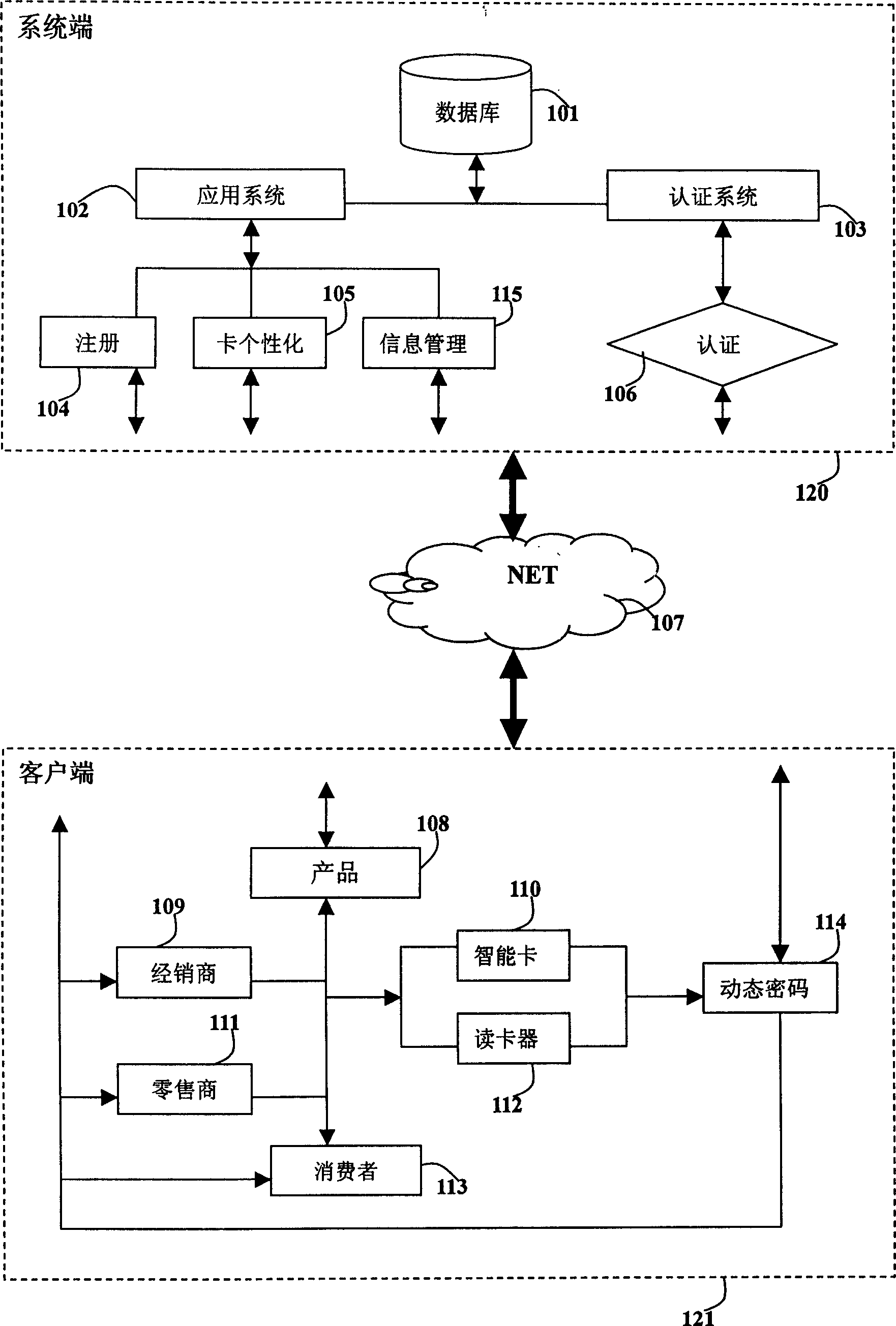

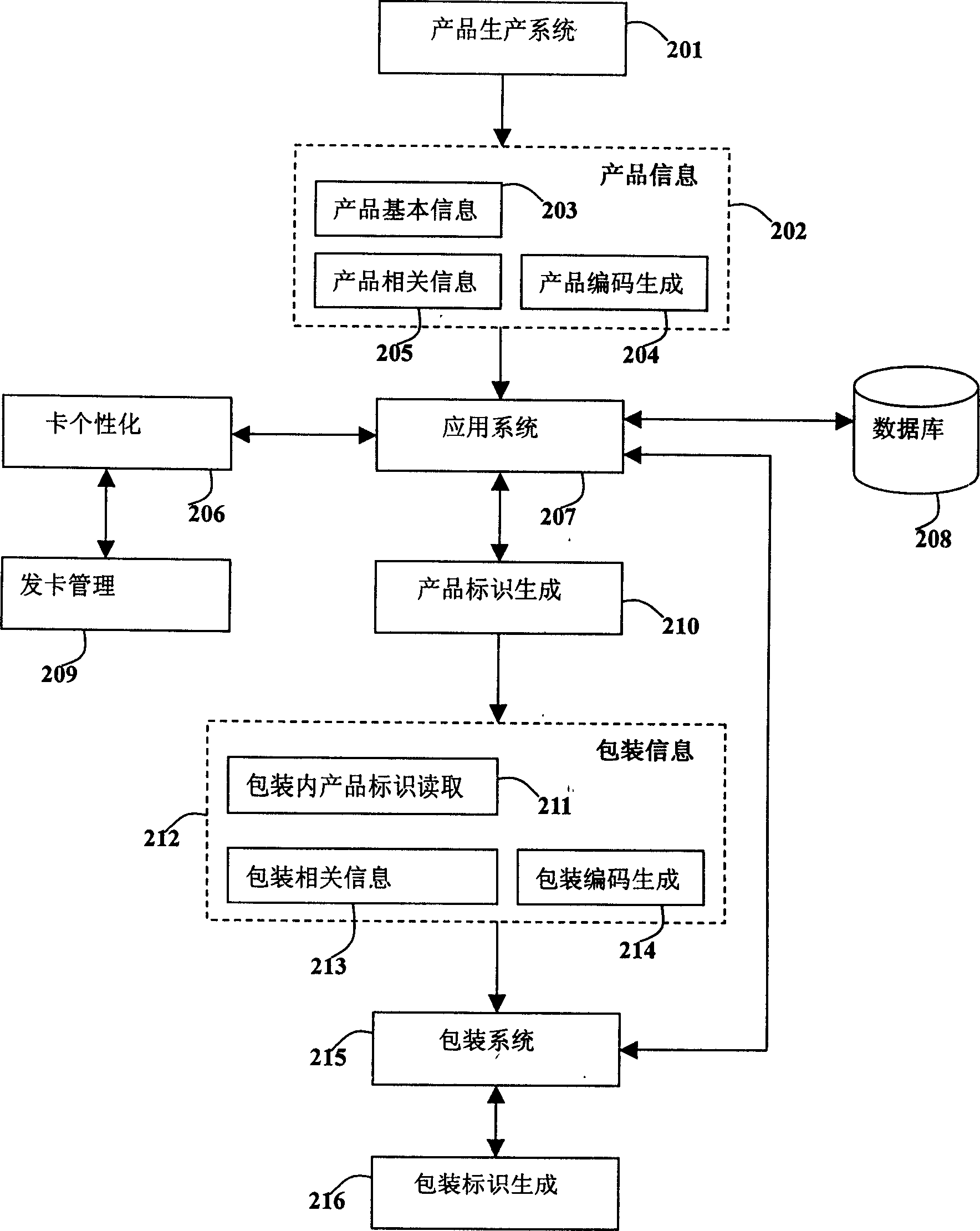

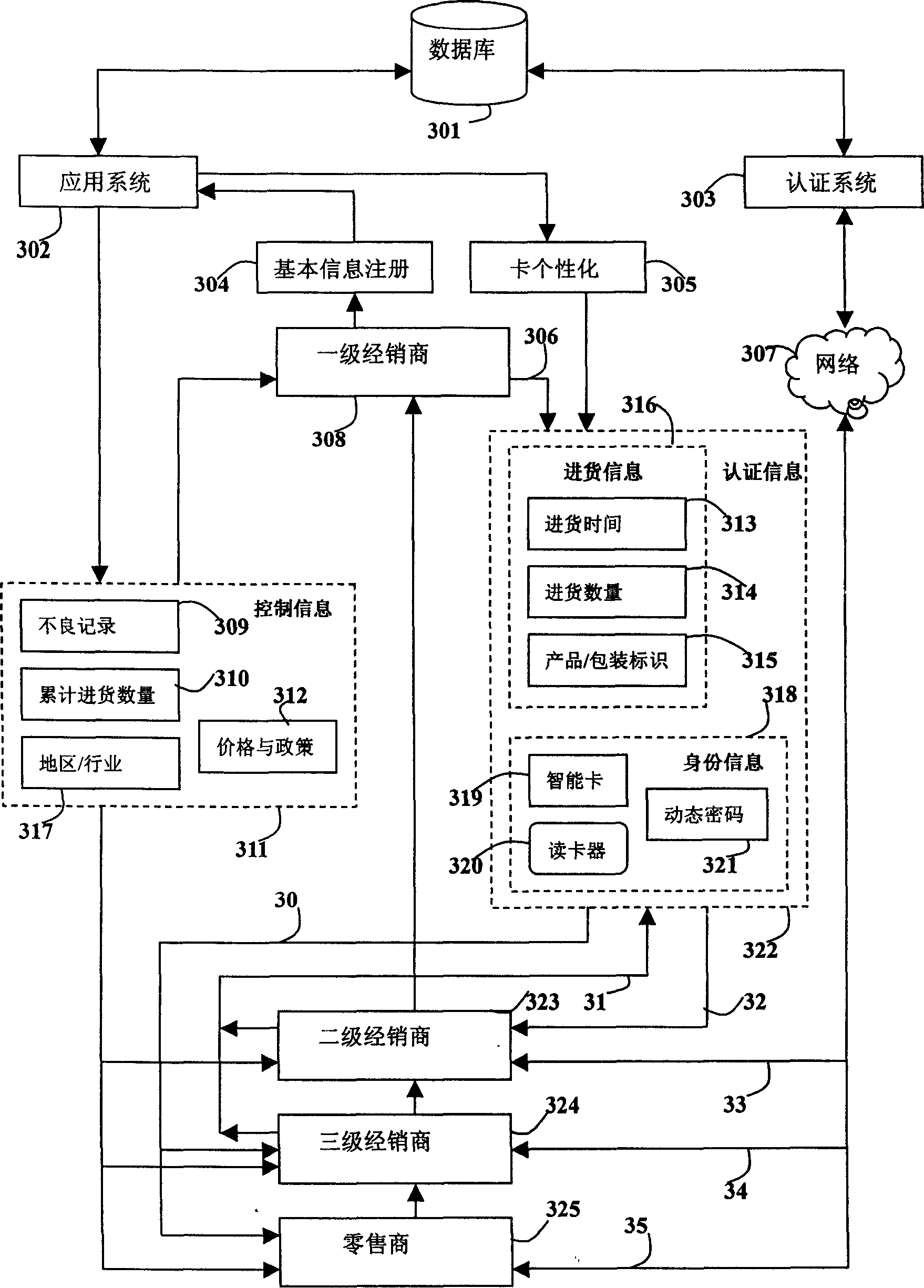

Anti-fake technology based on dynamic cipher

InactiveCN1617495ALow costSimple and fast operationUser identity/authority verificationSpecial data processing applicationsPasswordFacsimile

This invention discloses an anti-false technology based on dynamic password. The anti-false system is composed of customer ends connected by communication networks, an enterprise applied system and a certification system, the enterprise determines personal identification and allocates devices for generating certified identifications for products and their dealers via applied system, the dealers or consumers present the personal identification and certification identification generated by the above device to the certifying system for certification by communication measures including networks, phones, Fax, multimedia terminals or hand call short messages to identify the true or false of the products or dealers.

Owner:王小矿

Method for fabricating needling non-woven fabrics fabrics made from plant fiber having natural fragrance for slow releasing fragrance

InactiveCN1600929ABig investmentProduction is not complicatedLayered productsGaseous substancesPunchingPlant fibre

A nonwoven cloth releasing frangrance slowly is prepared by selecting one or above two natural plants having frangrant smells, opening plants to obtain plant fibres, using 50-75% of chemical fibre and 25-50% of obtained plant fibres as raw material, mixing and needle punching then for making nonwoven cloth with slowly-released frangrance.

