Patents

Literature

41results about How to "Reduce the rate of hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

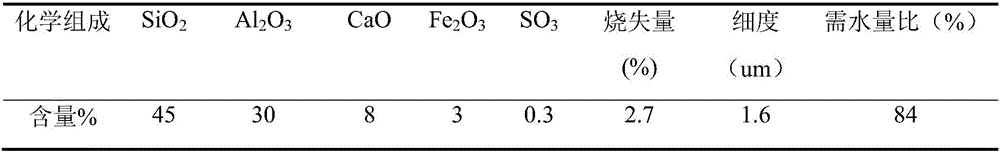

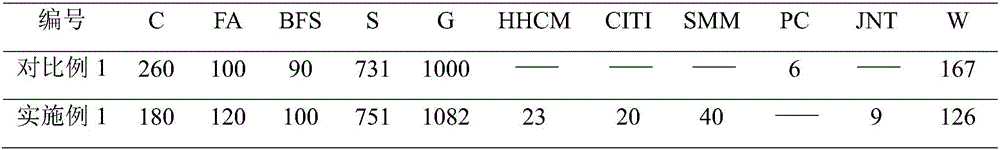

Super-elevation pumping marine concrete and preparation method thereof

ActiveCN106587831ASuppresses structural cracking problemsReduce the rate of hydrationTemperature stressTransport inhibitor

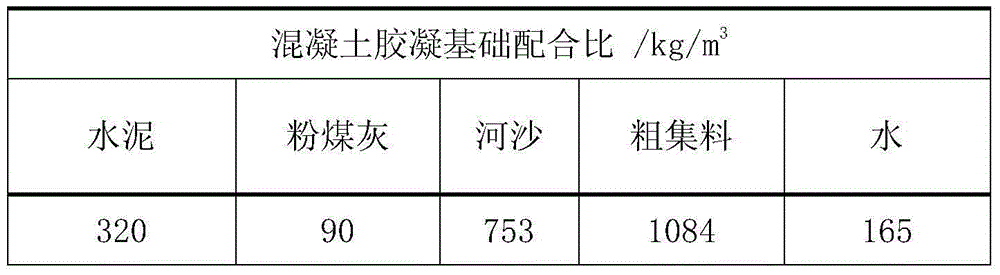

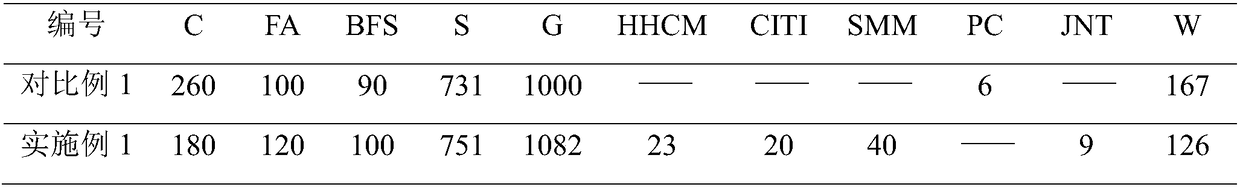

The invention discloses a super-elevation pumping marine concrete. The super-elevation pumping marine concrete is prepared from cement, fly ash, mineral powder, gravel, river sand, a hydration temperature rising regulation and control material, a corrosive ion transport inhibitor, a state modified material, an ultra dispersed water reducing shrinkage plasticity-maintaining additive and water in proportion. According to the super-elevation pumping marine concrete, by means of the hydration temperature rising regulation and control material, cracking caused by low high performance concrete, insufficient hydration and drying shrinkage in later period can be effectively avoided; by means of the hydration temperature rising inhibiting component, adiabatic temperature rising of the concrete can be lowered, and cracking generated by the temperature stress is reduced; by adopting the corrosive ion transport inhibitor, the pore structure of the concrete can be optimized, transport paths of ions such as Mg<2+> and Cl<->, and the concrete is better served in marine salt spray environment; the state modified material has the specific ball effect and water retention characteristic, and the phenomena of segregation and pipe blocking occurring in the super-elevation pumping process are avoided. The concrete is suitable for super-elevation pumping marine buildings and has the important engineering application value.

Owner:WUHAN UNIV OF TECH +1

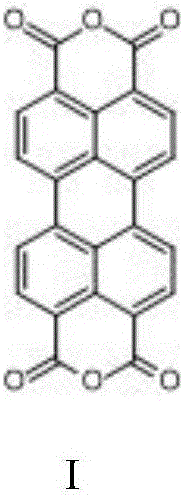

High-temperature-resistant phosphono-containing concrete retarder and preparation method thereof

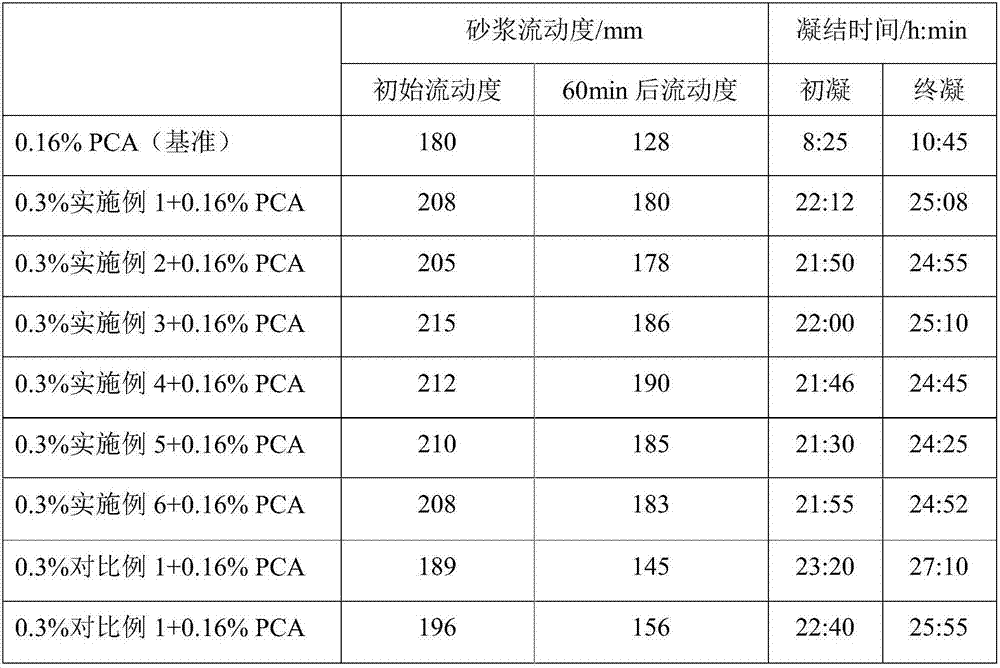

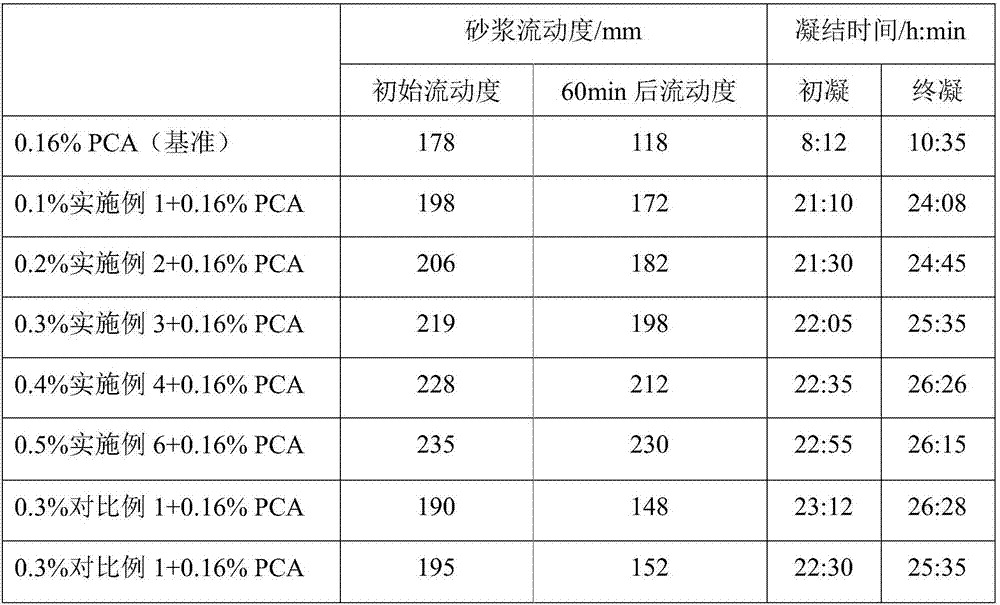

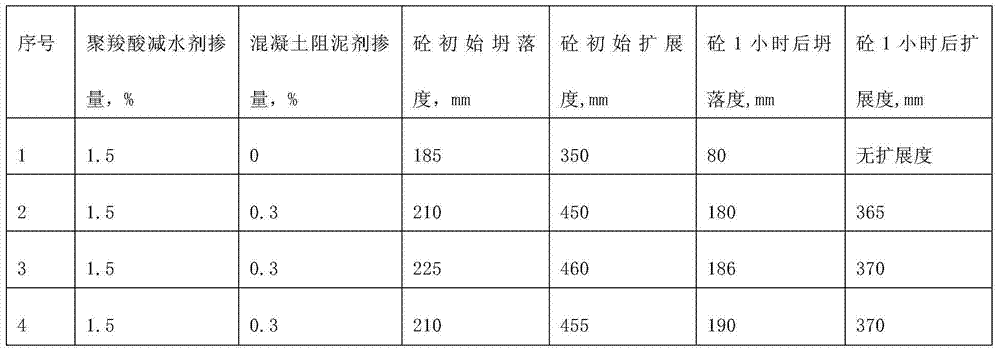

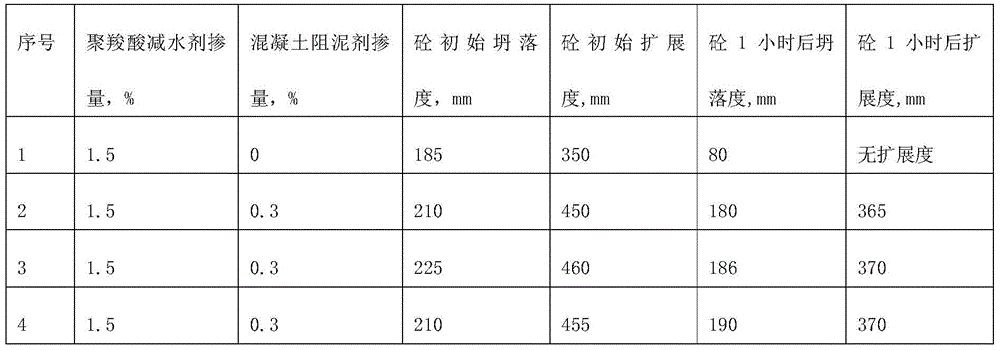

The invention provides a high-temperature-resistant phosphono-containing concrete retarder and a preparation method thereof. The phosphono-containing concrete retarder has the advantages of high temperature resistance and excellent setting retarding effects, can enhance the adaptability of a polycarboxylic acid water reducing agent to machine-made sand and low-activity admixtures, lowers the sensitivity to cement, temperature and water consumption, and enhances the sulfate and clay tolerance. Under the synergic action of the polycarboxylic acid water reducing agent, the concrete retarder obviously improves the concrete workability, and is suitable for preparing concrete under harsh working conditions, such as low sandstone material quality, high-temperature environment, long-time transportation and the like. The preparation technique is simple, and has high feasibility for industrial production and broad market application space. The concrete retarder has important technical support effects on promoting the market application of the polycarboxylic acid water reducing agent and enhancing the rheological properties, mechanical properties and durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Concrete mud retarder

The invention discloses a concrete mud retarder. The concrete mud retarder comprises 50-80wt% of an aqueous polymer, 5-20wt% of gallic acid and 10-30wt% of diethylene glycol. A production technology of the aqueous polymer comprises the following steps: 1, taking 4-7 parts by weight of hydrogen peroxide and 8 parts by weight of water, and completely dissolving hydrogen peroxide in water to obtain a solution I; 2, taking 2-4 parts by weight of rongalite and 8 parts by weight of water, and completely dissolving rongalite in water to obtain a solution; 3, adding 35-40 parts by weight of water, respectively adding 7 parts by weight of acrylamide, 9 parts by weight of maleic anhydride and 21 parts by weight of allyl ether, and stirring; 4, adding 0.5-2 parts by weight of a chain transferring agent; and 5, heating to 40DEG C, simultaneously adding the solution I and the solution II in a dropwise manner, and controlling the reaction temperature to be 40-50DEG C and the dropwise addition time to be 2-4h, and cooling to 30DEG C after the above reaction in order to obtain the aqueous polymer with the solid content of 38-42%. The concrete mud retarder can reduce adsorption of a concrete water reducer on soil particles, improves the fluidity of a high-mud concrete system, and greatly improves the slump keeping property of the concrete water reducer.