Owner:马赛麟

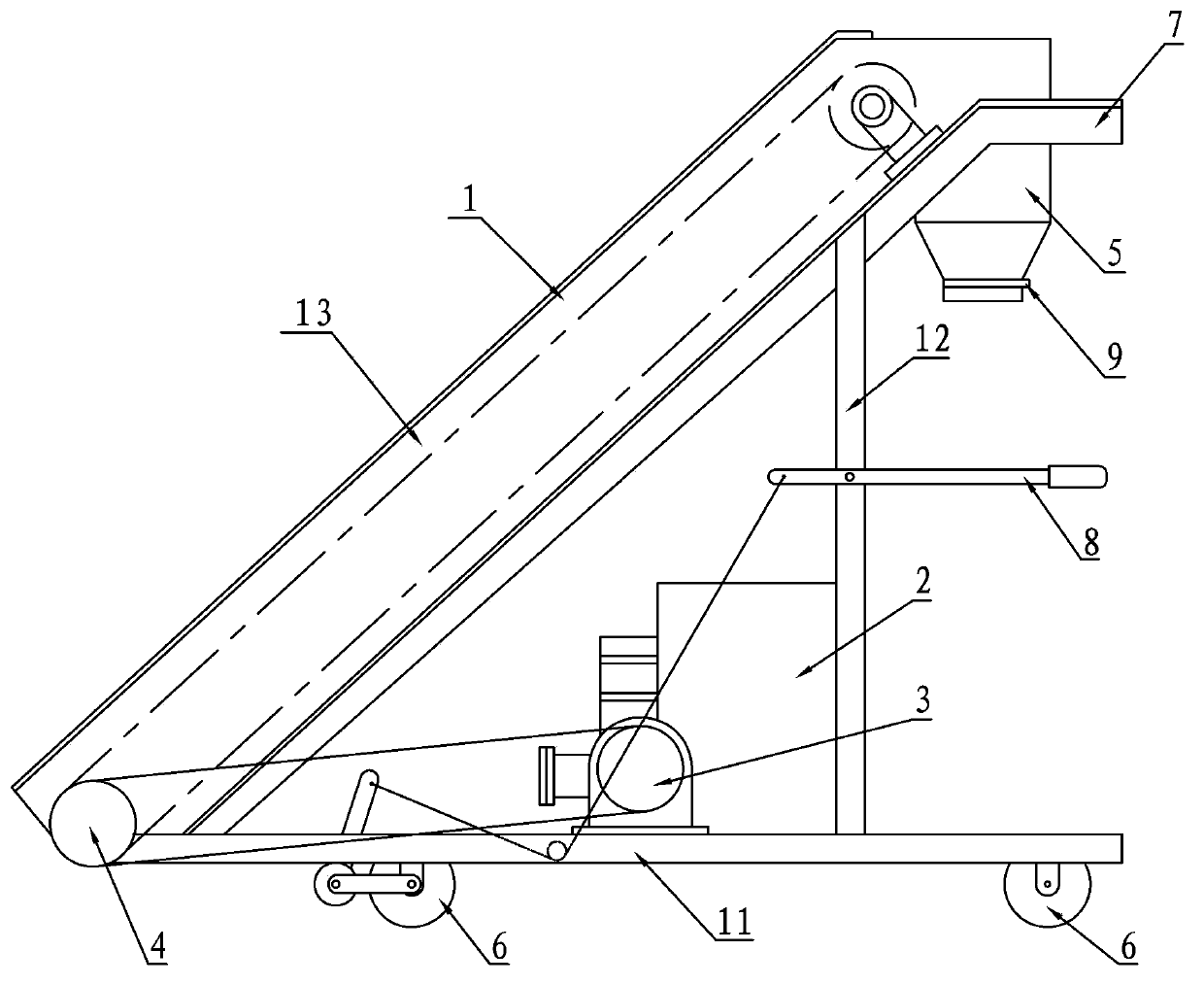

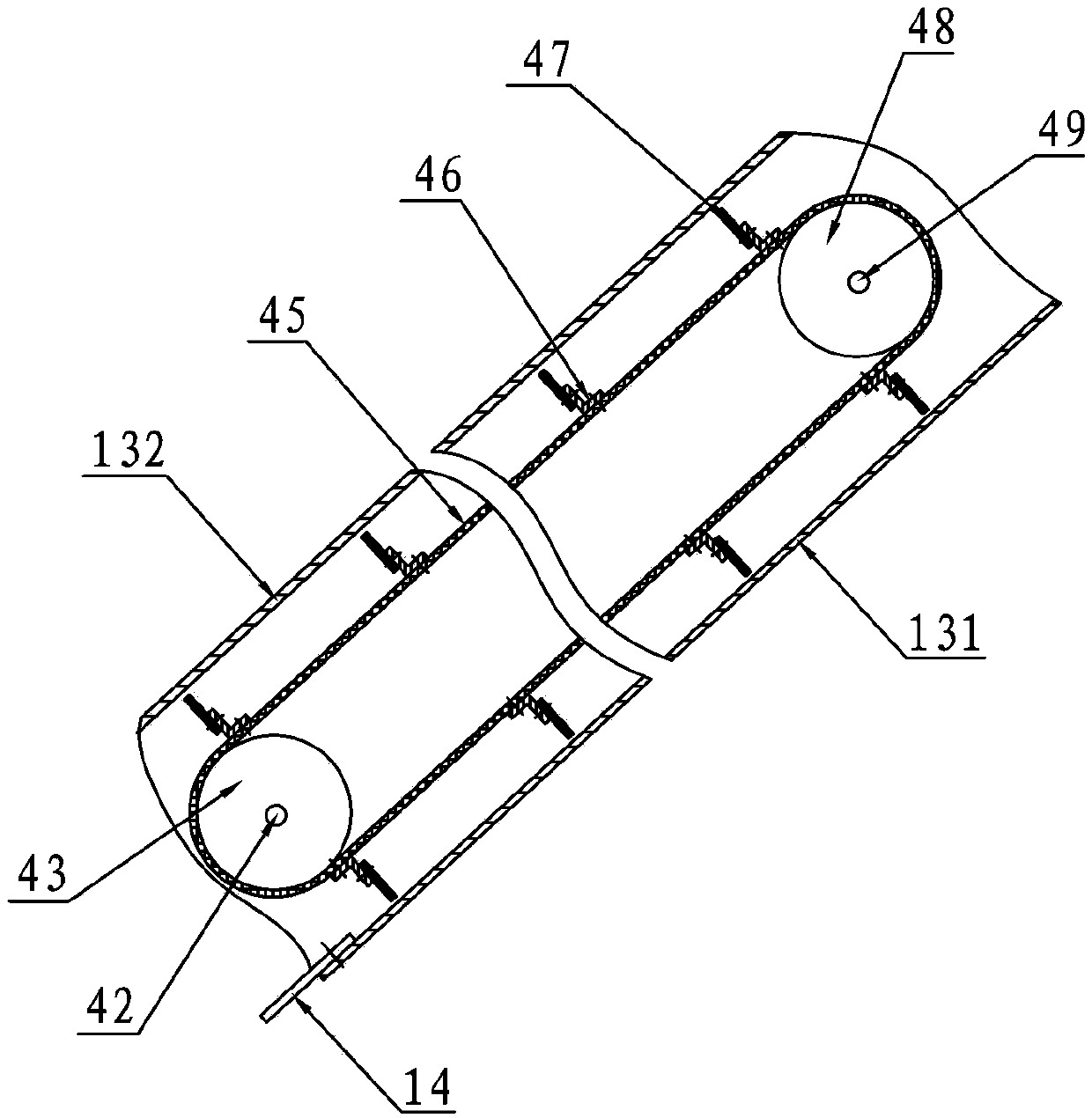

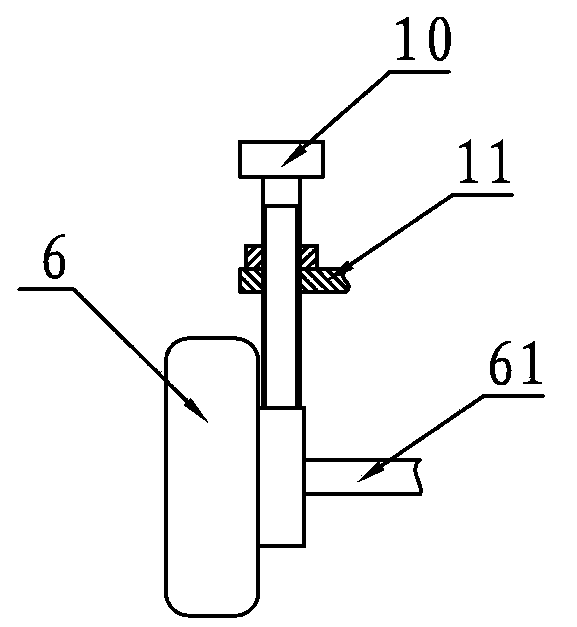

Hand-push type rapid grain collector for sunning ground

The invention discloses a hand-push type rapid grain collector for a sunning ground. The grain collector comprises a rack, a power machine, a gearbox, a cyclic grain collection device, a discharging box, movable rollers and a hand pushrod, wherein the rack is a right triangle-shaped frame body formed by fixedly connecting a bottom frame, a vertical frame and an inclined case; the power machine and the gearbox are arranged on the bottom frame; a power input wheel of the cyclic grain collection device is arranged at one end of a driving shaft; the driving shaft and a driven shaft are arranged at the lower end and the upper end of the inclined case through two bearing blocks respectively; a driving pulley and a driven pulley are arranged on the driving shaft and the driven shaft respectively; a belt is sleeved between the driving pulley and the driven pulley; grain raking rods with grain raking pieces are fixedly arranged on the belt; the discharging box is arranged at the upper end of the inclined case; the movable rollers are arranged below the bottom frame; and the hand pushrod is arranged on the discharging box. The grain collector is lower in cost and low in user investment, and has remarkable economic benefits and broad development prospect, the problem of difficulty in grain collection in busy seasons is completely solved, and a gap in the mechanization of a grain collection link of planting is filled.

Owner:柳锁兵

High-temperature-resistant phosphono-containing concrete retarder and preparation method thereof

The invention provides a high-temperature-resistant phosphono-containing concrete retarder and a preparation method thereof. The phosphono-containing concrete retarder has the advantages of high temperature resistance and excellent setting retarding effects, can enhance the adaptability of a polycarboxylic acid water reducing agent to machine-made sand and low-activity admixtures, lowers the sensitivity to cement, temperature and water consumption, and enhances the sulfate and clay tolerance. Under the synergic action of the polycarboxylic acid water reducing agent, the concrete retarder obviously improves the concrete workability, and is suitable for preparing concrete under harsh working conditions, such as low sandstone material quality, high-temperature environment, long-time transportation and the like. The preparation technique is simple, and has high feasibility for industrial production and broad market application space. The concrete retarder has important technical support effects on promoting the market application of the polycarboxylic acid water reducing agent and enhancing the rheological properties, mechanical properties and durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for producing color and differential polyester short fibre by melting body directly spinning online adding technology

InactiveCN1944719AImprove product qualityQuality improvementMelt spinning methodsStaple fibre formationPolyesterPolymer science

The present invention relates to synthetic fiber producing technology, and is direct melt spinning and on-line adding process for producing color and differential short polyester fiber. Technologically, the process includes injecting modifying material through drying, melting, filtering and metering to the polyester melt before entering to the spinning tank; mixing with the melt homogeneously in the static mixer, and spinning the mixture. The said process makes the agglomerate permeating into the inside of fiber easily to produce color fiber and other differential fibers with high quality, high fastness, high water washing resistance, excellent wear resistance, etc.

Owner:ANXING ENVIRONMENT PROTECTION COLOR FIBER CHUZHOU

Production method for copper-clad steel double-metal wire

ActiveCN101763916AMeet the qualityFulfil requirementsSingle bars/rods/wires/strips conductorsFurnace typesCopper-clad steelSolution treatment

The invention discloses a production method for a copper-clad steel double-metal wire, which includes the steps as follows: straightening a steel core, then removing rust, cleaning and mechanically polishing; heating and melting electrolytic copper, heating the steel core, then horizontally and continuously casting a coating copper layer; heating the copper-clad steel and implementing quick solid solution treatment; continuously pulling the copper-clad steel wire for a plurality of times to lead the diameter of a product to reach 4mm-26mm; annealing the pulled copper-clad steel wire and pulling a die to a specification needed by a finished product. The steel and copper in the product are connected in a melting way by malleable metallurgy and an interface can be completely and firmly combined to become a single compound. The pulling of the double-metal wire is just like pulling of a single metal wire. The invention can coat any products with different materials and different copper layer thicknesses, can meet the requirements of relevant industries on product quality and performances, can produce products with large diameter and long length, and does not pollute the environment. The production method for the copper-clad steel double-metal wire has the advantages of less equipment investment, quick effect and stable performance; moreover, the production method for the copper-clad steel double-metal wire can meet the high requirements on industries like war industry, high-speed railway, communications, electron and electric power, etc.

Owner:GANSU TINTO METALLURGICAL SCI & TECH

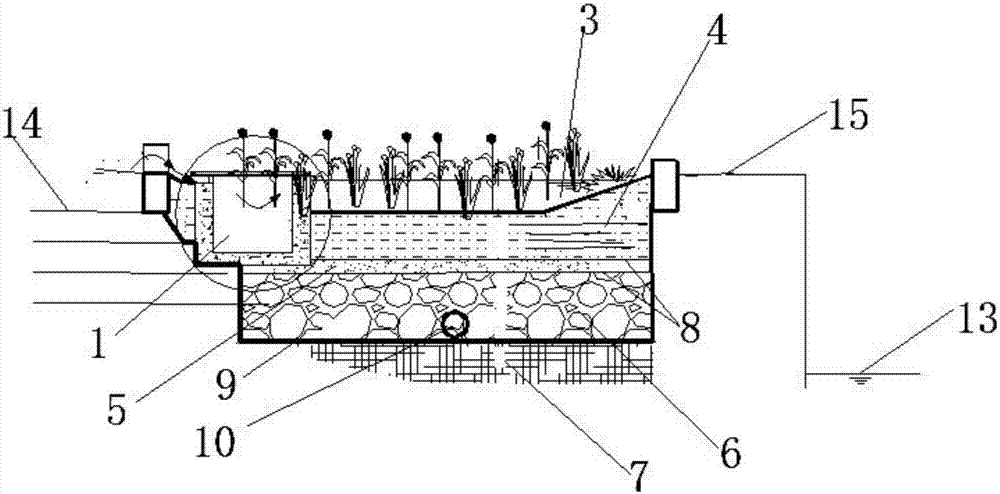

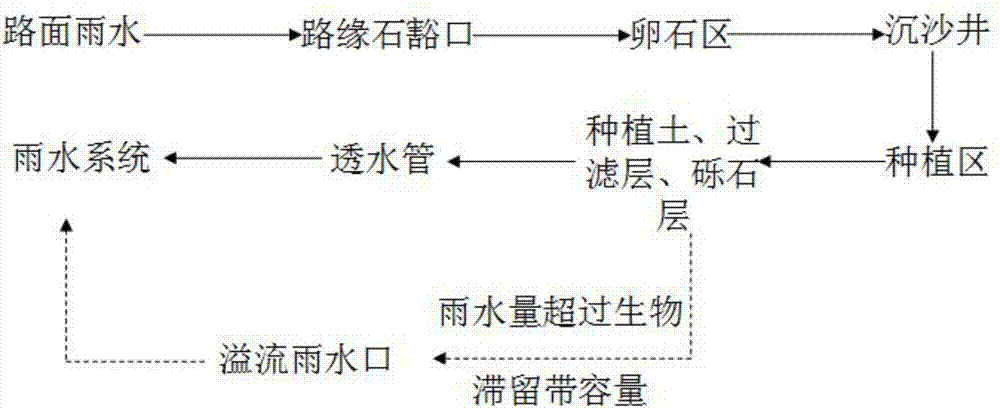

Biological retention device for controlling rainwater non-point pollution on two sides of river channel and design method of biological retention device

PendingCN107381825AEfficient use ofAvoid pollutionSewerage structuresClimate change adaptationWater storageWater resources

The invention belongs to the technical field of water resource environment protection and discloses a biological retention device for controlling rainwater non-point pollution on two sides of river channel and a design method of the biological retention device. The biological retention device is characterized in that the rainwater sand settling wells of the device are communicated with biological retention belts through overflow ports; each biological retention belt sequentially comprises a water storage layer, a planting soil layer, a sand filtering layer, a gravel layer and an original soil layer which are laid from top to bottom; a geotextile layer is laid between each planting soil layer and the corresponding sand filtering layer, and a geotextile layer is laid between each sand filtering layer and the corresponding gravel layer; an impermeable membrane layer is laid between each gravel layer and the corresponding original soil layer; water-permeable blind pipes are inserted in the bottoms of the gravel layers and communicated with rainwater inspection wells excavated in one side of the biological retention belts. The biological retention device has the advantages that the device is simple, high in flexibility, unlimited by sites, small in size, applicable to different regions of a city, and the like; meanwhile, the device is a small ecological system and can beautify environments and relieve the heat island effect of the city.

Owner:重庆环投生态环境监测网络与工程治理有限公司

Technique for producing coloured polyester filament yarn by melt direct spinning

InactiveCN101173372ARaise the gradeQuality improvementMelt spinning methodsFilament-forming treatmentAutomatic controlStatic mixer

The invention relates to a melt direct spinning technology for producing colored polyester filament, belonging to the technical field of chemical fiber production, which mainly solves the technical problem that a melt direct spinning producing method with low cost, high yield, simple technology, easy control of color difference and good color fastness of fabrics is provided. The invention is characterized in that the modified material after drying, melting, filtering and measuring are injected before the polyester melt enters a spinning box; and the modified material and the polyester melt enter the spinning box together for spinning after even mixing in a high-efficiency static mixer. The invention has the advantages of easy infiltration of master batch into fiber, good performance of the colored polyester filament product produced through the method such as high quality, good color fastness, wash resistance and abrasion resistance, simple technology, less equipment investment, easy control of material adding, convenient realization of automatic control, and avoidance of environmental pollution.