Owner:SOUTHEAST UNIV

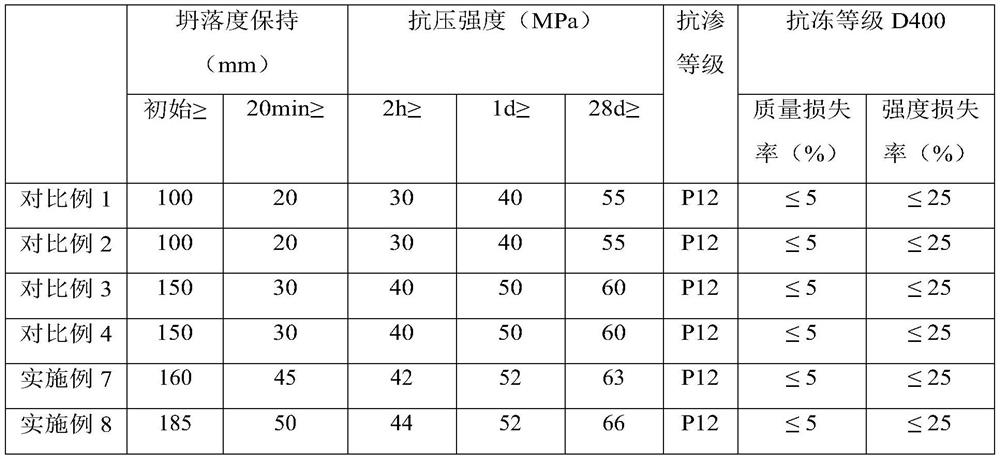

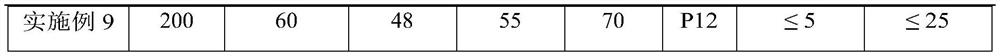

Ultra-high-stroke pumping anti-crack concrete suitable for cable bent tower structure and preparation method

InactiveCN111848019AExtended hydration induction periodRealize the control mechanismCrack resistanceSuperplasticizer

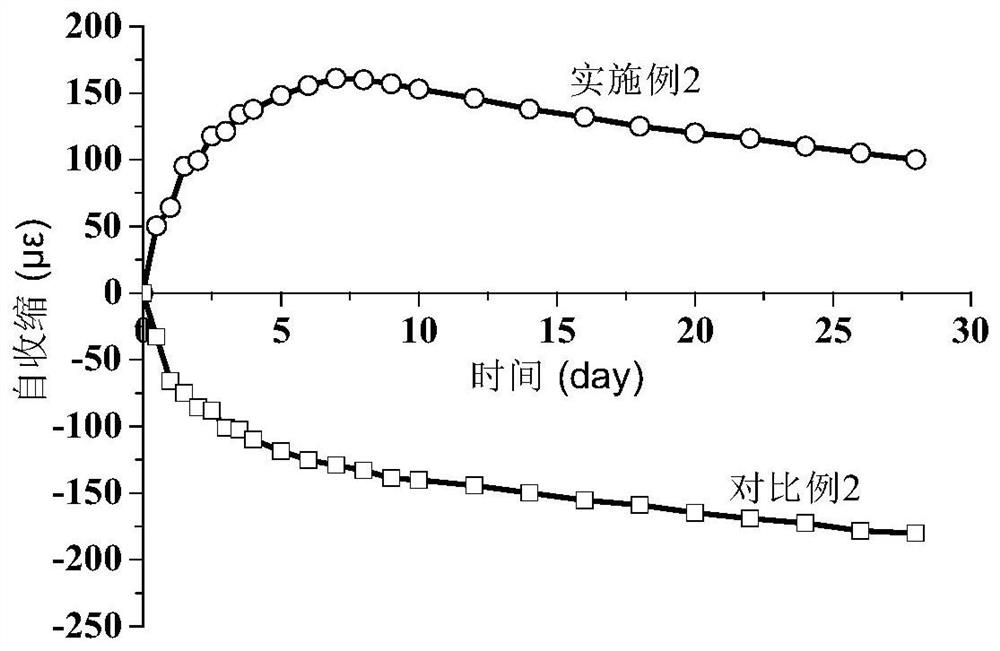

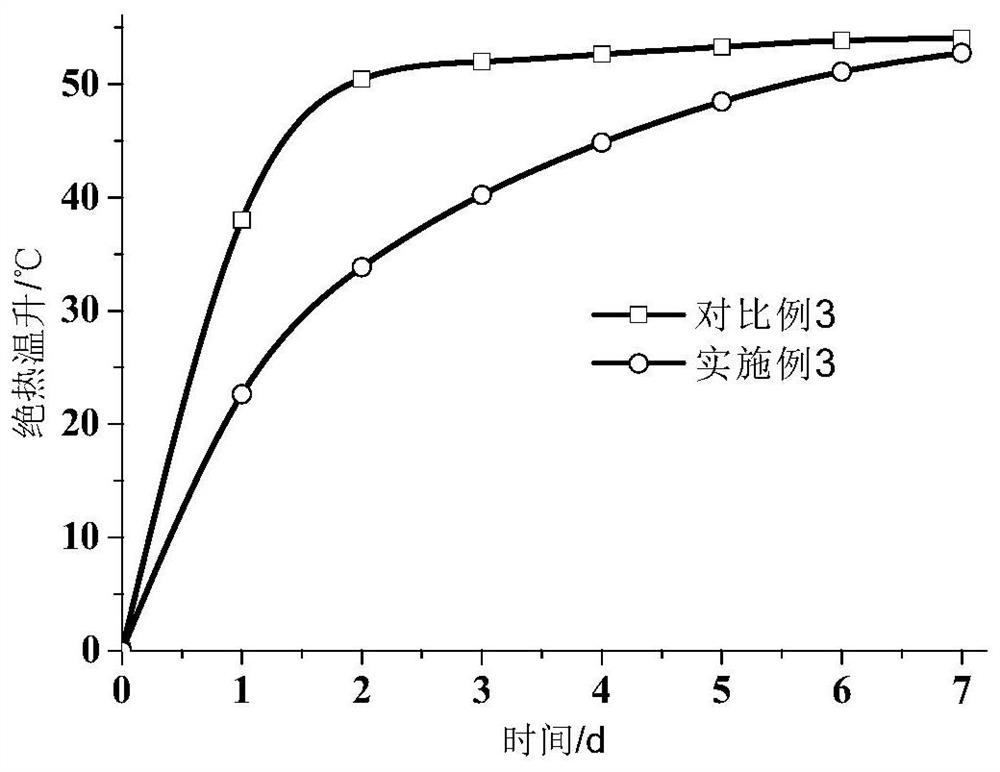

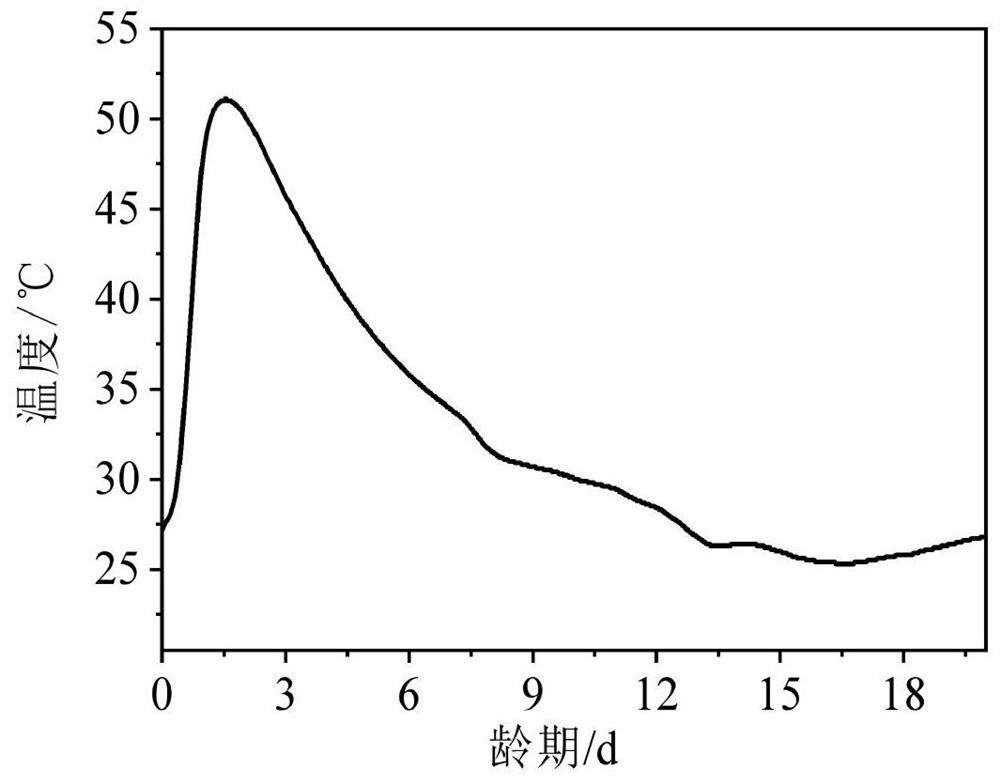

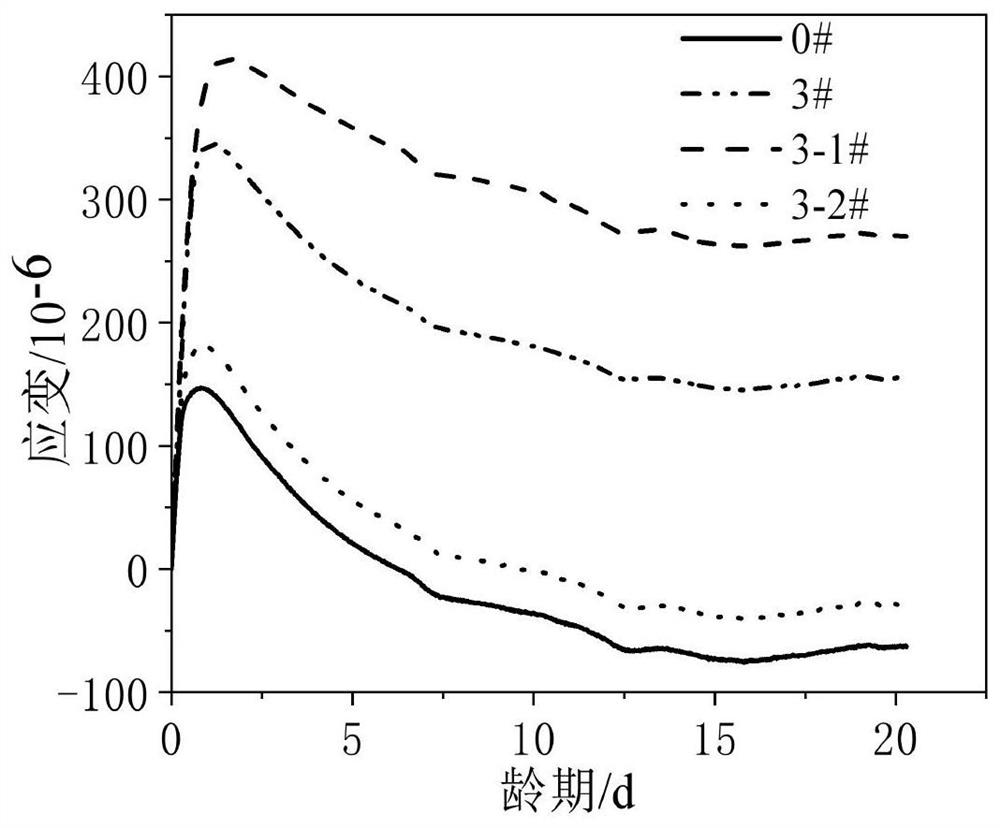

The invention discloses ultra-high-stroke pumping anti-crack concrete suitable for a cable bent tower structure and a preparation method thereofe. The anti-crack concrete is prepared from the following components: 240-300kg / m < 3 > of cement, 90-130kg / m < 3 > of fly ash, 50-80kg / m < 3 > of mineral powder, 35-45 kg / m < 3 > of an anti-crack agent, wherein the anti-crack agent is prepared from the following components; the content of each component is shown in the specification: 1-2.5 kg / m < 3 > of hydration temperature rise regulation material; 32.5-44 kg / m < 3 > of a calcium-magnesium compositeexpansion material, 30-40 kg / m < 3 > of a viscosity modification material, 950-1150 kg / m < 3 > of crushed stone, 700-820 kg / m < 3 > of river sand, 145-160 kg / m < 3 > of water and 5-8 kg / m < 3 > of ahigh-performance polycarboxylate superplasticizer. The concrete has the characteristics of better working performance, mechanical performance, pumping performance and crack resistance, better matchingof an expansion process with a concrete temperature process and a shrinkage process, better durability and important practical engineering application value.