Owner:SHENGHONG GRP CO LTD

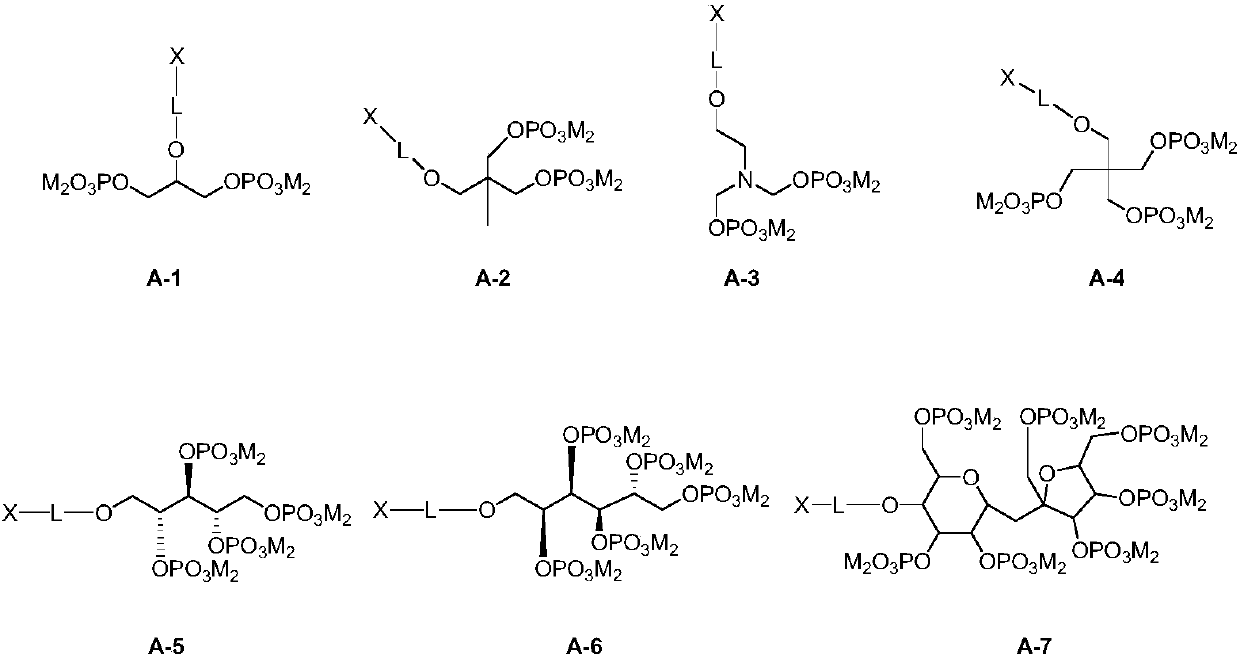

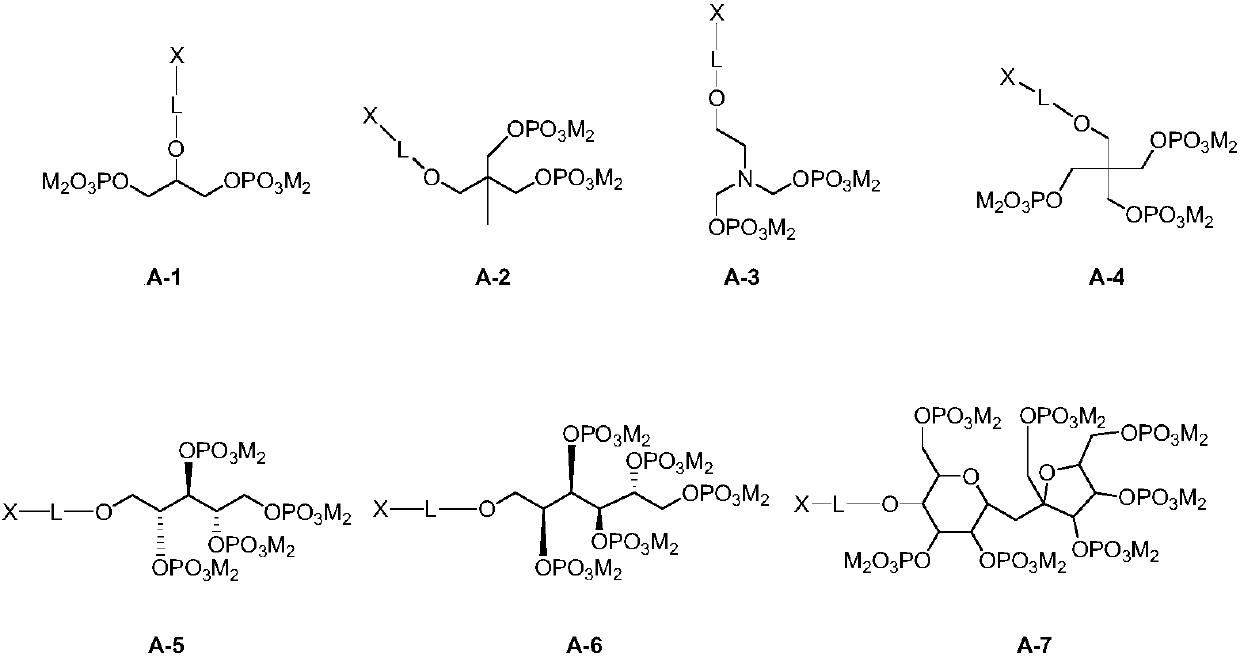

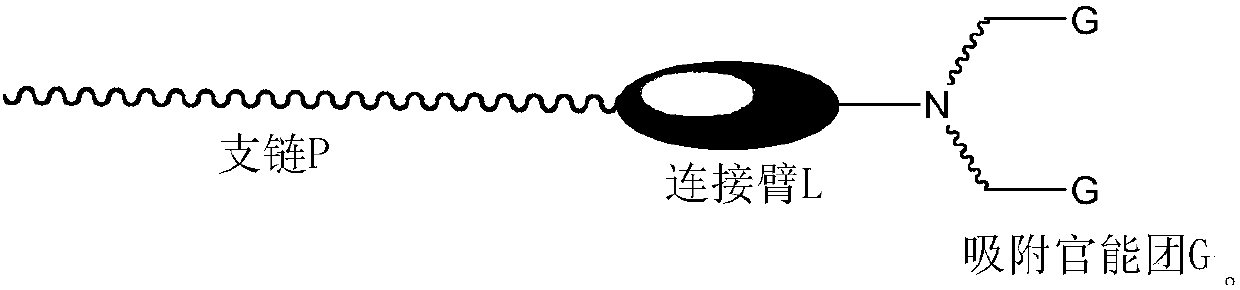

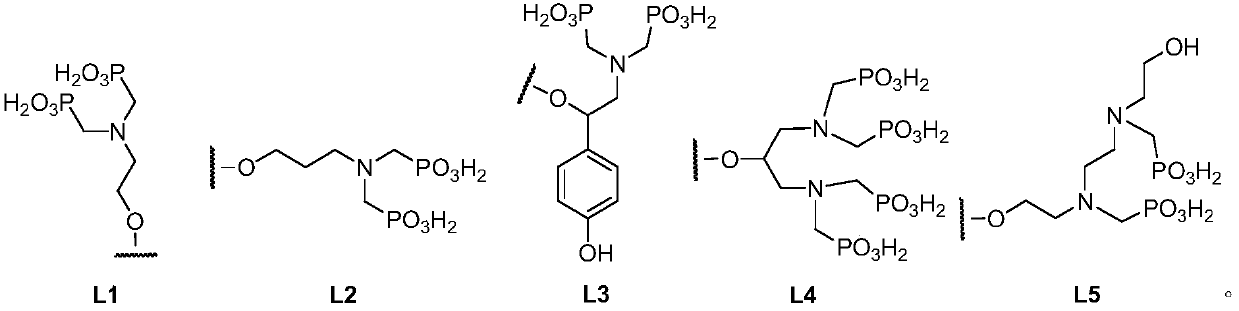

Polybasic phosphonic acid monomer, polybasic phosphonic acid polymer thereof and preparation method and application thereof

ActiveCN108033978AImprove workabilityAdsorption capacity acrossEsterified saccharide compoundsSugar derivativesPolymer scienceAlcohol

The invention discloses a polybasic phosphonic acid monomer, a polybasic phosphonic acid polymer thereof and a preparation method and application thereof. The polybasic phophonic acid monomer is prepared through phosphorylation of a primary hydroxyl group or a secondary hydroxyl group at the terminal of polyhydric alcohols, and the polybasic phosphonic acid polymer is prepared through esterification reaction of the polybasic phosphonic acid monomer and single-chain polyether. The polybasic phosphonic acid polymer can achieve long-term stable slump loss resistance of middle and low slump degreeconcrete, can improve the workability, can improve the mechanical property and endurance quality of the concrete, and is suitable for special type projects such as nuclear power, water and electricity, super high-rise, and large volume.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Preparation method of nano zinc oxide modified vermiculite

InactiveCN108246245APayloadNot easy to reuniteOther chemical processesWater contaminantsWater bathsSlurry

The invention discloses a preparation method of nano zinc oxide modified vermiculite. The preparation method comprises the following operation steps: a, pre-treating vermiculite; enabling the naturalvermiculite to pass through distilled water; repeatedly washing by adopting a pouring method until an upper-layer solution is clear and transparent; washing the vermiculite with absolute ethyl alcohol; putting the vermiculite into a drying oven and drying; taking out the vermiculite and cooling to room temperature; grinding and sieving for later use; b, preparing