Owner:SOUTHEAST UNIV +3

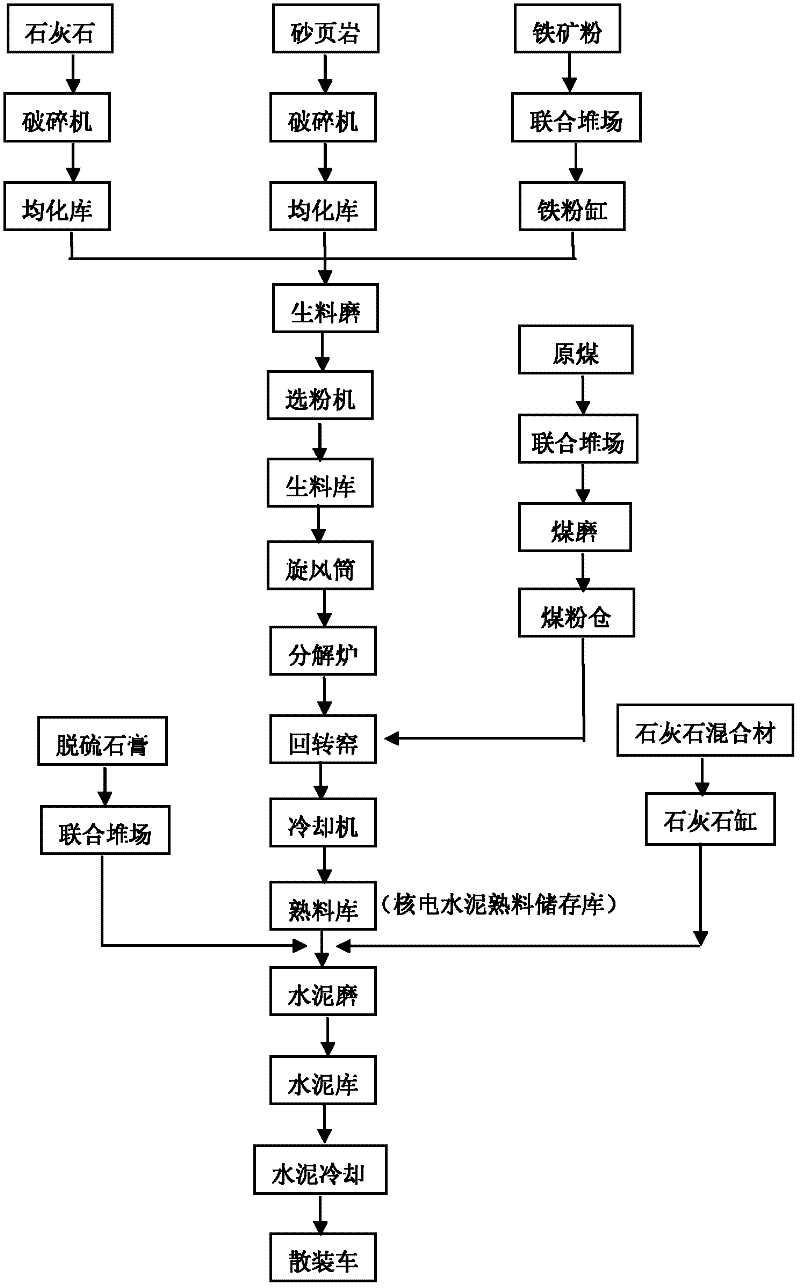

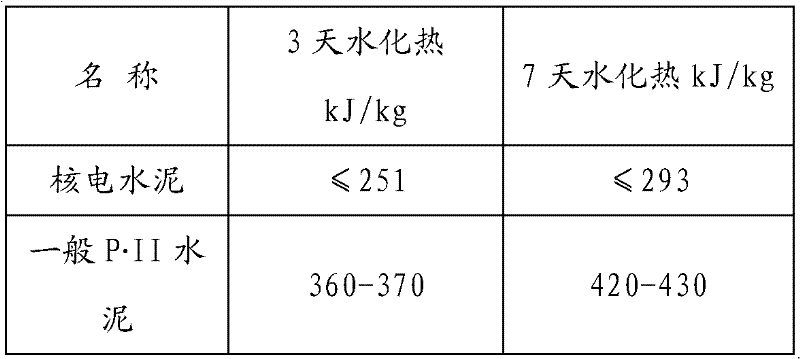

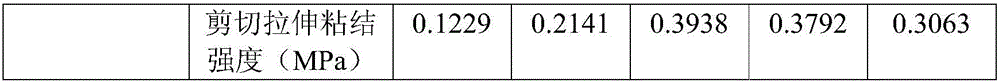

A special high-performance cement for nuclear power plant nuclear island and its preparation method

The invention discloses a special high-performance cement for the nuclear island of a nuclear power plant and a preparation method thereof. The proportion of high-performance cement dedicated to the nuclear island of the nuclear power plant is: cement clinker 90.5%-92.0%, limestone mixed material 4.0%-4.5%, desulfurized gypsum 4.0%-5.0%; among them, the cement clinker formula is: KH=0.910± 0.01, SM=2.0±0.1, IM=1.0±0.1. The preparation method is as follows: preparing raw material through grinding; controlling process parameters, calcining raw material in a rotary kiln to prepare the cement clinker; grinding with a cement mill system to obtain ground cement; cooling. The prepared high-performance cement special for nuclear power plant nuclear island has the advantages of low water demand, low heat of hydration (crack prevention), high durability and the like.

Owner:GUANGZHOU ZHUJIANG CEMENT +1

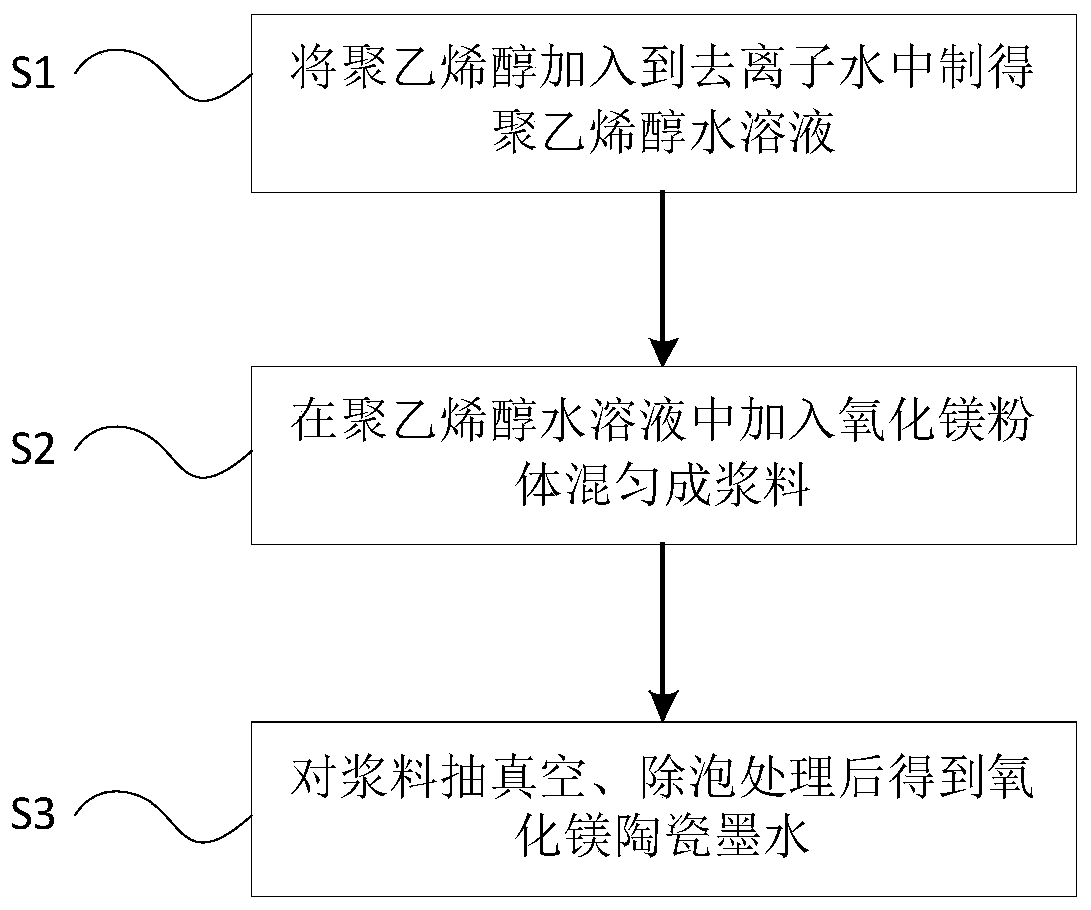

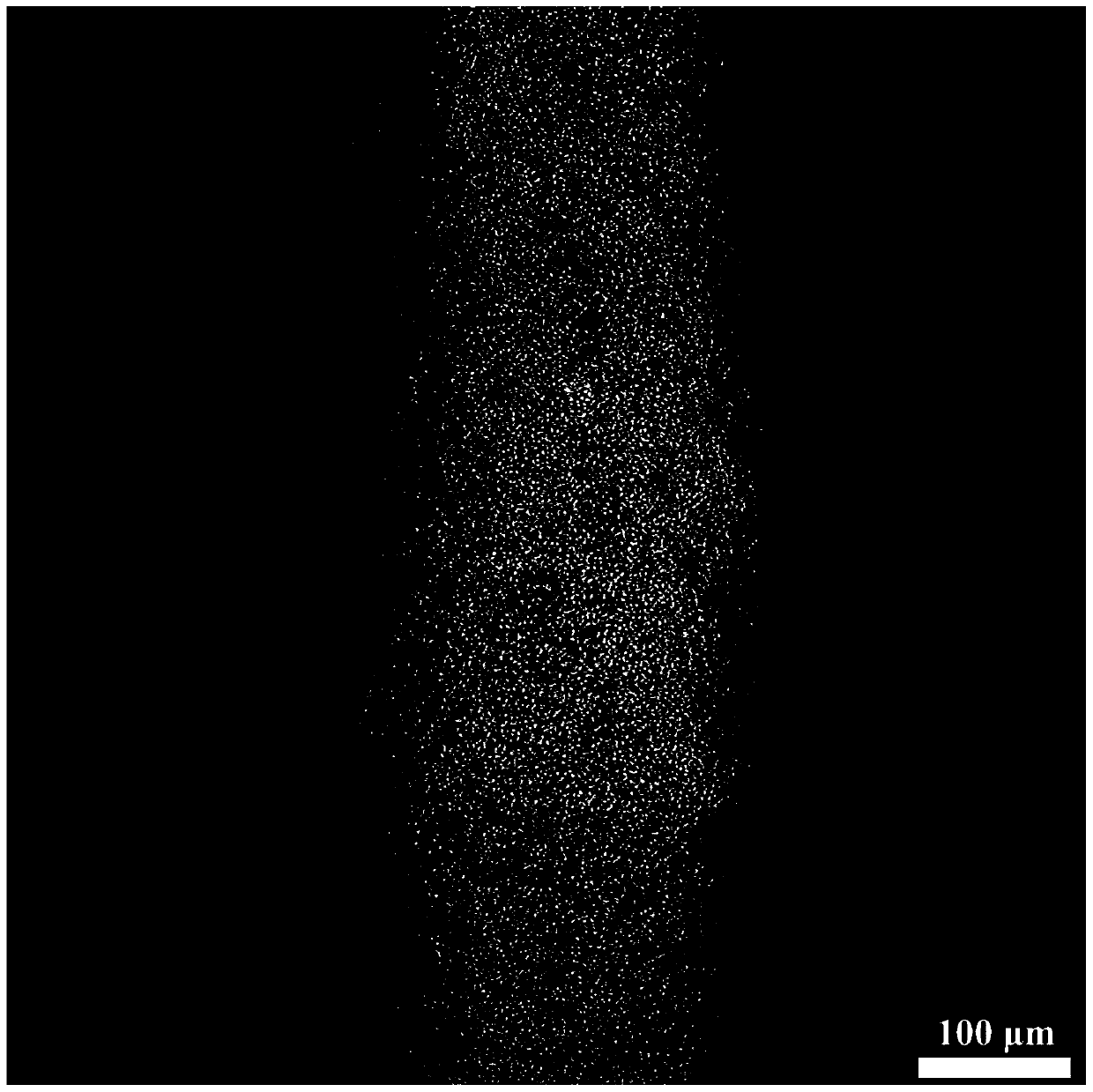

Magnesium oxide ceramic ink for 3D direct writing molding and preparation method thereof

ActiveCN110423515AImprove uniformitySimple controlAdditive manufacturing apparatusInksOxide ceramicPolyvinyl alcohol

The invention discloses a magnesium oxide ceramic ink for 3D direct writing molding and a preparation method thereof. The ceramic ink is obtained by mixing 57-70wt% of magnesium oxide powder, 2.5-10wt% of polyvinyl alcohol and 25-35wt% of deionized water evenly. The method includes: loading magnesium oxide ceramic ink into a syringe of a direct writing 3D printer, setting the printing program andstarting layer-by-layer printing, drying the printed three-dimensional structure to obtain a magnesium oxide green body, and finally conducting sintering at 1580-1680DEG C in an ordinary sintering furnace to obtain magnesium oxide ceramic. The above scheme achieves simple ink components, high solid content and good fluidity, the preparation method is simple and feasible, the silk thread extruded on the direct writing 3D printer has a smooth surface, the molded green body and the high temperature sintered ceramic have good shape preservation performance, and can be applied to the high temperature field, thus having high practical value and promotion value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Well cementation material suitable for low-temperature environment and production method of well cementation material

ActiveCN110105030AImprove liquidity impactReduce the rate of hydrationDrilling compositionPortland cementUltimate tensile strength

The invention provides a well cementation material suitable for a low-temperature environment and a production method of the well cementation material. The well cementation material is prepared by mainly mixing 75-89% of portland cement clinker, 1-8% of sulphoaluminate cement clinker, 1-8% of high-alumina cement clinker, 2-4% of dihydrate gypsum, 0.5-1.2% of a dispersing agent and 1-4% of a retarder by weight. The well cementation material has the advantages that selected raw materials of raw meal cooperate with one another, on the basis of meeting the early strength, the later strength is ensured, the hydration rate is also slowed down to a certain extent, the setting time is prolonged, time guarantee is provided for radial grouting, and the risk ratio of blockage caused by the generationof cement plugs during grouting is reduced.

Owner:葛洲坝石门特种水泥有限公司

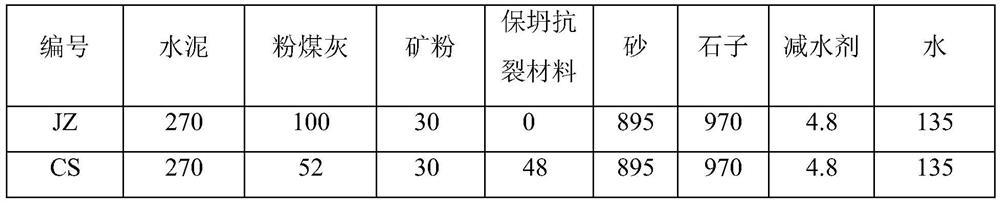

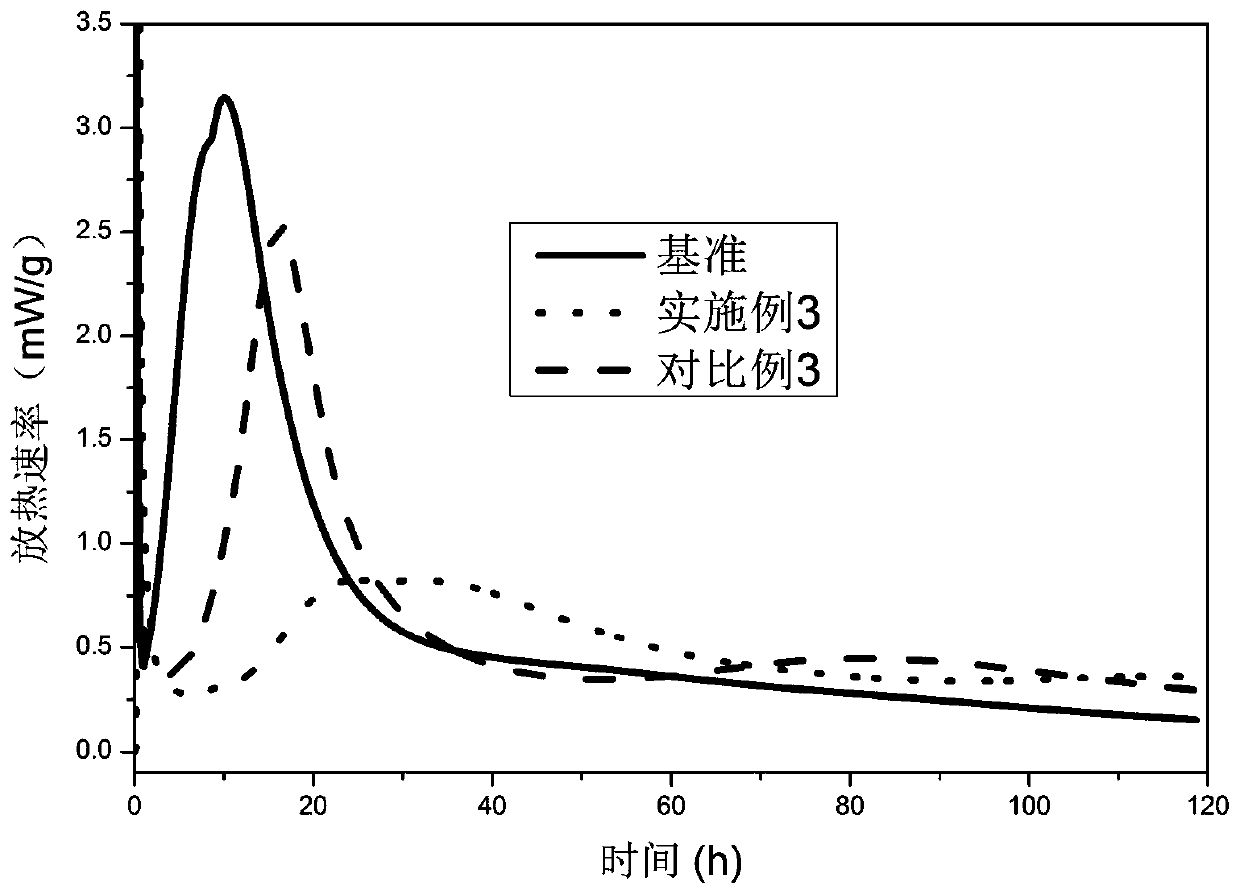

Ballastless track base concrete slump-retaining anti-cracking material and preparation method thereof

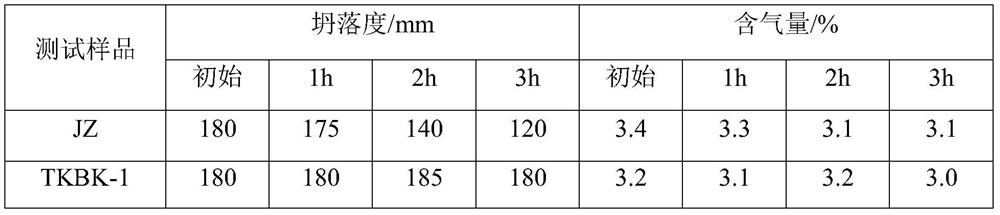

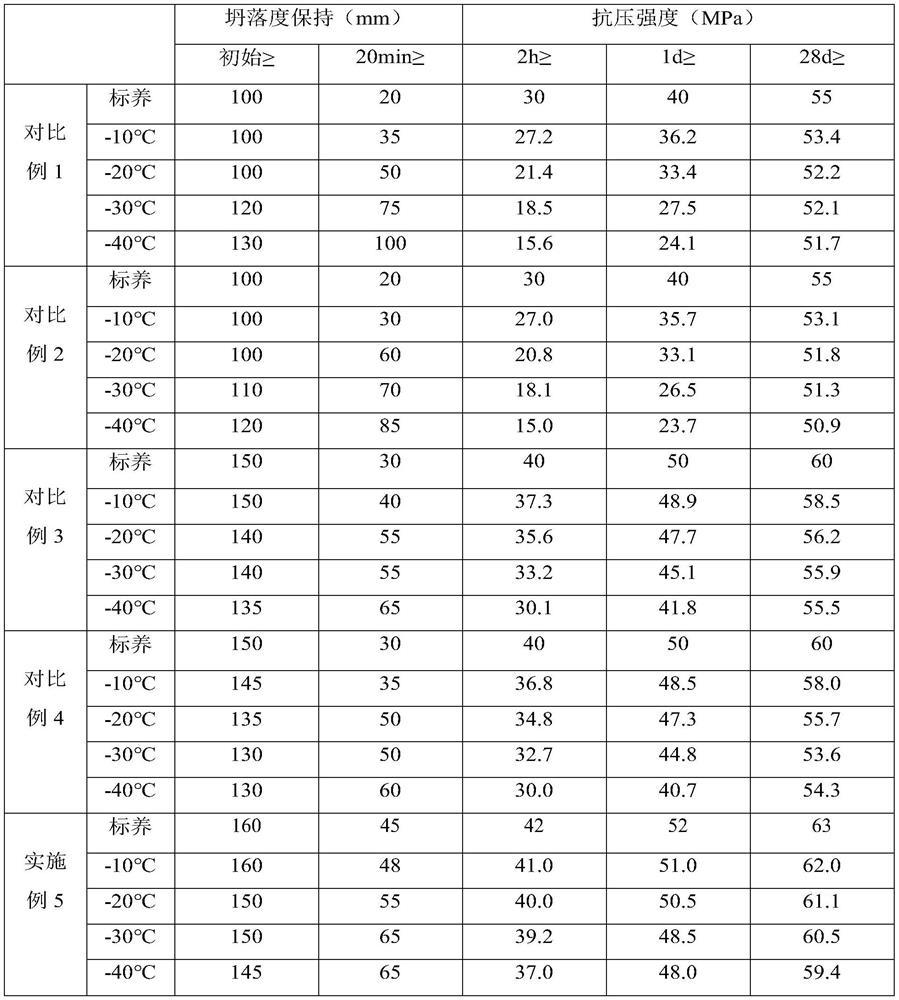

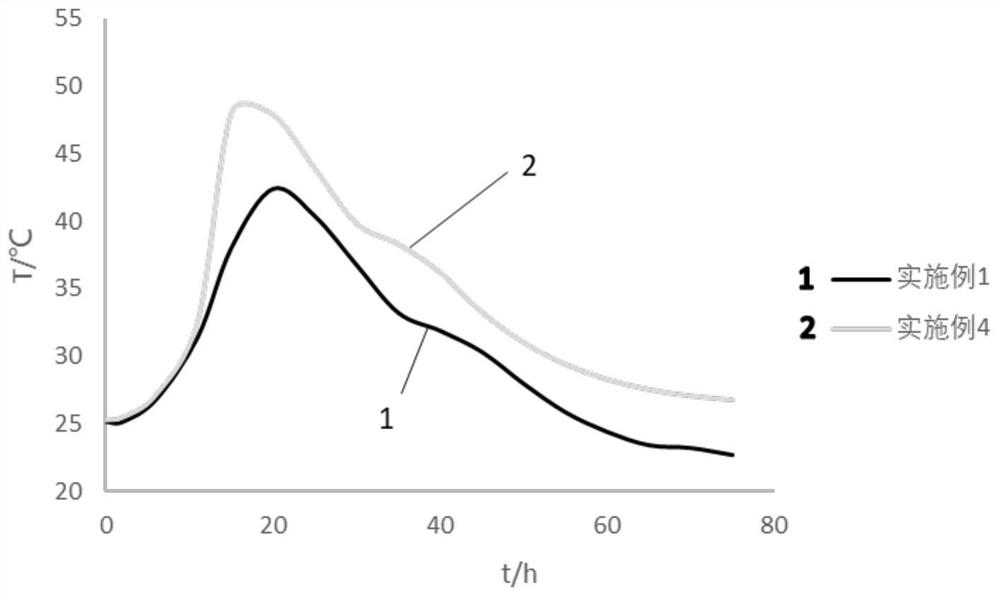

The invention belongs to the technical field of building materials, and particularly relates to a ballastless track base concrete slump-retaining anti-cracking material and a preparation method thereof. The slump-retaining anti-cracking material is prepared by mixing a shrinkage-reducing slump-retaining type polymer component, a retarding component, a hydration temperature rise inhibiting component, a composite anti-cracking component, a water storage component and a reinforcing and toughening component according to a certain proportion, wherein the mass ratio of each component is as follows:1.0-4.5 parts of the shrinkage-reducing slump-retaining type polymer component, 0.5-1.5 parts of the retarding component, 1-10 parts of the hydration temperature rise inhibiting component, 66-95 partsof the composite anti-cracking component, 0.5-10 parts of the water storage component and 2-8 parts of the reinforcing and toughening component. The ballastless track base concrete slump-retaining anti-cracking material provided by the invention is doped into concrete according to a proper mixing amount, the slump loss of the concrete can be avoided within 3 hours, the adiabatic temperature riseof the concrete is reduced by more than 20%, the shrinkage variation of the concrete in a plastic stage and a hardening stage is remarkably reduced, the maximum reduction coefficient of concrete cracks can reach 92%, and the anti-cracking efficiency grade reaches first grade.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