a ZnSO4.7H2O solution and an NaOHsolution; c, weighing the vermiculite sieved and treated in step a and preparing vermiculite slurry in the distilled water; adding the ZnSO4.7H2O solution and the NaOH solution, which are prepared bystep b, into the vermiculite slurry at the same time and stirring; continuously stirring in a constant-temperature water-bath pot and standing for 24h; filtering and washing with de-ionized water until no sulfate ions exist; then putting into a muffle furnace and calcining to obtain the nano zinc oxide modified vermiculite. According to the technical scheme disclosed by the invention, the preparation method of the nano zinc oxide modified vermiculite adopts a chemical precipitation method and zinc oxide generated by reaction can be effectively loaded on the surface of the vermiculite.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

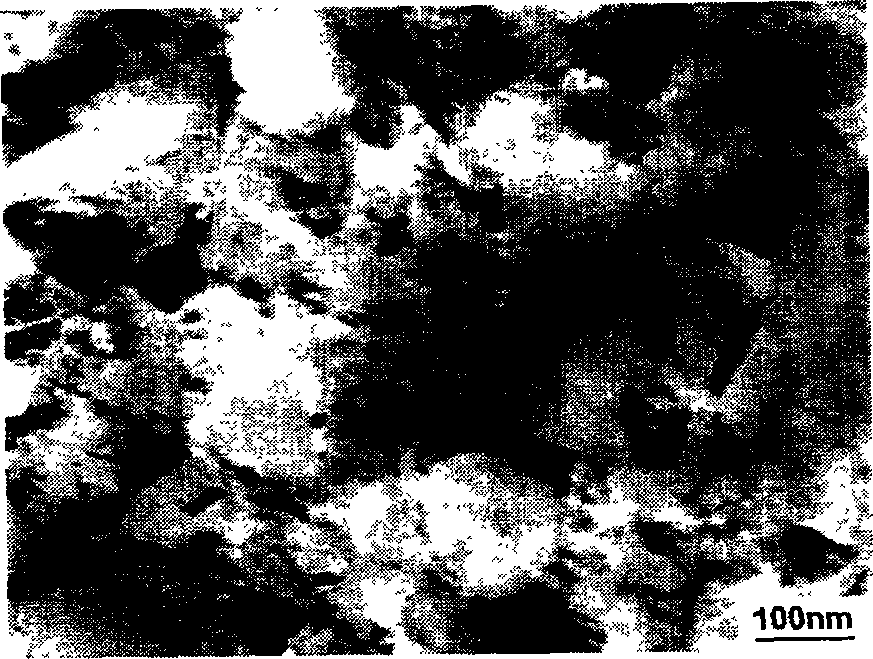

Anti-chlorine ion corrosion Ni-Cr nano composite coating and preparing method and use

InactiveCN1782138AImprove protectionGood resistance to Cl ion corrosionElectrolytic coatingsHydration reactionNicr alloy

The present invention discloses a kind of chlorine ion corrosion resisting nanometer composite Ni-Cr coating and its preparation and application. The nanometer composite Ni-Cr coating is prepared with nanometer metal Ni and Cr powder with Cr content of 4-15 wt%. The preparation process of the nanometer composite Ni-Cr coating is to electroplate Ni and Cr onto Ni substrate through conventional electric co-deposition. The nanometer composite Ni-Cr coating has obviously higher corrosion resistance than NiCr alloy with similar Cr content and composite Ni-Cr coating with micron Cr grains in similar content. The present invention has simple technological process, low cost, and compact and homogeneous coating. The nanometer composite Ni-Cr coating, when set in water solution containing Cl ion, will form hydrated Cr containing oxide and hydroxide to resist corrosion of Cl ion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