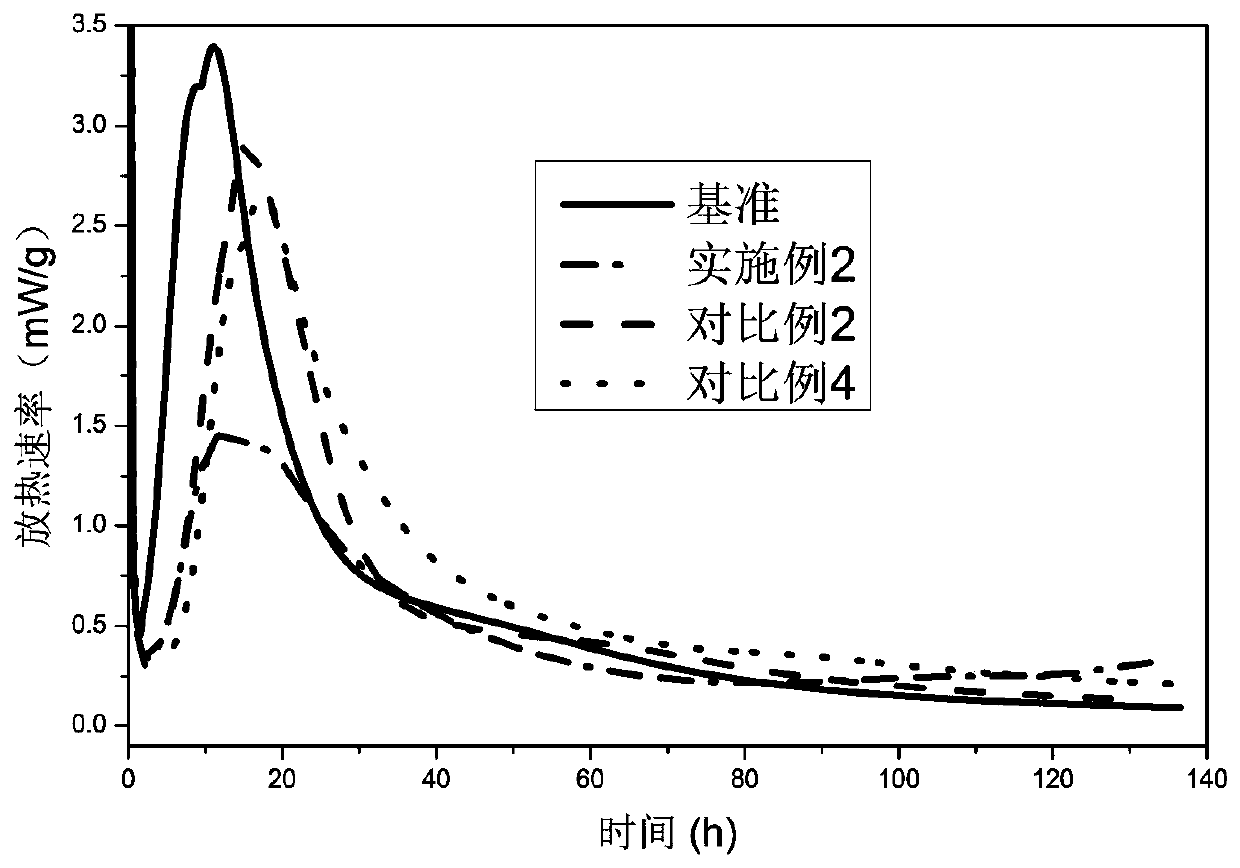

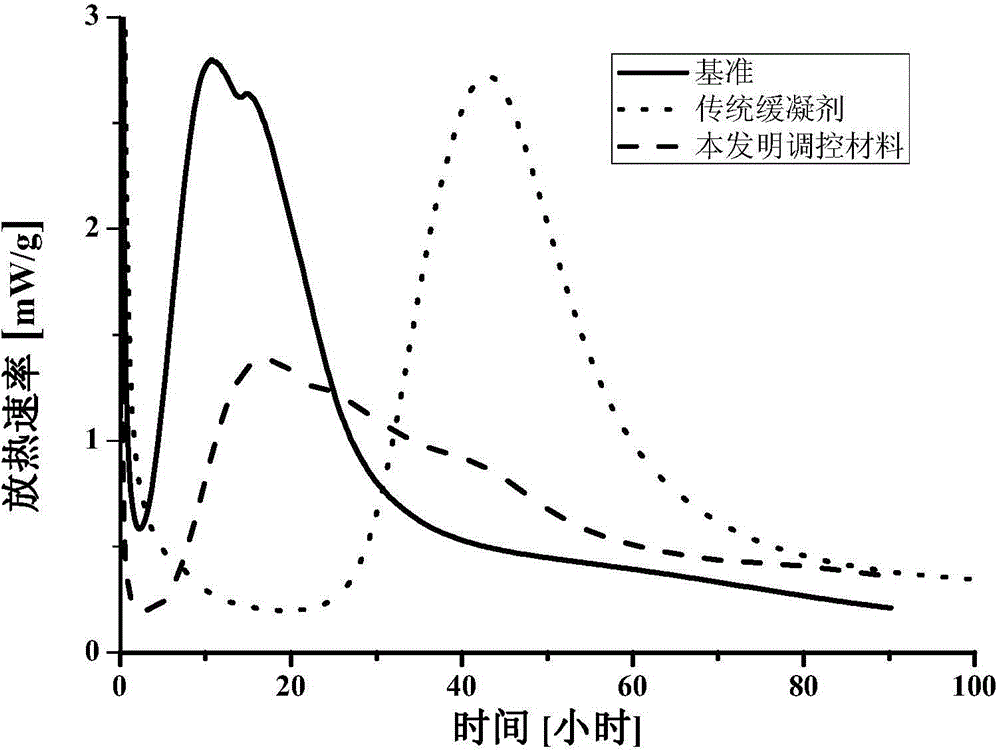

Anti-cracking additive for concrete

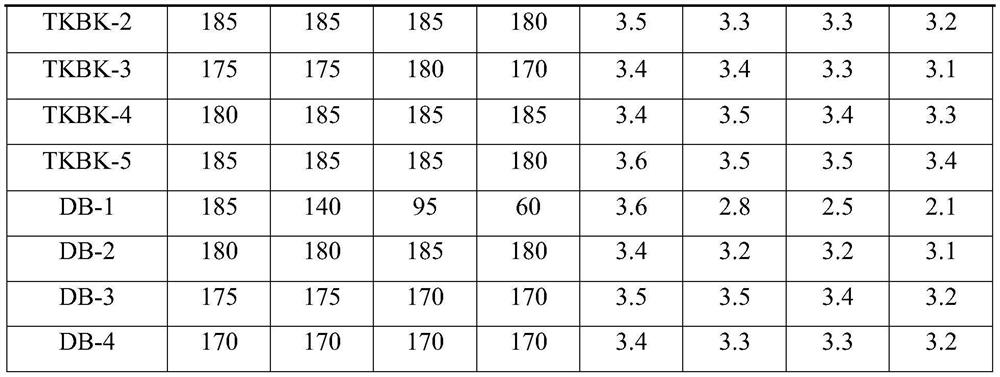

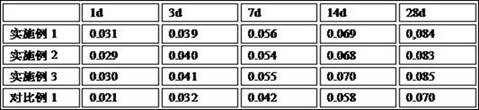

ActiveCN104591583AReduce temperature riseSimple preparation processTemperature stressMaterials science

The invention provides an anti-cracking additive for concrete and further provides application of the anti-cracking additive for concrete in cracking prevention of concrete. The anti-cracking additive for concrete is simple in preparation process and low in cost and can be used for directly regulating a hydration process of cement. On the premise that the final total heat release of cement is not affected, the hydration heat release of cement is uniformly distributed in a longer time and centralized heat release during hydration is reduced, so that the temperature rise of concrete is reduced and the temperature stress is reduced, and therefore, the anti-cracking purpose is achieved.

Owner:JIANGSU SOBUTE NEW MATERIALS

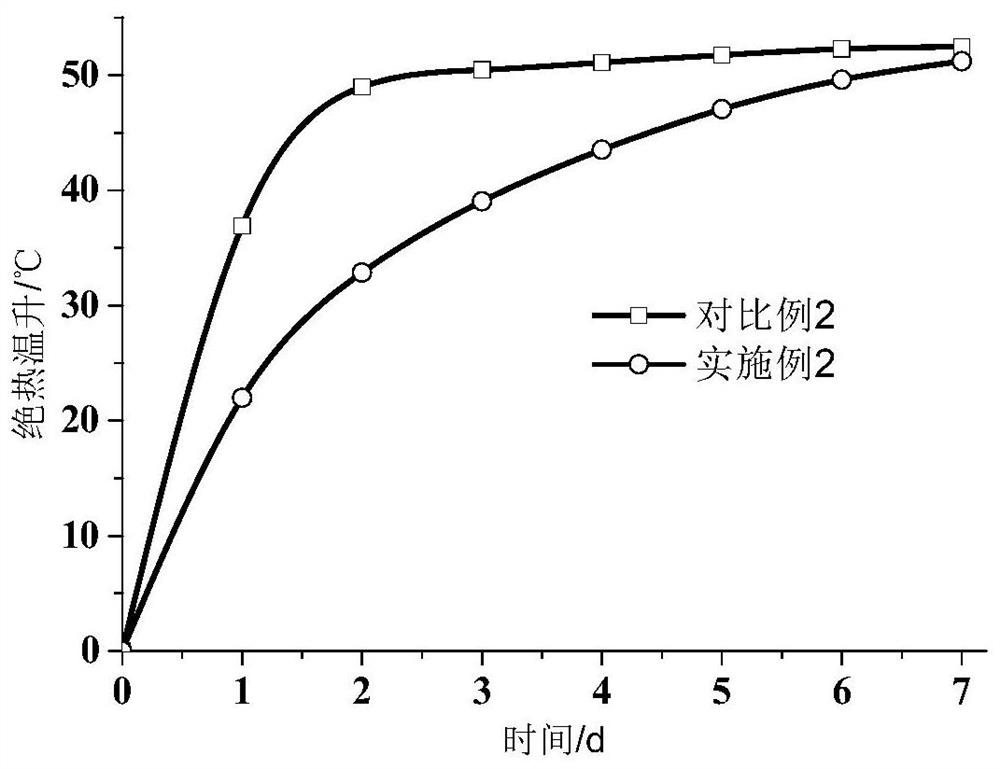

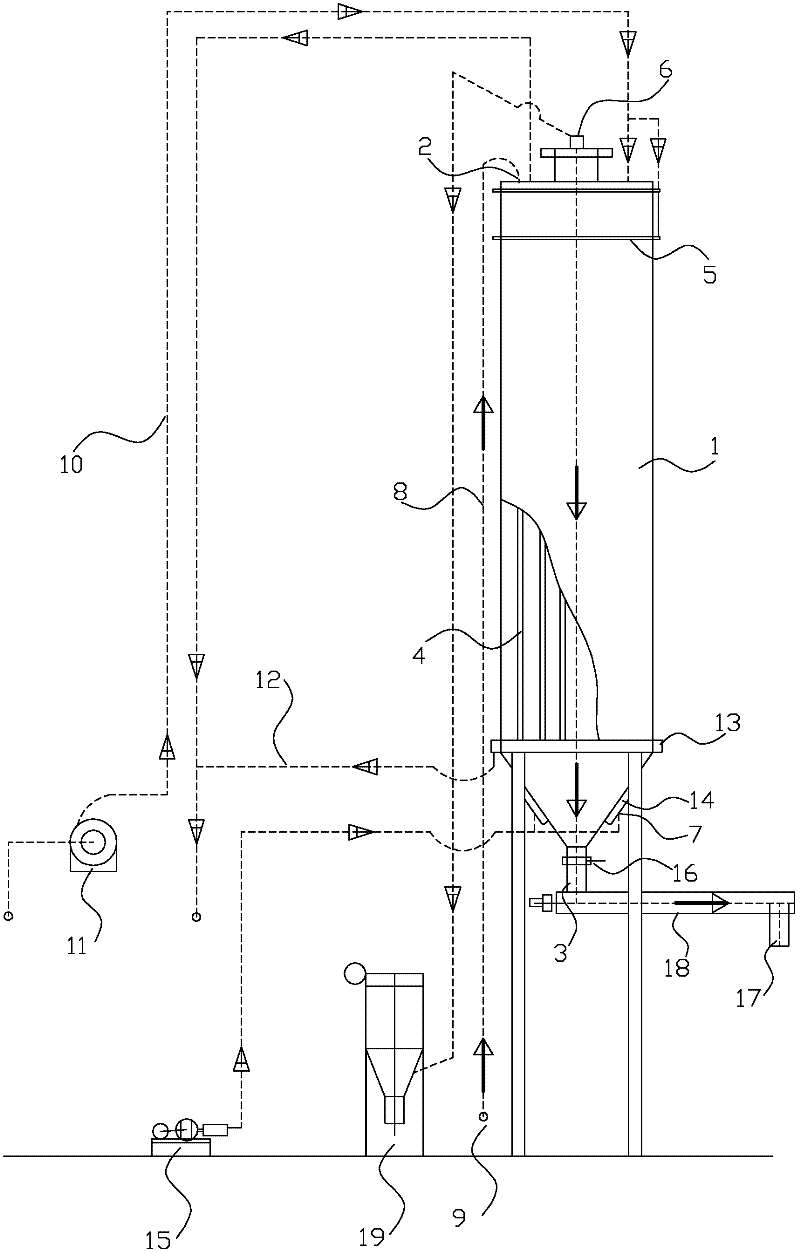

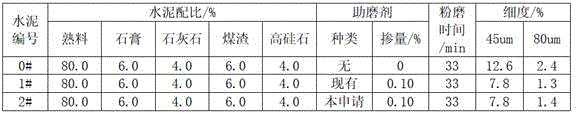

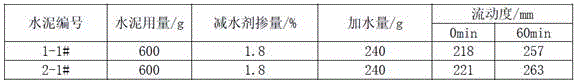

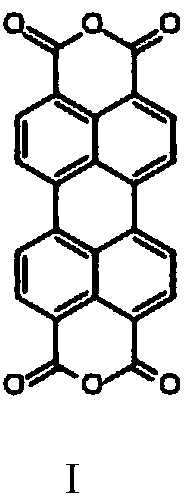

Multifunctional cement hydration thermal regulation and control material and preparation method thereof

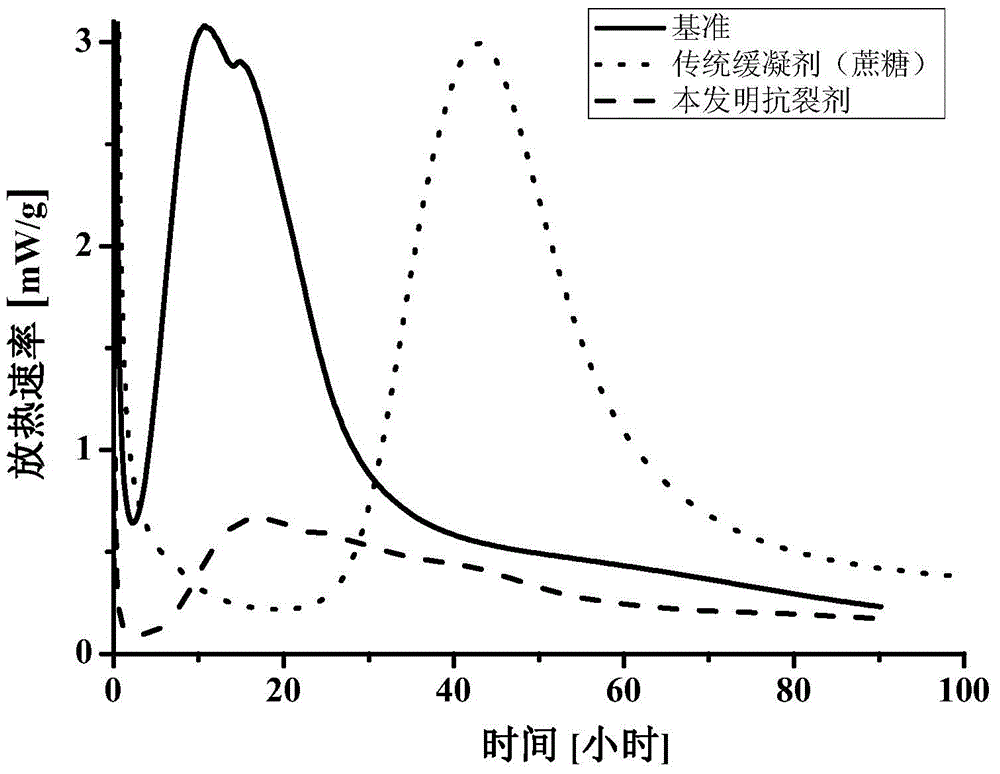

The invention discloses a multifunctional cement hydration thermal regulation and control material and a preparation method thereof. The cement hydration thermal regulation and control material is a comb shaped polymer of three side chain structures, wherein the three side chain structures are respectively a carboxyl structure, a sugar alcohol group structure and a polyether structure; a polymer main chain is a carbon chain structure formed by free radical polymerization of double bonds in a double-bond compound monomer. According to the multifunctional cement hydration thermal regulation andcontrol material prepared by the preparation method, the gathering of cement hydration thermal regulation and control performance, water reduction performance and reduction performance can be realizedin the same molecule, the focused regulation and control of performance can be realized through structure regulation, and multi-ingredient compounding is not required during use so as to be more convenient. The regulation and control material disclosed by the invention is nontoxic, has water solubility, can be prepared into proper concentration and is convenient in use.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