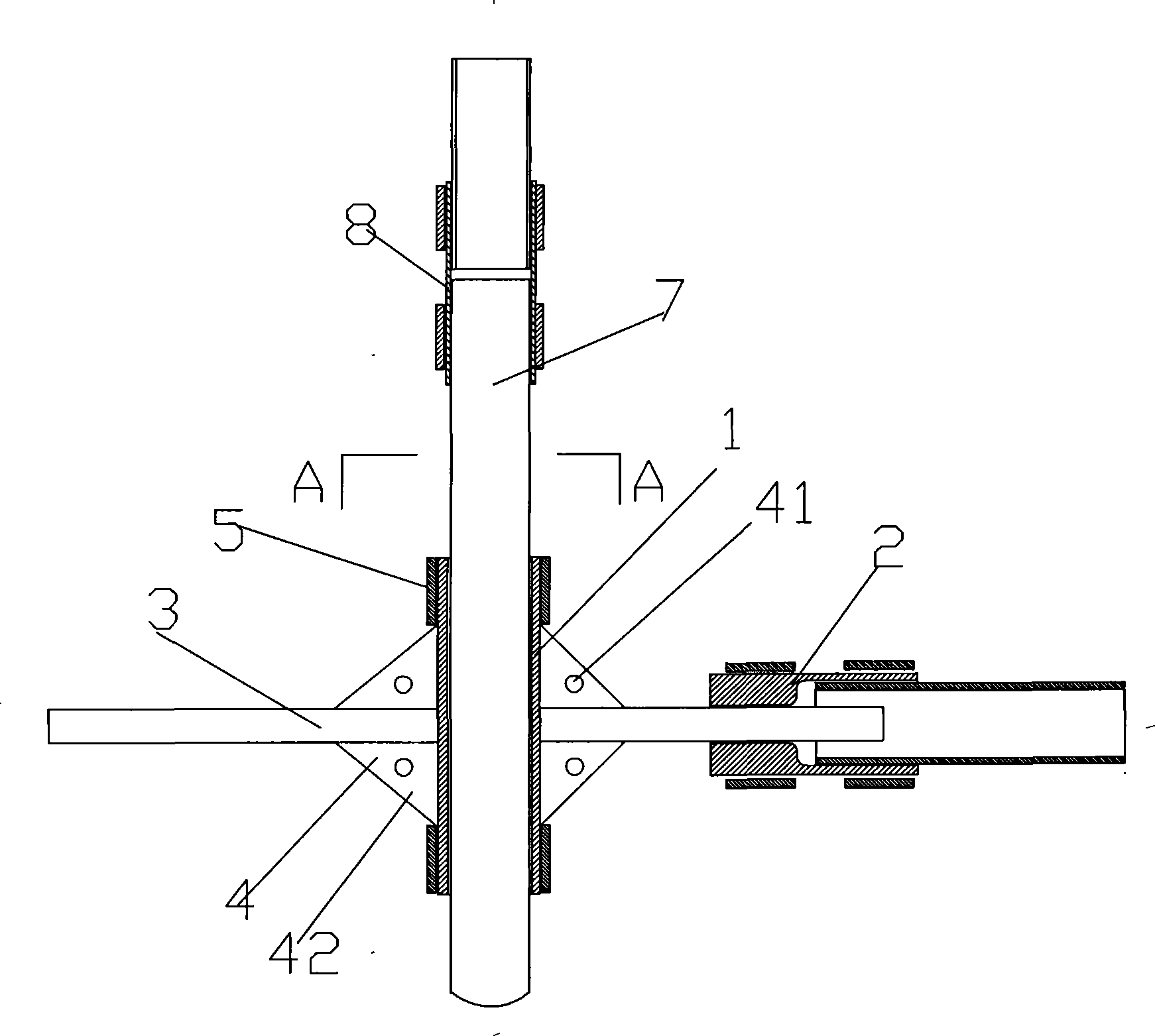

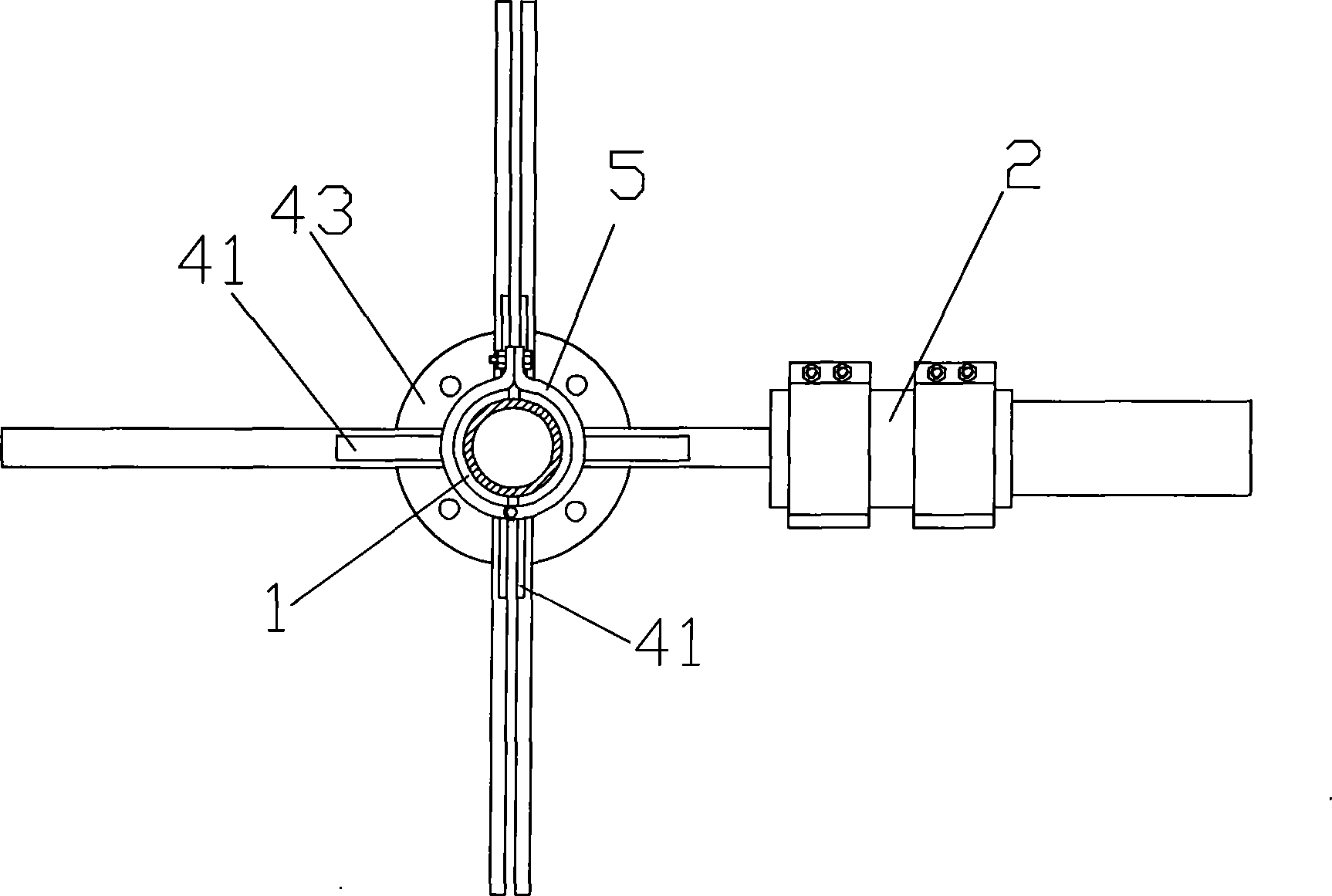

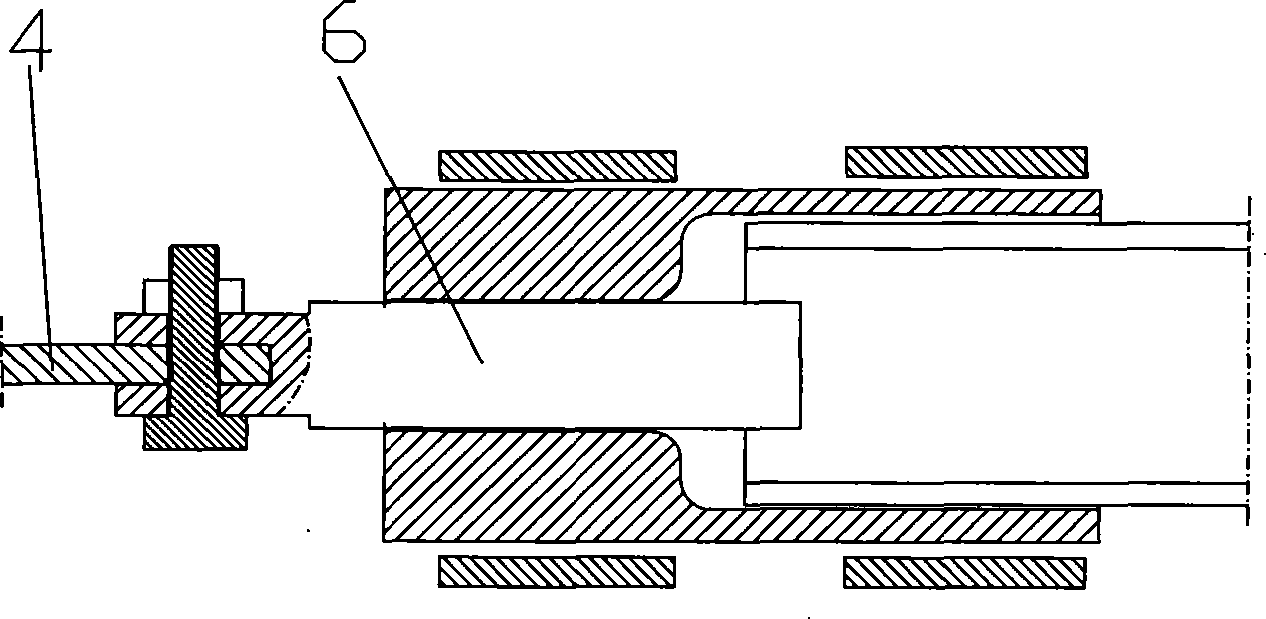

Connecting mechanism for improving tube-and-coupler scaffold

InactiveCN101250943AImprove mechanical propertiesImprove stabilityScaffold connectionsEngineeringMechanical property

The invention discloses a connecting device used to renovate a fastener type steel tube scaffold, comprising a joint connecting piece, a node connecting piece and a connecting rod fixed on the outer circumference of the node connecting piece, wherein both the joint connecting piece and the node connecting piece can be opened or closed along a vertical cross section; the inner hole of the node connecting piece is columnar after the node connecting piece is arranged; moreover, the diameter of the inner hole is not more than the outside diameter of a scaffold steel tube connected with the inner hole; the connecting rod is perpendicular to the node connecting piece with the extended line passing through the center line of the inner circle of the node connecting piece; after the joint connecting piece is arranged, the shape the cross section of one end of the inner hole is identical to the shape of the cross section of the connecting rod, and the size of the inner hole is not more than that of the cross section of the connecting rod; the other end of the inner hole is columnar with the diameter not more than the outside diameter of the scaffold steel tube connected with the other end of the inner hole. The connecting device improves the mechanical property of a fastener type steel tube scaffold and eliminates the phenomena of vertical member stress and additional bending moment; a diagonal member connecting device is arranged and is convenient for arranging a vertical diagonal member and a horizontal diagonal member, thereby further improving structural stability and safety.

Owner:CHONGQING UNIV

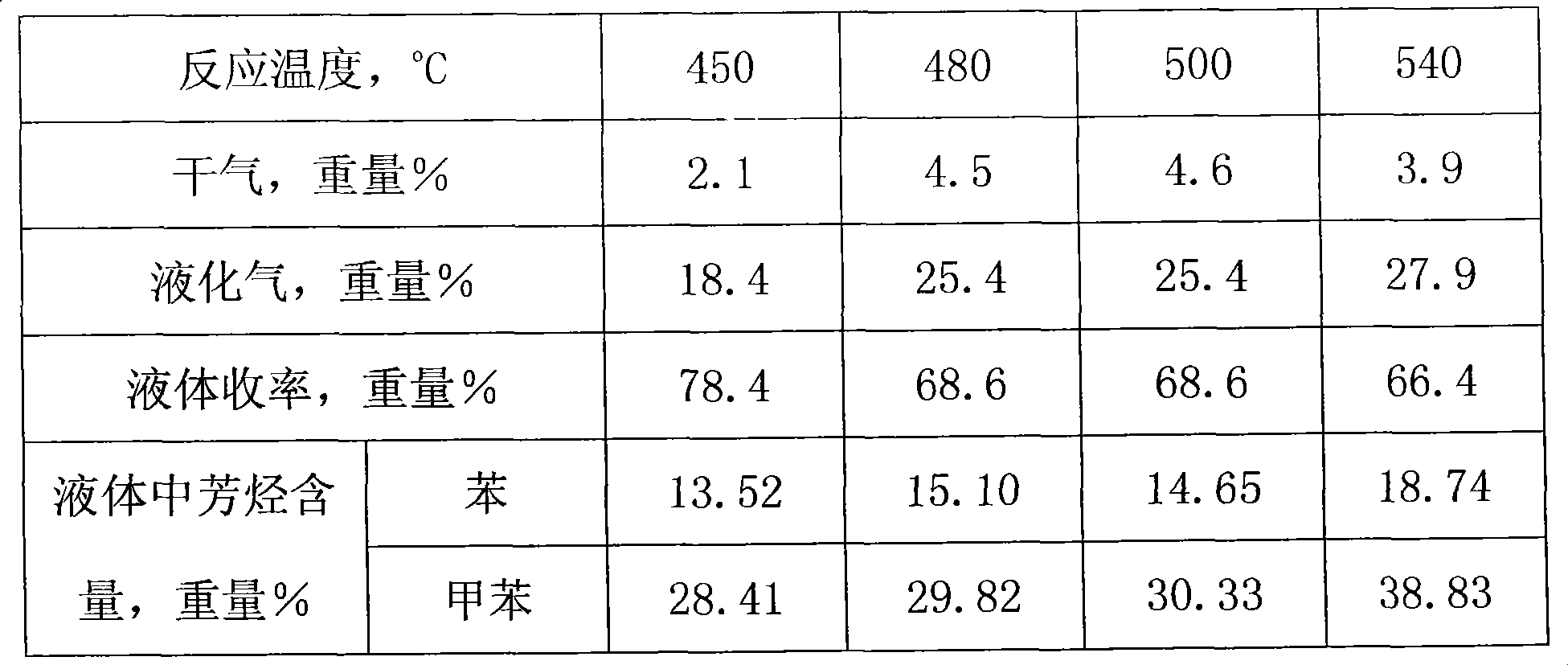

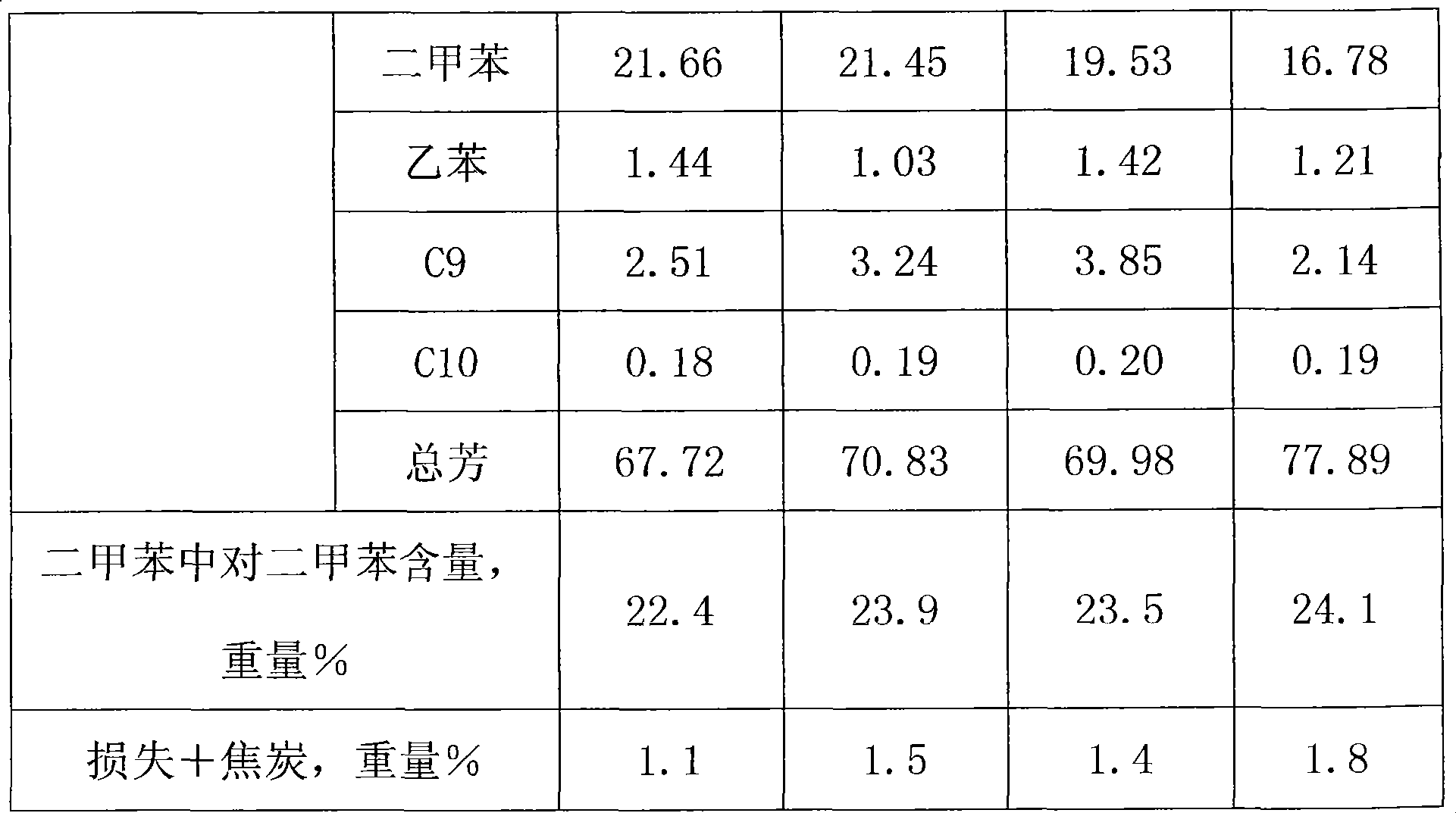

Preparation method and uses of condensate oil aromatization catalyst

InactiveCN101367048AIncrease profitHigh strengthHydrocarbon by isomerisationMolecular sieve catalystsMoving bedLiquid gas