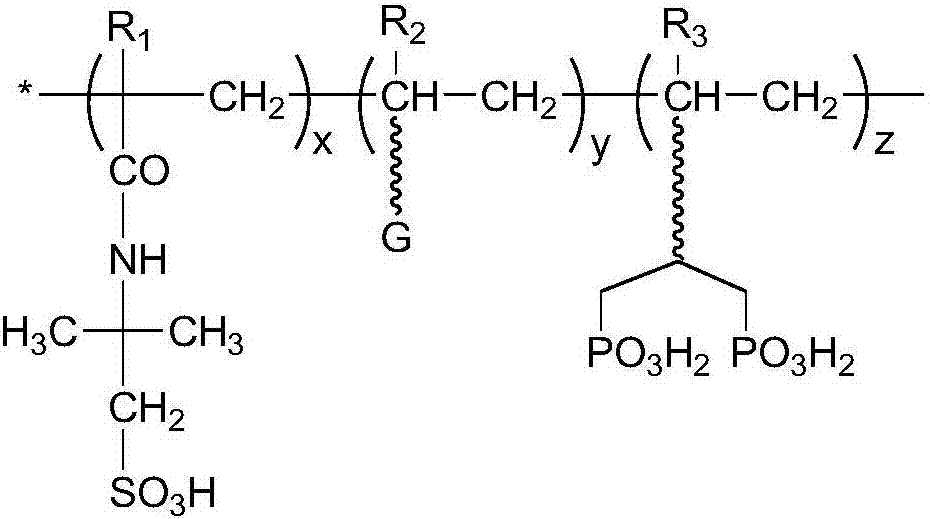

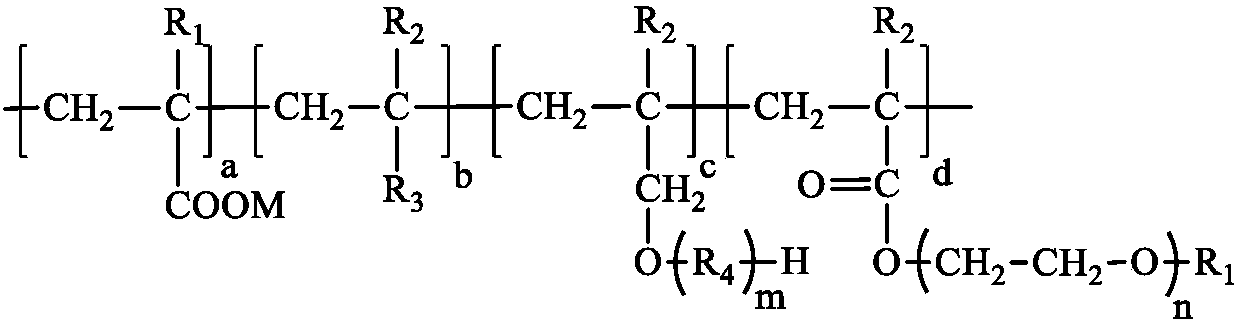

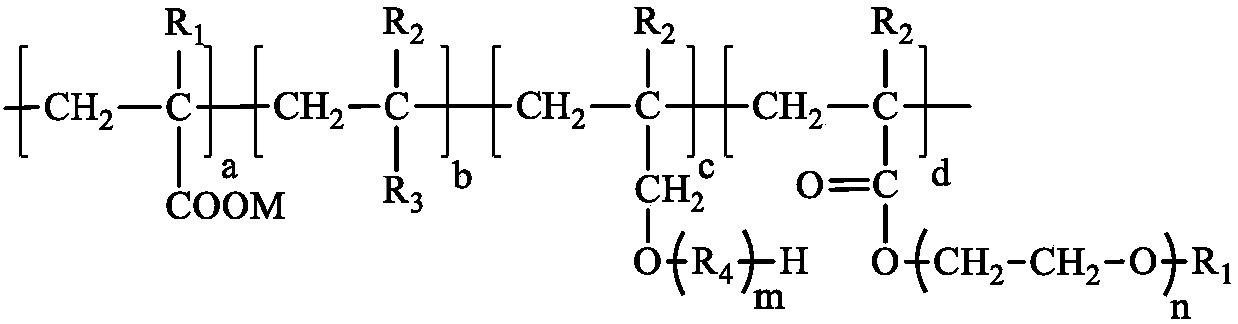

Workability keeping agent for ballastless track self-compacting concrete and preparation method of workability keeping agent

InactiveCN109956701AReduce the rate of hydrationReduce slump loss over timePlasticizerCarboxylic acid

The invention belongs to the technical field of concrete admixtures, and particularly relates to a workability keeping agent for ballastless track self-compacting concrete and a preparation method ofthe workability keeping agent. The workability keeping agent is formed by performing mixing under stirring on the following materials, in parts by mass: 17-28 parts of a polycarboxylic acid super plasticizer, 0.02-0.5 part of an HLB value regulating agent, 0.01-0.05 part of a dispersion keeping auxiliary agent, 0.5-2.5 parts of a retarder, 0.02-0.5 part of an antifoaming agent and 68.9-82.45 partsof deionized water; and the preparation method of the workability keeping agent is a normal-temperature normal-pressure polymerization reaction. The workability keeping agent for the ballastless track self-compacting concrete provided by the invention can realize the purpose that the concrete has no slump loss within 3 h in a high-temperature environment of 35 DEG C and does not affect the finalsetting time of the concrete; and in addition, the preparation method is simple, has a pollution-free preparation process, low raw material costs, and wide adaptability to concrete raw materials.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

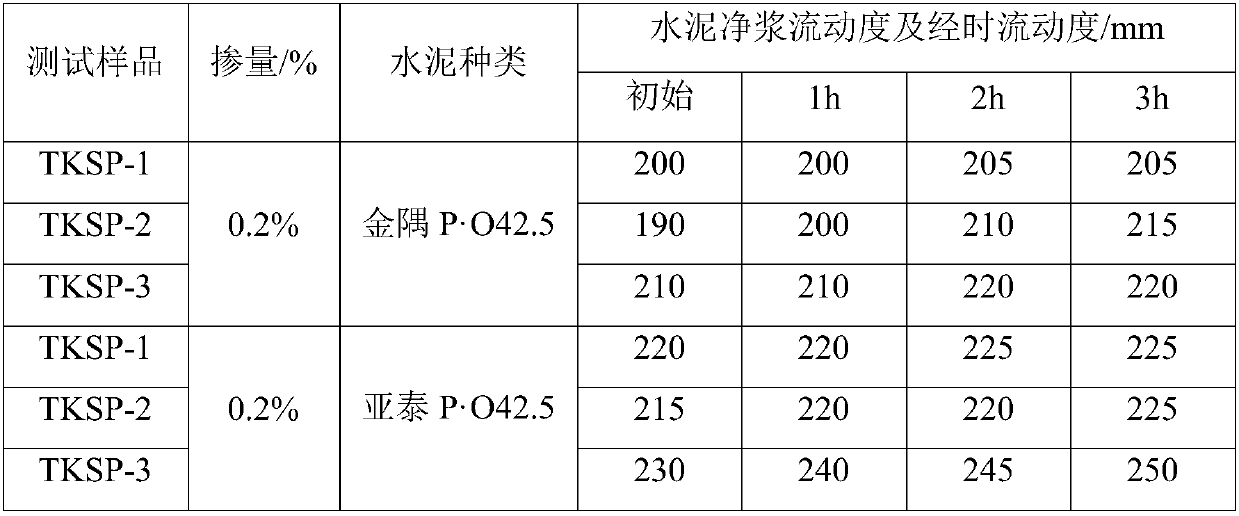

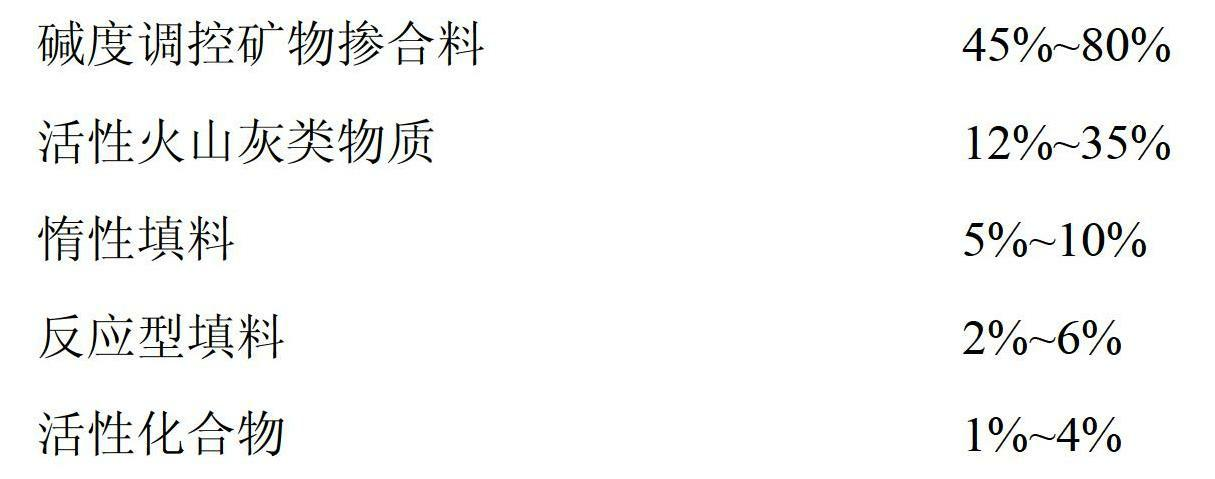

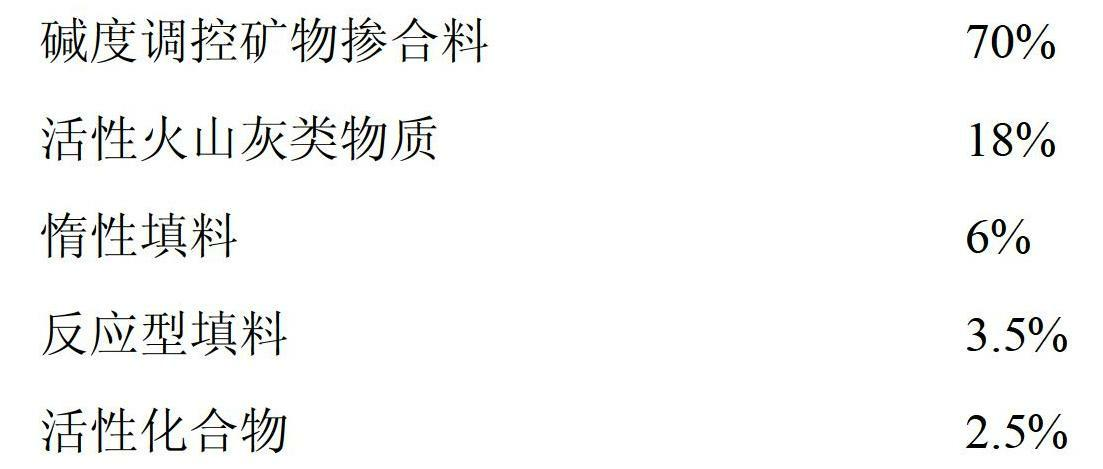

Multi-functional acid-resistant concrete gel powder

InactiveCN102674744AImprove volume stabilityGood acid corrosion resistanceEconomic benefitsAcid corrosion

The invention relates to multi-functional acid-resistant concrete gel powder. The multi-functional acid-resistant concrete gel powder comprises the following components in percentage by weight: 45 to 80 percent of mineral admixture for basicity regulation and control, 12 to 35 percent of active volcanic ash substances, 5 to 10 percent of inert filler, 2 to 6 percent of reactive filler and 1 to 4 percent of active compound. The multi-functional acid-resistant concrete gel powder can remarkably improve the acid corrosion resistance of cement concrete, reduce the risks of surface burst, peeling and strength reduction of concrete under acid environment erosion conditions, and remarkably improve the permeability resistance and volume stability of concrete matrixes, is convenient to construct, and has a remarkable economic benefit. The multi-functional acid-resistant concrete gel powder can be widely applied to concrete works such as ports, wharves, plants, sewage treatment plants, tunnels, roads, bridges and civil buildings which serve in acid environments.

Owner:JIANGSU SOBUTE NEW MATERIALS

Low-negative-temperature cement-based rapid repair material

The invention provides a low-negative-temperature cement-based rapid repair material. The material comprises the following components in parts by weight: 80 to 160 parts of ordinary Portland cement, 310 to 420 parts of sulphoaluminate cement, 320 to 410 parts of aluminate cement, 736 to 734 parts of fine aggregate, 989 to 1011 parts of coarse aggregate, 1.8 to 2.1 parts of a water reducing agent,7 to 11 parts of an anti-freezing agent, 0.2 to 0.4 part of a retarder and 0.3 to 0.7 part of a coagulation accelerator. Compared with an ordinary Portland cement system, the repair material providedby the invention has the effects of accelerating setting and hardening, shortening the demolding time, improving the early strength and increasing the later strength, and alleviating the problems of slow hydration and low strength in a low-temperature environment.

Owner:TIANJIN JUSHI TECH DEV

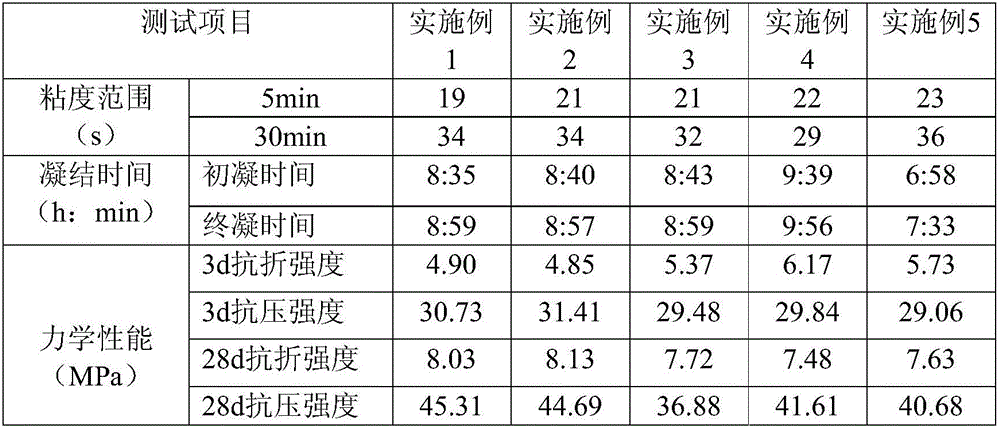

Silica powder modified superfine cement crack repair material and preparation method thereof

InactiveCN106186872AGood compatibilityImprove liquiditySolid waste managementSilica fumeEnvironmentally friendly

The invention discloses a silica powder modified superfine cement crack repair material and a preparation method thereof. The silica powder modified superfine cement crack repair material is prepared from, superfine cement, water, silica powder, a water reducing agent and a swelling agent, wherein the mass of the water is 40%-60% that of the superfine cement, the mass of the silica powder is 5%-15% that of the superfine cement, the mass of the water reducing agent is 0.5%-1.2% that of superfine cement, and the mass of the swelling agent is 8%-30% that of the superfine cement. The crack repair material has the advantages for being excellent in performance, low in manufacturing cost, environmentally friendly, convenient to construct and good in durability, and the preparation method is simpler.

Owner:CHANGAN UNIV

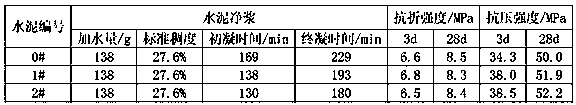

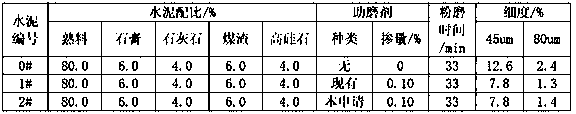

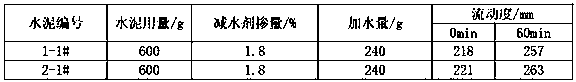

Grinding aid for improving compatibility of cement and water reducing agent

The invention relates to the technical field of cement grinding aids, in particular to a grinding aid for improving compatibility of cement and a water reducing agent. The grinding aid is prepared from, by weight, 20%-25% of diethanolisopropanolamine, 10%-15% of inorganic salt, 20%-30% of itaconic acid industrial effluent and the balance water. In use of the grinding aid, cement hydration can be decelerated, and cement paste is high in fluidity relatively and conducive to actions of the water reducing agent; since itaconic acid is binary unsaturated carboxylic acid, the itaconic acid is easier to compatible to a polycarboxylic water reducing agent according to the principle that the similar substances are more likely to be dissolved by each other, and a polymerization reaction between the itaconic acid and excessive macromonomers in the polycarboxylic water reducing agent can be realized under appropriate conditions to increase effective components of the polycarboxylic water reducing agent, so that effectiveness in use of the water reducing agent is improved. Therefore, compatibility of cement and the concrete water reducing agent is improved on the premise that grinding efficiency and cement strength are almost unchanged.

Owner:安徽海螺材料科技股份有限公司 +1

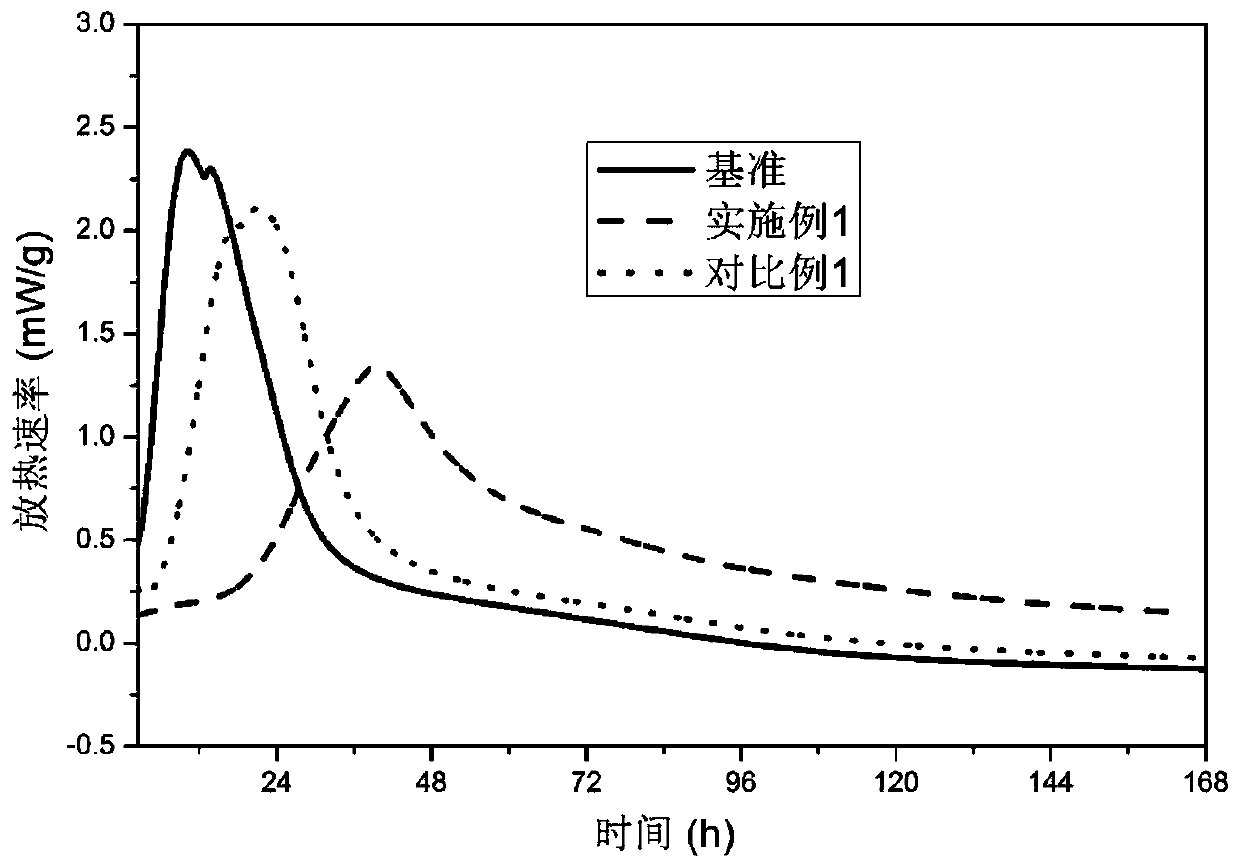

Cement hydration rate regulating material as well as preparation method and application of cement hydration rate regulating material

The invention provides a cement hydration rate regulating material which is dextrin grafted with a water-soluble polymer. The cement hydration rate regulating material is simple in preparation process and low in cost; the cement hydration rate regulating performance of the cement hydration rate regulating material is greatly improved as comparison with that of the prior art; and the peak value of the maximum heat release rate for cement hydration can be reduced by more than 80%.

Owner:JIANGSU SOBUTE NEW MATERIALS

Magnesium-calcium material and preparation method thereof

The invention relates to a magnesium-calcium material and a preparation method thereof. The preparation method comprises the following steps: mixing 60-70 wt% of magnesia-calcia particles, 20-30 wt% of magnesia-calcia fine powder, 2-5 wt% of cerium phosphate and 3-6 wt% of phosphotitanate, uniformly stirring, carrying out compression molding, and naturally drying for 20-30 h; and drying for 8-16 hat the temperature of 110 DEG C, firing for 2-5 h at the temperature of 1500-1700 DEG C, and cooling to obtain the magnesium-calcium material, wherein the MgO content of the magnesia-calcia is greater than or equal to 40 wt%, the particle size of magnesia-calcia particles is 0.2-11 mm, and the particle size of the magnesia-calcia fine powder is 3-200 [mu]m; the particle size of the cerium phosphate is 3-200 [mu]m; and the content of P2O5 in the phosphotitanateis greater than or equal to 1wt%, and the content of TiO2 in the phosphotitanate is greater than or equal to 1 wt%. The method is simple in process, low in cost and environmentally friendly, and the prepared magnesium-calcium material is excellent in hydration resistance, remarkable in metal melt purification effect and suitable forpurifying refractory materials for smelting.

Owner:WUHAN UNIV OF SCI & TECH

Super-retarded concrete for pile foundation and preparation method of super-retarded concrete

ActiveCN113277807AProlong clotting timeHigh compressive strengthSolid waste managementSodium triphosphatePulverised fuel ash

The invention relates to the technical field of concrete processing, and particularly discloses super-retarded concrete for a pile foundation and a preparation method of the super-retarded concrete. The super-retarded concrete is prepared from the following raw materials in parts by weight: 240 to 250 parts of water, 250 to 270 parts of cement, 1350 to 1540 parts of sand, 1940 to 2150 parts of stone, 30 to 35 parts of fly ash, 70 to 90 parts of slag powder, 9 to 10.5 parts of polycarboxylic acid water reducing agent, 3 to 4 parts of a thickening agent and 5.5 to 7.5 parts of a retarder. The retarder is prepared from the following raw materials in parts by weight: 18-22 parts of sodium tripolyphosphate, 20-30 parts of white granulated sugar and 4-6 parts of sodium hydroxide modified N,N-bis(phosphonomethyl)glycine. Through the synergistic effect of the raw materials, the super-retarded concrete has the advantages of long setting time, high compressive strength and high breaking strength, the practicability of the super-retarded concrete is improved, the application range of the super-retarded concrete is widened, and market requirements are met.

Owner:北京建工新型建材有限责任公司

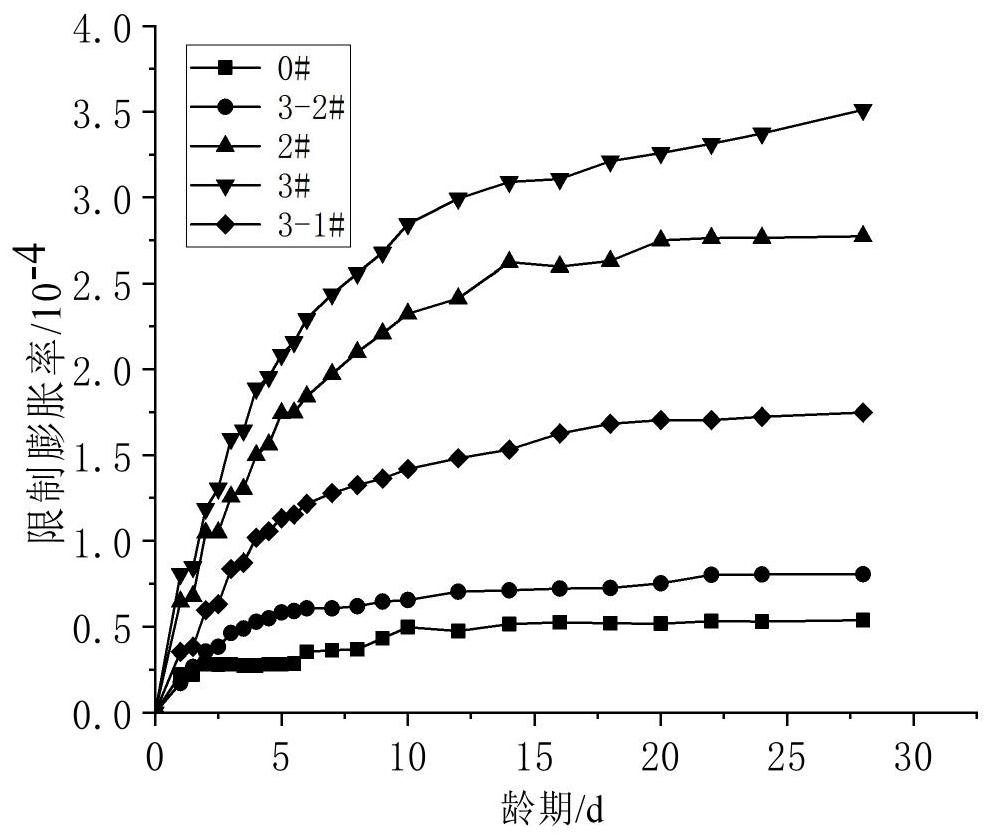

Multi-component composite reinforced anti-cracking agent for concrete and preparation method of multi-component composite reinforced anti-cracking agent

ActiveCN114477829AReduce the rate of hydrationLower eutectic pointSolid waste managementSlagPhosphogypsum

The invention discloses a multi-component composite reinforced anti-cracking agent for improving the anti-cracking performance of concrete and a preparation method of the multi-component composite reinforced anti-cracking agent. The anti-cracking agent is prepared from the following raw materials in parts by weight: 55-80 parts of dolomite, 1-5 parts of phosphogypsum, 0-5 parts of phosphorus slag, 10-15 parts of fly ash, 0-25 parts of limestone, 0.5-1 part of a hydration slow-release agent and 0.5-1.5 parts of a mineralizing agent. The preparation method comprises the following steps: uniformly mixing the raw materials, calcining at 1150-1300 DEG C for 60-90 minutes, quenching and cooling to below 400 DEG C, and grinding until the 80 mu m screen residue is less than or equal to 10%, thereby obtaining the multi-component composite reinforced anti-cracking agent finished product. The use amount of the anti-cracking agent in the concrete is 5-8% of the use amount of the cementing material. The multi-component composite reinforced anti-cracking agent disclosed by the invention has the advantages of low hydration heat release, long expansion lasting time, high concrete later strength and the like, and can be widely applied to concrete structures with high cracking risks, such as mass concrete, thin-wall structures, super-long structures and the like.