The invention discloses a preparation method and application of aromatization catalyst for gas condensate. The method is to load metal active components onto a nano molecular sieve, which comprises 0.1 to 10.0 weight percent of noble metal platinum, 1.0 to 10.0 weight percent of a second metal M, 89.0 to 98.9 weight percent of a carrier, wherein the carrier is composed of 60 to 90 weight percent of a nano HZSM-5 molecular sieve and titanium dioxide, the balance being aluminum oxide, the noble metal platinum is a fist active component. The catalyst is applicable to production of aromatic hydrocarbon through aromatization of gas condensate. With gas condensate as the raw material, benzene, toluene, xylene (BTX) together with a byproduct of 18 to 28 weight percent of high quality liquid gas are produced in a reactor of moving bed under the conditions of a total reaction pressure of between 0.5 and 2.0 Mpa, a temperature of between 400 and 580 DEG C, a weight space velocity of the raw material of between 0.5 and 4.0 h <-1>. The catalyst has high actively and selectivity anti-carbon capacity, reusability and high yield rate of aromatic hydrocarbon products.

Owner:CHINA NAT OFFSHORE OIL CORP +1

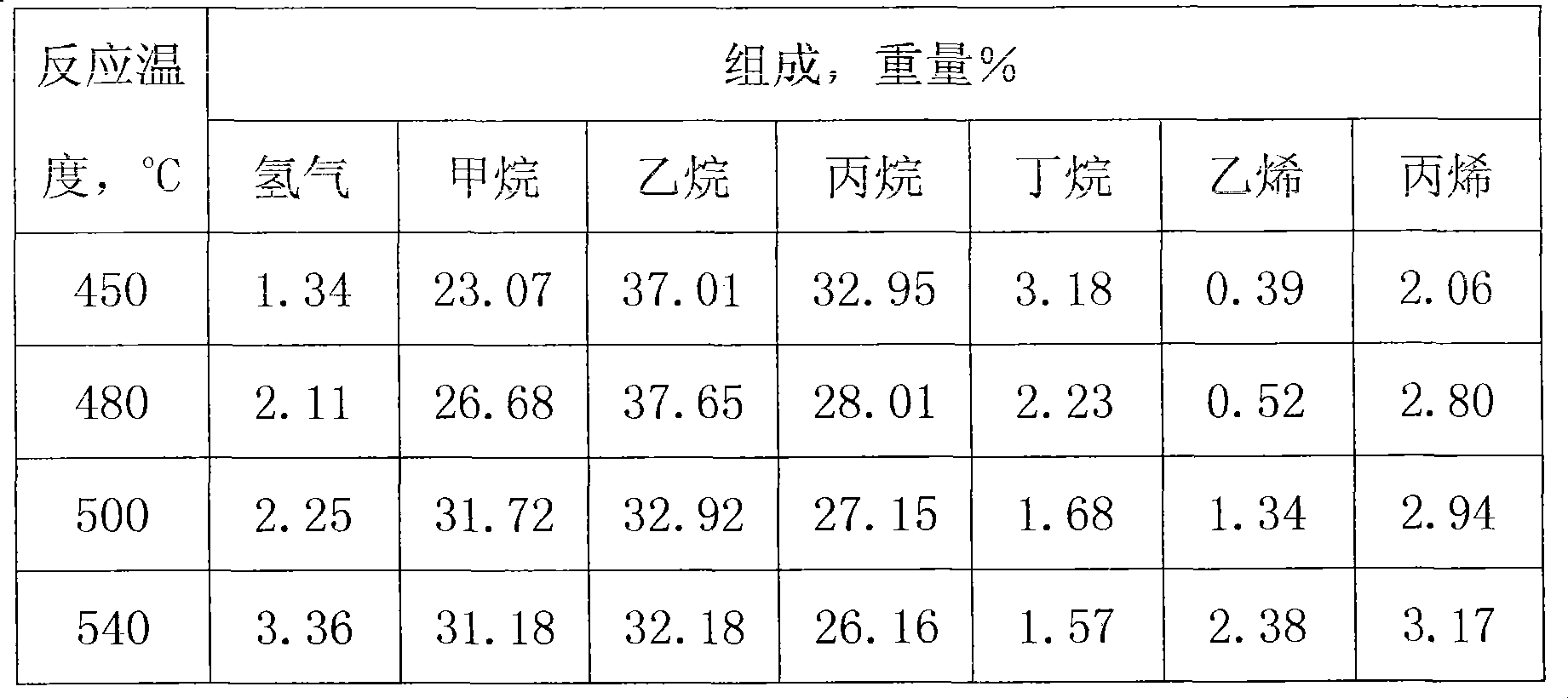

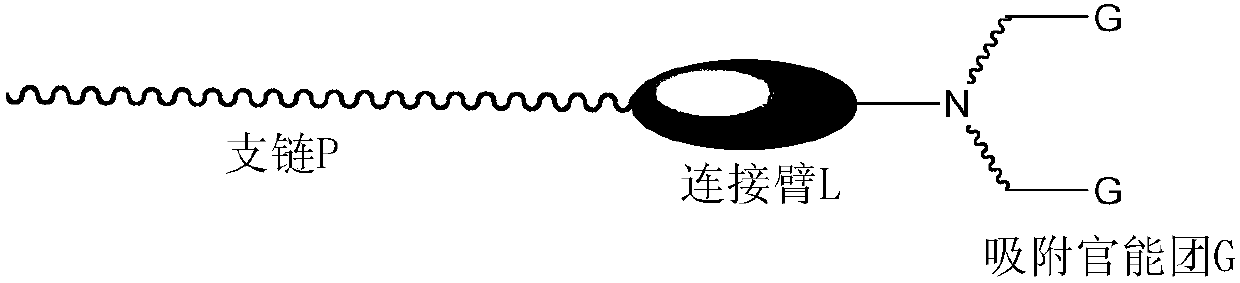

Special double-toothed phosphonic acid-based water reducing agent for medium and low slump concrete and preparation method thereof

The invention discloses a special double-toothed phosphonic acid-based water reducing agent for the medium and low slump concrete. The structure of the water reducing agent is as follows: one end is abis-phosphorous acid or bis-phosphite G linked by the N atom which is called as the terminal end double-toothed adsorption group, the other end is a polyether chain P prepared by carrying out the alkoxylation reaction of an initiating agent of a C1-C12 saturated alkyl or unsaturated alkyl and ethylene oxide or propylene oxide, the two ends are connected by a connecting arm L, and the connecting arm L is an aliphatic or aromatic group of C1-C10. According to the special double-toothed phosphonic acid-based water reducing agent for the medium and low slump concrete, the long-term stable slump retention of the medium and low slump concrete can be achieved, the workability is improved, and the mechanical properties and durability of the concrete are improved, so that the water reducing agentis suitable for special projects such as nuclear power, hydropower, super-high-rise buildings, super-long-span bridges and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for producing hot melt adhesive by using recovered nylon

The present invention relates to a method for producing a hot melt adhesive by using recovered nylon. Main steps of the method comprise: 1, adopting a composite solid acid catalysis method or a non-catalytic method to degrade recovered nylon and water at a high temperature under high pressure; adding the generated product to a reactor to carry out high temperature cracking; adding the generated middle and small molecular nylon to a high temperature and high pressure reactor; 2, adopting an air catalytic oxidation method to oxidize polyethylene wax and polypropylene wax; adding the oxidized polyethylene wax or the oxidized polypropylene wax to the reactor; 3, refining nylon acid, then adding the refined nylon acid to the reactor; 4, adding diamine to the reactor; 5, adopting a vacuum pump to carry out vacuumizing for the reactor, and then introducing nitrogen; 6, carrying out slow temperature increasing and pressure increasing for the reactor, carrying out the reaction for 0.1-6 hours at the temperature of 160-310 DEG C under reaction pressure of 0.5-3.8 MPa; 7, introducing cooling water after completing the reaction, reducing the pressure, reducing the temperature of the materials in the reactor, discharging the material, then carrying out treatments of pelletizing and crushing to prepare the hot melt adhesive powder, wherein the particle size of the hot melt adhesive powder meets the process requirement.

Owner:河南申豫之星空天技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com