Owner:西安建祥建材科技有限公司

Low-thermal-expansion concrete and admixture

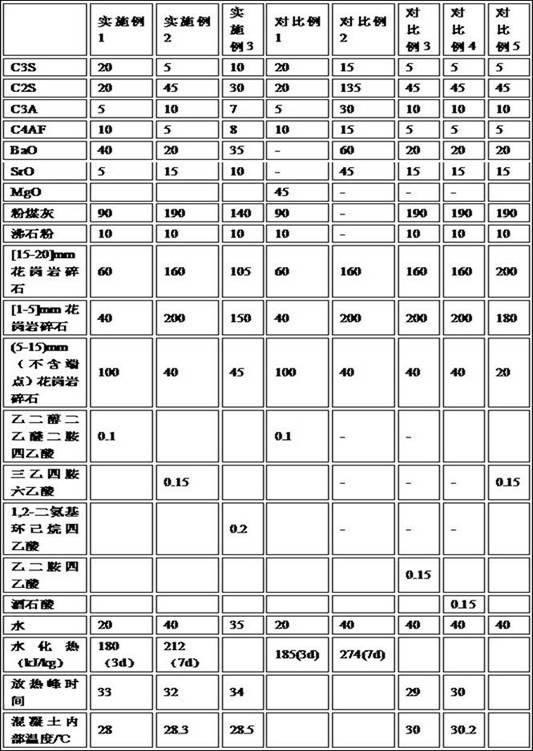

ActiveCN111454036AStable expansion rateReduce heat of hydrationSolid waste managementMineralogyStrontium oxide

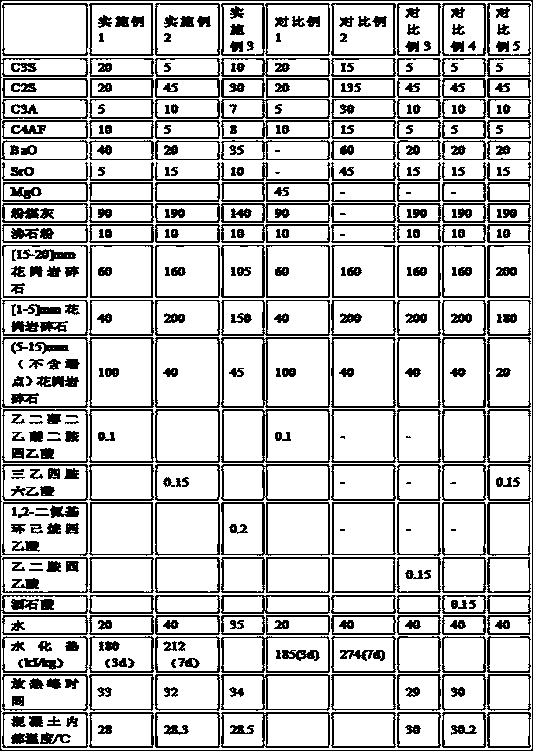

The invention relates to a low-thermal-expansion concrete and an admixture. The concrete comprises cement clinker, fly ash, zeolite powder, granite gravel and the balance being water. The cement clinker comprises the following components in percentage by weight: 5-20% of C3S, 20-45% of C2S, 5-10% of C3A and 5-10% of C4AF, and is characterized by further comprising 20-40% of barium oxide and 5-15%of strontium oxide. The ratio of the cement clinker to (fly ash and zeolite powder) to granite gravel is 1: (1-2): (2-4), and water to cement clinker is 0.2-0.4. Barium oxide and strontium oxide are used as expansion admixtures for the first time to replace fly ash in particular zeolite powder under the assistance of a newly developed retarder; and granite gravels with different sizes are matchedto realize a low-heat micro-expansion effect of concrete.

Owner:ZHEJIANG CHENGYU ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

Novel grouting agent

ActiveCN113173730AImprove swelling effectImprove stabilitySolid waste managementChemistryComposite material

The invention discloses a novel grouting agent, which comprises 10-20 parts of an expanding-water reducing compound, 15-30 parts of an expanding-retarding component and 5-7 parts of a retarder B. The expanding component in the expanding-water reducing compound is an expanding agent A, wherein the expanding-retarding component comprises an expanding agent B and a retarder A. According to the novel grouting agent provided by the invention, an expansion component and a water reducing component are combined to prepare an expansion-water reducing compound, so that the expansion effect of concrete in the early stage is improved; by combining the expansion component and the retarding component, the expansion and retarding effects in the later period of concrete hydration are improved; due to the two combination modes, all the components in the grouting agent can be matched with one another, and a greater effect can be achieved.

Owner:吉安市金羧科技有限公司

High-performance mortar capable of effectively preventing mortar cracking and preparation method

The invention discloses high-performance mortar capable of effectively preventing mortar cracking and a preparation method. The high-performance mortar comprises the following components: cement, quartz sand, a retarder, fly ash, silica fume, mineral powder, a water reducing agent and an anti-freezing agent. The retarder is prepared from modified ardealite, and the mineral powder is low-grade magnesite; according to the invention, the mortar prepared in the invention is mixed with water to form concrete, the modified ardealite and the low-grade magnesite do not react with water, and have an expansion mechanism, so that the collapse degree of the concrete can be effectively reduced, and the problem of cracking of the concrete caused by dry shrinkage can be effectively solved; in addition, the silica fume is used as a blending agent, so that the strength and corrosion resistance of the concrete can be further improved, the low-grade magnesite and the phosphogypsum both belong to solid wastes in production and have the characteristics of sufficient quantity and difficulty in treatment, and the environment can be protected while the cost is reduced by utilizing the low-grade magnesite and the phosphogypsum.

Owner:怀化明达建材有限公司

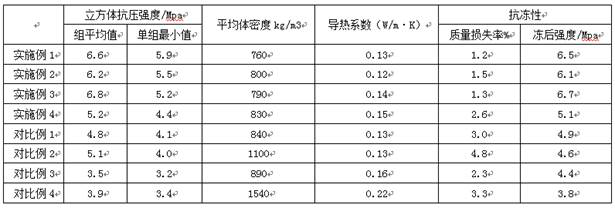

Reinforced foamed concrete and preparation method thereof

ActiveCN111943607AIncrease ultimate strengthExtended dose rangeCeramicwareFoam concretePolyvinyl alcohol

The invention relates to the technical field of building materials, and discloses reinforced foamed concrete and a preparation method thereof, the reinforced foamed concrete comprises Portland cement,fly ash, aggregate, polyvinyl alcohol particles, a foam stabilizer, a mixed emulsion, an acrylamide reinforcing agent, hydrogen peroxide and other components. Compared with the prior art, the invention has the following advantages and effects: 1, through the acrylamide type reinforcing agent, the strength of the foamed concrete is improved, the traditional bidirectional effect of only adding polyacrylamide is overcome, and the compressive strength of the foamed concrete is improved; 2, by adding the mixed emulsion, the water seepage of the concrete is reduced, the water retention effect of the concrete is better, the probability of various problems such as cracking of the concrete is reduced, and the strength of the concrete is improved;.

Owner:湖北保江建材有限公司

concrete mud inhibitor

The invention discloses a concrete mud retarder. The concrete mud retarder comprises 50-80wt% of an aqueous polymer, 5-20wt% of gallic acid and 10-30wt% of diethylene glycol. A production technology of the aqueous polymer comprises the following steps: 1, taking 4-7 parts by weight of hydrogen peroxide and 8 parts by weight of water, and completely dissolving hydrogen peroxide in water to obtain a solution I; 2, taking 2-4 parts by weight of rongalite and 8 parts by weight of water, and completely dissolving rongalite in water to obtain a solution; 3, adding 35-40 parts by weight of water, respectively adding 7 parts by weight of acrylamide, 9 parts by weight of maleic anhydride and 21 parts by weight of allyl ether, and stirring; 4, adding 0.5-2 parts by weight of a chain transferring agent; and 5, heating to 40DEG C, simultaneously adding the solution I and the solution II in a dropwise manner, and controlling the reaction temperature to be 40-50DEG C and the dropwise addition time to be 2-4h, and cooling to 30DEG C after the above reaction in order to obtain the aqueous polymer with the solid content of 38-42%. The concrete mud retarder can reduce adsorption of a concrete water reducer on soil particles, improves the fluidity of a high-mud concrete system, and greatly improves the slump keeping property of the concrete water reducer.

Owner:SOUTHEAST UNIV

Novel cement-based composite material with low hydration heat and preparation method thereof

The invention discloses a novel cement-based composite material with low hydration heat and a preparation method thereof. The cement-based composite material comprises, in parts by weight, 160 to 200 parts of Portland cement, 60 to 100 parts of water, 450 to 600 parts of siliceous fine sand, 0.25 to 0.6 part of biomass combined acid, 20 to 40 parts of a siliceous mineral admixture, 1 to 2 parts of a polycarboxylic acid water reducing agent, 16 to 30 parts of a silicon-aluminum mineral admixture and 0.08 to 0.4 part of an organic retarder, wherein the biomass combined acid is formed by compounding tara tannin and gallnut tannin. The cement-based composite material disclosed by the invention can effectively solve the problem of temperature cracks caused by serious heat release in the hydration reaction of mass concrete, the preparation method is simple to operate, and the strength and long-term stability of the cement-based composite material can be improved.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

A kind of reinforced foamed concrete and its configuration method

ActiveCN111943607BIncrease ultimate strengthExtended dose rangeCeramicwareFoam concretePolyvinyl alcohol

Owner:湖北保江建材有限公司

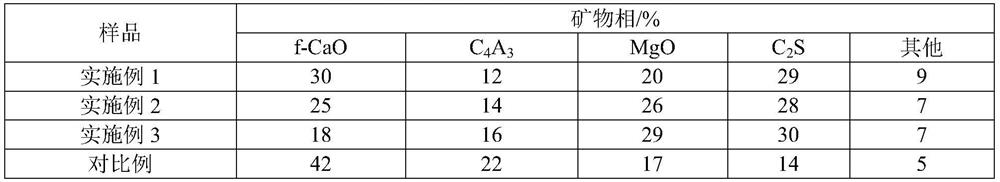

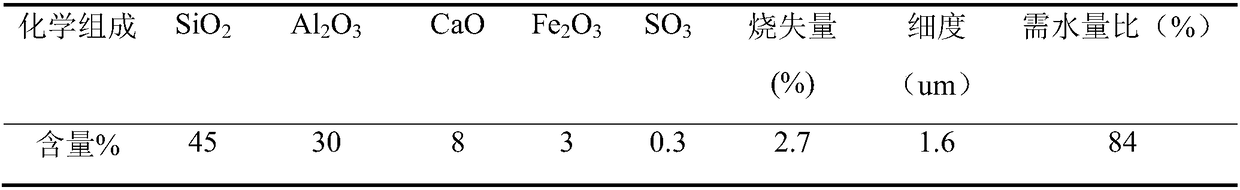

Calcium-magnesium composite expansion clinker, preparation method thereof and application of calcium-magnesium composite expansion clinker in low-shrinkage and high-crack-resistance marine mass concrete

ActiveCN114835422ASimple manufacturing processReduce hydrationCement productionBarium hydroxideClinker (cement)

The invention discloses a calcium-magnesium composite expansion clinker, a preparation method thereof and application of the calcium-magnesium composite expansion clinker in low-shrinkage and high-crack-resistance marine mass concrete.The calcium-magnesium composite expansion clinker is prepared from, by mass, 16-30% of calcium oxide, 6-11% of monocalcium dialuminate, 26-50% of barium oxide, 9-16% of barium aluminate and the balance magnesium oxide; monocalcium dialuminate wraps the surface of free calcium oxide, and barium aluminate wraps the surface of barium oxide. Monocalcium dialuminate is formed to melt and wrap free calcium oxide, hydration of the free calcium oxide is delayed, and invalid expansion of calcium expansion components in the plastic stage is reduced; the expansion efficiency of the expanding agent is improved through a formed inclusion of wrapping barium oxide with barium aluminate; barium oxide and barium aluminate are hydrated to expand, generated barium hydroxide forms barium sulfate crystals under the action of anhydrite, and barite crystals formed in a cement system have radiation-proof performance.

Owner:SOUTHEAST UNIV +2

A kind of ultra-elevation pumping marine concrete and preparation method thereof

ActiveCN106587831BSuppresses structural cracking problemsReduce the rate of hydrationSoil scienceMarine architecture

The invention discloses a super-elevation pumping marine concrete. The super-elevation pumping marine concrete is prepared from cement, fly ash, mineral powder, gravel, river sand, a hydration temperature rising regulation and control material, a corrosive ion transport inhibitor, a state modified material, an ultra dispersed water reducing shrinkage plasticity-maintaining additive and water in proportion. According to the super-elevation pumping marine concrete, by means of the hydration temperature rising regulation and control material, cracking caused by low high performance concrete, insufficient hydration and drying shrinkage in later period can be effectively avoided; by means of the hydration temperature rising inhibiting component, adiabatic temperature rising of the concrete can be lowered, and cracking generated by the temperature stress is reduced; by adopting the corrosive ion transport inhibitor, the pore structure of the concrete can be optimized, transport paths of ions such as Mg<2+> and Cl<->, and the concrete is better served in marine salt spray environment; the state modified material has the specific ball effect and water retention characteristic, and the phenomena of segregation and pipe blocking occurring in the super-elevation pumping process are avoided. The concrete is suitable for super-elevation pumping marine buildings and has the important engineering application value.

Owner:WUHAN UNIV OF TECH +1

A kind of low thermal expansion concrete and admixture

ActiveCN111454036BStable expansion rateReduce heat of hydrationSolid waste managementThermal dilatationMining engineering

The invention relates to a low thermal expansion concrete and an admixture. The concrete includes cement clinker, fly ash, zeolite powder, granite crushed stone, and the balance is water. The cement clinker is composed of C3S: 5-20% , C2S: 20-45%, C3A: 5-10%, and C4AF: 5-10%, characterized in that the cement clinker also includes barium oxide 20-40%, strontium oxide 5-15%, cement clinker: ( Fly ash + zeolite powder): granite crushed stone = 1:1‑2:2‑4, water: cement clinker = 0.2‑0.4. For the first time, barium oxide and strontium oxide were used as expansion admixtures, and at the same time, with the newly developed retarder, and the combination of fly ash as an alternative material, especially zeolite powder, and the particle size ratio of granite crushed stone aggregate, the final The effect of concrete with low heat and micro-expansion is realized.

Owner:ZHEJIANG CHENGYU ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

A Grinding Aid for Improving the Compatibility of Cement and Water Reducer

The invention relates to the technical field of cement grinding aids, in particular to a grinding aid for improving compatibility of cement and a water reducing agent. The grinding aid is prepared from, by weight, 20%-25% of diethanolisopropanolamine, 10%-15% of inorganic salt, 20%-30% of itaconic acid industrial effluent and the balance water. In use of the grinding aid, cement hydration can be decelerated, and cement paste is high in fluidity relatively and conducive to actions of the water reducing agent; since itaconic acid is binary unsaturated carboxylic acid, the itaconic acid is easier to compatible to a polycarboxylic water reducing agent according to the principle that the similar substances are more likely to be dissolved by each other, and a polymerization reaction between the itaconic acid and excessive macromonomers in the polycarboxylic water reducing agent can be realized under appropriate conditions to increase effective components of the polycarboxylic water reducing agent, so that effectiveness in use of the water reducing agent is improved. Therefore, compatibility of cement and the concrete water reducing agent is improved on the premise that grinding efficiency and cement strength are almost unchanged.

Owner:安徽海螺材料科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com